#hex nuts manufacturer

Explore tagged Tumblr posts

Text

Hex Nuts Manufacturers | Roll Fast

Roll Fast is the biggest manufacturers specializing in different types of industrial tools and places a lot of emphasis as well as focus on making sure that we can provide our customers or clients with the best possible tools. A hex nut is a piece of hardware that is six-sided and serves the purpose of fastening with internal screw threads. Hex nuts are also known as finished hex nuts, or hex full nuts. Hex Nuts manufacturers are as per Indian, European, and American standards. Various types of hex nuts are available in today’s market. Each type is used for a different reason. The hex nuts provided by us are no exception.

visit source URL : https://www.roll-fast.com/industries-served/petrochemical-industries/hex-nuts.html

0 notes

Text

Hex Nuts Manufacturer, Exporter in India | Bigboltnut

BigBoltNut is a leading manufacturer, supplier and exporter of standard hex nuts metric nuts and inch series nuts. Hex nuts are used along with bolts for joining and tightening. Available in 8, 9 and 12 grades. A nut is a type of fastener with a threaded hole. Nuts are almost always used with a mating bolt to fasten multiple parts together. Hex nuts are one of the most common nuts available and are used with anchors, bolts, screws, studs, threaded rods and on any other fastener that has machine screw threads. Hex is short for hexagon, which means they have six sides. Hex nuts are also known as: finished hex nuts, hex full nuts.

0 notes

Text

T-Slot Nuts Manufacturer, Supplier & Exporter

Introduction

T-slot nuts are essential components widely used in industries requiring robust and versatile fastening solutions. These specialized fasteners are designed to fit into T-slots of machines, equipment, and frames, enabling the secure attachment of other components. This blog explores the key features, types, applications, and the role of T-slot nuts manufacturers, suppliers, and exporters.

What Are T-Slot Nuts?

T-slot nuts are specifically designed nuts that fit into the T-shaped grooves of various machinery, frames, and workbenches. They are used to securely hold components in place when assembling or adjusting equipment. These fasteners come in various sizes and materials, tailored to meet the needs of different industries.

The unique T-shape allows the nut to slide along the track, making it ideal for modular assembly systems. T-slot nuts are designed to lock into position when they are turned, ensuring a tight and stable fit.

Types of T-Slot Nuts

T-slot nuts come in various designs and configurations, depending on the application and specific requirements. Some of the most common types include:

Standard T-Slot NutsThese are the most commonly used T-slot nuts. They are available in multiple sizes to fit different T-slot dimensions and are generally made from steel, stainless steel, or other durable materials.

Swivel T-Slot NutsThese nuts have a pivoting feature that allows them to swivel into place for easier installation and removal. They are ideal for applications where adjustment and flexibility are required.

Spring T-Slot NutsThese nuts include a spring mechanism that provides added tension, keeping the fastener securely in place even under vibration and movement.

Hexagonal T-Slot NutsThese nuts are hex-shaped and are designed to be used with standard hex bolt heads. They provide additional strength and support when used with heavier components.

Double T-Slot NutsThese are designed to fit two different T-slots, offering enhanced holding power and stability in large, modular systems.

Floating T-Slot NutsThese nuts are designed to float inside the slot, adjusting to the position of the component, making them ideal for systems that require precise alignment.

Key Features of T-Slot Nuts

Easy Installation and Removal: The T-slot design makes installation quick and efficient without the need for additional tools. This flexibility saves time during assembly.

Versatility: They can be used in various applications, including machinery, workbenches, conveyors, and frames, supporting different types of assembly systems.

Durability: Most T-slot nuts are made from corrosion-resistant materials, such as stainless steel or coated steel, ensuring long-term reliability even in harsh environments.

Adjustability: The ability to slide and adjust the nuts within the slot provides high precision when aligning components, making them ideal for modular and adjustable assembly systems.

Strength and Stability: T-slot nuts are engineered to handle significant loads, ensuring a secure and stable fastening solution for both light and heavy-duty applications.

Applications of T-Slot Nuts

T-slot nuts are used across various industries due to their versatile and robust design. Some of the key applications include:

Machine Tool IndustryT-slot nuts are extensively used in machine tools for securing workpieces, fixtures, and other components. Their ability to provide secure fastening while maintaining adjustability makes them a preferred choice.

Automotive IndustryIn automotive manufacturing, T-slot nuts are often used for assembling workstations, test rigs, and frames. Their precision and ease of use are crucial for production lines.

Construction & BuildingModular construction systems use T-slot nuts for assembling frames, shelving units, and structural elements, offering flexibility and support for large structures.

Furniture ManufacturingT-slot nuts are commonly found in the assembly of modular furniture, such as desks, shelves, and storage systems. Their simple installation and removal allow for easy assembly and disassembly.

Robotics and AutomationThe robotics industry uses T-slot nuts in the construction of robotic arms, frames, and other precision equipment. The ability to adjust and align components precisely is vital in this sector.

Benefits of Using T-Slot Nuts

Cost-Effectiveness: T-slot nuts offer an affordable fastening solution that can be used across a variety of applications, minimizing the need for specialized fasteners.

Ease of Use: The T-slot nuts can be installed and adjusted without additional tools, saving time and effort during assembly and disassembly.

Adaptability: The modular design of T-slot nuts makes them ideal for customizable setups, allowing users to make quick changes as per their requirements.

Reduced Maintenance: With corrosion-resistant options and durable construction, T-slot nuts provide long-term reliability, reducing the need for frequent maintenance or replacements.

Flexibility in Design: T-slot nuts are highly adaptable and can be used in a wide range of industries, offering flexibility for diverse design needs.

T-Slot Nuts Manufacturer, Supplier & Exporter: Ananka Group's Expertise

As a leading manufacturer, supplier, and exporter of fasteners, Ananka Group offers high-quality T-slot nuts tailored to meet the unique requirements of various industries. With a focus on precision engineering and high-grade materials, we ensure that every T-slot nut we produce meets the highest industry standards.

Why Choose Ananka Group?

Quality Assurance: We adhere to strict quality control measures to ensure that our T-slot nuts meet all relevant standards and specifications.

Customization: Ananka Group offers customized T-slot nuts, tailored to specific customer requirements in terms of size, material, and design.

Global Reach: We supply T-slot nuts to a global clientele, ensuring timely delivery and competitive pricing for customers worldwide.

Expert Engineering: Our team of engineers specializes in creating durable and innovative T-slot nuts for a range of applications, from automotive to industrial systems.

Reliable Support: Our customer service team is available to assist with any inquiries, from product selection to technical support, ensuring a seamless experience.

Conclusion

T-slot nuts are indispensable fasteners used in various industries for modular assembly systems, machine tools, robotics, and more. Their flexibility, ease of installation, and durability make them an ideal solution for a wide range of applications. Whether you're looking to source T-slot nuts for a small project or a large-scale industrial system, choosing a trusted manufacturer, supplier, and exporter like Ananka Group guarantees high-quality products tailored to your needs.

Frequently Asked Questions (FAQ)

1. What materials are T-slot nuts made from?T-slot nuts are typically made from steel, stainless steel, aluminum, or other corrosion-resistant materials to ensure durability and long-term use in various environments.

2. Can T-slot nuts be used in all types of T-slot profiles?No, T-slot nuts are designed to fit specific T-slot profiles. It is important to choose the right size and type of T-slot nut for your particular slot configuration.

3. Are T-slot nuts adjustable?Yes, one of the key features of T-slot nuts is their adjustability. They can be easily slid along the T-slot and locked into position for precise alignment.

4. How do I install T-slot nuts?T-slot nuts are simple to install. They are placed into the T-slot, then rotated or tightened into place using standard tools.

5. What are the main advantages of using T-slot nuts in modular systems?T-slot nuts provide flexibility, ease of installation, and the ability to make quick adjustments, making them perfect for modular and customizable assembly systems.

#Tslotnut#TNut#nut#Tslotnutmanufacturer#Manufacturing#manufacturer#linkedin#Article#nuts#nutmanufacturer#anankafasteners#ananka#fasteners#mumbai#supplier#hex#bolt#usa#uk

0 notes

Text

#horizontal visigauge manufacturer#bolts inspection machine manufacturer in pune#nuts inspection machine manufacturer in pune#washer inspection machine pune#inspects hex nuts#auto parts inspection system pune#o ring inspection machine manufacturer pune#robotics assembly india

0 notes

Text

Types of Brass Nuts Provided by Brass Nut Manufacturer in Jamnagar

If you are looking for quality brass nuts, you should look no further than the brass nut manufacturer in Jamnagar, India. They provide various types including brass hex nuts, brass lock nuts, brass wing nuts, hex jam nut, round nut, square nut and more according to specific client requirements.

#brass nuts#brass nut manufacturer jamnagar#brass nut manufacturer#brass nut suppliers#brass hex nut manufacturer#brass hexagonal nuts#hex jam nut#round nut#square nut#wing nut#fasteners#brass fasteners#brass fasteners manufacturers in jamnagar#brass fasteners exporters#brass fasteners suppliers

0 notes

Text

Fastener World India is a leading hex nut manufacturer in India, offering high-quality hex nuts designed for strength and durability. A Hex is a hexagonal shaped nut that is used to be fitted onto a bolt with the help of internal screw thread. Fastener World India has Hex nuts that come in all sizes for all purposes.

0 notes

Text

#Monel UNS N04400 Heavy Hex Nut#Monel Alloy 400 Hex Nuts Dealer in Mumbai#Monel Alloy 400 Hex Nuts#Monel 400 Nuts Manufacturers#Monel 400 Nuts Suppliers#ASTM F468 Monel Alloy DIN 2.4360 Hex Nuts#400 Monel Alloy Hex Coupling Nuts.

0 notes

Text

Monel 400 Nuts Suppliers in India

Introduction

Monel 400 is a highly versatile nickel-copper alloy known for its exceptional corrosion resistance, strength, and durability. It is widely used in various industries, including marine, chemical, and oil & gas, making Monel 400 nuts a critical component in many industrial applications. India has emerged as a leading manufacturer of Monel 400 nuts, with several companies specializing in the production of these high-quality fasteners. This article provides an overview of Monel 400 nuts manufacturers in India, highlighting their capabilities, offerings, and industry reputation.

What is Monel 400?

Monel 400, also known as Alloy 400, is a nickel-copper alloy with excellent resistance to a wide range of corrosive environments. It contains approximately 67% nickel, 23% copper, and small amounts of iron, manganese, carbon, and silicon. This unique composition makes Monel 400 highly resistant to corrosion, particularly in seawater, hydrofluoric acid, and alkalis. It also exhibits excellent mechanical properties, including high strength and good weldability, making it an ideal material for nuts and other fasteners.

Why Monel 400 Nuts?

Monel 400 nuts are used in applications where ordinary stainless steel or other materials would fail due to corrosion or other environmental factors. These nuts are widely employed in industries such as marine engineering, chemical processing, oil & gas exploration, and aerospace. Their ability to withstand extreme temperatures and corrosive environments makes them indispensable in critical applications.

Why Choose Indian Manufacturers?

Indian manufacturers of Monel 400 nuts are recognized for their commitment to quality, innovation, and customer satisfaction. These companies often invest in the latest technology and employ skilled professionals to ensure that their products meet the highest standards. Additionally, Indian manufacturers offer competitive pricing, making them a preferred choice for customers worldwide.

Chhajed Steel Limited is one of the extraordinary wholesalers of Monel 400 nuts, which are being offered to your custom subtleties, and we accreditation to meet your transport plan. Monel 400 Hex Nuts are exceptional for its high caliber and disintegration safe properties. We are busy with gathering and conveying Monel 400 Heavy Hex Nuts. Created using high-survey unrefined material, these Monel 400 Lock Nuts are known for their dimensional precision. Our Monel 400 Self-Locking Nuts offer a low utilization rate in salt and salty water. It is especially impenetrable to hydrochloric destructive and hydrofluoric acids. Monel 400 Nylon Insert Nuts shows high caliber and stunning utilization security in an extent of acidic and stomach settling agent circumstances and it's especially sensible for reducing conditions. Monel 400 Coupler Nuts furthermore has extraordinary adaptability and warm conductivity.

MONEL ALLOY 400 NUTS SPECIFICATION

Material

Specification

Standards

Size

Length

Monel Alloy 400

IS

BS

ASTM

ASTM F467

3 mm to 200 mm

M02 to M33

Conclusion

Monel 400 nuts play a crucial role in various industrial applications, and India has become a significant player in the global market for these fasteners. With a strong focus on quality, innovation, and customer service, Indian manufacturers are well-positioned to meet the growing demand for Monel 400 nuts. Whether you are looking for standard or custom solutions, the manufacturers mentioned in this article offer a wide range of options to suit your needs.

For More Information:

Visit Our Website -https://www.chhajedfastners.com

Call Us – +91-932-111-3630

Email Us- [email protected]

#Monel UNS N04400 Heavy Hex Nut#Monel Alloy 400 Hex Nuts Dealer in Mumbai#Alloy 400 nuts#400 Monel bolts#Monel 400 Nuts Manufacturers in India

0 notes

Text

As leading nut and bolt manufacturers, suppliers, and exporters in India, we at Mcneil Instruments pride ourselves on delivering a diverse range of high-quality products tailored to your specific needs. Our commitment to customer satisfaction is unwavering, ensuring that every client receives top-notch products and exceptional services. We specialize in comprehensive fabrication materials for overhead transmission lines, offering a wide selection of both mild steel (M S) and galvanized nut bolts in all sizes crucial for construction projects.

At Mcneil Instruments, we understand the critical role that well-finished and precision-made nut bolts play in fabrication construction. Our extensive inventory includes: 5/8″ (16mm) Nut, 1/2″ (12mm) Nut, 5/8″ (16mm) Bolt, 1/2″ (12mm) Bolt

Explore our diverse range of products, including Hex bolts, Round head bolts, Flat head bolts, Hex Nuts, Jam Nuts, and Cap Nuts. Trust Mcneil Instruments for unparalleled quality and performance in every nut and bolt.

" https://www.mcneilinstruments.com/nut-bolts-manufacturers-suppliers.html "

for more details contact us at: +91 9870883613 [email protected]

0 notes

Text

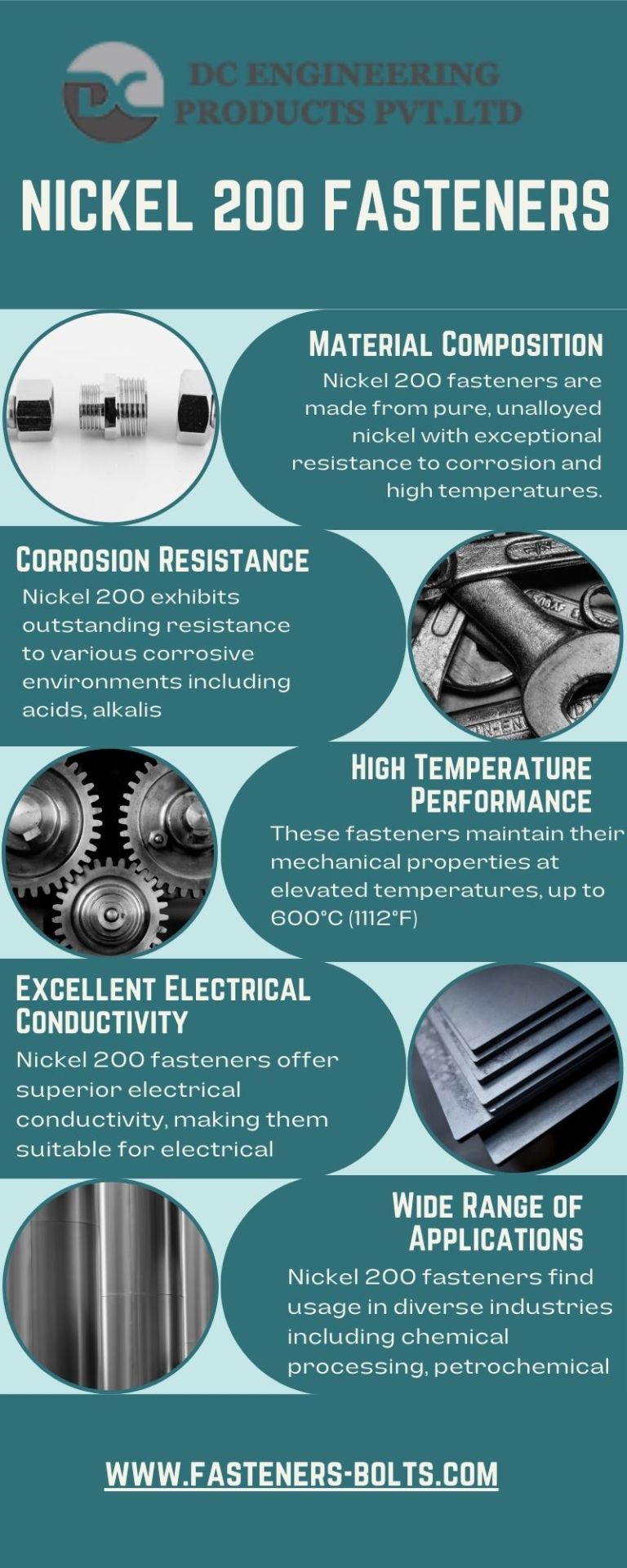

DC Engineering is leading Manufacture and Exporter of High quality of Nickel 200 Fasteners, UNS N02200 Fasteners, Alloy 200 Fasteners

#Nickel 200 Fasteners#High Nickel Alloy 200 Fastener Manufacturer#Nickel Alloy 200 Heavy Hex Nuts#Nickel 200 Hex Head Bolt#UNS N02200 Fastener#DIN 2.4066 Fasteners Supplier#Nickel 200 Spring Washer#Alloy 200 Socket Cap Screws#Nickel Alloy 200 U-bolts#Nickel Alloy 200 Hex Cap Screws#200 Nickel Alloy Hex Bolts

0 notes

Text

0 notes

Text

Hex Nuts Manufacturer India | Roll Fast

We are the Roll-Fast leading manufacturers of Hex Nut for the construction of Petrochemical Industries & general maintenance work on a daily basis. We offer thread Nuts in different grades like 8, 10, 12, 2, 2H, 2HM, 7, 7L, B16 etc. & we offer sizes from M10 to M100 or 1/2” to 4”. There are numerous grades and the heavy pattern is typically used for large diameter and high strength bolts. A nut is a type of fastener with a threaded hole. Nuts are almost always used with a mating bolt to fasten multiple parts together. Hex nuts are one of the most common nuts available and are used with anchors, bolts, screws, studs, threaded rods and on any other fastener that has machine screw threads. Hex is short for hexagon, which means they have six sides. Hex nuts are also known as: finished hex nuts, hex full nuts.

0 notes

Link

BigBoltNut is a leading manufacturer, supplier and exporter of standard hex nuts metric nuts and inch series nuts. Hex nuts are used along with bolts for joining and tightening. Available in 8, 9 and 12 grades. These Nuts are manufactured by us in carbon steel and stainless steel. Popular carbon steel grades include 8, 10, 2H, 2HM, 8, 8M, SS316, SS304, SS316L, SS316S31 etc. The requirements for these are mentioned in the American standard A 194 and A 3506-2. A nut is a type of fastener with a threaded hole. Nuts are almost always used with a mating bolt to fasten multiple parts together. Hex nuts are one of the most common nuts available and are used with anchors, bolts, screws, studs, threaded rods and on any other fastener that has machine screw threads. Hex is short for hexagon, which means they have six sides. Hex nuts are also known as: finished hex nuts, hex full nuts.

0 notes

Text

Lifting Eye Nuts: Comprehensive Guide and Overview

Introduction

Lifting Eye Nuts are vital components in industries requiring heavy lifting and secure fastening. Known for their robust construction and versatile design, these fasteners are used in various applications, ranging from industrial machinery to maritime equipment. This article provides an in-depth exploration of Lifting Eye Nuts, including their types, applications, materials, and advantages.

What are Lifting Eye Nuts?

Lifting Eye Nuts are specialized fasteners designed with a loop (or "eye") at the top, allowing for the attachment of hooks, cables, or ropes. These components are threaded internally, enabling them to be securely fastened onto bolts, studs, or other threaded surfaces. Their main function is to ensure safe and efficient lifting operations.

Types of Lifting Eye Nuts

Collared Eye Nuts:

Designed for heavy-duty lifting applications.

Provide added strength and stability due to the collar around the base.

DIN 582 Eye Nuts:

Manufactured as per DIN 582 standards.

Commonly used in Europe and conform to strict load capacity requirements.

Long Shank Eye Nuts:

Feature an extended shank for better thread engagement.

Suitable for applications requiring additional reach or depth.

Welded Eye Nuts:

Made from welded materials for added durability.

Ideal for demanding applications where high tensile strength is required.

Applications of Lifting Eye Nuts

Lifting Eye Nuts are extensively used in various industries for their reliability and versatility. Some common applications include:

Construction and Infrastructure:

Used for lifting heavy construction materials, equipment, and machinery.

Maritime and Offshore:

Essential for securing and lifting cargo, mooring lines, and anchor points.

Industrial Machinery:

Facilitates the lifting and transportation of large machines and components.

Automotive and Transport:

Helps in towing, lifting, and securing loads on vehicles and trailers.

Oil and Gas:

Utilized in rigging and lifting operations on oil rigs and pipelines.

Materials Used in Lifting Eye Nuts

The choice of material impacts the performance, durability, and safety of Lifting Eye Nuts. Common materials include:

Stainless Steel:

Corrosion-resistant, making it perfect for marine and outdoor applications

Carbon Steel:

Provides exceptional strength, making it ideal for heavy-duty lifting tasks.

Alloy Steel:

Provides excellent tensile strength and durability.

Brass and Bronze:

Used in environments requiring non-sparking properties, such as chemical plants.

Advantages of Lifting Eye Nuts

Safety:

Built to handle defined load capacities, reducing the likelihood of accidents.

Durability:

Made from high-quality materials that withstand extreme conditions.

Versatility:

Compatible with various lifting and rigging systems.

Ease of Use:

Simple installation and removal, making them convenient for repetitive tasks.

Corrosion Resistance:

Certain materials like stainless steel provide long-term performance in harsh environments.

Standards and Certifications

To ensure safety and performance, Lifting Eye Nuts are manufactured as per international standards, such as:

DIN 582: German standard defining load capacities and material specifications.

ISO 3266: A global standard for forged steel lifting components.

ASME B30.26: American standard for rigging hardware.

Choosing the Right Lifting Eye Nut

When selecting a Lifting Eye Nut, consider the following factors:

Load Capacity:

Ensure the eye nut can handle the intended load with an appropriate safety factor.

Thread Size:

Match the eye nut’s internal threading with the external threading of the bolt or stud.

Material:

Choose a material suitable for the application environment (e.g., stainless steel for corrosive settings).

Standards Compliance:

Confirm that the product meets the relevant safety and performance standards.

Conclusion

Lifting Eye Nuts are vital for safe and efficient lifting operations in various industries. Their robust design, diverse materials, and adherence to international standards make them a reliable choice for heavy-duty tasks. Whether in construction, maritime, or industrial applications, Lifting Eye Nuts ensure safety, durability, and functionality.

Frequently Asked Questions (FAQ)

1. What is the load capacity of a Lifting Eye Nut?

The load capacity is determined by the size, material, and design of the eye nut. Always refer to the manufacturer’s specifications.

2. Can Lifting Eye Nuts be used outdoors?

Yes, materials like stainless steel are ideal for outdoor applications due to their corrosion resistance.

3. Are Lifting Eye Nuts reusable?

Yes, provided they are not damaged or deformed during previous use. Regular inspections are recommended.

4. How do I ensure safety while using Lifting Eye Nuts?

Use eye nuts that meet international standards, inspect them regularly, and adhere to specified load limits.

5. Where can I purchase high-quality Lifting Eye Nuts?

Ananka Group is a leading manufacturer, supplier, and exporter of premium-grade Lifting Eye Nuts, offering products that meet global standards.

#ananka#fasteners#manufacturer#fastenersmanufacturer#linkedin#liftingeyenuts#eyenuts#nuts#anankafasteners#article#latestupdate#mumbai#supplier#hex#bolt#usa#uk

0 notes

Text

Glass Disk Based Optical Sorting Machine For Nuts and Washers in pune | India

With its base of a glass disk, Visimaster's Glass Disk Based Optical Sorting Machine For Nuts and Washers ensures that the manufacturing sector uses the least amount of defective fasteners, nuts,and washers. For that reason, any owner of a manufacturing company who is serious about growing their production line, increasing organizational efficiency, and significantly reducing errors has to have this equipment from Visimaster.

#Glass Disc Machine Plastic India#Rubber Parts Inspection Pune#Precision Parts Inspection Manufacturer Pune#Bolts Inspection Machine Manufacturer in Pune#Nuts Inspection Machine Manufacturer in Pune#Inspects Hex Nuts#O Ring Inspection Machine

0 notes

Text

Brass Nut Manufacturer and Supplier in Jamnagar India

GK Metals is a well-known brass nut manufacturer in Jamnagar, India. We manufacture, supply and export top-quality brass hex nuts including brass hexagonal nuts, hex jam nut, round nut, square nut, wing nut and more in various sizes, shapes and designs as per requirement.

#brass nuts#brass nut manufacturer jamnagar#brass nut manufacturer#brass nut suppliers#brass hex nut manufacturer#brass hexagonal nuts#hex jam nut#round nut#square nut#wing nut#fasteners#brass fasteners

0 notes