#glass reactors manufacturers

Explore tagged Tumblr posts

Text

Features and Benefits of GFS Tanks: The Ultimate Solution for Water and Waste Storage

At Glass Fused Steel Tank, we specialize in providing high-quality GFS tanks (Glass Fused Steel Tanks) that offer unmatched durability, versatility, and cost-effectiveness. Whether used for water storage, wastewater treatment, or industrial applications, our GFS tanks deliver long-lasting performance in the harshest conditions. In this article, we’ll explore the key features and benefits that make GFS tanks the preferred choice for industries across the globe.

What Are GFS Tanks?

GFS tanks are made by fusing molten glass to steel, creating a robust, corrosion-resistant surface that can withstand extreme environments. These tanks are bolted together and assembled on-site, making them a flexible and efficient storage solution for a variety of applications, including potable water storage, effluent treatment, and industrial wastewater management.

Key Features of GFS Tanks

Corrosion Resistance One of the standout features of GFS tanks is their exceptional resistance to corrosion. The glass coating applied to the steel protects the tank from rust, chemicals, and environmental factors that would otherwise deteriorate conventional storage tanks. This makes them ideal for harsh conditions such as wastewater treatment or storing chemicals.

Durability The fusion of glass and steel creates a durable surface that can last for decades with minimal maintenance. GFS tanks are designed to handle the physical and chemical stresses of both potable and non-potable water storage, as well as other industrial liquids.

Quick Installation Since GFS tanks are bolted together, they can be assembled quickly on-site without the need for complex construction methods. This feature significantly reduces project timelines and labor costs, making GFS tanks a more economical choice compared to traditional welded or concrete tanks.

Modular Design The modular design of GFS tanks means they can be customized to fit specific project needs. Whether you need a large-capacity water tank or a specialized wastewater treatment tank, GFS tanks can be easily expanded, relocated, or modified to accommodate changing requirements.

Low Maintenance Thanks to the non-porous glass coating, GFS tanks require very little maintenance. The glass surface resists the buildup of contaminants and is easy to clean, reducing operational downtime and maintenance costs over the tank’s lifespan.

Aesthetic Appeal GFS tanks are available in a range of colors, allowing them to blend seamlessly into any environment. The aesthetic flexibility makes them a preferred choice for public water supply projects, agricultural settings, and commercial applications where appearance matters.

Leak-Free Bolted Design The bolted design of GFS tanks ensures a leak-proof structure, providing secure storage for liquids, gases, and solids. The tank’s panels are bolted together with precision, creating a tight seal that prevents leaks and contamination.

Benefits of GFS Tanks

Long Lifespan Due to the glass coating and durable steel structure, GFS tanks can last up to 30 years or more with proper maintenance. This long lifespan translates into lower replacement and repair costs, making them a cost-effective solution in the long run.

Versatile Applications GFS tanks are used in a wide range of applications, from potable and raw water storage to Sewer Treatment (STP) Water Tanks, Effluent Treatment (ETP) Water Tanks, and even biogas digesters. Their versatility makes them an excellent choice for industries that require reliable, long-term storage solutions.

Cost-Effective The quick installation, minimal maintenance requirements, and long lifespan of GFS tanks make them a highly cost-effective solution compared to traditional storage tanks. Reduced labor, material, and downtime costs contribute to their overall affordability.

Environmentally Friendly GFS tanks are built with sustainability in mind. Their long lifespan reduces the need for frequent replacements, and the glass-fused surface helps prevent contamination and leaching of harmful chemicals, making them an environmentally responsible choice for water and waste management.

Compliance with Global Standards Our GFS tanks are manufactured to meet international standards such as AWWA D103, NFPA, and FM Global certifications. This ensures that they meet the safety, durability, and environmental requirements of projects worldwide.

Applications of GFS Tanks

Water Storage Solutions: From potable water storage to fire protection and irrigation, GFS tanks provide reliable solutions for water management.

Wastewater Treatment: The corrosion-resistant glass lining makes GFS tanks perfect for handling the harsh environments of Sewer Treatment (STP) Water Tanks and Effluent Treatment (ETP) Water Tanks.

Industrial Use: For industries that need to store chemicals, wastewater, or process water, GFS tanks offer a robust, low-maintenance solution that can handle even the toughest conditions.

Agriculture: Farmers and agricultural industries benefit from the long-term durability and customizable capacity of GFS tanks for irrigation, raw water storage, and fertilizer storage.

Conclusion

GFS tanks from Glass Fused Steel Tank provide an optimal balance between durability, flexibility, and cost-efficiency, making them the go-to solution for industries requiring reliable storage. Whether you need tanks for water, wastewater, or industrial applications, our GF

#gfs tank#biogas digester#gfs applications#UASB reactors#Manufacturer and supplier of gfs tank#water storage solutions#Sewer Treatment (STP) Water Tanks#Effluent Treatment (ETP) Water Tanks#Epoxy Coated Water Tanks#Glass Fused Water Tanks#Galvanized Steel Water Tanks

0 notes

Text

0 notes

Text

0 notes

Text

glass reactor with stainless steel jacket by Ablaze Export - Customer review

0 notes

Text

#Glass Lind Reactor Seal#carbon seal manufacturers#mechanical seal#mechanical shaft seals#reactor seals

0 notes

Text

Best Glass Reactor Suppliers and Manufacturer Best Glass Reactor Suppliers and Manufacturer is the best reactor manufacturers in China, who owns a vast amount of experience in the field of glass heatshields. We have taken great care to ensure each and every pendant is made using only premium materials that have been carefully selected to give your reactor the best possible performance.

0 notes

Text

Cylindrical vessels manufacturers in Vadodara | Ablazeglassworks

Ablaze Glass Works is one of the most distinguished Cylindrical vessels manufacturers in Vadodara. We provide complete corrosion resistance solution to the engineering needs of our clients in chemical, pharmaceutical, petrochemical and allied industries. Our products also find use in laboratories and academic institutions as well as for R&D purpose.

If you are looking for top-ranking Cylindrical vessels manufacturers in India, Ablaze Glass Works is the right place for you.

#Cylindrical vessels manufacturers in Vadodara#Cylindrical vessels manufacturers in india#Borosilicate glass reactors

1 note

·

View note

Text

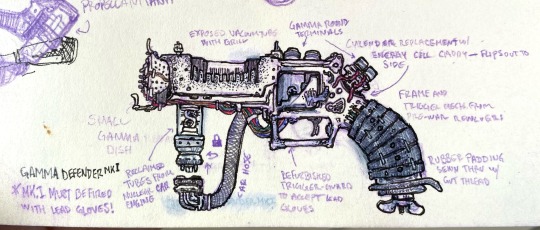

Whitehall Workshops Experimental Weapons pt 2/???

I got bit by the bug again & have booted up my console Fallout 4 files, which means the Wacky Weapons Workshop is back in my greedy little hands. Here’s some more ideas for arms that might come out of the various settlements being half-run by my Vault 49er, Whipstitch Whitehall.

Gamma Defender Mk I

Gamma Defenders were ideated as a solution to handmade energy weapons being able to carry a payload beyond traditional energy damage from lasers or plasma reactors. Parts were sourced from relatively common sights; glass tubes & hose connections from prewar Corvega engines, broken down Gamma Guns from scavenging the outskirts of the Glowing Sea, and any rusted-out revolver frame that still has a working trigger and cylinder hinge. The traditional revolver magazine is converted into a hinged energy cell caddy, and electrical components replace much of the revolver frame forward of the magazine.

Unfortunately, the weapon was quite clumsy and not easily transported over long distances, as it couldn’t fit into traditional chest or hip holsters. Another problem arose from the unstable radiation sinks installed around the “barrel tube”, which required operators to handle the active weapon strictly with lead-lined gloves. To accommodate this, a late-stage modification was added to the Mk I’s blueprints—an extended trigger guard to more-comfortably accept lead-lined gloves. With its long list of manufacturing nuances the Mk I saw minor use defending small settlements across the northern stretch of the Commonwealth. After a few short years however the availability of other Whitehall Workshop weapons like the Salvaged SynthLaz & the LACS began overshadowing the Gamma Defender Mk I, and its blueprints soon cluttered the shelves of many an isolated workshop.

Further experimentation needed.

#fallout#fallout 2#fallout 3#fallout 4#fallout 76#concept art#fallout concept art#fallout fanart#fallout fan art#fan concept#energy weapons#fallout energy weapons#gamma defender#whipstitch#whitehall workshop#art#mine#illustration#illustrators on tumblr#scifi#sci fi concept art

27 notes

·

View notes

Text

Quartz glass reactor: ideal for high temperature tolerance and precision chemical reactions

Quartz glass reactor is an instrument designed for high-precision chemical experiments and is widely used in scientific research laboratories and the chemical industry. Quartz glass is known for its excellent high temperature resistance, chemical resistance and high light transmittance, and is an ideal material for high-temperature reactions and observing process details.

This quartz reactor has a built-in spiral condenser, which can effectively control the temperature during the reaction and reduce the volatilization loss of reactants. This design not only ensures the safety and stability of the reaction, but also improves the experimental efficiency. It is an ideal choice for high-end laboratories and chemical companies. The transparent properties of quartz glass allow users to directly observe the changes in the internal reaction and provide more data support for the experiment.

Core features of quartz glass reactor:

High temperature resistance: Quartz glass maintains a stable shape under high temperature conditions and is suitable for a variety of high-temperature reactions.

Chemical corrosion resistance: Suitable for contact with a variety of chemical reagents and prolongs service life.

High light transmittance: It is easy to observe the reaction process and is suitable for high-demand experimental scenarios.

Built-in condensation system: Spiral condenser design, effective temperature control, to ensure experimental accuracy.

Whether it is organic synthesis, material preparation, or other high-temperature chemical experiments, quartz glass reactors are a reliable choice. Choose high-quality quartz glass instruments to help scientific research and industrial processes and provide support for precision experiments.

0 notes

Text

Best Double Jacketed Glass Unit | Goel Scientific | Canada

We Manufacture & Design Double Jacketed Reactor Wide Range Units, 35 Years of experience, in Goel Scientific Glass Canada, USA Ontario BC Quebec, Alberta

#Best#Top#We Manufacture & Design Double Jacketed Reactor Wide Range Units#35 Years of experience#in Goel Scientific Glass Canada#USA Ontario BC Quebec#Alberta

0 notes

Text

GFS Tank Applications: Innovative Solutions for Water and Waste Management

At Glass Fused Steel Tank, we specialize in the production of GFS tanks (Glass Fused Steel Tanks), offering versatile and durable solutions for a wide range of industries. From water storage to waste management, GFS applications cover critical sectors such as wastewater treatment, biogas production, and industrial processes. With our expertise as a manufacturer and supplier of GFS tanks, we provide innovative solutions tailored to meet the unique needs of businesses and communities worldwide.

What is a GFS Tank?

A GFS tank is a high-quality storage solution made by fusing glass with steel. This process creates a robust, corrosion-resistant tank that is ideal for storing liquids and gases in a wide range of applications. GFS tanks are known for their long-term durability, low maintenance, and resistance to harsh environmental conditions, making them an excellent choice for water and waste management systems.

GFS Applications in Biogas Digesters and UASB Reactors

One of the most innovative GFS applications is its use in biogas digesters and UASB reactors (Upflow Anaerobic Sludge Blanket). Biogas digesters convert organic waste into methane-rich biogas, which can be used as a renewable energy source. The corrosion resistance of GFS tanks makes them ideal for containing the organic matter and gases produced during this process.

UASB reactors, another key application for GFS tanks, are used in wastewater treatment to process high-strength industrial wastewater. The glass-fused coating protects the tank from the corrosive effects of the sludge and gases generated during anaerobic digestion.

Water Storage Solutions with GFS Tanks

Our GFS tanks are widely used in a variety of water storage solutions. Whether it's for potable water, raw water, or wastewater, GFS tanks offer the strength, durability, and flexibility needed to meet the demands of water management in both industrial and municipal settings. Some of our key water storage solutions include:

Sewer Treatment (STP) Water Tanks: GFS tanks are used to store and treat sewage before it undergoes further purification. The corrosion-resistant nature of the tanks ensures long-term performance in handling wastewater.

Effluent Treatment (ETP) Water Tanks: Industries that generate wastewater rely on ETP water tanks to store and treat effluents before discharge. Our GFS tanks are designed to safely contain and process these effluents, minimizing environmental impact.

Epoxy Coated and Glass Fused Water Tanks

We also offer epoxy coated water tanks and glass fused water tanks for specialized applications where extra protection from corrosion and chemicals is required. These tanks are highly suitable for environments that involve harsh chemicals or extreme conditions. The epoxy coating adds an extra layer of protection, while the glass-fused surface creates a non-porous, smooth finish that enhances the tank's lifespan.

Galvanized Steel Water Tanks

For projects that require additional structural strength and durability, our galvanized steel water tanks provide a dependable solution. These tanks are coated with zinc to prevent rust and corrosion, making them ideal for outdoor applications and environments with fluctuating weather conditions. Galvanized steel tanks are a cost-effective solution for large-scale water storage projects.

The Advantages of GFS Tanks for Multiple Applications

Durability: The glass fused to steel structure provides unmatched resistance to corrosion, chemicals, and weather extremes, ensuring a long service life.

Versatility: GFS tanks are suitable for various industrial applications, including biogas digesters, wastewater treatment plants, and potable water storage.

Low Maintenance: The glass coating makes the tank easy to clean and maintain, reducing downtime and operational costs.

Quick Installation: GFS tanks are bolted and assembled on-site, making them faster to install than traditional concrete or welded tanks.

Manufacturer and Supplier of GFS Tanks

As a leading manufacturer and supplier of GFS tanks, we are committed to providing high-quality products and services to our clients worldwide. Our tanks are manufactured to meet international standards, ensuring that they deliver reliable performance in diverse industries and climates. From initial consultation to installation, we provide end-to-end solutions for all your water storage and waste management needs.

Conclusion

Glass Fused Steel Tanks are the ideal solution for a variety of GFS applications across industries such as wastewater treatment, biogas production, and water storage. Whether you need Sewer Treatment (STP) water tanks, Effluent Treatment (ETP) water tanks, or galvanized steel water tanks, our GFS tanks provide the durability, versatility, and efficiency required for these applications.

#gfs tank#biogas digester#gfs applications#UASB reactors#Manufacturer and supplier of gfs tank#water storage solutions#Sewer Treatment (STP) Water Tanks#Effluent Treatment (ETP) Water Tanks#Epoxy Coated Water Tanks#Glass Fused Water Tanks#Galvanized Steel Water Tanks

0 notes

Text

0 notes

Text

Glass-Lined Dark Green Anaerobic Digester Tank with EGSB Reactor: A Sustainable Solution for Efficient Biogas Production

At Shijiazhuang Zhengzhong Technology Co., Ltd, we are dedicated to pioneering innovative solutions in the field of renewable energy and waste management. Our Glass-Lined Dark Green Anaerobic Digester Tanks, paired with the Expanded Granular Sludge Bed (EGSB) Reactor, offer a robust and efficient system for converting organic waste into valuable biogas. This combination not only maximizes biogas production but also ensures environmental sustainability.

Understanding Anaerobic Digestion

Anaerobic digestion is a biological process that transforms organic materials—such as agricultural residues, food waste, and livestock manure—into biogas in the absence of oxygen. This process is facilitated by specialized microorganisms that break down organic matter, producing biogas primarily composed of methane, which can be used for electricity generation, heating, or as a vehicle fuel. The remaining digestate can be utilized as a nutrient-rich fertilizer, supporting sustainable agricultural practices.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Key Features of Our Glass-Lined Dark Green Anaerobic Digester Tank with EGSB Reactor

1. Superior Glass-Lining Technology

Our anaerobic digester tanks are lined with high-quality glass enamel, offering exceptional resistance to corrosion and chemical degradation. The glass lining enhances the durability of the tank, ensuring a long operational life and minimizing maintenance costs. The dark green color not only provides an aesthetically pleasing appearance but also helps in temperature regulation, contributing to the efficiency of the digestion process.

2. Integrated EGSB Reactor Design

The EGSB reactor is designed to enhance the anaerobic digestion process by providing a high hydraulic retention time (HRT) while maintaining a compact footprint. This innovative design allows for efficient biogas production, even at high organic loading rates. The expanded granular sludge bed promotes effective contact between the microorganisms and the organic substrate, maximizing biogas yield.

3. High Airtightness

The airtight design of our glass-lined anaerobic digester tank ensures optimal anaerobic conditions, preventing the ingress of oxygen that could disrupt the digestion process. This feature is critical for maintaining the efficiency and stability of biogas production.

4. Efficient Biogas Production

The combination of the glass-lined tank and EGSB reactor allows for rapid degradation of organic materials, resulting in efficient biogas production. This biogas can be further processed to generate renewable energy, contributing to sustainable energy solutions.

Benefits of Glass-Lined Anaerobic Digester Tanks

Corrosion Resistance

The glass lining provides superior corrosion resistance, protecting the tank structure from aggressive materials and ensuring longevity. This is especially important in anaerobic digestion, where the environment can be harsh.

Reduced Maintenance

The smooth surface of glass lining makes cleaning and maintenance easier, helping to maintain hygienic conditions within the tank. This reduces downtime and operational costs, allowing for more efficient waste processing.

Environmental Benefits

Utilizing organic waste for biogas production significantly reduces greenhouse gas emissions compared to traditional waste disposal methods. Our glass-lined anaerobic digester tanks contribute to a circular economy by transforming waste into renewable energy, aligning with global sustainability goals.

Comprehensive Services Offered

At Center Enamel, we are committed to providing not just high-quality products, but also comprehensive services tailored to meet the needs of our clients:

Custom Engineering Design: Our experienced engineering team collaborates with you to develop tailored anaerobic digester solutions that meet your specific project requirements.

Professional Installation Services: We provide expert installation services to ensure that your anaerobic digester tank and EGSB reactor are set up correctly, optimizing performance and minimizing disruptions.

Ongoing Support and Maintenance: Our commitment extends beyond installation. We offer ongoing support and maintenance services to ensure the longevity and efficiency of your anaerobic digestion system.

Global Expertise and Reach

With over 30 years of experience, Center Enamel has established a strong global presence, delivering our Glass-Lined Dark Green Anaerobic Digester Tanks with EGSB Reactors to clients worldwide. We are dedicated to helping organizations transition to sustainable energy solutions that are economically viable and environmentally responsible.

Shijiazhuang Zhengzhong Technology Co., Ltd’s Glass-Lined Dark Green Anaerobic Digester Tanks with EGSB Reactors offer an ideal solution for organizations looking to harness the power of anaerobic digestion for renewable energy production. Our focus on quality, innovation, and sustainability positions us as a leader in the industry, enabling our clients to effectively manage organic waste while contributing to a cleaner, greener future. Choose Center Enamel for your anaerobic digestion needs and become part of the renewable energy revolution.

0 notes

Text

Safety Tips for Operating a Double Jacketed Glass Reactor: Best Practices to Follow

Operating a double jacketed glass reactor is a critical process in many chemical and pharmaceutical industries. These systems are invaluable for controlled reactions, allowing for precise temperature regulation, mixing, and containment of potentially hazardous substances. While their functionality and benefits are undeniable, safe operation is paramount. Ensuring proper handling and maintenance of these units not only extends their lifespan but also protects operators and the environment. This guide provides detailed safety tips and best practices for operating a double jacketed glass reactor.

Understanding the Double Jacketed Glass Reactor

Before diving into safety tips, it's important to understand what is a glass reactor and its significance in chemical process systems. A double jacketed glass reactor consists of two layers of glass – an inner vessel where the chemical reactions take place and an outer jacket where a heating or cooling fluid circulates. This design allows for precise control over the reaction environment, ensuring that the temperature can be regulated efficiently without direct contact between the heating/cooling medium and the reactants.

Glass reactors, in general, are versatile tools used in research and industrial applications for synthesizing chemicals, conducting chemical reactions, crystallization processes, and more. In chemical process systems, the ability to maintain an exact temperature while keeping the reaction environment closed and controlled is crucial, especially when handling sensitive or hazardous materials.

Safety Tips for Operating a Double Jacketed Glass Reactor

1. Understand the Equipment Thoroughly

One of the foundational steps to ensure safe operation is understanding what is a glass reactor and how it functions. Before you start using a double jacketed glass reactor, familiarize yourself with the user manual provided by the manufacturer. This will give you insights into the technical specifications, operating instructions, and safety precautions specific to the model you are using.

Each double jacketed glass reactor may have unique features, such as temperature controls, stirring mechanisms, and pressure management systems, which should be understood in detail. This knowledge helps prevent accidents resulting from misuse or misunderstanding of the equipment.

2. Inspect the Reactor Before Each Use

Before beginning any reaction, inspect the double jacketed glass reactor thoroughly. Look for cracks, chips, or any damage to the glassware, as this can lead to dangerous leaks or catastrophic failure during a chemical process. The outer jacket, in particular, should be free from defects to ensure that the circulating heating/cooling fluid does not leak or come into contact with the chemicals inside the reactor.

Additionally, check the seals and gaskets for wear and tear, as these components play a vital role in maintaining the pressure and integrity of the system. Faulty seals can result in leaks, pressure build-ups, or even contamination of the reaction process.

3. Ensure Proper Temperature Control

In chemical process systems, temperature control is one of the most critical aspects, particularly when operating a double jacketed glass reactor. The outer jacket allows for the circulation of heating or cooling fluids, which ensures that the internal temperature is kept within a safe range. It is essential to use a reliable thermostat and monitor the temperature closely throughout the process.

Temperature fluctuations or overheating can result in thermal stress on the glass, leading to cracks or breakage. Always ensure that the temperature ramp-up or cooldown is gradual to avoid shock to the glass material.

4. Use the Right Heating and Cooling Fluids

When using a double jacketed glass reactor, selecting the appropriate heating or cooling fluids for your system is critical. Common fluids include water, oil, or specific chemical solutions depending on the desired temperature range. Ensure that the fluid is compatible with the reactor's materials and operating conditions.

For example, if you're conducting a low-temperature reaction, the fluid needs to have a freezing point lower than the reaction's target temperature. Likewise, for high-temperature reactions, the fluid's boiling point should be higher than the temperature you're working with to prevent vaporization within the jacket.

5. Follow Pressure Guidelines

A double jacketed glass reactor can sometimes operate under vacuum or positive pressure, depending on the nature of the reaction. It is essential to adhere to the manufacturer’s recommended pressure limits. Over-pressurizing the reactor can result in the glass vessel shattering, while under-pressure (vacuum) operations require ensuring that the vessel can handle such conditions without imploding.

Before applying any pressure or vacuum, double-check all connections, fittings, and valves to ensure they are secure and leak-proof. Always use calibrated pressure gauges to monitor the internal conditions and prevent exceeding the limits of the reactor.

6. Use Personal Protective Equipment (PPE)

Operating a double jacketed glass reactor in chemical process systems involves handling chemicals that may be hazardous, as well as exposure to high temperatures and pressures. Therefore, personal protective equipment (PPE) is non-negotiable. Ensure that operators wear safety goggles, gloves, lab coats, and other necessary protective gear at all times.

In case of an accident, PPE can protect against chemical splashes, glass breakage, and other potential hazards. Additionally, it's good practice to have an emergency shower and eyewash station nearby in case of accidental chemical exposure.

7. Maintain Adequate Ventilation

Proper ventilation is essential when operating any chemical reactor, including a double jacketed glass reactor. The chemical reactions taking place inside the reactor may produce gases, some of which can be toxic or flammable. Ensure that the working area is well-ventilated to avoid the buildup of harmful vapors.

In cases where toxic or volatile chemicals are involved, operating the reactor inside a fume hood is highly recommended. This helps in safely venting away any dangerous fumes and protects the operator from exposure.

8. Avoid Thermal Shock

One of the most significant risks when handling glassware in chemical process systems is thermal shock. Glass is highly susceptible to cracking or shattering if exposed to sudden temperature changes. When working with a double jacketed glass reactor, avoid subjecting the glass to rapid temperature shifts. For instance, if the reactor has been heated, allow it to cool down gradually before introducing cold fluids.

Similarly, if the reactor has been chilled, avoid immediately applying heat. Gradual changes in temperature help protect the glass from stress and extend the lifespan of the reactor.

9. Perform Regular Maintenance and Calibration

Regular maintenance of the double jacketed glass reactor is essential to ensure its safe and efficient operation. This includes inspecting all components, replacing worn parts, and cleaning the reactor after every use to avoid contamination.

Calibration of temperature sensors, pressure gauges, and stirring mechanisms should also be performed routinely to ensure accurate readings and avoid malfunctions during critical processes. Following the manufacturer’s recommended maintenance schedule helps keep the reactor in peak condition.

10. Emergency Preparedness

Even with all precautions in place, accidents can happen when working with chemical process systems. Having a well-defined emergency plan is crucial. Operators should be trained on how to handle spills, leaks, and breakages. Know the location of the nearest fire extinguisher, first aid kit, and chemical spill kit.

Additionally, in the event of a glass breakage or chemical leak, evacuate the area and allow the ventilation system to remove any hazardous fumes before attempting to clean up the mess.

Conclusion

Operating a double jacketed glass reactor safely requires a thorough understanding of what is a glass reactor, as well as adherence to best practices specific to the equipment and chemical process systems. By following the tips outlined above—ranging from regular equipment inspection and temperature control to personal protective equipment and emergency preparedness—you can significantly reduce the risk of accidents and ensure that your chemical processes are carried out safely and efficiently.

For those looking for high-quality reactors, Kjhil offers reliable, durable, and expertly designed double jacketed glass reactors that adhere to the highest safety standards, ensuring both efficiency and safety in your laboratory or industrial setting. Always remember that safety starts with understanding the equipment and being prepared for any challenges that may arise during operation.

By implementing these safety tips and maintaining a proactive approach to the maintenance and operation of your double jacketed glass reactor, you can ensure a safer working environment and more successful chemical processes.

#jacketed glass reactor vessel#double jacketed glass reactor#chemical process system#chemical process plant

0 notes

Text

Barium Sulfide Manufacturing Plant Project Report 2024: Industry trends and Plant Setup

Introduction

Barium sulfide is a chemical compound widely used in various industries, including manufacturing, agriculture, and environmental management. It is particularly valued in applications such as fluorescent lights, ceramics, and as a precursor for other barium compounds. Given its diverse applications and market demand, establishing a manufacturing plant for barium sulfide represents a strategic business opportunity. This Barium Sulfide Manufacturing Plant Project Report provides a comprehensive guide to setting up a barium sulfide manufacturing facility, covering market analysis, plant setup, production processes, and financial considerations.

Market Analysis

Industry Overview

The global barium sulfide market is influenced by its various industrial applications. Barium sulfide is used in the production of barium pigments, which are essential in creating bright colors in ceramics and glass. It is also used in the manufacture of barium ferrites for magnets and in the treatment of wastewater to remove sulfate ions. The market for barium sulfide is expected to grow with increased industrial activities and advancements in technology.

Target Market

Manufacturers of Fluorescent Lights: Barium sulfide is used in the production of phosphors for fluorescent lamps.

Ceramic and Glass Manufacturers: The compound is used as a colorant and opacifier in ceramics and glass products.

Environmental and Water Treatment Facilities: Barium sulfide is utilized in processes for treating and purifying water.

Chemical Industry: Companies involved in the production of other barium compounds or chemicals may be key customers.

Competitive Landscape

The barium sulfide market is competitive, with several established players. Key competitors include chemical manufacturers specializing in barium compounds and companies in related industries. To stand out, focus on high-quality production, cost-efficiency, and strong customer relationships

Get a Free Sample Report with Table of Contents @

https://www.expertmarketresearch.com/prefeasibility-reports/barium-sulfide-manufacturing-plant-project-report/requestsample

Plant Setup

Location

Selecting the right location for your barium sulfide manufacturing plant is crucial:

Proximity to Raw Materials: Ensure access to barium carbonate and sulfur, the primary raw materials used in barium sulfide production.

Infrastructure: Choose a location with good infrastructure, including transportation links, utilities, and skilled labor.

Regulatory Environment: Opt for a location with favorable environmental and industrial regulations.

Facility Layout

A well-organized facility layout is essential for efficient operations:

Raw Material Storage: Secure storage for barium carbonate, sulfur, and other raw materials.

Production Area: Includes reactors for chemical reactions, filtration systems, and drying units.

Quality Control Lab: For testing and analyzing raw materials and finished products.

Packaging and Distribution: For packing the final product and preparing it for shipment.

Administrative Offices: For managing operations, compliance, and human resources.

Equipment and Technology

Invest in modern equipment and technology to ensure high-quality production:

Reactors: For conducting the chemical reactions required to produce barium sulfide.

Filtration Systems: For separating and purifying barium sulfide from the reaction mixture.

Drying Units: For drying the final product to obtain the desired physical form.

Quality Control Instruments: For analyzing the purity and quality of barium sulfide.

Production Process

Raw Materials

The primary raw materials for barium sulfide production are barium carbonate (BaCO₃) and sulfur (S). These materials are chemically reacted to produce barium sulfide.

Manufacturing Steps

Reaction: Barium carbonate and sulfur are combined in a high-temperature reactor to produce barium sulfide and carbon dioxide. The chemical reaction is as follows: BaCO3+S→BaS+CO2\text{BaCO}_3 + \text{S} \rightarrow \text{BaS} + \text{CO}_2BaCO3+S→BaS+CO2

Filtration: The reaction mixture is filtered to separate the barium sulfide from any remaining impurities or by-products.

Washing: The barium sulfide is washed to remove any residual reactants and impurities.

Drying: The washed barium sulfide is dried to obtain a fine powder or granules, depending on the required product form.

Packaging: The final product is packaged in suitable containers for distribution.

Quality Assurance

Implement stringent quality control measures:

Raw Material Testing: Ensure the quality of incoming barium carbonate and sulfur.

In-Process Monitoring: Regularly monitor the reaction parameters to maintain consistency and quality.

Final Product Testing: Conduct tests to verify the purity, particle size, and other properties of the barium sulfide.

Financial Considerations

Investment Requirements

Initial investments include costs for facility construction or leasing, purchasing equipment, and acquiring raw materials. Additional expenses cover licensing, regulatory compliance, and staffing.

Revenue Projections

Estimate revenue based on production capacity, market demand, and pricing strategies. Consider factors such as production costs, competitor pricing, and market potential.

Cost Management

Effective cost management involves:

Budgeting: Develop a detailed budget for plant setup and operations.

Efficiency: Implement cost-saving measures such as energy-efficient equipment and bulk purchasing of raw materials.

Monitoring: Regularly review financial performance and adjust strategies as needed.

FAQ

1. What is barium sulfide, and what are its main uses?

Barium sulfide is a chemical compound used in various applications, including the production of fluorescent lights, ceramics, and pigments. It is also used in water treatment processes and as a precursor for other barium compounds.

2. How long does it take to set up a barium sulfide manufacturing plant?

Setting up a barium sulfide manufacturing plant typically takes between 12 to 18 months. This includes facility construction or leasing, equipment installation, obtaining regulatory approvals, and training staff.

3. What are the primary challenges in manufacturing barium sulfide?

Challenges include ensuring consistent product quality, managing raw material supply, meeting environmental and safety regulations, and maintaining cost-efficiency in production.

4. How can I ensure quality control in barium sulfide production?

Implement comprehensive quality control measures, including testing raw materials, monitoring production processes, and conducting rigorous testing of the final product. Compliance with safety and industry standards is also crucial.

5. What environmental considerations should be addressed in this type of manufacturing plant?

Environmental considerations include managing chemical waste, reducing energy consumption, and ensuring compliance with environmental regulations. Implementing recycling practices and energy-efficient technologies can help mitigate environmental impact.

6. How can I differentiate my barium sulfide product from competitors?

Differentiate your product by focusing on high-quality manufacturing, competitive pricing, and excellent customer service. Building strong relationships with customers and suppliers can also provide a competitive edge.

Related Reports

https://www.expertmarketresearch.com/reports/packaged-food-market

https://www.expertmarketresearch.com/reports/north-america-customer-journey-analytics-market

https://www.expertmarketresearch.com/reports/flexible-plastic-packaging-market

Media Contact:

Company Name: Claight Corporation Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A. Email: [email protected] Toll Free Number: +1–415–325–5166 | +44–702–402–5790 Address: 30 North Gould Street, Sheridan, WY 82801, USA Website: www.expertmarketresearch.com Aus Site: https://www.expertmarketresearch.com.au

0 notes

Text

The Versatility and Benefits of Industrial Quartz Glass Tubes

Industrial quartz glass tubes are an essential component in a variety of high-tech applications, thanks to their unique properties and versatility. Manufactured from high-purity quartz, these tubes offer exceptional thermal, chemical, and optical performance, making them ideal for demanding industrial environments. Apex Quartz, a leader in the quartz glass industry, highlights the advancements and applications of industrial quartz glass tubes.

One of the primary advantages of quartz glass tubes is their outstanding thermal resistance. Unlike traditional glass, quartz glass can withstand extreme temperatures without deforming or breaking. This thermal stability makes quartz glass tube perfect for use in high-temperature processes, such as in furnaces, reactors, and lighting systems. Their ability to handle thermal shock without compromising performance ensures reliability and longevity in these applications.

Quartz glass tubes also offer superior optical clarity and transmission. Their low thermal expansion and high transmission across a wide range of wavelengths make them ideal for applications requiring precise optical performance. This includes uses in UV lamps, scientific instruments, and optical fibers. The clarity and consistency of quartz glass tubes contribute to accurate measurements and efficient operation in various technological systems.

Additionally, quartz glass tubes are highly resistant to chemical corrosion. Their durability against acids and other harsh chemicals ensures they remain intact and functional in corrosive environments, such as chemical processing and laboratory applications. This resistance to chemical attack enhances their reliability and reduces the need for frequent replacements.

Apex Quartz, renowned for its expertise in quartz glass manufacturing, provides high-quality quartz glass tubes designed to meet the specific needs of different industries. Their advanced production techniques and commitment to quality ensure that each quartz glass tube delivers optimal performance and durability.

In summary, industrial quartz glass tubes offer exceptional thermal resistance, optical clarity, and chemical durability, making them invaluable in high-tech and demanding applications. With innovations from leaders like Apex Quartz, quartz glass tubes continue to drive progress and efficiency across various industrial sectors.

0 notes