#glass bottle manufacturers in india

Explore tagged Tumblr posts

Text

The Evolution of Glass Packaging: A Journey Through Innovation and Sustainability

Glass packaging has long been admired for its durability, elegance, and versatility. From perfumes to food jars, glass packaging has seamlessly combined form and function to meet diverse industry needs. Over the years, the rise of modern technology and shifting consumer preferences have transformed glass packaging into a symbol of innovation and sustainability. Here’s an exploration of how glass packaging has evolved, featuring insights into the contributions of perfume bottle manufacturers, glass bottle manufacturers in India, and glass jar manufacturers.

1. Historical Significance: The Origins of Glass Packaging

The story of glass packaging dates back thousands of years, originating in ancient Mesopotamia and Egypt. Early glass containers were handcrafted, making them a luxury only a few could afford. Over time, advancements in glassblowing techniques revolutionized production, making glass accessible to more industries and consumers.

Today, glass bottle manufacturers in India and across the globe honor this rich heritage by combining traditional craftsmanship with modern manufacturing processes. Their products - from intricate perfume bottles to robust jars - echo the timeless appeal of glass while meeting contemporary demands.

2. Modern Applications: Meeting Diverse Industry Needs

Glass packaging has carved a niche in various sectors, thanks to its unmatched properties. In the fragrance industry, perfume bottle manufacturers create containers that not only preserve the aroma but also enhance the luxury quotient of the product. These bottles are often adorned with elegant designs, catering to both aesthetics and functionality.

Similarly, glass jar manufacturers cater to food and beverage companies by offering containers that ensure freshness and extend shelf life. The see-through nature of glass jars gives consumers a clear view of the product inside, building confidence and encouraging purchases. Glass packaging has also found applications in pharmaceuticals and cosmetics, where safety and hygiene are paramount.

3. Sustainability: A Key Driver in Glass Packaging’s Evolution

As sustainability becomes a global priority, glass packaging has emerged as a frontrunner in eco-friendly solutions. Unlike plastic, glass is fully recyclable and does not degrade in quality during the recycling process. This makes it an ideal choice for environmentally conscious brands and consumers.

Glass bottle manufacturers in India are actively adopting sustainable practices, such as using renewable energy in production and designing lightweight bottles to reduce carbon footprints. These efforts align with the growing demand for sustainable packaging, which is reshaping industry standards worldwide.

4. Innovation: Pushing the Boundaries of Design and Functionality

Innovation has been a cornerstone of glass packaging’s success. Modern technology has enabled manufacturers to create thinner yet stronger glass, reducing material use without compromising durability. Additionally, advanced decoration techniques, such as frosting and engraving, allow brands to customize glass bottles and jars to reflect their unique identity.

For instance, perfume bottle manufacturers are experimenting with bold shapes and intricate details to make their products stand out in a crowded market. Meanwhile, glass jar manufacturers are incorporating smart packaging features like UV protection and tamper-evident seals, further enhancing the functionality of their products.

5. The Role of India in the Global Glass Packaging Market

India has emerged as a key player in the global glass packaging industry, thanks to its robust manufacturing capabilities and growing consumer base. Glass bottle manufacturers in India are leveraging state-of-the-art technology and skilled labor to produce high-quality packaging solutions for domestic and international markets.

The country’s glass packaging sector is also supported by government initiatives promoting Make in India and sustainability. With increased investment in research and development, India is poised to become a global hub for innovative and eco-friendly glass packaging solutions.

6. Consumer Preferences: Driving Trends in Glass Packaging

Changing consumer preferences have played a significant role in shaping the evolution of glass packaging. Today’s consumers value aesthetics, sustainability, and functionality, all of which glass packaging offers in abundance.

In the fragrance industry, buyers often associate a perfume’s quality with the design of its bottle. Perfume bottle manufacturers understand this dynamic and create visually appealing containers that enhance the overall experience. Similarly, consumers in the food sector prioritize transparency and safety, making glass jars a preferred choice for premium products.

7. Challenges and Opportunities

Despite its many advantages, glass packaging faces challenges such as higher production costs and fragility compared to alternatives like plastic and metal. However, these challenges are being addressed through ongoing innovation and improved manufacturing processes.

For example, lightweight glass bottles reduce material usage and shipping costs, making them more competitive. Additionally, increased awareness about environmental issues is creating opportunities for glass jar manufacturers and other players to capitalize on the growing demand for sustainable packaging.

8. The Future of Glass Packaging

The future of glass packaging looks bright, driven by advancements in technology and a shift towards sustainable practices. Smart glass packaging, which integrates digital features like QR codes and NFC tags, is set to revolutionize the industry by offering enhanced consumer interaction and product traceability.

Glass bottle manufacturers in India are at the forefront of this transformation, combining innovation with a commitment to sustainability. Their efforts ensure that glass packaging remains a preferred choice for brands looking to balance elegance, functionality, and eco-consciousness.

Conclusion

Glass packaging has come a long way from its ancient origins, evolving into a versatile and sustainable solution for modern industries. Whether it’s a luxurious perfume bottle, a sturdy glass jar, or a cutting-edge container, glass packaging continues to set benchmarks in design, functionality, and environmental responsibility.

As the world moves towards a greener future, perfume bottle manufacturers, glass bottle manufacturers in India, and glass jar manufacturers will play a pivotal role in driving innovation and meeting the demands of consumers and industries alike. With its timeless appeal and endless possibilities, glass packaging is truly a cornerstone of modern living.

0 notes

Text

In-house glass bottling plant | In house water bottling plant - canadiancrystalline.com

Discover the exceptional quality of Canadian Crystalline’s precision in-house glass bottling plant. We manage the entire process, including rinsing, filling, capping, and labeling, to ensure every product meets our rigorous standards. Our in-house glass bottling plant delivers unmatched purity and taste, thanks to our meticulous handling of each bottle. Experience the difference in our comprehensive bottling process.

#in house hotel glass bottle bottling plant#in house glass bottling plant#in house hotel glass bottling plant#glass bottles in hotels#glass bottling plant#glass bottling plant manufacturer#in house glass water bottling plant#hotel water bottling plant manufacturers in india#in house water bottling plant#water bottling plant

0 notes

Text

@ https://airpackindia.com/inflatable-air-column-bag/

Protective Air Column bag & Air Cushion Packaging

Manufacturer of Inflatable Air Column Bag - Inflatable Air Column Bags, Glass Bottle Packing Air Column Bag

designed to secure and stabilize cargo in containers, strong resistance · 100% recyclable

#ManufacturerofInflatableAirColumnBag#Glass Bottle Packing Air Column Bag#air column bag manufacturers in india#inflatable

1 note

·

View note

Text

How to Start Pilfer Proof Caps Manufacturing Business

🎬 Dive into the world of Pilfer-Proof Caps Manufacturing with us! 🚀 Ready to turn your dreams into reality? Let's roll! Follow us for the full scoop. #PilferProofMagic #BusinessDreams #FollowForMore #EntrepreneurLife #CapsInnovation

The packaging industry is witnessing rapid growth due to the increasing demand for innovative and safe packaging solutions. One such product that has gained a lot of popularity in recent years is Pilfer-Proof Caps. Pilfer-proof caps are indispensable materials in the liquid packaging industry. Pilfer-proof closures are most widely used on glass and plastic bottles fitted with product caps. Often,…

View On WordPress

#best business ideas#bottle caps manufacturing business#business success#business tips#capping machine#Caps Industry Insights#Entrepreneurial Journey#entrepreneurship#glass bottle capping machine#how to start pilfer proof caps manufacturing business#manufacturing business#manufacturing business ideas in india#Manufacturing Guide#Pilfer Proof Caps#plastic bottle cap making machine#ropp capping machine#Secure Caps Production#small business ideas#start a business

0 notes

Text

to buy a glass bottle click on the link... https://bit.ly/40ieMpK

#bottle#cosmetics bottle#glass bottle company#glass bottles#glass jar#Glass Bottle Manufacturers Suppliers In Delhi#Glass Bottle Wholesalers in india#bulk glass bottles#glass bottle packaging

1 note

·

View note

Text

Case packer manufacturers | Technorobotic

Technorobotics is a leading manufacturer of packaging machinery in India, specializing in the production of case packers, plastic injection moulding machines, bottle unscrambler machines, and bottle screen printing machines. Their case packer machines are designed to handle various types of packaging materials and can be customized to meet specific customer requirements. Their plastic injection moulding machines are known for their high-speed and efficient production capabilities. Their bottle unscrambler machines are designed to sort and feed bottles to production lines seamlessly, increasing production efficiency. Technorobotics' bottle screen printing machines are equipped with advanced technology for high-quality printing on bottles. With a commitment to innovation and customer satisfaction, Technorobotics is a trusted choice for packaging machinery manufacturers in India.

#injection moulding machine#industrial equipments#linear conveyor system manufacturer in india#bottle screen printing machine#bottle screen printing machine manufacturers#oval glass bottle printing machine

0 notes

Text

Bottle Filling Line Solution

Company Overview: Shiv Shakti Machtech is Manufacturer, Exporter and Supplier of Bottle Filling Line Solution in Ahmedabad, Gujarat, India. Our Manufacturing Unit is in Ahmedabad, Gujarat, India. A Bottle Filling Line Solution efficiently fills bottles with liquids or other substances, ensuring precise filling, minimal waste, and high productivity through its fully automated system. Various industries, including food and beverage, pharmaceuticals, cosmetics, and chemicals, widely use it to streamline the packaging process. The system combines filling, capping, labeling, and inspection stages to ensure the final product is sealed and ready for distribution. Similar Name of Packaging Line Automation: Automated Bottle Filling Systems, Industrial Liquid Filling Machines, Bottle Packaging Line Equipment, Complete Bottle Filling Solutions, High-Speed Bottle Filling Lines, Beverage Bottle Filling and Packaging Systems, Liquid Bottle Filling and Sealing Machines, Turnkey Bottle Filling Line Solutions, Custom Bottle Filling Equipment, Liquid Filling and Bottling Systems Specifications of Bottle Filling Line Solutions: Filling Speed: Filling rates range from 30 bottles per minute (bpm) to over 1,000 bpm for high-speed production lines. Filling Volume: The system can handle different bottle volumes, typically ranging from 50 ml to 5 liters. Cap Types: The system can accommodate a variety of caps, such as screw caps, crimp caps, snap-on caps, and tamper-evident caps. Bottle Types: Compatible with a wide range of bottles, including glass, plastic, and metal containers. Material: Machines are made from high-quality, food-grade stainless steel for hygiene and corrosion resistance. Automation Level: From semi-automatic lines to fully automated systems, catering to different production scales. Shiv Shakti Machtech is a Bottle Filling Line Solution and an exporter worldwide, including to Algeria, Angola, Antigua, Barbuda, Argentina, Armenia, Australia, Austria, The Bahamas, Bahrain, Bangladesh, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, Botswana, Brazil, Brunei, Bulgaria, Burkina Faso, Cambodia, Cameroon, Canada, Central African Republic, Chad, Chile, Colombia, Congo, Democratic Republic of the Congo, Costa Rica, Cuba, Cyprus, Denmark, Dominica, Ecuador, Egypt, Guinea, Ethiopia, Fiji, Finland, France, The Gambia, Georgia, Germany, Ghana, Greece, Guyana, Hungary, Iceland, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, South Korea, North Korea, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Libya, Malawi, Malaysia, Maldives, Mali, Mauritania, Mauritius, Mexico, Moldova, Monaco, Mongolia, Morocco, Mozambique, Myanmar (Burma), Namibia, Nepal, Netherlands, New Zealand, Niger, Nigeria, Norway, Oman, Panama, Peru, Philippines, Poland, Portugal, Qatar, Romania, Russia, Rwanda, Saint Lucia, Saudi Arabia, Senegal, Serbia, Singapore, Slovakia, Somalia, South Africa, Spain, Sri Lanka, Sudan, South Sudan, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Togo, Tunisia, Turkey, Uganda, Ukraine, United Arab Emirates (UAE), United Kingdom, United States, Uruguay, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Yemen, Zambia, Zimbabwe. For further details or inquiries, feel free to reach out to us. View Product: Click Here Read the full article

#Algeria#Angola#Antigua#Argentina#Armenia#Australia#Austria#Bahrain#Bangladesh#Barbuda#Belarus#Belgium#Belize#Benin#Bhutan#Bolivia#Botswana#BottleFillingLineSolution#BottleFillingLineSolutioninGujarat#BottleFillingLineSolutioninIndia#Brazil#Brunei#Bulgaria#BurkinaFaso#Cambodia#Cameroon#Canada#CentralAfricanRepublic#Chad#Chile

2 notes

·

View notes

Text

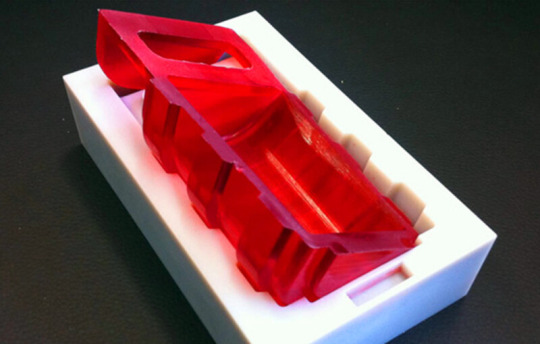

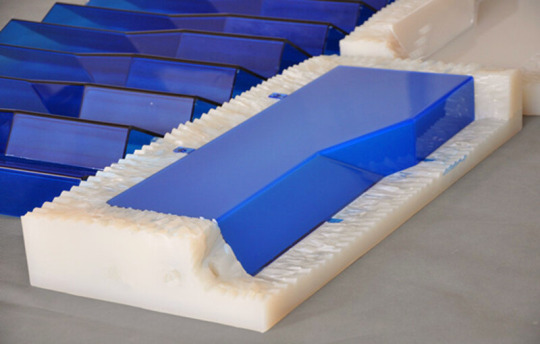

Working of Vacuum Casting and Its Multiple Uses

To make complicated components, a liquid substance is sucked into a silicone mold under vacuum. This method is known as vacuum casting. Rubber and plastic are examples of elastomers that are utilized as liquid materials in vacuum casting.

Since polyurethane resin, a kind of elastomer is employed as the casting medium, vacuum casting is also frequently referred to as polyurethane casting or urethane casting. When producing plastic components, vacuum casting is a more cost-effective method than injection molding because of its reduced manufacturing costs.

For batch manufacturing and other low-volume production tasks, vacuum casting is a great method of production. Vacuum casting is widely utilized in India's manufacturing of industrial electronics, FMCG, and consumer goods.

How do you work with vacuum casting?

Injection molding, in which cast material is poured into molds to create items, and vacuum casting services are very comparable processes. The kinds of molds used in injection molding and vacuum casting differ from one another.

Molds for injection molding might be formed of steel, aluminum, or other materials. Silicone molds are utilized in vacuum casting, nevertheless. This significantly lowers the mold-making cost because silicone is more affordable and has better durability.

Polyurethane is the most often utilized casting material in this procedure. The qualities of various polyurethanes vary, including good shock and temperature resistance, elasticity, flexibility, and structural stiffness. Thus, different polyurethanes may be employed depending on the kind of product being created.

Vacuum casting uses

Making complicated and sophisticated goods may be accomplished more cost-effectively and efficiently with vacuum casting as opposed to the conventional injection molding method.

Due to its efficient production process, vacuum casting finds widespread application in the fabrication of commercial items. The following are a few industries that employ vacuum casting:

Manufacturing of consumer goods

Vacuum casting is a more effective method of producing consumer goods including combs, hair brushes, makeup packaging, sunglasses, pens, and other stationery.

Industry of Food and Beverages

Vacuum casting is used to create food and beverage containers, bottles, cans, mugs, and glasses. Due to the process's great efficiency and ability to produce goods quickly, vacuum casting is widely utilized in various industries where rapid manufacture is essential.

Advanced industry

Excellent heat and shock resistance is a feature of polyurethanes. Therefore, the recommended production procedure for creating electrical device housings is vacuum casting by Vacuum Casting Manufacturer using polyurethanes.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Explore vacuum casting#Vacuum Casting Services China#Vacuum Casting Manufacturer#Vacuum Casting supplier

2 notes

·

View notes

Photo

National Iced Tea Day

When the weather gets too warm for hot tea, just ice it! Mint tea, fruity teas, even the Southern classic sweet tea will all refresh you on a warm and sunny day.

Drinks are such a key part of modern culture that they are so much than just a necessity for the body. We drink water to survive, we drink coffee to stay alert, we sip cocktails to feel refreshed and get in the mood, and we drink soda to relax and unwind. Different drinks feed into different moods and give us new and unique experiences that play a big role in our lives, both socially and at home. So, it is important to make sure you sample as many different beverages as you can.

When it comes to quenching thirst and being refreshed on a hot summer’s day, there are a lot of things you can choose from. Many will crack open a beer or a bottle of wine, but how about sampling some gorgeous iced tea. There are a lot of things you need to keep in mind when it comes to trying this delicious beverage. In fact, there is even an National Iced Tea Day, solely dedicated to the discovery and enjoyment of all things iced tea related; try to ensure you make the most of this as much as you can right now.

On a hot summer day, there’s nothing that quenches the thirst and fosters relaxation quite as much as a frosty cold glass of iced tea. While hot tea is delicious and certainly an excellent beverage for most situations, it’s purely inappropriate for picnics, and it only stays hot so long. Instead, it is necessary to branch out to the more versatile and refreshing alternatives. Sweet tea is one of the most popular beverages in the deep South, but it’s just one example of the variety that can be iced tea.

History of National Iced Tea Day

While recipes for Iced Tea go back as far as the 1870’s, it wasn’t until 1904 that it exploded in popularity. This was due in no small part to the World’s Fair and the heat of the summer that was baking it. Iced Tea was being served, and the fair goers were drinking it en masse, and in almost no time at all, it was being served in tall glasses so well known for this purpose that they were called iced-tea glasses. You know a drink has truly come into its own when special utensils are made for its preparation, and it wasn’t just the glasses, iced-tea spoons and lemon forks were developed to make its consumption both easier and more satisfying.

Iced Tea is typically made from the tea plant, but just like with hot teas, it can be made with just about anything, and herbal teas are often a popular choice for the cool drink. Imagine the parade of flavors available to you, a cool mint tea stirred with a bit of lime, or if you’re in India you may as well do as the locals do and enjoy your tea with a bit of ginger. Our personal favorite? Peach Iced Tea, it’s delightful.

National Iced Tea Day exists to pay homage to the popular and delicious beverage, and it’s something more of us should get involved with. This is a drink that is growing in popularity, and there is a growing consumer base for it, both in the United States and abroad. This is why manufacturers continue to come up with different and interesting flavors of iced tea that you can choose from moving forward.

How to celebrate National Iced Tea Day

Making the most of National Iced Tea Day by way of celebration is a great way of being able to sample some of the tasty and unique types of iced tea that are on offer. This is something you need to make sure you think about when you are looking to make the most of this. Now, there are plenty of things you can do if you are serious about celebrating this day properly.

See if you can get a coupon for free iced tea

Get creative and come up with your own recipe

Enjoy the different iced tea flavors that restaurants and bars are offering

Iced tea popsicles is a great addition to the day

Hosting an iced tea party would be the absolute best approach to take to celebrate this day

Add some booze into the mix to make adult iced teas

Of course, there are so many different flavors you can enjoy with iced tea, and this is the beauty of it. Make sure you take the time to enjoy and experiment with all the different flavors that you can use, and try to come up with some combinations of your own. This is something that can really go a long way toward enhancing and improving your enjoyment of National Iced Tea Day, and you can make a thing of it each year.

The best way to celebrate National Iced Tea Day is with a frosty glass of iced tea! But given that you’ll be enjoying it on a special occasion, why only work with one? Instead, you can prepare a positive banquet of delicious iced teas. Peach Iced Tea, Mango Iced Tea, Ginger Lemon, or just an old fashioned sweet tea like they can only make in the south, there’s simply nothing like it. Why not try to come up with your own combination?

Source

#Capilé#Tropical Ice Tea#Lavender Ice Tea#always unsweetened#travel#USA#Peach Green Tea#Lemon Black Tea Lemonade#Pineapple Black Tea#Strawberry White Tea#Peach Citrus Green Tea#Spiked Texas Tea#Canada#Portugal#original photography#don't drink and drive#vacation#no sugar#National Iced Tea Day#10 June#NationalIcedTeaDay#Jack's Dundee Tea

3 notes

·

View notes

Text

Metal Cans and Glass Jars Market Size, Trends, and Growth Forecast to 2025

The global Metal Cans and Glass Jars Market is experiencing steady growth, driven by increasing consumer demand for sustainable and durable packaging solutions.

Get free sample @ https://www.statsandresearch.com/request-sample/39371-global-metal-cans-and-glass-jars-market

Market Overview:

In 2022, the market was valued at approximately USD 27.11 billion and is projected to reach USD 34.26 billion by 2029, growing at a compound annual growth rate (CAGR) of 3.4% during the forecast period.

Key Market Segments:

By Product Type:

Metal Cans: Dominated the market in 2019 due to their extensive use in the food and beverage industry and the rising demand for ready-to-consume products.

Glass Jars: Valued for their ability to preserve product quality and their recyclability, contributing to their steady market share.

By Application:

Preserved Foods: Significant growth attributed to the use of these containers for various food items, including meat and ready-to-eat foods.

Pet Foods: Expected to witness decent growth due to the widespread adoption of pets globally.

Beverages: Increasing consumption of canned and bottled drinks supports this segment.

Get full report @ https://www.statsandresearch.com/report/39371-global-metal-cans-and-glass-jars-market/

Regional Analysis:

Asia-Pacific: Dominates the market, driven by rapid urbanization, industrialization, and a focus on sustainable products. Countries like India and China are major contributors due to their economic growth.

North America and Europe: Exhibit steady growth, supported by stringent environmental regulations and a mature food and beverage industry.

Key Players:

Prominent companies operating in the Metal Cans and Glass Jars Market include:

Ball Corporation

Ardagh Group S.A.

Crown Holdings, Inc.

Bormioli Rocco S.p.A

Gerresheimer AG

HEINZ-GLAS GmbH & Co. KGaA

Owens-Illinois, Inc.

Amcor Limited

Stölzle-Oberglas GmbH

Piramal Glass Private Limited

Market Trends and Challenges:

Sustainability: Growing environmental concerns and government regulations are pushing manufacturers to adopt eco-friendly packaging solutions, increasing the demand for recyclable materials like metal and glass.

Consumer Preferences: A shift towards ready-to-eat and convenience foods boosts the need for effective packaging, favoring metal cans and glass jars.

Competition from Alternative Packaging: The rise of flexible and lightweight packaging options presents challenges, requiring traditional packaging manufacturers to innovate continuously.

Get enquiry before buying @ https://www.statsandresearch.com/enquire-before/39371-global-metal-cans-and-glass-jars-market

Trending Reports

Metal Mesh Glove Market

Metal Middle Frame Market

Metal Mold Thermal Shields Market

Metal Polish Product Market

Metal Security Door Market

0 notes

Text

Automatic Test-Tube Filling and Capping Machine in Ahmedabad

SATV Industries is a Manufacturer and Supplier of Automatic Test-Tube Filling and Capping Machine in Ahmedabad, Gujarat, India. Our Manufacturer Unit are in Ahmedabad, Gujarat, India. Our product offerings include top-quality machines such as Bottle Washing Machines, Liquid Filling Machines, Automatic Labeling Machines, Powder Filling Machines, Round Bottle Labeling Machines, and Packing Conveyor Machine Spare Parts, all crafted by experts with years of experience. The Automatic Test-Tube Filling and Capping Machine from SATV Industries is an advanced, high-efficiency solution designed for laboratories, pharmaceutical companies, research institutions, and manufacturing facilities that require precise, high-speed filling and capping of test tubes. This machine automates the critical process of accurately filling test tubes with liquids, chemicals, or biological samples and securely capping them, ensuring tight seals to maintain integrity and prevent contamination. This innovative machine significantly enhances productivity, improves operational efficiency, and reduces the risk of human error. Features: The Automatic Test-Tube Filling and Capping Machine from SATV Industries is packed with features that enhance its functionality and performance: High-Speed Operation: Capable of filling and capping test tubes at high speeds, ensuring efficient production cycles. Precision Filling: Equipped with advanced volumetric or metering pumps to ensure accurate and consistent filling of each test tube. Automatic Capping: The machine features an automatic capping system that applies secure, tight-fitting caps to each test tube, ensuring leak-proof seals. User-Friendly Interface: The machine comes with a digital touch screen for easy control, monitoring, and operation. Flexible Operation: Can handle various sizes and types of test tubes, making it versatile for different industries and applications. Built-in Quality Control: The machine includes inspection systems that detect misalignment, overfilling, underfilling, or improperly capped test tubes, minimizing defects. FAQS: What is the purpose of an Automatic Test-Tube Filling and Capping Machine? An Automatic Test-Tube Filling and Capping Machine is designed to automatically fill test tubes with liquids, chemicals, or biological samples and apply caps securely, ensuring accuracy, speed, and contamination prevention. How does the machine ensure accurate filling? The machine uses advanced metering pumps or volumetric filling systems that provide precise measurement and filling of each test tube. What types of test tubes can the machine handle? The machine can handle a wide range of test tube sizes and types, including glass and plastic test tubes of various volumes. SATV Industries is a Manufacturer and Supplier of Automatic Test-Tube Filling and Capping Machine in Ahmedabad, Gujarat, India Including and surrounding areas including Sanand, Vani, Kathawada, Odhav, Vatva, Rakhial, Singarva, Bakrol, Kadi, Kalol, Kanbha, Kujad, Changodar, Naroda, Dhandhuka, Dholka, Viramgam, Kerala. Contact us today for inquiries or to place an order! View Product: Click Here Read the full article

#Ahmedabad#AutomaticLabelingMachines#AutomaticTest-TubeFillingandCappingMachine#AutomaticTest-TubeFillingandCappingMachineinAhmedabad#AutomaticTest-TubeFillingandCappingMachineinGujarat#AutomaticTest-TubeFillingandCappingMachineinIndia#Bakrol#BottleWashingMachines#Changodar#Dhandhuka#Dholka#Exporter#ExporterofAutomaticTest-TubeFillingandCappingMachine#Gujarat#India#Kadi#Kalol#Kanbha#Kathawada#Kerala#Kujad#Manufacturer#ManufacturerofAutomaticTest-TubeFillingandCappingMachineinAhmedabad#Naroda#Odhav#PowderFillingMachines#Rakhial#Sanand#SATVIndustries#Singarva

0 notes

Text

Explore top glass bottle manufacturers in Ahmedabad, known for producing high-quality, durable bottles for various industries. These manufacturers offer custom designs, bulk production, and eco-friendly packaging solutions. Rely on their expertise for reliable service, innovative glass bottle designs, and competitive pricing in the Ahmedabad manufacturing market.

0 notes

Text

CanadianCrystalline: A Leading Glass Bottling Plant in India

Canadian Crystalline is a renowned glass bottling plant located in India. With its commitment to quality, sustainability, and innovation, Canadian Crystalline has established itself as a leader in the industry. This blog post will explore the key features that make Canadian Crystalline stand out and the benefits it offers to its customers.

State-of-the-Art Infrastructure

Canadian Crystalline boasts a state-of-the-art infrastructure that ensures the highest standards of quality in glass bottle production. The plant is equipped with cutting-edge machinery and technologies, allowing for efficient and precise manufacturing processes. From the initial design to the final packaging, every step of the production is closely monitored to maintain superior quality control.

Sustainable Practices

As a responsible glass bottling plant, Canadian Crystalline places a strong emphasis on sustainability. The company actively seeks to minimize its environmental impact by implementing eco-friendly practices throughout its operations. This includes the use of recycled glass in the production process, reducing waste and conserving valuable resources. Canadian Crystalline also employs energy-efficient technologies, such as advanced heating and cooling systems, to minimize energy consumption and lower carbon emissions. By prioritizing sustainability, the company not only contributes to a greener future but also provides its customers with environmentally conscious packaging solutions.

Product Range and Customization

Canadian Crystalline offers a wide range of glass bottles suitable for various industries, including beverages, cosmetics, pharmaceuticals, and more. The plant's extensive product portfolio includes bottles of different shapes, sizes, and closures, allowing customers to find the perfect packaging solution for their specific needs. Moreover, Canadian Crystalline understands the importance of customization in today's market. The plant offers customization options such as embossing, labeling, and color variations, enabling businesses to create a unique brand identity and enhance product differentiation.

Quality Assurance :

At Canadian Crystalline, quality is of utmost importance. The plant follows rigorous quality assurance processes to ensure that every glass bottle meets or exceeds industry standards. Stringent quality checks are conducted at every stage, from raw material sourcing to the final inspection. The plant is also ISO certified, a testament to its commitment to maintaining the highest level of quality management. By choosing Canadian Crystalline, businesses can have the peace of mind that their products will be packaged in top-quality glass bottles.

Canadian Crystalline believes in building strong relationships with its customers. The company provides exceptional customer support, working closely with clients to understand their specific requirements and offer tailored solutions. From concept development to final delivery, Canadian Crystalline collaborates with its customers, ensuring a seamless and efficient experience. The plant's team of experts is always available to provide technical guidance and address any queries or concerns. With Canadian Crystalline, businesses can expect a reliable and responsive partner that is committed to their success.

Canadian Crystalline is a leading glass bottling plant in India, renowned for its state-of-the-art infrastructure, sustainability practices, diverse product range, and commitment to quality. By choosing Canadian Crystalline, businesses can benefit from superior packaging solutions and excellent customer support. Trust in Canadian Crystalline for all your glass bottle needs.

#Glass Bottling Plant#Glass Bottling Plant in India#Water Bottling plants India#hotel water bottling plant manufacturers in india

0 notes

Text

"No Effort, Maximum Clean: The Innovation Every Business Needs"

The Seppa Solutions Glass Bottle Washer provides a breakthrough in facilitating bottle operations for companies to do better on the operational side of bottle cleaning. This developed and advanced technology has indeed surpassed the traditional methods of getting cleaner and improved results that would leave no room for impurities. It is also time-saving and not easily done by any human, as it needs a lot of effort going into making cleanliness and consistency in such measures that nobody wishes to do in place of other methods. Seppa Solutions Glass Bottle Washer is capable of sophisticated cleaning while saving the best cleaning processes for businesses, which transforms and adapts most such companies towards better results and wholesome time and effort. Investing in this particular innovation secures almost everything worth about a business to make it highly safe and quality assured on bottling.

0 notes

Text

Automatic Rotary Gripper Type Washing Machine in Spain

Laxmi Pharma Equipment is a Manufacturer, Supplier, and Exporter of Automatic Rotary Gripper Type Washing Machine in Spain. We are based in Ahmedabad, Gujarat, India. Laxmi Pharma Equipment offers advanced machinery solutions for the pharmaceutical and healthcare industries. The Automatic Rotary Gripper Type Washing Machine is one of the top-selling products in our portfolio, designed to provide thorough cleaning and washing of pharmaceutical containers and equipment. This machine is ideal for maintaining the hygiene and quality standards required in pharmaceutical production. Specifications: Material Compatibility: Glass, Plastic, Metal Production Capacity: 50-200 bottles per minute (varies by model) Bottle Size: Customizable (50 ml to 2 liters or more) Washing Cycles: Single or Multi-Stage Construction Material: Stainless Steel (SS304/SS316) Control System: PLC-Based Power Requirement: 2-5 kW depending on configuration Water Consumption: 50-200 liters per hour Optional Features: Drying system, UV sterilization Dimensions: Customizable based on client requirements Why Choose the Automatic Rotary Gripper Type Washing Machine? High Efficiency: The machine ensures fast and thorough cleaning of equipment and containers with minimal manual intervention. Automation: It operates automatically, reducing labor costs and minimizing the risk of human error. Compliance: Meets the stringent hygiene and safety standards in pharmaceutical manufacturing. Durability: Made with high-quality stainless steel and other premium materials, ensuring longevity and resistance to corrosion. Customizable: The machine can be customized to meet specific cleaning requirements, such as the size and type of containers or equipment being washed. FAQs: How does the Automatic Rotary Gripper Type Washing Machine work? The machine uses rotary grippers to hold and rotate containers through multiple wash, rinse, and drying stations. Water or detergent is sprayed under high pressure to remove contaminants. Can the washing machine handle multiple cleaning solutions? Yes, the machine is compatible with various cleaning agents, including water, detergents, and sanitizers, depending on the application and requirements. Laxmi Pharma Equipment is Automatic Rotary Gripper Type Washing Machine in Spain including location Madrid, Barcelona, Valencia, Seville, Zaragoza, Málaga, Murcia, Palma, Las Palmas de Gran Canaria, Bilbao, Alicante, Córdoba, Valladolid, Vigo, Gijón, L'Hospitalet de Llobregat, Vitoria-Gasteiz, A Coruña, Granada, Terrassa, Badalona, Oviedo, Cartagena, Sabadell, Jerez de la Frontera, Móstoles, Santa Cruz de Tenerife, Pamplona, Almería, Alcalá de Henares, Fuenlabrada, Leganés, Donostia/San Sebastián, Getafe, Burgos, Albacete, Santander, Castellón de la Plana, Alcorcón, San Cristóbal de La Laguna, Logroño, Badajoz, Salamanca, Huelva, Marbella, Lleida, Tarragona, Dos Hermanas, Torrejón de Ardoz, Parla, Mataró, León, Algeciras, Santa Coloma de Gramenet, Alcobendas, Cádiz, Jaén, Ourense, Reus, Telde, Girona, Barakaldo. For detailed information and inquiries, please feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#AutomaticRotaryGripperTypeWashingMachineinAhmedabad#AutomaticRotaryGripperTypeWashingMachineinGujarat#AutomaticRotaryGripperTypeWashingMachineinIndia#AutomaticRotaryGripperTypeWashingMachineinSpain#CappingMachines#Exporter#ExporterofAutomaticRotaryGripperTypeWashingMachine#ExporterofAutomaticRotaryGripperTypeWashingMachineinSpain#FillingMachines#Gujarat#LaxmiPharmaEquipment#Manufacturer#ManufacturerofAutomaticRotaryGripperTypeWashingMachineinAhmedabad#PackagingMachines#Spain#Supplier#SupplierofAutomaticRotaryGripperTypeWashingMachineinSpain#WashingMachines

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] From the manufacturer This refrigerator uses an energy efficient inverter compressor, which is not only quieter but also adjusts the cooling as per the refrigerator operation. An aesthetically well designed refrigerator door that adds to the beauty of your kitchen. Best-in-category PUF insulation ensures the best cooling retention in the refrigerator for long-lasting freshness, even during power cuts. The defrost water gets heated and evaporates faster, resulting in no water spillage, no germ and insect breeding, and convenient cleaning. Largest vegetable storage space of 20 litres to store all your greens to avoid your frequent visits to the market. The insulation under the chiller tray ensures no water droplets formation. The star rating changes are as per BEE guidelines on or before 1st Jan 2023 Direct- Cool Refrigerator with Capacity: 185 litres, suitable for a small family Energy rating: 4 star, Annual energy consumption: 123 Kilowatt Hours (Please refer energy label on product page or contact brand for more details) 63 years of thoughtful appliances: Proudly Made in India Warranty: 1 year on product, 10 years on compressor Compressor: The refrigerator comes with Advanced inverter technology, Runs on Home Inverter Shelf type: Toughened glass shelves of 150 kg load bearing capacity 2.25L Aqua Space - Larger 2.25 L space in the door to store the extra large bottles of water or cola easily Anti Drip Chiller Technology: The insulation under the chiller tray ensures no water droplets formation Inside box: 1 Refrigerator, Warranty Card and Manual [ad_2]

0 notes