#galvanizing plant manufacturers

Explore tagged Tumblr posts

Text

Galvanizing Plant Manufacturers

Galvanizing Plant, also known as Hot Dip Galvanizing, is one of the most popular methods of protecting metal objects from corrosion and rust. This type of coating is typically applied to steel or iron and is formed when molten liquid zinc is applied to the surface of the metal. It is often used to protect metal parts from corrosion and to improve their aesthetic appeal.

As one of the leading Galvanizing Plant Manufacturers & Suppliers in India, we strive to provide our customers with the highest quality galvanizing plants and services for their industrial needs.

Our galvanizing plants are designed to handle heavy-duty galvanizing tasks efficiently and cost-effectively. We use state-of-the-art technology and machinery to construct our galvanizing plants, ensuring that they meet industry standards and customer specifications. We also employ experienced and qualified experts who understand galvanizing processes and can provide high quality products. Our galvanizing plants are energy-efficient, making them a cost-effective solution for industrial applications.

Visit Here - https://www.shivasprojects.com/hot-dip-galvanizing-plants.html

0 notes

Photo

Fume extraction systems are an essential component of galvanizing plant manufacturers, as they help to reduce emissions and improve air quality. The fume extraction system works by capturing and removing toxic fumes created as a result of the galvanizing process. This is important in order to protect the health and safety of workers in the factory, as well as reducing emissions which can harm the environment. Furthermore, the use of a fume extraction system is beneficial in terms of cost savings, as it can help to reduce the costs associated with maintenance and cleaning.

0 notes

Text

Best Quality Hot Dip Galvanizing Plant Manufacturers from India to Worldwide

Wire Machine Company is a Ghaziabad, India-based manufacturer of hot dip galvanizing plants. These plants are designed to provide superior corrosion protection to steel and other metals by applying a layer of zinc through a hot dip process. The company uses advanced technology and high-quality materials to produce galvanizing plants that are efficient, reliable, and durable. Their plants are capable of processing a wide range of metal products, including wires, pipes, tubes, and more. With a commitment to customer satisfaction, Wire Machine Company provides customized solutions tailored to the specific needs of their clients, ensuring that they receive the best possible product and service.

#galvanizing plant manufacturers#hot dip galvanizing equipment suppliers#zinc coating plant manufacturers#galvanizing kettle suppliers#galvanizing furnace manufacturers#zinc melting furnace suppliers#galvanizing line equipment manufacturers#automatic galvanizing plant manufacturers#continuous galvanizing plant suppliers#steel structure galvanizing plant manufacturers

0 notes

Text

Hot Dip Galvanizing Plant Manufacturer - Step® Techno Solutions LLP

Step® Techno Solutions LLP is the leading manufacturer and exporter of hot dip galvanizing plants in Gujarat, India. With over 25+ years of experience in the industry, we have built a strong reputation for delivering high-quality, efficient, and reliable galvanizing solutions. Our expertise extends beyond galvanizing plants to include the production of anodizing, electroplating, powder coating, and phosphating plants. Our hot dip galvanizing plants are designed to provide superior corrosion resistance and durability, assuring long-lasting protection for metal products. We offer competitive pricing and exceptional customer support, making us the preferred choice for businesses seeking top-notch galvanizing solutions. Visit our site - https://steptsl.com/hot-dip-galvanizing-plants/

#Galvanizing Plant#Hot Dip Galvanizing Plant#Hot Dip Galvanizing Plant Manufacturer#Hot Dip Galvanizing Plant Exporter#Manufacturer of Hot Dip Galvanizing Plant#Hot Dip Galvanizing Plant Manufacturer in India

0 notes

Text

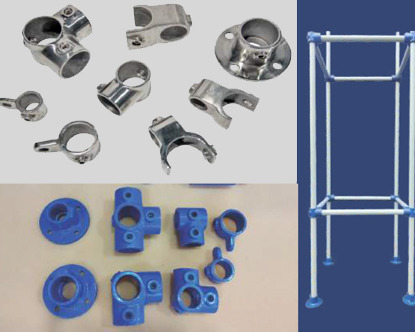

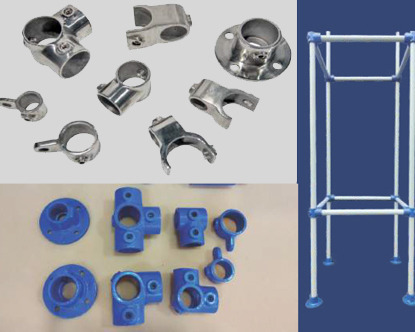

Structure and Support | Goel Scientific | Canada

We supply Glass plants that are supported in a tubular structure formed of galvanized steel tubes Manufacturers, in Canada, the USA Goel Scientific Glass

#Best#Top#supply Glass plants that are supported in a tubular structure formed of galvanized steel tubes Manufacturers#in Canada#the USA Goel Scientific Glass

0 notes

Text

Acid Fume Extraction System

Acid Fume Extraction acid fume extraction system, zinc white fume extraction system, acidic fume extraction systems manufacturer, supplier exporter in India. Acid Fume Extraction systems are designed for each application in such a way as to assure adherence to the emission restrictions of the acid fume neutralisation system while providing effective scrubbing.

#acid fume extraction system manufacturer#pickling tanks#pickling plant#galvanizing tank#scrubber system manufacturer#fume extraction system manufacturers in Bangalore#fume extraction system for welding

1 note

·

View note

Text

* * * *

LETTERS FROM AN AMERICAN

November 1, 2024

Heather Cox Richardson

Nov 02, 2024

Trump’s comments to right-wing media figure Tucker Carlson last night at an event in Glendale, Arizona, about former representative Liz Cheney (R-WY), coming as they have after the extraordinary racism and sexism of Trump’s Sunday event at New York City’s Madison Square Garden, have have highlighted the centrality of the campaign's attack on women.

“She’s a radical war hawk,” Trump told Carlson, “Let’s put her with a rifle standing there with nine barrels shooting at her, OK? Let’s see how she feels about it, you know, when the guns are trained on her face.”

Today, Trump surrogates have tried to say that he was referring to Cheney’s positions on American warfare, but it seems pretty clear he is fantasizing about seeing her in front of a firing squad. Journalist Magdi Jacobs noted the parallels between this statement and his 2020 command to the Proud Boys to “stand back and stand by,” the precursor to the Proud Boys’ attacking the U.S. Capitol on January 6, 2021, to try to overturn the results of the 2020 presidential election. In both statements, Trump avoided explicitly calling for violence, but absolutely set the stage for it.

This morning, Cheney responded to Trump’s threat “This is how dictators destroy free nations. They threaten those who speak against them with death. We cannot entrust our country and our freedom to a petty, vindictive, cruel, unstable man who wants to be a tyrant.”

While Trump began to attack Cheney openly when she accepted the role of vice-chair of the Select Committee to Investigate the January 6th Attack on the U.S. Capitol, where her presence clearly made Republicans—like Cassidy Hutchinson, aide to former White House chief of staff Mark Meadows—willing to share what they knew, Trump’s recent bloody fantasies appear to have broader meaning.

Cheney has emerged as the key figure to urge Republican women to vote against Trump, and it is becoming increasingly clear that Trump’s reelection is in trouble in part because white women are abandoning him. The early hints that this is happening, like the huge gender gap showing up in early voting, have sparked a right-wing frenzy of attempts to restore the power of white men over the women in their lives. Right-wing men are insisting that wives should vote as their husbands do, or that women should lose the ability to vote altogether.

Trump’s suggestion that Cheney should face a firing squad seems to be a general expression of the anger of white men accustomed to dictating the terms of public life when faced with the reality that they can no longer count on being able to cow the people around them.

Trump’s attack on Cheney has galvanized his unpopularity with women, while the larger meaning of the MAGAs’ attacks on women got additional illustration with the news broken today by Lizzie Presser and Kavitha Surana of ProPublica that a pregnant 18-year-old in Texas suffering from sepsis was turned away from emergency rooms twice before doctors at a third visit required two ultrasounds to make sure her fetus no longer had a heartbeat before they would move her into intensive care. She died within hours.

Today’s news continued to be bad for Trump. Last week, on the Joe Rogan podcast, Trump talked about the CHIPS and Science Act that authorized about $280 billion to encourage domestic research and manufacturing of semiconductors in the U.S. While the law has brought significant private investment into the construction of new manufacturing plants and has created manufacturing jobs, Trump complained to Rogan, “That chip deal is so bad.”

After listening to that conversation, journalist Luke Radel asked House speaker Mike Johnson in a report aired today whether, with Trump opposed to the bill and with Republicans having voted against it, the Republicans will try to repeal the law if they get majorities in Congress. Johnson responded “I expect we probably will, but we haven’t developed that part of the agenda yet.”

Republicans are determined to cut government spending to make way for more tax cuts for the wealthy and corporations. But the CHIPS and Science Act has brought important supply chains home and has created more than 115,000 new high-paying jobs in the U.S.

And it has brought significant investment to battleground states: $19.5 billion to Arizona, $75 million to Georgia, $325 million to Michigan, $750 million to North Carolina, and $93 million to Pennsylvania. Johnson quickly realized that acknowledging the Republicans’ hopes of repealing it was a bad mistake days before an election and, claiming he had not heard the question accurately, said he had no intent to undermine the CHIPS and Science Act.

At a closed-door meeting earlier this week, Johnson said repealing the Affordable Care Act is a Republican priority. He tried to walk this comment back, as well, but Pennsylvania Republican senatorial candidate Dave McCormick kept the issue in front of voters when he was caught on a hot mic saying he wants to reform the ACA and that he opposes the provision in the ACA that allows children to stay on their parent’s health insurance until they’re 26.

Trump’s mental state continues to deteriorate, taking with it the former president’s inhibitions. After going on a rant about the people he blamed for troubles with his microphone at a sparsely attended rally in Warren, Michigan, the Republican nominee for president of the United States of America simulated oral sex on stage.

An official with the Harris campaign told reporters today that they “fully expect” Trump will replay the game plan of 2020 and claim victory on election night, before all the votes are fully counted. In an interview on Wednesday, Harris noted that they were ready if Trump prematurely declared victory: “We are sadly ready if he does and, if we know that he is actually manipulating the press and attempting to manipulate the consensus of the American people...we are prepared to respond,” she said.

Washington State governor Jay Inslee has activated the state’s National Guard so it will be “fully prepared to respond to any…civil unrest” before or after the election.

The Department of Justice today announced it would monitor the polls in 86 jurisdictions in 27 states to make sure they comply with federal voting rights laws. Although the federal government has monitored certain polls since 1965, officials in the states of Florida, Missouri, and Texas promptly announced they would not permit Department of Justice officials inside polling stations.

Meanwhile, Democratic nominee Vice President Kamala Harris made two stops in Wisconsin today before packing the Wisconsin State Fair Exposition Center in West Allis near Milwaukee.

In Madison, Harris told a reporter: “What I am enjoying about this moment most is that in spite of how my opponent spends full time trying to divide the American people, what I am seeing is people coming together under one roof who seemingly have nothing in common and know they have everything in common, and I think that is in the best interest of the strength of our nation.”

LETTERS FROM AN AMERICAN

HEATHER COX RICHARDSON

#political cartoons#pregnancy#Mike Luckovich#Women#voter rights#Liz Cheney#Letters From An American#Heather Cox Richardson#civil unrest#election 2024#CHIPS and Science Act#MAGA attacks on women#Proud boys#Tucker Carlson

8 notes

·

View notes

Text

November 1, 2024

HEATHER COX RICHARDSON

NOV 2

Trump’s comments to right-wing media figure Tucker Carlson last night at an event in Glendale, Arizona, about former representative Liz Cheney (R-WY), coming as they have after the extraordinary racism and sexism of Trump’s Sunday event at New York City’s Madison Square Garden, have have highlighted the centrality of the campaign's attack on women.

“She’s a radical war hawk,” Trump told Carlson, “Let’s put her with a rifle standing there with nine barrels shooting at her, OK? Let’s see how she feels about it, you know, when the guns are trained on her face.”

Today, Trump surrogates have tried to say that he was referring to Cheney’s positions on American warfare, but it seems pretty clear he is fantasizing about seeing her in front of a firing squad. Journalist Magdi Jacobs noted the parallels between this statement and his 2020 command to the Proud Boys to “stand back and stand by,” the precursor to the Proud Boys’ attacking the U.S. Capitol on January 6, 2021, to try to overturn the results of the 2020 presidential election. In both statements, Trump avoided explicitly calling for violence, but absolutely set the stage for it.

This morning, Cheney responded to Trump’s threat “This is how dictators destroy free nations. They threaten those who speak against them with death. We cannot entrust our country and our freedom to a petty, vindictive, cruel, unstable man who wants to be a tyrant.”

While Trump began to attack Cheney openly when she accepted the role of vice-chair of the Select Committee to Investigate the January 6th Attack on the U.S. Capitol, where her presence clearly made Republicans—like Cassidy Hutchinson, aide to former White House chief of staff Mark Meadows—willing to share what they knew, Trump’s recent bloody fantasies appear to have broader meaning.

Cheney has emerged as the key figure to urge Republican women to vote against Trump, and it is becoming increasingly clear that Trump’s reelection is in trouble in part because white women are abandoning him. The early hints that this is happening, like the huge gender gap showing up in early voting, have sparked a right-wing frenzy of attempts to restore the power of white men over the women in their lives. Right-wing men are insisting that wives should vote as their husbands do, or that women should lose the ability to vote altogether.

Trump’s suggestion that Cheney should face a firing squad seems to be a general expression of the anger of white men accustomed to dictating the terms of public life when faced with the reality that they can no longer count on being able to cow the people around them.

Trump’s attack on Cheney has galvanized his unpopularity with women, while the larger meaning of the MAGAs’ attacks on women got additional illustration with the news broken today by Lizzie Presser and Kavitha Surana of ProPublica that a pregnant 18-year-old in Texas suffering from sepsis was turned away from emergency rooms twice before doctors at a third visit required two ultrasounds to make sure her fetus no longer had a heartbeat before they would move her into intensive care. She died within hours.

Today’s news continued to be bad for Trump. Last week, on the Joe Rogan podcast, Trump talked about the CHIPS and Science Act that authorized about $280 billion to encourage domestic research and manufacturing of semiconductors in the U.S. While the law has brought significant private investment into the construction of new manufacturing plants and has created manufacturing jobs, Trump complained to Rogan, “That chip deal is so bad.”

After listening to that conversation, journalist Luke Radel asked House speaker Mike Johnson in a report aired today whether, with Trump opposed to the bill and with Republicans having voted against it, the Republicans will try to repeal the law if they get majorities in Congress. Johnson responded “I expect we probably will, but we haven’t developed that part of the agenda yet.”

Republicans are determined to cut government spending to make way for more tax cuts for the wealthy and corporations. But the CHIPS and Science Act has brought important supply chains home and has created more than 115,000 new high-paying jobs in the U.S.

And it has brought significant investment to battleground states: $19.5 billion to Arizona, $75 million to Georgia, $325 million to Michigan, $750 million to North Carolina, and $93 million to Pennsylvania. Johnson quickly realized that acknowledging the Republicans’ hopes of repealing it was a bad mistake days before an election and, claiming he had not heard the question accurately, said he had no intent to undermine the CHIPS and Science Act.

At a closed-door meeting earlier this week, Johnson said repealing the Affordable Care Act is a Republican priority. He tried to walk this comment back, as well, but Pennsylvania Republican senatorial candidate Dave McCormick kept the issue in front of voters when he was caught on a hot mic saying he wants to reform the ACA and that he opposes the provision in the ACA that allows children to stay on their parent’s health insurance until they’re 26.

Trump’s mental state continues to deteriorate, taking with it the former president’s inhibitions. After going on a rant about the people he blamed for troubles with his microphone at a sparsely attended rally in Warren, Michigan, the Republican nominee for president of the United States of America simulated oral sex on stage.

An official with the Harris campaign told reporters today that they “fully expect” Trump will replay the game plan of 2020 and claim victory on election night, before all the votes are fully counted. In an interview on Wednesday, Harris noted that they were ready if Trump prematurely declared victory: “We are sadly ready if he does and, if we know that he is actually manipulating the press and attempting to manipulate the consensus of the American people...we are prepared to respond,” she said.

Washington State governor Jay Inslee has activated the state’s National Guard so it will be “fully prepared to respond to any…civil unrest” before or after the election.

The Department of Justice today announced it would monitor the polls in 86 jurisdictions in 27 states to make sure they comply with federal voting rights laws. Although the federal government has monitored certain polls since 1965, officials in the states of Florida, Missouri, and Texas promptly announced they would not permit Department of Justice officials inside polling stations.

Meanwhile, Democratic nominee Vice President Kamala Harris made two stops in Wisconsin today before packing the Wisconsin State Fair Exposition Center in West Allis near Milwaukee.

In Madison, Harris told a reporter: “What I am enjoying about this moment most is that in spite of how my opponent spends full time trying to divide the American people, what I am seeing is people coming together under one roof who seemingly have nothing in common and know they have everything in common, and I think that is in the best interest of the strength of our nation.”

—

7 notes

·

View notes

Text

Byron H. Robb’s Pertinacious Gall Got Him Evicted From Cincinnati And Honored In Texas

In the long and sordid roster of Queen City scalawags, Byron H. Robb holds a prominent place. He was delightfully incorrigible, congenitally incapable of telling the truth and absolutely unrepentant when exposed.

Robb fabricated so consistently that it is often difficult to separate any facts from the overwhelming flood of mendacity in his wake. It appears that he was born around 1836 in or near Parkman, Ohio, a tiny hamlet east of Cleveland and northwest of Youngstown. His parents named him Harvey, but he found that name uninspiring and relegated it to a middle initial. He began calling himself Byron, after the British poet.

At the age of 19, Robb launched a lifelong career as a bamboozler, selling a concoction guaranteed to produce luscious curls when applied to the scalp. At least one unfortunate customer went totally bald when she saturated her hair with the stuff. He got into the oil business by purchasing a dry well, then pouring oil stolen from nearby tanks into it. He then fobbed the now “productive” rig onto some credulous farmer. During the Civil War, Robb raised a cavalry company he dubbed the “Geauga Rangers” and offered it for service, claiming the rank of lieutenant on the basis of his own fabricated experience as a Texas Ranger. The United States Army wasn’t that desperate.

Among Robb’s myriad victims was Harriet Beecher Stowe, author of “Uncle Tom’s Cabin.” Mrs. Stowe ordered some “mammoth gourd seeds” from Robb to plant at her winter home in Florida. Robb claimed these seeds yielded gigantic gourds that could be used as washtubs. When her first shipment failed to sprout, Mrs. Stowe ordered another, and sent a letter inquiring what she had done wrong!

At various times, Robb popped up in St. Louis, New Orleans and a number of other locales, usually one step ahead of the law. When the constabulary sniffed too close to his fraudulent enterprises, Robb would “rent” another man’s name and resume business under that appellation until the coast was clear. During the 1860s, Robb paid a gardener named William Chappell $25 annually so he could advertise yet another hair tonic under the “Chappell’s Hyperion” brand.

It was reported that Robb dumped his first wife by encouraging her interest in another man. Robb sent her to Indiana to secure a divorce while he romanced an employee who would become the second Mrs. Robb.

Around 1875, Robb rented a house in Bellevue, Kentucky, establishing his business offices in Cincinnati. Entries in the city directories for the next half-dozen years indicate the constant churn of his schemes. At first, he listed himself as a “general agent,” which covered a multitude of sins. Next, he became the proprietor of the Monitor Manufacturing Company, then manager of the Monitor Lamp & Glass Works, and then President of the American and European Secret Service Company, then manager of the Electro Magnetic Hair and Flesh Brush Company.

Interestingly, at least two of these companies had some basis in actual inventions patented by Robb. In 1877, Robb was awarded a patent for a device that extinguished a kerosene lamp if it was knocked over. In 1879 and 1880, he earned patents for “galvanic” hairbrushes. Unfortunately, Robb preferred fraud to manufacturing. People who ordered his lamps often got nothing at all, while customers of his galvanic brushes received nothing but a cheap comb with a bit of copper wire wrapped around it.

It was his “Secret Service” company that achieved the pinnacle of Robb’s infamy. The American and European Secret Service Company placed hundreds of advertisements throughout the United States, offering to enlist any correspondent as a bona-fide detective, complete with a frameable certificate and a shiny new badge for the low, low price of only $3.60. After paying this fee, applicants were advised to keep their day jobs in order to remain undercover until an assignment came up. Young men throughout the country signed up in abundance – many of them career criminals who believed that an appointment as a detective offered a credible alibi. There are reports of bushels of mail arriving every day at Robb’s Fifth Street office, half containing money orders for $3.60 and half containing dunning letters from newspapers that were never paid for running Robb’s advertisements.

Eventually the postal inspectors caught up with Robb and he was subpoenaed to court. Robb procured the cream of the Cincinnati bar for his defense, including Stanley Matthews, later appointed to the United States Supreme Court, and George Hoadly, later elected governor of Ohio. His lawyers reviewed the evidence collected by the Post Office and informed Robb that he was undoubtedly going to lose the case. His best option was to plead guilty and throw himself on the mercy of the court.

Robb responded by firing his crack legal team. He then sent telegrams to a dozen or so of his “detectives,” directing them to take the next train westward, to proceed to some remote location and to apprehend a red-headed, one-eyed man missing one finger and walking with a limp. The young operatives, delighted to finally be on assignment, followed orders and reported back that no such man could be found. Robb thanked them for their diligence, paid their salary and expenses and told his proteges to await their next assignment.

In court, Robb produced several of these young men as witnesses. They testified under oath that they had applied to the Secret Service Company, paid the initiation fee, received their badge and certificate, and had received an assignment from Robb and had been paid for it. The Post Office case crumbled. No matter they could prove nothing in court, the United States Postmaster announced in 1880 that nine Cincinnati companies controlled by Robb were prohibited from using the postal service in any manner.

Byron H. Robb responded to this temporary setback with his usual flair. First, he went to court and had his name legally changed to Byron H. Van Raub, claiming it was the ancestral version of the family surname. Then he relocated to Texas and acquired some property he claimed was the famous Don Carlos Ranch, which it was not, and then got into the Shetland Pony business, and then the cowboy school business, and then the bloodhound dog business, and then the Buff Leghorn egg business and then the milch goat business. And he had the nearest Bexar County railroad whistle stop renamed Van Raub, after himself.

Every time Robb, or Van Raub, embarked on some new scam, newspapers around the country published scathing exposés of his extensive rap sheet. Newspaper owners were delighted to attack him because the one constant in Robb’s career was his reluctance to pay for advertising. Still, there was always someone willing to believe his folderol. One newspaper, reporting that Van Raub was seeking young men willing to become cowboys (and willing to send him $5.00 for particulars – sound familiar?) claimed he was a retired Prussian cavalry officer who insisted on stern discipline. When Robb died in 1913, the obituaries included some highly unlikely embellishments such as selling Shetland ponies to European nobility.

Amazingly, Robb’s bullshit endures to this very day. Out where Van Raub, Texas, once existed – by the 1920s, his namesake was nothing more than a ghost town – there is an official historic marker that reads in part:

“This community, named after Byron Van Raub, an English gentlemen rancher, was established along the route of the Kerrville Branch. It is said that this successful gentleman rancher developed the first dude ranch in Texas as a means to train fellow Englishman in the rigors of creating successful Texas ranching operations.”

The shifty little shyster from rural Ohio got himself memorialized as an English gentleman, capping a positively breathtaking life of unrelenting chutzpah.

5 notes

·

View notes

Text

GI Flanges Manufacture

Galvanized Iron (GI) flanges are essential components used in a variety of industrial applications, particularly in piping systems. They connect pipes, valves, pumps, and other equipment, ensuring a secure and efficient transfer of fluids or gases. Industries like water treatment, oil and gas, power plants, and chemical processing frequently rely on GI flanges due to their durability and resistance to corrosion.

What Are GI Flanges?

GI flanges are manufactured from galvanized iron, which is coated with zinc to prevent corrosion. This protective layer enhances their lifespan and makes them ideal for use in environments exposed to moisture, chemicals, and harsh conditions.

The main functions of GI flanges include:

Pipe Connection: They help form strong joints between pipes.

Maintenance Access: Flanges allow easy disassembly for cleaning, inspection, or repairs.

Valve Support: They secure valves in place within the piping system.

The GI Flange Manufacturing Process

Material Selection: High-quality iron or steel is selected for the manufacturing process.

Forging: The raw material is heated and shaped into a flange.

Galvanization: The flange is dipped in molten zinc to form a protective layer.

Machining: Final dimensions are achieved through precise machining processes.

Quality Inspection: A thorough inspection ensures that the flange meets the required standards.

Types of GI Flanges

Weld Neck Flanges: Designed for high-pressure systems, these flanges are welded to pipes, providing a strong connection.

Slip-On Flanges: These are slid over the pipe and then welded, commonly used in low-pressure applications.

Blind Flanges: Used to close the ends of pipes, they help isolate sections of a pipeline.

Socket Weld Flanges: Ideal for small-diameter pipes, they offer a smooth bore for better fluid flow.

Advantages of Using GI Flanges

Corrosion Resistance: The zinc coating protects the flange from rust, especially in environments with high moisture or chemical exposure.

Durability: GI flanges are known for their strength and long service life.

Cost-Effective: The extended lifespan of GI flanges reduces the need for replacements, saving costs in the long run.

Versatility: These flanges can be used in various industrial applications, from plumbing to firefighting systems.

Udhhyog: Leading GI Flanges Manufacturer

Udhhyog is a trusted manufacturer of high-quality flanges, including GI flanges, designed to meet the needs of different industries. The company ensures strict quality controls and precision manufacturing to deliver durable, efficient products for various piping systems.

For further information on Udhhyog’s GI flange products, visit their website or get in touch through their social media platforms.

#GIFlanges#FlangeManufacture#PipingSystems#GalvanizedIron#IndustrialFlanges#PipeConnection#CorrosionResistance#Udhhyog#IndustrialSolutions#ValveSupport#DurableFlanges#PipeFittings#EngineeringSolutions#IndustrialManufacturing

2 notes

·

View notes

Text

GI Flanges Manufacture in Chhattisgarh

Chhattisgarh, known for its mineral wealth and industrial potential, is making significant strides in the manufacturing of Galvanized Iron (GI) flanges. The state's industrial landscape is evolving, with a focus on enhancing its manufacturing capabilities to support the growing demand for GI flanges across various sectors, including construction, agriculture, and infrastructure development.

The process of manufacturing GI flanges in Chhattisgarh begins with the selection of high-quality steel, often sourced from local steel plants. The raw material undergoes various processes, including cutting, shaping, and galvanizing, to produce flanges that are durable and resistant to corrosion. Manufacturers employ advanced techniques and equipment to ensure that the flanges meet stringent quality standards required for industrial applications.

Chhattisgarh’s strategic location provides easy access to essential raw materials, which is a significant advantage for manufacturers. The presence of a well-developed transportation network further facilitates the efficient movement of goods, making it easier for manufacturers to distribute their products to markets across India. This logistical advantage is crucial in maintaining competitiveness and responding to market demands promptly.

The state government is actively promoting the growth of the MSME sector, offering incentives and support to local manufacturers. Various schemes aimed at enhancing infrastructure, providing financial assistance, and facilitating technology transfer are in place to help small and medium enterprises thrive. This supportive environment encourages entrepreneurs to invest in the manufacturing of GI flanges and expand their operations.

In recent years, the demand for GI flanges has surged due to increased infrastructure projects in Chhattisgarh. The state is witnessing significant investments in sectors such as construction, water supply,

#GIFlanges#FlangeManufacturing#IndustrialFlanges#GalvanizedIron#ManufacturingIndia#MetalFabrication#Chhattisgarh#MakeInChhattisgarh#MSMESector#InfrastructureDevelopment#LocalEconomy#QualityManufacturing#SteelIndustry#AdvancedManufacturing#GovernmentSupport#ConstructionIndustry#WaterSupply#LogisticsAdvantage#SustainableManufacturing#IndustrialGrowth

2 notes

·

View notes

Text

Galvanizing Plant Manufacturers

We are proud to collaborate with highly qualified staff and use the highest quality materials to manufacture Galvanizing plants. Our team of experts is dedicated to providing customers with the best possible products featuring the greatest attributes such as durability, strength, and corrosion resistance. We strive to make sure that our Galvanizing Plant meets all industry standards and exceeds customer expectations. With our commitment to excellence, we are proud to be one of the leading Galvanizing Plant Manufacturers in the industry.

Visit Here - https://www.shivasprojects.com/hot-dip-galvanizing-plants.html

Visit Here - https://www.shivasprojects.com/hot-dip-galvanizing-plants.html

0 notes

Text

How GI Flanges Manufacture Contributes to Industrial Efficiency

In today's fast-paced industrial world, efficiency is everything. Companies across sectors constantly seek ways to optimize their processes, cut costs, and ensure the longevity of their infrastructure. One often overlooked yet vital component in this equation is the humble GI flange. Galvanized Iron (GI) flanges are critical in connecting pipes and ensuring the smooth operation of industrial systems.

What many don't realize is that the way these flanges are manufactured plays a massive role in determining how well they perform and how long they last. High-quality GI flange manufacturing contributes directly to improving industrial efficiency by reducing downtime, ensuring a tight fit, and offering superior durability. At Udhhyog, our focus on producing top-tier GI flanges helps industries stay ahead of the curve with optimized, long-lasting solutions.

The Role of Precision in GI Flange Manufacturing

When it comes to manufacturing GI flanges, precision is not just a nice-to-have—it's an absolute necessity. The smallest error in production can lead to serious issues down the line, such as leaks or pipe misalignments, which can cause unplanned shutdowns and financial losses.

Udhhyog’s manufacturing process is designed to minimize these risks. Our flanges undergo multiple rounds of quality control and are produced using the latest technology, ensuring that every piece that leaves our factory floor meets the strictest industry standards.

Accurate dimensions are crucial, especially when dealing with high-pressure systems, where even a millimeter off could spell disaster. This precision not only helps to ensure that systems run smoothly but also allows for easy installation, saving valuable time and labor costs.

Durability and Material Quality in GI Flanges

Industrial operations depend heavily on the materials used in manufacturing their components. For GI flanges, material quality is the cornerstone of durability. The superior corrosion resistance of galvanized iron makes it ideal for harsh industrial environments, where exposure to moisture, chemicals, or extreme temperatures is common.

At Udhhyog, we only use high-grade galvanized iron to produce our flanges, which ensures a long service life. The galvanization process adds an extra layer of protection against rust, ensuring that the flanges can withstand the most demanding conditions.

Durability also reduces the frequency of replacements, making it a more cost-effective choice in the long term. Industrial facilities using Udhhyog’s high-quality GI flanges can minimize downtime, reduce the need for constant maintenance, and improve overall operational efficiency.

Case Studies: Real-World Applications of GI Flanges

Let’s look at some real-world examples where Udhhyog’s GI flanges have contributed to improved industrial efficiency.

Case Study 1: Oil & Gas Industry

A major oil company had experienced frequent downtime due to the corrosion of its pipe fittings in offshore drilling sites. After switching to Udhhyog's GI flanges, designed specifically for high corrosion resistance, they saw a 30% reduction in maintenance-related shutdowns. This translated into significant cost savings and increased productivity.

Case Study 2: Water Treatment Facilities

Water treatment plants require reliable and durable pipe fittings that can withstand the constant exposure to water and chemicals. A leading water treatment facility adopted Udhhyog’s GI flanges and was able to reduce leakage rates by 40%, improving overall operational efficiency and lowering repair costs.

These case studies highlight how high-quality GI flange manufacturing can have a tangible impact on industrial performance.

The Importance of Partnering with Reliable Suppliers like Udhhyog

Choosing the right supplier for industrial components can make or break your operation. A reliable supplier not only delivers on time but also ensures that the quality of the product meets or exceeds industry standards.

Udhhyog has built a reputation as one of the leading GI flange manufacturers in India, delivering products that consistently perform well in demanding conditions. Our commitment to quality assurance and customer satisfaction sets us apart from competitors. With Udhhyog, you are guaranteed flanges that are meticulously crafted and built to last, allowing your operation to run smoothly without costly interruptions.

A strategic partnership with a trusted supplier like Udhhyog allows industries to focus on growth rather than constantly dealing with operational hiccups caused by substandard materials.

How Udhhyog is Driving Innovation in GI Flange Manufacturing

In an industry where technological advancements are often slow to take root, Udhhyog stands out for embracing innovation in flange manufacturing. We leverage advanced manufacturing techniques, including CNC (Computer Numerical Control) machining, which ensures the highest level of precision.

Our team is also constantly researching new materials and coating techniques to improve the durability and performance of our GI flanges. By staying ahead of the curve in manufacturing technology, Udhhyog ensures that our clients receive the most efficient and long-lasting solutions on the market.

Moreover, we have integrated eco-friendly practices into our production processes, minimizing waste and reducing our carbon footprint. This commitment to sustainability resonates with industries that are looking to improve efficiency, not just in terms of operations but also in their environmental impact.

5 notes

·

View notes

Text

Cable Trays Manufacturers in India

Introduction

Cable trays are essential components in electrical and communication infrastructure, designed to support and organize cables in various settings. They provide a secure pathway for electrical wiring and data cables, ensuring they remain organized and protected. If you are searching for reliable Cable Trays Manufacturers in India, Santoshi Industries is your destination for high-quality products. Based in Bhilai, Chhattisgarh, we are recognized leaders in manufacturing and supplying perforated cable trays across the country. Our trays are expertly fabricated from M.S. sheets or pre-galvanized sheets, with perforations on top to ensure optimal ventilation and cable management.

Available in various widths and standard lengths, our cable trays provide versatile solutions for your needs. We source our raw materials from esteemed steel plants such as JSW, POSCO, TATA, and ESSAR steels, ensuring superior finishing and smoothness. Our pre-galvanized trays are ready for immediate use post-fabrication, while our M.S. trays receive treatments such as enamel paint, powder coating, or hot dip galvanizing. Trust Santoshi Industries for durable and reliable cable trays that prioritize safety and performance, making us a leading name among Cable Trays Manufacturers in India.

Durable and Reliable Cable Trays for All Applications from Leading Cable Trays Manufacturers in India

At Santoshi Industries, a leading name among Cable Trays Manufacturers in India, we understand the critical role that durable and reliable cable trays play in various applications. Based in Bhilai, Chhattisgarh, our commitment is to deliver cable trays that not only meet but exceed industry standards for strength and reliability.

Our cable trays are designed to withstand the toughest conditions and are ideal for a range of applications, including:

Industrial Factories

Warehouses & Manufacturing Plants

Office Buildings

Shopping Malls & Hotels

Data Centers

Electrical Installations

Utility Plants

Our cable trays are made from high-quality materials, including mild steel and pre-galvanized sheets, ensuring long-lasting durability. They feature perforated designs for ventilation and ease of cable tying, with options for finishing such as hot dip galvanizing, painting, and powder coating. Choose Santoshi Industries for your cable tray needs and benefit from our extensive expertise and dedication to quality. As one of the top choices among Cable Trays Manufacturers in India, we are committed to providing solutions that meet the diverse requirements of our clients across various industries.

Contact Us for Your Cable Trays Manufacturers in India Today

Looking for top-notch cable trays? Santoshi Industries, a prominent name among Cable Trays Manufacturers in India, is ready to assist with your requirements. From our base in Bhilai, Chhattisgarh, we offer a comprehensive range of high-quality cable trays across the country, including custom solutions tailored to your needs.

For inquiries or orders, reach out to us:Phone:+91-8109006000, 0788–4033833Email:[email protected] and [email protected]: 134/A, Light Industrial Area, Bhilai Nagar, Chhattisgarh 490026

Connect with us today for reliable cable trays and exceptional service!

2 notes

·

View notes

Text

Hot Dip Galvanizing Plant manufacturer - STEP® Techno

Step® Techno Solutions LLP is a well-known company that manufactures hot dip galvanizing plants in Gujarat, India. We have 25 years of expertise in this industry and specialize in the production and design of anodizing, electroplating plant, powder coating plant, and phosphating plant. We are manufacturers of plants used to treat metal surfaces and specialize in designing and building high-quality plants for various metal coating processes. A hot dip galvanizing plant is a facility where the hot dip galvanizing process takes place. These plants are important to the reliability and lifetime of galvanized products. Compared to other coating methods, hot dip galvanizing is highly cost-effective, offering superior protection at a competitive price point. Additionally, the environmental benefits of hot dip galvanizing plant, such as reduced greenhouse gas emissions and energy consumption, make it a sustainable choice for corrosion protection. STEP® Techno Solutions LLP is a India`s top manufacturer and exporter of hot dip galvanizing plants in india. Our focus is on providing innovative solutions that perfectly match the needs of your surface treatment industry. Visit our site: https://steptsl.com/ or Contact us for more info: +919898875757

#Hot Dip Galvanizing Plant#Anodizing Plant#Electroplating Plant#Powder Coating Plant#Phosphating Plant#Hot Dip Galvanizing Plant Manufacturer#Anodizing Plant Manufacturer#Electroplating Plant Manufacturer#Powder Coating Plant Manufacturer#Phosphating Plant Manufacturer

0 notes

Text

Structure and Support | Goel Scientific | Canada | USA

We supply Glass plants that are supported in a tubular structure formed of galvanized steel tubes Manufacturers, in Canada, the USA Goel Scientific Glass

#Best#Top#supply Glass plants that are supported in a tubular structure formed of galvanized steel tubes Manufacturers#in Canada#the USA Goel Scientific Glass

0 notes