#galvanizing line equipment manufacturers

Explore tagged Tumblr posts

Text

Best Quality Hot Dip Galvanizing Plant Manufacturers from India to Worldwide

Wire Machine Company is a Ghaziabad, India-based manufacturer of hot dip galvanizing plants. These plants are designed to provide superior corrosion protection to steel and other metals by applying a layer of zinc through a hot dip process. The company uses advanced technology and high-quality materials to produce galvanizing plants that are efficient, reliable, and durable. Their plants are capable of processing a wide range of metal products, including wires, pipes, tubes, and more. With a commitment to customer satisfaction, Wire Machine Company provides customized solutions tailored to the specific needs of their clients, ensuring that they receive the best possible product and service.

#galvanizing plant manufacturers#hot dip galvanizing equipment suppliers#zinc coating plant manufacturers#galvanizing kettle suppliers#galvanizing furnace manufacturers#zinc melting furnace suppliers#galvanizing line equipment manufacturers#automatic galvanizing plant manufacturers#continuous galvanizing plant suppliers#steel structure galvanizing plant manufacturers

0 notes

Text

True Story:

Throughout my life I have had many obsessions; fishing, the blonde I sat behind in high school biology, to have my own dog (Not just a 'family' dog), the redhead three doors down from our house, hockey, the brunette who would later become my wife, and a number of other things.

But when I was 10 years old I – like every other boy I knew – had a burning desire that made all other obsessions pale in comparison. My singular desire was to have to have a BB gun. I didn't care what kind, although for some reason I loved the look of the Daisy Model 30-30. Maybe it was because of all the Rawhide Kid, Kid Colt; Outlaw, or Cheyenne Kid comic books I consumed whilst hiding from my mother and her infernal chore list.

I wonder in retrospect if my mother believed that if a comic had 'Kid' in the title it couldn't possibly lead her flock astray, but I digress.

As far as BB guns go, I really didn't care what make or model. I just knew I had to have one. I dreamed about fighting off coyotes, black bear, and local bullies. The only requirement was that it be able to shoot a copper-clad projectile at a high rate of speed. Most of my friends already had their obsessions satisfied and it was a source of constant sorrow that I was BB gun-less.

My desire for a BB gun also filled me with a feeling of guilt because my parents ensured I had everything I needed and fulfilled many of my wants. My mother was never shy about providing me books, new or used, and Dad bought me all the fishing gear and hockey equipment I ever needed.

But Ivanhoe and shin pads couldn't fill the hole in my life left by something I had never possessed in the first place.

Any BB gun would have filled the hole.

One close friend, Skunk (don't ask), had the Holy Grail of the BB gun world – a Crosman pump rifle. This particular rifle was carried around town with much-deserved pride (oh, how I hated Skunk when he toted that gun around). I personally witnessed the sleek weapon puncture the side of a tomato juice can. I know it doesn't sound like much today, but back then, tomato juice cans were manufactured by the Ohio Boilermaker Company, made of 10 gauge, zinc-lined, galvanized steel, and, empty, they weighed 23 pounds.

Another friend actually had a BB pistol but his folks took it away from him because he put out one too many window.

There was a smattering of other BB guns in town. Most boys, who were born to more BB gun-friendly parents toted around Daisys, but I recollect other makes like Powermaster, Benjamin, and, of course, Crosman.

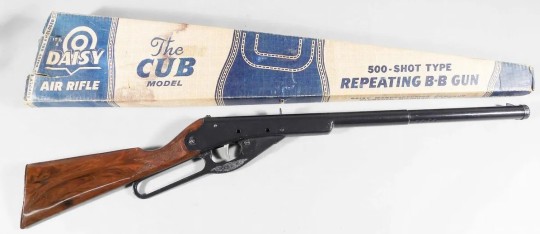

Mom apparently wasn't too worried about my brother and I shooting our eyes out because the Christmas after my 11th birthday my brother and I were presented with matching Daisy 102 Model 36 Cubs. My initial jealousy that my brother got his first gun at 10 while I had had to wait until I was 11 abated after a few seconds when I remembered he was my partner in crime and a pretty good friend all the way around.

The jealousy was immediately replaced with an ugly feeling of ingratitude that made me feel guilty and I tried to shake it off before my dad could see it in my eyes.

Cubs!

Yes, they were guns. Yes, they would shoot a BB. Yes, if you squinted at them, the rifles did sort of look menacing. But they were still Cubs, of all things. To those ignorant of the BB gun world, allow me to explain that the Daisy Cub was the AMC Pacer of the gun hierarchy. It was akin to eating a fast-food burger that has been sitting too long under the warmer; it looked vaguely burger-like, it would fill up an empty stomach, but no matter how you looked at it, it was never going to be a thick, mouth-watering, flame-broiled burger fresh from the barbecue grill in the back yard, dripping with grease, and topped off with the freshest of toppings.

-

Given that Christmas unreasonably seems to always fall in the dead of winter every year, and at least 8 feet of snow covered everything as far south as Des Moines and would until at least April, we were resigned that the guns wouldn't see much action until the Detroit Tigers were in spring training, at a minimum.

Dad, with a head toward solving our dilemma, came through in fine fashion. He covered the windows in the attic with a heavy, BB-proof tarp, hung up paper targets on a length of rope at one end of the cramped space and created an indoor shooting range for his two would be cowboys.

At this point it behooves me to again educate the BB gun ignorant; as a BB does not have a method of propelling itself down a barrel like a bullet, a BB gun has one of two ways to operate: 1. Compressed air (either manually pumped or by using a pre-filled CO2 cartridge), or, 2. Spring-loaded.

Take a wild stab at what method the fine folks at Daisy chose for the Daisy 102 Model 36 Cub.

Initially the BBs zipped to the targets just fine. The single light bulb hanging from the rafters was proof as it had to be replaced more than once, and we discovered the ricochet effect shooting at the chimney bricks.

By the end of January, the springs that provided the propulsion in the Cubs had lost some of their zip. To hit the targets we were required to raise the muzzles a few degrees to provide some elevation to the projectile's trajectory. By the beginning of March, the springs in both guns were so much al-dente fettuccine, and even if we managed to hit the targets – which wasn't a given – the BBs could no longer penetrate.

It wasn't long afterward that the blush fell off the rose and we were spending less and less time sharpening our sharpshooting skills.

I had some Two Gun Kid and Apache Kid comics to read.

-

Spring does show up every year, even to Northern Michigan's Keweenaw Peninsula. It's magical warmth causes the snow banks to shrink, gradually at first, and then disappear like cotton candy in a rain storm. It turned the roads into nearly impassable slush and mud, and boys' yearnings to everything summer: baseball, fishing, camping, freedom, no school.

In the spring and summer, Mom's infernal chore list was only a threat if one couldn't sneak out of the house before she latched onto an arm or ear. Avoiding Mom wasn't all that difficult, mostly because my brother and I had five younger siblings who always seemed to be crying for something or other and, as a result, Mom was almost continually distracted.

The first few glorious days of summer were spent in pursuit of birds and small animals with our new but impotent weapons. The hunts turned out to be exercises in futility because even if we managed to hit a chipmunk or squirrel, the BBs would do little more than tickle them.

It wasn't too many days before the Cubs were left in the hall closet to gather dust. What was the point of toting around a firearm that wouldn't fire? Nobody feared us, and the bears and coyotes were scarce, so our pursuits turned to fishing or swimming or that old trusty standby, finding ways to pester the neighborhood girls.

-

A few weeks into summer found a group of us kids, who had all successfully dodged our respective mother's chore lists, looking for mischief to get into. Picking on the girls was terrific fun but even that had gotten old. How often can you bomb a tea party with water balloons before it loses its attraction?

Fishing was always a draw for me, but nobody else wanted to slog the three miles to the river. A pick up baseball game was mentioned, but there were only eight of us, and, unless we wanted to play with older kids who would take over everything, or worse, girls, it was a non-starter.

Somewhere in our lethargy, the conversation turned to World War II. Over for some time, it was still a favorite subject. One friend's father had actually been in Normandy, and later on was stationed in Paris after it was liberated. He had been a supply clerk and never saw combat, but he still was a hero to us wide-eyed war junkies.

Most of us wouldn't have been able to find Normandy on a map, and whenever I heard of La Madeleine or other French towns I couldn't help picturing Mom's jar of orange marmalade that was always on the breakfast table. But even in our ignorance, we still loved talking about the war.

And then somebody casually asked, why not have a war of our own? For real. With guns. BB guns, albeit, but guns nevertheless. We could map out a large area south of town, stake out territories and try to capture the other's flags. We could set up rules of engagement and follow them to the letter. No targeting someone above the neck. No shooting if the target is closer than 10 feet. If you are hit anywhere but the arms or legs, you are out until the campaign was over and the new one began. Skunk could only pump his gun once; anything more would give him an unfair advantage.

The three boys who weren't already wearing Coke-bottle glasses had to see if they could filch safety goggles from their dad's garages or find something else to protect their eyes.

Breathless, my brother and I raced home to grab our guns and I crept up to our room to grab the half-filled, cardboard carton of ammunition Even employing stealth, we heard Mom yelling for us as the screen door banged behind us and we made our escape and headed to the field of battle.

Most boys are brain dead. At least I was and I can honestly say the thought of how stupid we were being never crossed my gray matter. I can't speak for my brother, but he was right by my side and I don't recall him voicing objections.

If we had stopped to think we would have recognized that if we were found out, not only would Dad bend our guns against the trunk of the maple tree in the back yard, but he'd wear out his razor strop on our heinies.

Perhaps common sense was out pestering the girls that afternoon because it was nowhere to be found when we all met up in the field under the giant cherry tree that we had designated as the demilitarized zone.

In short order we formed two, four-person armies and hammered out the theater of operations. We had to stay in between the two dirt roads to the east and west, and the northern edge of the pond was the southern boundary. The Pelkkanen's (who happened to be out of town) outhouse would represent the northern border of our combat arena.

We tore up the tee shirt pinched from somebody's clothesline and each team took half as a flag. We would split up, set up our head quarters and wait 20 minutes before launching hostilities.

None of us had a watch, so approximately 4 minutes later, we were all slinking through the waist-deep weeds and bramble bushes, crouching behind cedar bushes and pine trees looking for the enemy. Strategy? Ha! We just moved towards the opposite end of the war zone until, hopefully, we'd engage somebody to shoot at.

That's exactly what happened. The two skirmish lines met in an opening in the shrubbery and began firing as fast as we could work the levers on our guns. BBs flew like confetti and boys fell with over-dramatic flair. The BBs had a slightest of stings, except for Skunk's shots, but even those weren't terrible.

Through four successive battles the teams went at it. mostly adhering to the rules. One boy caught a BB in the ear that made him yelp, and in the fourth skirmish I took one in my lower lip which immediately began to swell. The pain wasn't too terrible and I fought on.

Tied two battles to two, we determined to settle the issue of supremacy in one last engagement. To the victor would belong the spoils, whatever they were. Possibly an empty tomato juice can.

Unfortunately, the other team had at least one boy who wasn't addle-minded and had something up their sleeves; they had no intention of a frontal assault.

We found out too late that three of the opposition moved to the west side of the combat zone and made somewhat of a ruckus, drawing our attacking force on the run, while their fourth slipped by unobserved on the east side, waltzed into our base, swiped our flag and redeployed back to his base.

We lost the battle and thus the war without firing a shot. While certainly the defeat stung, my brother and I took the whipping in stride and opined that we'd know better next time. One of our team yelled some of the worst Finnish words he knew; paska, and kusipaa and paskiainen being chief among them. (For those who don't speak Finn, trust me, they're pretty tame by today's standards.)

For some unknown reason that escaped the others in our army, Skunk was livid. How could we lose so easily with such superior firepower? The tyhmät päät must have cheated! He was going to exact some sort of revenge. I tried telling him we just lost and that's the way it goes sometimes. But he was beyond reasoning with.

Skunk set off to the other side of the field with the rest of the team following behind. He would later claim he only pumped his gun once, but my brother and I would both rat him out to the fellows that we both had seen him pumping the gun multiple times as he advanced on the other army's position. How many times did he pump the pump? I have no idea, but it was more than one.

The other team emerged from hiding and began rubbing it in as we approached - as we would have done had we been the victors. Without a word Skunk raised the Crosman and took bead on one of our friends, Jussi. The intended target yelled and spun around to take cover when the BB punctured the denim and skin that covered his keister.

We were all in shock as we watched a small, dark, wet spot appear and grow slowly larger on the wounded boy's left buttock. Even Skunk was mortified at what he'd done. We were all shocked and most of us were crying except for - oddly enough - the boy with the BB in his butt. He handled being shot with remarkable aplomb.

The youngest boy in our gang lost control of his bladder and he peed his pants. (nobody gave him flack for the leak - he was only 8 and, frankly, some of us struggled to keep from peeing in our drawers, too.)

Skunk tossed his gun aside and ran off, all the while crying how sorry he was. The rest of us gathered around our wounded comrade and dithered back and forth about what to do. Jussi gingerly lowered his trousers baring an expanse of pale white flesh with an ugly purplish circle the size of a nickel surrounding a BB-sized darker hole. Bright blood trickled from the wound and dripped down into his pant leg.

Someone suggested sucking out the BB like we might suck out rattlesnake venom. Even Jussi was taken aback by the suggestion and in no uncertain terms bellowed, "Ain't nobody sucking on my arse!"

I picked up Skunk's Crosman and we helped the only real casualty of what we'd come to refer to as the War of the Keweenaw hobble home to have his mom administer first aid.

-

Either Jussi's parents were brighter than we gave them credit for and didn't buy the story that their son was injured by a branch when he fell out of a tree, or Jussi just told them the truth.

Whatever the case, in short order, all of our parents were brought up to speed and that evening found my brother and me in the backyard with Dad. Our Cubs on the ground at our feet.

Without words he gestured for me to hand him my gun. I did so waited for him to slam the gun against the tree trunk. Instead, he raised his knee and bent the barrel of the gun over it like it was Play-Doh. He tossed my Cub aside and repeated the ceremony with my brother.

We waited for him to pull out his strop but it wasn't forthcoming. Even his belt stayed cinched around his waist. He just looked at us sadly and shook his head.

He hugged us both and whispered, "I'm disappointed in both of you."

We would have rather had him wear out the razor strop on our butts. That was a punishment we could understand, even if it was a painful. "Please yell at us, Dad!" I screamed in my head.

Both my brother and I were sobbing uncontrollably. The worst punishment imaginable had been handed down - Dad was disappointed in us. It was a pain we would strive hard to never feel again.

-

All of us who had participated in the War of the Keweenaw had received punishments of varying degrees. We all lost our guns, except Skunk, who, in his remorse and shame, presented it to Jussi in atonement.

My brother and I would spend the next several months trying to make Dad proud of us again. We stopped sneaking out of the house and even willingly worked on Mom's infernal chore list that seemed to keep growing, and completed everything on it that an 11 and 10 year-old could. As much as we would have liked to do so, we just weren't able to reshingle the house and garage roofs on our own, but we willingly helped Dad do the job.

Eventually, after a time, Dad returned to his normal, boisterous, and joking self and life went on and it was good.

-

I never owned another BB gun. A handful of years later I received a Remington .30-06 just in time for deer season, and I've owned multiple rifles, shotguns and pistols since then, but I've never had an 'obsession' for the guns. They are nothing more than tools that I always handle with the respect they deserve.

-

Note: A dozen or so years ago I was able to visit my old home town and reconnect with the few of my friends who still live in the area. Skunk and Jussi are still best of friends and I can still see the boy in both through the grey. Jussi grinned at me when I brought up The War of the Keweenaw, went to his basement and returned with the Crosman BB gun. He claimed it still worked perfectly.

Although I declined to do so when he offered to let me feel the bump, he asserts the BB is still lodged firmly in his buttock.

56 notes

·

View notes

Text

Guaranteed low price Dx51d Dx52d Dx66d galvanized steel coil

Galvanized steel coil is a specially treated steel product whose production process includes a number of fine steps. First, the raw material is all-hard board, which requires a pickling process to remove surface impurities and oxide layers, and then a rolling process to achieve the desired thickness and smoothness. The sheets are then fed into a zinc pan, where they are coated with a uniform and continuous zinc film. This layer of zinc film can not only effectively isolate the direct contact between the air and the substrate, thus greatly enhancing the corrosion resistance of the material; At the same time, because the zinc itself has good plasticity and ductility, the galvanized steel plate also has better processing and forming ability and good coating adhesion.

Hot-dip galvanizing technology is one of the most widely used methods for surface protection of steel products, which takes advantage of the unique electrochemical properties of zinc - when zinc is used as a sacrificial anode, it can be preferentially corroded by oxidation over iron, thereby protecting the internal base metal from damage. This method is especially suitable for those components or equipment that need to be exposed to the outside environment for a long time, such as building structures, Bridges, highway guardrails, etc.

According to the requirements of different application scenarios, the manufacturer can also adjust the specific thickness range of the galvanized layer, which can usually reach a maximum of about 120 grams per square meter. In addition, in cases where the appearance quality of the final product is required to be high, additional polishing treatment can also be selected to obtain a smoother and more delicate surface effect. According to whether such a follow-up processing process is carried out, the common galvanized steel coil on the market can be divided into two categories: zero spot type (that is, no additional treatment is done) and ultra-smooth type.

Our advantage

01. Advanced equipment: We have three production lines, all equipped with the most advanced production equipment in China. These devices not only improve production efficiency, but also ensure the quality and consistency of the product. Our factory covers an area of 30,000 square meters, and spacious production workshops provide ample space for large-scale production.

02. High-quality raw materials: We always adhere to the selection of high-quality raw materials, from the source to ensure the quality of products. We have established long-term and stable cooperation with many well-known suppliers to ensure that the quality of raw materials is reliable and meets international standards.

03. Strict quality inspection: We implement strict quality inspection standards, and strictly monitor and test every production link. Our products comply with ISO and SGS international standards, ensuring that every product can meet 100% of customer requirements.

04. Fast delivery: We use advanced production management processes, from order receipt to production arrangement to product delivery, the entire process is efficient and fast. Our goal is to complete customers' orders in the shortest possible time to ensure that customers receive satisfactory products in a timely manner.

05. Professional Sales services: We have a professional sales team who are fluent in Spanish, Portuguese, French, Arabic and Russian. This enables us to better communicate and cooperate with customers in different countries and regions, and provide customers with more intimate and professional services.

2 notes

·

View notes

Text

SS 304 Flange: Features, Applications, and Price List

The SS 304 flange is a key component in the world of industrial piping, offering outstanding durability, corrosion resistance, and strength. Whether you're managing a large-scale industrial project or a smaller application, SS 304 flanges play a vital role in ensuring secure and leak-proof connections. In this article, we will explore the features, applications, and pricing of SS 304 flanges, along with the latest SS 304 flange price list. At Udhhyog, we provide high-quality SS 304 flanges at competitive prices to meet all your project needs.

What is SS 304 Flange?

SS 304 flange refers to a flange made from Stainless Steel 304, an austenitic steel known for its excellent corrosion resistance, strength, and versatility. Grade 304 stainless steel is composed of 18% chromium and 8% nickel, making it highly resistant to rust and other forms of corrosion in both mild and harsh environments.

Flanges are used to connect pipes, valves, pumps, and other equipment in piping systems, ensuring a secure seal and facilitating easy assembly, disassembly, and maintenance. The SS 304 flange is one of the most commonly used types of stainless steel flanges in industries like oil and gas, chemical processing, food production, and water treatment.

Key Features of SS 304 Flanges

Corrosion Resistance The high chromium and nickel content in SS 304 flanges makes them resistant to corrosion from chemicals, moisture, and gases, making them ideal for both indoor and outdoor applications.

Heat Resistance SS 304 flanges can withstand high temperatures, making them suitable for steam lines, hot water systems, and other high-temperature applications.

Strength and Durability SS 304 flanges offer excellent mechanical strength, ensuring reliable performance even under high pressure. They are durable, long-lasting, and require minimal maintenance.

Ease of Fabrication These flanges are easy to weld and machine, allowing for customization based on specific project requirements. Whether you need special dimensions or configurations, SS 304 flanges are highly adaptable.

Versatility From chemical plants to marine environments, SS 304 flanges are used in a wide range of industries due to their resilience and ability to perform in extreme conditions.

Applications of SS 304 Flanges

SS 304 flanges are used in various industrial sectors, including:

Chemical Processing: With their ability to withstand corrosive chemicals and extreme temperatures, SS 304 flanges are frequently used in chemical plants and processing facilities.

Food and Beverage Industry: The sanitary properties of SS 304 make it a popular choice for food processing and packaging systems.

Oil and Gas Industry: The durability and resistance to corrosion make SS 304 flanges ideal for pipelines in the oil and gas sector.

Water Treatment: In water treatment plants, where corrosion and exposure to water are constant, SS 304 flanges provide reliable, long-lasting performance.

Pharmaceutical Industry: These flanges are suitable for pharmaceutical applications due to their hygienic properties and resistance to contamination.

Factors Influencing SS 304 Flange Prices

When considering the price of SS 304 flanges, several factors can affect the cost. Here's what you should consider:

Material Costs Fluctuations in the price of stainless steel raw materials, especially nickel and chromium, can impact the price of SS 304 flanges.

Size and Type of Flange Larger flanges or those with specialized designs (such as weld neck, slip-on, or blind flanges) are typically priced higher due to the additional material and labor required for production.

Surface Treatment and Finishing Flanges with additional surface treatments, such as polishing or galvanization, may have a higher price, especially if intended for use in corrosive environments.

Manufacturing Precision SS 304 flanges that undergo precision manufacturing processes, such as forging or CNC machining, are generally priced higher, but they offer superior performance and quality.

Quantity Bulk purchases usually offer better pricing. At Udhhyog, we provide attractive discounts for bulk orders, making our flanges more affordable for large-scale projects.

Market Demand Market conditions and demand for stainless steel products can also affect the price of SS 304 flanges.

SS 304 Flange Price List

Here’s a general price overview for common sizes of SS 304 flanges:

1 inch SS 304 flange: ₹300 to ₹650 per piece

2 inch SS 304 flange: ₹400 to ₹850 per piece

3 inch SS 304 flange: ₹600 to ₹1,400 per piece

4 inch SS 304 flange: ₹900 to ₹2,100 per piece

6 inch SS 304 flange: ₹1,600 to ₹3,500 per piece

Please note that these prices are subject to change based on market trends, material costs, and supplier terms. For an accurate and up-to-date SS 304 flange price list, we encourage you to contact Udhhyog directly.

Why Choose Udhhyog for SS 304 Flanges?

At Udhhyog, we are committed to providing high-quality SS 304 flanges at the most competitive prices. Here’s why businesses trust us:

Superior Quality: Our flanges are manufactured using premium-grade SS 304 stainless steel, ensuring maximum durability and performance.

Affordable Prices: We offer some of the most competitive prices in the market, along with bulk purchase discounts.

Customization: We can customize the dimensions and finishes of flanges to meet your project’s specific requirements.

Strict Quality Control: All our flanges undergo rigorous quality checks to ensure they meet industry standards for performance and safety.

Timely Delivery: Our streamlined supply chain ensures that orders are delivered on time, helping you stay on schedule.

2 notes

·

View notes

Text

18,000m³ Glass-Lined Steel (GLS) Tanks: A Reliable Solution for Water Storage and Wastewater Treatment

18,000m³ Glass-Lined Steel (GLS) Tanks: A Reliable Solution for Water Storage and Wastewater Treatment

In the realm of water storage and wastewater treatment, Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) has solidified its reputation as a global leader in providing innovative and durable solutions. Among our most advanced offerings are Glass-Lined Steel (GLS) tanks, renowned for their exceptional performance, reliability, and versatility. Recently, our team completed the design, fabrication, and installation of GLS tanks with a total storage capacity of 18,000m³, underscoring our capability to handle large-scale projects with precision.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Why Choose GLS Tanks for Water Storage and Wastewater Treatment?

GLS tanks, also known as Glass-Fused-to-Steel tanks, combine the strength and flexibility of steel with the corrosion resistance of glass. These tanks are specifically designed to meet the demanding requirements of water storage and wastewater treatment applications. Here are some of the key reasons why GLS tanks are a preferred choice:

1. Superior Durability and Corrosion Resistance

The fusion of glass and steel creates an inert, impermeable coating that offers exceptional resistance to corrosion, chemicals, and extreme weather conditions. This makes GLS tanks ideal for storing both potable water and aggressive industrial or municipal wastewater.

2. Modular and Scalable Design

Our GLS tanks feature a bolted design, enabling easy transportation and rapid assembly at project sites. The modular nature of these tanks allows for scalable storage solutions, accommodating diverse project needs from small installations to large capacities, such as the 18,000m³ configuration.

3. Compliance with International Standards

Center Enamel’s GLS tanks adhere strictly to international standards, including ISO 28765, AWWA D103-09, NSF/ANSI 61, and WRAS. This ensures that our tanks meet stringent quality, safety, and environmental requirements.

4. Cost-Effective and Long-Lasting

With a lifespan of over 30 years and low maintenance requirements, GLS tanks offer an economical solution for water storage and wastewater treatment. Their durability minimizes operational disruptions and reduces long-term costs.

Technical Specifications of the 18,000m³ GLS Tanks

The recently completed GLS tank project includes the following specifications:

Tank Capacity: 18,000m³ (divided into multiple tanks to meet operational needs)

Diameter: Customizable to site constraints

Height: Optimized for space efficiency and hydraulic requirements

Roof Type: Aluminum Geodesic Dome Roofs for enhanced durability and reduced evaporation

Application: Water storage and municipal wastewater treatment

Coating Technology: Advanced enameling techniques to ensure superior glass-to-steel bonding

Applications of GLS Tanks

1. Potable Water Storage

GLS tanks are widely used for storing drinking water, ensuring that the stored water remains safe, clean, and free from contamination.

2. Municipal and Industrial Wastewater Treatment

The corrosion-resistant properties of GLS tanks make them suitable for managing and treating wastewater from municipal and industrial sources, including aggressive chemicals and organic matter.

3. Agricultural Water Storage

Farmers rely on GLS tanks for efficient storage of irrigation water, ensuring consistent supply during dry seasons.

4. Bio-Energy Projects

GLS tanks serve as anaerobic digesters for biogas production, offering a reliable solution for renewable energy projects.

Advantages of Partnering with Center Enamel

As the first manufacturer in China to produce Glass-Fused-to-Steel tanks, Center Enamel brings over 30 years of expertise and innovation to every project. Our commitment to quality, advanced production techniques, and comprehensive after-sales support make us the preferred choice for clients worldwide. With projects completed in over 100 countries, we have the experience and capability to deliver solutions tailored to unique project requirements.

Project Highlights

Ecuador Sewage Treatment Project: GLS tanks successfully withstood a magnitude 7.8 earthquake, demonstrating their structural integrity.

Saudi Arabia Drinking Water Project: Multiple GLS tanks ranging from 600m³ to 6,000m³ for potable water storage, completed on schedule.

Indonesia Palm Oil Wastewater Project: GLS tanks served as anaerobic digesters, enhancing the efficiency of wastewater treatment in the palm oil industry.

Center Enamel’s 18,000m³ GLS tanks represent a pinnacle of engineering excellence, offering reliable and sustainable solutions for water storage and wastewater treatment. Their durability, scalability, and compliance with international standards make them the ideal choice for a wide range of applications.

For more information on our GLS tanks and how they can benefit your next project, contact Center Enamel today. Let us help you achieve your storage and treatment goals with innovative solutions that stand the test of time.

0 notes

Text

The Intermediate Guide to Wire Decking Manufacturers – Aceally

If you work in the warehouse industry, you may be familiar with pallet wire mesh decking. Pallet rack wire mesh decking, or wire mesh trim panels, provide a secure surface for pallet racking to support pallets. Wire mesh decking increase the security and versatility of your pallet racking system, allowing you to store more standard pallets. Bins, boxes and other products are often stored on wire mesh decking.

Profile of wire mesh decking manufacturer Aceally

Aceally (Kunshan) Logistics Equipment Co., Ltd. is an excellent Chinese manufacturer of logistics warehousing and handling products and welded wire mesh products. Our main products contents wire mesh decking, wire mesh cage, metal bin, trolley, stacking rack, steel pallet and other welded wire mesh products.

Our factory has not only many advanced automated production equipment but also automatic powder spraying production line and galvanizing production line of the fifth generation in Chinese technology; Moreover we possessing professional and stable production technology workers, professional sales and after-sales team, can provide you with all-round services of production, processing, surface treatment, shipment and transportation of the above products.

Types of wire mesh decking mesh

wire mesh decking can be divided into welded mesh woven mesh, galvanized mesh and dipped mesh, with welded mesh being the most commonly used.

What is wire mesh decking used for? Wire mesh decking is designed exclusively to provide users of pallet rack shelving the ability to store items on shelves without having to use a pallet. Wire decks also provide increased stability and protection to the pallet rack over conventional pallet support beams alone.

Common specifications of wire mesh decking

0 notes

Text

Common Mistakes to Avoid When Choosing Foundation Bolts for Your Project

When it comes to securing the structural integrity of your project, foundation bolts play a pivotal role. These bolts anchor structures to their foundations, ensuring stability and safety. But choosing the wrong type or overlooking key factors can lead to costly errors, structural issues, and potential safety hazards.

In this guide, I’ll walk you through the most common mistakes people make when selecting foundation bolts and how you can avoid them. By the end, you’ll have the confidence to choose the right bolts for your project every time.

What Are Foundation Bolts?

Foundation bolts are fasteners designed to secure heavy machinery, structures, and equipment to concrete foundations. They are commonly used in construction, industrial projects, and infrastructure development.

Types of foundation bolts include:

J type foundation bolts: Shaped like a "J," offering excellent grip in concrete.

Stud bolts: Double-threaded bolts for precise applications.

Anchor bolts: Designed to anchor structures securely.

Importance of Choosing the Right Foundation Bolts

Using the wrong foundation bolts can lead to:

Structural instability.

Increased maintenance costs.

Risk of accidents and failures.

Selecting the right bolts ensures:

Durability under heavy loads.

Resistance to environmental factors like corrosion.

Proper alignment and load distribution.

Common Mistakes to Avoid

1. Ignoring Load Requirements

One of the biggest mistakes is choosing bolts without considering the load they need to bear. Using bolts that can’t handle the stress can lead to structural failure.

2. Selecting the Wrong Material

Not all materials are suitable for every environment. For example:

Stainless steel foundation bolts offer corrosion resistance but may not be suitable for extremely high loads.

Galvanized bolts work well in outdoor environments but might not have the same tensile strength as other materials.

3. Overlooking Environmental Conditions

Environmental factors like moisture, temperature, and exposure to chemicals can weaken bolts. For example, in marine or industrial settings, corrosion-resistant bolts such as stainless steel U bolts or J type foundation bolts are essential.

4. Neglecting Certification Standards

Using bolts that don’t meet industry standards can compromise the safety and durability of your project. Always check for certifications like ISO or ASTM compliance.

5. Choosing the Wrong Size or Length

Improper sizing can result in loose or overly tight fittings, both of which can compromise structural integrity.

6. Not Accounting for Customization Needs

Standard bolts might not always meet your project’s unique requirements. Many reputable anchor bolt manufacturers offer custom sizes and specifications.

7. Buying from Unreliable Suppliers

Low-cost, substandard bolts from unknown suppliers may save money initially but can lead to failures and costly repairs down the line.

Tips for Selecting the Best Foundation Bolts

Here are my top tips to help you make the right choice:

1. Understand Your Project’s Requirements

Assess the load, environmental conditions, and specific needs of your project. This will help you narrow down the type of bolts to use.

2. Choose High-Quality Materials

Opt for durable materials like stainless steel or high-grade galvanized steel to ensure longevity and performance.

3. Work with Reputable Manufacturers

Look for trusted foundation bolt suppliers or shim manufacturers in India known for their quality and reliability.

4. Check Certifications

Ensure the bolts meet recognized standards such as ISO, ASTM, or other relevant certifications.

5. Request Samples

Before making a bulk purchase, request samples to verify the quality and suitability of the bolts.

6. Consider Customization

If your project has unique specifications, collaborate with manufacturers who offer custom solutions for foundation J bolts, U bolts, or other specialized fasteners.

Conclusion

Choosing the right foundation bolts is critical for the safety, stability, and longevity of your project. By avoiding common mistakes like ignoring load requirements or selecting substandard materials, you can ensure your foundation bolts perform as intended.

Take the time to understand your project’s needs, work with trusted manufacturers, and invest in high-quality bolts. Remember, the right foundation bolts today can save you from costly repairs and structural failures tomorrow.

#FoundationBolts#ConstructionEssentials#ProjectPlanning#BuildingStrength#FasteningSolutions#BoltingMistakes#EngineeringTips

0 notes

Text

The Different Types of Wire Ropes and Their Uses in Various Industries

Wire ropes play a crucial role across many industries, offering strength, durability, and reliability for various applications. From construction sites to marine operations, wire ropes are indispensable. Understanding their types and uses can help businesses make informed decisions when sourcing from steel rope manufacturers in India or wire rope manufacturers in India.

What Are Wire Ropes?

Wire ropes are a collection of individual wires twisted together to form strands, wound around a core. These components make wire ropes versatile, robust, and capable of handling significant loads. A wire rope's material, structure, and design determine its suitability for specific applications.

Types of Wire Ropes

Wire ropes come in several varieties, each designed for specific uses. Let’s explore the most common types:

1. Stainless Steel Wire Ropes

Features: Resistant to corrosion, durable, and versatile.

Uses: Commonly used in marine environments, architectural projects, and medical equipment manufacturing.

Industry Spotlight: Sourced heavily from steel rope manufacturers in India due to their superior quality.

2. Galvanized Wire Ropes

Features: Coated with zinc to resist rust and wear.

Uses: Widely used in outdoor settings like fencing, cable railing, and industrial lifting operations.

3. Fiber Core Wire Ropes

Features: Have a fiber core, offering flexibility and lightweight design.

Uses: Ideal for applications requiring minimal abrasion, such as crane ropes and winch lines.

4. Independent Wire Rope Core (IWRC)

Features: Include a steel core for added strength and resistance to crushing.

Uses: Preferred in heavy-duty applications like mining and oil exploration.

5. Rotation-Resistant Wire Ropes

Features: Designed to minimize spinning under load.

Uses: Essential for tasks involving high vertical lifts, such as in tower cranes and elevators.

How Wire Ropes Are Classified

Wire ropes are categorized based on:

Material: Stainless steel, carbon steel, or synthetic materials.

Construction: Number of strands and wires per strand.

Core: Fiber or steel core.

Coating: Galvanized or uncoated.

Applications of Wire Ropes in Various Industries

1. Construction Industry

Wire ropes are vital in cranes, elevators, and hoisting equipment. Their ability to handle heavy loads makes them indispensable on construction sites.

2. Marine Industry

Corrosion-resistant stainless steel wire ropes are perfect for mooring lines, towing, and rigging.

3. Mining Industry

Heavy-duty wire ropes are used for hauling, lifting, and dragline operations in mining. Wire rope manufacturers in India specialize in high-strength ropes tailored to this industry.

4. Oil and Gas Industry

Wire ropes with high tensile strength are critical for offshore drilling rigs, winching, and anchor handling.

5. Agriculture and Forestry

Galvanized wire ropes are used in fencing, logging, and material handling.

6. Aerospace and Automotive Industries

Wire ropes are integral in control systems, safety cables, and testing equipment.

Why Source from Steel Rope Manufacturers in India?

India is home to some of the most trusted steel rope manufacturers. Known for their adherence to international standards and innovative production methods, these manufacturers cater to global markets. Whether for construction, marine, or industrial use, Indian wire ropes are highly sought after for quality and affordability.

Selecting the Right Wire Rope

When choosing a wire rope, consider:

Load requirements

Environmental conditions

Flexibility vs. strength needs

Longevity and maintenance requirements

Consulting with experienced wire rope manufacturers in India can ensure you find the perfect match for your industry needs.

Conclusion

Wire ropes are indispensable in modern industries, with diverse types catering to specific applications. Whether you need corrosion-resistant stainless steel ropes for marine use or high-tensile ropes for mining, sourcing from reputed steel rope manufacturers in India ensures quality and reliability. By understanding the different types and their applications, businesses can maximize efficiency and safety in their operations.

0 notes

Text

Costa Power taking ups amc services in mumbai for all brands of ups like APC ups amc services in Mumbai, Emerson ups amc services in mumbai, industrial ups amc services, Thane and all pan India location. online ups amc services in mumbai will be taken for ups products after specific warranty period. Our work talk better than us and by that we are leading and well-known ups repair services in Mumbai for all recognized global ups brands. We always believe in ups amc contract in mumbai at regular interval to avoid break down maintenance so can all equipment’s run smoothly without any disturbance and take care of your ROI. We are ready to take any kind of challenge in ups amc services in thane with comprehensive as well as non-comprehensive ups amc vendors in mumbai. In part one we covers all parts failure in maintenance part with almost no down time. Our amc division also caters in ups on hire for specific time with battery back up suppliers or without battery backup in mumbai

Costa Power offers through the organization ALWAYS MAINTENANCE 10 - 120 kVA up to 8 units in parallel operation galvanic isolation at output line with the protect of latest technology of international brand you will benefit from a robust and easy to operate UPS meeting the relevant EMC and other international standards. It can be custom-designed for use in harsh industrial environments. With an expected lifetime of at least 20 years, the Protect 8 is a robust and cost-effective solution optimized for minimal operating costs.

ups amc vendors in mumbai | ups amc contract in mumbai

We just don’t do sales but take care of after sales service with core interest. As we are best ups dealers in Mumbai and after warranty period able to provide ups amc services in Mumbai, India and try to reach up to client satisfaction. Being a leading ups suppliers in Mumbai we never forget client after sales but giving top priority to service also. Costa Power carry’s standard from the date of installation or dispatch for any manufacturing defects. Costa have fare network to reach any location of India for service with all kinds of part availability. At crucial juncture if necessary we provide stand by solution up to repair if ups repair in mumbai,India with us. We serve client as such throughout the year our team is in touch with them for any kind of solution for ups battery suppliers in Mumbai or ups suppliers in Mumbai. Our service team is very dedicated to work at any location with any given time and day consists of experienced and highly professional Engineers for ups preventive maintenance and ups breakdown with time bound.

In any infrastructure and industrial unit or commercial center a site survey is always a critical first step. ups system dealers ensures the appropriate power solution is in place for your business or facility to save energy and keeps equipment’s in good condition. For designing and providing proper solution takes the extra time upfront to ensure all power requirements and considerations have been taken into account before designing a power backup system in mumbai with system integration.

Using our technical experience, we guide you through the data center design process; ensuring that all facility infrastructure issues are thoroughly addressed prior to product procurement and installation

Top ups amc services Provider in Mumbai - AMC

Best online ups supplier in each KVA rating and ups amc service provider in mumbai are very sensitive issue and so it should be taken care utmost to enhance life of ups amc service for ups system and battery life for almost 99% uptime during performance. Costa having expertise and experience in the field to ensure hassle-free in ups repairing in Mumbai as well in all parts of Mumbai. Therefore Costa ups amc service division classified its service in three major parts with so called different services and covers.

ups amc in Mumbai | ups amc in India - Platinum

It covers all the spare parts during maintenance excluding Wound and natural calamities. Provide high priority assistance in breakdown and regular ups amc services in mumbai if necessary. Reports are provided with recommendation and precaution for 99% uptime in critical application. Some time, we provide standby unit with minimal cost if downtime takes longer duration for repair to reduce downtime.

ups amc services in Mumbai,India - Gold

Costa has again special features of ups amc vendor in Mumbai like platinum and mostly clients prefer it. Almost it covers all features like Platinum having except standby unit. We provide this annual maintenance contract with great importance considering criticalness of equipment’s at their best.

#upsamcinmumbai#upsaminpune#upaamccinindia#maintanceinmumbaiforups#upsamservice#amc#uninterrupted power supply#ups#industrial online ups#online ups

0 notes

Text

A350lf2 flanges in UAE

A350 LF2 flanges are designed for low-temperature packages. those flanges are made from carbon metal or low-alloy steels. There are forms of A350 LF2 flanges: magnificence 1 and class 2. each sorts undergo effect finding out to make certain they meet the required durability necessities for low-temperature average overall performance. The ASTM A350 LF2 flanges are available diverse shapes, sizes, specs, and grades, and we're a manufacturer and dealer of these sort of different sorts. With years of enjoy inside the enterprise, we produce a wide sort of flanges in more than one fabric grades.

The ASTM A350 LF2 artificial flanges are stronger due to the fact they will be made from a single piece of metal, making them perfect for programs wherein energy is important. you can purchase A350 LF2 magnificence 1 flanges right away from the manufacturers in Dubai. these flanges also can be without issue welded into piping systems. For programs that require superior sturdiness and hardenability, ASME A350 LF2 flanges are the preferred desire. In some programs, killed carbon products are required. to meet the ones needs, we provide A350 LF2 killed carbon metal flanges.

We provide flanges in numerous sizes and grades, as in line with your unique necessities. Please do not hesitate to touch us for similarly data or to inquire approximately our products. All forgings supplied by the usage of the SA 350 Gr LF2 Cl1 flanges manufacturer are generally ultrasonically examined for great assure.

Specification Chart for ASTM A350 LF2 Flanges

Size Range:

1/2″ to 48″

(15 NB) to (1200 NB)

Pressure Rating Chart (ANSI):

300 LBS, 150 LBS, 600 LBS, 900 LBS, 2500 LBS, 1500 LBS

DIN Pressure Calculation:

40 Bar, 16 Bar, 25 Bar, 6 Bar, 10 Bar

PN10, PN25, PN64, PN16, PN6, PN40

JIS Pressure Rating:

20 K, 10 K, 40 K, 16 K, 5 K, 30 K, 63 K

Manufactured According to Standards:

UNI, BS, AS2129, ANSI, DIN, GOST, JIS, SABS, NFE, AWWA, EN, etc.

Testing Methods:

X-ray detector

Ultrasonic flaw detector

Direct-reading spectrograph

Magnetic particle detector

Hydrostatic testing machine

Coatings Available:

Zinc Plated

Yellow Transparent

Cold and Hot Dip Galvanized

Anti-rust Paint

Oil Black Paint

Common Types of Flanges:

Threaded

Screwed

Forged

Plate

Equipment Used in Manufacturing:

Press machine

Bending machine

Sand-blasting machine

Pushing machine

Electric bevelling machine

UNI / EN Pressure Ratings:

16 Bar, 6 Bar, 10 Bar, 40 Bar, 25 Bar

Connection Type / Flange Face Type:

RF (Raised Face)

Small Tongue

RTJ (Ring Type Joint)

FF (Flat Face)

LJF (Lap Joint Flange)

Large Tongue & Groove

Origin:

Western Europe

Japan

India

USA

Korea

Applicable Standards:

API 7S-43

API 605

ISO 70051

JIS B2220

API 7S-15

ANSI/ASME B16.5

BS 4504

BS 10

EN 1092

DIN

B16.47 Series A & B

MSS S44

BS 1560-3.1

B16.48

EN 1092

This specification chart provides a comprehensive overview of the available options, standards, pressure ratings, and testing methods for ASTM A350 LF2 flanges, ensuring compatibility across a wide range of applications. For more detailed inquiries or specific requirements, please feel free to reach out.

#ASTM A350 LF2 Flanges Manufacturers in UAE#ASTM A350 LF2 Flanges Suppliers in UAE#ASTM A350 LF2 Flanges Stcokists in UAE#ASTM A350 LF2 Flanges Exporters in UAE#CS Flanges in UAE#Carbon Steeel Flanges in UAE#Carbon Steel Flanges Stockist in UAE#Adnoc Approved Flanges in UAE

0 notes

Text

GI Flange Types: A Comprehensive Guide

GI (Galvanized Iron) flanges are vital components in piping systems, providing a secure connection between pipes, valves, and other equipment. Understanding the various types of GI flanges is essential for selecting the right one for your specific application. At Udhhyog, we offer a range of GI flange types to meet diverse industrial needs, ensuring reliability and efficiency.

What are GI Flanges?

GI flanges are circular plates with holes that allow for bolting together various components in a piping system. The galvanization process involves coating the iron with zinc to prevent corrosion, making these flanges ideal for use in environments exposed to moisture, chemicals, or high temperatures.

Common Types of GI Flanges

1. Blind Flange

A blind flange is a solid flange with no opening, used to close off the end of a pipe. It effectively seals the line, preventing any fluid or gas from escaping. Blind flanges are commonly used in high-pressure applications and maintenance operations where isolation is required.

2. Slip-On Flange

A slip-on flange is designed to slide over the pipe's end. It is easy to install and can be welded in place after positioning. Slip-on flanges are often used in lower pressure applications and are preferred for their cost-effectiveness and versatility.

3. Weld Neck Flange

A weld neck flange features a long tapered neck that is welded to the pipe. This type of flange is particularly suitable for high-pressure applications as it distributes stress evenly. The weld neck design also allows for easy alignment during installation, making it a popular choice in critical systems.

4. Socket Weld Flange

A socket weld flange is similar to a slip-on flange but includes a socket for the pipe end. The pipe fits inside the flange, and the two are welded together. This type is ideal for small-diameter pipes and high-pressure applications, providing a strong and leak-proof joint.

5. Lap Joint Flange

A lap joint flange is used in conjunction with a stub end and is primarily used in applications where frequent dismantling is required. It allows for easier alignment and installation, making it a favorite in industries such as shipbuilding and chemical processing.

6. Threaded Flange

A threaded flange has internal threads that allow it to be screwed onto the pipe. This type of flange is ideal for situations where welding is not feasible, such as in systems with thin walls. It provides a reliable seal and is commonly used in gas and oil pipelines.

7. Orifice Flange

An orifice flange is specifically designed for flow measurement applications. It features holes for inserting flow meters and is used in systems where monitoring the flow of liquids or gases is crucial. This type of flange is often found in chemical and petrochemical industries.

Choosing the Right GI Flange Type

Selecting the appropriate GI flange type depends on several factors, including:

Pressure Rating: Consider the pressure conditions under which the flange will operate.

Material Compatibility: Ensure the flange material is suitable for the fluid or gas being transported.

Installation Requirements: Evaluate whether welding or threading is feasible for your application.

Environmental Conditions: Take into account exposure to moisture, chemicals, or high temperatures.

Udhhyog’s Offering of GI Flanges

At Udhhyog, we provide a comprehensive selection of GI flanges to meet the diverse needs of industries across India. Our products are characterized by:

High Quality: Manufactured using premium materials, our GI flanges ensure durability and reliability.

Competitive Pricing: We offer some of the lowest prices for GI flanges in India, making them accessible for various budgets.

Customization: Our flanges can be customized based on specific requirements, ensuring a perfect fit for your project.

Expert Guidance: Our knowledgeable team is available to assist you in selecting the right type of GI flange for your applications.

Applications of GI Flanges

GI flanges are widely used in various applications, including:

Water Supply and Distribution: For sealing connections in municipal water systems.

Chemical Processing: To secure pipes and vessels in chemical plants.

Oil and Gas Industries: For joining pipes and ensuring leak-proof connections.

HVAC Systems: To connect ducts and facilitate airflow.

#GIFlangeTypes#Udhhyog#GalvanizedIron#PipingSolutions#IndustrialFlanges#BlindFlanges#WeldNeckFlanges#SlipOnFlanges#ThreadedFlanges#HVAC

1 note

·

View note

Text

Electrical Steel Coatings Market — Forecast(2024–2030)

Electrical Steel Coatings Market Overview

The Purpose of Coatings

Electrical steel coatings serve several essential functions. Primarily, they reduce energy losses by minimizing hysteresis and eddy current losses. These losses occur when the magnetic field fluctuates within the steel, generating heat that leads to inefficiencies. By applying an insulating coating, manufacturers can enhance the magnetic performance of the steel, making it more efficient and effective for electrical applications.

Request Sample

Types of Coatings

There are various types of coatings used on electrical steel, each designed for specific applications. The most common coatings include:

Silicon Coatings: Silicon enhances the magnetic properties of the steel, improving its efficiency in electrical applications.

Epoxy and Polymer Coatings: These provide excellent insulation and are resistant to corrosion, which is vital for the longevity of electrical components in harsh environments.

Oxide Coatings: Often used for high-temperature applications, oxide coatings improve thermal stability and further reduce energy losses.

Zinc Coatings: These provide excellent protection against corrosion while also enhancing the electrical properties of the steel.

Inquiry Before Buying

Benefits of Coated Electrical Steel

The application of coatings on electrical steel yields numerous benefits:

Improved Efficiency: By reducing energy losses, coated electrical steel enhances the overall efficiency of electrical machines, leading to lower operational costs and reduced environmental impact.

Increased Durability: Coatings protect against corrosion and wear, extending the lifespan of electrical components and reducing maintenance needs.

Enhanced Performance: Coated electrical steel maintains superior magnetic properties, ensuring optimal performance in various applications, from power generation to electric vehicles.

Buy Now

Conclusion

As the demand for energy-efficient solutions grows, the importance of electrical steel coatings cannot be overstated. By improving performance, reducing energy losses, and increasing durability, these coatings play a vital role in advancing electrical machinery technologies. Manufacturers and engineers must prioritize the selection and application of the right coatings to ensure the longevity and efficiency of their products in an ever-evolving market. Embracing innovative coating technologies will pave the way for more sustainable and efficient electrical systems in the future.

Electrical Steel Coatings Industry Outlook Technology launches, acquisitions, and R&D activities are key strategies adopted by players in this market. Electrical Steel Coatings top 10 companies include:

Axalta Coating Systems Chemetall GmbH ArcelorMittal Dorf Ketal PPG Industrial Coatings Valmont Coatings Silco Tek JFE Steel Corporation Novolipetsk Steel Nippon Steel Corporation Recent Developments In April 2023, an industry leader in steel processing and technology, Fives has launched and supplied thermal sections for two new annealing and coating lines (ACL) and a new annealing and pickling line (APL). The performance and quality of electrical steel are largely dependent on the thermal section. In May 2022, The Precoat Metals business division of Sequa Corporation, a portfolio company of international investment firm Carlyle, has been acquired by AZZ Inc., a global provider of welding solutions, specialty electrical equipment, galvanizing and metal coating solutions, and highly engineered services for maintaining and building critical infrastructure. The acquisition was completed as previously announced, with a purchase price of approximately $1.28 billion.

0 notes

Text

Large-Size Enamel GLS/GFS Steel Water Tanks: Super Corrosion-Resistant Solutions

Large-Size Enamel GLS/GFS Steel Water Tanks: Super Corrosion-Resistant Solutions

At Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), we specialize in designing and manufacturing large-size Enamel Glass-Lined Steel (GLS) / Glass-Fused-to-Steel (GFS) tanks renowned for their superior corrosion resistance. With over three decades of experience, our tanks are the go-to solution for industrial, municipal, and agricultural water storage applications worldwide.

Unmatched Corrosion Resistance for Demanding Environments

Our GLS/GFS tanks combine the structural strength of steel with the exceptional corrosion resistance of a glass coating. This fusion process results in a durable, high-performance storage solution ideal for:

Potable water storage.

Wastewater and sludge treatment.

Industrial effluents.

Agricultural water applications.

The glass coating provides a chemically inert, smooth surface that prevents corrosion even in the most aggressive environments, including highly acidic or alkaline conditions

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Key Features of Center Enamel’s GLS/GFS Tanks

Super Corrosion Resistance

Our tanks are designed to withstand a pH range of 3 to 11 under standard conditions and 1 to 14 with special coatings.

The glass layer protects against chemical and biological degradation, ensuring a long service life with minimal maintenance.

Durable and Reliable Construction

Manufactured to AWWA D103-09 and EN ISO 28765 standards.

Engineered for robust performance in harsh environments, including areas with high humidity and extreme temperatures.

Customizable Large Sizes

Tanks are available in diameters up to 60 meters and heights of over 30 meters, meeting the needs of large-scale storage projects.

Bolted Modular Design

Pre-fabricated panels allow for quick assembly and disassembly, reducing installation time and costs.

Ideal for remote locations and sites with limited access.

Multiple Roof Options

Aluminum dome roofs for lightweight, corrosion-resistant performance.

Glass-Fused-to-Steel roofs for complete structural integrity.

Double membrane roofs for biogas applications.

Applications of Large-Size GLS/GFS Tanks

Our large-size tanks are ideal for a wide range of storage applications, including:

Fire water storage for industrial and municipal facilities.

Potable water storage to meet growing urban and rural demands.

Industrial wastewater treatment for petrochemical, textile, and pharmaceutical industries.

Agricultural water storage for irrigation and livestock needs.

Rigorous Quality Standards and Testing

To ensure the highest quality, every tank panel undergoes:

1500V Spark Holiday Test: Detecting any discontinuities in the glass coating.

High-temperature testing to verify thermal resistance.

Corrosion resistance testing to confirm suitability for aggressive environments.

Our commitment to quality is backed by international certifications, including ISO 9001, NSF/ANSI 61, and WRAS.

Advantages of Choosing Center Enamel’s Tanks

Cost-Efficiency

Long-lasting design minimizes maintenance and replacement costs.

Quick installation reduces labor and downtime expenses.

Environmentally Friendly

Modular design minimizes construction waste.

High recyclability of materials reduces environmental impact.

Aesthetic Appeal

Available in various colors, including cobalt blue and forest green, for seamless integration into the surrounding environment.

Proven Track Record

Over 30 years of experience with installations in more than 100 countries.

Successful Case Studies

Indonesia Wastewater Treatment Project

Tank Size: φ25.4 x 18m (H)

Capacity: 12,000m³

Application: Industrial wastewater storage.

Saudi Arabia Fire Water Storage

Tank Size: φ30 x 20m (H)

Capacity: 14,000m³

Features: Aluminum dome roof and corrosion-resistant panels.

Ecuador Potable Water Storage

Tank Size: φ18.7 x 12m (H)

Capacity: 8,500m³

Application: Municipal drinking water supply.

Why Partner with Center Enamel?

Industry Leadership: We are Asia’s most experienced manufacturer of bolted storage tanks and the first in China to produce GLS/GFS tanks.

Innovative R&D: With over 20 enameling patents, we continuously push the boundaries of storage tank technology.

Global Reach: Serving clients across industries in over 100 countries.

End-to-End Service: From design and manufacturing to installation and after-sales support, we ensure seamless project execution.

Contact Us Today

Discover how our large-size Enamel GLS/GFS steel water tanks can meet your project’s requirements with unmatched corrosion resistance and durability. With Center Enamel, you can trust in a partner that delivers exceptional performance and reliability.

Contact us now to learn more about our solutions or request a customized design for your project!

0 notes

Text

Mild Steel Pipes in Uttar Pradesh

Meghmani Metal Industries is a Manufacturer and Supplier of Mild Steel Pipes in Uttar Pradesh, India. We established our company in 2011 in Ahmedabad, Gujarat, India. Various industries widely use Mild Steel (MS) pipes because of their excellent strength, ductility, and weldability. Low-carbon steel makes these pipes versatile and affordable, making them an ideal choice for various applications, including construction, plumbing, and infrastructure projects. Types of MS Pipes: ERW (Electric Resistance Welded) Pipes Seamless Pipes MS Black Pipes MS Galvanized Pipes Features: Durability: Excellent mechanical properties for high pressure and temperature. Corrosion Resistance: Can be treated or coated for enhanced durability. Cost-Effectiveness: More affordable than stainless steel or plastic pipes. Ease of Fabrication: Easily cut, welded, and shaped for design flexibility. Applications of MS Pipes: Construction: They are extensively used in building structures, scaffolding, and supporting frames. Plumbing: MS pipes serve as a cost-effective option for water supply lines and drainage systems. Automotive: Manufacturers utilize them to create automotive parts and frames due to their strength and lightweight nature. Manufacturing: MS pipes are essential in creating machinery, equipment, and industrial tools. Meghmani Metal Industries is a Manufacturer and Supplier of Mild Steel Pipes in Uttar Pradesh, India Including Agra, Aligarh, Amroha, Ayodhya, Azamgarh, Bahraich, Ballia, Banda, Bara Banki, Bareilly, Basti, Bijnor, Bithur, Budaun, Bulandshahr, Deoria, Etah, Etawah, Faizabad, Farrukhabad-cum-Fatehgarh, Fatehpur, Fatehpur Sikri, Ghaziabad, Ghazipur, Gonda, Gorakhpur, Hamirpur, Hardoi, Hathras, Jalaun, Jaunpur, Jhansi, Kannauj, Kanpur, Lakhimpur, Lalitpur, Lucknow, Mainpuri, Mathura, Meerut, Mirzapur-Vindhyachal, Moradabad, Muzaffarnagar, Partapgarh, Pilibhit, Prayagraj, Rae Bareli, Rampur, Saharanpur, Sambhal, Shahjahanpur, Sitapur, Sultanpur, Tehri, Varanasi. Feel free to contact us for more information and inquiries. View Product: Click Here Read the full article

0 notes

Text

Enhances the Visual Appeal of Structures while Ensuring Long-Term Performance

AST PIPES is a renowned provider of industrial pipe solutions, offering a comprehensive range of products to meet the diverse needs of industries around the world. With an emphasis on quality, precision, and innovation, AST PIPES specializes in the production of wordpile tubes, precision pipes, GP pipes, and a variety of other pipes that serve critical roles in industrial, construction, and infrastructure projects.

Precision Pipes: Unmatched Accuracy and Strength

At the core of AST PIPES' offerings are precision pipes, which are known for their exact specifications and reliability. Precision pipes are used in a range of industries where accuracy is paramount, such as automotive, mechanical engineering, and manufacturing. These pipes are designed to handle high-pressure environments and provide optimal performance. ASTM pipes are also part of the range, meeting stringent standards set by the American Society for Testing and Materials, ensuring high-quality materials and durability in every product.

GP Pipes and Rolling Pipes: Versatility in Construction

AST PIPES offers GP pipes (Galvanized Pipes), which are widely used in construction, plumbing, and fencing due to their corrosion-resistant coating. GP pipes come in various sizes, including GP square pipes, making them suitable for a wide range of applications.

Rolling pipes are another crucial product in the AST PIPES portfolio, known for their flexibility and durability in different industrial applications. These pipes are ideal for projects that require high strength and adaptability, such as in construction or machinery assembly.

API Pipes: Meeting Global Standards

AST PIPES also produces API pipes, adhering to the strict standards set by the American Petroleum Institute. These pipes are primarily used in the oil and gas industry for transporting fluids, ensuring that they can withstand the harsh conditions of drilling and extraction processes. AST PIPES' API pipes are manufactured to provide long-lasting performance, reliability, and safety in critical applications.

Piling and Wordpile Tubes: Robust Solutions for Infrastructure

For large-scale infrastructure projects, piling pipes are essential for deep foundation work, supporting heavy structures such as bridges, buildings, and offshore platforms. AST PIPES produces wordpile tubes that are designed to meet the demands of heavy-duty piling, offering strength and stability even in the most challenging environments. These pipes are crucial for ensuring the longevity and safety of large construction projects.

Furniture Pipes and Boom Tubes: Innovative Applications

AST PIPES caters to the furniture and design industry by offering furniture pipes that combine both aesthetics and functionality. These pipes are commonly used in modern furniture design, providing structural support while maintaining a sleek appearance.

Boom tubes are another innovative product in the AST PIPES line up, used in various industrial applications, including construction equipment, machinery, and automotive components. These tubes are designed for high performance and durability, making them a reliable choice for demanding applications.

ERW Precision Tubes and Steel Conduit Pipes: Engineered for Excellence

AST PIPES manufactures ERW precision tubes (Electric Resistance Welded), which are known for their high strength and smooth finish. These tubes are used in a variety of industries, including automotive, construction, and engineering. Steel conduit pipes are another offering from AST PIPES, providing electrical wiring protection in commercial and residential buildings. These pipes are known for their durability and ability to withstand extreme conditions, making them a reliable choice for electrical and construction applications.

Corten Steel Tubes and Boom Pipes: Resilience in Harsh Conditions

For industries that require pipes with superior corrosion resistance, AST PIPES offers corten steel tubes. These tubes are made from weathering steel, which forms a protective layer of rust, making them ideal for outdoor and industrial applications. Boom pipes, on the other hand, are designed for heavy-duty use in machinery and construction, providing strength and reliability in demanding environments.

Commitment to Quality and Innovation

AST PIPES is committed to providing top-notch products that meet the highest standards of quality and performance. Whether it's GP tubes, precision pipes, or ASTM pipes, the company's focus on innovation and customer satisfaction sets it apart in the industry. With a strong emphasis on research and development, AST PIPES continues to evolve its product offerings to meet the changing needs of industries worldwide.

AST PIPES is a leader in the industrial pipe sector, offering a wide range of products including wordpile tubes, precision pipes, GP pipes, API pipes, and more. Whether you're looking for high-strength piling pipes, corrosion-resistant corten steel tubes, or versatile furniture pipes, AST PIPES has the right solution for every application.

#wordpile tubes#precision pipes#gp pipe v#rolling pipe#astm pipe#precision tubes#api pipe#gp pipe price per kg#gp tubes#gp square pipe#piling pipe#furniture pipes#boom tube#erw precision tubes#gp pipe price#steel conduit pipes#corten steel tubes#boom pipe

0 notes

Text

Anti-rust treatment of pig manure organic fertilizer equipment

The anti-rust treatment of pig manure organic fertilizer equipment is very important to ensure the long-term stable operation of organic fertilizer production line. Here are some key anti-rust treatments: