#fully automatic pet bottle blowing machine

Explore tagged Tumblr posts

Text

PET Blow Moulding Machines for PET/PP Bottles

Blow Machines Manufacturer in India – Explore our range of Automatic and Semi-automatic Water Bottle Blowing Machine and get the Price for them. Call now.

Explore more - PET Blow Moulding Machines for PET/PP Bottles.

#blow moulding machines#pet blow moulding machine#fully automatic blow moulding machine#Semi-automatic Water Bottle Blowing Machine

0 notes

Text

All about Automatic PET Blow Moulding Machine

The packaging world has undergone a massive transformation over the years, and one of the most groundbreaking innovations is the Automatic PET Blow Moulding Machine. This high-tech equipment has revolutionized how PET bottles are produced, making the process faster, more efficient, and consistent.

Imagine trying to create thousands of uniform, high-quality bottles manually—sounds like a nightmare, right? That's where automation steps in. The PET Blow Moulding Machine is designed to streamline the bottle-making process, eliminating the need for constant human supervision and drastically reducing the margin for error.

So, what exactly is this machine? Simply put, it's a sophisticated device that transforms preforms—small, test-tube-like plastic pieces—into fully-formed PET bottles using heat, pressure, and air. With the help of cutting-edge technology, these machines automate every stage of the process, from loading the preform to ejecting the final product.

These machines are a game-changer for industries where mass production of bottles is essential. Whether you're in the beverage sector, cosmetics, pharmaceuticals, or cleaning products, an Automatic Blow Molding Machine can help boost production rates while maintaining top-notch quality. It's no wonder these machines have become a staple in high-demand manufacturing units worldwide.

What makes this even better? The integration of smart features such as touch-screen interfaces, programmable logic controllers (PLC), and energy-saving functions. Modern versions like the fully auto blow moulding machine are capable of running round-the-clock with minimal human oversight, significantly lowering labor costs.

All in all, investing in an Automatic PET Blow Moulding Machine is not just about keeping up with the competition—it's about setting new industry standards.

Understanding the Blow Moulding Process

Before diving deeper into the features and benefits of these machines, it’s crucial to understand how the blow moulding process works—especially when automation takes center stage.

The process starts with a plastic preform. These are small tubes made from PET (polyethylene terephthalate), which are the basic building blocks for your final product—think of them as the seeds for your plastic bottles. These preforms are loaded into the machine, where they go through a heating section that brings them to the ideal temperature for forming.

Now comes the magic: the heated preforms are transferred to a mould cavity. Here, a stretch rod pushes the plastic downward while high-pressure air is blown inside. This dual action causes the plastic to expand and take the shape of the mould. The result? A perfectly formed PET bottle.

In a fully auto blow moulding machine, all these steps are automated. The machine handles the preform feeding, heating, stretching, blowing, cooling, and bottle ejection in one seamless loop. This not only increases production speed but also ensures each bottle is consistent in size, weight, and thickness.

But there’s more to it. Automation reduces the chances of contamination—a crucial factor in industries like food and pharmaceuticals. It also minimizes material wastage, thanks to precise controls over every parameter, including temperature, pressure, and timing.

In short, the blow moulding process becomes smarter, faster, and far more reliable when you switch to an automatic blow molding machine. No more manual monitoring. No more quality inconsistencies. Just efficient, non-stop production that meets even the most demanding requirements.

Types of Automatic Blow Moulding Machines

When you're shopping for blow moulding equipment, it's important to know that not all machines are created equal. There's a variety of automatic blow molding machine types out there, each tailored for different production needs and bottle designs.

Let’s break down some of the key types:

Automatic Blow Molding Machine: This is your standard, high-speed system designed to handle large production volumes. It features continuous operation, allowing for 24/7 output with little downtime. These machines are often used in large-scale beverage bottling plants where speed and precision are non-negotiable.

Auto Blow Moulding Machine: A variation of the automatic machine, the Auto Blow Moulding Machine offers enhanced customization. Ideal for businesses that need flexibility in mold sizes and production volumes, it strikes a great balance between efficiency and adaptability.

Automatic Blow Moulding Machines (plural): These typically refer to production lines that consist of multiple machines or multi-cavity systems. They allow for the simultaneous production of several bottles, dramatically increasing output while maintaining quality.

Fully auto blow moulding machine: This is the top-tier option for manufacturers looking for hands-free, ultra-reliable production. These machines often come equipped with robotic arms, touchscreens, and self-diagnostic systems that make them virtually foolproof.

Auto PET Blow Molding Machine: Specifically designed for PET materials, these machines are optimized to deal with the unique properties of PET plastic. They ensure uniform material distribution and reduced wastage—an excellent choice for eco-conscious manufacturers.

Each machine type serves a unique purpose, so understanding your specific needs—like bottle design, production volume, and available space—will help you pick the right one. Investing in the right automatic blow molding machines can significantly impact your ROI and long-term growth.

Key Components of an Automatic PET Blow Moulding Machine

To really grasp the efficiency of PET Blow Molding Machine, you need to understand its core components. Think of it like a well-oiled orchestra, with each part playing a crucial role in ensuring flawless bottle production.

Here’s what typically makes up one of these machines:

Preform Loader: This section automatically loads the PET preforms into the machine. It's equipped with sensors and feeders to ensure a continuous flow without jamming.

Heating Section: Using infrared heaters, this part brings the preforms to the ideal temperature for blowing. Uniform heating is key to maintaining bottle integrity and avoiding weak spots.

Stretching and Blowing Station: This is where the magic happens. A stretch rod pulls the heated preform while high-pressure air is injected, shaping the preform into a bottle. The molds determine the final shape and size of each bottle.

Mold Clamping Unit: Strong clamps hold the molds in place under intense pressure during the blowing process. This ensures that the bottle forms correctly without any air leaks or deformations.

Cooling System: Once formed, the bottle is rapidly cooled to maintain its shape and strength. This cooling system prevents warping and ensures dimensional accuracy.

Bottle Ejector: After cooling, the finished bottle is automatically ejected onto a conveyor belt or into a collection bin. No manual handling needed, which reduces contamination risks.

Together, these components make the Blow Moulding Machine a powerhouse of efficiency. With minimal human intervention, these systems can churn out thousands of high-quality bottles per hour, making them indispensable for modern packaging operations.

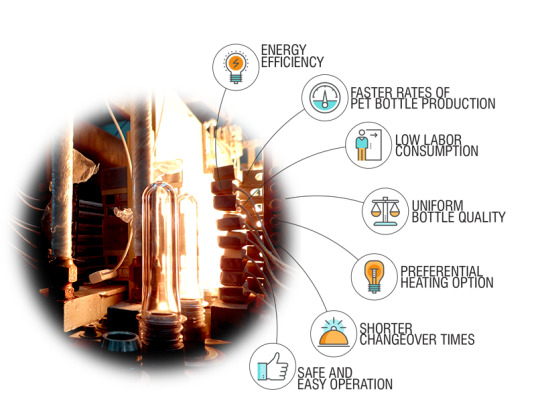

Advantages of Automatic PET Blow Moulding Machine

Let’s face it—manual labor is both time-consuming and prone to error. That’s why industries across the board are switching to automation. When it comes to bottle production, the PET Blow Moulding Machine manufacturer offers a slew of advantages that make it a no-brainer investment.

Increased Production Speed: These machines are engineered for high-volume output. Some models can produce thousands of bottles per hour, all with identical quality and size.

Consistency & Quality Control: With pre-set parameters and computer-controlled operations, every bottle meets exact specifications. Say goodbye to variations and defects.

Labor Cost Reduction: Since the process is automated, there’s less need for manual labor. Fewer workers mean lower costs and fewer errors.

Lower Material Waste: Precise temperature and pressure control ensure optimal material usage, cutting down on waste and boosting profitability.

Space Efficiency: Many Blow Molding Machines are designed with compact footprints. This allows them to fit into existing production lines without taking up much room.

Energy Efficiency: Modern models come with power-saving features that lower operational costs without compromising performance.

Less Downtime: Self-diagnostic tools and easy maintenance access keep the machine running smoothly with minimal interruptions.

Applications of Automatic Blow Moulding Machines

The versatility of Blow Molding Machine Manufacturer is one of its strongest selling points. These machines aren't just confined to producing beverage bottles—they serve a wide range of industries with precision and efficiency.

Let’s take a tour through the various sectors that benefit from these machines:

Beverage Industry: This is probably the biggest user of automatic blow molding machines. From small 200ml bottles to large 2-liter soda containers, these machines handle it all. Their ability to produce uniform bottles quickly is vital for soft drink, water, juice, and milk companies.

Pharmaceutical Sector: Accuracy and hygiene are critical here. These machines produce small, intricate bottles for syrups, tablets, and other medications, maintaining the strictest quality standards and reducing the risk of contamination through touchless production.

Cosmetics and Personal Care: Think of shampoo bottles, lotions, sprays, and creams. The variety of bottle shapes and sizes in this sector demands a high degree of customization, which a fully auto blow moulding machine can easily provide.

Household Products: Items like cleaning supplies, liquid detergents, and oils require strong, leak-proof containers. These machines produce sturdy PET containers that are resistant to breakage and maintain shape integrity under pressure.

Edible Oils and Sauces: The food-grade compliance of these machines ensures that bottles are safe for oil, vinegar, ketchup, and other condiments. Plus, the machines can be adjusted to create tamper-evident closures and ergonomic designs.

Industrial Uses: From lubricants to automotive fluids, PET bottles produced using Auto PET Blow Molding Machine are suitable for chemical-resistant applications too.

The wide range of mold compatibility and high-speed functionality make these machines indispensable across different production lines. If your product needs a PET container, chances are, there’sBlow Moulding Machine Manufactures out there that can make it happen.

Top Features to Look For in a Blow Moulding Machine

Choosing the right machine isn’t just about capacity—it’s also about features that enhance productivity, reduce downtime, and deliver consistent quality. Here's what you should keep an eye out for when investing in an automatic blow molding machine:

Servo Motor Integration: Machines with servo-driven systems are more energy-efficient and precise. They offer better control over movements, leading to faster cycle times and less wear and tear.

Advanced PLC Controls: A modern Automatic Blow Moulding Machine should come with a user-friendly PLC (Programmable Logic Controller) system. These allow operators to set and adjust parameters with ease, view real-time diagnostics, and troubleshoot quickly.

Touchscreen HMI Interface: A smart interface boosts operator efficiency. Look for machines with large, intuitive screens that display temperature settings, pressure controls, mold configurations, and production stats.

Multi-Cavity Capability: Need more output? Multi-cavity machines allow the simultaneous production of multiple bottles. This is crucial for meeting high-demand requirements without sacrificing quality.

Infrared Heating System: Modern Auto Blow Moulding Machines feature advanced infrared heating tunnels for uniform preform heating. Consistency here ensures uniform bottle thickness and strength.

Automatic Lubrication System: Prevent wear and extend machine life with systems that auto-lubricate moving parts at scheduled intervals.

Energy-Efficient Features: From variable-frequency drives (VFDs) to power-saving standby modes, these features lower energy bills while keeping productivity high.

Safety Features: Emergency stop buttons, safety doors, and overload protections aren’t optional—they’re essential. A top-tier machine will have all these built-in.

Selecting a machine with these high-performance features will not only ensure smooth operations but also save your business money in the long term. Remember, the right fully auto blow moulding machine pays for itself through efficiency and reliability.

Comparison: Auto PET Blow Molding Machine vs Traditional Systems

It's easy to assume that traditional bottle-making systems still hold their ground, but when you stack them up against an Auto PET Blow Molding Machine, the differences are night and day. Let's look at why modern systems are miles ahead:

Speed and Output: Traditional methods often rely on manual loading and unloading of preforms and bottles. This slows down production and introduces human error. In contrast, an automatic blow molding machine operates continuously with almost no manual intervention, drastically increasing output.

Consistency: Traditional systems tend to vary from batch to batch. But automation delivers bottle-after-bottle uniformity—perfect weight, wall thickness, and dimensions every time.

Labor Dependency: Manual machines require skilled workers to handle different operations. This not only increases payroll but also risks production halts due to absenteeism. Automated machines require only supervision and occasional maintenance.

Maintenance and Downtime: Older systems tend to wear out faster due to constant manual interaction. Modern machines come with self-diagnostic tools, remote monitoring, and smart alerts to prevent failures before they occur.

Customization: Need to switch from a 500ml to a 1-liter bottle? Traditional systems take hours to reconfigure. A modern Auto Blow Moulding Machine can adapt to new molds in minutes, offering rapid changeovers and flexibility in production.

Energy Use: Older machines are energy guzzlers. But today’s automatic blow molding machines are designed to be eco-friendly, with infrared heating, servo systems, and smart energy-saving modes.

The takeaway? Investing in a modern, PET blow moulding machine manufacturer gives you the edge in terms of cost, speed, quality, and sustainability. It’s not just an upgrade—it’s a transformation of your production capability.

Blow Molding Machine Installation and Maintenance Tips

So you've decided to go all-in on an Automatic Blow Moulding Machine. Great choice! But what comes next? Installation and upkeep are key factors in maximizing your investment. Here’s what you need to know:

Installation Checklist:

Space Planning: Ensure you have enough room for the machine, material flow, and maintenance access.

Power Supply: Confirm that your facility meets the voltage and phase requirements.

Water & Air Lines: Most machines require chilled water and compressed air. Plan these utilities in advance.

Ventilation: Infrared heaters emit heat, so adequate ventilation is crucial.

Safety Zones: Allocate areas for emergency exits and safety clearances.

Training Operators: Even if the machine is automatic, human oversight is still needed. Make sure your operators are trained to use the control panel, change molds, and perform basic troubleshooting.

Routine Maintenance:

Daily: Check air filters, oil levels, and clean heating chambers.

Weekly: Inspect moving parts, test emergency systems, and recalibrate sensors.

Monthly: Lubricate joints, tighten bolts, and examine belts and motors.

Annually: Conduct a full machine audit and replace worn-out parts.

Smart Maintenance Tips:

Keep a logbook for maintenance schedules.

Use OEM (original equipment manufacturer) parts for replacements.

Follow the manufacturer's service intervals strictly.

Always keep spare parts like sensors, heating rods, and belts in stock.

With proper installation and regular maintenance, your automatic blow molding machines will serve you for years without breaking a sweat.

Challenges Faced with Automatic Blow Moulding Machines

Like any technology, Automatic Blow Moulding Machines come with their own set of challenges. Knowing them upfront helps you prepare better and avoid costly mistakes.

Initial Investment: These machines are not cheap. The upfront cost can be daunting for small and medium enterprises. However, this is often offset by long-term gains in productivity and labor savings.

Technical Downtime: While modern machines are highly reliable, software glitches or sensor failures can still cause downtime. This is why operator training and real-time diagnostics are so crucial.

Mold Wear and Replacement: Molds are subject to constant pressure and heat. Over time, they wear out or get damaged. Investing in high-quality molds and performing regular checks will save money and prevent defective products.

Dependence on Skilled Technicians: Though the machine is automatic, you’ll still need a knowledgeable technician for setup, calibration, and servicing. Make sure you have access to reliable support, either in-house or from your blow moulding machine manufacturerin India.

Parts Availability: Some machines require proprietary components that may not be readily available. Always confirm that the supplier offers strong after-sales support and has spare parts on hand.

Energy Consumption: While most modern machines are energy-efficient, older automatic models can still be power-hungry. Monitoring your usage and upgrading to newer systems can help mitigate this.

Recognizing these challenges doesn't mean you shouldn’t invest—it means you’ll be better prepared. With the right planning and support, even these hurdles can be easily overcome.

youtube

1 note

·

View note

Text

Water Bottle Making Machine: Technology, Types & Industry Applications

Introduction to Modern Water Bottle Making Machine

The plastic bottle manufacturing machine has now become advanced due to the demand for Water Bottle Making Machines in bottled water production, which has been growing substantially worldwide. These advanced plastic bottle manufacturing machines are equipped with almost the latest stretch blow molding (SBM) engineering for effectively producing the much-needed high-quality PET containers for various industries.

The latest and modern-style Blow Molding Machines can boast of:

✔ Precision automation to ensure consistent output

✔ Energy-efficient operating systems

✔ Flexible production capacities

✔ Integration of smart technology

These machines are used in several sectors including but not limited to:

✔ Beverage and drinking water

✔ Pharmaceutical and healthcare

✔ Personal care and cosmetics

✔ Food and household products

A Detailed Dissection of a PET Bottle Manufacturing Process

1. Preform Treatment and Adjustment

The first stage in the whole production cycle is a PET preforming - test-tube shaped plastic blanks which are:

✔ Being automatically loaded into the machine

✔ Heated correctly to optimum temperature (190-210°C)

✔ Rotated for uniform heat distribution.

2. Blow Molding Phase

Preforms at elevated temperatures undergo:

✔ Stretching using precision rods;

✔ High-pressure air expansion (30-40 bar);

✔ Molding for cavity shapes;

✔ then, rapid cooling to set the bottle structure. All this occurs at a speed of about 2-5 seconds per bottle.

3. Quality Control and Output

The processing draughts are:

✔ Automatically ejected from the machine.

✔ Following quality they are subjected to leak and defect testing.

✔ Then put on for packaging and distribution.

Also read, Choosing the Right Water Bottle Making Machine for Your Production Needs

Types and Capacity of Machines

1. Semi-Automatic Systems

✔ Perfect for small production

✔ Manual preform loading

✔ Basic automation

✔ Suitable for product development

2. Fully Automatic Machines

✔ Costs medium or large operations

✔ Robotic material handling

✔ multi cavity mold options

✔ advanced process controls

3. Rotary Blow Systems:

✔ Suited for high-volume production solutions.

✔ Facility for continuous operation.

✔ Design for maximum efficiency.

✔ Output of industrial levels.

Essential Features of Advanced Technology

Energy Management Systems

✔State of-the-art servos

✔Heat recovery systems

✔Smart metering of energy usage

Precision Engineering

✔Microprocessor temperature regulation

✔Extremely accurate stretch rod systems

✔Equal pressure regulation by air

Smart Manufacturing

✔Highly defined HMI touchscreen interfaces

✔Barcoding on production data

✔Remote monitoring facility

✔Predictive Maintenance System – PPM

Factors that can be considered while selecting a Water Bottle Manufacturing Machine

1. Production requirements - volume and speed needs

2. Characteristics of products - sizes and designs

3. Technological considerations - automation and control features��

4. Future expansion - scalability options

5. Support services - maintenance and training

Advantages of modern bottle production systems

✔ Consistent high-quality output

✔ Efficient utilization of material

✔ Reduced energy consumption

✔ Flexible production capability

✔ Good long-term performance

Conclusion: Boosting Skills to Produce

The industry of the Water Bottle Making Machine is always advancing by technology which is being improved by means of production and product quality. Aim Technologies present this modern-day PET Blowing Machine to cater to manufacturers of high operation standards and allow greater production to satisfy a growing market.

Understanding such advanced production systems allows a business to make wise decisions for their equipment. For those companies wishing to get started in bottle manufacturing or wish to expand their market, an understanding of advanced production systems is pertinent for wise choices on perfect Bottle Blowing Machines. A very good Bottle Blowing Machine would create a phenomenal difference in production capacity, product quality, and operation efficiency.

#water bottle making machine#PET blowing machine#Plastic Bottle Manufacturing Machine#Bottle Blowing Machine#Water bottle manufacturing machine

0 notes

Text

Key Benefits of Semi-Automatic Pet Blowing Machine in Delhi

In the ever-evolving world of manufacturing, efficiency, and precision are paramount. The plastic bottle industry, a critical sector, relies heavily on advanced machinery to meet growing demands and maintain high standards. G.S Machinery, a leading manufacturer, stands out in this domain by providing cutting-edge solutions. Their semi-automatic PET blowing machines offer remarkable benefits, making them an essential investment for manufacturers in Delhi.

Enhanced Efficiency and Productivity

One of the most significant advantages of the semi-automatic PET blowing machine is its ability to enhance efficiency and productivity. These machines are designed to streamline the production process, reducing manual intervention and increasing output. As leading Semi Automatic Pet Blowing Machine Manufacturers in Delhi, G.S Machinery ensures that their machines are equipped with the latest technology to maximize efficiency. The semi-automatic nature of these machines allows for quick setup and minimal downtime, enabling manufacturers to meet high production targets with ease. This increased efficiency not only boosts productivity but also ensures consistency in the quality of the produced PET bottles.

Ease of Use and Maintenance

User-friendliness and ease of maintenance are critical factors that influence the choice of machinery in any manufacturing setup. Its semi-automatic PET blowing machines are designed with simplicity in mind, ensuring that operators can easily manage and control the production process. The intuitive interface and straightforward operating procedures reduce the learning curve for operators, minimizing the risk of errors and increasing overall efficiency. Additionally, these machines are built with durability and ease of maintenance in mind. The robust construction and high-quality components used by It ensure that their machines require minimal maintenance, reducing downtime and maintenance costs for manufacturers.

Cost-Effective Solution

Cost-effectiveness is another crucial benefit of the semi-automatic PET blowing machine. Investing in fully automatic systems can be financially challenging for many small to medium-sized manufacturers. The semi-automatic machines offered by G.S Machinery provide an excellent balance between automation and affordability. As premier Semi Automatic Auto Drop Pet Blowing Machine Manufacturers in Delhi, It delivers machines that require lower initial investment while still offering substantial automation benefits. This cost-effective solution allows manufacturers to scale their operations without incurring prohibitive costs, making it an attractive option for businesses looking to optimize their production processes.

It stands out in the competitive landscape of manufacturing machinery due to its unwavering commitment to quality, innovation, and customer satisfaction. As leading Semi Automatic Pet Blowing Machine Manufacturers, they have established a reputation for delivering reliable and efficient machinery that meets the highest industry standards. Their machines are designed to provide long-term value, ensuring that manufacturers can rely on them for years to come. Moreover, Its dedication to customer support ensures that clients receive comprehensive assistance, from installation and training to ongoing maintenance and support.

Flexibility and Versatility

Flexibility and versatility are vital in the manufacturing sector, where the ability to adapt to different production needs can significantly impact a company’s success. Semi-automatic PET blowing machines from G.S Machinery are designed to handle various bottle sizes and shapes, providing manufacturers with the versatility they need to cater to diverse market demands. This adaptability ensures that manufacturers can quickly switch between different production runs without the need for extensive reconfiguration. The expertise of Fully Automatic Auto Loader Manufacturers in Delhi ensures that these machines can seamlessly integrate with existing production lines, enhancing overall operational flexibility.

#Semi Automatic Pet Blowing Machine Manufacturers in Delhi#Semi Automatic Auto Drop Pet Blowing Machine Manufacturers in Delhi#Fully Automatic Auto Loader Manufacturers in Delhi

1 note

·

View note

Text

What Is Bottled Water Production Process Flow Chart

Written by: John

Checked by: Mark

June 28, 2024

Home - Water filling machine technology - What is bottled water production process flow chart

Share This Post

Table of Contents

What is The Bottled Water Production Flow Chart

Raw Water Sourcing and Pumping

Mechanical Filtration

Carbon Filtration

Reverse Osmosis (RO) System

Bottle Blowing

Bottle Washing and Sterilization

Filling and Capping

Inspection and Packaging

1) Raw water pump

2) Mechanical filter

3) Activated carbon filters

4) Water softener system

5) Precision filters

6) Reverse osmosis system

Types of Equipment

Maintenance and Considerations:

1) Air conveyor system

2) Water bottling machine

3) Cap feeder machine

4) Fully automatic bottle blow dryer

5) Laser coding machine

6) Self-adhesive labeler machine

Importance in Bottled Water Production

Types of Self-Adhesive Labeler Equipment

Maintenance and Considerations:

7) Shrink sleeve label machine

8) Shrink wrap machine

9) Pallet wrapping machine

1) Fully automatic bottle blow molding machine

2)Semi-automatic blow molder

3) Air compressor

4) Bottle blowing machine water chiller

5) Blowing machine air dryer

6) Air filter of bottle blowing machine

7) Mold temperature controller

8) Air storage tank of bottle blow molding machine

Conclusion

How many types of water bottling equipment are there?

The 9 Secrets To Effective BLOW MOULDER

Complete Production Process Flow Chart Of Bottled Water Production As Below

Section 1

Water Treatment

Raw Water Pump

Mechanical Filter

Activated Carbon Filters

Water softener system

Precision filters

Reverse osmosis system

Ozone system

UV light sterilizer

Section 2

Filling & Packaging

Air conveyor

Water bottling machine

Cap feeder machine

Bottle blow dryer

Laser coding machine

Self-adhesive labeler machine

Shrink sleeve label machine

Shrink wrap machine

Pallet wrapping machine

Section 3

Bottle Blowing

Automatic bottle blow molding machine

Semi-automatic blow molding machine

Air compressor

Water chiller

Air dryer

Air filter

Mold temperature controller

Air storage tankororCap FeederLight Inspection PanelBottle DryerSleeve Shrink LabelerShrink Wrapping Machine

Film Stretch Pallet Wrapper

Code Inkjet Printer

Mineral Water Filler

Auto bottle blower

Semi-auto bottle blowerSelf-adhesive LabelerOPP Hot Melt Labeleror

Water Storage Tank

RO water treatment system

High pressure compressor

Air storage tank

Air filter

air dryer

Air filter

water cooler

High pressure compressor

Air filter

air dryer

Air filter

Auto Unscrambler

Semi-auto Unscrambler

BOTTLE BLOWING SYSTEM

WATER TREATMENT SYSTEM

FILLING AND PACKAGING LINE

What is The Bottled Water Production Flow Chart

The production process of bottled water is comprehensive, involving multiple stages to ensure the highest quality and safety standards. This detailed guide covers each critical step, from water treatment to bottling and packaging, and finally to the blowing line and auxiliary equipment. Here’s an overview of the main steps:

Raw Water Sourcing and Pumping

The process begins with sourcing raw water, which is then pumped into the filtration system.

The raw water pump provides the necessary pressurization for the filtration equipment.

Mechanical Filtration

A mechanical filter removes impurities such as manganese, iron, and suspended particles larger than 20 microns.

This step helps to prepare the water for further purification.

Carbon Filtration

The carbon filter further purifies the water by removing organic compounds, chlorine, and other contaminants.

This stage helps to improve the taste and odor of the water.

Reverse Osmosis (RO) System

The RO system removes dissolved salts, minerals, and microorganisms, producing high-purity water.

This step ensures the water meets the required quality standards.

Bottle Blowing

The PET preforms are heated and then blown into the desired bottle shape using a blow molding machine.

The blow molding machine combines preform heating and bottle blowing in an automated process.

Precise control of parameters like stretching speed, pressure, and timing ensures proper material distribution and bottle quality.

Bottle Washing and Sterilization

The bottles are cleaned and disinfected before filling to ensure they are free from any contaminants.

Filling and Capping

The bottles are automatically filled and capped to maintain the integrity of the product.

Inspection and Packaging

The filled bottles are inspected for any defects.

The approved bottles are then packaged for distribution.

The entire production process is designed to ensure the safety and quality of the bottled water in compliance with relevant regulations.

01.

Water Treatment

1) Raw water pump

Description: The raw water pump is a critical component that provides the necessary pressure and flow for the pretreatment equipment and the reverse osmosis (RO) system.

Working Principle: The pump pressurizes incoming water to ensure a stable and sufficient inlet pressure for sand filters, carbon filters, and fine filters. This pressure must exceed the permeation resistance of the mechanical filters, enabling efficient water passage and providing a sufficient source for the RO system.

Key Functions:

Pressurizes raw water.

Ensures stable inlet pressure.

Overcomes permeation resistance.

Provides a reliable water supply for the RO system.

Applications: Bottled water production, municipal water treatment, industrial water purification, desalination and seawater treatment.

Importance in Bottled Water Production: Essential for the efficiency and effectiveness of the entire water treatment process, ensuring the quality and uniformity of the packaged water produced.

Types of Equipment:Equipment TypeDescriptionCentrifugal PumpCommonly used for raw water pressurization, providing high flow rates and moderate pressure.Positive Displacement PumpSuitable for high-pressure applications, such as RO systems.Submersible PumpInstalled directly in the water source, used for drawing water from wells or surface water.Booster PumpInstalled downstream of the pretreatment system to further increase pressure for the RO system.

Maintenance and Considerations:

Regular inspection and maintenance, including cleaning, lubrication, and impeller replacement.

Monitoring of pump performance, including flow rate, pressure, and energy consumption.

Proper sizing of the pump based on the system’s water demand and pressure requirements.

Ensuring the pump is compatible with the water quality and any potential corrosive or abrasive substances.

2) Mechanical filter

Description: Also known as the quartz sand filter, this multi-layered filtration device removes manganese, iron, heavy metals, silt, rust, colloidal matter, and suspended particles larger than 20 microns from raw water.

Working Principle: Performs backwashing and forward washing to ensure consistent water output and prolong equipment lifespan.

Key Functions:

Removes mechanical impurities, colloids, microorganisms, organic matter, and active chlorine from raw water.

Provides pre-treatment for downstream processes like reverse osmosis and ion exchange.

Improves water quality and extends the lifespan of water treatment systems.

Applications: Bottled water production, municipal water treatment, industrial water purification, surface and groundwater treatment.

Importance in Bottled Water Production: Vital in the pretreatment phase by removing turbidity, suspended solids, and other contaminants, ensuring the quality and consistency of the final product and protecting downstream equipment like RO membranes.

Types of Equipment:Equipment TypeDescriptionFilter CartridgePE, steel-lined rubber, steel-sprayed plastic, stainless steel, fiberglass-reinforced plastic.Filter MediaQuartz sand, activated carbon, manganese sand, anthracite.Filter ConfigurationSingle-flow, double-flow.

Maintenance and Considerations:

Regular backwashing and forward washing to maintain filter performance.

Monitoring pressure drop and turbidity levels to determine filter element replacement.

Proper selection of filter media based on water quality and treatment requirements.

Ensuring the filter is sized correctly to handle the system’s flow rate and water demand.

3) Activated carbon filters

Description: Activated carbon filters effectively remove residual chlorine, organic molecules, colloids, pigments, and heavy metal ions, ensuring water quality and extending downstream equipment lifespan.

Working Principle: Operate on the principle of adsorption, capturing contaminants on activated carbon particles.

Key Functions:

Removal of residual chlorine to protect downstream equipment.

Adsorption of organic molecules, colloids, pigments, and heavy metals.

Reduction of COD and SDI values to improve water quality.

Extending the lifespan of RO membranes and ion exchange resins.

Applications: Pretreatment for reverse osmosis and desalination systems, drinking water purification, industrial water treatment, wastewater treatment.

Importance in Bottled Water Production: Essential in the pretreatment process, ensuring the quality and safety of the final product while protecting the RO system and other downstream equipment.

Types of Equipment:Equipment TypeDescriptionCarbon TypePowdered activated carbon, granular activated carbon.Filter ConfigurationSingle-layer, multi-layer.Housing MaterialStainless steel, fiberglass-reinforced plastic.

Maintenance and Considerations:

Regular replacement of activated carbon and sponge layers.

Monitoring pressure drop and water quality to determine replacement frequency.

Proper cleaning of new activated carbon before installation.

Ensuring the filter is sized correctly to handle the system’s flow rate and water demand.

4) Water softener system

Description: The automatic water softener system removes hardness minerals, such as calcium and magnesium, through ion exchange.

Working Principle: It replaces calcium and magnesium ions with sodium ions, softening the water and preventing scale buildup in plumbing and equipment.

Key Functions:

Removes hardness minerals.

Prevents scale buildup.

Improves the efficiency and lifespan of reverse osmosis systems.

Applications: Residential and commercial water treatment, boiler and cooling tower water treatment, laundry and dishwashing applications, food and beverage processing.

Importance in Bottled Water Production: Maintains the quality and uniformity of the end product by preventing scale buildup in the RO system, extending membrane lifespan and improving water purification efficiency.

Types of Equipment:Equipment TypeDescriptionSoftening TankContains the ion exchange resin.ControllerManages system operation.Salt Tank and ValveProvides brine solution for resin regeneration.

Maintenance and Considerations:

Regular regeneration of the resin bed to maintain softening capacity.

Monitoring salt levels in the salt tank.

Periodic cleaning and maintenance of system components.

Proper sizing based on water usage and hardness levels.

5) Precision filters

Description: High-performance filtration devices that remove fine particles, impurities, and contaminants from various liquids using different filter elements.

Working Principle: Use various filter media and design processes to meet specific effluent water quality requirements, with filtration precisions ranging from 0.5 to 10 microns.

Key Functions:

Filtration, clarification, and purification of liquids.

Removal of fine particles, impurities, and contaminants.

Ensuring the safety and quality of downstream water and membrane elements.

Applications: Pharmaceutical, chemical, food and beverage industries, water treatment, brewing, petroleum, printing, and dyeing.

Importance in Bottled Water Production: Maintains the purity and safety of the final product by removing fine particles and contaminants, protecting downstream equipment like RO membranes.

Types of Equipment:Equipment TypeDescriptionFilter HousingPrimarily made of stainless steel (304 or 316), flange or clamp type.Filter ElementsPP meltblown, wire-wound, activated carbon, etc.Filter ConfigurationSingle or multiple elements, depending on processing capacity.

Maintenance and Considerations:

Regular replacement of filter elements based on usage and pressure drop.

Proper selection of filter media and precision based on application requirements.

Cleaning and maintenance of filter housing and components.

Monitoring flow rate, pressure drop, and effluent water quality.

6) Reverse osmosis system

Description: Highly effective water purification technology that uses selective permeation through a semi-permeable membrane to remove dissolved salts, colloids, microorganisms, and organic matter, producing high-purity water.

Working Principle: Uses a high-pressure pump to force raw water through the RO membrane, allowing only water molecules to pass through while retaining other contaminants.

Key Functions:

Removes dissolved salts and impurities.

Produces high-purity water.

Energy-efficient and low-pollution technology.

Applications: Bottled water production, pharmaceutical and electronics manufacturing, seawater and brackish water desalination, industrial water purification.

Importance in Bottled Water Production: Ensures the quality and safety of the final product by eliminating various impurities, adhering to strict industry standards.

Types of Equipment

RO Membrane TypeDescriptionBrackish Water RO (BWRO)– Used for feedwaters with relatively low total dissolved solids (TDS) compared to seawater – Require lower operating pressure (125-250 psi) – Maintain high salt rejection (>95-99%) – Typical recovery rates of ≥75%Seawater RO (SWRO)– Used for seawater or feedwaters with high TDS (35,000 mg/L or greater) – Require much higher operating pressure (800-1200 psi) – Maintain very high salt rejection (>99.5%) – Typical recovery rates of 50-70%Nanofiltration (NF)– Similar to RO but has lower rejection of monovalent ions like sodium chloride – Highly effective at rejecting divalent ions like magnesium sulfate (>97%) – Also rejects organic macromolecules to varying degrees – Operates at lower pressures than traditional RO membranesThin-Film Composite (TFC)– Most common type of industrial RO membrane – Consists of a polyamide top barrier layer, polysulfone support layer, and polyester layer – Prevents molecules greater than 100 molecular weight from passing throughCellulose Triacetate (CTA)– Alternative to TFC membranes – More resistant to chlorine but less effective at salt rejection

This table covers the key characteristics and applications of the main types of industrial RO membranes, including brackish water, seawater, nanofiltration, and the common membrane materials used (TFC and CTA).

Maintenance and Considerations:

Regular cleaning and maintenance of the RO membrane to prevent fouling and scaling.

Monitoring water quality parameters such as TDS, conductivity, and SDI.

Proper selection of membrane elements based on raw water characteristics and production needs.

Ensuring the RO system is sized correctly to handle the required water flow and quality.

02.

Filling & Packaging

1) Air conveyor system

Description: Uses fan-generated wind energy to transport empty PET containers from the bottle blowing machine to the filling or labeling machine.

Working Principle: Wind energy propels the containers through ducts with air storage capabilities, ensuring a stable and continuous flow.

Key Functions:

Efficient transportation of empty PET containers.

Compatibility with high-speed filling and labeling machines.

Gentle handling of containers to prevent damage.

Flexible layout options for horizontal, vertical, and curved conveyance.

Applications: Bottled water and beverage production, industries requiring the transportation of empty PET containers.

Types of Equipment:Equipment TypeDescriptionFan Power UnitProvides the wind energy for bottle conveyance.Air DuctStraight, turning, and up-and-down sections made of 304 stainless steel.Bottle Handling DevicesDividing, merging, and dropping mechanisms.Bottle Clamping DevicesEnsures stable bottle transport.

Maintenance and Considerations:

Regular cleaning and inspection of the air duct and bottle handling components.

Monitoring the fan performance and airflow to maintain optimal conveyor operation.

Adjustments to accommodate changes in bottle size or production requirements.

Ensuring the system is properly integrated with the overall bottling line.

2) Water bottling machine

Description: The PET water filling machine automates washing, filling, capping, and other functions with high precision, using advanced electrical components and high-quality stainless steel parts.

Working Principle: A suspended filling equipment design allows operation with various bottle types, sizes, and thicknesses, controlled automatically.

Key Functions:

Bottle rinsing.

Bottle filling.

Screw capping.

Cap sorting.

Applications: Filling production of 200-2000ml PET water bottles, suitable for a wide range of bottle types and sizes.

Types of Equipment:Machine TypeDescriptionLiquid Bottling MachinesDesigned to bottle liquids, including water, using volume or weight measurement to fill bottles.Rotary Bottling MachinesHave a rotary design where bottles move in a circular motion through the filling, capping, and sealing process.Linear Bottling MachinesHave a linear design where bottles move in a straight line through the different filling, capping, and sealing stations.Fully Automatic Bottling MachinesAutomate the entire bottling process from bottle rinsing to capping, requiring only a few operators.Semi-Automatic Bottling MachinesRequire more manual operation, with steps like bottle loading and unloading done by workers.Gravity, Pressure, and Vacuum Overflow Bottle FillersSpecific types of liquid filling mechanisms used in water bottling machines.Pump FillersAnother type of liquid filling mechanism used in water bottling machines.

Maintenance and Considerations:

Regular cleaning and maintenance of the filling valves and other components in contact with water.

Proper adjustment and calibration of the bottle handling and capping mechanisms.

Monitoring and addressing any issues with the electrical and control systems.

Ensuring the availability of spare parts and trained technicians for timely repairs.

3) Cap feeder machine

Description: The cap feeder machine sorts and feeds caps automatically, using standardized and interchangeable parts.

Working Principle: It arranges caps using their center of gravity, ensuring smooth output.

Key Functions:

Automatic cap feeding and arrangement.

Automatic cap removal.

Applications: Can be used with three-in-one filling machines or separate capping machines, suitable for various types of caps.

Types of Equipment:Equipment TypeDescriptionThree-Screw Cap Sorting and Capping MachineDesigned based on the characteristics of three-screw caps, with different weights on both sides.Other Capping MachinesCan be provided for plastic screw caps, aluminum caps, crown caps, and other capping applications.

Maintenance and Considerations:

Regular cleaning and maintenance of the cap sorting and feeding mechanisms.

Monitoring and addressing any issues with the electrical and control systems.

Ensuring the availability of spare parts and trained technicians for timely repairs.

Adjusting the production capacity based on the specifications and characteristics of the product.

4) Fully automatic bottle blow dryer

Description: The blow dryer uses high-pressure air to dry water droplets on bottle surfaces, preparing them for subsequent processing steps like coding and labeling.

Working Principle: It uses wind instead of high temperature, suitable for plastic bottles that are not heat-resistant.

Key Functions:

Dries water droplets using high-pressure air.

Facilitates coding, labeling, and packaging.

Applications: Suitable for drying various types of plastic bottles, can be used in water bottling production lines.

Components of Equipment:ComponentDescriptionAir KnifeGenerates high-pressure air flow to dry the bottles.Vortex FansHigh-powered vortex fans produce the necessary air volume.FrameMade of stainless steel and glass, providing a sturdy structure.Heating SystemHigh-pressure vortex pump generates heat during operation.Electrical ControlsIncludes control box for easy operation and monitoring.ConveyorAutomatically feeds the containers through the drying chamber.SensorsDetect the presence of containers and control the drying cycle.

Maintenance and Considerations:

Regular cleaning and maintenance of the air knives and air intake/exhaust components.

Monitoring and addressing any issues with the electrical and control systems.

Ensuring the availability of spare parts and trained technicians for timely repairs.

Adjusting the air knife positioning and airflow based on the bottle dimensions and drying requirements.

5) Laser coding machine

Description: The laser coding machine applies high-quality, permanent text, logos, and barcodes onto bottles and packaging materials.

Working Principle: A focused beam of light precisely etches or marks the desired information onto the target surface.

Key Functions:

Applies text, logos, and barcodes.

Provides high-resolution, permanent markings.

Applications: Bottled water production, canned and packaged food and beverages, pharmaceutical and medical device packaging, consumer electronics and industrial product labeling.

Types of Equipment:Equipment TypeDescriptionCO2 Laser CodersUse a carbon dioxide laser to mark on a variety of materials, including plastic, glass, and metal.Fiber Laser CodersEmploy a fiber-optic laser for high-speed, high-contrast coding on a wide range of substrates.UV Laser CodersUtilize ultraviolet laser technology to mark on sensitive materials like plastics and films.Hybrid Laser CodersCombine multiple laser technologies to offer versatile coding capabilities.

Maintenance and Considerations:

Regular cleaning and maintenance of the laser optics and components.

Proper alignment and calibration of the laser system.

Ensuring adequate ventilation and cooling for the laser unit.

Adherence to safety protocols and guidelines for laser operation.

Consideration of substrate compatibility and pre-treatment requirements.

6) Self-adhesive labeler machine

Description: The self-adhesive labeler machine automates label application onto bottles with high precision.

Working Principle: It uses mechanical, electrical, and software components to align and apply labels accurately.

Key Functions:

Accurate label positioning and alignment.

High-speed label application.

Adjustable label size and placement.

Applications: Bottled water production, beverage bottling, personal care and cosmetic products, pharmaceutical packaging.

Importance in Bottled Water Production

In the containerd water industry, the self-adhesive labeler machine plays a crucial role in ensuring consistent, high-quality labeling of containers. Accurate and efficient label application enhances the visual appeal of the product, reinforces brand identity, and provides important information to consumers.

Types of Self-Adhesive Labeler Equipment

EquipmentDescriptionRotary LabelerApplies labels to containers as they rotate on a turntableIn-Line LabelerApplies labels to bottles moving along a conveyor beltWrap-Around LabelerApplies labels that wrap around the entire bottle circumferencePrint-and-Apply LabelerIntegrates label printing and application in a single machine

Maintenance and Considerations:

Regular cleaning and maintenance of label feeding and application components.

Ensuring proper label stock compatibility and quality.

Monitoring label alignment and adjusting as needed.

Implementing preventive maintenance schedules.

Training operators on proper machine operation and troubleshooting.

7) Shrink sleeve label machine

Description: The shrink sleeve label machine applies and shrinks sleeve labels onto bottles, providing 360-degree coverage and enhanced branding opportunities.

Working Principle: Bottles are fed into the machine, where pre-cut sleeve labels are positioned and heat-shrunk onto the bottle surfaces.

Key Functions:

Accurate sleeve label positioning and alignment.

Precise heat application for shrinking labels.

Adjustable label size and bottle diameter compatibility.

Integrated label feeding and application.

Seamless integration with bottling line.

Applications: Bottled water production, beverage bottling, personal care and cosmetic products, pharmaceutical packaging.

Types of Equipment:Equipment TypeDescriptionContinuous Motion Shrink Sleeve LabelerApplies labels to bottles moving on a conveyor belt.Intermittent Motion Shrink Sleeve LabelerApplies labels to stationary bottles.Sleeve ApplicatorApplies pre-cut sleeve labels onto bottles.Shrink TunnelProvides controlled heat to shrink and secure sleeve labels.

Maintenance and Considerations:

Regular cleaning and maintenance of label feeding and application components.

Ensuring proper label stock compatibility and quality.

Monitoring label alignment and adjusting as needed.

Maintaining optimal heat settings for effective shrinking.

Implementing preventive maintenance schedules.

Training operators on proper machine operation and troubleshooting.

8) Shrink wrap machine

Description: The shrink wrap machine wraps bottled beverages in shrink film, using a constant temperature PE shrinking furnace to achieve the packaging effect.

Working Principle: The machine uses steel and stainless steel components with a compact design, incorporating electrical and pneumatic components from renowned brands for efficient operation.

Key Functions:

Automatic wrapping, sealing, cutting, heat shrinking, and cooling.

Suitable for shrink films like PE and PVC.

Provides a neat, compact, and secure packaging of the bottles.

Applications: Packaging of bottled beverages such as purified water and mineral water, cans and glass bottles, various food, pharmaceutical, and chemical products.

Types of Equipment:Machine TypeDescriptionThroughputSuitable ProductsAutomatic Bottle Stack Sleeve Shrink Wrapping MachineDesigned for automatic bottle stacking, film feeding, sealing, and shrinking.8-30 bottles/minuteBottles, cans, glass bottlesContinuous Motion Shrink Wrapping MachineUses a direct feeding method with no length limit for packaged items.Up to 120 bottles/minuteLong-length objects, beverages, beer, mineral water, cans, glass bottlesSemi-Automatic Shrink Wrapper with Shrink TunnelProvides a reliable solution for high-quality shrink-wrapped packs.10,800 bottles/hourBottles, cans, and other containersIntermittent Motion Tray Shrink Wrapper with Integral Shrink TunnelSuitable for wrapping bottles, cans, and other containers on a tray or with a cardboard pad.6-20 bottles/minuteCylindrical, flat, square, and complex-shaped containers

Maintenance and Considerations:

Regular maintenance of the machine components, including cleaning and lubrication.

Proper storage and handling of the shrink film to ensure its quality and performance.

Monitoring of the temperature and air circulation in the shrinking furnace to ensure consistent and effective shrinking.

Adjusting the machine settings to accommodate different bottle sizes and packaging requirements.

Ensuring the proper alignment and functioning of the conveyor belt and bottle separating board.

9) Pallet wrapping machine

Description: The pallet wrapping machine wraps goods stacked on pallets with LLDPE stretch film, providing stability, protection, and waterproofing during storage and transportation.

Working Principle: Controlled by a PLC programmable controller, it offers adjustable film tension, automatic photoelectric tracking, and multifunctional packaging modes.

Key Functions:

Automatic wrapping of palletized goods.

Adjustable film tension for optimized packaging.

Partially enhanced wrapping for reinforced top/bottom.

Manual/automatic switching and automatic protection.

Multifunctional packaging modes (standard, quasi, single-layer, enhanced).

Automatic reset to initial position after each use.

Dynamic pre-stretching film frame system.

Applications: Food and beverage production, irrigation equipment, paper manufacturing, dyes and chemicals, glass and ceramics, electro-mechanical castings.

Types of Equipment:Equipment TypeDescriptionTray-type Pallet Wrapping MachineWraps palletized goods using LLDPE stretch film.Top-pressure Resistance-stretch Pallet Wrapping MachineApplies top pressure during wrapping.Pre-tension Automatic Pallet Wrapping MachineAutomatically pre-tensions the stretch film.

Maintenance and Considerations:

Regular inspection and maintenance of machine components.

Proper storage and handling of stretch film.

Monitoring of film tension and wrapping patterns.

Adjusting settings for different pallet sizes and products.

Ensuring proper alignment of sensors and lifting mechanisms.

Maintaining a clean work environment.

03.

Blowing Line

1) Fully automatic bottle blow molding machine

Description: The fully automatic bottle blow molding machine is used to blow all kinds of plastic containers and beverage bottles using PET raw material.

Working Principle: The machine features a user-friendly interface, smooth operation, high and stable output, low energy consumption, and a high degree of automation. It uses a double toggle and primary link hinge mechanism with solid clamping force for stable and reliable blowing action.

Key Functions:

Automatic preform loading and feeding.

Precise temperature control and even heating of preforms.

Stable and fast mold clamping and bottle blowing.

Automatic bottle ejection and transfer to filling machine.

Integrated PLC control with automatic fault detection.

Applications: Production of water bottles, juice, soda, and other beverage bottles, plastic containers for food, cosmetics, and household products.

Types of Equipment:Machine TypeDescriptionLinear Stretch Blow Molding MachineUses linear motion to stretch and blow preforms into bottles. Cost-effective with a good balance of production speed and quality.Rotary Stretch Blow Molding MachineUses rotary motion to stretch and blow preforms. Faster production speed compared to linear machines. Can achieve higher quality bottles.

Maintenance and Considerations:

Regular inspection and maintenance of mold clamping, heating, and blowing components.

Proper storage and handling of the preform raw material.

Monitoring temperature control system and energy consumption.

Adjusting machine settings for different bottle sizes and production requirements.

Ensuring proper alignment and functioning of automatic feeding, ejection, and transfer systems.

2)Semi-automatic blow molder

Description: Semi-automatic blow molding machines are versatile equipment used for producing a variety of plastic bottles and containers.

Working Principle: These machines use a combination of manual and automated processes to blow mold plastic preforms into the desired bottle shapes.

Key Functions:

Preform heating and softening.

Mold clamping and bottle blowing.

Bottle ejection and trimming.

Applications: Beverage bottles (water, juice, soda, etc.), personal care bottles (shampoo, lotion, etc.), household chemical containers, pharmaceutical packaging.

Types of Equipment:FeatureManual Preform LoadingAutomated Preform LoadingPreform LoadingManual hand-feedingAutomatic preform insertionBottle RemovalManual removalManual removalEfficiencyLowHigherLabor Required1-2 workers1 workerCostVery lowModeratePreform HandlingRequires gloves for hot preformsAutomated preform handling

Maintenance and Considerations:

Regular cleaning and maintenance of molds and machine components.

Proper temperature and pressure control for consistent bottle quality.

Operator training for safe and efficient machine operation.

Consideration of energy efficiency and environmental impact.

3) Air compressor

Description: An air compressor converts power into potential energy stored in pressurized air.

Working Principle: It works by drawing in ambient air, compressing it to a higher pressure, and discharging the compressed air for various applications.

Key Functions:

Intake and compression of air.

Storage of compressed air.

Delivery of compressed air to end-use applications.

Applications: Powering pneumatic tools and equipment, inflating tires, spray painting, cleaning and drying, controlling and operating industrial machinery.

TypeDescriptionReciprocatingPiston-driven compressors that use a back-and-forth motion to compress air.Rotary ScrewUse two meshing helical screws to draw in and compress air.CentrifugalUse rotating impellers to draw in and accelerate air, increasing pressure.ScrollUse two spiral-shaped scrolls to compress air in a continuous process.

Maintenance and Considerations:

Regular filter and oil changes.

Monitoring for air leaks.

Proper sizing and selection for the application.

Ensuring adequate cooling and ventilation.

Adhering to safety protocols when operating.

4) Bottle blowing machine water chiller

Description: A water chiller regulates the temperature of the water used in the bottle blowing process.

Working Principle: The chiller circulates water through the bottle blowing mold to maintain a consistent temperature, ensuring proper formation and cooling of the plastic bottles.

Key Functions:

Temperature regulation of the bottle blowing mold.

Consistent cooling of the molded plastic bottles.

Efficient heat transfer from the hot mold to the circulating water.

Applications: Bottle blowing in PET, HDPE, and other plastic bottle production, cooling of molds in injection molding and extrusion blow molding processes, temperature control in various industrial cooling applications.

Types of Equipment:TypeDescriptionRecirculating ChillerContinuously circulates and cools a closed-loop water system.Inline ChillerCools water as it flows through the system, without a closed loop.Portable ChillerSelf-contained, mobile units for temporary or flexible cooling needs.Integrated ChillerBuilt-in to the bottle blowing machine for a compact, all-in-one solution.

Maintenance and Considerations:

Regular cleaning and maintenance of the water system.

Monitoring and adjusting water temperature and flow rate.

Ensuring proper ventilation and heat dissipation.

Adhering to manufacturer’s recommendations for maintenance and service intervals.

Considering the cooling capacity and efficiency requirements for the specific bottle blowing application.

5) Blowing machine air dryer

Description: An air dryer removes moisture from the compressed air used in the bottle blowing process.

Working Principle: The air dryer uses various drying techniques, such as refrigeration or desiccant adsorption, to reduce the moisture content of the compressed air before it is used in the bottle blowing mold.

Key Functions:

Removal of water vapor from compressed air.

Preventing condensation and moisture buildup in the bottle blowing system.

Ensuring a consistent, dry air supply for the blowing process.

Applications: Bottle blowing in PET, HDPE, and other plastic bottle production, drying of compressed air for various industrial processes, preventing moisture-related issues in pneumatic equipment and tools.

Types of Air Dryers:TypeDescriptionRefrigerant DryerUses refrigeration to cool the air and condense water vapor.Desiccant DryerUtilizes a desiccant material to adsorb moisture from the air.Membrane DryerEmploys a semi-permeable membrane to selectively remove water vapor.Heatless DryerRegenerates the desiccant using a portion of the dried air.

Maintenance and Considerations:

Regular cleaning and replacement of filters and desiccant materials.

Monitoring and adjusting air flow and pressure.

Ensuring proper ventilation and heat dissipation.

Adhering to manufacturer’s recommendations for maintenance and service intervals.

Considering the air flow and drying capacity requirements for the specific bottle blowing application.

6) Air filter of bottle blowing machine

Description: An air filter removes contaminants such as dust, oil, and moisture from the compressed air stream.

Working Principle: The air filter uses a combination of mechanical filtration, coalescence, and gravity separation to capture and remove harmful particles and liquids from the compressed air.

Key Functions:

Removal of solid particulates (dust, rust, etc.).

Separation of liquid water and oil droplets.

Providing clean, dry compressed air for downstream equipment.

Applications: Compressed air systems in industrial facilities, pneumatic tools and equipment, instrument air systems, bottling and packaging machinery, painting and coating applications.

Types of Air Filters:TypeDescriptionCoalescing FilterRemoves liquid water and oil droplets through coalescence.Particulate FilterCaptures solid particulates such as dust and rust.Combination FilterIntegrates both coalescing and particulate filtration.Desiccant FilterRemoves water vapor through adsorption on a desiccant material.

Maintenance and Considerations:

Regular inspection and replacement of filter elements.

Monitoring pressure drop across the filter.

Proper drainage of collected liquids.

Ensuring adequate air flow and system compatibility.

Adhering to manufacturer’s recommendations for maintenance and service intervals.

7) Mold temperature controller

Description: A mold temperature controller regulates the temperature of the mold in the bottle blowing process, ensuring proper appearance and quality of the final plastic bottles.

Working Principle: It maintains the mold at a constant, optimal temperature to prevent defects such as lack of gloss, deformation, bubbles, and uneven wall thickness.

Key Functions:

Precise temperature control and fast heating/cooling response.

Stable and accurate temperature maintenance within ±1°C.

Automatic temperature regulation and monitoring.

Liquid level alarm to prevent damage from low heat transfer fluid.

Applications: Plastic bottle manufacturing, other blow molding processes for plastic products.

Types of Equipment:EquipmentFeaturesHorizontal High-Temperature Resistant PumpStable flow, reliable performance.Stainless Steel Pipelines and Fuel TanksRust-resistant, long service life.Visualized Heat Transfer Oil Level TubeEasy to monitor oil level.Brand-Name Components (Omron, Fuji, LG, Schneider)Excellent performance, long lifespan.Imported Heating ComponentsSuperior quality and durability.

Maintenance and Considerations:

Regularly check and maintain the heat transfer fluid level.

Ensure proper insulation of pipelines to minimize heat loss.

Perform periodic cleaning and inspection of system components.

Monitor temperature control accuracy and make adjustments as needed.

Properly store and handle the heat transfer fluid to prevent contamination.

8) Air storage tank of bottle blow molding machine

Description: The air storage tank stores compressed air generated by the air compressor and provides a consistent and controlled supply of compressed air for the bottle blow molding process.

Working Principle: The tank stores pressurized air and releases it as needed to inflate the preform during the blow molding stage, shaping the bottle.

Key Functions:

Stores compressed air.

Ensures a consistent and reliable air supply.

Regulates air pressure and flow to the blow mold.

Applications: Bottle blow molding for water, beverages, and other liquid products, plastic container manufacturing, hollow plastic part production.

Types of Equipment:Equipment TypeDescriptionVertical Air Storage TankCompact design, suitable for limited space.Horizontal Air Storage TankLarger capacity, suitable for high-volume production.Stainless Steel Air Storage TankDurable, corrosion-resistant, suitable for food-grade applications.Aluminum Air Storage TankLightweight, suitable for mobile or portable applications.

Maintenance and Considerations:

Regular inspection and cleaning of the tank to prevent contamination.

Monitoring and maintaining proper air pressure levels.

Checking for leaks and ensuring airtight seals.

Replacing worn or damaged components as needed.

Adhering to the manufacturer’s recommended maintenance schedule.

04.

Conclusion

The production process of bottled water involves several intricate steps, from initial water treatment through bottling, packaging, and bottle blowing. Each stage requires specific equipment, regular maintenance, and careful monitoring to ensure the highest quality and safety standards are met. By following this detailed process flow, you can ensure efficient and effective bottled water production, meeting industry standards and consumer expectations.

For more detailed information, expert assistance, or to get quotes for your specific bottled water filling needs, feel free to get in touch with us through the contact form provided. We are here to help you achieve the best results in your bottled water production endeavors.

0 notes

Text

Maruti Machines' Carbonated Soda Plant: Empowering Beverage Brands with Excellence in Manufacturing

Introduction :

Maruti Machines, a leading name in the beverage industry, introduces its revolutionary product, the Carbonated Soda Plant. Built on precision engineering and cutting-edge technology, this state-of-the-art plant sets new standards for carbonated soda manufacturing. Maruti Machines' commitment to delivering exceptional solutions is evident in the design and functionality of the Carbonated Soda Plant. In this article, we will explore the remarkable features and advantages of Maruti Machines' plant, highlighting its ability to enhance production efficiency, product quality, and market competitiveness for beverage brands.

Streamlined Production Process :

The Carbonated Soda Plant by Maruti Machines streamlines the entire production process, ensuring seamless operations and optimal efficiency. From precise ingredient handling and mixing to carbonation and packaging, this plant integrates advanced automation and intelligent controls to eliminate bottlenecks and reduce human intervention. The plant ensures consistent taste and quality by accurately measuring and dispensing ingredients, guaranteeing the perfect balance of flavors. With state-of-the-art carbonation technology, the plant controls the carbonation levels precisely, resulting in a refreshing and effervescent soda experience for consumers.

Enhanced Quality Control :

Maruti Machines' Carbonated Soda Plant places a strong emphasis on maintaining impeccable quality standards. The plant incorporates robust quality control mechanisms throughout the production cycle, ensuring that each bottle of soda meets the highest standards of taste, consistency, and safety. Advanced sensors and monitoring systems constantly track variables such as temperature, pressure, and quality parameters, allowing for immediate detection of any deviations. This meticulous quality control system enables swift corrective actions, ensuring that only the finest carbonated sodas are produced under the Maruti Machines brand. We also offers Automatic Carbonated Soft Drink Plant, Fully Automatic Pet Blow Molding Machine, Automatic Soda Soft Drink Packaging Machine, Carbonated Soda Soft Drink Plant, Automatic Soda Drink Packaging Plant for futher details visit our Website.

Flexibility and Customization :

Maruti Machines understands the importance of flexibility and customization in the beverage industry. The Carbonated Soda Plant offers unparalleled versatility to accommodate a wide range of flavors, bottle sizes, and packaging formats. Whether a brand desires classic cola or wishes to experiment with unique flavor profiles, Maruti Machines' plant can adapt to cater to diverse consumer preferences. The modular design of the plant allows for easy customization based on specific brand requirements, empowering beverage brands to create distinctive products that resonate with their target markets.

Sustainability and Efficiency :

Maruti Machines' Carbonated Soda Plant prioritizes sustainability and efficiency in its design and operation. The plant incorporates energy-efficient components and optimized power consumption, reducing environmental impact while maintaining high production output. Additionally, the plant integrates advanced recycling and waste management systems, minimizing material wastage and promoting responsible production practices. By embracing sustainable measures, the plant enables beverage brands to align with eco-conscious consumer preferences, enhancing brand reputation and market positioning.

Cost-Effectiveness and Scalability :

For beverage brands, cost-effectiveness and scalability are vital considerations. Maruti Machines' Carbonated Soda Plant offers significant cost savings through streamlined processes, reduced labor requirements, and optimized resource utilization. The plant's modular design allows for easy scalability, enabling beverage brands to expand their production capacity as their business grows. This flexibility ensures that the Carbonated Soda Plant is a long-term investment that can adapt to changing market demands and support the brand's future growth.

Conclusion :

Maruti Machines' Carbonated Soda Plant represents a game-changing solution for beverage brands. With its streamlined production process, enhanced quality control, flexibility, sustainability features, and cost-effectiveness, this plant empowers brands to achieve excellence in carbonated soda manufacturing. By choosing Maruti Machines, beverage brands can benefit from cutting-edge technology, precision engineering, and unmatched efficiency, ultimately positioning themselves as leaders in the competitive market. The Carbonated Soda Plant by Maruti Machines is poised to transform the industry, helping brands deliver exceptional carbonated sodas and meet the evolving preferences of consumers.

0 notes

Text

Choosing the Right Semi-Automatic PET Blowing Machine for Your Business

When choosing a semi automatic PET blowing machine for your business, there are several factors to consider. Firstly, the capacity of the machine should match your production requirements. Secondly, the type of PET preform that the machine can handle should be suitable for your product. Additionally, the ease of use, maintenance, and availability of spare parts are crucial factors. You should also consider the level of automation and the associated cost, as well as the machine's energy efficiency. Finally, it is essential to choose a reliable manufacturer with a good track record in the industry. Careful consideration of these factors will ensure that you choose the right semi-automatic PET blowing machine for your business.

#pet bottle blowing machine#automatic pet stretch blow molding machine#pet plastic bottle blowing machine#semi-automatic pet bottle blowing machine#pet bottle making machine#pet preform blowing machine#fully automatic pet bottle blowing machine#pet blow molding machine cost

0 notes

Text

This surgery procedure will eliminate your discomfort

From plastic surgery to beauty treatments, cosmetic medical care spans a large range of procedures that helps men and women look and feel their best. A cosmetic surgeon can help you choose the best cosmetic procedure for you. Read this article if you want to find out what a viable plastic surgeon can do for you.Breast Augmentation: Breast augmentation is a plastic surgery procedure that was designed to enlarge the breasts with the use of breast implants such as silicone or saline breast implants. Liposuction: Liposuction is a wonderful plastic surgery procedure that was designed to remove fully automatic PET bottle blowing machine Factory localized fat deposits from the body. Liposuction can help you get the extra fat off your body and it will boost your self-confidence.Tummy Tuck: Tummy tuck surgery is a cosmetic surgery procedure that is used to flatten the stomach. During this cosmetic surgery procedure, excess fat is removed from the stomach and the underlying abdominal muscles are tightened.