#pet blow moulding machine

Explore tagged Tumblr posts

Text

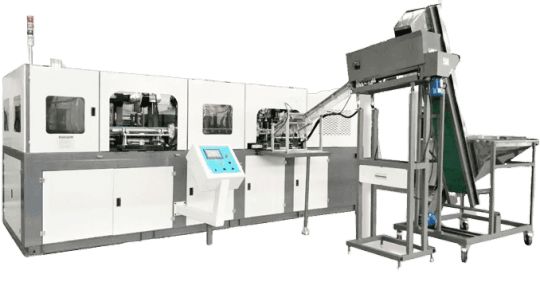

SP Nexa Series PET Blow Moulding Machine.

SP Nexa Series - Fully Automatic Electric Blow Moulding Machine with 7 to 10000 BHP having performed handlings, heat conditioning, stretching & mould clamp.

Explore more - SP Nexa Series PET Blow Moulding Machine.

0 notes

Text

youtube

PET BOTTLE BLOW MOLDER

We would be happy to help and advise if you have any questions or inquiries.

PET BOTTLE BLOW MOLDING MACHINE

CAPACITY

Up to 15,000 bottles per hour

CAVITIES

Up to 8 cavities

PERFORMANCE

Satisfaction Guaranteed

2 Years Quality Warranty

On Time Delivery Guaranteed

OVERVIEW

Steplead’s BMA series blow molding machines produce the highest quality PET containers for a wide range of applications, sizes, and production demands. Our blow molders exceed previous blowing capacity, cost, and bottle quality benchmarks. Steplead’s industrial blow molding equipment reliably manufactures PET bottles and containers with precision engineering. Advanced temperature controls and adjustable blowing pressure deliver consistent, high-quality results. Trust Steplead for customizable stretch blow molding systems optimized for your PET bottle production needs. Contact our experts today to learn more about our high-performance blow molders for various industries.

youtube

ADVANTAGES

UP TO 50%

Steplead certified parts with additional warranty

UP TO 25%

Less maintenance

UP TO 20%

Less energy using lower engine speed and larger hydraulic pump.

Save Cost

The great advantage of stretch blow moulding machine is to stretch the container in both the axel and hoop directions, which name biaxial stretching and it will greatly improve the container’s top load, clarity, drop impact tolerance, barrier abilities and tensile strength. As a result, the raw material cost can be save for about 10-15% by reducing the weight of container.

Wide Application

The stretch blow molding process making PET bottles is popular in beverage industry production for juice, water, soda, and many other products. Since 1970’s, this blow moulding technique is applied widely to package chemical detergent and soda bottles.

High Efficiency

This blow moulder can achieve you any extra ambition of blowing production. No matter considering production output, reliability or efficiency, for non-carbonated water, csd (carbonated soft drink), and hotfill products, with maximum 6 cavities to produce up to 6,000 containers per hour.

PRODUCT SPECIFICATIONS

Download

2,000 ~15,000 Bottles500ml / Per Hour

Max Container Volume: 2L

Max Cavities: 8

Clamping Force: 320KN

Power: 120Kw

Dimension: 3,600 x 2,000 x 2,210MM

PREMIUM

LAYOUT COLLECTION

The best way to experience our wide collection of production layouts for your project.

Layout for 10,000BPH

Factory layout of 10,000bph soda drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 2,000-3,000BPH

Factory layout of 2,000-3,000bph cola drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 10,000BPH

Factory layout of 10,000bph soda drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 2,000-3,000BPH

Factory layout of 2,000-3,000bph cola drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 10,000BPH

Factory layout of 10,000bph soda drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 2,000-3,000BPH

Factory layout of 2,000-3,000bph cola drink filling line for 500ml - 2L PET bottles

Click to Download

Previous slide

Next slide

RELATED EQUIPMENT

HOW TO ENSURE THE SAFE AND EFFICIENT PRODUCTION OF BOTTLE BLOW MOLDING MACHINE.

Here is a list of all the types of technical questions concerning bottle blowing molding machine that you can find.

What Safety Precautions Would Be Needed For Blow Molding Machine Operation

Safety Precautions for blow molding machine operation

These precautions are for the sake of preventing operators and other staff from being hurt or preventing machine from being damaged when trouble occurs. Because devices of this machine use pneumatic and electrical control, which features big power and quick working speed, therefore any errors of operation may lead to dangerous consequences. The machine is equipped with some safety devices to protect the operators. Before operation, please check whether these safety devices work properly.

1. Safety Precautions: 1) Operator must wear safety helmet, slip-proof shoes and working clothesduring installation, inspection and maintenance. 2) Make sure to install the machine in a dry, bright and clean location. The ground around the machine should be solid and its surface should be slip-proof. 3) Never put tools and other articles onto the machine or any other moving parts. 4) Don’t climb onto the machine when it is running and don’t touch the moving parts. Before inspection and maintenance, the power and gas source must be switched off and ensure that air pressure of gas circuit is environmentalatmosphere.Note: Once the pressure of operation gas circuit is environmental atmosphere, mold base components will automatically descend. 5) When operate parts of heating devices, turn off the power first and operate after it completely cools down. 6) Please pay special attention to the safety warning board installed on dangerous parts of the machine.

2. The Safety Guard and Safety Door on the Machine 1) A limit switch is installed on the safety door to pick up the bottles. When the safety door opens, this limit switch will be activated to stop the machine from operation. Therefore, it’s important to check whether this limit switch can work normally before operating the machine. 2) It’s forbidden to dismantle the safety door on the machine and the safety cover on automatic chainsunless necessary maintenance and inspection are needed. And after maintenance and inspection, the safety door and the safety cover on automatic chains must be reinstalled as its original way. 3) Emergency Stop Button There are two buttons for emergency stop on the machine. One is on the operation panel and the other is on the back of the machine. They are used for emergencies. If each of the emergency stop buttons being pressed, both the power and gas source are switched off simultaneou sly and the machine stops all operation immediately. 4) Overpressure Protection The machine uses compressed air. The safety valve is respectively installed on high and low-pressure air collector. If the pressure in air intake is too high, the safety valve will be automatically opened to ensure of the safety. Air pressure for operation: Air intake 0.8Mpa Air pressure for blowing: Air intake 3.5MPa 5) Grounding The machine has contact for grounding. Before using the machine, connect the earth wire, which should be chosen according the local standard.

What Are Precautions Else Needed For Operation Of Blow Molding Machine

Precautions Related with Operation of Blow Molding Machine

Before operating the machine, read and understand the operation regulation in the operation manual or have relative training for operation.

(1) Emergency Stop

① There are two emergency stop buttons on this machine. The gas supplies stops and piston of air cylinder at the mold base and press preform falls down when each one of the buttons is pressed. The piston returns when turning and releasing the emergency button clockwise.

② There is a safety lever installed at the right side of bottle picker connected with the switch to prevent the bottle or preform from going to the next circle. If bottles or preform press on the safety lever, the machine will stop immediately until they are

removed. Note: Don’t operate the machine until you are sure of the security.

(2) Adjustment of Position and Speed

The position and speed valve of magnetic switch and approach switch on gas cylinder of movement devices has been properly adjusted before the machine leaves the factory. Don’t try to make the machine run quicker by changing their position or adjust the speed valve. Otherwise, it may cause damage of the machine or lead to malfunction.

(3) Inspections Related with Automatic Operation

① Confirm the safety for the operator. Check with eyes carefully the surrounding of the machine to make sure that it is safe in this area.

② Make sure that all safety devices can function normally.

③ Ensure all limit switches are in position and properly tightened.

④ Check whether the air pressure for operation and blowing is normal.

⑤ Check the adjustment of various speed

⑥ Check the temperature and circulation of cooling water.

(4) Safety during Bottle Blowing

① Never open the guarding gate or climb into it during bottle blowing.

② Never touch movement parts during bottle blowing.

③ Keep close attention to the working status of the machine. If abnormal situation or noise occurs, stop the machine immediately. Look for reasons and get rid of the troubles. If alarm occurs, the machine will stop automatically. The machine can be operated again only after the troubles are eliminated.

What is The Safety of Maintenance and Repairation of Blow Molding Machine

The Safety of Maintenance and Repairation of Blow Molding Machine

(1) Before repairing the machine, switch off the power and hang a warning plate of “Repairing, Switch on Prohibited” at the power switches. Before repairing, use electroscope to check that the power has already being switched off.

(2) It should bear regulated pressure to replace pneumatic units such as gas pipe, valve and connectors. It should get the approval from professional engineers to replace these units. Before replacing, make sure that the air pressure of gas circuit has been reduced to environmental atmosphere.

(3) The capacity should be in accordance with corresponding regulation when replacing fuses or other electric units. It should get approval from professional engineers or technicians for the replacement.

(4) Never touch any electrical devices with wet hands.

(5) When repairing the mold on the machine, insert a cushion (A rectangle wood block of 15×20 cm, which length should be the same with the length when the mold opens to its maximum extent) into the opened mold clamp device.

(6) Lubricate the machine after it stops.

(7) Use proper tools to maintain and repair the machine. Exert proper moment when tightening the bolts and nuts.

(8) Carefully check the repaired area after maintenance and repair to prevent any tools from being left in the machine.

What Precautions You May Need for The Gas Circuit System of Blow Molding Machine

Precautions of Gas Circuit System of Blow Molding Machine

Note: The density of high-pressure air is very high and any leakage of it shall lead to serious consequences.

(1) It’s strictly forbidden to change the position of safety valve on the air collector. (2) Impact of compressed air collector is strictly prohibited. (3) Open the gas outlet valve slightly to discharge the gas slowly when relieving the pressure. (4) Switch off the gas source and open the outlet valve as well as ensure that the reading on pressure meter is zero before removing parts on gas circuit. (5) Discharge the gas thoroughly if the machine has stops operation for a long time. (6) When replacing any pneumatic units, check under low pressure to reconfirm its safety and gradually increase the air pressure.

(7) Check the safety of gas circuit regularly. Check Every Day ① Check pressure meter of air collector to make sure that every pressure value is normal. ② Check and monitor the gas circuit system (air collector, pipes, valves and air cylinder) to make sure that there is no gas leakage. ③ Ensure that hoses are not bent or damaged and every part of gas circuit system is solidly tightened.

Check Every Week ① Dry the accumulated water in high and low pressure air collector and filters. ② Check whether the magnetic coil and bolt is loose. ③ Check and clean the air muffle.

Check Every Six Month Check the accuracy of every pressure meter on air collector and gas circuit.

#pet bottle blowing machine#bottle blowing machine#blowing machine#blow moulding#blow moulding machines#pet bottle blower#pet bottle blower australia#pet bottle blowing machine uk#pet bottle blowing machine australia#pet bottle blow molding machine#Youtube

0 notes

Text

#PET Blowing Machine in Delhi#PET Blow Moulding Machine in Delhi#PET Blowing Machine Manufacturers in Delhi#PET Blow Moulding Machine Manufacturers in Delhi#PET Blowing Machine Suppliers in Delhi#PET Blow Moulding Machine Suppliers in Delhi#PET Blowing Machine Exporters in Delhi#PET Blow Moulding Machine Exporters in Delhi

0 notes

Text

"Inside the Manufacturing Process: How PET Blowing Machines Shape Our Everyday Lives"

Plastic bottles are a necessary component of our daily existence. Their toughness and lightweight design make them indispensable for everything from cleaning solutions to refreshments. Are you curious about the manufacturing process of these bottles? PET blowing machines hold the key to the solution. This article looks at the various types of PET blowing machines, their applications, and why Seppa Solutions is the best solution for your manufacturing needs.

What Are PET Blowing Machines?

Plastic bottles and containers are manufactured using PET (Polyethylene Terephthalate) blowing machines. Using heat and air pressure, these machines shape PET preforms into bottles of various sizes and styles. Regardless of the complexity of the detergent container or the basic water bottle, the Pet Bottle Blowing Machine guarantees accuracy and effectiveness.

Types of PET Blowing Machines

1. Fully Automatic PET Blowing Machines

Fully automated PET-blowing machines are the gold standard of modern industry. These devices are designed for fast production and require little human intervention. This explains their popularity: Efficiency: They work well in industries with strong demand because they can manage large-scale production with ease. Precision: State-of-the-art features guarantee that every bottle is of the same quality. Versatility: Adaptable to creating bottles with different dimensions and forms.

“Automation is not just the future; it’s the present.” Fully automatic machines exemplify this statement, reducing labor costs while maximizing productivity.

2. Semi-Automatic PET Blowing Machines

Semi-automatic machines strike a balance between cost and function. They work well for small to medium-sized processes, even though they need some manual input. Important characteristics include: Cost-Effectiveness: Less money up front than completely automated equipment. Flexibility: More precise control over production by operators enables customization. Ease of Use: Even tiny organizations can use them due to their simplified operation.

Think of semi-automatic machines as the middle ground—powerful enough for quality production without the heavy price tag.

3. Stretch Blow Molding Machines

Manufacturers who prioritize strength and accuracy choose stretch blow molding machines. PET preforms are stretched and blown during the procedure to increase durability. Strength: The bottles produced are lightweight yet strong, capable of withstanding pressure and impacts. Applications: These bottles are commonly used for carbonated beverages because they must withstand high pressure. Quality assurance: Ensures consistent wall thickness and appearance.

4. Rotary PET Blowing Machines

The purpose of rotary PET-blowing machines is speed. They are frequently utilized by large-scale manufacturers who want to maximize volume without sacrificing quality. High-Speed Manufacturing: Able to make thousands of bottles in an hour. Space-efficient: Despite having a large output capacity, the design is compact. Ideal applications: Beverages, cosmetics, and pharmaceuticals.

5. Linear PET Blowing Machines

Cost-effectiveness and simple operations are the main goals of linear machines. Businesses needing a reasonable manufacturing capacity favor them. Simplicity: Simple to assemble and run. Scalability: Ideal for expanding companies that want to increase output gradually. Decreased Maintenance: Less complexity translates into fewer malfunctions and cheaper upkeep.

Why Choose Seppa Solutions for PET Blowing Machines?

Seppa Solutions is more than just a producer; it is also a collaborator in innovation. Here are some reasons to pick Seppa Solutions: 1. Innovative Technology Seppa Solutions incorporates the newest developments into their devices to keep ahead of the curve. Whether you require automation or precision, Seppa Solutions provides exceptional results. 2. Personalization Choices The needs of every firm are different. To ensure a smooth integration into your production line, Seppa Solutions provides PET blowing machines that can be customized to meet your unique needs.

3. Outstanding Assistance Seppa Solutions offers complete assistance from installation to upkeep. Their staff of professionals makes sure your business is operating efficiently and with minimal downtime. 4. Sustainable Solutions Sustainability is a priority for Seppa Solutions. Their equipment is built to cut down on waste and energy use, which is in line with international environmental standards.

The Bottom Line PET blowing machine is the foundation of bottle manufacturing, and selecting the proper type can have a big impact on your business. Whether you require the speed of rotary machines or the precision of stretch blow molding, we have a solution for you. And Seppa Solutions is the obvious choice for dependable, superior machinery. Are you prepared to change your production line? Reach out to Seppa Solutions right now to grow your company.

#pet blowing machine#automatic pet bottle blowing machine#bottle blowing machine#pet bottle blowing machine#pet making machine#pet bottle making machine

0 notes

Text

Canadian Crystalline – Pet Bottle Blowing Machine

Canadian Crystalline PET Bottle Blowing Machines are reshaping the beverage packaging industry with unmatched precision, speed, and efficiency. Designed to produce lightweight, durable, and eco-friendly PET bottles, these machines serve diverse industries such as beverages, cosmetics, and pharmaceuticals. They stand out for their high production speed, energy-saving capabilities, adaptable designs, intuitive operation, and minimal maintenance needs. With cutting-edge technology, a global footprint, and tailored solutions, Canadian Crystalline delivers exceptional packaging quality while prioritizing sustainability. Trusted by businesses worldwide, these machines offer great returns and reliable support. Choose Canadian Crystalline to lead packaging innovation and enhance your brand’s market impact.

#pet bottle blowing machine#pet blowing machines#pet blowing machine#pet blow machine#automatic pet blowing machine#pet blower machine

0 notes

Text

Biotronix Physio Magneto Physiotherapy Device PM ST Neo Touch Screen Type

Description of the ProductMusculoskeletal disorders affecting the muscles, bones, joints, nerves, tendons, and tissues are treated using the EMTT device.Physio Magneto treatment is easy to use and comfortable: It is not necessary for the patient to undress. productive activity that doesn't wear the user out Positioning the applicator by hand or using the flexible holding armDepending on the indication, a therapy session can run anywhere from five to twenty minutes. Frequency adjustment up to 10 pulses per secondPartially Automated Blowing Machine for PET Bottles Machine for Making Bottles Machine for Moulding Bottles All shapes of PET plastic bottles and containers can be produced with a PET bottle making machine.Extracorporeal Magnetic Therapy Benefits: Painless The care is easy and comfy. It is not necessary for the patient to undress.Free of hands productive activity that doesn't wear the user out Positioning the applicator by hand or using the flexible holding arm allows for quick treatment.

physio magneto physiotherapy device, PM-ST Neo, touch screen physiotherapy device, magneto therapy device, advanced PM-ST Neo device, physiotherapy magneto technology, pain relief magneto device

Contact us / What's app - 9711991264,9015251243,8076205625 ,8076549111 Website : www.solutionforever.com www.linktr.ee/biotronixcareinternational EMAIL : [email protected] ADDRESS : F-400, Sudershan Park ,Moti Nagar ,Near Gopal ji Dairy ,ND-110015 Location : Biotronix Care 097119 91264

#physiotherapy#Physiotherapist#physio#rehabilitation#rehab#health#PhysioMagneto#PMSTNeo#PhysiotherapyDevice#MagnetoTherapy#TouchScreenDevice#PainReliefTherapy#ElectromagneticTherapy#RehabilitationDevice#AdvancedPhysiotherapy

0 notes

Text

2500W, 240V, length 350mm IR lamps for KHS Pet blow moulding machines

0 notes

Text

Plastic Injection Moulding Dies — Plastic Die Making Machine Manufactures & Suppliers in Ahmedabad, India

Manufacturer of Plastic Injection Moulding Dies — Plastic Die Making Machine, Pet Blow Mould Die, Plastic Bucket Moulding Dies, Moulding Die, Plastic Injection Molding Equipment, Injection Moulding Parts offered by Shivam Engitech, Ahmedabad, India

Shivam Engitech in Ahmedabad, India, specializes in moulding die manufacturing, injection molding dies, and plastic moulds dies. Quality and precision for all your molding needs.

All of our products are valued for their affordable quotation, multiple machines, lots of experience, and quick service.

0 notes

Text

Introducing the PPS Automatic 4 Cavity All-Electric PET Blowing Machine

Revolutionize your PET bottle production with our cutting-edge technology designed for precision, speed, and efficiency.

Why Choose Us?

SERVO-Based Link Indexing System: Delivers unmatched speed, accuracy, and maintenance-free operation.

SERVO-Based Stretching System: Say goodbye to center-out and pinhole issues for good.

SERVO-Based Preform Loading System: Ensures smooth, accurate, and trouble-free performance.

Advanced Pneumatic Mould Clamping System: Unique toggle mechanism guarantees high precision, zero jerks, and minimal maintenance.

Built for the beverage industry to streamline operations and ensure top-notch quality. Upgrade to PPS technology today.

Contact Us Now: 098187 57548 | Visit: www.ppsmachineries.com

#AutomaticBlowingMachine#4CavityPETBlowingMachine#PPSWaterMachineries#PETBottleBlowing#IndianEngineering#ServoTechnology#HighSpeedBlowing#AdvancedMachinery#BlowingSolutions#MaintenanceFreeMachine#IndianManufacturing#WaterPackaging#JuiceIndustry#CarbonatedDrinks#PackagingSolutions#PETBottleProduction#ServoDriven#MadeInIndia#BottleBlowingExpert#InnovationInPackaging#EfficientMachinery#BeverageIndustryMachines#SmartEngineering#NextGenMachines#AutomationInIndustry#BlowingMachineTechnology#RoPlant#petblowingmachine#waterplants

1 note

·

View note

Text

Crafting Quality: Awanti Polymoulds’ Precision moulds for PET

Plastic bottles and containers serve a diverse range of purposes across industries such as beverages, food processing, pharmaceuticals, liquor, and home care products. They are utilized for packaging water, soda, juice, oil, jams, medicines, liquor, as well as personal and home care items, with sizes varying from small volumes to several litres.

At Awanti, we specialize in manufacturing blow moulds for PET bottles, employing advanced designing, high precision manufacturing and accelerated testing. Established in 1990, Awanti Polymoulds has been at the forefront of designing, manufacturing, and testing PET blow moulds to meet international standards. Precision and accuracy are paramount in our manufacturing process to ensure consistent, high-quality bottles that meet our customers’ expectations.

Our commitment to customer satisfaction extends both domestically and internationally, driving our continuous efforts to excel. Our moulds are engineered for durability, precision, and longevity. Properly matched with moulding machines, they have the capacity to endure for years and produce millions of bottles. We prioritize precision, customization, and attention to detail throughout the bottle designing, mould manufacturing, and testing phases.

With a longstanding presence in the beverage industry and tooling industry, Awanti Polymoulds has been a trusted supplier of blow moulds for brands like Coca-Cola, Unilever, Parle Agro, Bisleri, Pepsi, AJE and many more. Whether it’s fruit juices, carbonated beverages, natural mineral water, packaged drinking water, personal care products, or edible oils, Awanti has consistently delivered, always aiming for customer satisfaction.

0 notes

Text

Premier Injection Blow Moulding Machine Manufacturers in India

Injection blow moulding is a pivotal process in the manufacturing of plastic products, combining the precision of injection moulding with the flexibility of blow moulding. This process is essential for producing high-quality, consistent, and durable plastic containers, bottles, and other hollow products. In India, several manufacturers have established themselves as leaders in producing state-of-the-art injection blow moulding machines. This blog explores the premier injection blow moulding machine manufacturers in India, highlighting their innovations, technological advancements, and contributions to the industry.

Understanding Injection Blow Moulding

Before delving into the manufacturers, it’s essential to understand the injection blow moulding process. This method involves three main stages: injection, blowing, and ejection. Initially, plastic is injected into a perform mold to create a perform. Finally, the product is ejected from the mold. This process is highly efficient, allowing for the production of complex shapes with excellent surface finish and structural integrity.

Technological Excellence in Manufacturing

India's premier injection blow moulding machine manufacturers have leveraged advanced technology to enhance the efficiency, precision, and versatility of their machines. These manufacturers utilize cutting-edge CNC (Computer Numerical Control) machinery, automation, and robotics to ensure that their machines meet the highest standards of performance and reliability. The integration of Iota (Internet of Things) and Industry 4.0 principles further enables real-time monitoring and control, optimizing the production process and minimizing downtime.

Customization and Versatility

One of the hallmarks of leading manufacturers in India is their ability to offer customized solutions tailored to the specific needs of their clients. Whether it’s designing machines for producing small pharmaceutical bottles or large industrial containers, these manufacturers provide versatile options that cater to various industries, including pharmaceuticals, food and beverage, cosmetics, and automotive. Their machines are designed to handle different types of plastics, such as PET, PP, HDPE, and LDPE, ensuring broad applicability.

Innovation and Research

Innovation is at the core of the top injection blow moulding machine manufacturers in India. By continuously exploring new materials, process improvements, and design innovations, they are able to introduce machines that offer superior efficiency, reduced energy consumption, and enhanced product quality. Collaboration with academic institutions and global industry leaders also plays a crucial role in driving innovation.

Quality Assurance and Certification

Quality is paramount in the production of injection blow moulding machines, and India’s leading manufacturers adhere to stringent quality assurance protocols. These companies are often ISO certified and comply with international standards, ensuring that their machines deliver consistent performance and longevity. Rigorous testing and inspection at various stages of manufacturing guarantee that each machine meets the specified quality criteria before it reaches the customer.

After-Sales Support and Training

a significant advantage of working with premier injection blow moulding machine manufacturers in India is the comprehensive after-sales support they provide. These manufacturers offer installation assistance, maintenance services, and prompt troubleshooting to ensure smooth operation of the machines. Additionally, they provide training programs for the clients’ technical staff, equipping them with the necessary skills to operate and maintain the machines effectively.

Sustainable Manufacturing Practices

In response to the growing emphasis on sustainability, leading manufacturers in India are adopting eco-friendly practices in their production processes. They are focusing on energy-efficient machines that reduce carbon footprint, utilize recyclable materials, and minimize waste. These efforts align with global sustainability goals and help clients achieve their own environmental objectives.

Conclusion

India is home to some of the premier injection blow moulding machine manufacturers in india that have made significant strides in technology, innovation, and quality. Their commitment to excellence, customization, and sustainable practices makes them reliable partners for businesses across various industries. By choosing to work with these manufacturers, companies can ensure that they have access to advanced, efficient, and versatile injection blow moulding solutions that meet their specific production needs and contribute to their overall success.

#injection blow moulding machine manufacturers in india#injection blow moulding machine manufacturers#injection blow moulding machine

0 notes

Text

SP Pristine Series-II PET Blow Moulding Machine.

SP Pristine Series-II is a Fully Automatic Electric Pet Stretch Blow Moulding Machine by Shaym Plastic with 9000-18000 BHP & 7-12000 bottles per hour.

Explore more - SP Pristine Series-II PET Blow Moulding Machine.

0 notes

Link

0 notes

Text

"Lightweight, Durable, Recyclable: The Magic of PET Bottles in Modern Packaging"

Understanding PET Blowing Machines and Their Importance

In the contemporary packaging sector, PET (polyethylene terephthalate) blowing machines are essential, especially for producing eco-friendly, long-lasting, and lightweight containers. These devices use a complex process that includes heating, stretching, and blowing to turn preforms into bottles or containers of different sizes and shapes. PET-blowing machines find employment in a wide range of industries, including beverages, medicines, cosmetics, and household items. Because of their accuracy, efficiency, and adaptability, they are essential in large-scale manufacturing.

Applications of PET Blowing Machines

1. Beverage Industry

These equipment are essential to the beverage industry, which consumes the most PET bottles. PET blowing machines allow producers to produce containers that are not only lightweight but also incredibly durable and impact-resistant, from water and soft drink bottles to specialty packaging for juices and dairy items. Their adaptable designs make branding and labeling possible, which is crucial in areas with fierce competition.

2. Pharmaceutical Sector

Hygiene and accuracy are critical in the pharmaceutical sector. These machines produce PET bottles and are frequently used to store tablets, syrups, and disinfectants. PET's non-reactive nature ensures that the contents remain uncontaminated while adhering to strict safety regulations.

3. Personal Care and Cosmetics

PET blowing machines serve the cosmetics and personal care sectors by producing aesthetically pleasing bottles for shampoos, lotions, oils, and scents. These containers usually have intricate graphics that bolster the brand's upscale image.

4. Household Products

PET bottles are widely used to package cleaning products, detergents, and culinary oils. Their sturdy and impermeable characteristics, attained by means of accurate blowing procedures, guarantee security during storage and transit.

5. Food Packaging

Due to their non-toxic, lightweight, and recyclable qualities, PET containers are being utilized more and more for food storage as the demand for ready-to-eat meals and sauces rises.

What Makes Seppa Solutions’ PET Blowing Machines Stand Out?

Seppa Solutions has emerged as a leader in PET blowing machine technology, offering innovative solutions tailored to diverse industrial needs. Here’s why our machines excel:

1. Advanced Technology

Seppa Solutions builds cutting-edge technology into every PET blowing machine to ensure precision and efficiency. Our equipment uses modern heating systems and blow molds, allowing us to produce bottles with constant wall thickness and quality.

2. Energy Efficiency

We recognize the significance of sustainability in the current industrial environment. The energy-efficient parts used in the design of Seppa Solutions' PET blowing machines drastically lower operating expenses and lessen their environmental impact.

3. High-Speed Production

Depending on the model, our equipment may produce up to 2,000 bottles per hour. Because of their fast production speed, they are perfect for large-scale businesses that want to meet market demand without sacrificing quality.

4. Flexibility and Customization

Machines from Seppa Solutions are capable of handling a variety of preform sizes and bottle styles. This versatility enables manufacturers to design containers that are specific to their brand identity and practical requirements.

5. Robust Construction and Durability

Premium-grade materials are used in the construction of our PET blowing machines to ensure their long-term durability and reliable operation. This dependability raises overall production and lowers maintenance expenses.

6. User-Friendly Interface

Seppa Solutions' equipment is known for being easy to use. With automated procedures and user-friendly control panels, workers can oversee production with little training, which lowers downtime and boosts productivity.

7. After-Sales Support

Our top objective at Seppa Solutions is customer happiness. To ensure the smooth operation of our machines, we offer extensive after-sales service, which includes installation, training, maintenance, and technical assistance.

How Seppa Solutions Contributes to Industry Sustainability

1. Recycling and Reusability

The circular economy is supported by Seppa Solutions' PET blowing machines, which make it easier to employ recycled PET (rPET). The bottles are 100% recyclable, which helps to decrease plastic waste.

2. Energy-Saving Designs

Our machines are an environmentally friendly option since they drastically reduce energy consumption through the use of low-energy heating systems and efficient blowing operations.

3. Lightweight Packaging

Our equipment makes it possible to produce lightweight bottles, which lowers transportation expenses and material consumption. This improves cost-efficiency in addition to reducing the carbon footprint.

Industries Benefiting from Seppa Solutions’ PET Blowing Machines

Seppa Solutions caters to a wide array of industries, including:

Drinks: juices, carbonated drinks, energy drinks, and water.

Pharmaceuticals: Syrups, antiseptics, and medical-grade liquids.

Food Products: Sauces, cooking oils, and dairy products.

Cosmetics: Perfume, lotion, and shampoo packaging.

Household Goods: Cleaning products and detergents.

Why Choose Seppa Solutions?

Seppa Solutions' PET blowing machines raise the bar for efficiency, dependability, and environmental responsibility. Our machines provide unmatched performance whether your goal is to increase production, enhance packing quality, or implement greener manufacturing techniques. A commitment to quality, innovation, and sustainability is what drives the decision to invest in Seppa Solutions' technology.

#automatic pet bottle blowing machine#pet blowing machine#bottle blowing machine#pet bottle blowing machine#pet bottle making machine#automatic pet blowing machine#pet making machine

0 notes

Text

Canadian Crystalline | Pet Blowing Machine

PET blowing machines are essential for producing versatile, long-lasting, eco-friendly bottles widely used in beverages, pharmaceuticals, and cosmetics. Canadian Crystalline PET blowing machines excel with cutting-edge technology, energy efficiency, customization, and reliability. They ensure high-speed, precise production with minimal environmental impact while offering excellent after-sales support. Designed for businesses of all sizes, their machines cater to diverse industry needs, helping companies meet sustainability goals and gain a competitive edge.

Elevate your packaging solutions with Canadian Crystalline PET blowing machines—contact us today to transform your production efficiency!

#pet blowing machine#pet bottle blowing machine#automatic pet blowing machine#bottle blowing machines#pet blowing machines#pet blow machine

1 note

·

View note