#flour-manufacturers

Explore tagged Tumblr posts

Text

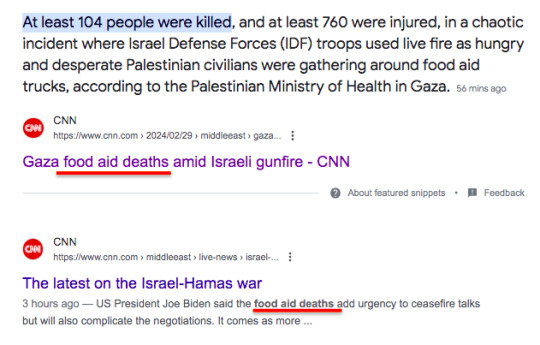

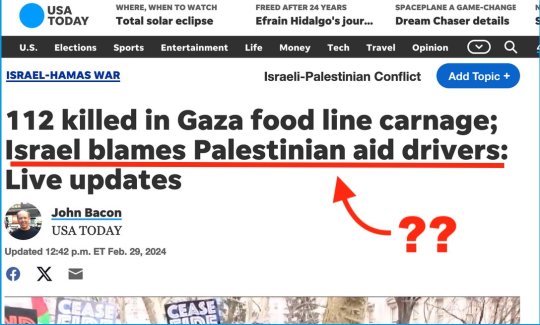

Remember the first Flour Massacre? Well, CNN has finally dropped the official Israeli story to give you an investigation that basically repeats what Palestinians have been saying all along

#yemen#jerusalem#tel aviv#current events#palestine#free palestine#gaza#free gaza#news on gaza#palestine news#news update#war news#war on gaza#flour massacre#gaza genocide#media bias#manufactured consent#genocide#famine

17K notes

·

View notes

Text

Gayatri Psyllium Industries - Psyllium Husk powder manufacturers in India

Gayatri Psyllium has built its reputation as a most reliable exporter of psyllium products worldwide upon serving quality products, prompt service & support, in time delivery and competitive pricing.

Products:

Psyllium Seeds,

Psyllium Husk,

Psyllium Husk Powder,

Organic Psyllium Husk,

Organic Psyllium Husk Powder,

Psyllium Kha-Kha Powder,

EAGLE Sat-Isabgol,

Process Of Psyllium

#Gayatri Psyllium#Gayatri Psyllium Industries#Psyllium Husk Powder Manufacturers In India#Psyllium Husk Powder Exporters#Psyllium Products Manufacturers In India#Psyllium Products Exporters#Psyllium Products Suppliers India#Psyllium Seeds#Psyllium Seeds Manufacturer India#Psyllium Seeds Exporters#Psyllium Seeds Suppliers India#Psyllium Husk#Psyllium Husk Manufacturers In India#Psyllium Husk Exporters#Psyllium Husk Suppliers India#Psyllium Husk Powder#Psyllium Husk Powder Suppliers India#Psyllium Kha-Kha Powder#Industrial Grade Psyllium Kha-Kha Powder#Psyllium Kha-Kha Powder Manufacturer India#Psyllium Kha-Kha Powder Exporters#Psyllium Kha-Kha Powder Suppliers India#Eagle Sat–Isabgol#Isabgol Manufacturer India#Isabgol Exporters In India#Isabgol Suppliers India#Chickpeas Flour/ Besan#Chickpeas Flour/ Besan Manufacturer In India#Chickpeas Flour/ Besan Exporters#Chickpeas Flour/ Besan Suppliers India

2 notes

·

View notes

Text

my personal favourite is this bizarre freestyle poetry by the NYT

Credit to Irish press for keeping it real, unlike everyone else.

7K notes

·

View notes

Text

Contract Manufacturing of Malt Extract: Partnering for Effectiveness and Quality

The processing of malt results in dried or liquid forms of sweeteners known as malt extract. Standard malt extracts, specialty and black malt extracts and coextracts are the different types of malt extracts. Standard Malt Extracts represented the initial sweeteners derived from grains. A mixture of malted barley and water produces high-maltose syrup through the process. The Malt Extract contract manufacturing helps food industries obtain high-quality production outputs.

Advantages of Contract Manufacturing for Malt Extract

Malt extract manufacturing under contract represents a precise industrial method. A process exists to make malted milk food products that serve various brand requirements. Major companies decide to work with external manufacturers to produce their products. The combination protects quality while producing cost reductions. Manufacturing contracts remove the requirement for significant investments in production facilities.

Enterprises gain the ability to develop their brands while conducting marketing initiatives. The production expertise of third-party manufacturers includes malted milk food manufacturing operations. The manufacturers maintain uniformity in taste along with texture and product quality standards. Scalability is another major advantage. The manufacturing facilities run by contractual agreements can adjust to market requirements without needing additional financial investments.

The manufacturing practices allow for meeting industry-established requirements. Positive reputation growth among customers arises from how much they trust the brand. Many third-party manufacturers provide whole manufacturing solutions directly to their client organisations. All stages from raw material acquisition to processing and packaging through distribution are part of these service offerings. The process reduces operational complexity for companies. Companies escape the limited burden of producing logistics management.

Find the Appropriate Third-Party Manufacturer for Malted Milk Products

Selecting an appropriate third-party manufacturer for producing malted milk foods represents a crucial decision path. A reliable malted milk foods third-party manufacturer constitutes a crucial element for selection. The evaluation process starts with analyzing their background in producing malted milk foods.

The obtaining of quality certifications represents an essential condition. Every manufacturer operating in the food industry needs to follow existing food safety regulations. The industrial operation must hold quality certifications for ISO FSSAI and GMP. The certifications act as guarantees to verify product safety aspects and hygiene standards. A business must address production capability as a fundamental aspect.

The manufacturer needs enough capacity to handle the required order levels from customers. Companies that experience strong market interest need to choose manufacturers who can fulfil their production requirements efficiently. The process of efficiency depends heavily on advanced technology and equipment.

Cost-effectiveness functions as a significant factor in market decisions. Compactree Brands needs to evaluate different pricing systems to decide which manufacturer to choose.

Conclusion

The Malt Extract contract manufacturing proves beneficial for brand operations. Through this approach, manufacturers receive budget-friendly solutions while maintaining guaranteed product quality. Pick the right third-party manufacturer as it will secure your market presence in the long term.

for more information about: malt extract Powder Please visit at https://www.mahalaxmimaltextract.com/

#malt extract powder#malted barley powder manufacturers#barley malt powder#liquid malt extract#malt extract powder manufacturer#barley malt flour#malt extract liquid#malt extract#barley malt extract#barley malt extract manufacturers

0 notes

Text

Top 10 Small-Scale Food Dehydration Business Ideas

✨ Turn your passion into profit! Discover the Top 10 Small Scale Food Dehydration Business Ideas that can make you high profits. Don’t miss out—follow us now for more game-changing ideas! 🚀 #FoodDehydration #SmallBusiness #ProfitableIdeas #Entrepreneur

Food dehydration is a process that helps in preserving fruits, vegetables and herbs and increasing their shelf life. Nowadays, the demand for processed and packaged food is increasing rapidly. Yes, people are paying more attention to healthy and natural foods. So, dehydrated food also has a huge demand in the market. Also, the market for dehydrated food is growing rapidly in India. According to…

#banana flour processing machine#banana powder making machine#banana powder processing plant#banana powder production line#best business ideas#business ideas 2025#dehydrate vegetables business#food business ideas#food dehydration business ideas#fruit and vegetable powder manufacturing business#fruit drying machine#how to make tomato powder#new business ideas#new business ideas 2025#onion powder business#onion powder machine#potato powder manufacturing business#potato powder production line#small business ideas#sweet potato starch machine#vegetable dehydration business#vegetable drying machine#vegetable powder manufacturing business

0 notes

Text

Why Flour Mill Companies in India Are the Backbone of the Grain Industry

Indian flour mill companies have a crucial place in the nation’s agriculture and food industry and form a crucial part of life. If we didn’t have flour, getting many of the staple foods in our lives would be challenging – bread, chapattis, cakes, or even your favourite cookies. Flour Mill Company in India, today, make use of high technology to ensure that their activities are efficient. Modern machines help the mills grind large quantities of grains quickly.

#Flour Mill Company in India#Flour Mill#grain flour mill#flour mill in india#flour grain#wheat flour#grain flour mill in india#flour manufacturers in india#wheat flour manufacturers in india

1 note

·

View note

Text

The Journey of Corn: Understanding the Corn Flour Production Process

Corn flour is a versatile ingredient used in a variety of industries, including food production, pharmaceuticals, and personal care products. But how does raw corn transform into the fine powder that’s used in these products? The journey of corn from farm to flour is a meticulous process that involves several critical steps to ensure the highest quality end product. In this blog, we will explore the corn flour production process and highlight the importance of choosing a reliable corn flour manufacturer for businesses.

1. The First Step: Sourcing the Corn

The journey of corn begins with sourcing high-quality raw corn, which plays a vital role in determining the final product’s quality. Corn is grown in fields, and selecting the right type of corn—usually yellow corn with a high starch content—is essential for making corn flour. Reliable corn flour suppliers ensure that the corn they source is free from contaminants and meets the required standards for processing. Whether the supplier is local or international, partnering with those who understand the importance of sourcing the finest corn for production is crucial.

2. Cleaning and Preparing the Corn

Once the corn is sourced, the next step is cleaning and preparation. Corn kernels are thoroughly cleaned to remove any dirt, dust, and other impurities that might affect the quality of the flour. This stage is essential to ensure that no foreign particles remain in the flour, which could compromise the final product's quality and safety. Corn flour manufacturers in India use state-of-the-art equipment to perform these cleaning tasks efficiently and effectively, setting the stage for the next stages of processing.

3. De germination: Removing the Germ for Fine Flour

De-germination is a crucial step in corn flour production. During this process, the germ, which contains oils that can spoil the flour, is separated from the endosperm, which contains starch. The removal of the germ ensures that the corn flour has a longer shelf life and a better texture. By focusing on corn flour production methods that remove the germ, manufacturers ensure that the flour remains pure and of high quality. The process also helps in achieving a finer, more consistent texture in the final product, which is essential for applications ranging from baking to manufacturing food products.

4. Milling: Turning Corn into Flour

The next step is milling, where the cleaned and de germinated corn is ground into fine flour. There are two primary milling techniques: dry milling and wet milling. In dry milling, the corn is ground without adding any moisture, resulting in a fine powder. Wet milling, on the other hand, involves soaking the corn in water before grinding. Most corn flour manufacturers in India use dry milling for standard corn flour production. The milling process is crucial as it determines the texture and quality of the flour. Top manufacturers invest in high-tech milling equipment to ensure the flour is ground to the right consistency for various applications.

5. Testing and Quality Control

Quality control is a critical part of the corn flour production process. After milling, the flour undergoes several quality checks to ensure it meets safety, taste, and texture standards. Common tests include checking for moisture content, particle size, and the presence of any foreign particles. Corn flour suppliers who are committed to delivering high-quality products conduct rigorous testing to ensure the final product is free from contaminants and maintains consistent quality. Manufacturers with robust quality control processes guarantee that businesses receive premium corn flour that meets their specifications.

6. Packaging and Distribution: Finalizing the Product

Once the corn flour has been milled and tested, it’s packaged for distribution. Proper packaging is essential to preserve the freshness and quality of the flour. Packaging also plays a role in ensuring the flour remains free from contamination during transportation. Corn flour manufacturers in India use airtight packaging to extend shelf life and protect the flour from moisture. After packaging, the flour is distributed to suppliers and end-users. Reliable manufacturers ensure that their products reach businesses on time, minimizing delays and maintaining the supply chain's efficiency.

7. The Role of Technology in the Corn Flour Production Process

Modern technology plays a significant role in improving the efficiency of corn flour production. Automation and advanced machinery have streamlined many processes, from cleaning to milling. The use of technology allows corn flour manufacturers to produce large quantities of high-quality flour while maintaining consistency. Additionally, technology has made it easier to monitor and control quality at every stage of production, ensuring that businesses receive products that meet their standards.

Ensuring Quality from Corn to Flour

The journey of corn from farm to flour is a complex process that involves multiple stages, each crucial for ensuring the final product's quality. By understanding these stages and selecting a reliable corn flour manufacturer, businesses can ensure they receive consistent, high-quality flour that meets their needs. The right manufacturer, such as Mittal Conezza, not only ensures top-notch production but also offers efficient distribution and excellent customer support. Whether you're in the food industry or other sectors, choosing a trusted supplier can make all the difference in achieving superior product outcomes.

0 notes

Text

Get customized flour mill plant designs tailored to meet your unique operational needs. Visit JoriPress to learn more about innovative solutions!

0 notes

Text

Defatted Soya Manufacturers - Gujarat Ambuja Exports Limited

https://www.ambujagroup.com/

Gujarat Ambuja Exports Limited is a leading manufacturer of defatted soya, known for producing high-quality soya products. Located in Gujarat, the company specializes in extracting oil from soybeans, leaving behind defatted soya meal that is rich in protein and ideal for animal feed, as well as a key ingredient in various food products. With advanced processing technology and a commitment to quality, Gujarat Ambuja Exports ensures that their defatted soya is free from impurities and retains optimal nutritional value. The company’s dedication to sustainability and customer satisfaction has made it a trusted name in the industry, providing reliable and consistent products to clients both in India and internationally.

#Defatted Soya Manufacturers in India#Defatted Soya Flour Manufacturers in India#Defatted Soya Flakes Manufacturers in India#Consistent production#Customer satisfaction#Industry standards

0 notes

Text

#besan manufacturer in Gujarat#gram flour#besan#Tips for Staying Healthy#Simple Tips for Staying Healthy#Eat Good Food

0 notes

Text

Top 10 Flour Mill Machinery For Home and Commercial Use

Flour mills are a key part of your equipment line if you want to produce your own fresh quality flour for personal or commercial usage. Whether you bake out of your home kitchen or a full-blown food business, it’s important to understand how to choose the right flour mill for your needs, as it can affect your product, your efficiency and your bottom line. Here’s the list of Best 10 flour mill machines for home and commercial use.

0 notes

Text

Wheat Flour Companies

sakthimurugangroup stands as a trusted name among Wheat Flour Companies, delivering high-quality flour tailored for various culinary needs. With a commitment to purity and nutritional value, sakthimurugangroup’s wheat flour undergoes meticulous processing to ensure consistent quality. Their expertise and dedication make them a preferred choice for wheat flour in Coimbatore.For more details visit here:-https://www.sakthimurugangroup.com/infrastructure.php

#gram flour suppliers in coimbatore#samba wheat rava suppliers in coimbatore#asafoetida powder in coimbatore#refined wheat flour in coimbatore#wheat flour manufacturers in coimbatore#wheat flour suppliers in coimbatore#rice flour manufacturers in coimbatore#wheat flour manufacturers#wheat flour companies#wheat flour companies in coimbatore

0 notes

Text

Challenges Faced by Refined Wheat Flour Manufacturers in West Bengal

Refined wheat flour manufacturers in West Bengal operate in a dynamic and competitive landscape, facing a variety of challenges that impact their production processes and market viability. As demand for high-quality flour continues to rise, manufacturers must navigate complexities such as maintaining consistent product quality, managing supply chain disruptions, and responding to evolving consumer preferences.

Additionally, rising production costs and stringent regulatory requirements add layers of difficulty to their operations. Understanding these challenges is crucial for manufacturers seeking to innovate and remain competitive in an increasingly health-conscious market, while also striving to enhance efficiency and sustainability in their practices.

Here are some of the key challenges that faced by Refined Wheat Flour Manufacturers in West Bengal.

Quality of Raw Materials: The quality of wheat used in flour production is crucial. Variability in crop yields, due to factors such as weather conditions, pests, and diseases, can lead to inconsistent quality. Manufacturers must establish strong relationships with reliable suppliers to ensure a steady supply of high-quality wheat.

Competition: The refined wheat flour market is highly competitive, not just within West Bengal but also from other states. Local manufacturers often compete with large national brands that benefit from economies of scale and established distribution networks, making it challenging for smaller players to maintain market share.

Technological Advancements: Keeping up with technological advancements in milling processes and equipment can be a challenge for manufacturers, particularly smaller ones with limited capital. Investing in modern machinery is essential for improving efficiency and maintaining quality, but it can be prohibitively expensive.

Regulatory Compliance: Compliance with food safety and quality regulations can be complex and demanding. Manufacturers must adhere to local and national standards, including quality checks, labeling requirements, and health regulations. Failure to comply can result in penalties and loss of consumer trust.

Market Demand Fluctuations: Changes in consumer preferences can impact demand for refined wheat flour. As health trends shift towards whole grains and organic products, manufacturers may need to adapt their product lines to stay relevant. Understanding market dynamics is essential for forecasting demand accurately.

Supply Chain Disruptions: The supply chain for raw materials and distribution can be vulnerable to disruptions due to political factors, transportation issues, or economic fluctuations. Such disruptions can lead to increased costs and delays in production and delivery.

Labor Challenges: The industry may face difficulties in sourcing skilled labor, particularly in rural areas where many flour mills are located. Training and retaining a skilled workforce is essential for maintaining quality and operational efficiency.

Sustainability Concerns: Increasing consumer awareness regarding sustainability poses a challenge. Manufacturers must consider environmentally friendly practices in sourcing, production, and packaging to meet consumer expectations and comply with regulations.

Pricing Pressures: Fluctuations in wheat prices can affect production costs, leading to challenges in pricing strategies. Manufacturers must balance competitive pricing with maintaining quality, which can be particularly difficult in times of rising raw material costs.

Conclusion

Despite these challenges, refined wheat flour manufacturers in West Bengal have opportunities to innovate and grow. By focusing on quality, investing in technology, and understanding market trends, they can navigate the competitive landscape and meet the evolving demands of consumers. Adaptability and strategic planning will be key to overcoming these challenges and ensuring long-term success in the industry.

1 note

·

View note

Text

Malt-Based Foods for Children: What You Should Know

Barley malt comes in many different types. Barley Malt Extract can be used in many ways, from syrup to powder. They are used in cooking and baking for a lot of different things. Milk powders and chocolate malts are used as baby foods that get mixed with milk to create nutritious meals for kids.

Malt-Based Foods for Children

Malt drinks for kids are an easy and tasty way to help them get the nutrients they need. Kids can be picky about what they eat, but the sweet and creamy taste of malt helps make it easier to get them to drink this healthy drink.

Including malt drinks in kids' daily routine can help with their growth and thinking skills, boosting their energy and brainpower. Many parents are choosing malt-based food because they see it as a healthier option compared to regular drinks. Other drinks can have artificial flavors, preservatives, and too much sugar.

Do Kids Really Need Healthy Drinks?

What counts as a healthy drink can vary from person to person. If a child is thin, picky about food, and gets sick often, adding Barley Malt Powder can be a smart option. If a child is eating well, getting all the nutrients they need from their food, and staying active, there's really no reason for healthy drinks.

What’s The Difference between Malt Powder and Malted Milk Powder?

Malt powder is not the same as malted milk powder, so be careful not to mix them up. Malt powder is frequently used in making bread, and in this situation, it’s usually called diastatic malt powder. When you add diastatic malt powder to the dough, it helps the yeast grow, making the dough rise faster, and the bread puffs up nicely.

Malt powder is also added to some processed foods to give them a caramel color. It also has a taste similar to malt. Malted milk powder is a mix of malt powder and milk solids. It’s a light yellow powder that has a creamy, slightly nutty taste. It is commonly used to make malts, which are also known as malted milkshakes.

Conclusion

Malted milk food in India comes in many flavors and is a great source of vitamins and minerals. Some health drinks often have a lot of hidden sugar in them, which can cause you to gain weight you don't want. If your child doesn't need extra nutrients beyond what they eat every day, you can skip the health drinks. But giving healthy drinks is a better choice for kids who don’t eat well.

for more information about: malt extract Liquid Please visit at https://www.mahalaxmimaltextract.com/

#barley malt powder#liquid malt extract#malt extract powder#barley malt extract#malt extract liquid#malt extract#malted barley powder manufacturers#malt extract powder manufacturer#barley malt flour#barley malt extract manufacturers

0 notes