#flocculant chemicals

Explore tagged Tumblr posts

Text

Angel Chemindia: Mastering the Magic of Flocculation

Nestled in the vibrant industrial landscape of Ankleshwar, Gujarat, India, lies Angel Chemindia Industries Ltd., a company synonymous with excellence in the realm of Flocculant Chemicals Manufacturers. For over two decades, Angel Chemindia has been weaving its magic through a diverse range of flocculants, transforming murky waters into crystal-clear streams and revolutionizing industries from wastewater treatment to papermaking.

A Symphony of Science and Innovation

Through meticulous research and development, they unlocked the secrets of these remarkable polymers, understanding how their unique properties could bridge the gap between suspended particles and water molecules, fostering the formation of settleable clumps and Flocculant Chemicals.

Today, Angel Chemindia repertoire boasts an impressive array of flocculants, each meticulously formulated to tackle specific challenges in various industries. Whether it's the removal of heavy metals, dyes, or organic matter from wastewater, clarifying drinking water, or enhancing the papermaking process, Angel Chemindia has a flocculant tailor-made for the task.

Unveiling the Angel Chemindia Advantage

What sets Angel Chemindia apart is its unwavering commitment to quality and innovation. Every step of the production process, from sourcing raw materials to meticulously monitoring each batch, adheres to stringent quality control measures. This dedication translates into:

Exceptional performance: Angel Chemindia flocculants deliver superior clarity and efficiency in diverse applications, minimizing water usage and treatment costs.

Unwavering reliability: Backed by robust research and development, Angel Chemindia flocculants are formulated to withstand challenging conditions and perform consistently over time.

Environmental consciousness: Angel Chemindia prioritizes eco-friendly practices, developing biodegradable and non-toxic flocculants that minimize environmental impact.

Technical expertise: Angel Chemindia team of seasoned chemists and engineers offer comprehensive technical support, ensuring optimal flocculant selection and application for each client's unique needs.

Beyond the Lab: Building Partnerships

Angel Chem understands that success lies not just in the efficacy of its products but also in fostering strong relationships with its clients. The company takes pride in its customer-centric approach, providing prompt technical assistance, on-site consultations, and training programs to ensure their clients maximize the potential of their flocculants.

A Vision for a Clearer Tomorrow

As the world grapples with growing water scarcity and pollution challenges, Angel Chemindia stands tall as a beacon of hope. With its unwavering commitment to innovation and sustainability, the company is at the forefront of developing advanced flocculant solutions that not only purify water but also conserve this precious resource for future generations.

Flocculation: A Force for Good

Flocculation may seem like a complex scientific concept, but its impact is nothing short of transformative. Angel Chemindia mastery of this powerful process has led to cleaner rivers, safer drinking water, and more efficient industrial processes. It is a testament to the power of science and innovation in tackling some of the world's most pressing challenges.

In conclusion, Angel Chemindia is more than just a manufacturer of flocculant chemicals; it is a story of dedication, innovation, and a deep commitment to a cleaner, healthier future. As the company continues to push the boundaries of flocculation technology, one can be certain that Angel Chemindia will continue to write its name in the annals of environmental progress, one crystal-clear drop at a time.

#Polyelectrolyte#Anionic Polyelectrolyte#Flocculant Chemicals#Cationic Polyelectrolyte#Polyelectrolyte Powder#Color Removal Chemicals#Activated Carbon Granular#Ro Antiscalant#Bacteria Culture#Calcium Hypochlorite#Defoamer Chemicals#Cooling Water Chemicals#Boiler Water Chemicals#Bactaslyde#Sand Media

0 notes

Text

The Chemistry Behind Clean Water: How Flocculant Chemicals Make a Difference

Introduction

Pure water stands as an irreplaceable treasure, upholding existence throughout the expanse of our planet. The presence of secure and uncontaminated water stands as a foundational requirement for human continuation, a significance that cannot be exaggerated. Yet, the assurance of consuming water devoid of impurities demands an intricate fusion of scientific fundamentals, engineering methods, and inventive advancements. At the core of this pursuit resides the captivating realm of chemistry, where the significance of flocculant chemicals becomes paramount. These chemicals assume a pivotal role in metamorphosing muddled, tainted water into a lucid, revitalizing potion.

Importance of Clean Water

Clean water transcends luxury; it's a fundamental entitlement of every human being. The availability of unpolluted and secure drinking water stands as a cornerstone for preserving well-being and averting waterborne ailments. Water tainted with impurities can pave the way for an array of health complications, spanning from gastrointestinal disturbances to grave infections. Thus, the urgency for efficient techniques of water treatment remains of the utmost importance.

Role of Chemistry in Water Treatment

The quest for clean water is where chemistry truly shines. Chemistry provides us with the tools to understand the properties of water, the nature of contaminants, and the mechanisms through which they can be removed. The application of chemical principles in water treatment has revolutionized the way we purify water on a large scale.

Overview of the Flocculation Process

At the heart of water treatment lies the process of flocculation, a phenomenon driven by the interaction between flocculant chemicals and suspended particles in water. Flocculation involves the aggregation of these particles into larger clusters called flocs, which can then be easily separated from the water. This process not only removes visible impurities but also eliminates microscopic contaminants, ensuring the water is safe for consumption.

What are Flocculant Chemicals?

Flocculant chemicals, often referred to simply as flocculants, are substances that facilitate the aggregation of suspended particles in water. They are like molecular maestros orchestrating a complex dance of particles, turning chaos into order. Flocculants play a critical role in water treatment by aiding in the removal of contaminants and turbidity.

Definition and Purpose

Flocculants are polymers with a high molecular weight that possess an affinity for both water and the particles present in them. When added to water, these chemicals interact with suspended particles, causing them to clump together and form flocs. These flocs are heavier and settle down, making it easier to separate them from the clear water.

The Science of Flocculation

Flocculation may sound like a complex scientific process, but at its core, it's all about creating order out of chaos. Imagine a crowded dance floor where individuals are moving chaotically. Now, imagine a skilled dance instructor stepping in and guiding dancers to form couples and groups. Flocculation does something similar to particles in water.

Dispersion and Aggregation

When flocculant chemicals are introduced into water, they disperse evenly due to their affinity for both water and particles. As these molecules spread, they come into contact with suspended particles. This contact leads to the aggregation of particles, much like dancers forming pairs on the dance floor. Particles that were once scattered now begin to clump together.

Bridging and Enmeshment

Here's where the chemistry gets interesting. Organic flocculants act as matchmakers, creating bridges between particles. Think of it as dancers holding hands to form a chain or circle. This bridging creates a loose network of particles, and smaller particles get trapped within this network. It's like dancers in a circle holding hands, preventing anyone from escaping the dance.

Formation of Flocs

As the bridges between particles strengthen and more particles join the network, larger flocs begin to take shape. These flocs are like well-coordinated dance groups, moving together as a unit. Due to their increased size and weight, flocs start to settle down under the influence of gravity. Eventually, they become heavy enough to separate from the clear water, leaving behind a purified liquid.

Application of Flocculants in Water Treatment

Flocculants have found their way into various sectors, contributing significantly to water treatment and purification. Let's dive into some of the key areas where flocculants play a vital role:

Municipal Water Treatment

In the realm of municipal water treatment, flocculants are essential for transforming raw water from rivers, lakes, and reservoirs into potable water. As water sources contain a mix of suspended particles, bacteria, and organic matter, flocculants aid in removing these impurities, ensuring the water meets safety standards.

Industrial Water Treatment

Industries rely on vast amounts of water for various processes. However, the water used in industrial operations often contains contaminants that can impact both product quality and equipment efficiency. Flocculants help industries treat and recycle water, reducing the environmental impact and ensuring smooth operations.

Mining Industry

Mining operations generate significant amounts of wastewater, which can be laden with minerals, sediments, and other pollutants. Flocculants are used to clarify and dewater the wastewater, allowing for safe disposal or reuse. This not only minimizes the environmental impact but also helps recover valuable resources.

Wastewater Treatment

Wastewater treatment plants handle domestic and industrial sewage, aiming to remove pollutants before releasing the treated water back into the environment. Flocculants assist in the sedimentation and filtration processes, aiding in the removal of solids and contaminants from wastewater.

Factors Influencing Flocculation

Certainly, let's delve into the various factors that influence the effectiveness of the flocculation process:

pH Levels

pH plays a crucial role in flocculation. The optimal pH range varies depending on the type of flocculant used. Deviations from this range can lead to reduced flocculation efficiency, affecting the quality of the treated water.

Temperature

Temperature affects the kinetics of flocculation. Higher temperatures can accelerate the process, leading to faster floc formation. However, extreme temperatures can also impact the stability of flocs, potentially affecting the overall treatment process.

Mixing Intensity

The energy applied during mixing affects the collision and adhesion of particles. Proper mixing ensures uniform dispersion of flocculants and enhances the chances of effective particle aggregation.

Particle Size

The size of suspended particles plays a role in flocculation. Smaller particles have a higher surface area, making them more challenging to aggregate. Therefore, the choice of flocculant and process parameters should consider the particle size distribution.

Advancements in Flocculant Technology

As technology advances, so does the field of flocculation. Innovations continue to enhance the efficiency and sustainability of water treatment processes:

Nanotechnology and Flocculation

Nanotechnology has paved the way for the development of nanomaterial-based flocculants. These tiny particles offer high surface area and unique properties, improving flocculation efficiency and reducing the required dosage of chemicals.

Eco-friendly Flocculants

The environmental impact of traditional flocculants has led to the exploration of eco-friendly alternatives. Biopolymers and natural materials are being studied for their flocculation potential, minimizing the ecological footprint of water treatment.

Automation and Precision

Automation and digital technologies are transforming water treatment plants. Advanced sensors and algorithms monitor flocculation processes in real-time, adjusting parameters for optimal performance. This level of precision ensures consistent water quality and reduces operational costs.

Environmental and Health Considerations

While flocculants contribute to cleaner water, their use raises important environmental and health considerations:

Disposal of Flocculated Particles

Once the flocs are separated from the water, they need to be properly disposed of or treated. The disposal method can impact soil and water quality, necessitating careful handling and management.

Impact on Aquatic Ecosystems

The release of treated water back into aquatic ecosystems can have unintended consequences. Flocs that make their way into natural water bodies can affect sedimentation patterns, potentially disrupting aquatic life and habitats.

Human Health Concerns

The presence of residual flocculant chemicals in treated water raises questions about their potential impact on human health. Research is ongoing to ensure that the benefits of water treatment outweigh any potential risks.

Conclusion The chemistry behind clean water is a captivating tale of science working hand in hand with nature to ensure our most precious resource remains pure and safe for consumption. Flocculant chemicals, those unassuming molecular magicians, play a central role in this endeavor. By harnessing their unique properties, we can witness the transformation of cloudy, contaminated water into a crystal-clear liquid fit for quenching our thirst and sustaining life.

The dance of particles, the orchestration of forces, and the delicate balance between science and engineering create a symphony of purification. From municipal water treatment plants to industrial processes and wastewater management, flocculants shine as the unsung heroes of the clean water revolution. Their ability to aggregate particles and form flocs may seem simple, but the intricacies of this process demonstrate the wonders of chemistry at play.

#flocculant#flocculant chemicals#mining chemicals#flocculant chemical suppliers#mining chemical suppliers#flocculant chemicals manufacturing#chemical manufacturing industries#chemical manufacturing#specialty chemicals#flocculation#nonionic flocculant

0 notes

Text

There's No better alternative to PHPA while treating Wastewater Treatment know how? | Chemtex Speciality Limited

PHPA and anionic polyelectrolytes are far better than compared to other common wastewater treatment chemicals like ferric chloride, and alum. In terms of performance, PHPA is more efficient, providing better water quality with lower chemical usage.

Chemtex Speciality Limited deals with the chemical treatment of wastewater, globally accepted by leading treatment plants, enhancing wastewater process and clarification operations. The application of PHPA and anionic polyelectrolytes helps in the removal and elimination of harmful pathogens, taking out hazardous chemicals, detergents, and toxins, reducing odor, and separating sediments from wastewater.

#phpa#wastewater treatment#anionic polyelectrolyte#sewage treatment plant#effluent treatment#Alstrafloc#water treatment chemicals#polyacrylamide flocculant#anionic polyacrylamide#etp plant chemicals#chemtex#chemical manufacturer

0 notes

Text

Which Sort of Polyacrylamide is Utilized in Water Treatment?

Water treatment is a basic interaction that guarantees the accessibility of spotless and safe water for different purposes. It includes the expulsion of pollutions and impurities from water to make it appropriate for utilization or modern use. Polyacrylamide, a manufactured polymer, assumes a critical part in this cycle by helping with the flocculation and sedimentation of suspended particles. Zoomri Synthetic, a legitimate supplier of substance arrangements, offers an extensive variety of polyacrylamide items explicitly intended for water treatment applications.

Polyacrylamide is a flexible substance compound that can be modified to meet the particular prerequisites of various water treatment processes. Zoomri Synthetic grasps the different requirements of the business and gives a far reaching choice of polyacrylamide things to address different water treatment challenges really.

One of the essential uses of polyacrylamide in water treatment is as a coagulant help. By adding polyacrylamide to the water treatment process, it improves the effectiveness of coagulants, for example, aluminum sulfate or ferric chloride. This guides in the arrangement of bigger and denser flocs, which settle all the more quickly during sedimentation, bringing about better water explanation.

Anionic polyacrylamide is ordinarily utilized in water treatment because of its high charge thickness and great flocculation properties. It is successful in eliminating suspended solids, colloids, and natural matter from water. Zoomri Compound offers different grades of anionic polyacrylamide, permitting clients to choose the most appropriate item founded on their particular water treatment prerequisites.

Cationic polyacrylamide is one more sort broadly utilized in water treatment, especially in the treatment of wastewater. It has positive charges that draw in adversely charged particles, making it exceptionally compelling in flocculating and settling suspended solids. Zoomri Substance gives cationic polyacrylamide items that display superb execution in wastewater treatment, guaranteeing the expulsion of toxins and impurities for a cleaner climate.

Notwithstanding anionic and cationic polyacrylamide, Zoomri Substance additionally offers non-ionic polyacrylamide for water treatment applications. Non-ionic polyacrylamide is viable in the expulsion of natural matter, oil, and oil from water. It is especially helpful in enterprises where the presence of hydrocarbons or surfactants is a worry.

The choice of the fitting polyacrylamide item relies upon different factors, for example, the idea of the water source, the sort and convergence of pollutants, and the ideal treatment goals. Zoomri Synthetic's group of specialists can give direction and help with picking the most appropriate polyacrylamide item for explicit water treatment applications.

Besides, Zoomri Synthetic guarantees the quality and dependability of their polyacrylamide items by sticking to severe assembling guidelines. Their items are produced utilizing trend setting innovation and go through thorough testing to guarantee ideal execution and consistence with industry guidelines.

All in all, the decision of polyacrylamide in water treatment is pivotal for accomplishing powerful and proficient outcomes. Zoomri Compound offers a different scope of polyacrylamide items custom-made to meet the particular necessities of water treatment processes. Whether it is anionic, cationic, or non-ionic polyacrylamide, Zoomri Compound gives top notch answers for address different water treatment challenges. Trust in their mastery and items to guarantee the arrangement of spotless and safe water for a large number of utilizations.

1 note

·

View note

Text

Harnessing Nature: Insights into the Organic Coagulant Market

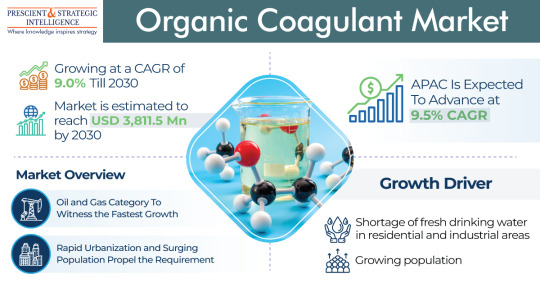

The organic coagulant market is projected to reach at USD 3,811.5 million in 2030 with a CAGR of 9% in the years to come. The major reasons for this development of the industry are the scarcity of drinking and fresh water in residential and industrial areas along with the rising population, and urbanization.

And the rising demand for facilities like sewage treatment, industrial water treatment, fertilizer production, food & beverage industry, and paper manufacturing helps the demand for the chemical to grow.

And another major reason for the increasing demand is the growing population, which is creating an enormous demand for clean water and for which a need for advanced purification methods and also with the expansion of infrastructure for water treatment by government to meet the demand are all contributing the growth of eco-friendly water purification.

The oil & gas category will grow at a highest CAGR of 10% over the years, which is driven by the increasing use of organic chemicals with water at a required concentration for drilling and petroleum extraction purposes.

While, onshore and offshore operations both require different filtration processes as in onshore normal water is available, whereas offshore require advanced system to filter seawater. In addition, research and development activities are also contributing to the demand for organic coagulants, with eco-friendly solutions being explored for wastewater treatment.

Moreover, the increasing government focus to implement policies for water quality monitoring because of the increasing population all over the world. Strict regulations to prevent the direct release of harmful chemicals from industries and untreated sewage into water bodies.

APAC will grow the fastest in the organic coagulant market at a CAGR of 9.5% in the years to come due to the rapid urbanization and industrialization with rising population along with the rising investments in water treatment plant development and strict regulations on sewage disposal. Countries like India, China, South Korea, and Japan are expanding their contribution for the water treatment.

#organic coagulant#water treatment#wastewater treatment#coagulation solutions#eco-friendly chemicals#sustainable water treatment#natural coagulants#organic flocculants#water purification#organic coagulant applications#environmental sustainability#industrial water treatment#market growth#coagulation technology#organic chemicals

0 notes

Text

Global Flocculant and Coagulant Market

Global Flocculant and Coagulant Market is Estimated to Witness High Growth Owing to Increasing Water Treatment Activities and Growing Demand for Enhanced Oil Recovery Opportunities

The global Flocculant and Coagulant Market is estimated to be valued at USD 6738.6 Mn in 2023 and is expected to exhibit a CAGR of 5.5% over the forecast period of 2023-2030, as highlighted in a new report published by Coherent Market Insights.

A) Market Overview:

The Flocculant and Coagulant Market provides essential chemicals for various industries, including water treatment and oil recovery. Flocculants are used to separate suspended particles in water, while coagulants help in binding these particles together for easy removal. These chemicals play a vital role in ensuring clean water supply and efficient oil recovery processes. Their applications range from municipal water treatment to industrial wastewater treatment and from oil refineries to enhanced oil recovery processes.

B) Market Dynamics:

The Flocculant and Coagulant Market is driven by two key factors. Firstly, the increasing water treatment activities across the globe propel market growth. With the rise in industrialization and urbanization, the demand for clean water is increasing, driving the need for efficient water treatment processes. Flocculants and coagulants are essential in removing impurities from water and achieving the desired water quality.

Secondly, the growing demand for enhanced oil recovery presents a significant opportunity for market growth. As the conventional oil reserves deplete, oil companies are turning to enhanced oil recovery techniques to extract more oil. Flocculants and coagulants are used in these processes to separate oil from water and improve oil recovery efficiency.

C) Segment Analysis:

In the Flocculant and Coagulant Market, the water treatment segment dominates the market due to the increasing focus on clean water supply. The municipal water treatment sub-segment dominates the water treatment market, as governments and regulatory bodies impose stricter regulations on water quality standards to ensure safe drinking water supply.

D) PEST Analysis:

Political: In the political aspect, governments and regulatory bodies are implementing stricter regulations regarding water quality, driving the demand for flocculants and coagulants in water treatment processes.

Economic: The economic aspect plays a significant role in market growth as industries invest in efficient water treatment processes to comply with regulations and ensure sustainable operations.

Social: On the social front, the growing awareness among the population about the importance of clean water and the need for efficient oil recovery techniques drives the demand for flocculants and coagulants.

Technological: Technological advancements in the water treatment and oil recovery sectors contribute to the development of more efficient flocculants and coagulants, enhancing their performance and driving market growth.

E) Key Takeaways:

The global Flocculant and Coagulant Market is expected to witness high growth, exhibiting a CAGR of 5.5% over the forecast period, due to increasing water treatment activities and the growing demand for enhanced oil recovery. The market provides essential chemicals for these industries, ensuring clean water supply and efficient oil recovery processes.

In terms of regional analysis, Asia-Pacific is the fastest-growing and dominating region in the Flocculant and Coagulant Market. The region's rapid industrialization and urbanization drive the demand for efficient water treatment processes, boosting market growth.

Key players operating in the global Flocculant and Coagulant Market include BASF SE, Ecolab Inc., Solvay SA, SNF Ltd, Cytec Industries Inc., Akferal, Kemira Oyj, Jayem Engineers, and TRIO Chemicals & Allied Products. These companies focus on research and development activities to develop innovative products and meet the increasing industry demand.

0 notes

Text

The Science and Strategy behind Filtration Aid Manufacturers

In today's complex industrial landscape, where processes and technologies intersect, filtration aid manufacturers stand as integral players, driving efficiency, quality, and innovation within diverse sectors. The intricate science that underpins their operations, coupled with strategic approaches, forms the backbone of numerous industries that heavily rely on efficient filtration systems. In this comprehensive and detailed guide, we will embark on a journey to explore the profound science, strategic methodologies, and utmost significance of filtration aid manufacturers in various industrial applications.

1. Understanding Filtration Aids

Filtration aids, often referred to as filter aids, are indispensable components within the realm of filtration processes. These aids are specially designed substances, both organic and inorganic, meticulously engineered to enhance the efficacy of filtration systems across various industries. By aiding in the separation of solid particles from liquids or gases, filtration aids fundamentally improve the filtration process, ensuring the removal of impurities and the attainment of desired product quality.

2. The Intricacies of Filtration Aid Development

2.1 The Role of Material Science

The development of filtration aids is rooted in the principles of material science, where the physical and chemical properties of materials are studied and manipulated to achieve desired outcomes. Through meticulous research and experimentation, filtration aid manufacturers gain insights into the behavior of different materials under varying filtration conditions. This scientific understanding enables the creation of filtration aids with specific characteristics that optimize particle capture and flow dynamics.

2.2 Harnessing Surface Chemistry

Surface chemistry plays a pivotal role in filtration aid design, as the interactions between the aid's surface and the particles to be separated significantly influence the filtration process. Manufacturers delve into the realm of surface science to modify the surface properties of filtration aids. By controlling factors such as surface charge, polarity, and affinity for certain particles, manufacturers can enhance the adsorption capacity of filtration aids, thereby improving their ability to retain particles during filtration.

2.3 Pore Structure Optimization

The intricate network of pores within filtration aids contributes to their particle-trapping efficacy. Manufacturers employ advanced techniques to optimize pore size distribution and structure. This optimization process involves striking a delicate balance between pore size and mechanical strength. An ideal pore structure ensures efficient particle entrapment while maintaining the aid's structural integrity throughout the filtration process.

3. Strategies for Optimal Utilization

3.1 Tailoring Filtration Aids for Specific Applications

Filtration needs vary across industries, and successful filtration aid manufacturers recognize the importance of customization. By collaborating closely with industries, manufacturers gain valuable insights into the unique challenges each sector faces. This collaboration allows for the tailoring of filtration aids to suit specific applications, ensuring optimal performance and maximal efficiency.

3.2 Precise Dosage and Application Techniques

Achieving optimal filtration efficiency involves a keen understanding of dosage and application techniques. Filtration aid manufacturers utilize their expertise to determine the precise amount of aid required for a given filtration process. Additionally, they employ specialized application techniques, such as pre-coating filter media or employing different dosage strategies, to ensure uniform aid distribution and maximum particle capture.

3.3 Balancing Filtration Pressure for Enhanced Efficiency

Filtration pressure plays a crucial role in determining the rate and efficacy of particle separation. Filtration aid manufacturers strategize to find the optimal balance between filtration pressure and aid utilization. By adjusting pressure parameters, manufacturers can enhance the aid's performance, preventing clogging and ensuring continuous, efficient particle removal.

4. Collaboration, Research, and Technological Advancements

4.1 Synergizing Research and Industry Expertise

The dynamic landscape of filtration technology demands continuous innovation. Filtration aid manufacturers engage in collaborative partnerships with research institutions, industry experts, and end-users to drive advancements. Through these collaborations, manufacturers gain access to cutting-edge research, novel insights, and diverse perspectives that shape the evolution of filtration aid technology.

4.2 Innovations in Filtration Aid Materials

Innovation in filtration aid materials is a constant pursuit for manufacturers aiming to push the boundaries of filtration efficiency. Research and development efforts focus on identifying new materials with superior adsorption capacities, enhanced mechanical properties, and compatibility with various filtration processes. These innovative materials redefine the possibilities of filtration aid performance.

4.3 Advancing Manufacturing Techniques

Manufacturing techniques continually evolve to meet the demands of efficiency, sustainability, and quality. Filtration aid manufacturers embrace advancements in manufacturing processes, such as nanotechnology and additive manufacturing, to create aids with precisely controlled properties. These techniques allow for the production of aids with intricate structures, tailored particle size distributions, and enhanced filtration capabilities.

5. Sustainability Integration in Filtration Aid Manufacturing

5.1 Embracing Eco-Friendly Materials

The pursuit of sustainability drives filtration aid manufacturers to explore eco-friendly material alternatives. As environmental awareness grows, manufacturers seek renewable and biodegradable materials that reduce the ecological footprint of aid production. By incorporating eco-friendly materials, manufacturers contribute to the overall sustainability of filtration processes.

5.2 Energy Optimization and Resource Efficiency

Sustainable manufacturing extends beyond materials to energy consumption and resource utilization. Filtration aid manufacturers employ energy-efficient processes and optimize resource allocation to minimize waste and reduce carbon emissions. These sustainable practices align with global efforts to mitigate environmental impact.

6. Addressing Common Queries About Filtration Aids

6.1 Which Industries Benefit from Filtration Aid Manufacturers?

Filtration aid manufacturers serve a wide array of industries, including pharmaceuticals, food and beverage, chemical processing, wastewater treatment, and many more. Each industry benefits from tailored filtration solutions that enhance product quality and process efficiency.

6.2 How Exactly Do Filtration Aids Enhance Filtration Efficiency?

Filtration aids create a porous structure that acts as a physical barrier, effectively trapping particles that would otherwise clog filtration media. This not only prevents premature filter blockage but also maintains consistent flow rates, optimizing filtration efficiency.

6.3 Can Filtration Aids Be Regenerated and Reused?

Yes, in many cases, filtration aids can be regenerated and reused. Through specialized regeneration processes, trapped particles are removed, and the aid's adsorption capacity is restored. This eco-friendly approach contributes to cost savings and resource conservation.

6.4 Ensuring Consistency and Quality in Filtration Aid Production

Manufacturers implement rigorous quality control measures to ensure the consistency and quality of filtration aids. Particle size analysis, surface property testing, and strict production protocols are employed to guarantee reliable filtration aid performance across different batches.

6.5 Synergy of Filtration Aids with Other Filtration Technologies

Filtration aids often complement other filtration technologies, such as membrane filtration and depth filtration. By working synergistically, these technologies enhance overall filtration efficiency, resulting in improved particle removal and product quality.

7. In Conclusion:

In the ever-evolving landscape of industrial processes, the science and strategy behind filtration aid manufacturers hold the key to enhanced efficiency, product quality, and environmental sustainability. Through continuous scientific exploration, strategic customization, collaborative innovation, and sustainable practices, these manufacturers shape the trajectory of filtration technology. As industries advance and environmental consciousness deepen, the role of filtration aid manufacturers becomes increasingly pivotal, driving progress toward greener, more efficient, and more sustainable filtration processes.

#filtration aid#filtration aid manufacturers#filtration#flocculation#filtration chemicals#phosphoric acid plant#chemical suppliers#chemical manufacturer#chemical industry

0 notes

Text

Choosing the Right Boiler Treatment Chemicals for Longevity and Safety

Boilers are essential to many industries, ensuring efficient heating and energy production. However, the proper maintenance and care of boilers are vital for their longevity and safe operation. One crucial aspect of boiler maintenance is the selection of the appropriate treatment chemicals. This article will explore the importance of choosing the right boiler treatment chemicals and their role in ensuring longevity and safety.

The Significance of Boiler Treatment Chemicals

Boiler treatment chemicals play a pivotal role in maintaining optimal performance and extending the lifespan of boilers. These chemicals are created to address common issues such as corrosion, scaling, and fouling, which can significantly impact the efficiency and safety of the boiler system. By implementing a comprehensive treatment program, boiler operators can prevent costly breakdowns, reduce energy consumption, and minimize the risk of accidents.

Understanding Boiler Treatment Chemicals

Before selecting boiler treatment chemicals, it is crucial to understand their various types and functions. Common chemicals used in boiler treatment include oxygen scavengers, scale inhibitors, corrosion inhibitors, and pH adjusters. Oxygen scavengers remove dissolved oxygen from the feedwater, preventing corrosion. Scale inhibitors prevent the formation of mineral deposits that can reduce heat transfer efficiency. Corrosion inhibitors form a protective layer on metal surfaces to inhibit corrosion. pH adjusters maintain the water's pH level within the recommended range to prevent corrosion and scaling.

Factors to Consider when Choosing Boiler Treatment Chemicals

Several factors should be considered when selecting boiler treatment chemicals. Firstly, it is essential to assess the specific needs and challenges of the boiler system, such as the water quality, operating pressure, and temperature. Environmental considerations, such as local regulations and discharge limits, should also be considered. Compatibility with existing equipment and other chemicals used in the system is another crucial factor to consider.

Furthermore, it is advisable to consult with reputable water treatment specialists or boiler manufacturers to ensure the selection of suitable chemicals. These experts can analyze water samples, evaluate system conditions, and recommend the most effective treatment program tailored to the specific boiler system.

Conclusion: Choosing the correct boiler treatment chemicals is vital for the longevity and safety of boiler systems. The appropriate chemicals can prevent corrosion, scaling, and fouling, improving efficiency and reducing maintenance costs. Boiler operators can make informed decisions by understanding the different types of best reverse osmosis water filter australia and considering factors such as water quality, system conditions, and environmental regulations. Consulting with water treatment specialists or boiler manufacturers can provide valuable insights and recommendations. Investing in the right boiler treatment chemicals and implementing a comprehensive treatment program is an investment in boiler systems' long-term performance, reliability, and safety.

#boiler treatment chemicals#coagulation and flocculation in water treatment#flocculants water treatment

1 note

·

View note

Text

Best water treatment chemicals supplier in UAE - Chemway

Chemway Chemicals is the leading supplier of water treatment chemicals in Dubai, UAE. These water treatment chemicals ingredients are employed as disinfectants, flocculants, coagulants, and cleaning, oxidizing, and bleaching agents which is useful for the best water treatment chemicals supplier in UAE. We Offer High-Quality water treatment Products at reasonable prices.

Website:https://chemwaychemicals.com/water-treatment-chemicals-uae/

Contact :+971 58 667 8649

#chemwaychemicals #bestchemicalsuppliers #leadingchemicalsuppliers #chemicalsuppliersindubai #chemicalsuppliersinuae #ChemicalDistributorCompanyinDubai #dubai #UAE #topchemicalsuppliersinUAE#best #watertreatment #bestwatertreatment #watertreatmentchemicals #chemicals #chemicalsupplier #watertreatmentchemicalsupplier #watertreatmentchemicalsupplierinuae #uae #chemicalsinuae #chemicalmanufacturing

#Chemway Chemicals is the leading supplier of water treatment chemicals in Dubai#UAE. These water treatment chemicals ingredients are employed as disinfectants#flocculants#coagulants#and cleaning#oxidizing#and bleaching agents which is useful for the best water treatment chemicals supplier in UAE. We Offer High-Quality water treatment Products#Website:https://chemwaychemicals.com/water-treatment-chemicals-uae/#Contact :+971 58 667 8649#chemwaychemicals#bestchemicalsuppliers#leadingchemicalsuppliers#chemicalsuppliersindubai#chemicalsuppliersinuae#ChemicalDistributorCompanyinDubai#dubai#UAE#topchemicalsuppliersinUAE#best#watertreatment#bestwatertreatment#watertreatmentchemicals#chemicals#chemicalsupplier#watertreatmentchemicalsupplier#watertreatmentchemicalsupplierinuae#uae#chemicalsinuae#chemicalmanufacturing

0 notes

Text

OK, time for something cursed. Here's how my brain works:

@dieffenbacia wanted something "somewhere between sweet and savory" that used a coffee liqueur. Jumping off of coffee/vodka combos like the espresso martini or the black Russian, I went to thinking about Grey Goose. Specifically, it's got a bit of a peppery taste to it. I wonder if I can heighten that?

So I decided to infuse a peppercorn melange into vodka. It uh. Yeah it sure exists. As usual, it's about a tbsp of spice to a quarter cup of vodka. I'm not too precise here because there's a lot of other variables that go into infusions and you always have to tinker with it afterwards.

Quick infuse produced this. I strained through cheesecloth and then strained again through a coffee filter. There's too many micro particles from the pepper, so I won't be able to get it perfectly clear without either a chemical flocculant or a protein coagulant, and I don't care enough to set either of those up. (but send me an ask if you want me to explain those!)

Anyways. It tastes like pepper. Big surprise on that. It kind of hurts to drink. I diluted it down with more vodka and it's still pretty intense. For the hell of it, I threw it into a martini and

It's still pretty strong, sorry. Tastes bad too.

16 notes

·

View notes

Text

Flocculant Chemicals Manufacturers

Flocculant chemicals are critical for water treatment, wastewater management, and various industrial techniques. These specialized compounds promote the clumping of particles, helping in sedimentation and purification. Leading flocculant chemical manufacturers provide a wide variety of merchandise tailor-made to specific programs, making sure efficient and effective treatment solutions.

#Flocculant Chemicals Manufacturers#Cationic Polyelectrolyte Manufacturers#Polyelectrolyte Manufacturers

0 notes

Text

What Is an Industrial Water Treatment System and How Does It Work?

Water is the lifeblood of countless industrial processes. But unlike the kind that comes out of your tap, industrial water often needs a little extra TLC before it's ready for action. That's where industrial water treatment systems come in. At PureBact, we understand the importance of clean, reliable water for your facility's operations.

Here's a breakdown of what industrial water treatment systems are and how they work:

What is an Industrial Water Treatment System?

An industrial water treatment system is a customized set of processes designed to remove impurities and adjust the properties of water to make it suitable for a specific industrial application. This could involve anything from making boiler feed water ultra-pure to treating wastewater before it's released back into the environment.

Why is Industrial Water Treatment Important?

Untreated water can wreak havoc on your industrial processes. Minerals can cause scaling and corrosion in pipes and equipment, while contaminants can affect product quality. Proper water treatment helps to:

Protect equipment: By removing impurities that can cause corrosion and scaling, you can extend the lifespan of your valuable machinery.

Ensure product quality: Consistent water quality is essential for producing consistent, high-quality products.

Minimize environmental impact: Industrial wastewater treatment helps to remove pollutants before they are released back into the environment.

Reduce operating costs: By preventing equipment damage and ensuring efficient operation, proper water treatment can save you money in the long run.

How Does Industrial Water Treatment Work?

The specific treatment processes used will vary depending on the source water and the desired end product. However, some common methods include:

Pre-treatment: This stage removes large particles such as sand, debris, and organic matter through filtration or sedimentation.

Clarification: Coagulation and flocculation techniques help suspended solids clump together and settle out of the water.

Filtration: Various filtration technologies, like sand filters or membrane filters, remove finer particles and contaminants.

Ion exchange: This process removes unwanted ions by exchanging them for harmless ones.

Deionization: A specialized form of ion exchange that removes both positively and negatively charged ions to create high-purity water.

Disinfection: Chemicals like chlorine or ultraviolet light can be used to kill bacteria and other microorganisms.

PureBact: Your Partner in Industrial Water Treatment

At PureBact, we offer a comprehensive range of industrial water treatment solutions. Our team of experts will work with you to assess your specific needs and design a custom system that ensures optimal water quality for your operations.

Contact PureBact today to learn more about how we can help your business thrive with clean, reliable industrial water.

2 notes

·

View notes

Text

FLOCCULANTS MANUFACTURE

In the dynamic realm of drilling fluids, Universal Drilling Fluids distinguishes itself as a pioneer in the development and manufacturing of flocculants. This industry leader's commitment to innovation and precision is evident in its unique approach to flocculant design and production. Let's delve into the intricate processes, versatile applications, and inherent advantages that characterize Universal Drilling Fluids' mastery in the manufacture of flocculants.

Precision in Polymerization: Universal Drilling Fluids begins its flocculant manufacturing process with a focus on precision through polymerization. Similar to an artist selecting the finest materials for a masterpiece, this company carefully selects and polymerizes specific monomers. The result is a molecular architecture that ensures optimal performance, tailored to the diverse and dynamic conditions encountered in drilling operations.

Formulation Expertise: The role of Universal Drilling Fluids extends beyond manufacturing; it takes on the persona of a formulator extraordinaire. By tailoring flocculants to the unique characteristics of different drilling environments, the company demonstrates a level of formulation expertise that goes beyond a standard chemical composition. Rigorous quality assurance ensures that each formulation meets stringent standards of consistency and industry compliance.

On the Drilling Stage: Consider the application of flocculants as a theatrical production:

Choreographing Settling Dynamics: Flocculants act as choreographers, orchestrating the graceful settling of solids. This process enhances the separation of cuttings from the drilling fluid, contributing to overall operational efficiency.

Spotlight on Fluid Clarity: The performance of flocculants shines in the spotlight of fluid clarity, transforming the drilling fluid into a crystal-clear medium. This not only enhances visibility but also ensures that filtration processes operate with artistic precision.

Ensuring Wellbore Stability: Flocculants play a vital role in the grand finale, contributing to wellbore stability by preventing the accumulation of fine particles. This ensures a stable and reliable performance throughout drilling operations.

Advantages of Universal Drilling Fluids' Innovations:

Elevating Filtration Efficiency: Flocculants from Universal Drilling Fluids elevate filtration efficiency by promoting the formation of larger particles, optimizing the overall performance of drilling fluids.

Fluidic Harmony: By reducing mud viscosity, these flocculants introduce a sense of fluidic harmony to drilling operations. The result is a well-balanced and optimized performance.

Tailored Solutions: Universal Drilling Fluids doesn't merely supply flocculants; it crafts tailored solutions. Each formulation is a unique composition designed to address the specific challenges presented by diverse drilling environments.

Conclusion

In the ever-evolving landscape of drilling operations, Universal Drilling Fluids emerges as a beacon of innovation, providing solutions that redefine efficiency and clarity. With a symphony of precision, customization, and excellence, their flocculants showcase a commitment to advancing the fluidic dynamics of oil and gas exploration.

3 notes

·

View notes

Note

i would say yes! there are pollution issues caused from the city of dis above

Well that certainly limits the romantic bubble baths… I bet homie drinks bottled water and wine, wears perfume, and uses a lot of talcum powder as dry shampoo in his hair. Maybe even bathes with oil and scrapers as the Romans did. Maybe I need to elope with Kayn and enjoy his hot springs instead.

But… while Dorian probably already does some or all of this water cleaning I’m thinking about how to automate it or do it on a bigger more efficient scale.

Imagine if Aeron made beautiful marble sculptures of trees that were hollow in the middle, and the branches funnelled rainwater down the centre through layers of gravel, sand and charcoal. Like the ancient sand filtration columns, cleaning and storing large volumes of water passively.

Or Dorian’s cathedral could have gargoyles on the back that spout the roof runoff through filters into water tanks for treatment. The falling of the water would aerate it too, against anaerobic bacteria. The tank also allows sediments to fall to the bottom, the water to be flocculated with iron or alum, and all the resulting coagulated junk to sink to the bottom.

Actually none of it should be marble though. Filtering water through ash can make it extremely alkaline (doing that with wood ash makes lye) and if it was acid rain from the smog… either would quickly erode the soft marble. I wonder how the cathedral and gravestones resist damage.

Better alternatives would be metal, resistant asphalt concrete, or a more resistant stone. There is also the Roman concrete that ‘self heals’ by recrystallising to resist erosion. But that requires the inclusion of quicklime which may leach excessive minerals like calcium into the water and raise the pH.

However if the water is acidic (low pH) that may help buffer and impurities can be addressed later?

Dorian totally knows about aqueducts, which slow the movement of water to let crud settle out, aerate it, keep it moving to avoid stagnation.

However the lead levels in Roman aqueducts were so incredibly high compared with non-aqueduct water. Maybe it doesn’t matter if you’re a demon or dead but it’s not good. Perhaps this explains Dorian’s emotionality and mood swings if this is what he’s doing and can be somewhat affected.

However this contamination was due to lining them with sheets of lead, and as lead was known to be dangerous clay pipes were preferred.

All this stuff is mostly for physical impurities and maybe charcoal removes some of the other chemicals but not all.

Distillation is very energy intensive, time consuming and would be bulky in equipment but Dorian does at least have eternal fire available and space for tanks.

It removes salinity, minerals and heavy metals but not things with lower boiling points than water ie oil, alcohol or petroleum. Boiling and recollecting the condensation was done to seawater by the ancient Greeks. However heating some of the contaminants can create dangerous compounds.

Reverse osmosis is possible with very old tech (pigs bladder in the 1700s) but hard to do on a large scale with a low tech setting and flesh won’t stay usable for long. Frequent replacement, inadequate size or strength, biohazard.

Disinfection is possible with iodine or chlorine (sunlight too but there’s little in Heresy and no electricity for ultraviolet lights unless a generator is made). pH can be fixed by buffer chemicals.

All of this is in the wrong order and has glaring issues but I am trying to apply ancient water purification methods and environmental engineering to Hell!

i saw this at work and blew up so sorry for the late answer.

Imagine if Aeron made beautiful marble sculptures of trees that were hollow in the middle, and the branches funnelled rainwater down the centre through layers of gravel, sand and charcoal. Like the ancient sand filtration columns, cleaning and storing large volumes of water passively.

he probably did. by accident.

Dorian totally knows about aqueducts, which slow the movement of water to let crud settle out, aerate it, keep it moving to avoid stagnation. However the lead levels in Roman aqueducts were so incredibly high compared with non-aqueduct water. Maybe it doesn’t matter if you’re a demon or dead but it’s not good. Perhaps this explains Dorian’s emotionality and mood swings if this is what he’s doing and can be somewhat affected. However this contamination was due to lining them with sheets of lead, and as lead was known to be dangerous clay pipes were preferred.

you know this guy is lead poisoned. maybe that's why his hair is falling out and isn't as poofy as it was once before. and why he can't ejaculate? that's a joke.

maybe what the church is made out of does not matter. maybe it resists damage. is made of something that looks like marble but is not. he doesn't remember how it got there. but he remembers...making it?

i know he makes noise complaints to the city of dis, because despite it being usually quiet, he does hear it sometimes, very late in the "night."

but hell has no day, has no night, it has eternity.

2 notes

·

View notes

Text

The Role of Water Treatment Plant in Public Health and Environmental Sustainability

Introduction

Water is a fundamental resource essential for human health, agriculture, industry, and ecosystem stability. However, access to clean and safe water remains a significant challenge due to pollution, industrial waste, and population growth. Water treatment plant play a crucial role in addressing this issue by treating raw water and ensuring it is safe for human use and environmental sustainability. In this article, we explore the impact of water treatment plant on public health, their role in protecting the environment, and how they contribute to sustainable water resource management.

The Importance of Water Treatment Plant for Public Health

Untreated water can harbor a variety of pathogens, including bacteria, viruses, and parasites, which pose serious health risks when ingested. Water treatment plant are designed to remove these contaminants, ensuring that communities have access to safe drinking water. By addressing both microbial and chemical contaminants, water treatment plant help to reduce the incidence of waterborne diseases such as cholera, typhoid, and dysentery.

Preventing Disease Spread: Waterborne diseases are a global public health concern, especially in areas lacking adequate water treatment infrastructure. By filtering and disinfecting water, water treatment plant act as a primary defense against the spread of these diseases, significantly lowering mortality rates and healthcare costs.

Addressing Emerging Contaminants: The increase in industrial pollutants and pharmaceuticals in water sources has led to the emergence of new contaminants that are challenging to remove. Advanced water treatment plant are increasingly adopting processes like activated carbon adsorption and advanced oxidation to remove these pollutants, ensuring safer water for communities.

Improving Quality of Life: Access to clean water is closely linked to improved quality of life and well-being. Clean water reduces healthcare costs, promotes child development, and supports economic activities by maintaining a healthier workforce. Water treatment plant thus play a fundamental role in elevating the quality of life within communities.

Components and Processes of a Water Treatment Plant

A typical water treatment plant incorporates several processes to ensure thorough purification of water. Each stage targets specific types of contaminants, allowing for efficient removal and consistent water quality.

Coagulation and Flocculation: These initial stages involve adding chemicals that cause particles in the water to stick together, forming larger clumps, or flocs. These clumps make it easier to remove contaminants in the following stages.

Sedimentation: The flocs formed during coagulation settle to the bottom of the tank in the sedimentation phase, leaving clearer water on top. This process helps to separate solids from the water before filtration.

Filtration: Water passes through various filters, typically consisting of sand, gravel, and activated carbon layers, to remove any remaining particles. Filtration is highly effective in trapping pathogens and other contaminants, making the water suitable for further disinfection.

Disinfection: The final stage in most water treatment plant involves disinfection, where chemicals like chlorine or alternative methods, such as ultraviolet (UV) light, are used to kill any remaining pathogens. This ensures that the water is safe for consumption when it reaches consumers.

Environmental Benefits of Water Treatment Plant

Water treatment plant not only ensure safe drinking water but also play a significant role in environmental protection. By treating wastewater before it re-enters natural water bodies, these facilities help prevent pollution, preserve aquatic ecosystems, and contribute to sustainable resource management.

Preventing Water Pollution: Wastewater from industrial and agricultural sources contains pollutants that can harm natural ecosystems if released untreated. Water treatment plant help by removing contaminants such as heavy metals, chemicals, and organic waste, ensuring cleaner rivers, lakes, and oceans.

Maintaining Ecosystem Health: Aquatic ecosystems are sensitive to changes in water quality. Excessive nutrients, pesticides, and toxins in water bodies can disrupt these ecosystems, harming fish and other aquatic species. By removing these pollutants, water treatment plant help maintain biodiversity and the ecological balance of these habitats.

Reducing Water Scarcity through Reuse: Water treatment plant are now increasingly designed to recycle water, reducing the demand for freshwater sources. Treated wastewater is often reused for irrigation, industrial processes, and even groundwater recharge, contributing to water conservation and reducing stress on natural water sources.

Advancements in Water Treatment Technologies

The challenges faced by modern water treatment plant have spurred significant technological advancements, enhancing their efficiency and environmental impact. Some of the key technologies that are transforming water treatment include:

Membrane Filtration: Membrane technologies, such as ultrafiltration and reverse osmosis, are highly effective in removing contaminants, including dissolved salts, pathogens, and chemicals. Membrane filtration is especially useful for treating brackish water or wastewater for reuse, making it a valuable addition to any modern water treatment plant.

Advanced Oxidation Processes (AOPs): AOPs use chemical reactions, often involving ozone or hydrogen peroxide, to break down organic pollutants that traditional methods cannot remove. This technology is ideal for treating industrial wastewater, where pollutants are more complex.

Artificial Intelligence (AI) and Machine Learning: AI and machine learning have started to impact water treatment by helping operators monitor and optimize processes in real-time. Predictive models can help in adjusting chemical dosages, improving energy efficiency, and predicting equipment maintenance needs.

Smart Sensors and IoT: Internet of Things (IoT) devices and smart sensors provide real-time monitoring of water quality parameters, such as pH, turbidity, and contaminant levels. These technologies allow water treatment plant to respond quickly to changes in water quality, ensuring the highest safety standards for consumers.

Sustainable Practices in Water Treatment Plant

To address the environmental footprint of their operations, water treatment plant are increasingly adopting sustainable practices. These efforts not only reduce costs but also contribute to overall environmental sustainability and resource conservation.

Energy Efficiency: Treating water is an energy-intensive process, making energy efficiency a key focus. Many water treatment plant have integrated renewable energy sources, such as solar panels or wind turbines, to lower their carbon footprint and reduce dependence on fossil fuels.

Water Recycling and Reuse: Water recycling helps reduce demand on natural water sources. Treated wastewater can be reused for agriculture, industrial applications, or recharging groundwater. This practice is especially important in arid regions where water scarcity is a concern.

Nutrient and Resource Recovery: Sludge, a byproduct of water treatment, can be processed to recover valuable nutrients like nitrogen and phosphorus, which can be used in agriculture. Some water treatment plant also generate biogas from sludge, providing a renewable energy source and offsetting operational energy costs.

Reduced Chemical Use: Many water treatment plant are exploring natural alternatives to reduce the use of chemicals. Techniques like electrochemical treatment and natural filtration with biofilters help minimize chemical dependency, reducing the environmental impact of chemical disposal.

Case Studies: Successful Sustainable Water Treatment Plant

NEWater in Singapore: Singapore’s national water recycling program, known as NEWater, is a highly successful example of water recycling. It uses advanced membrane technology to treat and purify wastewater to a level suitable for potable reuse, reducing Singapore’s reliance on imported water.

East Bay Municipal Utility District (EBMUD) in California: The EBMUD water treatment plant uses anaerobic digestion to generate biogas from sludge. This not only provides a renewable energy source but also significantly reduces the volume of sludge waste, showcasing an innovative approach to sustainable waste management.

AQUAVIVA in Italy: AQUAVIVA, a water treatment plant in Italy, uses solar panels and wind turbines to generate 100% of its operational energy needs, making it one of the first energy-positive water treatment plant. This facility has set a benchmark for energy efficiency and sustainable practices.

Conclusion

Water treatment plant are essential for providing safe drinking water, protecting public health, and sustaining the environment. With advancements in technology and a growing focus on sustainability, these facilities are becoming more efficient and eco-friendly. From preventing pollution and safeguarding ecosystems to implementing sustainable practices like water recycling and resource recovery, water treatment plant play a vital role in building a sustainable future. By continuing to adopt innovative technologies and sustainable methods, water treatment plant will remain indispensable in meeting the water needs of communities worldwide while minimizing their environmental impact.

4o

0 notes

Text

Understanding the Role of Questoll Chemical in Water Treatment Solutions

Water is an essential resource that touches every aspect of our daily lives, from drinking and cooking to cleaning and industry. With the increasing need for clean and safe water, water treatment solutions have become more important than ever. This is where Questoll Chemical plays a crucial role. But what exactly is Questoll Chemical, and how does it contribute to keeping our water clean and safe? Let's explore its role in water treatment in simple, easy-to-understand terms.

What is Questoll Chemical?

Questoll Chemical is a key component used in water treatment processes to help purify and improve water quality. In essence, it helps remove harmful contaminants, making the water safer for both people and the environment. These chemicals are designed to target various types of impurities found in water, whether it’s for drinking water, wastewater, or industrial use.

How Does Questoll Chemical Work in Water Treatment?

Questoll Chemical is formulated to perform various functions in the water treatment process. Here are some of the key roles it plays:

Coagulation and Flocculation: One of the primary functions of Questoll Chemical is to help in the coagulation and flocculation process. In simple terms, this means it helps small particles in the water stick together, forming larger clumps (flocs) that can be easily removed. These flocs often consist of dirt, bacteria, and other impurities. Once formed, they can be filtered or settled out of the water, leaving behind cleaner water.

Scale and Corrosion Control: Questoll Chemical is also used to prevent scale buildup and corrosion in pipes and water systems. Scale refers to the accumulation of minerals, which can cause blockages and reduce the efficiency of water systems. Corrosion, on the other hand, can lead to leaks and damage over time. By using Questoll Chemical, industries can protect their equipment and infrastructure, ensuring smooth operations and reduced maintenance costs.

Disinfection: In many water treatment processes, Questoll Chemical helps disinfect the water by eliminating harmful microorganisms such as bacteria and viruses. This is particularly important for drinking water, ensuring that the water that reaches our homes is free from disease-causing pathogens.

pH Control: Questoll Chemical can also be used to adjust the pH levels of water. pH is a measure of how acidic or alkaline the water is. Maintaining the correct pH balance is essential for both the efficiency of the treatment process and the safety of the water for consumption or industrial use.

Questoll Chemical: Supporting Sustainable Water Solutions

One of the great benefits of using Questoll Chemical in water treatment is its contribution to sustainable water management. By improving the efficiency of water treatment processes and reducing the need for excessive water consumption, it helps conserve this precious resource. Furthermore, it allows industries to recycle and reuse water more effectively, minimising waste and environmental impact.

Conclusion

Questoll Chemical plays a significant role in water treatment, helping to remove impurities, prevent scale and corrosion, and support sustainable practices. Doing so ensures that water is not only safe for consumption but also available for various other essential uses. As we look toward the future, Questoll Chemical will undoubtedly remain a key player in water treatment solutions, contributing to a cleaner and healthier planet.

0 notes