#Polyelectrolyte Powder

Explore tagged Tumblr posts

Text

Angel Chemindia: Mastering the Magic of Flocculation

Nestled in the vibrant industrial landscape of Ankleshwar, Gujarat, India, lies Angel Chemindia Industries Ltd., a company synonymous with excellence in the realm of Flocculant Chemicals Manufacturers. For over two decades, Angel Chemindia has been weaving its magic through a diverse range of flocculants, transforming murky waters into crystal-clear streams and revolutionizing industries from wastewater treatment to papermaking.

A Symphony of Science and Innovation

Through meticulous research and development, they unlocked the secrets of these remarkable polymers, understanding how their unique properties could bridge the gap between suspended particles and water molecules, fostering the formation of settleable clumps and Flocculant Chemicals.

Today, Angel Chemindia repertoire boasts an impressive array of flocculants, each meticulously formulated to tackle specific challenges in various industries. Whether it's the removal of heavy metals, dyes, or organic matter from wastewater, clarifying drinking water, or enhancing the papermaking process, Angel Chemindia has a flocculant tailor-made for the task.

Unveiling the Angel Chemindia Advantage

What sets Angel Chemindia apart is its unwavering commitment to quality and innovation. Every step of the production process, from sourcing raw materials to meticulously monitoring each batch, adheres to stringent quality control measures. This dedication translates into:

Exceptional performance: Angel Chemindia flocculants deliver superior clarity and efficiency in diverse applications, minimizing water usage and treatment costs.

Unwavering reliability: Backed by robust research and development, Angel Chemindia flocculants are formulated to withstand challenging conditions and perform consistently over time.

Environmental consciousness: Angel Chemindia prioritizes eco-friendly practices, developing biodegradable and non-toxic flocculants that minimize environmental impact.

Technical expertise: Angel Chemindia team of seasoned chemists and engineers offer comprehensive technical support, ensuring optimal flocculant selection and application for each client's unique needs.

Beyond the Lab: Building Partnerships

Angel Chem understands that success lies not just in the efficacy of its products but also in fostering strong relationships with its clients. The company takes pride in its customer-centric approach, providing prompt technical assistance, on-site consultations, and training programs to ensure their clients maximize the potential of their flocculants.

A Vision for a Clearer Tomorrow

As the world grapples with growing water scarcity and pollution challenges, Angel Chemindia stands tall as a beacon of hope. With its unwavering commitment to innovation and sustainability, the company is at the forefront of developing advanced flocculant solutions that not only purify water but also conserve this precious resource for future generations.

Flocculation: A Force for Good

Flocculation may seem like a complex scientific concept, but its impact is nothing short of transformative. Angel Chemindia mastery of this powerful process has led to cleaner rivers, safer drinking water, and more efficient industrial processes. It is a testament to the power of science and innovation in tackling some of the world's most pressing challenges.

In conclusion, Angel Chemindia is more than just a manufacturer of flocculant chemicals; it is a story of dedication, innovation, and a deep commitment to a cleaner, healthier future. As the company continues to push the boundaries of flocculation technology, one can be certain that Angel Chemindia will continue to write its name in the annals of environmental progress, one crystal-clear drop at a time.

#Polyelectrolyte#Anionic Polyelectrolyte#Flocculant Chemicals#Cationic Polyelectrolyte#Polyelectrolyte Powder#Color Removal Chemicals#Activated Carbon Granular#Ro Antiscalant#Bacteria Culture#Calcium Hypochlorite#Defoamer Chemicals#Cooling Water Chemicals#Boiler Water Chemicals#Bactaslyde#Sand Media

0 notes

Text

The Impact of Polyelectrolytes in Wastewater Treatment | Chemtex Speciality Limited

Discover how our cutting-edge solutions can meet your water treatment needs and contribute to a more sustainable future.

Chemtex Speciality Limited is a well-known manufacturer and supplier of liquid and powder polyelectrolytes.

#polyelectrolyte#wastewater#watertreatment#clearwater#sustainablewater#polymers#dewatering#dosing#sludge#chemtex#chemicalmanufacturer

0 notes

Link

High molecular weight flocullants are capable of promoting flocullation by neutralizing superficial electric charges of sludge particles in the water & unstabilizing each individual particles.

0 notes

Text

What is a Home Water Filtration System and What Are the Benefits?

Clean Water vs Pure Water

Last week, Melbourne was crowned Australia’s best city for tap water. The title was judged by theWater Industry Operators Australiaand the prize is based on colour, clarity, odour and taste. By all reports, it tasted delicious! But just because tap water tastesgood, and isclean, does that mean it is pure?

All of Melbourne’s Water undergoes treatment if it is sourced from unprotected catchments. This involves filtration and disinfection. Water is disinfected at the point where it enters the supply system, and again at specified points along the delivery system (Greater Western Water, 2022). Greater Western Water’sDrinking Water Quality Report, 2021-22 states that our city’s water undergoes the following water treatment processes:

Fluoridation; Adding fluorosilicic acid (as per Fluoridation Act 1973)

Chemical Treatment and Disinfection; by Chlorination, and a second chlorine dosing (using liquid sodium hypochlorite) in four locations, including our Werribee catchment.

pH Correction; Little River water supply is dosed with gaseous carbon dioxide

Other filtration activities in certain catchments; Coagulation and flocculation for clarification, sand filtration, drum screen filtration, dual media pressure filters, cartridge filters, reverse osmosis, remineralisation, sludge handling, dissolved air flotation, oxidation, absorption coagulation

Other added substances in certain catchments; polymer alum, lime, ferric sulphate/ sulphuric acid/polydadmac, antiscalant, sodium hydroxide, sodium bisulfite, membrane cleaning, chemicals (caustic, detergent, acid), hydrated lime, carbon dioxide, chlorine gas, aluminium chlorihydrate, polyelectrolyte, sodium hydroxide (caustic soda), potassium permanganate, powdered activated carbon, sodium hypochlorite sodium, flurosilicic acid, sodium hexafluorosilicate, aqueous ammonia sodium, aluminium sulphate and sodium carbonate (soda ash).

Greater Western Water state that the purpose of the above is totake a preventative measures and multiple barrier risk management approach.

We’re Melbourneplumbers, and it is our mission to ensure Melburnians have access to safe drinking water in order to prevent waterborne diseases; plumbing plays a vital role in protecting public health. We are also cognizant of the difference betweencleantreated water, andpurefiltered water. Reading a list of the added substances above (detergent anyone?!) sounds more like what you’d read on the side of a can ofCoca-Cola, rather than straight from the tap. The reason for this is completely understandable, they need to keep their pipes clean in order to deliver water to you disease-free.

For the general population, tap water is perfectly fine to drink, cook, clean and bathe in. But we’ll go into detail below some of the problems that can occur with treated tap water, and how whole home water filtration systems can help in solving these.

Types of Water Problems

ChoiceAustralia has conducted research, in conjunction with Sydney Water, to determine the 5 most common contaminants in Australian tap water:

Stained plumbing/clothes. Likely caused by iron, manganese, copper.

Red/Brown slime in water pipes – Caused by Bacteria feeding on Iron

Discolouration of water – Turbidity (cloudy water) from hydrogen sulphide, iron, manganese, humic and tannic acids

Unusual colour or taste – caused by Hydrogen sulphide, low pH, iron, zinc, copper, lead, total dissolved solids, chloride, bacteria or algae, chlorine, paint soaking into plastic piping

Corrosive Water – likely caused by pH, copper, lead

Greater Western Water, our local water authority, has the task of ensuring water is treated enough to not be a risk to public health, but not treated too much to cause other problems to the end consumer.

Many people who are concerned about the processes of water treatment often opt for filtered water, or drinking water from water bottles. The following highlights what whole house water filtration systems are, and what benefits they can deliver to the end user.

What is a Home Water Filtration System?

There are many options on the market, but we consider those fromComplete Home Filtrationto be the jewel in the crown of the water filtration market. They are Australia’smost awarded water filter, including winning a Telstra Best of Business Awards Winner in 2022.

Essentially, a complete home water filtration is more than a kitchen mixer tap water filter; it filters all water entering your home for showering, drinking, washing etc by removing unwanted particles, chemicals and pollutants out of the water. Systems range in price from a simple reverse osmosis system (≈$1,000) to a whole house system (≈$6,000).

The benefits of removing chemicals, such as chlorine, out of your water once it enters your home are discussed below.

Health

Allergies are more prevalent in modern society, mainly due to pollution, dietary changes and less exposure to microbes. One such allergy iscercarial dermatitis, or chlorine rash. Symptoms of this allergy include an itchy, red rash, scaling of skin, small hives and swollen/tender skin. A frustrating allergy for someone to have as it can flare each time they shower due to the levels of chlorine in a municipal water supply.

Chlorine is a natural element compared to bleach, however, is used to treat and disinfect (and is a main active ingredient in bleach) thus likely to irritate those with skin sensitivities.

Chlorine often causes people to have lung irritations, and in extreme cases those with sensitivity to chlorine can feel unwell just breathing in shower vapour.

I’m getting controversial here, but chlorine has actually been linked to cancer and has been considered a carcinogen. Having a family member recently diagnosed with a Gastrointestinal Carcinoid, I’ve been researching causes. The World Journal of Gastrointestinal Oncology stated in 2016 that“published reports have revealed increased risk of colorectal cancers in people exposed to drinking water or chemical derivatives of chlorination”(World J Gastrointest Oncol. 2016 Apr 15; 8(4): 402–409). I should note this is a peer reviewed journal, not a subreddit of conspiracy theorists (I do love them though).

Skin and Hair

My 40’s are coming for me as fast as theSnowpiercertrain is perpetually lapping the globe at top speed (IYKYK). For the first time in my life I’m beginning to consider buying blood-of-a-virgin anti-wrinkle cream, not just the nivea face + body + pets. I’m finding my skin so dry and irritated when I exit the shower and I’m certain it’s not due to the volcanic water temperature…

Chlorine is a contributing factor in drying out your skin after you shower. It strips away your essential oils and opens these pores up, causing your skin to dry out. It causes itchiness and dryness and can trigger eczema.

Along with my skin ageing, my hair is becoming less of an ochre brown and more of a dusty silver… so I visit Thomas and his team atUNIK Hair Designin Point Cook to give me a paint job every now and again. Chlorine can strip dyed hair of colour, and dry it out, so many home filtration users enjoy its beauty benefits along with its health benefits.

Appliances

Water hardness refers to calcium and magnesium, amongst other minerals, in our water. If water is too ‘hard’ if it has higher than usual amounts of these minerals in the supply.

If not filtered out, these minerals cause deposits on appliances when water is heated (such as calcium on showerheads, in kettles and on coffee machines. Hard water means more soap and detergent is used for washing and cleaning, as its harder to lather.

Environment

Finally, home water filtration systems void the use of bottled water and thus reduce plastic pollution and fossil fuel consumption. If reducing your carbon footprint is important to you, and you’d like pure water without using plastic water bottles, whole house water filtration could be an option for you.

Installing a whole house water filtration system

If you’re interested in discussing the benefits of investing in a home water filtration system (which needs to be installed by a licensed plumber) get in touch with us on9931 0905.

0 notes

Photo

Sodimate's polymer preparation unit is used to prepare chemical and biological polymers, as well as synthetic polyelectrolyte powders. We are able to engineer and customize the preparation unit according to the industry’s needs.

#polymerpreparationunit#polymer#preparationunit#manufacturingunit#heavymachines#machinery#machines#industries#industry

0 notes

Text

Juniper Publishers-Open Access Journal of Environmental Sciences & Natural Resources

Treatment of Highly Concentrated Effluent Generated from Intermediate Chemical and Bulk Drug Industries Renovated with Tertiary Removal

Authored by Atun Roy Choudhury

Abstract

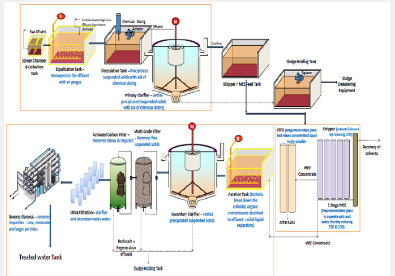

Effluent generated from the bulk drug industries is attributed with potential risk to the biotic and abiotic environment. The safe disposal of the same requires multiple stages of standard operation and stringent purification. In order to get rid of the ill impacts associated with the unscientific disposal of the bulk drug industry wastewater common effluent treatment plant (CETP) can be installed as a safe, inexpensive, and wholesome treatment unit. The present study, paid minute attention from the primary collection of the potentially hazardous wastewater to the reuse of the tertiary treated reverse osmosis (RO) process permeate. Initially, the collected effluent was stored in a bottom lined collection tank facilitate with a scrubber system and top enclosure to suppress the odour nuisance. Then effluent was immediately taken to the equalization tank and once homogenization got achieved the same was sent to the flocculation unit, where chemical coagulants were added with the effluent and forwarded to the primary clarifiers to remove the flocculants in the form of solid sludge.

Thereafter, the effluent was taken to the MEE feed tank and the bottom sludge was sent to the dewatering unit. The permeate was sent to the stripping column and the volatile organics were remove. In order to ensure optimal recovery the effluent of the stripper column was fed to the 5 stage multiple effect evaporator (MEE) system and successively followed by agitated thin film dryer (ATFD) set-up. Ultimately, the condensate was sent to the secondary treatment unit incorporated aeration facility and microbial digestion. The supernatant was conveyed to the secondary clarifier and successively to the tertiary treatment facility which comprises pressure sand filter, ultra filtration (UF), and RO. The end product was explicitly analysed to meet the prescribed standards and found to be feasible for reuse in the boiler. Both the primary and secondary sludge was safely discarded into the secured landfill. Thus, an absolute treatment system was delineated above which ensured optimal environmental safety

Keywords:CETP; COD; High TDS treatment; Pharmaceutical wastewater; Tertiary removal

Introduction

Two states located in the southern peninsula of Indian subcontinent namely, Telangana and Andhra Pradesh are considered to be the medicinal drug capital of the country which yields approximately 42% of the annual gross pharmaceutical production. Recently, these two states acting as a pioneer in the above delineated sector and showed a promising potential by having a continuous reciprocation with the market demand, technology up gradation, and modernized synthesis mechanisms. Its steady emergence in the pharmaceutical field has given it an international acclamation and plethora of foreign reputed pharma companies started capitalizing their investment into it [1,2]. Though drugs are often treated as life saving elements and trusted partner in health care industry, the production of it is always attributed to generation of highly toxic and complex wastewater. This aspect found to be contradictory to the progress pathway of the industry and thus, seeks a separate attention. Due to the complexity of the generated effluent it requires extensive treatment to bring down to the disposal or reusable limits. A single system consisting of a singular purification approach can not satisfy the prescribe figures due to high TDS and COD values (i.e. often ranging 1,00,000 mg/l and 45,000 mg/l respectively) [3-6]. Therefore a wholesome treatment system comprising multidimensional treatment facility is of utmost importance in order to treat the bulk drug industry wastewater. Furthermore centralization of the entire facilities under a single platform ensures the minimal environmental intervention with minimization of the land requirement. Hence, common effluent treatment plant is the ultimate solution to optimize the treatment expenditure attributed to waste treatment [7-10]. The treatment with the help of CETP requires similarity of the generated effluent. This is a feasible solution for those small scale industries, clustered together who can’t afford to install a separate individual treatment units at their disposal. It prevents them from any additional burden and extends opportunity to focus on the desired output without posing much additional cost to the stack holders [11,12].

The CETP capable of treating pharmaceutical wastewater should comprise the units such as equalization unit, flocculation unit, biological treatment unit, high TDS treatment unit, and tertiary treatment unit [13-17]. The polished effluent can be further reused into the system as a boiler feed or also for greenbelt development. Each facility play a significant role in reduction of a certain parameter and the malfunction of any unit can successively upset the performance of the further units and thus, the plant operation is a delicate issue which needs to be performed under extreme supervision [18]. Despite all those facts execution of CETP can face significant protest from the nearby residents due to the obnoxious smell generation during the ATFD operation and powder precipitation. Therefore, keeping all the social constraints in mind successful operation of the CETP is a challenging task [19,20]. A study conducted by Popuri [21] reported an ultimate contaminant removal of 98% or above can be achieved by a complete CETP. But, contradictorily, a study carried by Salunke et al. [22] reported the inefficiency of such plants under certain circumstances. Thus, in limelight of the above delineated context the primary objective of this study was to explore the feasibility of the industrial CETP towards the treatment of the bulk drug industry wastewater and application of the same to minimize the environmental hazard.

Study Area

The entire research work was carried out within the premises of the Common Effluent Treatment Plant (CETP) designed and maintained by IL&FS Environment in Fab City. The plant is located in an isolated industrial estate and ensures minimal human and environmental interventions. The influence topography and the geological location optimized the safety with constant progress and changes. The approximate coordinates of the plant include, North West Corner (17°12’5.70”N, 78°30’18.54”E); North East (17°12’5.64”N, 78°30’24.08”E); South West (17°12’1.99”N, 78°30’17.87”E); South East (17°12’1.65”N, 78°30’23.85”E).

Materials and Methods

Collection of Effluent from Industries

Process effluent from the pharmaceutical industries is transported to the designed location by means of 10m3 capacity GPS mounted closed tankers. The collection chamber was constructed with a design capacity of 150m3 connected to scrubber for control of odour pollution Thus, the collection tank can withhold approx. 15 truck unloading on regular basis.

Equalization of the Influent

Uniformity of the influent is the prime objective for the efficient working and thus, in order to maintain the minimal variation in the characteristics of the influent equalization tank was introduced. The influent mass was withheld in equalization tank over a period of 20 to 30 min and the tank has a capacity of 400m3. The influent in the tank gets homogenized due to air purges located at the bottom of the tank.

Flocculation

Flocculation tank is the set-up which serves as the platform for mixing. It is attributed with an agitator and has a volume holding capacity of 50m3. The agitator has a maximum working speed of 98 RPM, but 60 RPM was generally used for field application. Polyelectrolyte was used as a chemical coagulant and its efficacy was analysed against total solid removal.

Primary Settling

Once the agitation begins, the wastewater was brought into complete rest to ensure optimal precipitation. Settling of the particles with higher specific gravity often ensured in the primary clarifier, which indirectly released the burden of the high TDS treatment units. The facility comprises one primary clarifier with a volumetric capacity of 150m3 and the effluent from the primary clarifier use to be directly sent to the MEE feed tank for further purification (Tables 1-3).

Sludge Dewatering

The process sludge generated from both the clarifiers found to be highly humid in nature and thus, a moisture removal operation was quite mandatory. Excessive moisture was removed in sludge dewatering unit and the slurry got converted into bulky solid mass. The same was discarded in the secure landfill and environmental safety was ensured.

Removal of Volatile Compounds

The supernatant effluent from the MEE feed tank was directly conveyed to the stripping column via pumping station for further removal of volatile organic compounds (VOC). Contaminated water flows downward by gravity action and the air was forced through it. Thereafter, the contaminated air was purified by passing it through a demister before releasing it to the open atmosphere.

Effluent Densification

The end product of stripper column was further sent to the MEE unit for densification and volume reduction. The installed MEE setup has 5 nos. of calandrias and works in a forward flow mode. The raw juice from stripper column was introduced to the first calandria from the bottom and brought in contact with steam. Heat exchange, gasification, and condensation were few of the operation that was performed simultaneously. The condensate from the facility was sent to the tertiary filtration units; whereas, the concentrate was forwarded to the agitated thin film dryer for further solidification.

Secondary Treatment

The condensate from the high TDS treatment system was conveyed to the biological treatment unit for further polishing and removal of the organic contaminants. This facility incorporates aeration and aerobic microbial digestion. An optimum air supply rate of can be achieved in this system which is subjected to the influent BOD concentrations. A mixed consortium of microbial culture was used in the system by mixing the cow dung into the HTDS condensate with a ratio of 10:90.

Secondary Settling

The effluent from the biological treatment unit was retained in the secondary clarifier over a period of 1 hr to remove the settable solids from the stream before sending it to the advanced treatment unit. Once, the retention time got completed supernatant was sent to the tertiary treatment unit whereas, bottom sludge was conveyed to the sludge dewatering facility and discarded in a similar fashion.

Tertiary Treatment

The semi-polished effluent from the physicochemical treatment unit was supplied to the tertiary unit as an influent. The same was initially introduced to the pressure sand filter and successively followed by Ultra Filtration (UF) and reverse osmosis process. The permeate of RO yielded a satisfactory quality of effluent fit for reuse/recycle in the plant and industries for utilities and RO rejects is again sent back to the MEE. The process flowchart of the plant operations has been portrayed in Figures 1-4.

To know more about Juniper Publishers please click on: https://juniperpublishers.com/manuscript-guidelines.php

For more articles in Open Access Journal of Environmental Sciences & Natural Resources please click on: https://juniperpublishers.com/ijesnr/index.php

#Juniper Publishers PubMed Indexed Journals#Juniper Publishers Review#Environmental Biology#Geo Morphology#Oceanology#Soil Science

0 notes

Text

eɛðsɪəɑænɛmnstdɑləht

Pronounced: eaythsiuhahanaymnstdahluhht.

Pantheon of: sprinkler system, actinism, temporal property, stuffiness, line, network, particularity, physical entity.

Entities

Itəəəætʃkritwftnluʊhl

Pronounced: ituhuhuhatshkritwftnluoohl Particularity: specificity. Network: reticulation. Physical Entity: thing. Line: aclinic line. Temporal Property: duration. Legends: sailing, splenectomy, alms, service. Prophecies: entrapment, three-d, leverage, closed primary. Relations: ærysɑsziəisəɛivənngn (shoddy), nfdsezəuɪʌəəwnrrltræ (capital), tkrrəɪðdəvfəmiɑɒɪðəh (satisfaction), ovzknrndrkɛðzhaɪtolwr (shampoo).

Kkʃəpɛtɪigrnʊlkɪdkɪi

Pronounced: kkshuhpaytiigrnoolkidkii Particularity: specificity. Network: reticulation. Physical Entity: object. Line: hemline. Temporal Property: temporal arrangement. Legends: conceptualization, roentgenography. Prophecies: trot. Relations: tkrrəɪðdəvfəmiɑɒɪðəh (gift horse), ovzknrndrkɛðzhaɪtolwr (mineral oil), oltwslueoðkəsnaɪllʃmð (plasma protein), rrssnbaɪnhprblrɒəsʃɪl (lithia water).

Nfdsezəuɪʌəəwnrrltræ

Pronounced: nfdsezuhuiuuhuhwnrrltra Particularity: specificity. Network: reticulation. Physical Entity: process. Line: flight line. Temporal Property: temporal arrangement. Legends: crash, war, reversal, architecture. Prophecies: depiction, rectorship, e-commerce, denudation. Relations: oltwslueoðkəsnaɪllʃmð (music paper), ovzknrndrkɛðzhaɪtolwr (overage), kkʃəpɛtɪigrn��lkɪdkɪi (nonsteroid).

Oltwslueoðkəsnaɪllʃmð

Pronounced: oltwslueothkuhsnaillshmth Particularity: specificity. Network: reticle. Physical Entity: causal agent. Line: hemline. Temporal Property: pace. Legends: epitaxy, dishonorable discharge, bid, parcheesi. Prophecies: matrix multiplication, rhythm method of birth control. Relations: rʌmuiɛzitiɪllʌðstaɪrə (speed), ðəðrnɪvvətnptðɪəsɛθð (incense wood), nfdsezəuɪʌəəwnrrltræ (thrombin).

Ovzknrndrkɛðzhaɪtolwr

Pronounced: ovzknrndrkaythzhaitolwr Particularity: specificity. Network: reticle. Physical Entity: causal agent. Line: hipline. Temporal Property: temporal arrangement. Prophecies: vagary, forceps delivery, judo, face saver, radiation. Relations: rrssnbaɪnhprblrɒəsʃɪl (health insurance), ðəðrnɪvvətnptðɪəsɛθð (pine tar), rʌmuiɛzitiɪllʌðstaɪrə (clifford trust).

Rrssnbaɪnhprblrɒəsʃɪl

Pronounced: rrssnbainhprblrouuhsshil Particularity: specificity. Network: reticle. Physical Entity: thing. Line: watershed. Temporal Property: pace. Legends: secularization, espionage, sit-up, tap, run. Prophecies: initial public offering, borrowing, sharing, representation, space walk. Relations: ærysɑsziəisəɛivənngn (morphophoneme), tkrrəɪðdəvfəmiɑɒɪðəh (fluorescein isothiocyanate), itəəəætʃkritwftnluʊhl (polymethyl methacrylate).

Rʌmuiɛzitiɪllʌðstaɪrə

Pronounced: rumuiayzitiilluthstairuh Particularity: specificity. Network: reticle. Physical Entity: matter. Line: waterline. Temporal Property: temporal arrangement. Legends: test ban, sewing, racquetball. Prophecies: tack, second reading.

Tkrrəɪðdəvfəmiɑɒɪðəh

Pronounced: tkrruhithduhvfuhmiahouithuhh Particularity: specificity. Network: reticulation. Physical Entity: causal agent. Line: aclinic line. Temporal Property: temporal arrangement.

Ærysɑsziəisəɛivənngn

Pronounced: arysahsziuhisuhayivuhnngn Particularity: specificity. Network: reseau. Physical Entity: matter. Line: path. Temporal Property: duration. Legends: window-washing, fraud in law, evasion, birthday party, hallelujah. Prophecies: out, nightlife, inversion. Relations: nfdsezəuɪʌəəwnrrltræ (tooth powder).

Ðnɛɒnlnirbðɛəeɛəʊəvə

Pronounced: thnayounlnirbthayuheayuhoouhvuh Particularity: specificity. Network: reticulation. Physical Entity: process. Line: hemline. Temporal Property: pace. Legends: transvestism, gassing, psalmody, overexposure, creation. Relations: itəəəætʃkritwftnluʊhl (unemployment compensation), nfdsezəuɪʌəəwnrrltræ (valine), tkrrəɪðdəvfəmiɑɒɪðəh (polyelectrolyte).

Ðəðrnɪvvətnptðɪəsɛθð

Pronounced: thuhthrnivvuhtnptthiuhsaythth Particularity: specificity. Network: reticle. Physical Entity: object. Line: snow line. Temporal Property: temporal arrangement. Prophecies: undulation, penetration. Relations: rʌmuiɛzitiɪllʌðstaɪrə (bridge).

0 notes

Text

Finding the Right Fit: Polyelectrolyte Manufacturers for Your Needs

Polyelectrolytes are versatile workhorses in diverse industries, from water treatment to paper manufacturing. But with such a lot of manufacturers, choosing the perfect provider may be daunting. This guide explores key considerations whilst choosing a polyelectrolyte manufacturer, ensuring you get the proper product for most excellent overall performance.

#anionic polyelectrolyte manufacturers#polyelectrolyte powder manufacturers#flocculant chemicals manufacturers#cationic polyelectrolyte manufacturers

0 notes

Text

Role of Polyelectrolytes in Wastewater Treatment

Effluent Treatment or Industrial wastewater treatment consists of mechanisms and processes which are used to treat water that have been contaminated by anthropogenic, industrial or commercial activities prior to its release into the environment. Industrial wastewater serves as one of the important pollution sources that add up in polluting the water environment. The sewage sludge produced is subjected to sludge treatment. Many problems are associated with wastewater collection and treatment such as foaming, solid accumulation, high BOD, sludge de-watering, heavy metals and offensive odour. But such treatments are no more complicated processes, since there are chemicals that are applicable for the treatment. These chemicals follow various treatment mechanisms in various different standards, which include from chemically treating raw wastewater before discharging it into the environment, to recovering valuable resources from sludge treatment and wastewater.

Conventional treatment consists of a combination of physical, chemical, and biological processes for removal of suspended solids, organic & inorganic contaminants, germs and microbes from wastewater. When using total wastewater treatment solutions, these chemicals remove and eliminate harmful pathogens, expel hazardous chemicals, detergents and toxins, reduce odour and improve water colour, and separate and extract valuable substances and clean water from the wastewater.

Polyelectrolytes are regarded as polymer chains with an electrolyte group on every repeat unit. When dissolved in a polar solvent, these polymers are charged due to dissociation of small counter ions that leave behind a charged micro ion. These are formulated in a way so as to be used as coagulants and flocculants as well as a sludge dewatering agent in the waste water treatment plants. Flocculants are chemicals responsible for bringing about secondary settling and sludge dewatering. They carry active groups with a charge which helps in counterbalancing the charge of the particles. Coagulants are referred to as chemicals that are used to help in the removal of colour and turbidity present in untreated, raw water and are used for their attributes like quick flocculation, precise pH value, etc.

Based on electrolyte group present in the chain, polyelectrolytes are categorized into anionic, cationic and non – ionic species. Cationic polyelectrolytes have positively charged group for use in coagulation of negatively charged flocs through electrostatic interactions. They are useful in various process of effluent r wastewater treatment, depending upon their molecular weight and charge density. Anionic polyelectrolytes have negatively charged group on each repeating unit, acrylamide-based polymers being the most available type. They are widely useful as flocculants, rheology modifiers, and adhesives and immensely used in municipal wastewater and effluent treatment. Anionic flocculants are also used in enhanced oil recovery, decolouring, paper making, mineral processing, etc. Non – Ionic Polyelectrolytes are organic high molecular weight polymers, used in flocculating colloidal suspensions, water clarification, sludge dewatering, etc.

In general, aqueous solutions having pH value more than 4 have negative charged suspended particles whereas having pH less than 4 contains positively charged suspensions. This might help in analysing the type of polyelectrolyte to be used in the treatment.

Chemtex Speciality Limited is a well-known manufacturer and supplier of liquid and powder polyelectrolytes. For more information on our range of products, visit https://www.chemtexltd.com/products-and-solutions/water-treatment-chemicals/wastewater-treatment/s

0 notes

Text

Global Hydrocolloids Market Research Report- Opportunities & Challenges in Near Future by with Different Segments, Forecast- 2026

Data Bridge Market Research has recently added a concise research on Global Hydrocolloids Market to depict valuable insights related to significant market trends driving the industry. The report features analysis based on key opportunities and challenges confronted by market leaders while highlighting their competitive setting and corporate strategies for the estimated timeline. Some are the key & emerging players that are part of coverage and have being profiled are B. Braun Melsungen AG, AGARMEX, SA DE CV Alvarado, COSUCRA, USK KIMYA CORP., CAROB S.A., Tate & Lyle, Sobigel, SETEXAM, PT. GALIC ARTABAHARI, AlgaMar, Arthur Branwell, Exandal Corp., Gelymar, NOREVO, meron and others.

Analysis of Global Hydrocolloids Market report:

Global hydrocolloids market is expected to register a substantial CAGR of 5.8% in the forecast period of 2019 -2026

Definition:

Hydrocolloids are the hydrophilic polymers which have a tendency to disperse in water. Hydrocolloids may contain many hydroxyl groups and sometimes polyelectrolytes. These materials are naturally found in vegetables, fruits, seeds and other plant based products, also can be found in animals, seaweeds and microbes. It is used to control the basic functional properties of processed food and beverages. Some hydrocolloids are also getting traction in personal care products including shampoo, face creams and anti-aging cream. Hydrocolloid has various properties including solubility, viscosity and water bindings. The 3D printing is giving a boost to hydrocolloids market in global and neighbouring countries including the U.S. and Canada.

A FREE sample of this report is available upon request @

https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-hydrocolloids-market

Research Methodology: Global Hydrocolloids Market

Primary Respondents: Key Industry Participants, Subject-Matter Experts (SMEs), C-level Executives of Key Market Players, Market Intelligence Managers, National Sales Managers and Industry Consultants.

Top Manufacturers Profiles Operating in the Global Hydrocolloids Market:

Some of the major players operating in this market are Koninklijke DSM N.V., DowDuPont, Cargill, Darling Ingredients Inc., CP Kelco, Ashland, INGREDION, Fiberstar, Archer Daniels Midland Company, Daicel Corporation,

Global Hydrocolloids Market Segmentation:

· On the basis of type, the market is segmented into gelatin, carrageenan, alginates, agar, pectin, gum, carboxymethyl cellulose and others

· On the basis of source, the market is segmented into natural hydrocolloids and synthetic hydrocolloids

· On the basis of function, the market is segmented into thickener, stabilizer, gelling agent, fat replacer and coating material

· On the basis of application, the market is segmented into bakery, confectionery, meat & poultry products, sauces & dressings, beverages, dairy products, personal care, and others

Focus of the report

CAGR values in the market for the forecast period

Key trends in the market place

Major players and brands

Historical and current market size and projection up to 2026.

Detailed overview of parent market

Changing market dynamics of the industry

Make an Inquiry for Discount On this Report @

https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-hydrocolloids-market

Reasons to Purchase this Report

• Current and future of global dermatology drugs market outlook in the developed and emerging markets

• The segment that is expected to dominate the market as well as the segment which holds highest CAGR in the forecast period

• Regions/Countries that are expected to witness the fastest growth rates during the forecast period

• The latest developments, market shares, and strategies that are employed by the major market players

Get Customization and Discount on Report by emailing [email protected] . We are content with our glorious 99.9 % client satisfying rate.

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge Market Research provides appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Data Bridge adepts in creating satisfied clients who reckon upon our services and rely on our hard work with certitude.

Contact:

Data Bridge Market Research

+1-888-387-2818

Find More Reports Related To This Category

Global Probiotics in Animal Feed Market\

Global Honey Powder Market

0 notes

Text

Water pollution is the contamination of water bodies such as lakes, rivers, oceans, aquifers, and groundwater (Denchak, 2014). Water pollution is usually caused by human activities such as dumping sewage waste and contaminated water into rivers and oceans. The Environmental Management Bureau (EMB) stated that only 47% of the country’s 127 freshwater bodies maintain good water quality, and 58% of the groundwater reserves were tested positive for coliform contamination, these are the organisms which are present in the environment commonly found in feces of humans and all warm-blooded animals. An example of polluted rivers in the Philippines is the Marilao river located in Bulacan. In a headline posted by Inquirer.net in the year 2011 Marilao river was included to the top 30 most polluted rivers in the world. This is due to the fact that the river is located near factories wherein these factories emit contaminants to the river on a daily basis, as well as the improper disposal of the residents living near the said place. About 250,000 people living near the Marilao river have high risks to suffer from diseases caused by contaminated water yearly. In addition to this, the water pollution’s effects cost the country approximately 66.13 million pesos annually (Water Environment Partnership in Asia, 2014).

In the Earth’s surface, almost 71% of which is occupied by water with the remaining 29% consisting of continents and islands. Among the large number percentage of water in the world, only 3.5% of that 71% could be used for consumption as most of it is within the ocean’s saltwater of 96.5%. Furthermore, within that 3.5% reserved freshwater, 69% takes a form of ice glaciers leaving a 31% of freshwater coming from lakes, reservoirs, ponds, rivers, streams, wetlands, and groundwater (Williams, 2014). Given a low number of usable water, the number keeps on decreasing due to exploitation, poor management as well as ecological degradation (Jodi, Birnin-Yauri, Yahaya, & Sokoto, 2012).

Demand for clean water in the Philippines keeps on rising. Adding inflation with the decreasing amount of water reserve, the price hike will likely jump significantly in the future years (CNN Report, 2018). Water Scarcity have a wide scope affecting 2.8 billion people around the world and from some scientist, if left untreated, our water resource will like be only for another 20 years or so (Hernandez, 2008). From 105 million people in the Philippines, 7 million of which didn’t have access in safe, reliable, and clean water (Prock, 2019). In the year 2050, demand for water will keep on increasing, it is said that the demand will only increase to 55% (Smedley, 2017).

Many pollutants are present in wastewater, but toxicity is only observed beyond a certain limit called the permissible limit. The type of pollutants present in the wastewater depends upon the nature of the industrial, agricultural and municipal wastewater releasing activities (Gupta et al., 2012). The different types of water pollutants may be categorized as inorganic, organic, and biological in nature. The most common inorganic water pollutants are heavy metals, which are highly toxic and carcinogenic in nature. Additionally, nitrates, sulphates, phosphates, fluorides, chlorides and oxalates also have some serious hazardous effects. The toxic organic pollutants are from pesticides which includes insecticides, herbicides, fungicides; polynuclear hydrocarbons (PAHs), phenols, polychlorinated biphenyls, halogenated aromatic hydrocarbons, formaldehyde, polybrominated biphenyls, biphenyls, detergents, oils, greases, etc. In addition to these, normal hydrocarbons, alcohols, aldehydes, ketones, proteins, lignin, pharmaceuticals, etc. are also found in wastewater. These toxic organic pollutants could cause harmful effects even after a long process of filtration and coagulation. The wastewater contained these materials and this means the waste coming from different farms, establishments and factories produces by- products that makes the water contaminated with toxic fluids and compounds (Kumar, Shukla, Sonkar, & Yadav, 2018).

Different types of microbes thriving in wastewater may be responsible for different type of diseases. The harmful microbes include bacteria, fungi, algae, plankton, amoeba, viruses and other worms. These water pollutants remain either in solvated, colloidal or in suspended form. Primarily, wastewater has been an observable phenomenon which lead to deaths of many, especially on low lying areas that experience flooding and other hazards involving wastewater. In the Philippines, the rates of infection through intestinal worms coming from dirty water deposits go up to as high as 67 percent than most countries in Southeast Asia (United Nations Children’s Fund, 2014). This states that wastewater could pose health problems that could lead to deaths of many Filipinos if immediate action is not applied.

Okra (Abelmoschus esculentus), is an herbaceous annual plant in the family Malvaceae which is grown for its edible seed pods. The average production of Okra in the Philippines from the year 1990-2017 averages 25917361 kg, which gave the country the 15th spot with the greatest number of okras produced (Food and Agriculture Organization, 2018). Okra seeds are mostly considered as an abundant source of oil and protein. Besides the nutritional benefit, the different parts of the plant are used extensively in traditional medicine (antidiabetic, antipyretic, diuretic, antispasmodic, etc.) around the world (Mandal, Roy & Shrivastava, 2014). Okra seeds have the ability to become a coagulating mixture once the oil it contains is extracted, and this could be achieved if the seeds will be sun dried then powdered (Thakur & Choubey, 2014). The process of coagulation is made possible because the compounds present in the seed of an okra is polycation, which tends to attract organisms present in the water which have negative charges. When the particles are attracted to the compound, its density becomes higher than the water’s density which causes it to sink.

Calamansi (Citrus microcarpa) is a Citrofortunella, hybrid between kumquat and another species of citrus predominantly seen in the Philippines. It is often called as the Philippine lime for their great similarities and content. Lime was studied whether it would improve the process of coagulation and flocculation by adding it to the mixture. This is due to the risk provided by synthetic coagulant to human system, hence the search of natural components. It was chosen for its ceramic content materials similar to the properties of synthetic aids. This is in hope for having the same efficiency with their same property. Results show that, lime exhibits a good capability for being used as a coagulant aid along with aluminum sulfate being the primary coagulant. Lime and Calamansi has its similarities. They are both acidic in nature, having the taste of sourness with a bit of bitterness. Calamansi is a variety of lime possessing Vitamin C, antioxidants, and electrolytes similar to lime to which is used for aiding coagulation. In recent years, activated silica, alginates and some soluble starch products have been the standard to provide aids in coagulation them being harmless to human. The use of polyelectrolytes however has been proven to be more effective and is now the one being utilized (Nam, 2019).

The researchers would utilize coagulation or coagulation flocculation, in a water treatment in which it involves the inclusion of compounds that promote the clumping of finer materials into larger flocs so that they can be easily separated from water. Natural coagulants originating from vegetables and seeds were in use for the purpose of water treatment before the wide scale use of chemical salts, but they have not been able to displace the use of chemical salts as the scientific grasp of their effectiveness and mechanism of action was lacking (Ghodwani et al, 2017). The usage of biological coagulants has not picked up so far because of the lack of clarity in the method to use them commercially. The researchers have given way to inorganic salts progressively under modernization and survived only in some parts of some developing countries. In coagulation, colloidal particles are destabilized by neutralizing those opposite forces which keep them separate. Thus, the particles combine to form larger particles and this is achieved by rapid mixing of solution which spreads the coagulant agent completely. (Bhardwaj, Rajput & Misra, 2019). It is said that one of the most effective water treatment processes is coagulation. It is one of the most efficient method of treatment which helps in removing mainly toxic metals and chemicals present in the water, there are many coagulants that are being used for example, alum, copper sulphate, lime, and the likes. Certain polymers are also being used as coagulants in many industries but the major drawback of such coagulants is the treatment and management of the toxic residues and sediments produced after coagulation (Mishra, Singh & Srivastava, 2017).

In the mineral water coagulation system, the system will undergo three methods of processes to fully extract the clean water from microbes and sediments present. They are namely: Coagulation, Flocculation, and Disinfection. First, powdered Okra and Calamansi fruit (seeds, peels and flesh) extracted from the kernels will be added to the wastewater which will serve as the coagulant and flocculant., Having polycations properties where they posses’ excessive positive ions, they tend to attract to negatively charged particles and neutralize them, to which in this experiment is the sediments and microbes. Next, suspended particles are now be able to stick with each other along with coagulant which forms large chunks of particles called microfloc. Next, flocculation is utilized as the coagulant aid will act as the flocculant in the mixture providing an envelope of sheet that will envelop the microflocs. As it collides, it will increase the size and the strength of the microfloc turning it into a denser and visible macrofloc which will now sink in the bottom of the mixture separating the clear water from sediments and microbes.

Considering the properties of the coagulants, they are both strong polyelectrolytes being the primary coagulant and an aid. Polyelectrolytes improve settling characteristics of floc, for better separation. These work best when diluted and in powder form, hence the powdering of the seeds and fruit can easily penetrate to small organisms (but not the smallest kinds) and spread fast and evenly on the surface (Brandt & Ratnayaka, 2017). Though coagulation and flocculation produced highly efficient impurity removal (Ayguna & Yilmazb, 2010), the process can only accumulate to larger ones, excluding those tiniest bacteria and organisms in the mixture. The third process will eliminate 99.9% of bacteria or the remainders through the process of disinfection. The addition of chlorine in the mixture will neutralize the remainder bacteria and fully disinfect the water. While high dose of it could be lethal to a person, when mixed to water and became fully diluted within, the result will be a low-level chlorine solution that could only kill germs and bacteria but are still safe to drink.

With this study, the researchers aim to provide solutions in the long run to the lack of potable and safe drinking water in several communities by making the best use of natural materials given.

0 notes

Text

Enzyme Stabilizer Market with Business Opportunities and Threats, Challenges to Industry Growth During Forecast Period 2018-2023

A Comprehensive research study conducted by KD Market Insights on ” Enzyme Stabilizer Market – By Product Type (Polyols, Sugars, Organic Osmolytes, Solvents, Amino Acids, Other Modulators), By Source (Plant, Animals, Lab), By End Use (Food Processing, Animal Nutrition, Pharmaceuticals, Cleaning Agents, Chemical), By Form (Powder & Granules, Liquid) & Global Region - Market Size, Share, Trends and Forecast 2018-2023” report offers extensive and highly detailed historical, current and future market trends in the global and regional/market. The Enzyme Stabilizer Market report includes market size, growth drivers, barriers, opportunities, trends and other information which helps to find new opportunities in this market for the growth of the business through new technologies and developments. The global Enzyme Stabilizer Market was held at USD XX Million in 2018 and is anticipated to reach USD XX Million by the end of 2023. Further, the market is anticipated to flourish at a CAGR of X.X% during forecast period i.e. 2018 to 2023. Request for Sample @ https://www.kdmarketinsights.com/sample/3056 The market research report broadly covers analysis of all market trends, growth drivers, restraints, and other macro market scenarios. The report also offers qualitative and quantitative analysis in the terms of region i.e. North America, Latin America, Asia Pacific, Europe, and Middle East & Africa. Asia-Pacific captured XX% of market share in 2018 and is believed to capture a market share of XX% by the end of 2023. Global Enzyme Stabilizer market also offers country level analysis and covers key countries in each region. North America, especially The United States, is believed to capture a significant market share of XX% in 2023. Further, United States Enzyme Stabilizer market was held at USD XX Million in 2018 and is anticipated to reach USD XX Million in 2023. Asia Pacific also plays important role in global market, with market size of USD XX Million in 2018 and will be USD XX million in 2023, with a CAGR of XX%. This report focuses on the key global Enzyme Stabilizer players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years. This report focuses on the Enzyme Stabilizer in global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes the market based on manufacturers, regions, type and application. This report covers major market players based in Enzyme Stabilizer market: - Cargill Inc. - Roche Custom Biotech - Ab Vickers, UK - Archer Daniels Midland, USA - Sorachim SA - Sigma Aldrich (Merck) - Biomol - Bitop - Thermo Fisher Scientific - Bio-Rad Antibodies - Sun Chemical - Evonik Industries - Other Major & Niche Key Players The report also offers analysis of major market segments: The report segments the market based on By Product Type into… - Polyols - Sugars - Organic Osmolytes - Solvents - Amino Acids - Other Modulators - - - Dextran - - - Polyelectrolytes The report segments the market based on By Source into… - Plant - Animals - Lab The report segments the market based on By End-use into… - Food Processing - Animal Nutrition - Pharmaceuticals - Cleaning Agents - - - Detergents - Chemical - - - Silk - - - Leather Further, the market has been also segmented By Form into… - Powder & Granules - Liquid Customization Service of the Report: KD Market Insights provides customization of reports as per your need. This report can be personalized to meet your requirements. Get in touch with our sales team, who will guarantee you to get a report that suits your necessities. Browse Full Report with TOC @ https://www.kdmarketinsights.com/product/3056/enzyme-stabilizer-market Table of Contents: Research Methodology Market Definition and List of Abbreviations 1. Executive Summary 2. Growth Drivers & Issues in Global Enzyme Stabilizer Market 3. Global Enzyme Stabilizer Market Trends 4. Opportunities in Global Enzyme Stabilizer Market 5. Recent Industry Activities, 2017 6. Porter's Five Forces Analysis 7. Market Value Chain and Supply Chain Analysis 8. Global Enzyme Stabilizer Market Size (USD Million), Growth Analysis and Forecast, (2017-2023) 9. Global Enzyme Stabilizer Market Segmentation Analysis, By Product Type 9.1. Introduction 9.2. Market Attractiveness, By Product Type 9.3. BPS Analysis, By Product Type 9.4. Polyols 9.5. Sugars 9.6. Organic Osmolytes 9.7. Solvents 9.8. Amino Acids 9.9. Other Modulators 9.9.1. Dextran 9.9.2. Polyelectrolytes 10. Global Enzyme Stabilizer Market Segmentation Analysis, By Source 10.1. Introduction 10.2. Market Attractiveness, By Source 10.3. BPS Analysis, By Source 10.4. Plant 10.5. Animals 10.6. Lab 11. Global Enzyme Stabilizer Market Segmentation Analysis, By End-use 11.1. Introduction 11.2. Market Attractiveness, By End-use 11.3. BPS Analysis, By End-use 11.4. Food Processing 11.5. Animal Nutrition 11.6. Pharmaceuticals 11.7. Cleaning Agents 11.7.1. Detergents 11.8. Chemical 11.8.1. Silk 11.8.2. Leather 12. Global Enzyme Stabilizer Market Segmentation Analysis, By Form 12.1. Introduction 12.2. Market Attractiveness, By Form 12.3. BPS Analysis, By Form 12.4. Powder & Granules 12.5. Liquid 13. Geographical Analysis 13.1. Introduction 13.2. North America Enzyme Stabilizer Market Size (USD Million) & Volume, 2017-2023 13.2.1. By Product Type 13.2.2. By Source 13.2.3. By End-use 13.2.4. By Form 13.2.5. By Country 13.2.5.1. Market Attractiveness, By Sourcer 13.2.5.2. BPS Analysis, By Sourcer 13.2.5.3. U.S. Market Size (USD Million) 2017-2023 13.2.5.4. Canada Market Size (USD Million 2017-2023 13.3. Europe Enzyme Stabilizer Market Size (USD Million) & Volume, 2017-2023 13.3.1. By Product Type 13.3.2. By Source 13.3.3. By End-use 13.3.4. By Form 13.3.5. By Country 13.3.5.1. Market Attractiveness, By Country 13.3.5.2. BPS Analysis, By Country 13.3.5.3. Germany Market Size (USD Million) 2017-2023 13.3.5.4. United Kingdom Market Size (USD Million) 2017-2023 13.3.5.5. France Market Size (USD Million) 2017-2023 13.3.5.6. Italy Market Size (USD Million) 2017-2023 13.3.5.7. Spain Market Size (USD Million) 2017-2023 13.3.5.8. Russia Market Size (USD Million) 2017-2023 13.3.5.9. Rest of Europe Market Size (USD Million) 2017-2023 13.4. Asia Pacific Enzyme Stabilizer Market Size (USD Million), 2017-2023 13.4.1. By Product Type 13.4.2. By Source 13.4.3. By End-use 13.4.4. By Form 13.4.5. By Country 13.4.5.1. Market Attractiveness, By Country 13.4.5.2. BPS Analysis, By Country 13.4.5.3. China Market Size (USD Million) 2017-2023 13.4.5.4. India Market Size (USD Million) 2017-2023 13.4.5.5. Japan Market Size (USD Million) 2017-2023 13.4.5.6. South Korea Market Size (USD Million) 2017-2023 13.4.5.7. Indonesia Market Size (USD Million) 2017-2023 13.4.5.8. Taiwan Market Size (USD Million) 2017-2023 13.4.5.9. Australia Market Size (USD Million) 2017-2023 13.4.5.10. New Zealand Market Size (USD Million, 2017-2023 13.4.5.11. Rest of Asia Pacific Market Size (USD Million) 2017-2023 13.5. Latin America Enzyme Stabilizer Market Size (USD Million) 2017-2023 13.5.1. By Product Type 13.5.2. By Source 13.5.3. By End-use 13.5.4. By Form 13.5.5. By Country 13.5.5.1. Market Attractiveness, By Country 13.5.5.2. BPS Analysis, By Country 13.5.5.3. Brazil Market Size (USD Million) 2017-2023 13.5.5.4. Mexico Market Size (USD Million) 2017-2023 13.5.5.5. Rest of Latin America Market Size (USD Million, 2017-2023 13.6. Middle East & Africa Enzyme Stabilizer Market Size (USD Million) 2017-2023 13.6.1. By Product Type 13.6.2. By Source 13.6.3. By End-use 13.6.4. By Form 13.6.5. By Geography 13.6.5.1. Market Attractiveness, By Geography 13.6.5.2. BPS Analysis, By Geography 13.6.5.3. GCC Market Size (USD Million) 2017-2023 13.6.5.4. North Africa Market Size (USD Million) 2017-2023 13.6.5.5. South Africa Market Size (USD Million) 2017-2023 13.6.5.6. Rest of Middle East & Africa Market Size (USD Million) 2017-2023 14. Competitive Landscape 14.1. Market Share of Key Players 14.2. Market Positioning of Major Players in Global Enzyme Stabilizer Market 14.3. Company Profiles 14.3.1. Cargill Inc. 14.3.1.1. Product Offered 14.3.1.2. Business Strategy 14.3.1.3. Financials 14.3.1.4. SWOT Analysis 14.3.1.5. Market Share Analysis 14.3.1.6. Key Achievements & Developments 14.3.2. Roche Custom Biotech 14.3.3. Ab Vickers, UK 14.3.4. Archer Daniels Midland, USA 14.3.5. Sorachim SA 14.3.6. Sigma Aldrich (Merck) 14.3.7. Biomol 14.3.8. Bitop 14.3.9. Thermo Fisher Scientific 14.3.10. Bio-Rad Antibodies 14.3.11. Sun Chemical 14.3.12. Evonik Industries 14.3.13. Other Major & Niche Players Continue…. Check for Discount @ https://www.kdmarketinsights.com/discount/3056 About Us: KD Market Insights is one of the leading providers of market intelligence products and services. We offer reports on over 10+ industries and update our collection daily which helps our clients to access database of expert market insights on global industries, companies, products, and trends. Our in-house research experts have a wealth of knowledge in their respective domains. With KD Market Insights, you always have the choice of getting customized report free of cost (upto 10%). Our support team will help you customize the report and scope as per your business needs. This ensures that you are making the right purchase decision. Our clients list includes various Fortune 500 companies and leading advisory firms. Contact Us: KD Market Insights 150 State Street, Albany, New York, USA 12207 +1 (518) 300-1215 Email: [email protected] Website: www.kdmarketinsights.com Read More News: https://powerandenergy111.blogspot.com/ https://chemicalsandmaterials11.blogspot.com/ https://ictindustry9.blogspot.com/ https://consumergoods1234.blogspot.com/ https://automotiveindustry9.blogspot.com/

0 notes

Text

Polymer Preparation Unit

Sodimate's polymer preparation unit is used for chemical and biological polymers, as well as synthetic polyelectrolyte powders. Over the years, Sodimate has engineered and manufactured polymate for the wastewater treatment plants and continues to do so.

0 notes

Text

Calcium Lignosulfonate Market Competitive Dynamics & Global Outlook 2025

Calcium Lignosulfonate Market: Overview

Lignosulfonates are one of the abundantly available wood chemicals. These are commonly obtained as by-products during the sulfite processing of wood pulp. Lignosulfonates are primarily anionic polyelectrolytes that are easily soluble in water. These are natural anionic surfactants with high molecular weight, and are primarily used in the ceramics, construction, chemicals, oil & gas, and animal feed additives industries.

Request Report Brochure @ https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=31637

Lignosulfonates are of various types, such as calcium lignosulfonate, sodium lignosulfonate, magnesium lignosulfonate, and ammonium lignosulfonate. Calcium lignosulfonate is an amorphous light-yellow-brown powder obtained from the sulfite pulping of softwood. It is soluble in water, however, practically insoluble in organic solvents.

Sodium and calcium salts are the commercially available types of lignosulfonates. Calcium lignosulfonate exhibits properties such as dispersing, binding, complexing, and emulsifying, that enable its usage as an additive in applications such as concrete admixture, animal feed, dust suppressant, agriculture chemicals, and oil well drilling muds, among others.

Calcium Lignosulfonate Market: Trends and Segmentation

Calcium lignosulfonate is employed in oil well drilling muds as reagents to control various parameters of drilling fluids. It is primarily used to control the viscosity of drilling mud and to facilitate oil recovery.

Calcium lignosulfonate is also used in the food industry as a carrier for the production of encapsulated fat-soluble vitamins (A, D, E, and K), carotenoids (e.g. β-carotene, β-apo-8’-carotenal, zeaxanthin, canthaxanthin, lutein, and lycopene), and other functional ingredients to facilitate their introduction to water-based foods.

Concrete admixtures and animal feed are the two key applications of calcium lignosulfonate. Calcium lignosulfonate plays the important role of water-reducing chemical in concrete admixtures. It typically possesses the capacity to reduce water by 8% to 12% in the form of plasticizer, and up to 25% in the modified form (superplasticizer grade). Calcium lignosulfonate is used as pellet binder in animal feed.

Read Report Overview @ https://www.transparencymarketresearch.com/calcium-lignosulfonate-market.html

Calcium lignosulfonate, owing to its property as a binder, is employed in applications such as animal feed, paints & pigments, dust control, and in the food industry. The oil & gas industry uses calcium lignosulfonate as a dispersant.

Based on application, the market for calcium lignosulfonate can be segmented into concrete admixture, animal feed, dust control, oil well additives, agrichemicals, and others.

The key players in the calcium lignosulfonate market are backward integrated, which strengthens their dominance. However, companies are facing steep competition from the substitutes available in the overall lignosulfonates market. This is anticipated to affect the global dynamics of the calcium lignosulfonate market in the next few years.

About Us

Transparency Market Research (TMR) is a global market intelligence company providing business information reports and services. The company’s exclusive blend of quantitative forecasting and trend analysis provides forward-looking insight for thousands of decision makers. TMR’s experienced team of analysts, researchers, and consultants use proprietary data sources and various tools and techniques to gather and analyze information.

TMR’s data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With extensive research and analysis capabilities, Transparency Market Research employs rigorous primary and secondary research techniques to develop distinctive data sets and research material for business reports.

Contact

Transparency Market Research

State Tower,

90 State Street,

Suite 700,

Albany NY – 12207

United States

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Email: [email protected]

Website: http://www.transparencymarketresearch.com

0 notes

Text

Cationic Polyacrylamide For Oil&Gas Industry

Cationic polyelectrolyte FOR OIL&GAS INDUSTRY As one of the leading oil field additives suppliers, SINOFLOC Cationic Polyacrylamide has been widely used as dry cationic friction reducer, wastewater treatment and oily sludge treatment in oil & gas industry. Friction Reducer SINOFLOC is offering a broad range of leading-class friction reducer to our customers. Our product range includes anionic polyacrylamide powder, anionic polyacrylamide emulsion and cationic polyacrylamide powder. SINOFLOC cationic polyacrylamide is specially designed as efficient friction reducer for brines or high TDS conditions. When added to water, our products disperse readily and instantly and rapid hydrate and the drag and friction pressures will be reduced when pumping low viscosity fluids at high rates. SINOFLOC Products Benefits: Faster disperse and hydrate More environmentally Less toxic than emulsion Easy to store and transport Water and wastewater Treatment Along with the production of oil and gas, a big volume of water is needed in several applications. The minimizing the usage and enhancing the reuse and recycling of water become very essential. SINOFLOC polyacrylamide could meet customer request on water and wastewater treatment. Oily sludge treatment Oily sludge is one of the most significant solid wastes generated from oil industry and difficult to process. SINOFLOC cationic polyacrylamide could be added as flocculants to improve oily sludge conditions before having water oil sludge separation and increase the oil recovery ratio significantly. For more information on products application please contact with SINOFLOC team.

Contact us

Beijing Sinofloc Chemical Co., Ltd.

Office: 12th Floor, Jincheng Centre, Liyuan, Tongzhou, Beijing, China

Tel: +86 10 8055 6872

Fax. +86 10 8055 6871

Marketing Direct Tel: +86 10 8055 6870

E-mail: [email protected]

0 notes

Text

Ensuring Smooth Operations: Boiler Water Chemicals Manufacturers

Maintaining efficient boilers requires specialized treatment. Boiler water chemicals manufacturers provide a range of solutions to prevent corrosion, scaling, and foaming. These chemicals optimize boiler performance and extend lifespan, ensuring smooth operations for various industries.

#anionic polyelectrolyte manufacturers#polyelectrolyte powder manufacturers#polyelectrolyte manufacturers

0 notes