#filament makers

Explore tagged Tumblr posts

Text

Comprehensive Guide to 3D Print Supplies in the UK: Everything You Need for Success

The world of 3D printing continues to evolve, offering endless possibilities across industries, from manufacturing and design to art and education. To harness the full potential of this transformative technology, having the right 3D print supplies is paramount. Whether you’re a beginner or a seasoned professional, this guide will help you understand and select the essential supplies to achieve success in your 3D printing projects.

Why Are Quality 3D Print Supplies Important?

Using the right 3D print supplies ensures:

Enhanced Print Quality: Precision materials reduce errors and deliver exceptional results.

Cost Efficiency: High-quality supplies minimise material waste and reprints.

Longevity of Equipment: Proper tools and maintenance supplies protect your 3D printer from wear and tear.

Choosing reliable supplies is an investment in both your projects and your 3D printer.

Essential 3D Printing Supplies for a Successful Setup

To achieve top-notch results, a well-stocked 3D printing workspace is key. Here are the must-have supplies:

1. Filaments: The Core of FDM Printing

Filaments are the backbone of FDM (Fused Deposition Modelling) 3D printing. Selecting the right type and quality of filament significantly impacts the final output.

PLA (Polylactic Acid):

Easy to use and ideal for beginners.

Biodegradable and available in a wide range of colours.

Commonly used for prototypes, decorative objects, and educational models.

ABS (Acrylonitrile Butadiene Styrene):

Durable and resistant to high temperatures.

Suitable for functional parts and tools.

Requires a heated bed to prevent warping.

PETG (Polyethylene Terephthalate Glycol):

Combines strength, flexibility, and moisture resistance.

Used for mechanical parts and food-safe containers.

Specialty Filaments:

Include wood, metal, or carbon fibre-infused options.

Add unique textures or properties for advanced applications.

When purchasing filaments, ensure they are compatible with your 3D printer and suitable for your project needs.

2. Resins: Precision for SLA Printing

For SLA (Stereolithography) and DLP (Digital Light Processing) printers, resins are the material of choice. These liquid polymers create high-resolution, detailed prints.

Standard Resin: Perfect for general-purpose projects.

Tough Resin: Ideal for functional parts requiring strength and durability.

Flexible Resin: Provides elasticity for specialised designs.

Specialised Resins: Includes castable, dental, or bio-compatible options.

Store resins in a cool, dark place and use appropriate safety gear, such as gloves and goggles, during handling.

3. Adhesion Aids for Build Surfaces

Achieving strong bed adhesion is critical to successful 3D printing. Adhesion issues can lead to print failures and wasted materials.

Glue Sticks: An affordable and easy solution for improving bed adhesion.

Adhesive Sprays: Provide an even coating for larger print jobs.

Specialised Bed Tapes: Include Kapton or painter’s tape for specific filament types.

Ensure your adhesion method is compatible with your printer’s build surface and material.

4. Maintenance and Cleaning Tools

Proper maintenance keeps your 3D printer in optimal condition. Essential tools include:

Nozzle Cleaning Kits: Prevent blockages and ensure smooth material flow.

Hex Keys and Screwdrivers: Useful for assembly and calibration.

Lubricants: Maintain smooth movement of mechanical parts.

Cleaning Solutions: Remove residue from nozzles, beds, and other components.

Regular upkeep prolongs the lifespan of your printer and reduces the risk of malfunctions.

5. Post-Processing Supplies

Post-processing is essential for achieving professional-quality prints. Equip yourself with the following tools:

Sandpaper: Smooth out imperfections and achieve a polished finish.

Cutting Tools: Precision knives or clippers for removing supports and excess material.

Painting Supplies: Enhance the aesthetic appeal of your models with paints and brushes.

Polishing Compounds: Add a shine or gloss to finished pieces.

Post-processing allows you to refine your prints and bring your designs to life.

6. Software for Design and Slicing

Software is an integral part of 3D printing, bridging the gap between design and execution.

CAD Software: Create and edit 3D models. Popular choices include Tinkercad and Fusion 360.

Slicing Software: Converts 3D models into printer-friendly instructions. Examples include Cura and PrusaSlicer.

Keep your software updated to ensure compatibility with the latest printer technologies.

7. Storage Solutions for Supplies

Proper storage ensures the longevity and quality of your supplies.

Filament Storage: Use airtight containers with desiccants to protect against moisture.

Resin Containers: Store resins in UV-proof bottles to prevent degradation.

Tool Organisers: Keep tools and accessories neatly arranged for easy access.

A well-organised workspace improves productivity and reduces downtime.

8. Safety Gear for 3D Printing

Safety is paramount when working with 3D print supplies. Equip yourself with the following:

Gloves: Protect your hands from chemicals and sharp tools.

Safety Glasses: Shield your eyes during sanding or cutting.

Respirators: Prevent inhalation of fine particles or fumes during post-processing.

Following proper safety protocols ensures a secure and enjoyable 3D printing experience.

Factors to Consider When Purchasing 3D Printing Supplies

Selecting the right 3D print supplies involves considering several factors:

Printer Compatibility: Ensure materials and accessories match your printer’s specifications.

Project Requirements: Choose supplies based on the intended application, whether decorative, functional, or structural.

Quality and Reliability: Invest in reputable brands for consistent results.

Budget: Balance cost with quality to avoid compromising on print outcomes.

Researching and comparing options before purchasing can save you time and money in the long run.

Benefits of Buying Locally in the UK

Choosing local suppliers offers several advantages:

Faster Shipping: Reduced delivery times ensure you receive materials promptly.

Customer Support: Local suppliers provide tailored advice and assistance.

Quality Assurance: Products adhere to UK safety and quality standards.

Environmental Impact: Supporting local businesses reduces the carbon footprint associated with international shipping.

Shopping locally strengthens the UK’s 3D printing community while providing practical benefits.

Common Challenges and How to Overcome Them

Even with the best supplies, 3D printing may present challenges. Here’s how to address common issues:

Warping: Use a heated bed and proper adhesion aids to prevent edges from lifting.

Clogs and Jams: Regularly clean nozzles and use high-quality filaments.

Layer Shifting: Check belt tension and calibrate your printer to maintain alignment.

Print Failures: Optimise slicing settings and ensure proper bed levelling for consistent results.

Troubleshooting and maintaining your printer ensures a smoother and more successful 3D printing experience.

Future Trends in 3D Printing Supplies

As technology advances, the world of 3D print supplies continues to innovate:

Eco-Friendly Materials: Increasing availability of biodegradable and recyclable options.

Smart Filaments: Materials with embedded sensors for monitoring print quality.

Advanced Resins: Expanding applications for medical, aerospace, and automotive industries.

Staying updated on emerging trends ensures you remain at the forefront of 3D printing innovation.

Conclusion

Equipping your 3D printing setup with the right 3D print supplies is the foundation for achieving exceptional results. From selecting the perfect filaments and resins to investing in essential tools, adhesives, and safety gear, every element contributes to the success of your projects.

By prioritising quality, organisation, and safety, you can unlock the full potential of your 3D printer while enjoying a seamless and productive experience. Whether you’re printing prototypes, artistic creations, or functional parts, this comprehensive guide ensures you are well-prepared to bring your ideas to life.

Explore the wealth of options available in the UK and embark on your 3D printing journey with confidence. With the right supplies and a commitment to excellence, the possibilities are truly limitless.

#3d printing buy#3d printer supplies#3d print supplies#3d printing supply#supplies for 3d printing#3d printing supplies#3d printing supplier#3d printing suppliers#filament makers#print supplies uk#printing supplies uk#3d filament maker#3d printer filament maker#filament maker 3d printer#filament maker for 3d printers#3d printing filament maker#uk 3d printing supplies#3d printer supplies uk#3d print supplies uk#3d printing supplies uk

0 notes

Photo

I used @adskfusion360 to design this nice Coffeeshop Bebop Leiden key tag. It is double-sided and look great in my opinion. Simple and clean how we like it. This one is printed on the Prusa i3 MK3S+ & MMU2S by @josefprusa in @filament_pm PETG. #3dprinting #3dprintingcommunity #3dprinter #3dprinted #3dprint #3dmodel #3dmodeling #3dp #autodesk #fusion360 #prusa3d #prusai3mk3s #mmu #filamentpm #petg #filaments #coffeeshopbebop #bebopleiden #maker #additivemanufacturing #de3dprintman (at Leiderdorp) https://www.instagram.com/p/Cn4jCx5NP44/?igshid=NGJjMDIxMWI=

#3dprinting#3dprintingcommunity#3dprinter#3dprinted#3dprint#3dmodel#3dmodeling#3dp#autodesk#fusion360#prusa3d#prusai3mk3s#mmu#filamentpm#petg#filaments#coffeeshopbebop#bebopleiden#maker#additivemanufacturing#de3dprintman

3 notes

·

View notes

Text

I'm rather annoyed, if not outright angry that I spent almost twice what I normally spend on a 1Kg roll of filament (including shipping!) to only get maybe a half-dozen successful prints out of it. The rest was wasted as spaghetti (which would start some 1/2-2/3 of the way through a print ftr) and detached from the print bed, even after creating a completely new filament profile for it accounting for "correct" temperatures and speeds, and then, just for good measure, changing the entire nozzle assembly.

Fuck getting the color right, I just wanted the prints to finish successfully.

I'm not even going to waste my time finishing the roll. Absolute dogshit.

#3D Printing#I'm not gonna call out the filament maker but it starts with M and ends with AtterHackers.

0 notes

Text

#dprintinghealthcare#3dhealthcare#3dprint#3dprinter#3dprinted#design#3dmodeling#3dmodel#ender#3dart#art#3dprints#3ddesign#pla#maker#diy#additivemanufacturing#creality#engineering#filament#impresion#cosplay#technology#dprinters#prusa#thingiverse#ddruck#dprintinglife#print#warhammer

0 notes

Photo

Upcycled 3d 🖨️ vase fits a standard coke bottle #dprinting #d #dprint #dprinter #dprinted #design #dmodeling #dmodel #ender #dart #art #dprints #ddesign #pla #maker #diy #additivemanufacturing #creality #engineering #filament #impresion #cosplay #technology #dprinters #prusa #thingiverse #ddruck #dprintinglife #print #warhammer (at Sweden) https://www.instagram.com/p/CpI2RbeLlOf/?igshid=NGJjMDIxMWI=

#dprinting#d#dprint#dprinter#dprinted#design#dmodeling#dmodel#ender#dart#art#dprints#ddesign#pla#maker#diy#additivemanufacturing#creality#engineering#filament#impresion#cosplay#technology#dprinters#prusa#thingiverse#ddruck#dprintinglife#print#warhammer

0 notes

Note

I was just talking about this "mass handmade cookie cutter product" phenomenon, I was just at a con with four discreet 3d printer booths all of whom had the exact same articulated dragon with roses on it's back? and I literally own one of these at a small scale it's adorable i like the model quite a lot, but like. it's a $4 STL file online, the filaments are $20 each on amazon, once you buy the printer you can just print them in any size forever and charge whatever people will buy because they don't realize the seller has don't like. none of the design or labor involved in producing this item, despite the fact that they did factually make it themselves on a small enough scale that it's not out of place at a handmade maker con. it's odd.

IT MAKES ME FEEL LIKE I AM INSANE. IT MAKES ME FEEL OUT OF TOUCH WITH CONSENSUS REALITY!!!! like it's not the same as dropshipped items bc i think those should just flatout not be allowed without VERY clear signposting - like if you are selling mass produced notions for other people's creative products you should be legally required to state who your supplier is so ppl can look up how much you're upmarking shit, bc like. there IS a market for "the factory sells those buttons in batches of 100 and i only need 5, so i'll pay a little more for a middleman to have purchased the batch of 100 and handle all the inventory" like that is a service that makes sense. to have exist. but ohhhhh my fucking god.

but what you're describing is really true, i think there's a mix between like... i know small artists who sell stuff at markets and cons and stuff pay a table fee, so they want to make back what they spent on that, and so it makes sense to want to be sure that some of what you're making is going to sell, and maybe it even makes sense to do what you describe - buy an STL file, print off some proven winners.

but from the buyers' perspective, it means that half the art markets i go to are full of enamel pins that say CAT MOM and stickers about liking avocados and pride flag keychains, bc that's what sells, and anything that's original sits unsold - or it's more expensive bc it wasn't mass-produced and had higher labor costs, so it takes longer to move... so ppl stop stocking or bringing it... and it's like if all of this is the same why am i even here. T_T

#i thought we were supposed to be creative and follow the beat of our own drum... are we all just copying now?#read subcultures the meaning of style by hebdige (1979)#also it's the thing of why are all cars grey now. if it doesn't appeal to EVERYONE it's not worth doing. and it's like. please...

66 notes

·

View notes

Text

The Vod's List: Part 1.5

Fox sat in the medcenter staring blankly at the 'sensor's read out. They all were. A numb sort of horror silencing the normally busy room. The only real noise was the steady churning hum of the substance analyzer off on a table to the side, still busy churning away at what exact compound EXACTLY were in the liquid drying on his face. Running in random chaotic lines of slowly drying death, down his neck.

He really needed to change before he got reinfected.

But... but all he could do was stare.

There was a chip in his head.

WAS. It was half gone and disappearing even as they watched. Whatever let it hide itself the first thing destroyed, by what now flowed in his blood. His head felt like it was going to pop. Yet? As... WHATEVER those things were? Worked? Processed. Attacked. Did what ever it was they were designed to DO... the less his head hurt.

The medic said it looked like they went after the connection filaments first. Then traced them back to the chip itself. Because... because he had a CHIP in his brain.

He was compromised.

How long had he been compromised?

Were the others? Or was it just him? Was it because of his position of command? Should the other commanders get checked? What is he saying. Of course they should. They have too. He has no idea when this could even have OCCURRED. It could be a threat to the Republic. To the Vod.

The analyzer chimes. His vod numbly going through the motions to check the read out. Only to pause. Check again. Then again. Fixer calls over another medic. Well... that reassuring.

They have samples, scraped from his cheek and neck. He expect then to pop them into another machine, when they pick the vial up. But instead? The rest of them watch in confused horror as the two medics apply some two a swab, grab a vibroscalpel, and make cuts along their arms. Pressing the swabs to the fresh wounds.

Deliberately... infecting... themselves...

VOD WHAT IN THE FRESH HELLS?!

One set chrono and a vicious shouting match later? The truth reveals itself. Two more scans. Two matching chips, being eaten away. It's Kamino cure, they say. Half way across the known galaxy, probably has all sorts of side effects they'll have to look out for, but? Assuming they SURVIVE it?

This could fix every karked up thing the long necks ever put in them, known or unknown.

It's DESIGNED to "fix" it's host, no matter the cost. That is... assuming the host can endure the pain. Kriff. His mind can't help but shoot back. The civilian. An aid to an aid so many layers down in the senate, they're barely one step above the Vod themselves. Glorified furniture with a purpose.

She'd been...

The sheer HORROR in her eyes, when she realized she'd shared what was inside her. When they met, she was in a karking muzzle, too. Sure, it was designed to be "humane". But she couldn't even run in it. It suffocated her. Did she endure? Was that why she froze up? Every injury the threat of something so much WORSE?

He could see the same thought, spreading like everything always does with the Vod.

Fast and impossible to contain.

Kriff... he ran a hand down his face, exhausted. They hadn't even figured out who was behind THIS attack. Anti-war protesters, kidnapping attempt, assassination attempt. Some sleemo who wanted to watch the galaxy burn, maybe. It didn't matter. What DID was that they contain it.

....maybe get a gaurd or two on their new friend.

I mean... it wasn't UNREASONABLE, right? She... she COULD be a target. Natural bioweapon. People can be terrible. Wouldn't put it past somebody right? And they really SHOULD have complete coverage of the senate building. Even the lower levels. That's were trouble makers try to slip in.

It's reasonable.

It's not like she's THEIR Civilian. They don't HAVE an anything. The other Vod have their generals. Various officers, if their Generals aren't that great. The Gaurd doesn't... they don't NEED...

I mean... it would be NICE...

No. Focus.

Just because she helped you and yours... just because she's SOFT and CIVILIAN and VULNERABLE to threats-! Don't. Do not. Vod, I can FEEL you-

"Did you know most Technoganic never leave their planet?" Nose piped up from near the door, little shit could never leave anything alone if he TRIED. He had his datapad out. "Says here they are highly priority targets for slavers."

Every Vod in the room twitched.

Well... there went HIS calm. His hand went to his com-link, already fighting to keep from clenching his jaw. A.. FEW gaurds wouldn't hurt. For Senatorial safety. They aren't giving anyone preferential treatment! Just. Being cautious.

Doing their job.

They should check in.

Just in case.

#threepandas#yandere#the vods list#and so their descent begins#their are TOTALLY gonna be SO normal about this guys#SO NORMAL#yandere star wars#yandere clone troopers#clone troopers#yandere x reader

72 notes

·

View notes

Text

So it’s weird to come back a couple years after you leave a place and see how it’s changed, right?

In my first year of college, a group of friends and I were the first iteration of our college’s Makers Club. The tech teachers helped us get set up, taught us to apply for funding, got us a room for meetings

And, y’know, for most of the year what we in the club had access to was the room, a projector, and the xbox one of the members brought in for our weekly Smash Bros tournament

(Before the xbox came in the Makers Club did vitally important and scientific activities like taping a member to a chair with painter’s tape to see how easily he could break out)

And as we did the budget request, we all made jokes about stupid things we could buy, because we needed to have an itinerary of everything we wanted to submit with the budget, and the teachers advised us to ask at least double what we actually wanted

(So, 10’ diamond coated charger cables, better tape, a 3D printer to print a trophy for the winner of the tournament each week, etc.)

It was basically a lunch club, almost entirely of people from our software development classes, where we all hung out and dicked around

I graduated a couple years later, and the year after that snuck back to the Maker’s Club because we’d finally gotten a 3D printer the year I graduated and I wanted to get a sneaky print cuz we charged for the filament and not much else

And gang

I saw this club when we had A Room

We didn’t even claim it full time for two years there were still other classes in it

I saw it when we had one printer, when the coolest thing we could buy was a programmable robot kit for one of those cute lil guys you can program to move his cube around and we all had to share one

The goddamn budget request must have gone through as we all fucking left, because the next year they had not just the room permanently set aside, but the closet next door set up with TWO 3D printers and a laser cutter

I booped in and out over the next year too, mostly for curiosity (and to use the printers cuz the people now running the club were members when I’d been a founder and so long as none of us admitted I wasn’t paying tuition anymore it was fair game)

The last time I saw it, they had FOUR 3D printers, two laser cutters, three more craft machines I didn’t recognize, a working fume hood, and one guy had used club resources to build a working robot hand and was teaching it to pick locks

It was. It was amazing. It was a proper, actual piece of school infrastructure, providing benefits to the whole student body

And I was there when we just played Smash and helped each other with our homework

26 notes

·

View notes

Text

Multimaterial 3D printing enables makers to fabricate customized devices with multiple colors and varied textures. But the process can be time-consuming and wasteful because existing 3D printers must switch between multiple nozzles, often discarding one material before they can start depositing another. Researchers from MIT and Delft University of Technology have now introduced a more efficient, less wasteful, and higher-precision technique that leverages heat-responsive materials to print objects that have multiple colors, shades, and textures in one step. Their method, called speed-modulated ironing, utilizes a dual-nozzle 3D printer. The first nozzle deposits a heat-responsive filament and the second nozzle passes over the printed material to activate certain responses, such as changes in opacity or coarseness, using heat.

Read more.

16 notes

·

View notes

Text

Glimpses into arctic Pandora (all artwork is by me, and the signatures are my more used online nickname)

Tauk lives with a lot of lakes. She's a skilled maker of fishing nets and other fish traps. She also makes dyed fabrics. Her grandmother is an expert of local natural pigments, fungi and berries alike, and she's a keen student. She's strong, outspoken and adventurous. An energetic powerhouse with her feet in the ground. While she has her heart in the right place for the most part, she does not always understand those who have less social skills, and might appear judgemental/intimidating to such cases. This is because she grew up being quite secure in herself, and doesn't seem to understand that not everyone can take such for granted.

Mokri'ena is bit of a daydreamer and an introvert. She loves to learn about stories from across Pandora. She has heard of the Sky People, Toruk Makto and the legendary warrior Neytiri. Many say she kind of exists outside of the moment she's in, outside of her body. She's interested in news and history. She always feels intimately aware of how frail safety and peace are. She can't stop thinking about the Sky People, or the Omaticaya and the Metkayina she has never met. She grew up being a little weird, - or well, just not really understanding other kids' concept of fun. She was a little artist who preferred her imagination over her loud and more sociable peers. As an adult she's keen to help those in need, as she has known the pain of being forgotten.

Tulìm is from a coastal settlement, from a terrain broken into many islands.

He was always an adventurer, - as he was born in a mainland tribe. The coastal islands always made him curious because he wanted to see more of his world, so he moved there and joined a trader ship crew.

For most of his life he was simply a trader ship navigator, and later a the captain.

He commands one of the biggest trader ships of the region. He has seen many lands outside of his own, and is known for his skills with diplomacy and leadership. He doesn't lead to benefit himself, but to serve his people and especially his crew.

His nemesis for life is an ice na'vi pirate. He spends his old, last days in a bitter hunt of his nemesis, until his worn-out body succumbs into the ocean for the last time.

Keyuk is the Olo'Eyktan of one of the many ice na'vi tribes. The era of his leadership has been a stable and quiet one. While a part of his humour is making a serious face to trick people, he's actually more known for his easygoing and humble personality. He knows his responsibilities, but has a pretty egalitarian approach to his social life. He breaks some of the traditions of his people by dressing like an average member of his society. He's never been a fan of trying to act like more than you are, - he's all bite and with none of the bark! This makes him well-respected and liked among his people.

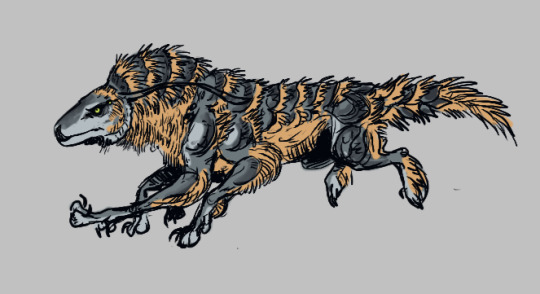

The two main types of arctic na'vi:

(Left) Those of the land, - descenants of forest na'vi similiar to the Omaticaya, but with adaptations to cold, long winters. Most of their body is covered in fur.

(Right) Those of the waters, - arctic cousins to reef na'vi like Tau'nui and Metkayina. These 'ice na'vi' are even more extremely adapted to spending time in water than reef na'vi are, having even more powerful swimming tails and upwards-facing nostrils for easily getting air between their long dives. They don't have fur, but regulate their body heat by the layers of fat under their skin, much like cetaceans on Earth. Like reef na'vi, ice na'vi also have a symbiotic relationship with a tulkun-like sapient species.

This is an arctic viperwolf. Fur grows between their armor plates and most of the plateless regions of rheir bodies. Their shape is rounder and stubbier than that of the tropical viperwolves, for trapping more heat in their bodies.

Arctic ikran relatives also exist, and are popular flying steeds to many snow na'vi tribes. They're covered in filamentous structures resembling little hair fans.

#pandora#avatar#james cameron's avatar#na'vi#na'vi clan#na'vi oc#reef na'vi#arctic na'vi#snow na'vi#ice na'vi#avatar 2009#avatar the way of water#atwow#avatar oc#my art

89 notes

·

View notes

Text

Choosing the Right 3D Printer: A Comprehensive Guide

The world of 3D printing offers boundless creative possibilities, making it an exciting technology for makers, hobbyists, and professionals alike. However, with a wide array of 3D printers available on the market, selecting the right one can be a daunting task. This guide will help you navigate the important factors to consider when choosing a 3D printer that suits your needs so that you can get the right 3D printer.

How to Choose the Right 3D Printer

Define Your Purpose

The first step in choosing the right 3D printer is defining your purpose. What do you intend to create? Are you interested in artistic endeavors, functional prototypes, or educational projects? Understanding your specific use case will help narrow down your choices.

Budget Considerations

Your budget plays a significant role in determining the 3D printer that’s right for you. 3D printers vary widely in price, from budget-friendly options to high-end models. While affordability is essential, it’s also crucial to consider the long-term costs, including maintenance, filament, and accessories.

Determine the Types of 3D Printers

There are several types of 3D printers available, with the two most common being Fused Filament Fabrication (FFF) and Stereolithography (SLA).

– FFF Printers: These printers extrude filament (typically PLA or ABS) layer by layer to build objects. They are known for their affordability and ease of use, making them a great choice for beginners.

– SLA Printers: SLA printers use liquid resin cured by a UV laser to create highly detailed and precise objects. They are excellent for producing intricate designs but may be more challenging to operate.

Consider Build Volume

The term “build volume” pertains to the largest dimensions of items a 3D printer can produce. Take into account the size of your intended prints and verify that the printer’s build volume is sufficient for your requirements.

Choose Print Resolution

Print resolution determines the level of detail and quality of your 3D prints. It’s measured in microns, with lower values indicating higher resolution. If you require highly detailed and smooth prints, opt for a printer with a lower micron value.

Check Filament Compatibility

Different 3D printers are compatible with various filament types, such as PLA, ABS, PETG, or specialty materials like flexible filaments or metal-infused filaments. Ensure that the printer you choose supports the type of filament you intend to use.

Find Ease of Use

For beginners, a user-friendly 3d printer is crucial. Look for models that come pre-assembled or require minimal assembly and calibration. Intuitive software and a supportive online community can also make your 3D printing journey smoother.

Consider Printing Speed

Printing speed varies among 3D printers. Faster printers can complete prints more quickly, but they may sacrifice print quality. Consider your priorities—whether speed or print quality is more important for your projects.

Consider Connectivity and Software

Examine the connectivity options and software compatibility of the 3D printer. USB, SD card, or Wi-Fi connectivity can impact your workflow. Ensure that the printer works with slicing software compatible with your operating system.

Final Words

In conclusion, choosing the right 3D printer involves careful consideration of your specific requirements, budget, and skill level. It’s an investment that can open up a world of creative possibilities. By researching and weighing the factors mentioned in this guide, you can confidently select a 3D printer that aligns with your goals and sets you on an exciting 3D printing journey. Remember that the right 3D printer can be a versatile tool for turning your ideas into tangible creations.

4 notes

·

View notes

Text

Fancy iot printer -> CNC plate maker -> non iot printer -> CNC lathe -> CNC Mini mill -> industrial shredder -> Filament recycling setup -> plastic injection molds -> home vacuum seal -> possibly a forge? -> metal casting -> dude what couldn't I build at that point?

If only I had my executive function back.

3 notes

·

View notes

Text

Exploring the World of 3D Printing

Hey there, fellow tech enthusiasts! 👋

In today's blog post, we're diving headfirst into the fascinating world of 3D printing. If you're new to this technology or a seasoned pro, we've got something for everyone. Let's get started!

The Basics of 3D Printing If you're new to 3D printing, you're in for a treat. It's a revolutionary technology that allows you to turn digital designs into physical objects. We'll break down the basics, including how it works and the types of 3D printers available.

Applications Galore 3D printing isn't just for hobbyists; it's changing industries from healthcare to aerospace. Discover the incredible real-world applications of 3D printing, from custom prosthetics to space-ready components.

Choosing the Right Filament One of the key decisions in 3D printing is selecting the right filament material. We'll discuss the various options like PLA, ABS, and PETG and guide you in choosing the perfect material for your projects.

Designing for 3D Printing Ready to create your own 3D models? We'll introduce you to 3D design software and provide tips for designing models that print flawlessly. Plus, we'll share some fantastic resources for free 3D models to kickstart your creativity.

Troubleshooting and Maintenance Like any tech, 3D printers can have their quirks. We'll go over common issues you might encounter and how to troubleshoot them. Maintenance tips to keep your printer in top shape will also be on the menu.

Inspiration and Community Be inspired by jaw-dropping 3D printing projects and join the vibrant online 3D printing community. Share your creations, learn from others, and be part of the maker movement.

Don't miss out on the 3D printing revolution! Stay tuned for more exciting content as we explore this innovative world. Follow us for updates, and feel free to reach out with your questions and ideas. Happy printing, folks! 🔧🖨️🌟

11 notes

·

View notes

Note

hello! i rly like ur art and your cross stitch makes me envious as a cross stitcher as well!! do you have any tech topics you're dying to talk about? do you have a neocities? do you use DMC thread or "off brand"?

Aw thank you 😭!! I do use DMC, the fiber craft store right near my apt sells them for 89 cents per skein which from what I've heard is a really good deal so I've been taking advantage of that to enjoy the Authentic Product. And I do have a neocities! I've been neglecting it for a while but there's some stuff on there so it's still fun to poke around for a few minutes I think (it is NOT, however... mobile-friendly)

https://antisocialxconstruct.neocities.org/

As far as tech topics..... oh! During this trip I've been talking to my dad about the whole Pet Surprise project and he reminded me that I had at least briefly been interested in learning more about 3D printing, and that that could be a viable approach to making duplicate heads, and honestly I can't believe I didn't think of that sooner! Seattle has several maker spaces, a couple based in libraries and others that are private businesses, and as far as I know they all include 3D printers and at least some of them also have 3D scanners. The free maker space at the library where I actually did the little introductory 3D printing class has some pretty strict size/time/filament width limits (understandable because it's a free service) so I doubt those limitations would let me get the smooth edges that I would really prefer to have, but if I can get my kitten and puppy heads scanned and converted into viable print files for free, I could take them to one of the private spaces for higher quality test prints. Once I have a better idea of what materials and settings are best for what I want, I could?? potentially??? invest in a little 3D printer of my own. I'm kind of astounded by how quickly those have become a fairly accessible consumer technology, you can get a decent brand new one for under $500 which means I might be able to get a gently used slightly older one for a lot less from someone who's upgrading or bought one and decided it wasn't the hobby for them lmao

#granted... the more serious i get about these craft undertakings the more i desperately need an apartment with more rooms 😭#i need to stake out my niche more clearly like those people who sell their ooak art dolls for thousands of dollars#ask#rom speaks#carinakuma

3 notes

·

View notes

Text

One beak yawned and then a second followed. It was past the witching hour when even things that went bump in the night were starting to nod off. The night was waning toward the early hours of the morning but still hours away until the sun would come out. Most of the citizens of Duckburg were nestled snug in their beds, and only those who worked the night shift were up and about. Oh, and two dedicated scientists who had been working on their newest pet project for their employee, Scrooge McDuck. Time wasn’t of the essence, but they had hit their stride around one AM and they weren’t back down until one of them collapsed.

But their determination still wasn’t beyond the temptation of the body.

“Intern, I’m going out for an espresso,” Gyro called, his face the usual grumpy-slash-sardonic expression.

Fenton rubbed his eyes. “Are you sure you don’t want me to get it for you?” Fenton asked. He was used to being Gyro’s errand-boy, so he was curious as to why his boss and advisor decided to fore-go his exclusive uses of a none-paid intern. Plus, sometimes Gyro bought Fenton coffee as well.

“No. My doctor says that I need ‘fresh air’ and ‘exercise’,” Gyro said with a laborious eye-roll. “Apparently walking to and from my car doesn’t constitute this.”

“Okay. Could you get me one, too?” Fenton asked. The coffee maker that Mr. McDuck kept in the employee’s lounge a few floors up always had the consistency of mud and tasted very similar no matter how often the filter was cleaned or how expensive of beans were used. And it would be a miracle if Mr. McDuck ever deigned to replace it.

“What do I look like? A money tree?” Gyro asked, stepping onto the elevator. “Lil Bulb is in charge.” The elevator doors closed on him with a cheerful ding.

Fenton sighed. It had been a nice try. It would have been nice to have a good cup of coffee once in a while, but until his internship was over, he was making squat. He relied on his mother for room, board and all the necessities, so he never asked for spending cash. And on top of that, his student loans were looming over his head. Luckily the bank was willing to hold off on any payments since employment with McDuck Industries would be an exceptional place to live.

Lil Bulb clambered onto Fenton’s desk, flashing red while his filament bent down in an angry look. The device pointed its little “hand” at its “face” then at Fenton, then back at itself. A clear indication of I’m watching you.

Fenton ignored the little invention. He had better things to do other than be bossed around by an artificial intelligent. For now, he was trying to figure out why oil kept leaking from the engine that he was working on. The engine was to be used on a new type of submarine that Scrooge McDuck wanted, but there still were a few problems that needed to be fixed.

Just as Fenton decided the whole engine needed to be taken apart—again—and he began removing a nut, the wrench in his hands slipped and he fell on top of the engine.

“Ah, nuts,” he grumbled as he felt the slick, wetness spread on his shirt.

When he pushed himself off the machine, he saw the large blot across his shirt, soaking into his feathers. He knew that working in a lab could be dirty business, and normally he would wear a lab coat, but he had forgotten to put one on in his haste when he clocked in. And this wasn’t the first time. This was his fourth work shirt to get oil on it this week, and he was running out. Not to mention, oil was really hard to get out—as his mother kept telling him—so he might have to buy some more soon.

Sitting down next to the engine, Fenton tilted his head back and rested his eyes a little, trying to ignore the grease that was in his feathers, between his fingers and who knows where else on his body. He remembered he had rubbed his eyes earlier when he was beginning to feel tired. Did he have two black marks around his eyes?

Perhaps it was time for him to quit for the day—er—night. At least it was Friday, which meant he could sleep all day tomorrow. Well, not all day. He would have to help Mama around the house, but between Saturday and Sunday, he could catch up on his rest and on the household chores.

Getting up, Fenton went to the sink that was located on the far side of the large, clear windows that looked out into the ocean. The very basement of the McDuck Lighthouse had been repurposed into a lab several years ago—as Fenton was told—and before that it had been a type of aquatic life observatory for one of Scrooge McDuck’s nephews. It had been one of Duckburg’s major tourist attractions where people could pay to tromp up hundreds of steps to go to the very top of the lighthouse and even hear the foghorn blow.

Then they would go all the way down into the basement where they could see the ocean, a coral bed and dozens of fish. Fethery—Mr. McDuck’s nephew—had taken great care of the coral reef that grew around the light house and kept track of dozens of animals. There were even aquatic tubes that were built into the lighthouse basement that led to holding tanks somewhere else in the lab. Someone could even put on diving equipment and go through the tubes right into the ocean. Fethery used these tubes to bring in sick or injured animals into the aquatic observatory where he could treat them before releasing them again.

Fenton remembered coming to the lighthouse for a school trip once, remembered the excitement in Fethery’s voice and how he spoke to the children about taking care of the oceans, conservation and eliminating pollution. It had been very fascinating.

But Fenton always wondered what had happened to Fethery. A few years ago, the aquatic observation had been closed down without any explanation, and it was only when Fenton was hired as an intern to work with Gyro that he found out that the space was now utilized as a lab.

As Fenton cleaned his hands—and his face, because he really did have greasy circles around his eyes—he thought about Fethery, the lab, and what had happened a few years ago. He had never dared as Mr. McDuck—he barely said more than a few words with the elderly duck in his time as intern—and Gyro never said anything if Fenton broached the subject. His best theory was that Mr. McDuck had a falling out with his nephew and that was the end of it.

His eyes wandered out to the ocean, although only the lights in the lab penetrated the darkness. He wondered if there was more to the story. He remembered reading an article in a newspaper about this very thing, that Scrooge McDuck’s nephew, Fethery Duck, had gone missing yet nobody reported anything about it to the police. The reporter claimed that nobody had seen Fethery since the closing of the lighthouse, and there were no records of him leaving Duckburg or any other activity of where Fethery Duck could be. Later, the newspaper printed a retraction and as far as Fenton could see, the reporter who wrote the article never worked for the paper again.

As much as Fenton’s imagination could come up with a dozen different scenarios as to what happened to Fethery Duck, he couldn’t believe any of them. Mr. McDuck might be unapproachable and stand-offish, but Fenton couldn’t believe that he would harm an innocent person, let alone his family.

With his thoughts floating through the subject of Fethery, he hadn’t realized how long he had been standing at the sink with his eyes looking through the window unfocused. It wasn’t until the hot water turned extremely hot that he was brought back to reality.

And he came face to face with a beautiful woman.

He was caught unguarded, blinking a few times as she stared back at him, her mouth open a little. Then a few bubbles poured out of her beak, racing through the water.

Water?! She was in the ocean.

Fenton stumbled back, his mind coming to the conclusion that there was a person drowning just outside the lighthouse. The lab wasn’t the only underwater level in the building, and they were over thirty feet below sea level. If she had sunk this far, could he get to her in time before she drowned.

Just as he was startled by her appearance, her face jumped in surprise as well. Her body twisted and pointed downward, her motion followed by a long, scaly tail that whipped out a few times, then she was gone.

Fenton fell flat on his butt, just as stunned as if he had been kicked by a horse in the stomach. What did he just see? Did he just see a creature that was half-woman, half-fish? A mermaid?

Want to read more? Keep track of my daily progress on AO3.

9 notes

·

View notes

Text

Workshop: 3D printing

Today I participated in the 3D workshop. We were introduced to the makers station and giving a short presentation on the basics of printing. We then went to the computer room and used the Rhino application to create forms.

I downloaded a pig from the printables website. We learned how to use the tools and how to slice the object.

We finished by starting the process using the 3D printing machine with white filament.

3 notes

·

View notes