#feathered mitered edge

Explore tagged Tumblr posts

Photo

Contemporary Kitchen - Enclosed An illustration of a small modern l-shaped kitchen with a limestone floor and stainless steel appliances, an island, flat-panel cabinets, white cabinets, marble countertops, and white and glass backsplashes.

#london grey limestone#european kitchen#feathered mitered edge#appliance garage work station#pendant lighting#best pro hood#white kitchen

0 notes

Text

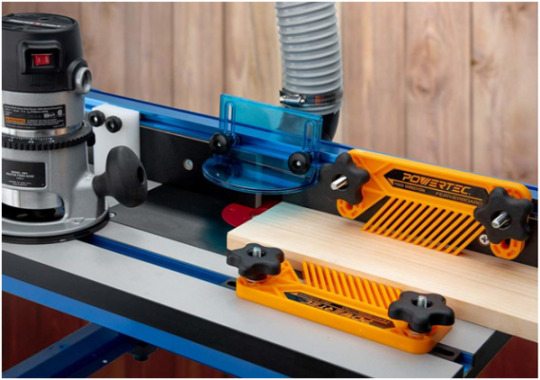

Why to Use a Featherboard?

Working on saw machine and using feather board along with the fence is just like working with extra hands! Featherboards keep your fingers safe and in good shape while operating power saws.

Featherboard:

Feather board is basically a safety device. It is used when working with stationary power saws like bandsaws, table saws, mitre saws shapers, router tables, radial arm saws etc. A feather board is simply a board with a series of defect free slits cut into a uniform fixed angle like 45 degree, forming a row of flexible fingers that bends just like the barbs of a feather. It applies pressure against the wood to be cut and keeps it flat on the saw machines table or the fence while steering the work piece to the blade.

A feather board can also be created at workshop from an approximately 3/4 × 3 × 11 inch piece of straight grained, defect-free wood, cut crosswise at a 45-degree angle on one end. Many slits parallel to this direction of the grain can be cut manually but creating a good defect free feather board is a time consuming and tedious task. So, purchasing a good one will prove its worth in the long run and save your precious time too.

Features of Featherboard:

Featherboards are usually made from a high quality polymer and each feather board consists of angular slits known as fingers.

The angle of the fingers allows the wood piece to pass in an unwavering, straight line but offers resistance movement in the opposite direction.

These fingers exert some pressure on the work piece to be cut while feeding to the saw that produces cleaner cuts with rare chances of kickback, chattering or displacing of work piece.

It comes with wedge-lock hardware which works in T-slots or miter slots on table saws, router tables or band saws.

The featherboard slide into miter-gauge slots in the router table or fence, and are locked in place by tightening a pair of knobs attached at the ends.

Key Benefits of Using Featherboard:

The most important benefit is again your safety. It keeps your hands and fingers safe while feeding wood piece to the saw machine.

It enhances the accuracy and quality of cuts tremendously.

It can be connected to its place very easily and quickly.

It is useful for edge jointing, and making moulding on router tables.

It performs especially well at the table saw and router table. It can also be used on shaper, band saw or any other woodworking machine with a miter gauge slot.

It takes care of the thin wood pieces, especially when feeding wood piece by hand is somewhat difficult.

Double Featherboard:

Using double featherboards give extra control over feeding mechanism. On router tables and shapers, you can use one featherboard before and the other one after the cutter. It is a good practice to attach featherboards to both the fence and the tabletop while routing long and thin wood piece on the router table.

Where to Get One?

Featherboard is a specialty tool and hence may not be available at your local stores but will be stocked at high quality building supply stores and woodworking tools dealers. You can also place your online orders from here in case you are searching for some good quality at decent price.

How to Use a Featherboard?

Using featherboard is quite simple and a quick process. A purchased featherboard will easily slide in the mitre groove on your table saw. Place the featherboard with fingers aligned in the direction in which the wood piece is fed.

The saw blade should never touch the fingers of the featherboard so just keep it little bit away from the blade. Also, make sure that its both the knobs are properly tightened so that the wood piece is secured and moves in forward feeding direction only.

For the most accurate cuts, lower the blade with the tool off and place the stock against the fence. Now, set the featherboard against the wood piece and tighten the locking mechanism with knobs attached. Test the wood piece if it is fixed properly or not in a dry run with the blade lower down. Ideally, the work piece should move in forward direction and not move back. Now, raise the blade up and push the wood piece for cutting.

#feather board#Finger Safety Featherboard#Small Feather Board for Table Saw#Featherboard for table saw

0 notes

Text

Mid Century Modern Style Home In Silicon Valley

Brimming with Californian mid century modern design, including wood wall paneling, floor-to-ceiling glazing and a gabled ceiling, this place is reminiscent of an Eichler home. Created by Klopf Architecture, with landscape design by Outer Space Landscape Architects, this is a custom build that uses materials and technologies that are commonplace today to translate the mid century aesthetic. The house promotes an indoor-outdoor lifestyle for a young and growing family, located at the heart of Silicon Valley in a Los Altos neighbourhood. The goal was to create a light atmosphere and an energy-efficient lifestyle in the new 3,000 square foot dwelling, which replaces an older ranch style home.

The house is a 3 bedroom, 2 and a half bathroom abode, with a private outdoor pool.

Exterior lighting under the eaves means that the family’s outdoor living areas can still be used and enjoyed long after dark.

One glazed wall of the master bedroom slides open to the outdoors, linking it seamlessly to the modern pool patio design – perfect for a refreshing early morning dip. If exercise isn’t on the agenda so early in the day, then the selection of modern outdoor chairs provide opportunity for an al fresco breakfast or to peruse the morning papers.

Up on the raised deck, a railing doubles as a bench seat, complete with bright scatter cushions.

The deck also serves as an outdoor dining room, furnished with Eames style Eiffel chairs to continue the mid century modern look on from the interior.

Inside, the home has been created on a grid, to section out separate spaces for different activities, like relaxing, cooking, dining, playing, and a music area that houses a baby grand piano. Clerestory windows were included in this mid century modern living room to help make the space feel light and airy. A white armchair and unique plant stands lift the dark sofa arrangement, whilst yellow accents and art add sunny warmth.

The lounge section opens out into a lofty dining space, where more impressive clerestory windows flood the generous floor plan with natural light. The walls and ceilings are plain crisp white but the honey tones of the oak wood flooring works toward warming the scheme through. A rich wood dining set sits by sliding glass exterior doors, which lead out onto the pool deck.

The dining area leads directly off an open plan kitchen diner, decked out in white and wood kitchen cabinets and clean white countertops.

Four grey bar stools line up along one side of a central kitchen island. A few yellow accents dot the white and wood decor, tying it in with the nearby lounge decor. You can find more gorgeous white and wood kitchens here.

Two linear pendants are suspended over the kitchen island, their low profiles keep the space uncluttered.

The piano stands to one side of the kitchen installation, tucked by a huge window. The high sloping roof creates a feeling of grandeur.

At the other end of the kitchen bar stools there is a colourful playroom for the two children of the family, allowing them to be close to their parents whilst meals are being prepared. A fenced-in play area is attached to this room at the front of the house, providing an indoor-outdoor play space. This connected zone is a flexible space that can morph and change in use for the family over the years.

The playroom can also be closed off from the great room by sliding out a large pocket door.

The colourful kid’s decor pieces are toned down by one black painted wall and one wood panelled wall. The huge window and glass door bring in green views from the children’s garden.

An atrium brings extra light and nature to the great room.

A Heath tile wall has been fashioned at the back of the atrium for privacy, to block out the direct view of the rear yard from the entry door.

The three bedrooms, 1.5 bathrooms, the playroom and the sitting room are under flat roofs, which balance out either side of the sloping gable roof of the main space.

The white decor, walnut cabinetry and dark window frames tie all of the individual spaces together as one unified design, creating a peaceful flow throughout the house. Huge pocketing glass doors foster a feeling of openness, and encourage use of outdoor spaces. In this room, a bedroom chair has a swivel base so that it can easily turn to take in the nature view.

Soft planting feathers the edges of the contemporary build.

Concrete paving creates cool contrast with warm wood decking and garden steps.

A concrete bench stands solidly in a mud room, and is echoed by an identical bench design on the other side of the window wall. Chrome wall hooks hang coats and hats against a wood panelled wall.

Wood siding has been used for both interior and exterior spaces, to accentuate the indoor-outdoor nature of the house.

The wood siding has been mitered at the corners, including where it meets interior drywall. Materials are held up just off the floor, with a tight minimal reveal.

Inside a grey and white bathroom, custom cabinetry matches the joinery in the rest of the house, with a trim-less, minimalist appearance.

Chrome accessories add shine to the wash space.

By the basin, a small planter introduces a little greenery to the stark scheme.

Sunlight pours through a skylight.

A large picture window opens up the look of the narrow bathroom.

The outdoor lounge area nestles beneath mature trees.

The garage door has been set completely flush with the wall to de-emphasise it, and provide a more pleasing presentation to the street.

The clerestory windows create privacy.

A sunshine yellow front door gives out happy vibes.

The yellow entry door also provides the first hint of accent colour used inside.

Hidden pocket doors make the building appear open sided.

Windows along each side of the roofline allow the line of sight to pass straight through the structure.

Recommended Reading: Detailed Guide & Inspiration For Designing A Mid-Century Modern Living Room The Complete Mid Century Modern Classic Chair Guide 36 Mid Century Modern Coffee Tables That Steal Centre Stage

Related Posts:

30 Mid-Century Modern Sofas That Make Your Lounge Look The Era

30 Mesmerizing Mid-Century Modern Living Rooms And Their Design Guides

A Colour Rich Indian Home With Concrete Architecture And Interiors

Eclectic Single Bedroom Apartment With Open Floor Plan

A Luxurious Mid-Century Inspired Home in California

3 Modern Small Apartment Designs Under 50 Square Meters That Don't Sacrifice On Style [Includes Floor Plans]

0 notes

Text

Mid Century Modern Style Home In Silicon Valley

Brimming with Californian mid century modern design, including wood wall paneling, floor-to-ceiling glazing and a gabled ceiling, this place is reminiscent of an Eichler home. Created by Klopf Architecture, with landscape design by Outer Space Landscape Architects, this is a custom build that uses materials and technologies that are commonplace today to translate the mid century aesthetic. The house promotes an indoor-outdoor lifestyle for a young and growing family, located at the heart of Silicon Valley in a Los Altos neighbourhood. The goal was to create a light atmosphere and an energy-efficient lifestyle in the new 3,000 square foot dwelling, which replaces an older ranch style home.

The house is a 3 bedroom, 2 and a half bathroom abode, with a private outdoor pool.

Exterior lighting under the eaves means that the family’s outdoor living areas can still be used and enjoyed long after dark.

One glazed wall of the master bedroom slides open to the outdoors, linking it seamlessly to the modern pool patio design – perfect for a refreshing early morning dip. If exercise isn’t on the agenda so early in the day, then the selection of modern outdoor chairs provide opportunity for an al fresco breakfast or to peruse the morning papers.

Up on the raised deck, a railing doubles as a bench seat, complete with bright scatter cushions.

The deck also serves as an outdoor dining room, furnished with Eames style Eiffel chairs to continue the mid century modern look on from the interior.

Inside, the home has been created on a grid, to section out separate spaces for different activities, like relaxing, cooking, dining, playing, and a music area that houses a baby grand piano. Clerestory windows were included in this mid century modern living room to help make the space feel light and airy. A white armchair and unique plant stands lift the dark sofa arrangement, whilst yellow accents and art add sunny warmth.

The lounge section opens out into a lofty dining space, where more impressive clerestory windows flood the generous floor plan with natural light. The walls and ceilings are plain crisp white but the honey tones of the oak wood flooring works toward warming the scheme through. A rich wood dining set sits by sliding glass exterior doors, which lead out onto the pool deck.

The dining area leads directly off an open plan kitchen diner, decked out in white and wood kitchen cabinets and clean white countertops.

Four grey bar stools line up along one side of a central kitchen island. A few yellow accents dot the white and wood decor, tying it in with the nearby lounge decor. You can find more gorgeous white and wood kitchens here.

Two linear pendants are suspended over the kitchen island, their low profiles keep the space uncluttered.

The piano stands to one side of the kitchen installation, tucked by a huge window. The high sloping roof creates a feeling of grandeur.

At the other end of the kitchen bar stools there is a colourful playroom for the two children of the family, allowing them to be close to their parents whilst meals are being prepared. A fenced-in play area is attached to this room at the front of the house, providing an indoor-outdoor play space. This connected zone is a flexible space that can morph and change in use for the family over the years.

The playroom can also be closed off from the great room by sliding out a large pocket door.

The colourful kid’s decor pieces are toned down by one black painted wall and one wood panelled wall. The huge window and glass door bring in green views from the children’s garden.

An atrium brings extra light and nature to the great room.

A Heath tile wall has been fashioned at the back of the atrium for privacy, to block out the direct view of the rear yard from the entry door.

The three bedrooms, 1.5 bathrooms, the playroom and the sitting room are under flat roofs, which balance out either side of the sloping gable roof of the main space.

The white decor, walnut cabinetry and dark window frames tie all of the individual spaces together as one unified design, creating a peaceful flow throughout the house. Huge pocketing glass doors foster a feeling of openness, and encourage use of outdoor spaces. In this room, a bedroom chair has a swivel base so that it can easily turn to take in the nature view.

Soft planting feathers the edges of the contemporary build.

Concrete paving creates cool contrast with warm wood decking and garden steps.

A concrete bench stands solidly in a mud room, and is echoed by an identical bench design on the other side of the window wall. Chrome wall hooks hang coats and hats against a wood panelled wall.

Wood siding has been used for both interior and exterior spaces, to accentuate the indoor-outdoor nature of the house.

The wood siding has been mitered at the corners, including where it meets interior drywall. Materials are held up just off the floor, with a tight minimal reveal.

Inside a grey and white bathroom, custom cabinetry matches the joinery in the rest of the house, with a trim-less, minimalist appearance.

Chrome accessories add shine to the wash space.

By the basin, a small planter introduces a little greenery to the stark scheme.

Sunlight pours through a skylight.

A large picture window opens up the look of the narrow bathroom.

The outdoor lounge area nestles beneath mature trees.

The garage door has been set completely flush with the wall to de-emphasise it, and provide a more pleasing presentation to the street.

The clerestory windows create privacy.

A sunshine yellow front door gives out happy vibes.

The yellow entry door also provides the first hint of accent colour used inside.

Hidden pocket doors make the building appear open sided.

Windows along each side of the roofline allow the line of sight to pass straight through the structure.

Recommended Reading: Detailed Guide & Inspiration For Designing A Mid-Century Modern Living Room The Complete Mid Century Modern Classic Chair Guide 36 Mid Century Modern Coffee Tables That Steal Centre Stage

Related Posts:

30 Mid-Century Modern Sofas That Make Your Lounge Look The Era

30 Mesmerizing Mid-Century Modern Living Rooms And Their Design Guides

A Colour Rich Indian Home With Concrete Architecture And Interiors

Eclectic Single Bedroom Apartment With Open Floor Plan

A Luxurious Mid-Century Inspired Home in California

3 Modern Small Apartment Designs Under 50 Square Meters That Don't Sacrifice On Style [Includes Floor Plans]

0 notes

Text

Mid Century Modern Style Home In Silicon Valley

Brimming with Californian mid century modern design, including wood wall paneling, floor-to-ceiling glazing and a gabled ceiling, this place is reminiscent of an Eichler home. Created by Klopf Architecture, with landscape design by Outer Space Landscape Architects, this is a custom build that uses materials and technologies that are commonplace today to translate the mid century aesthetic. The house promotes an indoor-outdoor lifestyle for a young and growing family, located at the heart of Silicon Valley in a Los Altos neighbourhood. The goal was to create a light atmosphere and an energy-efficient lifestyle in the new 3,000 square foot dwelling, which replaces an older ranch style home.

The house is a 3 bedroom, 2 and a half bathroom abode, with a private outdoor pool.

Exterior lighting under the eaves means that the family’s outdoor living areas can still be used and enjoyed long after dark.

One glazed wall of the master bedroom slides open to the outdoors, linking it seamlessly to the modern pool patio design – perfect for a refreshing early morning dip. If exercise isn’t on the agenda so early in the day, then the selection of modern outdoor chairs provide opportunity for an al fresco breakfast or to peruse the morning papers.

Up on the raised deck, a railing doubles as a bench seat, complete with bright scatter cushions.

The deck also serves as an outdoor dining room, furnished with Eames style Eiffel chairs to continue the mid century modern look on from the interior.

Inside, the home has been created on a grid, to section out separate spaces for different activities, like relaxing, cooking, dining, playing, and a music area that houses a baby grand piano. Clerestory windows were included in this mid century modern living room to help make the space feel light and airy. A white armchair and unique plant stands lift the dark sofa arrangement, whilst yellow accents and art add sunny warmth.

The lounge section opens out into a lofty dining space, where more impressive clerestory windows flood the generous floor plan with natural light. The walls and ceilings are plain crisp white but the honey tones of the oak wood flooring works toward warming the scheme through. A rich wood dining set sits by sliding glass exterior doors, which lead out onto the pool deck.

The dining area leads directly off an open plan kitchen diner, decked out in white and wood kitchen cabinets and clean white countertops.

Four grey bar stools line up along one side of a central kitchen island. A few yellow accents dot the white and wood decor, tying it in with the nearby lounge decor. You can find more gorgeous white and wood kitchens here.

Two linear pendants are suspended over the kitchen island, their low profiles keep the space uncluttered.

The piano stands to one side of the kitchen installation, tucked by a huge window. The high sloping roof creates a feeling of grandeur.

At the other end of the kitchen bar stools there is a colourful playroom for the two children of the family, allowing them to be close to their parents whilst meals are being prepared. A fenced-in play area is attached to this room at the front of the house, providing an indoor-outdoor play space. This connected zone is a flexible space that can morph and change in use for the family over the years.

The playroom can also be closed off from the great room by sliding out a large pocket door.

The colourful kid’s decor pieces are toned down by one black painted wall and one wood panelled wall. The huge window and glass door bring in green views from the children’s garden.

An atrium brings extra light and nature to the great room.

A Heath tile wall has been fashioned at the back of the atrium for privacy, to block out the direct view of the rear yard from the entry door.

The three bedrooms, 1.5 bathrooms, the playroom and the sitting room are under flat roofs, which balance out either side of the sloping gable roof of the main space.

The white decor, walnut cabinetry and dark window frames tie all of the individual spaces together as one unified design, creating a peaceful flow throughout the house. Huge pocketing glass doors foster a feeling of openness, and encourage use of outdoor spaces. In this room, a bedroom chair has a swivel base so that it can easily turn to take in the nature view.

Soft planting feathers the edges of the contemporary build.

Concrete paving creates cool contrast with warm wood decking and garden steps.

A concrete bench stands solidly in a mud room, and is echoed by an identical bench design on the other side of the window wall. Chrome wall hooks hang coats and hats against a wood panelled wall.

Wood siding has been used for both interior and exterior spaces, to accentuate the indoor-outdoor nature of the house.

The wood siding has been mitered at the corners, including where it meets interior drywall. Materials are held up just off the floor, with a tight minimal reveal.

Inside a grey and white bathroom, custom cabinetry matches the joinery in the rest of the house, with a trim-less, minimalist appearance.

Chrome accessories add shine to the wash space.

By the basin, a small planter introduces a little greenery to the stark scheme.

Sunlight pours through a skylight.

A large picture window opens up the look of the narrow bathroom.

The outdoor lounge area nestles beneath mature trees.

The garage door has been set completely flush with the wall to de-emphasise it, and provide a more pleasing presentation to the street.

The clerestory windows create privacy.

A sunshine yellow front door gives out happy vibes.

The yellow entry door also provides the first hint of accent colour used inside.

Hidden pocket doors make the building appear open sided.

Windows along each side of the roofline allow the line of sight to pass straight through the structure.

Recommended Reading: Detailed Guide & Inspiration For Designing A Mid-Century Modern Living Room The Complete Mid Century Modern Classic Chair Guide 36 Mid Century Modern Coffee Tables That Steal Centre Stage

Related Posts:

30 Mid-Century Modern Sofas That Make Your Lounge Look The Era

30 Mesmerizing Mid-Century Modern Living Rooms And Their Design Guides

A Colour Rich Indian Home With Concrete Architecture And Interiors

Eclectic Single Bedroom Apartment With Open Floor Plan

A Luxurious Mid-Century Inspired Home in California

3 Modern Small Apartment Designs Under 50 Square Meters That Don't Sacrifice On Style [Includes Floor Plans]

from Interior Design Ideas http://www.home-designing.com/mid-century-modern-style-home-in-silicon-valley

0 notes

Text

5 best Table saw tips and tricks

We will show you practical tips and techniques for using your table saw. Use this accessory to create clean, straight, and safe cuts for your next woodworking project. You can easily cut extra long, extra wide and extra thick wood.

Tip 1: Use feather boards for an extra set of hands

Feather boards help keep boards straight

Use feather boards to hold wood for a straight cut against the fence.

If it is difficult to align a board with the fence, pull a spring board for smooth, straight cuts. Feather boards have a series of wooden "fingers" that hold the wood firmly on the fence fence.

The fingers are slightly bendable and cut at an angle so you can push the wood through while maintaining a firm, even pressure. They also dig in and hold wood in place when it starts to hit back. You are a great "third hand" if you want the perfect rip. Simply press the spring wood in front of the saw blade firmly against the piece of wood 1 to 3 in. And clamp firmly to the saw table.

It should be pretty easy to push the wood forward, but hard to pull it back. And if you are ripping big boards, add a second clip for extra firm pressure.

Create your own spring boards from a 2-ft. Length of the knot-free 1 × 4. Cut one end by 45 degrees. Then cut a bunch of 4-in. - long scores every 1/8 to 1/4 in. (narrower on stiff hardwoods, wider on conifers) -thin enough for the long fingers to flex easily.

Tip 2: Set up simple output support

An output table supports long cards

Use an output feature when copying long cards.

Trying to rip the last few feet of a long board without help or support at the other end is virtually impossible. An expensive roll holder can solve the problem. However, if you do not have one, provide a temporary output support with brackets, two 2x4s and plywood. The 2x4s attached to the saw table hold the plywood perfectly on the table surface. The boards you cut slip on the support without hanging.

To create a temporary output table, clamp two 8-ft. - Place 2x4s long on the saw table and round it out about 5 ft above the outlet side. Then screw or clamp 1/4-in. Plywood at the bottom of the 2x4s.

Note that this only works with large table saws and larger table saws with heavy steel or iron tables. It could cause lighter table saws to tilt or tilt.

Tip # 3: Add a fence to the miter bar to facilitate cross-sections.

Attach a stop block

Stop block for the fence for repeated cuts of the same size.

The narrow width of most miter gauges provides poor cross-cutting support, especially for oblique cutting. For better support, screw a wooden fence to the miter gauge. (Most gauges have holes for this purpose.)

Use a straight 1 × 3 or 1 × 4, and make it high enough so that the knife does not completely cut it off. Then it's easy to add a detachable stop block to make multiple cuts or to change the angle and make miter cuts with the same fence. However, always check the accuracy of the miter gauge with a square or protractor before making any cuts.

To avoid binding and kickback when cutting, always push the workpiece and fence completely past the blade. Then turn off the saw before retracting the fence and removing newly cut pieces.

Tip 4: Clamp to a long fence on long boards

Use a long fence

Attach a horizontal or long board to the fence to carry long boards.

It's a challenge to keep a long, heavy board or plywood tight against a short fence, especially if you're working alone. It is all too easy for the wood to wander off the fence, ruining the cut or binding the blade and leaving burn marks along the edge. To avoid these problems, pin a long or long, straight board to the fence. The longer the fence, the easier it is to hold the wood tight.

Tip 5: Use half a fence for complicated grain

Clamp thin wood on the fence

Place 3/4-inch. Lumber against the fence to prevent wavy wood from binding the saw blade.

Wood with branches or wavy grain and unevenly dried wood often tightens when tearing. When the halves bend outward, you push against the fence, causing burn marks, a setback, or an uneven cut.

When this happens, clamp a smooth, straight length of 3/4 inch. Wood against the fence and ends in the middle of the saw blade. This half fence gives the enclosed part (the section between the blade and the fence) room to bend without pressing against the blade. Hold several pushers at hand so you can bypass the staples and smooth the cut.

When the two halves bend toward each other while pinching the splitter at the end of the blade guard, turn off the saw and wed a disc between the two parts. Then complete the cut.

0 notes

Text

Making A Concrete Coffee Table Top

Hey, good news! I finally have a place to put my feet up in the beach house living room. Or, as Sherry would state this good news: we finally have a coffee table!

light fixture / ceiling medallion / similar rug / similar sofa / similar curtains / curtain rods

And it was a DIY that was SO MUCH CHEAPER than the high end alternative, so three cheers for that. Oh and people who follow our InstaStories know we’ve switched out the rug in here for this rug since taking these pics, so there will be a post all about that (and the other dining room tweak we’ve made) coming up in a week or two. But back to the coffee table.

We’ve actually had the table base for a while, but it’s been completely topless for months. We scored this wooden octagonal table base from a neighbor who had planned on adding a top to it at some point, but after months of doing nothing with it she put it on our neighborhood buy/sell board for a whopping $7. After paying 700 pretty pennies for it, it remained topless in our garage for several months before moving to the beach house last fall (see below)… where it remained – still topless – until last month.

Our grand scheme was to get a stone top custom cut for it. Marble would look great, but we also considered more durable options like quartz. But quotes from two different stone yards – even for remnant pieces – came back between $700 – $900. I KNOW. They were MUCH higher than we expected, partially because of the size (it’s 38″ at its widest, which makes it deeper than a standard countertop by a fair amount) and the octagonal shape.

So we quickly shifted from “buying a stone top for it” to “DIYing a stone-like top for it” – and after weighing all sorts of solutions (faux stone laminate, a wood top we painted white or even tried to “marble”, etc) we landed a white concrete top that would give us a nice chunky stone look, but at a much cheaper cost. Unfortunately, the project kept getting nudged behind bigger tasks like installing the kitchen and building bunk beds. Hence why I was forced to uncomfortably prop my feet up on this edge of this puppy each time we visited. Feel bad for me, please.

We feared that a solid poured concrete slab would (a) be very heavy and (2) be very prone to cracking or breaking – especially without adding lots of extra support under the table top. Plus little kid heads + a solid hunk of concrete sounded worrisome. So instead we decided to create a wood top and then cover the wood with Ardex Feather Finish, which is a thin concrete material that we used years ago to give our laminate kitchen counters the appearance of solid concrete.

Making The Wood Coffee Table Top

We picked up a 4 x 4′ sheet of 3/4″ plywood because we wanted something sturdy enough to span the tabletop without sagging. To mark my cuts, I simply flipped the table over on top of the plywood and traced the edges with a pen. Don’t worry, I’ll show you how I made it overhang the table’s edge in a moment.

Using my circular saw outside, I trimmed off the edges to get an octagon that perfectly fit the top of our table base. No overhang. Yet.

Next I cut 8 pieces of 1 x 2″ whitewood to create a border around my cut plywood. After summoning some of my 8th-grade geometry, I determined that I needed to cut each one at a 22.5-degree angle to fit them around the octagon. But surprise-surprise, my miter saw was one step ahead of me and already had that as a preset angle.

Then, with the plywood laid on top of the base with the edges flush, I started nailing each of my 1 x 2″ pieces around the edges (into the plywood, not the table base). I put wood glue on it before I nailed, which help things hold for the long haul. Adding this border did a few helpful things:

It made the wood top slightly larger than the base, giving it a nice overhang

It made the wood top look twice as thick as it really is, without adding much more weight to it

It helped keep the top in place by making it almost like a snug shoebox top. I still screwed it to the base from underneath just to be safe.

Once it was all nailed in, I used wood putty to fill in all of my gaps and nail holes. This probably wasn’t a super critical step (I was going to coat this with a skim coat of concrete, after all) but I discovered the table isn’t a perfect octagon, so some of my corners weren’t as tight as I’d hoped. This shot is from before I sanded the excess wood filler off:

Applying The Concrete Finish

We haven’t used Ardex Feather Finish since our first project with it: our old kitchen’s laminate counters (here’s the tutorial for applying it and then sealing them to be food safe). While we decided the application was awesome for a quick makeover, they did get a little oil-stained around the stove since we used food-safe sealer as opposed to some of the more heavier duty sealers. No worries, we just added a cutting board to cover the small splatters – and we loved the imperfections and movement that was created in the application process. Definitely a whole lot better than the old plastic-y counters the house came with. Overall: we’d definitely recommend this method for a kitchen counter update – especially if you use a stronger sealer.

For the coffee table we decided to use the white Ardex instead of the standard gray color, so we tracked down a 10 pound bag online for $40. The dry Ardex mix just combines with water, so to apply it all you really need are some mixing/measuring buckets and various sized trowels to apply and smooth it. Oh, and sandpaper and a power sander (this is the one we have).

The bag suggested a 2 to 1 mix of Ardex powder to water, but I read our old post and reminded myself that I had liked a bit more water than that – it helped keep the mix looser and easier to spread. So I started by measuring one small batch at a time (I think I needed about twice this much to complete one coat).

I mixed them together using a small trowel, making sure to getting any remaining powder mixed in. I aimed for a thick pancake batter consistency – like it would sorta hold to my trowel for a moment before dripping off on its own.

Then I just scooped everything onto my table and started spreading it smooth, using larger trowels on the top and smaller ones on the edges. Note: whatever surface you’re doing this on should be sanded enough to be rough. Our plywood was already slightly textured, so I could skip this step, but if you’re doing it on the top of a piece of furniture, be sure to take a pass with low-grit sandpaper first (like 60-80 grit).

Ardex takes more than one coat (we did two this time) so my first pass was really about coverage, not smoothness. I was worried about sanding too much off during the next step, especially on the edges and corners, so I threw caution to the wind and really laid it on thick around the edge.

I gave it several hours to dry and then came back to start smoothing. The first thing I did (and my favorite part) was to use a putty knife to scrape all of the stalactites that dripped down the bottom edge. It was so satisfying and it gave us a really clean edge on the bottom.

Then I took some low-grit sandpaper (80) and went to town on the rest of the top with my palm sander. Since I knew another coat was coming after this one, I wasn’t concerned about getting it flawlessly smooth. I mostly wanted to eliminate any hard ridges that would catch clumps of Ardex during my next application.

This is what the top looked like after I sanded the first coat. Obviously, you can see lots of my trowel marks as well as little pockets where the Ardex didn’t spread completely smoothly. It’s a bit rougher than we wanted for the final product, but it was fine for a first coat.

The second coat went on in pretty much the exact same method – except I did mix the Ardex a bit thinner and I took a bit more care getting a smoother application since this would be the top one that’s seen by everyone. Plus, when I sanded it, I moved from my initial low-grit (80) sandpaper down to 120 then 220, so that the finished table was super smooth. I didn’t remember to snap any photos of the coffee table after we sanded the second coat, but took lots of them once it was sealed and finished, so if we skip ahead for a second, here’s the finished result:

Sealing The Concrete

There are lots of products out there for sealing concrete. As I mentioned, we used food safe eco-sealer on our kitchen counters, which we think might be the reason tiny little grease spatters sunk in next to the stove – but since we’re not planning to prepare food on this table, we went with something heavier duty for a nice super-durable finish this time. Our final choice? This “Wet-Look” Sealer by Behr. Sherry suggested something high-gloss, which would really mimic that glossy stone look, and we were both really happy with how it turned out. Almost a mirror-like shine – which you can sort of see in the photo above.

I just used a small foam roller to apply a thin coat along the top and all of the sides. Once it had dried for a few hours, we did a second coat (and later a third coat, just to be safe). I barely made a dent in the 1 gallon container (it was the smallest one they sold) but at least I have some on hand to do a touch-up sealing coat every year or two, just to be safe.

Once it was all fully dry, we brought it in and let it cure for a week before putting any objects on it (not that it needs that long – we just weren’t at the beach house for a week). And BOY DOES IT FEEL GOOD TO HAVE A COFFEE TABLE!

light / ceiling medallion / similar rug / similar curtains / curtain rods / TV stand / similar chair

The white top breaks up the darker rug and couch nicely, and also helps tie together some of the other bright white accents like the bookshelf and the curtains.

It’s hard to tell from these photos, but although the concrete is super glossy and chunky, it still has imperfections, which is definitely part of the charm. Instead of looking like a big block of shiny plastic, it gives off that raw concrete vibe – even in the glossy white color. This next picture probably best shows a few light trowel marks. It all feels smooth to the touch, but when you look closely they’re definitely there. Again, this is some of the “interest” that we expected from the Ardex process (or at least my version of it – ha!) and for us it takes the place of the movement we would’ve gotten from a stone like marble.

Sherry and I have also discussed everything from staining the wood base a little bit darker (especially to disguise the light edges) to painting the while base a glossy white to emphasize the interesting shape of the legs. But for now I’ve argued that we should just kick up our feet and enjoy having a place to actually kick up our feet. IS THAT TOO MUCH TO ASK?

bookcase / similar pink pillow / similar blue pillow / white faux wood window blinds

And don’t even get me started on the other furniture adjustments we’re thinking about in this room. Actually since we took these photos we’ve painted and recovered two armchairs for that wall on the right, so there’s a lot more comfy seating in here now (although we’re thinking about a few other adjustments before calling it done). But that’s a topic for another day!

Also! If you have any where-did-you-get-that questions about the beach house (or paint color questions, which we also get a lot) this page has all the answers for you.

P.S. Do you get our free weekly emails? We love sending bonus details, design tips, random style thoughts, and other house-related stuff. Click here to get them delivered right to your inbox. And thanks to everyone who is on the list already – Sherry loves putting them together for you each week.

*This post contains affiliate links*

The post Making A Concrete Coffee Table Top appeared first on Young House Love.

Making A Concrete Coffee Table Top published first on https://aireloomreview.tumblr.com/

0 notes

Text

Making A Concrete Coffee Table Top

Hey, good news! I finally have a place to put my feet up in the beach house living room. Or, as Sherry would state this good news: we finally have a coffee table!

light fixture / ceiling medallion / similar rug / similar sofa / similar curtains / curtain rods

And it was a DIY that was SO MUCH CHEAPER than the high end alternative, so three cheers for that. Oh and people who follow our InstaStories know we’ve switched out the rug in here for this rug since taking these pics, so there will be a post all about that (and the other dining room tweak we’ve made) coming up in a week or two. But back to the coffee table.

We’ve actually had the table base for a while, but it’s been completely topless for months. We scored this wooden octagonal table base from a neighbor who had planned on adding a top to it at some point, but after months of doing nothing with it she put it on our neighborhood buy/sell board for a whopping $7. After paying 700 pretty pennies for it, it remained topless in our garage for several months before moving to the beach house last fall (see below)… where it remained – still topless – until last month.

Our grand scheme was to get a stone top custom cut for it. Marble would look great, but we also considered more durable options like quartz. But quotes from two different stone yards – even for remnant pieces – came back between $700 – $900. I KNOW. They were MUCH higher than we expected, partially because of the size (it’s 38″ at its widest, which makes it deeper than a standard countertop by a fair amount) and the octagonal shape.

So we quickly shifted from “buying a stone top for it” to “DIYing a stone-like top for it” – and after weighing all sorts of solutions (faux stone laminate, a wood top we painted white or even tried to “marble”, etc) we landed a white concrete top that would give us a nice chunky stone look, but at a much cheaper cost. Unfortunately, the project kept getting nudged behind bigger tasks like installing the kitchen and building bunk beds. Hence why I was forced to uncomfortably prop my feet up on this edge of this puppy each time we visited. Feel bad for me, please.

We feared that a solid poured concrete slab would (a) be very heavy and (2) be very prone to cracking or breaking – especially without adding lots of extra support under the table top. Plus little kid heads + a solid hunk of concrete sounded worrisome. So instead we decided to create a wood top and then cover the wood with Ardex Feather Finish, which is a thin concrete material that we used years ago to give our laminate kitchen counters the appearance of solid concrete.

Making The Wood Coffee Table Top

We picked up a 4 x 4′ sheet of 3/4″ plywood because we wanted something sturdy enough to span the tabletop without sagging. To mark my cuts, I simply flipped the table over on top of the plywood and traced the edges with a pen. Don’t worry, I’ll show you how I made it overhang the table’s edge in a moment.

Using my circular saw outside, I trimmed off the edges to get an octagon that perfectly fit the top of our table base. No overhang. Yet.

Next I cut 8 pieces of 1 x 2″ whitewood to create a border around my cut plywood. After summoning some of my 8th-grade geometry, I determined that I needed to cut each one at a 22.5-degree angle to fit them around the octagon. But surprise-surprise, my miter saw was one step ahead of me and already had that as a preset angle.

Then, with the plywood laid on top of the base with the edges flush, I started nailing each of my 1 x 2″ pieces around the edges (into the plywood, not the table base). I put wood glue on it before I nailed, which help things hold for the long haul. Adding this border did a few helpful things:

It made the wood top slightly larger than the base, giving it a nice overhang

It made the wood top look twice as thick as it really is, without adding much more weight to it

It helped keep the top in place by making it almost like a snug shoebox top. I still screwed it to the base from underneath just to be safe.

Once it was all nailed in, I used wood putty to fill in all of my gaps and nail holes. This probably wasn’t a super critical step (I was going to coat this with a skim coat of concrete, after all) but I discovered the table isn’t a perfect octagon, so some of my corners weren’t as tight as I’d hoped. This shot is from before I sanded the excess wood filler off:

Applying The Concrete Finish

We haven’t used Ardex Feather Finish since our first project with it: our old kitchen’s laminate counters (here’s the tutorial for applying it and then sealing them to be food safe). While we decided the application was awesome for a quick makeover, they did get a little oil-stained around the stove since we used food-safe sealer as opposed to some of the more heavier duty sealers. No worries, we just added a cutting board to cover the small splatters – and we loved the imperfections and movement that was created in the application process. Definitely a whole lot better than the old plastic-y counters the house came with. Overall: we’d definitely recommend this method for a kitchen counter update – especially if you use a stronger sealer.

For the coffee table we decided to use the white Ardex instead of the standard gray color, so we tracked down a 10 pound bag online for $40. The dry Ardex mix just combines with water, so to apply it all you really need are some mixing/measuring buckets and various sized trowels to apply and smooth it. Oh, and sandpaper and a power sander (this is the one we have).

The bag suggested a 2 to 1 mix of Ardex powder to water, but I read our old post and reminded myself that I had liked a bit more water than that – it helped keep the mix looser and easier to spread. So I started by measuring one small batch at a time (I think I needed about twice this much to complete one coat).

I mixed them together using a small trowel, making sure to getting any remaining powder mixed in. I aimed for a thick pancake batter consistency – like it would sorta hold to my trowel for a moment before dripping off on its own.

Then I just scooped everything onto my table and started spreading it smooth, using larger trowels on the top and smaller ones on the edges. Note: whatever surface you’re doing this on should be sanded enough to be rough. Our plywood was already slightly textured, so I could skip this step, but if you’re doing it on the top of a piece of furniture, be sure to take a pass with low-grit sandpaper first (like 60-80 grit).

Ardex takes more than one coat (we did two this time) so my first pass was really about coverage, not smoothness. I was worried about sanding too much off during the next step, especially on the edges and corners, so I threw caution to the wind and really laid it on thick around the edge.

I gave it several hours to dry and then came back to start smoothing. The first thing I did (and my favorite part) was to use a putty knife to scrape all of the stalactites that dripped down the bottom edge. It was so satisfying and it gave us a really clean edge on the bottom.

Then I took some low-grit sandpaper (80) and went to town on the rest of the top with my palm sander. Since I knew another coat was coming after this one, I wasn’t concerned about getting it flawlessly smooth. I mostly wanted to eliminate any hard ridges that would catch clumps of Ardex during my next application.

This is what the top looked like after I sanded the first coat. Obviously, you can see lots of my trowel marks as well as little pockets where the Ardex didn’t spread completely smoothly. It’s a bit rougher than we wanted for the final product, but it was fine for a first coat.

The second coat went on in pretty much the exact same method – except I did mix the Ardex a bit thinner and I took a bit more care getting a smoother application since this would be the top one that’s seen by everyone. Plus, when I sanded it, I moved from my initial low-grit (80) sandpaper down to 120 then 220, so that the finished table was super smooth. I didn’t remember to snap any photos of the coffee table after we sanded the second coat, but took lots of them once it was sealed and finished, so if we skip ahead for a second, here’s the finished result:

Sealing The Concrete

There are lots of products out there for sealing concrete. As I mentioned, we used food safe eco-sealer on our kitchen counters, which we think might be the reason tiny little grease spatters sunk in next to the stove – but since we’re not planning to prepare food on this table, we went with something heavier duty for a nice super-durable finish this time. Our final choice? This “Wet-Look” Sealer by Behr. Sherry suggested something high-gloss, which would really mimic that glossy stone look, and we were both really happy with how it turned out. Almost a mirror-like shine – which you can sort of see in the photo above.

I just used a small foam roller to apply a thin coat along the top and all of the sides. Once it had dried for a few hours, we did a second coat (and later a third coat, just to be safe). I barely made a dent in the 1 gallon container (it was the smallest one they sold) but at least I have some on hand to do a touch-up sealing coat every year or two, just to be safe.

Once it was all fully dry, we brought it in and let it cure for a week before putting any objects on it (not that it needs that long – we just weren’t at the beach house for a week). And BOY DOES IT FEEL GOOD TO HAVE A COFFEE TABLE!

light / ceiling medallion / similar rug / similar curtains / curtain rods / TV stand / similar chair

The white top breaks up the darker rug and couch nicely, and also helps tie together some of the other bright white accents like the bookshelf and the curtains.

It’s hard to tell from these photos, but although the concrete is super glossy and chunky, it still has imperfections, which is definitely part of the charm. Instead of looking like a big block of shiny plastic, it gives off that raw concrete vibe – even in the glossy white color. This next picture probably best shows a few light trowel marks. It all feels smooth to the touch, but when you look closely they’re definitely there. Again, this is some of the “interest” that we expected from the Ardex process (or at least my version of it – ha!) and for us it takes the place of the movement we would’ve gotten from a stone like marble.

Sherry and I have also discussed everything from staining the wood base a little bit darker (especially to disguise the light edges) to painting the while base a glossy white to emphasize the interesting shape of the legs. But for now I’ve argued that we should just kick up our feet and enjoy having a place to actually kick up our feet. IS THAT TOO MUCH TO ASK?

bookcase / similar pink pillow / similar blue pillow / white faux wood window blinds

And don’t even get me started on the other furniture adjustments we’re thinking about in this room. Actually since we took these photos we’ve painted and recovered two armchairs for that wall on the right, so there’s a lot more comfy seating in here now (although we’re thinking about a few other adjustments before calling it done). But that’s a topic for another day!

Also! If you have any where-did-you-get-that questions about the beach house (or paint color questions, which we also get a lot) this page has all the answers for you.

P.S. Do you get our free weekly emails? We love sending bonus details, design tips, random style thoughts, and other house-related stuff. Click here to get them delivered right to your inbox. And thanks to everyone who is on the list already – Sherry loves putting them together for you each week.

*This post contains affiliate links*

The post Making A Concrete Coffee Table Top appeared first on Young House Love.

Making A Concrete Coffee Table Top published first on https://ssmattress.tumblr.com/

0 notes

Text

Making A Concrete Coffee Table Top

Hey, good news! I finally have a place to put my feet up in the beach house living room. Or, as Sherry would state this good news: we finally have a coffee table!

light fixture / ceiling medallion / similar rug / similar sofa / similar curtains / curtain rods

And it was a DIY that was SO MUCH CHEAPER than the high end alternative, so three cheers for that. Oh and people who follow our InstaStories know we’ve switched out the rug in here for this rug since taking these pics, so there will be a post all about that (and the other dining room tweak we’ve made) coming up in a week or two. But back to the coffee table.

We’ve actually had the table base for a while, but it’s been completely topless for months. We scored this wooden octagonal table base from a neighbor who had planned on adding a top to it at some point, but after months of doing nothing with it she put it on our neighborhood buy/sell board for a whopping $7. After paying 700 pretty pennies for it, it remained topless in our garage for several months before moving to the beach house last fall (see below)… where it remained – still topless – until last month.

Our grand scheme was to get a stone top custom cut for it. Marble would look great, but we also considered more durable options like quartz. But quotes from two different stone yards – even for remnant pieces – came back between $700 – $900. I KNOW. They were MUCH higher than we expected, partially because of the size (it’s 38″ at its widest, which makes it deeper than a standard countertop by a fair amount) and the octagonal shape.

So we quickly shifted from “buying a stone top for it” to “DIYing a stone-like top for it” – and after weighing all sorts of solutions (faux stone laminate, a wood top we painted white or even tried to “marble”, etc) we landed a white concrete top that would give us a nice chunky stone look, but at a much cheaper cost. Unfortunately, the project kept getting nudged behind bigger tasks like installing the kitchen and building bunk beds. Hence why I was forced to uncomfortably prop my feet up on this edge of this puppy each time we visited. Feel bad for me, please.

We feared that a solid poured concrete slab would (a) be very heavy and (2) be very prone to cracking or breaking – especially without adding lots of extra support under the table top. Plus little kid heads + a solid hunk of concrete sounded worrisome. So instead we decided to create a wood top and then cover the wood with Ardex Feather Finish, which is a thin concrete material that we used years ago to give our laminate kitchen counters the appearance of solid concrete.

Making The Wood Coffee Table Top

We picked up a 4 x 4′ sheet of 3/4″ plywood because we wanted something sturdy enough to span the tabletop without sagging. To mark my cuts, I simply flipped the table over on top of the plywood and traced the edges with a pen. Don’t worry, I’ll show you how I made it overhang the table’s edge in a moment.

Using my circular saw outside, I trimmed off the edges to get an octagon that perfectly fit the top of our table base. No overhang. Yet.

Next I cut 8 pieces of 1 x 2″ whitewood to create a border around my cut plywood. After summoning some of my 8th-grade geometry, I determined that I needed to cut each one at a 22.5-degree angle to fit them around the octagon. But surprise-surprise, my miter saw was one step ahead of me and already had that as a preset angle.

Then, with the plywood laid on top of the base with the edges flush, I started nailing each of my 1 x 2″ pieces around the edges (into the plywood, not the table base). I put wood glue on it before I nailed, which help things hold for the long haul. Adding this border did a few helpful things:

It made the wood top slightly larger than the base, giving it a nice overhang

It made the wood top look twice as thick as it really is, without adding much more weight to it

It helped keep the top in place by making it almost like a snug shoebox top. I still screwed it to the base from underneath just to be safe.

Once it was all nailed in, I used wood putty to fill in all of my gaps and nail holes. This probably wasn’t a super critical step (I was going to coat this with a skim coat of concrete, after all) but I discovered the table isn’t a perfect octagon, so some of my corners weren’t as tight as I’d hoped. This shot is from before I sanded the excess wood filler off:

Applying The Concrete Finish

We haven’t used Ardex Feather Finish since our first project with it: our old kitchen’s laminate counters (here’s the tutorial for applying it and then sealing them to be food safe). While we decided the application was awesome for a quick makeover, they did get a little oil-stained around the stove since we used food-safe sealer as opposed to some of the more heavier duty sealers. No worries, we just added a cutting board to cover the small splatters – and we loved the imperfections and movement that was created in the application process. Definitely a whole lot better than the old plastic-y counters the house came with. Overall: we’d definitely recommend this method for a kitchen counter update – especially if you use a stronger sealer.

For the coffee table we decided to use the white Ardex instead of the standard gray color, so we tracked down a 10 pound bag online for $40. The dry Ardex mix just combines with water, so to apply it all you really need are some mixing/measuring buckets and various sized trowels to apply and smooth it. Oh, and sandpaper and a power sander (this is the one we have).

The bag suggested a 2 to 1 mix of Ardex powder to water, but I read our old post and reminded myself that I had liked a bit more water than that – it helped keep the mix looser and easier to spread. So I started by measuring one small batch at a time (I think I needed about twice this much to complete one coat).

I mixed them together using a small trowel, making sure to getting any remaining powder mixed in. I aimed for a thick pancake batter consistency – like it would sorta hold to my trowel for a moment before dripping off on its own.

Then I just scooped everything onto my table and started spreading it smooth, using larger trowels on the top and smaller ones on the edges. Note: whatever surface you’re doing this on should be sanded enough to be rough. Our plywood was already slightly textured, so I could skip this step, but if you’re doing it on the top of a piece of furniture, be sure to take a pass with low-grit sandpaper first (like 60-80 grit).

Ardex takes more than one coat (we did two this time) so my first pass was really about coverage, not smoothness. I was worried about sanding too much off during the next step, especially on the edges and corners, so I threw caution to the wind and really laid it on thick around the edge.

I gave it several hours to dry and then came back to start smoothing. The first thing I did (and my favorite part) was to use a putty knife to scrape all of the stalactites that dripped down the bottom edge. It was so satisfying and it gave us a really clean edge on the bottom.

Then I took some low-grit sandpaper (80) and went to town on the rest of the top with my palm sander. Since I knew another coat was coming after this one, I wasn’t concerned about getting it flawlessly smooth. I mostly wanted to eliminate any hard ridges that would catch clumps of Ardex during my next application.

This is what the top looked like after I sanded the first coat. Obviously, you can see lots of my trowel marks as well as little pockets where the Ardex didn’t spread completely smoothly. It’s a bit rougher than we wanted for the final product, but it was fine for a first coat.

The second coat went on in pretty much the exact same method – except I did mix the Ardex a bit thinner and I took a bit more care getting a smoother application since this would be the top one that’s seen by everyone. Plus, when I sanded it, I moved from my initial low-grit (80) sandpaper down to 120 then 220, so that the finished table was super smooth. I didn’t remember to snap any photos of the coffee table after we sanded the second coat, but took lots of them once it was sealed and finished, so if we skip ahead for a second, here’s the finished result:

Sealing The Concrete

There are lots of products out there for sealing concrete. As I mentioned, we used food safe eco-sealer on our kitchen counters, which we think might be the reason tiny little grease spatters sunk in next to the stove – but since we’re not planning to prepare food on this table, we went with something heavier duty for a nice super-durable finish this time. Our final choice? This “Wet-Look” Sealer by Behr. Sherry suggested something high-gloss, which would really mimic that glossy stone look, and we were both really happy with how it turned out. Almost a mirror-like shine – which you can sort of see in the photo above.

I just used a small foam roller to apply a thin coat along the top and all of the sides. Once it had dried for a few hours, we did a second coat (and later a third coat, just to be safe). I barely made a dent in the 1 gallon container (it was the smallest one they sold) but at least I have some on hand to do a touch-up sealing coat every year or two, just to be safe.

Once it was all fully dry, we brought it in and let it cure for a week before putting any objects on it (not that it needs that long – we just weren’t at the beach house for a week). And BOY DOES IT FEEL GOOD TO HAVE A COFFEE TABLE!

light / ceiling medallion / similar rug / similar curtains / curtain rods / TV stand / similar chair

The white top breaks up the darker rug and couch nicely, and also helps tie together some of the other bright white accents like the bookshelf and the curtains.

It’s hard to tell from these photos, but although the concrete is super glossy and chunky, it still has imperfections, which is definitely part of the charm. Instead of looking like a big block of shiny plastic, it gives off that raw concrete vibe – even in the glossy white color. This next picture probably best shows a few light trowel marks. It all feels smooth to the touch, but when you look closely they’re definitely there. Again, this is some of the “interest” that we expected from the Ardex process (or at least my version of it – ha!) and for us it takes the place of the movement we would’ve gotten from a stone like marble.

Sherry and I have also discussed everything from staining the wood base a little bit darker (especially to disguise the light edges) to painting the while base a glossy white to emphasize the interesting shape of the legs. But for now I’ve argued that we should just kick up our feet and enjoy having a place to actually kick up our feet. IS THAT TOO MUCH TO ASK?

bookcase / similar pink pillow / similar blue pillow / white faux wood window blinds

And don’t even get me started on the other furniture adjustments we’re thinking about in this room. Actually since we took these photos we’ve painted and recovered two armchairs for that wall on the right, so there’s a lot more comfy seating in here now (although we’re thinking about a few other adjustments before calling it done). But that’s a topic for another day!

Also! If you have any where-did-you-get-that questions about the beach house (or paint color questions, which we also get a lot) this page has all the answers for you.

P.S. Do you get our free weekly emails? We love sending bonus details, design tips, random style thoughts, and other house-related stuff. Click here to get them delivered right to your inbox. And thanks to everyone who is on the list already – Sherry loves putting them together for you each week.

*This post contains affiliate links*

The post Making A Concrete Coffee Table Top appeared first on Young House Love.

Making A Concrete Coffee Table Top published first on https://bakerskitchenslimited.tumblr.com/

0 notes

Photo

Making A Concrete Coffee Table Top https://ift.tt/2IzVEdg

Hey, good news! I finally have a place to put my feet up in the beach house living room. Or, as Sherry would state this good news: we finally have a coffee table!

And it was a DIY that was SO MUCH CHEAPER than the high end alternative, so three cheers for that. Oh and people who follow our InstaStories know we’ve switched out the rug in here for this rug since taking these pics, so there will be a post all about that (and the other dining room tweak we’ve made) coming up in a week or two. But back to the coffee table.

We’ve actually had the table base for a while, but it’s been completely topless for months. We scored this wooden octagonal table base from a neighbor who had planned on adding a top to it at some point, but after months of doing nothing with it she put it on our neighborhood buy/sell board for a whopping $7. After paying 700 pretty pennies for it, it remained topless in our garage for several months before moving to the beach house last fall (see below)… where it remained – still topless – until last month.

Our grand scheme was to get a stone top custom cut for it. Marble would look great, but we also considered more durable options like quartz. But quotes from two different stone yards – even for remnant pieces – came back between $700 – $900. I KNOW. They were MUCH higher than we expected, partially because of the size (it’s 38″ at its widest, which makes it deeper than a standard countertop by a fair amount) and the octagonal shape.

So we quickly shifted from “buying a stone top for it” to “DIYing a stone-like top for it” – and after weighing all sorts of solutions (faux stone laminate, a wood top we painted white or even tried to “marble”, etc) we landed a white concrete top that would give us a nice chunky stone look, but at a much cheaper cost. Unfortunately, the project kept getting nudged behind bigger tasks like installing the kitchen and building bunk beds. Hence why I was forced to uncomfortably prop my feet up on this edge of this puppy each time we visited. Feel bad for me, please.

We feared that a solid poured concrete slab would (a) be very heavy and (2) be very prone to cracking or breaking – especially without adding lots of extra support under the table top. Plus little kid heads + a solid hunk of concrete sounded worrisome. So instead we decided to create a wood top and then cover the wood with Ardex Feather Finish, which is a thin concrete material that we used years ago to give our laminate kitchen counters the appearance of solid concrete.

Making The Wood Coffee Table Top

We picked up a 4 x 4′ sheet of 3/4″ plywood because we wanted something sturdy enough to span the tabletop without sagging. To mark my cuts, I simply flipped the table over on top of the plywood and traced the edges with a pen. Don’t worry, I’ll show you how I made it overhang the table’s edge in a moment.

Using my circular saw outside, I trimmed off the edges to get an octagon that perfectly fit the top of our table base. No overhang. Yet.

Next I cut 8 pieces of 1 x 2″ whitewood to create a border around my cut plywood. After summoning some of my 8th-grade geometry, I determined that I needed to cut each one at a 22.5-degree angle to fit them around the octagon. But surprise-surprise, my miter saw was one step ahead of me and already had that as a preset angle.

Then, with the plywood laid on top of the base with the edges flush, I started nailing each of my 1 x 2″ pieces around the edges (into the plywood, not the table base). I put wood glue on it before I nailed, which help things hold for the long haul. Adding this border did a few helpful things:

It made the wood top slightly larger than the base, giving it a nice overhang

It made the wood top look twice as thick as it really is, without adding much more weight to it

It helped keep the top in place by making it almost like a snug shoebox top. I still screwed it to the base from underneath just to be safe.

Once it was all nailed in, I used wood putty to fill in all of my gaps and nail holes. This probably wasn’t a super critical step (I was going to coat this with a skim coat of concrete, after all) but I discovered the table isn’t a perfect octagon, so some of my corners weren’t as tight as I’d hoped. This shot is from before I sanded the excess wood filler off:

Applying The Concrete Finish

We haven’t used Ardex Feather Finish since our first project with it: our old kitchen’s laminate counters (here’s the tutorial for applying it and then sealing them to be food safe). While we decided the application was awesome for a quick makeover, they did get a little oil-stained around the stove since we used food-safe sealer as opposed to some of the more heavier duty sealers. No worries, we just added a cutting board to cover the small splatters – and we loved the imperfections and movement that was created in the application process. Definitely a whole lot better than the old plastic-y counters the house came with. Overall: we’d definitely recommend this method for a kitchen counter update – especially if you use a stronger sealer.

For the coffee table we decided to use the white Ardex instead of the standard gray color, so we tracked down a 10 pound bag online for $40. The dry Ardex mix just combines with water, so to apply it all you really need are some mixing/measuring buckets and various sized trowels to apply and smooth it. Oh, and sandpaper and a power sander (this is the one we have).

The bag suggested a 2 to 1 mix of Ardex powder to water, but I read our old post and reminded myself that I had liked a bit more water than that – it helped keep the mix looser and easier to spread. So I started by measuring one small batch at a time (I think I needed about twice this much to complete one coat).

I mixed them together using a small trowel, making sure to getting any remaining powder mixed in. I aimed for a thick pancake batter consistency – like it would sorta hold to my trowel for a moment before dripping off on its own.

Then I just scooped everything onto my table and started spreading it smooth, using larger trowels on the top and smaller ones on the edges. Note: whatever surface you’re doing this on should be sanded enough to be rough. Our plywood was already slightly textured, so I could skip this step, but if you’re doing it on the top of a piece of furniture, be sure to take a pass with low-grit sandpaper first (like 60-80 grit).

Ardex takes more than one coat (we did two this time) so my first pass was really about coverage, not smoothness. I was worried about sanding too much off during the next step, especially on the edges and corners, so I threw caution to the wind and really laid it on thick around the edge.

I gave it several hours to dry and then came back to start smoothing. The first thing I did (and my favorite part) was to use a putty knife to scrape all of the stalactites that dripped down the bottom edge. It was so satisfying and it gave us a really clean edge on the bottom.

Then I took some low-grit sandpaper (80) and went to town on the rest of the top with my palm sander. Since I knew another coat was coming after this one, I wasn’t concerned about getting it flawlessly smooth. I mostly wanted to eliminate any hard ridges that would catch clumps of Ardex during my next application.

This is what the top looked like after I sanded the first coat. Obviously, you can see lots of my trowel marks as well as little pockets where the Ardex didn’t spread completely smoothly. It’s a bit rougher than we wanted for the final product, but it was fine for a first coat.

The second coat went on in pretty much the exact same method – except I did mix the Ardex a bit thinner and I took a bit more care getting a smoother application since this would be the top one that’s seen by everyone. Plus, when I sanded it, I moved from my initial low-grit (80) sandpaper down to 120 then 220, so that the finished table was super smooth. I didn’t remember to snap any photos of the coffee table after we sanded the second coat, but took lots of them once it was sealed and finished, so if we skip ahead for a second, here’s the finished result:

Sealing The Concrete

There are lots of products out there for sealing concrete. As I mentioned, we used food safe eco-sealer on our kitchen counters, which we think might be the reason tiny little grease spatters sunk in next to the stove – but since we’re not planning to prepare food on this table, we went with something heavier duty for a nice super-durable finish this time. Our final choice? This “Wet-Look” Sealer by Behr. Sherry suggested something high-gloss, which would really mimic that glossy stone look, and we were both really happy with how it turned out. Almost a mirror-like shine – which you can sort of see in the photo above.

I just used a small foam roller to apply a thin coat along the top and all of the sides. Once it had dried for a few hours, we did a second coat (and later a third coat, just to be safe). I barely made a dent in the 1 gallon container (it was the smallest one they sold) but at least I have some on hand to do a touch-up sealing coat every year or two, just to be safe.

Once it was all fully dry, we brought it in and let it cure for a week before putting any objects on it (not that it needs that long – we just weren’t at the beach house for a week). And BOY DOES IT FEEL GOOD TO HAVE A COFFEE TABLE!

The white top breaks up the darker rug and couch nicely, and also helps tie together some of the other bright white accents like the bookshelf and the curtains.

It’s hard to tell from these photos, but although the concrete is super glossy and chunky, it still has imperfections, which is definitely part of the charm. Instead of looking like a big block of shiny plastic, it gives off that raw concrete vibe – even in the glossy white color. This next picture probably best shows a few light trowel marks. It all feels smooth to the touch, but when you look closely they’re definitely there. Again, this is some of the “interest” that we expected from the Ardex process (or at least my version of it – ha!) and for us it takes the place of the movement we would’ve gotten from a stone like marble.

Sherry and I have also discussed everything from staining the wood base a little bit darker (especially to disguise the light edges) to painting the while base a glossy white to emphasize the interesting shape of the legs. But for now I’ve argued that we should just kick up our feet and enjoy having a place to actually kick up our feet. IS THAT TOO MUCH TO ASK?

And don’t even get me started on the other furniture adjustments we’re thinking about in this room. Actually since we took these photos we’ve painted and recovered two armchairs for that wall on the right, so there’s a lot more comfy seating in here now (although we’re thinking about a few other adjustments before calling it done). But that’s a topic for another day!

P.S. Do you get our free weekly emails? We love sending bonus details, design tips, random style thoughts, and other house-related stuff. Click here to get them delivered right to your inbox. And thanks to everyone who is on the list already – Sherry loves putting them together for you each week.

*This post contains affiliate links*

The post Making A Concrete Coffee Table Top appeared first on Young House Love.

0 notes

Text

Making A Concrete Coffee Table Top

Hey, good news! I finally have a place to put my feet up in the beach house living room. Or, as Sherry would state this good news: we finally have a coffee table!

And it was a DIY that was SO MUCH CHEAPER than the high end alternative, so three cheers for that. Oh and people who follow our InstaStories know we’ve switched out the rug in here for this rug since taking these pics, so there will be a post all about that (and the other dining room tweak we’ve made) coming up in a week or two. But back to the coffee table.

We’ve actually had the table base for a while, but it’s been completely topless for months. We scored this wooden octagonal table base from a neighbor who had planned on adding a top to it at some point, but after months of doing nothing with it she put it on our neighborhood buy/sell board for a whopping $7. After paying 700 pretty pennies for it, it remained topless in our garage for several months before moving to the beach house last fall (see below)… where it remained – still topless – until last month.

Our grand scheme was to get a stone top custom cut for it. Marble would look great, but we also considered more durable options like quartz. But quotes from two different stone yards – even for remnant pieces – came back between $700 – $900. I KNOW. They were MUCH higher than we expected, partially because of the size (it’s 38″ at its widest, which makes it deeper than a standard countertop by a fair amount) and the octagonal shape.