#Finger Safety Featherboard

Explore tagged Tumblr posts

Text

Crafting Safely: Essential Woodworking Tips for an Injury-Free Workshop

Woodworking is a fulfilling and creative hobby or profession that allows you to turn raw materials into beautiful, functional pieces of art. However, it also comes with its fair share of risks. Sharp tools, heavy machinery, and complex processes can lead to accidents if safety precautions are not taken seriously. Following these essential safety tips to ensure your woodworking experience remains enjoyable and injury-free.

Wear Appropriate Safety Gear

Before picking up a tool, ensure you're adequately equipped with safety gear. This includes:

Safety Glasses: Wear safety glasses or goggles to protect your eyes from flying debris, dust, and wood chips.

Hearing Protection: Prolonged exposure to loud machinery can damage your hearing. Use earmuffs or earplugs to safeguard your ears.

Respirator or Dust Mask: Wood dust can be harmful if inhaled. A respirator or dust mask will keep your lungs safe.

Work Gloves: Gloves protect splinters, cuts, and other potential hand injuries.

Keep Your Workspace Organized

Maintaining an organized workshop is crucial for safety. Clutter can lead to accidents and make it challenging to find the tools you need. Ensure your workspace is neat by:

Storing Tools Properly: Use wall-mounted racks, pegboards, or tool chests to keep your tools organized and within easy reach.

Sweeping Regularly: Clean up wood chips and sawdust to prevent slips and trips.

Marking Hazardous Areas: If any uneven surfaces or tripping hazards exist, keep them with brightly colored tape or paint.

Know Your Tools

Understanding how each tool works is essential for your safety. Take the time to read the manufacturer's instructions and practice using them safely. Some key points to remember include:

Maintain Sharp Blades: Dull blades are more likely to kick back or slip, increasing the risk of accidents. Keep your tools sharp and well-maintained.

Use Push Sticks and Featherboards: When cutting small pieces of wood, use push sticks to keep your hands away from the blade. Featherboards help maintain a consistent and safe feed when working with table saws.

Keep Hands Away from Blades: Always keep your hands and fingers safe from cutting edges and spinning blades.

Follow Proper Techniques

Woodworking has specific techniques that, when followed correctly, can significantly reduce the risk of accidents:

Measure Twice, Cut Once: Accurate measurements are critical to achieving precise results. Double-check your measurements before making any cuts.

Never Force the Wood: Forcing wood through a saw or other machinery can lead to kickbacks and injuries. Let the tool do the work at its own pace.

Plan Your Cuts: Plan your cuts to avoid any potential kickback, and ensure the wood is adequately secured.

Be Mindful of Dust and Fumes

Woodworking generates a lot of dust and, depending on the type of wood, can release harmful fumes. To protect yourself:

Use Dust Collection Systems: Install a dust collection system in your workshop to minimize airborne particles. Make sure it's regularly emptied and maintained.

Ventilation: If you're working with treated or exotic woods, ensure good ventilation to dissipate harmful fumes.

Wear a Respirator: When dust collection and ventilation aren't sufficient, wear a respirator to protect your lungs.

Practice Fire Safety

Woodworking involves various heat-producing tools, such as sanders and routers. To prevent fires:

Keep Flammable Materials Away: Store flammable substances like paint, solvents, and rags in a designated fireproof cabinet.

Use Fire Extinguishers: Have a fire extinguisher and know how to use it in emergencies.

Inspect Electrical Wiring: Regularly check your workshop's electrical wiring for damage or wear that could spark a fire.

Stay Focused and Avoid Distractions

Woodworking requires concentration and attention to detail. Avoid distractions such as phone calls or conversations that could lead to errors and accidents.

Seek Professional Guidance

If you're new to woodworking, consider taking a class or seeking guidance from an experienced woodworker. Learning from someone with expertise can help you develop good habits and safe practices.

Know When to Seek Medical Help

Despite all precautions, accidents can still happen. If you sustain an injury, no matter how minor it may seem, seek medical attention promptly. Minor injuries can quickly escalate if not treated properly.

Woodworking can be a rewarding and enjoyable pursuit, but it should always be approached with safety as a top priority. You can significantly reduce the risk of accidents in your woodworking workshop by wearing appropriate safety gear, maintaining an organized workspace, understanding your tools, and following proper techniques. Remember, safety first, so you can continue crafting beautiful woodwork creations without unnecessary risks to your well-being.

0 notes

Text

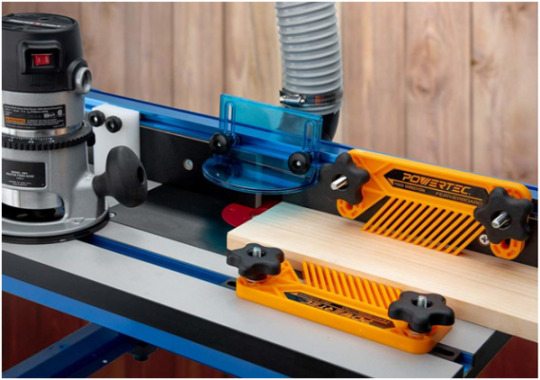

Why to Use a Featherboard?

Working on saw machine and using feather board along with the fence is just like working with extra hands! Featherboards keep your fingers safe and in good shape while operating power saws.

Featherboard:

Feather board is basically a safety device. It is used when working with stationary power saws like bandsaws, table saws, mitre saws shapers, router tables, radial arm saws etc. A feather board is simply a board with a series of defect free slits cut into a uniform fixed angle like 45 degree, forming a row of flexible fingers that bends just like the barbs of a feather. It applies pressure against the wood to be cut and keeps it flat on the saw machines table or the fence while steering the work piece to the blade.

A feather board can also be created at workshop from an approximately 3/4 × 3 × 11 inch piece of straight grained, defect-free wood, cut crosswise at a 45-degree angle on one end. Many slits parallel to this direction of the grain can be cut manually but creating a good defect free feather board is a time consuming and tedious task. So, purchasing a good one will prove its worth in the long run and save your precious time too.

Features of Featherboard:

Featherboards are usually made from a high quality polymer and each feather board consists of angular slits known as fingers.

The angle of the fingers allows the wood piece to pass in an unwavering, straight line but offers resistance movement in the opposite direction.

These fingers exert some pressure on the work piece to be cut while feeding to the saw that produces cleaner cuts with rare chances of kickback, chattering or displacing of work piece.

It comes with wedge-lock hardware which works in T-slots or miter slots on table saws, router tables or band saws.

The featherboard slide into miter-gauge slots in the router table or fence, and are locked in place by tightening a pair of knobs attached at the ends.

Key Benefits of Using Featherboard:

The most important benefit is again your safety. It keeps your hands and fingers safe while feeding wood piece to the saw machine.

It enhances the accuracy and quality of cuts tremendously.

It can be connected to its place very easily and quickly.

It is useful for edge jointing, and making moulding on router tables.

It performs especially well at the table saw and router table. It can also be used on shaper, band saw or any other woodworking machine with a miter gauge slot.

It takes care of the thin wood pieces, especially when feeding wood piece by hand is somewhat difficult.

Double Featherboard:

Using double featherboards give extra control over feeding mechanism. On router tables and shapers, you can use one featherboard before and the other one after the cutter. It is a good practice to attach featherboards to both the fence and the tabletop while routing long and thin wood piece on the router table.

Where to Get One?

Featherboard is a specialty tool and hence may not be available at your local stores but will be stocked at high quality building supply stores and woodworking tools dealers. You can also place your online orders from here in case you are searching for some good quality at decent price.

How to Use a Featherboard?

Using featherboard is quite simple and a quick process. A purchased featherboard will easily slide in the mitre groove on your table saw. Place the featherboard with fingers aligned in the direction in which the wood piece is fed.

The saw blade should never touch the fingers of the featherboard so just keep it little bit away from the blade. Also, make sure that its both the knobs are properly tightened so that the wood piece is secured and moves in forward feeding direction only.

For the most accurate cuts, lower the blade with the tool off and place the stock against the fence. Now, set the featherboard against the wood piece and tighten the locking mechanism with knobs attached. Test the wood piece if it is fixed properly or not in a dry run with the blade lower down. Ideally, the work piece should move in forward direction and not move back. Now, raise the blade up and push the wood piece for cutting.

#feather board#Finger Safety Featherboard#Small Feather Board for Table Saw#Featherboard for table saw

0 notes

Link

This small featherboard works on a table surface towards a fence or on the fence down to the table top. We use two on the drill press when we are drilling a long piece with inline holes. Made of Ultra high molecular weight polyethylene (UHMW)and comes with two 1/4" hex head bolts and two knobs.

IF you have any query, Please contact us:+44 (0)161 439 5683 Name:Roy Arrowsmith Mail: [email protected] Visit Us : https://www.woodfordtooling.com/

0 notes