#extruder screw barrel for plastic extrusion machine

Explore tagged Tumblr posts

Text

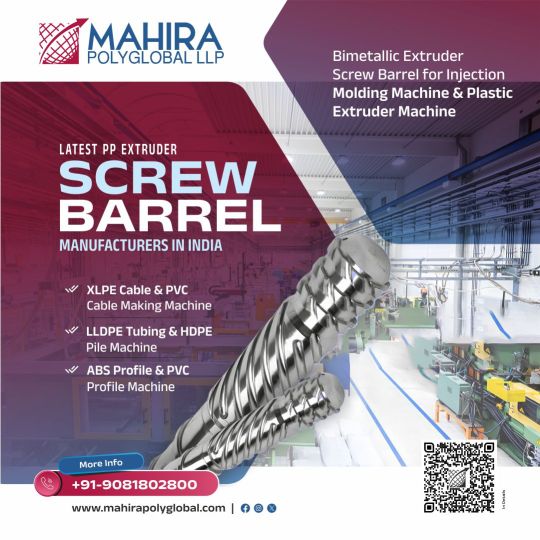

Extruder Screw Barrel

we are leading manufacturer and supplier of Extruder Screw Barrel in india & worldwide, we assure the finest quality, robustness, and accuracy in our extruder screw barrels, facilitating smooth plastic processing for various kinds of industries. Our extruder screw barrel, which effectively melts and shapes raw materials, is an essential part of the plastics manufacturing process.

For more information, please contact us : +91- 9081802800, email : [email protected] https://www.mahirapolyglobal.com/product/screw-barrel-extruder-screw-barrel

#extruder screw barrel#plastic extruder screw barrel#hs code for extruder screw barrel#extruder screw and barrel#extruder screw barrel manufacturer#screw barrel#extruder screw barrel for plastic extrusion machine#mahira#mahirapolyglobal#commercial#marketing#sales#ecommerce#manufacturingexcellence

0 notes

Text

Benefits of Single Screw Extruder

A single screw extruder consists of a single rotating screw housed within a barrel. Its primary function is to melt, mix, and shape plastic materials. The screw’s rotation generates heat and shear, effectively transforming solid plastic pellets into a molten state, ready for extrusion.

Advantages of Using a Single Screw Extruder

1. Simplicity of Design

The straightforward design of single screw extruders makes them easier to operate and maintain compared to more complex systems, such as twin-screw extruders. This simplicity can lead to reduced training time for operators and lower maintenance costs.

2. Cost-Effectiveness

Single screw extruders are generally more affordable than their multi-screw counterparts. Their lower initial investment and reduced operating costs make them a popular choice for manufacturers looking to optimize their budgets.

3. Versatility in Processing

Single screw extruders can handle a wide range of thermoplastic materials, making them suitable for various applications. They can process everything from basic polyethylene to more complex polymers, including filled and modified materials.

4. Continuous Operation

Designed for continuous production, single screw extruders allow for high throughput. This capability is essential for industries that require large volumes of products without interruption, enhancing overall efficiency.

5. Effective Melting and Mixing

The design of the screw and barrel enables effective melting and mixing of materials. The heat generated by the screw’s rotation, combined with shear forces, ensures that raw materials are thoroughly melted and blended, leading to a uniform output.

6. Easy Scale-Up

Single screw extruders can be scaled up relatively easily for larger production runs. This scalability is crucial for manufacturers looking to expand their output without needing to invest in entirely new equipment.

7. Low Energy Consumption

Compared to other types of extruders, single screw extruders often operate at lower energy levels, which can result in cost savings in energy bills, especially in large-scale operations.

8. Customization Options

Manufacturers can customize screw designs and barrel configurations to optimize performance for specific materials and applications. This flexibility allows for tailored solutions that meet unique processing requirements.

9. Reliability and Durability

Single screw extruders are known for their robust construction and durability, leading to long service life. This reliability translates to less downtime and more consistent production output.

10. Compatibility with Downstream Processes

Single screw extruders can be easily integrated with downstream equipment, such as cooling and cutting systems, facilitating a smooth production line and enhancing overall workflow efficiency.

Conclusion

The advantages of using a single screw extruder make it a valuable asset in the plastics processing industry. From cost-effectiveness and versatility to reliable performance and ease of operation, these machines are well-suited for a variety of manufacturing applications. Whether you’re a small business or a large manufacturer, investing in a single screw extruder can significantly enhance your production capabilities and efficiency.

1 note

·

View note

Text

Sunkaier SK3000S-Extruding Kneader Reactor

DESCRIPTION

SK3000S Kneader is ideally suited for operations involving mixing, kneading, reaction, polymerization, crystallization, compounding and heating or cooling of materials up to many million-centipoise viscosity.

SUNKAIER Kneader is a horizontal, twin screw, closed type continuous kneading/reacting processor. The Kneader has a number of recent successful accomplishments as continuous polymerization / reacting processor for engineering plastics and others. Compared to twin screw extruder, SK3000S Kneader has compact structure such as short L/D and low power while having equivalent kneading and dispersion performance and contributing to rationalization of manufacturing process and cost reduction.

SK3000S KNEADER COMBINATION

Maintaining, repairing, and servicing large extruders is crucial for ensuring optimal performance, prolonging the lifespan of the equipment, and minimizing downtime. Large extruders, such as the ones used in the production of polymers and other materials, often require specialized knowledge and tools.

PARTS FOR SK3000S KNEADER

SUNKAER reactive extruding kneader, specifically the SK3000S model, is designed to handle demanding processes that require precise and intensive mixing. The quality of the machine's components, especially the screw elements, is critical for achieving optimal performance and durability. Here's more information on the key aspects of the kneader's construction and the manufacturing process for its screw elements:

Key Components of SK3000S Reactive Extruding Kneader:

Screw Elements: The screw elements are the heart of the kneader, responsible for conveying, mixing, and reacting the materials. They are precision-machined to ensure high accuracy and reliability.

Barrel: The barrel is where the materials are processed. It is designed to withstand high temperatures and pressures. It is typically made from high-strength materials and may include heating/cooling jackets for temperature control.

Drive System: The drive system powers the rotation of the screw elements. It includes motors, gearboxes, and other components that are selected for their ability to handle the torque and speed requirements.

Controls: The kneader is equipped with sophisticated control systems to monitor and adjust process parameters such as temperature, pressure, and screw speed.

SK3000S JACKED REACTIVE EXTRUDER

The jacketed reactive extruder is an advanced piece of equipment used in polymer processing and chemical reactions where precise temperature control is essential. This type of extruder is designed with a jacket, which is a layer or casing around the barrel of the extruder that allows for heating or cooling media to be circulated through it. This feature provides better temperature control compared to non-jacketed extruders because it can manage the heat input more effectively during the extrusion process.

SPANDEX PROCESS KNEADERING REACTOR

SK3000E self-cleaning kneader reactor lab unit sounds like a specialized piece of equipment designed for use in laboratory settings, particularly for research and development purposes. This type of equipment is typically used for mixing, kneading, and reacting various materials under controlled conditions.

REACTIVE EXTRUSION KNEADER

SK3000S twin co-rotating reactive extruding kneader is a specialized piece of equipment designed for processing materials that require long residence times and intensive mixing. This type of machine is particularly useful for applications such as emulsion polymerization, where precise control over the mixing and residence time is crucial for achieving the desired product properties.

MODELS

If you have any need of equipment please contact me without hesitation, thanks.

Helena Xiao / Sales Manager

Email: [email protected]

Phone: +86 510 8758 8707

Mobile: +8618261586225

0 notes

Text

Mono Danline Extrusion Plant Manufacturers | Aawadkrupa Plastomech

Mono Danline Extrusion Plant Manufacturers | Akiropes

Akiropes, a renowned manufacturer based in India with a global presence. Our mono danline extrusion plants are known for their exceptional quality and reliability, trusted by customers in over 65 countries worldwide.

At Akiropes, we understand the importance of reliable support, which is why we offer 24/7 assistance to ensure your operations run smoothly. Whether you have questions, need technical support, or require maintenance services, our dedicated team is here to help.

Key Features

Extra strength & shining of yarn.

Barrel Heater with double insulated glass wool with SS made cover for power saving.

Air oven for double hot circulation system.

Longer life of screw and barrel.

AC variable frequency drive & motor that synchronises the entire extruder.

Latest technology used to make plastic granules melts smoothly by Extruder.Less noisy pollution.

Less power consumption.

One of the key advantages of our mono danline extrusion plants is their cutting-edge technology, which ensures consistent performance and efficiency. Whether you're producing ropes for marine, agricultural, or industrial use, our machinery delivers superior results every time.

We also understand that every business is unique, which is why we offer customised solutions to meet specific client needs. Our experienced engineers work closely with customers to tailor our extrusion plants to their exact requirements, ensuring optimal performance and productivity.

When you choose Akiropes, you can trust that your order will be delivered on time, every time. We prioritize timely delivery to help you meet your production deadlines and keep your operations running smoothly.

In conclusion, Akiropes is your go-to destination for high-quality mono danline extrusion plants. With our commitment to quality, global reach, 24/7 support, and on-time delivery, we're here to meet all your extrusion plant needs. Get in touch with us today to request a quote and experience the Akiropes difference for yourself.

For More Information:

"Aawadkrupa" survey no-131-A,Navagam Bhavnagar-Rajkot highway Bhavnagar, Gujarat 364060

9510186014,9879615963

#Mono Danline Extrusion Plant#danline extrusion#danline extrusion plant#mono danline extrusion#danline extrusion plant for sale#danline extrusion plant price#mono dan line extrusion exporter#mono dan line extrusion manufacturer#mono danline extrusion plant in india

0 notes

Text

ABA Blown Film Machine in Bihar Adroit Extrusion is a Manufacturer, Exporter, and Supplier of ABA Blown Film Machine in Bihar. We are ISO 9001:2015 certified company, in Ahmedabad, Gujarat, India. Adroit Extrusion Specializes in Monolayer Blown Film, ABA and AB Blown Film Machines, and MultiLayer Blown Film Machines. Manufacturers use an ABA blown film machine as a type of extrusion equipment in plastics manufacturing. It produces multi-layer films by extruding three layers of plastic through a circular die. The layers typically consist of a central layer (B) sandwiched between two outer layers (A), offering enhanced strength, barrier properties, and versatility for various packaging applications. Working Process: Extrusion Process: Plastic pellets are fed into the extruder hopper. Heating elements and frictional heat generated by screws melt the pellets inside the extruder barrel. Layer Formation: In an ABA configuration, operators use three extruders to force molten plastic through a circular die, forming layers.

One inner layer (B) is typically a different material for specific properties like strength or barrier. Cooling and Shaping: Operators use air to inflate the tube to the desired diameter and cool it with air or water for solidification. Processing: Rollers flatten and pull the cooled tube to create a flat film during the process. Optionally, the film may undergo treatments like corona treatment for improved surface properties. Winding: Automatic winding equipment ensures film winding into rolls, controlling thickness, width, and layer composition for quality assurance. Applications: The packaging industries widely use ABA-blown films for applications that require enhanced strength, barrier properties, and versatility. Adroit Extrusion is Supplier of ABA Blown Film Machine in Bihar and including locations like Patna, Gaya, Muzaffarpur, Darbhanga, Bhagalpur, Katihar, Purnia, Buxar, Bettiah, Chapra, Bihar Sharif, Siwan, Arrah, Sasaram, Begusarai, Munger, Saharsa, Kasba, Habibpur, Nalanda, Danapur, Nawada, Sitamarhi, Madhubani, Jamui, Bagaha, Kishanganj, Madhubani. Contact us today to explore how our multi-layer blown film machines can elevate your packaging solutions with advanced technology and versatility.

0 notes

Text

The Importance and Customization of DRTS Pipe Extruders

Introduction

In the dynamic world of manufacturing, the role of Pipe Extruders is paramount. These machines are the backbone of the pipe production line, responsible for heating, mixing, and forming plastic into high-quality pipes. DRTS Pipe Extruders, renowned for their reliability and customization, offer industry-leading solutions tailored to various production needs. This article delves into the features, benefits, and customization options of DRTS Pipe Extruders, specifically focusing on the DRTS Pipe Extruders and pipe plastic extruder systems.

What Are Pipe Extruders?

Pipe extruders are specialized machines that transform raw plastic materials into pipes through a continuous extrusion process. The process involves heating the plastic, mixing it to a homogeneous state, and then forcing it through a die to create the desired pipe shape. The quality of the extruder directly impacts the consistency and quality of the produced pipes, making it a critical component in any pipe manufacturing setup.

Key Features of DRTS Pipe Extruders

DRTS Pipe Extruders are designed with precision and durability in mind. They incorporate high-quality components from leading brands, ensuring long-term performance and reliability. Some standout features include:

Customizable Screw Designs: DRTS offers both single-screw and twin-screw extruders, each tailored to specific materials and production requirements. The screws are designed to ensure optimal mixing and plastification, enhancing production efficiency and product quality.

High-Quality Components: DRTS extruders are built using top-tier components such as Zambello gearboxes, ABB/Siemens/Baumuller motors, and Reiloy bimetallic screws and barrels. These components ensure stability, durability, and consistent performance.

Advanced Control Systems: The extruders are equipped with 12-inch HMI/PLC systems from B&R/Siemens/Omron, providing intuitive control and monitoring of the extrusion process. This level of control allows for precise adjustments, leading to better product quality and reduced waste.

Versatility in Production: DRTS extruders can handle various types of plastic, including PE, PVC, and PPR. This versatility makes them suitable for a wide range of applications, from drip irrigation systems to large-scale industrial pipes.

Customized Solutions for Different Needs

DRTS understands that different production environments have unique requirements. Hence, they offer customized solutions to meet specific needs. Whether it's the type of plastic being used or the desired output, DRTS can tailor their extruders to ensure optimal performance.

Single Screw vs. Twin Screw Extruders

Single Screw Extruders: Ideal for materials like PE and drip irrigation pipes, single screw extruders are simpler in design and operation. They are highly effective for homogeneous materials and offer a cost-effective solution for many production lines.

Twin Screw Extruders: These are designed for more complex materials like PVC, which require thorough mixing and high resistance to wear. The twin screw design provides better handling of the raw material, ensuring consistent quality and extending the lifespan of the machine.

Why Choose DRTS Pipe Extruders?

Quality and Reliability: DRTS extruders are built to last, with high-quality components that ensure long-term stability and performance.

Customization: The ability to customize extruders to specific production needs ensures that manufacturers get the best possible solution for their requirements.

Efficiency: With advanced control systems and precise engineering, DRTS extruders maximize production efficiency and minimize waste, leading to cost savings and higher output.

Support and Service: DRTS provides comprehensive support and service, from initial consultation to ongoing maintenance, ensuring that their customers get the most out of their investment.

Conclusion

In plastic pipe production, DRTS Pipe Extruders stand out for their quality, customization, and efficiency. Whether you're producing PE, PVC, or PPR pipes, DRTS offers solutions tailored to your specific needs, ensuring optimal performance and product quality. By investing in a DRTS pipe plastic extruder, manufacturers can enhance their production capabilities, reduce waste, and ultimately achieve greater success in their operations.

For more information about DRTS Pipe Extruders and to explore the options available, visit DRTS Pipe Extruders.

#pipe extruders#extruding machine#pipe extruder#pipe plastic extruder#pipe production line#plastic pipe extruders#drts pipe extruders#turnkey extrusion pipe machinery

0 notes

Text

Exploring the Structure and Working Principle of Lab Extruder Machine Factory Products

Lab extruder machine factory stands at the front of material processing and research, offering versatile solutions for a wide range of industries and applications. These machines, designed and manufactured by specialized facilities such as the lab extruder machine factory, are integral to the development and production of various materials, including plastics, polymers, and pharmaceuticals. In this article, we delve into the structure and working principle of products from the lab extruder machine factory, highlighting their functionality, versatility, and impact on research and industry.

At the core of lab extruder machine factory products lies a sophisticated yet robust design optimized for precision and efficiency. These machines typically consist of several key components, each playing a crucial role in the extrusion process. The primary components include the extruder barrel, screw assembly, heating and cooling systems, die head, and control panel.

The extruder barrel, typically made of high-grade stainless steel or other durable materials, serves as the main chamber where raw materials are fed and processed. It provides a controlled environment for material melting, mixing, and homogenization, ensuring consistent output quality. The barrel is often equipped with heating and cooling jackets to regulate temperature and optimize material flow during extrusion.

The screw assembly, comprising a rotating screw shaft and various screw elements, is responsible for conveying, compressing, and melting the raw material as it moves through the extruder barrel. The screw geometry and configuration can be customized to accommodate different materials and processing requirements, allowing for precise control over extrusion parameters such as pressure, temperature, and residence time.

The heating and cooling systems integrated into the lab extruder machine factory play a critical role in maintaining processing conditions throughout the extrusion process. Heating elements, such as electric heaters or thermal oil jackets, ensure that the material reaches the desired processing temperature, facilitating melting and flow. Conversely, cooling systems, such as water-cooled jackets or air-cooling fans, help regulate temperature and prevent overheating, ensuring product stability and quality.

The die head, located at the end of the extruder barrel, defines the final shape and dimensions of the extruded product. It consists of a specially designed opening or series of openings through which the molten material is forced to form the desired shape. Die heads can be customized to produce a wide range of extruded profiles, including rods, tubes, films, and sheets, making them highly versatile for diverse applications.

The control panel, equipped with advanced electronics and software, serves as the brain of the lab extruder machine factory, allowing operators to monitor and adjust various parameters in real-time. From temperature and screw speed to pressure and material flow rate, the control panel provides precise control over the extrusion process, ensuring consistent product quality and performance.

In operation, the lab extruder machine factory follows a sequential process that begins with the loading of raw materials into the extruder barrel. As the screw rotates, it conveys the material forward while simultaneously applying heat to melt it. The molten material is then forced through the die head, where it takes on the desired shape and dimensions. Finally, the extruded product is cooled and solidified before being collected or further processed.

In conclusion, lab extruder machine factory products represent precision and efficiency in material processing and research. With their sophisticated design, versatile functionality, and precise control capabilities, these machines play a vital role in the development and production of a wide range of materials across various industries. From plastics and polymers to pharmaceuticals and food products, the lab extruder machine factory continues to drive innovation and advancement in research and industry, shaping the future of materials science and technology.

0 notes

Text

Exploring the World of Lab-Scale Plastic Extruders

Plastic extrusion is a widely used manufacturing process that involves melting raw plastic material and then shaping it into a continuous profile. While industrial-scale extruders dominate the manufacturing landscape, lab-scale extruders play a crucial role in research, development, and small-scale production. In this article, we delve into the intricacies of lab scale plastic extruder, exploring their significance, functionalities, and applications.

Understanding Lab-Scale Plastic Extruders

Lab-scale plastic extruders are compact machines designed for research laboratories, educational institutions, and small-scale production facilities. These extruders typically operate on a smaller scale compared to their industrial counterparts but offer similar functionalities. They allow researchers and engineers to experiment with different plastic materials, formulations, and processing parameters without the need for large-scale production setups.

Components of a Lab-Scale Plastic Extruder

Extrusion Barrel: This is where the raw plastic material is fed into the machine. The barrel contains a heating element to melt the plastic and a screw mechanism to push the molten material through the die.

Screw Mechanism: The screw inside the extrusion barrel plays a crucial role in plastic extrusion. It rotates and pushes the molten plastic forward while also mixing and homogenizing the material.

Die: The die is a crucial component that shapes the molten plastic into the desired profile. Lab-scale extruders often come with interchangeable dies, allowing researchers to create different shapes and sizes of extruded products.

Temperature Control System: Precise temperature control is essential in plastic extrusion to ensure the proper melting of the material and prevent degradation. Lab-scale extruders are equipped with temperature sensors and control systems to maintain optimal processing conditions.

Cooling System: After exiting the die, the extruded plastic needs to be cooled rapidly to maintain its shape. Lab-scale extruders typically have built-in cooling systems to achieve this.

Applications of Lab-Scale Plastic Extruders

Material Development: Researchers use lab-scale extruders to develop and test new plastic materials with specific properties, such as strength, flexibility, or thermal stability. By adjusting processing parameters and experimenting with different formulations, they can optimize material performance.

Prototyping: Lab-scale extruders are invaluable tools for prototyping new products or components. Engineers can quickly produce small batches of extruded parts for testing and evaluation before moving to full-scale production.

Education and Training: Educational institutions use lab-scale extruders to teach students about plastic processing techniques. Hands-on experience with these machines helps students understand the principles of extrusion and prepares them for careers in manufacturing and materials science.

Small-Scale Production: Some small businesses or research facilities use lab-scale extruders for limited production runs of specialized plastic products. These extruders offer a cost-effective solution for small-scale manufacturing without the need for large investments in industrial equipment.

Conclusion

Lab-scale plastic extruders play a vital role in research, development, and small-scale production within the plastics industry. These compact machines offer versatility, precision, and ease of use, making them indispensable tools for researchers, engineers, and educators alike. As advancements in materials science and manufacturing technology continue, the importance of lab-scale extruders in innovation and product development is expected to grow further.

0 notes

Text

Navigating Regulatory Frameworks in the Purging Compound Market

Purging Compound: A Vital Tool in Plastic Molding Operations What are Purging Compounds? Purging compounds are cleaning agents that are injected into plastic processing equipment to flush out residual material from previous production runs. They are formulated with filler materials and thermoplastic binders that resemble the properties of the base plastic resin. This allows them to effectively push out contaminants like residual dried polymer, color pigments and additives from the previous material. Purging compounds come in pellet, granular or liquid forms depending on the type of plastic molding or extrusion machine they are meant for. Application in Injection Molding In injection molding, purging compounds are primarily used to prevent color contamination between different production runs involving different resin colors or additive packages. They are loaded into the hopper after the previous material has been used up. During the purging process, the compound is injected into the barrel, screw and nozzle exactly like the resin to flush out any remnants of prior pigmented or custom-formulated plastic. Keeping Extrusion Equipment Clean Extruders process plastic continuously through the use of a rotating screw inside a heated barrel. Even a tiny amount of residue from a previous material left clinging to the hot walls or the screw flights can cause issues down the line. Purging compounds optimized for extrusion equipment clean up these hard to remove remnants. They are passed through during non-production periods to displace any degraded polymers or carbonized contaminants. Ensuring Purity in Reactive Processing Reactive extrusion and injection involve premixing functional additives or reactive components into the plastic melt prior to molding. Even microscopic amounts of unintended contamination could interfere with the chemistry and cause off-spec parts. Specialty purging compounds designed for reactive systems thoroughly displace residual reactive materials, impurities or degraded by-products after each manufacturing run. Customizable for Specific Processes Not all plastic processing equipment or material types require the same level of cleaning. Purging compound formulations have evolved to match the precise needs of different molding or extrusion systems. Variants exist to suit dry, wet or paste-like purge needs. Fillers and tackifiers within can be tailored to the hardness, stickiness and stiffness characteristics of the base resins commonly used. Reducing Environmental Waste Conventional purging materials leave behind polymer-filled purge waste that must be properly disposed as it cannot be recycled. However, new bio-based and recyclable options emerge that address this sustainability issue. Water-soluble mediums flush easily down the drain while innovative compostable formulations decompose without harming the environment. These ‘green’ purging tools achieve purer processing while lowering purge scrap volumes and disposal costs. Managing Costs with Strategic Purging While necessary for quality production, excessive purging also increases material, labor and trim waste expenses. Process experts help custom design optimized purging programs for individual production schedules. Numbers of purges, amounts used, wait times between jobs and selection of right purging agents are key parameters. In summary, purging compounds remain a vital tool in plastic processing operations demanding clean material transfers and maximum product consistency. Choice of the appropriate formulation tailored for each unique process setup helps equipment operators mitigate risk of defects and quality issues due to contamination. With innovative formulations addressing efficiency and sustainability needs, purging ensures durable production hygiene for the modern manufacturing enterprise.

0 notes

Text

Extruder Screw Barrel

We specialize in manufacturing high-quality Extruder Screw Barrels, meticulously designed for optimal performance in plastic extrusion processes. As a leading manufacturer, we ensure precision engineering, durability, and efficiency to meet the diverse needs of our clients. Trust us for reliable solutions that enhance your extrusion capabilities.

PP Extruder Screw Barrel | Manufacturing in India | Bimetallic Extruder Screw Barrel for injection machine & plastic extruder machine

For more information, contact us : +91- 9081802800, e-mail : [email protected]

#ScrewBarrel#PlasticProcessing#IndustrialTools#ManufacturingComponents#MachineryParts#ecommerce#marketing#commercial#sales#ppbag#artwork

0 notes

Text

Plastic Extrusions: Opt for the Most Pocket Friendly Method that is Extremely Effective

The process of transforming plastic ingredients from solid to liquid and then reassembling them into final products is known as plastic extrusions. It is one of the most widely utilised processes in the plastics business since plastic producers all over the globe trust it because of its many advantages. Extruding plastic sheets is effective and inexpensive. It is regarded as the most cost-effective method of producing plastic goods.

Plastic Extrusion Moulding and Its Benefits

Because truck pelmet rubber can withstand repeated melting, hardening, which and reshaping, "waste" may be utilised rather than thrown away. Since complicated forms may be created with profile extrusion moulding, this method is the most adaptable and versatile. With the help of flat sheet extrusion, which Euro Extrusions does, a variety of plastic kinds with variable thicknesses, hardness, sizes, colours, and textures may be utilised in a huge range of sectors.

Guide to Plastic Extrusion

The hopper of an extruder is loaded with solid raw material during the initial step of the plastic extrusion process. This substance is fed into the extrusion barrel of the machine through the feed throat, where it is heated and pushed by one or more rotating screws.

The material is then fed into a specially-made die with the specified extrusion profile using a feed pipe. In order to produce consistent components, the melted, squeezed plastic maintains the shape of the die.

Water baths and cooling rollers are two examples of cooling techniques. Based on the form of the extruded product and the necessary cooling capacity, the best cooling method is chosen. The completed extruded profiles can be prepared for any further steps in the production process by being cut, shaped, or in another way.

Australian Rubber Stoppers

Rubber stoppers are tiny, cylindrical plugs that are used to shut bottles, test tubes, and other containers. They are often employed in the pharmaceutical and food sectors, as well as in laboratory settings. Rubber barriers are a significant part of these industries in Australia.

They are therefore perfect for use in the food and pharmaceutical sectors, where maintaining product integrity is crucial. Rubber stoppers may be used in a number of applications because of their great resistance to chemicals and changes in temperature.

Source

0 notes

Text

Plastic Extruder

A plastic extruder is a device that uses molten plastic to push through a die and produce a continuous profile to produce a variety of plastic items. Extrusion is a prominent production technique in the plastics sector since it is both extremely effective and economical. The plastic is heated and melted, then mixed, shaped, cooled, and cut into the desired shape as part of the plastic extrusion process. Construction, agricultural, automotive, and packaging are just a few of the industries that employ plastic extruder machines due to their adaptability.

Types of Plastic Extruder

SJ Single Screw Extruder

Read More

SJ Single Screw Extruder

SJSZ Conical Twin Screw Extruder

Read More

SJSZ Conical Twin Screw Extruder

The Advantages of Using a Plastic Extruder in the Manufacturing Process

Construction Machinery Spare Parts Case

Elephant Fluid Power produces stirring motor BMH500 (replaces OMH500) of the same quality as the original, A11VLO, A4VG series plunger pumps, which are used for pump truck production, repair, maintenance and refurbishment, reducing sales and end-user production costs and increasing productive forces. Elephant Fluid Power has a fast delivery time, provides good technical support and after-sales service, and reduces customers' worries.

The Components of A Plastic Extruder and How They Work

A standard plastic extruder is made up of a hopper, a feeding system, a barrel, a screw, a die, and a cooling system, among other parts. Plastic pellets are put in the hopper to be fed into the extruder. The feeding mechanism regulates how quickly plastic enters the barrel. The barrel holds both the die, which shapes the molten plastic into a continuous contour, and the screw, which compresses and melts the plastic.

As the finished product emerges from the die, the cooling system chills and solidifies it. These elements combine to effectively generate a range of plastic items. The output and caliber of the finished product may be varied by changing the shape and speed of the screw.

The Materials Used with A Plastic Extruder

A plastic extruder can work with a wide variety of materials, including both thermoplastic and thermosetting materials. Thermoplastics, such as polyethylene (PE), polypropylene (PP), polystyrene (PS), and PVC, are widely used in extrusion due to their ability to be melted and cooled repeatedly without undergoing any chemical change or degradation. Thermosetting plastics, such as phenolic resins, epoxy resins, and melamine-formaldehyde, are used in the extrusion of electrical components and other specialized applications. Moreover, composite materials, including wood-plastic composites and thermoplastic elastomers, have been used extensively in the construction industry. Such versatility makes plastic extruders a cost-effective solution for manufacturing a broad range of products.

0 notes

Text

Masterbatch manufacturing process

Masterbatches are a concentrated mixture of pigments or additives that is used in the plastics industry to color or enhance the properties of plastic materials. The masterbatch manufacturing process involves several steps, including formulation, compounding, and pelletizing. Here's a general overview of the process:

Formulation: The formulation stage involves determining the composition of the masterbatch, including the type and concentration of pigments or additives to be used. The formulation is typically based on specific customer requirements or industry standards.

Weighing and Mixing: Once the formulation is determined, the raw materials are weighed and mixed together. This step ensures the proper dispersion of pigments or additives in the masterbatch. The mixing process can be done manually or using specialized mixing equipment.

Extrusion/Compounding: The mixed raw materials are then fed into an extruder or compounding machine. The extruder consists of a heated barrel with a rotating screw that melts and mixes the materials under controlled temperature and pressure conditions. The extruder also helps in achieving a homogeneous mixture.

Cooling and Pelletizing: After the materials are melted and thoroughly mixed, the resulting molten mass is cooled down using a cooling system, such as water or air cooling. The cooled material is then passed through a pelletizing system, where it is cut into small pellets or granules. Pelletizing facilitates easy handling, storage, and transportation of the masterbatch.

Quality Control: Throughout the manufacturing process, quality control checks are performed to ensure that the masterbatch meets the required specifications. This may involve testing the color strength, dispersion, physical properties, and other relevant parameters.

Packaging: Once the masterbatch pellets are produced and quality-checked, they are typically packaged in bags or containers for shipment to customers. The packaging is designed to protect the masterbatch from moisture, sunlight, and other potential sources of degradation.

It's important to note that the actual manufacturing process may vary depending on the specific requirements of the masterbatch and the equipment used by the manufacturer. Additionally, some manufacturers may incorporate additional steps or variations in the process to optimize the final product.

0 notes

Text

ABS Wholesale

Ordinary nitriding screw barrel

Technical indicators:

Use distinction: injection molding machine / extruder

Processing range: Ф12mm - Ф300mm

Effective length: 12000mm

Nitriding depth: 0.4mm-0.7mm

Nitriding hardness: HRC58 ° -62 °

Chrome-plated thickness: 0.02mm-0.20mm

Straightness: 0.015mm / m

Applicable plastic range: ABS, PP, PE, 475, PEV and other ordinary plastic.

Bakelite special alloy screw barrel

Use distinction: injection molding machine / extrusion machinery / bakelite machinery

Processing range: diameter Ф20mm-Ф250mm

Effective length: 8000mm

Alloy composition: 88wc / 12c0.Crc / 25Nicr.XaloY108

Alloy hardness: HRC60 ° -65 °

Surface roughness: R0.4

Screw Straightness: 0.015mm

Applicable to all kinds of glass fiber, plastic PPA, PO, PPS, LCP, ABS fire, bakelite powder, magnetic powder, PC and other special engineering plastics.

0 notes

Text

What is Plastic Extrusion? What Are The Types of Custom Extrusion and Molding?

Extrusion is a process where the material gets passed through a specialized shape called a die. It helps produce objects with a definite cross-sectional profile. Plastic extrusion is a mass-production process where desired additives get melted and formed in an extensive process.

Polymer is the raw material that gets commonly used and fed into the hopper and the feed throat is dropped on a rotating screw. Screw rotation gets powered by an electric motor. Note that the design of the screw varies and depends on the design of the final product.

How does the Custom Mouldings Extrusions process get executed?

The rotation of the screw forces the plastic forward and passes through a heated barrel. When the plastic gets passed through the barrel, the channel or thread of the screw decreases. It, in turn, compresses the plastic. The melting temperature of the plastic is more than the verge temperature of the controllers. The custom molding extrusion process produces additional heat through a combination of shear friction and compressive force.

What are the different types of custom molding extrusion means?

Depending on the shape of the die, different materials get formed using a plastic Custom Mouldings Extrusions process. In general, there are three types of plastic extrusion methods. It is as follows.

Tube extrusion

The plastic molding and extrusion process gets followed for pipes and tubes. In this process, air with positive internal pressure gets applied. Plastic containers and pipes after exiting the machine get pulled into the cooling tank. It is where the pipe or tube gets water-cooled.

Blow film extrusion process

This kind of Custom molding and extrusion get applied to plastic films of tubes using extensive sheeting. The molten plastic package designs a semi-solid tube before leaving the die. It gets blown to produce the plastic to its desired thickness or expanded size. It's how plastic shopping bags and other items get dropped.

Plastic Sheet Extrusion

This method of plastic Custom Mouldings Extrusions process gets followed for plastic sheets. It is ideal for items that are too thick to be blown. As it exits the die, plastic rolls get cooled and pulled to a series of cooling poles. It also regulates the thickness of the plastic sheet.

Over Jacket extrusion

This type of plastic extrusion and moulding process gets followed by wire coating. In over Jacket extrusion, the wire gets pulled through the center of the die. If it requires an adhesive between the coating and the wire, it requires a pressure tool.

What are the services offered by our firm?

We are a global plastic extruder and provide plastic extrusion and finishing.

Profile plastic extrusion: It produces custom sizes and shapes to meet the requirement of a wide range of applications and industries.

Custom tube extrusion: It profiles custom tubes Varieties of the consumer and industrial application.

Co-extrusion process: It combines two or more resins that meet exact performance requirements.

For quotes on Custom Mouldings and Extrusions, contact us today.

0 notes

Text

Pipe Extruders – High-Quality Extrusion Machines

Innovative Pipe Extruders

We offer top-tier plastic Pipe Extruders designed to meet your specific production needs. Our extruders ensure superior performance and durability, catering to a range of materials including PE, PVC, and PPR. With a focus on quality and customization, our extruder machines enhance your production efficiency and product consistency.

Understanding Plastic Pipe Extruders

A plastic pipe extruder is the heart of any pipe production line. This crucial machine heats, mixes, and pushes molten plastic through a die to form pipes. A well-designed extruder guarantees high-quality pipe production, reducing waste and increasing efficiency.

Customized Extruder Solutions

We provide both single and twin screw extruders. Single screw extruders are ideal for materials like PE and PP, while twin screw extruders are perfect for PVC due to their ability to handle tougher materials without compromising the machine's integrity. Our custom-built machines ensure that your production line meets your unique requirements.

Why Choose Twin Screw Extruders for PVC?

PVC materials are abrasive and can cause significant wear on single screw extruders. Twin screw extruders are designed to handle these materials more efficiently, reducing wear and tear and ensuring consistent production quality. Using durable materials for the screw and barrel further extends the machine’s lifespan.

Premium Components for Superior Performance

Our extruders are built using high-quality components from leading global brands, including gearboxes, screws, barrels, motors, and control panels. These components ensure reliable performance, ease of maintenance, and availability of spare parts worldwide, providing you with a seamless production experience.

Complete Extrusion Solutions

We offer turnkey solutions for producing pipes ranging from small diameters to large sizes. Our machines can produce single, double, and triple-layer pipes, catering to various production needs. We also integrate advanced systems such as gravimetric feeders, pipe measuring equipment, and laser printers to enhance your production capabilities.

The Extrusion Process Simplified

The extrusion process starts with feeding plastic material, either in pellet or powder form, into the extruder. The heated barrel melts the plastic, and the rotating screw pushes it towards the die head. The die head shapes the molten plastic into the desired pipe form. The downstream equipment, including vacuum and cooling tanks, pullers, and cutters, further processes the pipe, ensuring it retains its shape and meets the required specifications.

Quality and Efficiency Guaranteed

Our extruders are designed for efficiency and longevity. Key components like the barrel, screws, motor, heater bands, and control panel work together to ensure smooth and efficient pipe production. With our high-quality machines, you can achieve consistent results, reduce waste, and optimize your production line.

By choosing our extruders, you invest in a reliable and efficient production process, ensuring your pipes meet the highest standards of quality.

#pipe extruders#drts pipe extruders#extruding machine#plastic pipe extruders#pipe extruder#turnkey extrusion pipe machinery#pipe plastic extruder#pipe production line#books#cars

0 notes