#extruder screw barrel manufacturer

Explore tagged Tumblr posts

Text

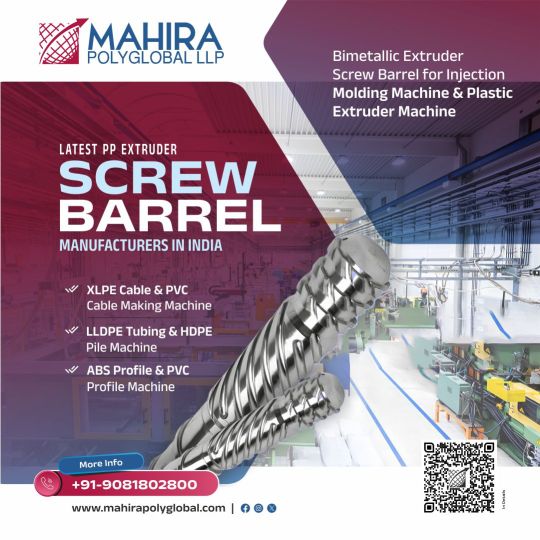

Extruder Screw Barrel

we are leading manufacturer and supplier of Extruder Screw Barrel in india & worldwide, we assure the finest quality, robustness, and accuracy in our extruder screw barrels, facilitating smooth plastic processing for various kinds of industries. Our extruder screw barrel, which effectively melts and shapes raw materials, is an essential part of the plastics manufacturing process.

For more information, please contact us : +91- 9081802800, email : [email protected] https://www.mahirapolyglobal.com/product/screw-barrel-extruder-screw-barrel

#extruder screw barrel#plastic extruder screw barrel#hs code for extruder screw barrel#extruder screw and barrel#extruder screw barrel manufacturer#screw barrel#extruder screw barrel for plastic extrusion machine#mahira#mahirapolyglobal#commercial#marketing#sales#ecommerce#manufacturingexcellence

0 notes

Text

Meltblown Extruder Screw Barrel Manufacturers

Zhoushan Changjia Plastic machinery Co., LTD is located in the middle of Jintang Island of the city of Zhoushan,As is a professional China Meltblown Extruder Screw Barrel Manufacturers and Extruder screw factory, Company combines scientific research development, production and business operation and business property as a whole,our Extruder screw are based upon high quality steel 38CrMoALA, which is conditioned, surface nitridized (or coated with hard alloy) and polished, showing very high precision, wear resistance and long service life, therefore, used by many famous brand molding machines at home and abroad. we are also able to customize specific products according to the users' requirements and serve its users with designing of sample preparation. our factory providing its users with wholesale Extruder screw of reliable performance, good quality and reasonable price. It is sincerely inviting clients, both new and old, to give instruction and to negotiate for cooperation so as to achieve shared success.

0 notes

Text

HDPE Thermoforming Plate Extrusion line

Jwell supply advanced extrusion system, it is suitable to produce HMW-HDPE material which have low MFI and high-strength into plate, the plates are mainly used to produce auto carriage board, pick-up's box liner, cover of truck, anti-rain cover etc. The plate thickness can reduce more than 30% when it has same impact strength, it reduce the production cost for manufacturers. Plate thickness 2-12mm, width 2000-3000mm. Main technical specification Model Products width(mm) Products thickness(mm) Capacity(kg/h) JW130+JW70 2200 1.5-12 600-700 JW150+JW90 2600 1.5-12 800-900 Note: The specifications are subject to change without prior notice. Product image display Transmission system The function of the drive system is to drive the screw and supply the torque and speed required by the screw in the extrusion process. It usually consists of a motor, a reducer and a bearing. Heating and cooling device Heating and cooling are necessary conditions for the plastic extrusion process to take place. 1. The extruder usually uses electric heating, which is divided into resistance heating and induction heating. The heating sheet is installed in the body, neck and head. The heating device heats the plastic in the cylinder externally to increase the temperature to reach the temperature required for the process operation. 2. The extruder cooling device is set to ensure that the plastic is in the temperature range required by the process. Specifically, it is to exclude the excess heat generated by the shear friction caused by screw rotation, so as to avoid the temperature being too high to make the plastic decompose, scorch, or shape difficult. The barrel cooling is divided into two types: water cooling and air cooling. Generally, small and medium-sized extruders are more suitable for air cooling, and large-sized ones are mostly water-cooled or combined with two forms of cooling. Read the full article

2 notes

·

View notes

Text

Quality PP PE Film Water Ring Plastic Pelletizing line

Plastic pelletizing line is used to produce plastic pellets from waste plastic PE/PP films and bags. It is widely used in the recycling factories, plastic films manufacturing factories, other companies who use package films and bags.

The plastic pelletizing line includes the cutting compactor, single screw extruder, double position hydraulic screen changer, water-ring pellet cutter, dewatering machine, cyclone silo and control cabinet.

Plastic pelletizing process:

Step 1, cutting compactor: cut the big plastic films and shrink the materials, then feed the materials into extruder.

Step 2, single screw extruder: for good plasticizing and degassing.

Step 3, hydraulic screen changer: filter out the impurities from the plasticized materials,

Step 4, die face water-ring pelletizer: cut the plasticized materials into pellets while materials out from the perforated plate mould.

Step 5, centrifugal dewatering machine: dehydrate the plastic pellets.

Step 6, vibration sieve: classify the plastic pellets.

Step 7, cyclone system: transfer the pellets into cyclone silo for easy package.

Centralized control system is used for the whole plastic pelletizing line, easy operation and more convenience.

Features

Advantage of plastic pelletizing line in MG Machinery:

1, wide usage for kinds of waste plastic PE PP films and bags.

2, good plasticizing and degassing for materials.

3, 38CrMoAlA barrel and screw with nitrogen procession, wearable, long lifetime.

4, hard teeth reducer, big torque.

5, SIEMENSE or WN motors with ABB inverter, steady running.

6, ceramic heater, even heating result.

7, OMRON temperature meter, precision control.

8, double position hydraulic screen changer for alternative working, high efficiency.

9, alloy knives for pelletizing cutter, smooth cutting, long use time.

10, embedded circular water cooling system, good cooling result for die and pellets.

11, easy operation and maintenance.

12, low power consumption

13, less manpower, high automation.

14, strong machine structure.

#Wood plastic composite machine#wpc production line#wpc machine#plastic recycling washing machines#plastic shredder machine#plastic crusher machine

0 notes

Text

Expert Bore Alignment Services

Bore, Extruder & Propeller Shaft Alignment Services make sure the proper alignment of the important machinery components to increase the performance lowers the wear and tear and also avoid the costly freedom.

The Extruder Alignment Services improves the screw and barrel positioning in the processing equipment.

The Propeller Shaft assures the smooth transmission in marine and an industrial system.

Bore Alignment Services

This service in industries is essential in maintaining the efficiency, improves the performance that scale the lifespan of machinery. They are mainly using in many sectors like marine, energy, manufacturing, mining and oil & gas. Therefore, here heavy duty machinery needs to work accurately.

What is Bore Alignment?

Bore Alignment ensures the proper alignment of the bores (cylindrical holes). So, this helps to perfectly straight and alignment that necessary for the smooth functioning of all components like engines, compressor, and turbines. Misaligned bores can also result to higher vibrations, friction, excess wear and get mechanical failure.

Benefits of Bore Alignment Services

Investing in the expert bore alignment services has numerous advantages:

Ensures the lower mechanical stress and the rough wear & tear. So, this is important to increasing the machinery longevity.

Avoiding the alignment checks can recognise the potential problems before they results in major failures. Thus you can save your money and time.

These components consume more energy to operate. Make sure that the energy is being used effectively.

Well lined up machinery helps to operate more flawlessly. So, it has less risk of accidents and malfunctions.

Reduces the break down and improves the needs to lowers the repairs cost.

Extruder Alignment Services

Extruder alignment services are using in several industries, including plastics, rubber and the food processing. The main extrusion process lies in the accuracy operation of extruder. Slightest misalignment in complex machines can cause major performance problems.

What is Extruder Alignment?

Extruder Alignment refers to the accurate positioning of the components like gearbox, barrel, motor, and screw. Due to the thermal expansion mostly components become misaligned. If it happens, it results in many problems like uneven wear, high power consumption and worst quality product.

Why Extruder Alignment Matters

The extruders mainly operate under the high pressure and temperatures. The conditions are as follows:

Maximise the friction and wear on the screws and barrels

More consumption of motor or the gear components can leads to overheating.

Lowers the product quality can pose incompatible flow or pressure

Periodic maintenance and costly unplanned downtime

Reduces the equipment longevity

These are the problems results in the lost production time and maximise the operational costs. This alignment services are precautionary and precaution solutions to these services.

Propeller Shaft Alignment Services

This laser alignment service are necessary for and industrial power transmission systems to get better performance of machinery. This ensures that the shaft is being connecting the engine to the propeller to avoid the excessive wear and tear.

What is Propeller Shaft Alignment?

Propeller Shaft alignment is the process that helps to get the efficient energy consumption from the engines to the propulsion system. Along with, lowers reduction also ensures to improve overall performance. The misalignment places immoderate the stress on couplings, bearings, seals and other compounds. Results in the vibration, increase in the fuel consumption, noise and mechanical failure.

Methods and Tools Used

We do follow all manufacturing standards for precise shaft alignment. And, these tools help to measure in multiple dimensions that provide the real feedback.

Mainly using in marine applications to check the straightness and angle of the shaft.

Professional performs the vibration tests to recognise the alignment problems that are not seen through the basic measures.

Adjustments made depend on operating techniques when thermal expansion affects the alignment.

So, propeller shaft alignment services let you the big output in the operational reliability, effectiveness and cost savings. Either marine sector or industrial, the experts’ shaft alignment service make certain if your equipment is moving at high performance with lower risk failures.

1 note

·

View note

Text

Conical Twin Screw Manufacturers: Trends and Innovations

The polymer processing industry is constantly evolving, driven by the demand for higher efficiency, improved product quality, and sustainable solutions. At the heart of this evolution lies the technology of conical twin screw extruders, and the manufacturers who develop and refine these machines are pivotal in pushing the boundaries of what's possible. This article explores the current trends and innovations driving conical twin screw manufacturers, shaping the future of extrusion.

Enhanced Efficiency and Output

One of the primary trends dominating the conical twin screw manufacturing sector is the relentless pursuit of enhanced efficiency and output. Manufacturers are investing heavily in research and development to optimize screw designs, barrel configurations, and drive systems. This focus aims to maximize throughput while minimizing energy consumption. Advancements in screw geometry, such as improved mixing elements and optimized channel depths, contribute to better melt homogeneity and higher extrusion rates. Furthermore, manufacturers are incorporating sophisticated control systems that allow for precise process monitoring and adjustments, ensuring consistent product quality and maximizing operational efficiency.

The integration of advanced automation into conical twin screw extruders is also becoming increasingly prevalent. Automated material feeding, temperature control, and profile dimension monitoring systems are streamlining production processes, reducing manual intervention, and minimizing the risk of errors. This automation not only boosts efficiency but also enhances product consistency and reduces waste.

Focus on Material Versatility and Flexibility

The demand for greater material versatility is another significant trend influencing conical twin screw manufacturers. As polymer formulations become more complex and diverse, extruders need to handle a wider range of materials, including recycled plastics, bio-based polymers, and highly filled compounds. Manufacturers are responding by developing screw and barrel designs that can accommodate these challenging materials. This includes the use of wear-resistant materials for screws and barrels, specialized mixing elements for improved dispersion, and optimized heating and cooling systems for precise temperature control.

Flexibility is also a key consideration. Manufacturers are designing modular extruders that can be easily reconfigured to meet changing production requirements. This modularity allows for quick adjustments to screw configurations, barrel lengths, and die designs, enabling manufacturers to adapt to different product lines and market demands. This flexibility is particularly important in industries where product lifecycles are short and customization is essential.

Sustainability and Circular Economy

The growing emphasis on sustainability and the circular economy is driving significant innovation in the conical twin screw manufacturing sector. Manufacturers are developing extruders that can efficiently process recycled plastics, reducing reliance on virgin materials and minimizing waste. This includes the development of robust screw designs that can handle contaminated or inconsistent recycled feedstocks.

Furthermore, manufacturers are focusing on reducing the energy consumption of their extruders. Innovations in drive systems, heating elements, and insulation are contributing to lower energy costs and a smaller environmental footprint. The integration of energy recovery systems, such as heat exchangers, is also becoming more common.

Digitalization and Industry 4.0

The principles of Industry 4.0 are transforming the manufacturing landscape, and conical twin screw manufacturers are embracing digitalization to enhance their products and services. The integration of sensors, data analytics, and cloud computing is enabling real-time monitoring of extruder performance, predictive maintenance, and remote diagnostics.

This digitalization allows manufacturers to optimize process parameters, identify potential issues before they lead to downtime, and improve overall operational efficiency. Furthermore, digital platforms are facilitating remote support and training, enabling customers to maximize the performance of their extruders.

Looking Ahead

Conical twin screw manufacturers are at the forefront of innovation in the polymer processing industry. The trends and advancements outlined above are shaping the future of extrusion, driving the development of more efficient, versatile, and sustainable solutions.

As technology continues to evolve, manufacturers will undoubtedly continue to push the boundaries of what's possible, enabling the production of high-quality products with minimal environmental impact.

0 notes

Text

The Efficacy of Compounding Twin Screw Extruders and Double Screw Extruder Machines in Biodegradable

The Compounding Twin Screw Extruder and Double Screw Extruder Machine have emerged as pivotal technologies in the manufacturing of biodegradable materials, changing the way we approach sustainable production. These machines are designed to handle a variety of polymers and additives, making them indispensable in the compounding process of eco-friendly materials. Their versatility and efficiency are well, particularly in the context of producing biodegradable plastics that are increasingly in demand in a world striving for environmental sustainability.

The Compounding Twin Screw Extruder's dual-screw design allows for more mixing and blending of biodegradable polymers with additives that enhance their properties. This is crucial in ensuring that the final product meets the stringent requirements of biodegradability without compromising on strength or flexibility. The machine's ability to maintain precise temperature control and pressure within its barrels is essential for the consistent production of high-quality biodegradable materials. The controlled environment within the extruder ensures that the materials do not degrade prematurely, maintaining their integrity throughout the compounding process.

Similarly, the Double Screw Extruder Machine plays a significant role in the compounding of biodegradable materials by providing a continuous and uniform output. Its twin-screw configuration facilitates a more efficient distribution of heat and mechanical energy, which is vital for the proper blending of biodegradable polymers and additives. The uniformity of the output is particularly important in the production of films, fibers, and other forms of biodegradable materials where consistency in thickness and composition is paramount.

Both the Compounding Twin Screw Extruder and Double Screw Extruder Machine offer high throughput rates, which are essential for meeting the growing demand for biodegradable materials. Their ability to process materials at a faster pace without sacrificing quality is a testament to their robust design and engineering. Moreover, these machines are equipped with advanced control systems that allow for precise adjustments to the compounding process, ensuring that the biodegradable materials produced meet the desired specifications.

In terms of energy efficiency, both the Compounding Twin Screw Extruder and Double Screw Extruder Machine are designed to reduce energy consumption. This is particularly important in the production of biodegradable materials, as the goal is to reduce the overall environmental impact of the manufacturing process. By optimizing the use of energy, these machines not only contribute to the sustainability of the end product but also reduce the operational costs for manufacturers.

Maintenance and cleaning of these machines are also simplified due to their modular design, which allows for easy disassembly and reassembly. This is crucial in the production of biodegradable materials, as frequent cleaning and maintenance are often required to prevent cross-contamination and ensure product purity. The ease of maintenance also contributes to the longevity of the machines, ensuring a cost-effective solution for the production of biodegradable materials.

The Compounding Twin Screw Extruder and Double Screw Extruder Machine are not only essential in the manufacturing of biodegradable materials but also play a critical role in advancing the sustainability of the plastics industry. Their ability to efficiently and effectively compound biodegradable polymers with the necessary additives is a testament to their importance in the production of environmentally friendly materials. As the demand for biodegradable materials continues to grow, these machines will remain at the forefront of innovation, driving the industry toward a more sustainable future.

https://www.extruderfactory.com/product/extruding-machine/twostage-compounding-extruder.html

0 notes

Text

Single Extruder: Reliable and Cost-Effective Plastic Processing

A single extruder operates with a single rotating screw within a barrel, efficiently melting and shaping materials. It is widely used in plastic processing, pipe production, and sheet extrusion. Compared to twin-screw extruders, single extruders are simpler, more cost-effective, and ideal for continuous manufacturing processes. Their reliability and ease of maintenance make them a popular choice in various industries. Omegabarrelscrew offers high-quality single extruders with precision engineering, ensuring efficient material flow, durability, and superior product consistency.

0 notes

Text

High-Quality Extruder Screw Barrels | Baijiu Machinery

Baijiu Machinery is your trusted source for high-quality extruder screw barrels, designed to enhance the efficiency and performance of your extrusion processes. Our expertly engineered screw barrels are crafted using premium materials and advanced manufacturing techniques, ensuring durability and reliability in various applications, including plastic and rubber processing.

0 notes

Text

extruder screw barrel

There are plenty of enterprises these days creating plastic derivatives. Yet, every firm or manufacturing corporation requires a plastic type of tool. one essential part of plastic processing tools is a screw barrel, which has a threaded design for melting, mixing, and shaping plastic materials. This unique barrel, which is used in conjunction with a screw to efficiently melt, compress, and inject molten plastic into molds, is essential to the manufacturing processes that produce plastic goods. Without an Extruder Screw Barrel technique, any plastic derivative department can't achieve the final stage. Also, with the service of these Screw Barrels, the derivative unit can effortlessly achieve the crucial quantity of creation.

For more information, contact us : +91- 9081802800, e-mail : [email protected]

#ScrewBarrel#PlasticProcessing#IndustrialTools#ManufacturingComponents#MachineryParts#commercial#marketing#ecommerce#branding#sales

1 note

·

View note

Text

BAIJIU Machinery - Leading Screw Barrel Manufacturer in China

BAIJIU Machinery stands out as a leading screw barrel manufacturer in China, specializing in high precision and wear-resistant products. Our extensive range includes injection screw barrels, extruder screw barrels, twin screw barrels, and more. Experience unmatched quality and performance with BAIJIU Machinery's screw barrels made in China.

0 notes

Text

Shaping Success The Art of Rubber Extrusion Manufacturing

In our everyday life, we come across a lot of products that are made up of rubber. From automobile parts to medical equipment, rubber is known to be an essential item of our everyday lifestyle. But, have you ever wondered about the process behind these useful products. Today, we will talk about this process and introduce various other facts connected to rubber extrusion manufacturing and introduce to a top rubber extrusion manufacturer in Canada. So, let us begin by understanding this term.

What is Rubber Extrusion?

It is a shaping technique that is used to mold rubber into desired products. It is a very popular process in the manufacturing industry that deals with rubber (either natural or synthetic). During this process, rubber gets the desired characteristics with the help of certain additives. When the rubber is prepared as per the requirement, it is then fed into an extruder. An extruder is a powerful machine that introduces the raw material to a rotating screw. This screw acts like a giant corkscrew that pushes the material through a mold which is known as a die. The die can be of any desired shape. After it passes this step, the raw material now takes the shape of the object.

What Are the Factors Affecting Rubber Extrusion?

The shape and size of the product depends on various factors like precise control, viscosity, pressure, temperature etc. Let us take a look at some of them:

● Rubber Compound Formulation: It is one of the major factors that plays a role in rubber extrusion.The way the rubber is prepared, from its fillers to additives, plays an important role in shaping the final outcome. Take viscosity for example. The raw material’s viscosity determines the flow characteristics. If it is too low, it leads to poor dimensional stability and if its too high, it may leads to inconsistencies and damage,

● Temperature: This is a leading factor as it affects the flow capacity of rubber. If the temperature is too low, you get a stiff raw material and if it’s too high, the raw material will be damaged which leads to inconsistencies. Perfect temperature is essential for a smooth flow and a high-quality end result.

● Die design: It is the mold that shapes the raw material to the desired shape and size. Therefore, its qualities have a huge impact on the final product. To understand this, you need to understand terms like die land length (the distance the raw material travels after leaving the screw) and included angle (the angle at which the raw material flows through the die). All such points lead to your desired shape.

● Process parameters: Certain aspects like screw speed, feed rate, etc affects the final outcome. Let’s understand this with the help of an example. Imagine a high screw speed. It means that the rubber will be forced through the extruder quickly than it is recommended. What do you think will happen? High speed leads to overheating and degradation. Now imagine the speed below the recommended rate. It will lead to low pressure. Both such scenarios lead to an unwanted final outcome. Therefore, precise parameters must be kept in mind.

● Extruder maintenance: To get any kind of outcome, you need to take care of the equipment. Dirt and lack of lubrication of the screw and barrel leads to high friction and wear and tear. Therefore, the quality in which your extruder is kept impacts the results. Make sure to keep it clean and take care of the recommended replacements before it forces your hand.

What Is the Importance of Rubber Extrusion in the Manufacturing Industry?

Rubber is a highly popular material that is known for its various qualities like efficiency, cost-effectiveness, versatility, durability and performance. Therefore, it is used in various industries like automotive industry (hoses, belts, and weather seals), construction industry (window and door seals) and medical field (sterile tubing, catheters, etc).

The future for extruded rubber manufacturers appears to be highly promising. Due to the constant advancements in material science, there is a high probability of the discovery of new rubber compounds. If we don’t consider the future, the rubber profile manufacturers are still in demand and will continue to be so.

How to Choose the Best Rubber Extrusion Manufacturer?

A high quality extruded rubber has many qualities. From dimensional accuracies to chemical resistance, it must possess all the qualities that makes it a cost effective and highly efficient material. In order to choose a trustworthy rubber extrusion manufacturer, keep the following points in mind:

● Material Selection: Raw material is the most important aspect of this process. Efficient silicone extrusion companies always provide suitable material that have all the qualities of an excellent rubber.

● Custom Profiles: Having rubber profile manufacturers that provide custom changes in the product are a great way to invest without settling for what’s available.

● Minimum Order Quality: If you’re buying in bulk, then having a certain amount of products is essential. Therefore, opt for a rubber extrusion manufacturer that provides your desired MOQ.

● Value Added Services: After the delivery of the final product, there are a number of services like splicing and assembly that need to be taken care of. Therefore, choose silicone extrusion companies that provide post extrusion services.

Custom Rubber Extrusions, one of the best rubber profile manufacturers fits all the above mentioned points. On top of that, the company comes with a proven track record of success, a team of highly skilled extrusion advisors and all necessary certifications.

0 notes

Text

The Science Behind Conical Twin Screw Technology

Conical twin screw extruders are a cornerstone of polymer processing, particularly in the manufacturing of rigid PVC products like pipes, profiles, and siding. Their unique design offers distinct advantages over parallel twin screw extruders, making them a preferred choice for specific applications. Understanding the science behind this technology is crucial for optimizing processing parameters and achieving desired product quality.

The Conical Configuration: A Design Advantage

The fundamental difference lies in the screw geometry. Unlike parallel twin screws where the diameter remains constant, conical twin screws feature screws that taper from a larger diameter at the feed end to a smaller diameter at the discharge end. This conical configuration introduces several key scientific principles that contribute to its effectiveness.

Firstly, the tapering design creates a compaction effect. As the material moves along the screws towards the discharge end, the decreasing volume between the screws forces the polymer melt to become more compressed. This increased pressure promotes efficient melting and homogenization of the polymer.

Secondly, the conical shape facilitates improved material transport. The larger flight pitch at the feed end allows for efficient intake of raw materials, while the decreasing pitch and diameter towards the discharge end ensure positive and controlled conveying of the melt. This minimizes material slippage and ensures consistent output rates.

The Role of Screw Design and Intermeshing

The design of the screws themselves is critical. The flight geometry, number of flights, and intermeshing of the screws play a significant role in the processing efficiency. Conical twin screws typically feature counter-rotating screws, meaning they rotate in opposite directions. This intermeshing action creates shear forces within the polymer melt.

These shear forces are essential for breaking down agglomerates of additives and pigments, ensuring a homogeneous blend. Furthermore, the shear heating generated contributes to the melting process, reducing the reliance on external heating elements. The degree of intermeshing can be varied depending on the application and the material being processed. Tightly intermeshing screws provide higher shear and better mixing, while loosely intermeshing screws offer gentler processing.

Temperature Control and Residence Time

Precise temperature control is paramount in conical twin screw extrusion. The barrel is typically divided into multiple heating zones, allowing for fine-tuning of the temperature profile along the extruder. This control is crucial for managing the melting process, preventing thermal degradation of the polymer, and ensuring the desired melt viscosity.

The conical design also influences the residence time of the material within the extruder. Residence time refers to the average time a polymer particle spends inside the extruder. The controlled material transport and the compaction effect in conical twin screws lead to a more uniform and predictable residence time distribution. This is important for achieving consistent product properties and minimizing variations in melt quality.

Applications and Future Developments

The unique characteristics of conical twin screw technology make it particularly well-suited for processing heat-sensitive polymers like PVC. The efficient melting and controlled shear minimize the risk of degradation, while the excellent mixing capabilities ensure uniform incorporation of additives like stabilizers and lubricants.

While primarily used for PVC, advancements in screw design and processing techniques are expanding the applications of conical twin screw extruders to other polymers, including WPC (Wood Plastic Composites) and certain engineering plastics. Ongoing research focuses on optimizing screw geometry, improving temperature control systems, and developing new processing techniques to further enhance the efficiency and versatility of this vital technology.

In conclusion, the science behind conical twin screw technology lies in its unique design, which leverages principles of compaction, material transport, and shear mixing. Understanding these principles is essential for optimizing processing parameters and unlocking the full potential of this powerful tool in the polymer processing industry. The continued evolution of this technology promises even greater efficiency and broader applications in the future.

0 notes

Text

Art of Precision Manufacturing and Assembly in Building Block Twin Screw Extruder

In the intricate world of polymer processing, the Building Block Twin Screw Extruder and Twin Screw Granulator stand of engineering is designed to handle a myriad of material transformations with precision and efficiency. The manufacturing and assembly processes of these machines are critical to their performance, as they determine the durability, reliability, and output quality.

The heart of the Building Block Twin Screw Extruder is its screws, which are meticulously machined to ensure uniform distribution and mixing of materials. The screws are typically made from high-grade steel, which undergoes a series of processes including turning, milling, and grinding to achieve the desired dimensions and tolerances. The precision of these operations is paramount, as any deviation can cause uneven material flow and reduced efficiency of the Twin Screw Extruder.

The barrels that house the screws in both the Building Block Twin Screw Extruder and Twin Screw Granulator are also subject to stringent manufacturing processes. They are often made from materials that can withstand high pressures and temperatures, such as stainless steel or specialized alloys. The barrels are bored and honed to tight tolerances to ensure a suitable fit with the screws, which is crucial for maintaining the integrity of the extrusion or granulating process.

Heat exchange is another critical aspect of the Building Block Twin Screw Extruder and Twin Screw Granulator, with heating and cooling systems being integral to controlling the temperature of the materials being processed. The manufacturing of these systems involves the fabrication of jackets and plates that are precisely fitted to the barrels. The assembly of these components requires specialized techniques to ensure even heat distribution, which is vital for the quality of the end product.

The drive systems of these machines, including motors and gearboxes, are also manufactured with high precision. The gears must be hardened and ground to exact specifications to ensure smooth operation and long service life. The assembly of these drive systems involves aligning the motor with the gearbox and the screws, which is a delicate process that requires expert craftsmanship to prevent any misalignment that could cause increased wear and tear or machine failure.

The assembly of a Building Block Twin Screw Extruder or Twin Screw Granulator is a complex process that involves the careful alignment and integration of all its components. This includes the screws, barrels, heating and cooling systems, and drive systems. Each part must be assembled with precision to ensure that the machine operates as a cohesive unit. The use of specialized tools and jigs is common in this process to ensure that all components are correctly positioned and that there is no room for error.

The manufacturing and assembly of the Building Block Twin Screw Extruder and Twin Screw Granulator components are processes that require a high level of expertise and precision. From the machining of screws to the alignment of drive systems, each step is crucial in ensuring that these machines perform. The attention to detail in these processes is what sets apart a well-crafted extruder or granulator from one that is merely functional, making the difference in the quality of the end product and the overall efficiency of the production process.

https://www.extruderfactory.com/product/

0 notes

Text

0 notes

Text

0 notes