#extruded rubber seals

Explore tagged Tumblr posts

Text

6 Tips for Extending the Lifespan of Rubber Extrusions and Seals

Extruded Rubber Seals are omnipresent in our day-by-day lives, from the tires on our cars to the seals in our machines. They're known for their solidness and adaptability, but like every fabric, elastic can wear out and endure harm over time.

Read More: https://customrubberextrus.wixsite.com/custom-extrusion/post/6-tips-for-extending-the-lifespan-of-rubber-extrusions-and-seals

#Extruded Rubber Seals#Extruded Rubber Parts#Extruded Rubber Tubing#Extruded Rubber Hose#Custom Rubber Extrusion

0 notes

Text

extruded rubber seals and customized silicone mould

Elevate your sealing solutions with our top-tier extruded rubber seals and customized silicone mould. Our expert craftsmen specialize in creating precision-engineered rubber seals, ensuring impeccable performance and durability. Additionally, we offer customized silicone molds tailored to your unique requirements. Whether you need seals for industrial applications or intricate silicone molds for creative projects, Krishani products guarantee superior quality and reliability. Experience seamless operations and unmatched creative freedom with us.

0 notes

Text

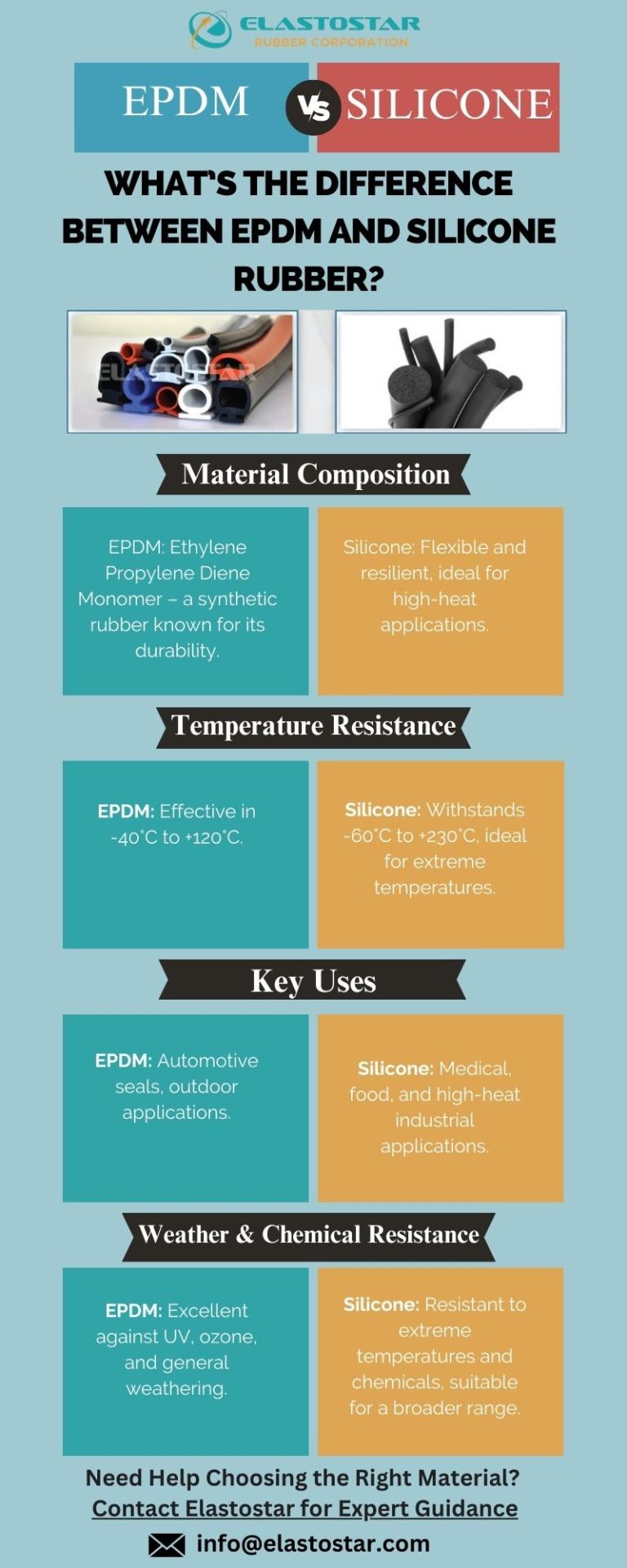

EPDM and Silicone Rubber differ in composition, temperature resistance, and applications. EPDM, a durable synthetic rubber, operates between -40°C to +120°C and is ideal for automotive and outdoor use, offering excellent UV and weather resistance. Silicone, known for its flexibility and resilience, withstands -60°C to +230°C, making it perfect for extreme temperatures, medical, food, and high-heat industrial applications. Silicone also provides superior chemical resistance for broader use. Need Help Choosing the Right Material? Contact Elastostar for Expert Guidance

#silicone rubber tubing#epdm rubber seals#siliconerubber#high-temperature silicone rubber tubing#extruded silicone rubber tubing#food grade silicone rubber cord

0 notes

Text

Extruded Rubber Strips, Manufacturer, Mumbai, India

Contact here to get more details of Extruded Rubber Strips, We are manufacturer, supplier and best service provider of Extruded Rubber Products in Mumbai, India.

#Rubber Products#Moulded Rubber Parts#Extruded Rubber Parts#Sponge Moulded Parts#Metal Bonded Parts#Manufacturers Of Rubber Components#Manufacturers Of Moulded Rubber Parts#Manufacturers Of Extruded Rubber Parts#Rubber Moulded Parts#'O' Rings#Oilseal#U Seal#V Seal#Chevron Packing For Pumps#Hydraulics Seal#Mechanical Seal#Neoprenen Rubber#Nitrile Rubber#Epdm Rubber#Hypalon Rubber#FKM Rubber#Natural Rubber#Polymers#Flourinated Rubber#Silicone Rubber#Polyurethane Rubber#Ethylene Propylene Terpolymers#Synthetic Rubber#Chemical Resistance#O Rings

0 notes

Text

#rubber-extrusions-suppliers#rubber-extrusion-companies#rubber-extrusion-manufacturers#extruded-rubber-product-manufacturers#extruded-rubber-U-channels#extruded-rubber-seals

0 notes

Text

#silicone gasket suppliers#rubber tubing manufacturer#closed cell sponge rubber gaskets#rubber extruded#rubber seal parts manufacturer

0 notes

Text

TPO Waterproof Sheet Extrusion Line

Jwell company adopts the solid roll for combining multilayers, this new technology make the TPO sheet having a good function against wind uncovering.TPO waterproof sheet is a new type of waterproof product, which is produced with thermoplastic polyole-fin plus antioxygen and plastifier and so on, the middle layer is polyester fabric for reinforcement, the surface is laminated with textile fiber and aluminum foil. This kind of TPO waterproof sheet has the features of good weatherproof and suppleness. It is mainly used for house, tunnel, basement architecture and other waterproof fields. Used for different kinds of plastic material, such as PVC, TPO,etc.Being able to produce below sheets: Plastic roll sheet (model: H): without coating with inner reinforced material or outer material. Roll sheet with outer fiber (Model: L): coating with fiber or non-woven fabric. Inner reinforced roll sheet (Model: P): Inner layer coats with polyester mesh. Inner reinforced roll sheet (Model: G): Inner layer coats with glass fiber. Features of TPO waterproof coiled material 1. Ethylene propylene rubber and polypropylene are combined by advanced polymerization technology, which has both excellent weather resistance of ethylene propylene rubber and weldability of polypropylene. 2. The special formulation technology does not need to add any plasticizer that is easy to make the material brittle, does not produce the embrittlement of general hot welded coiled materials (such as PVC) due to the migration of plasticizer, and maintains the long-term waterproof function. 3. Excellent high and low temperature resistance. Like rubber materials, it still maintains flexibility at - 50 ℃ and mechanical strength at higher temperature. 4. Chemical resistance, acid, alkali, salt, animal oil, vegetable oil, lubricating oil corrosion, algae, mold and other microbial growth. 5. It has excellent root puncture resistance and can be used as root puncture resistant coiled material for planting roof. 6. Heat aging resistance and good dimensional stability. 7. The light colored surface dominated by white has smooth surface and high reflectivity, which has energy-saving effect 8. The lap joint is constructed by thermal welding, which can form a high-strength and reliable sealing waterproof layer. 9. The reinforced TPO waterproof coiled material is sandwiched with a layer of polyester fiber fabric in the middle, which provides the coiled material with high tensile performance, high tear strength, fatigue resistance and puncture resistance, and is more suitable for mechanically fixing the roof system. 10. The backing TPO waterproof coiled material is the fabric on the lower surface of the coiled material, which makes the coiled material easier to bond with the base layer. 11. Homogeneous TPO waterproof coiled material has good plasticity and can be processed into various shapes after heating to adapt to the practice of complex nodes Main technical specification Model SJP130/36-SJZ92/188-3400 JWP130/26+JWP130/26-2400 Product structure TPO+(Net)+TPO PVC+(Net)+PVC Products width 3200mm 2200mm Products thickness 0.8-3mm 0.5-3mm Extruder model SJP130/36-SJZ92/188 JWP130/26+JWP130/26 Capacity 1200kg/h 1500kg/h Read the full article

#Chinajwell#CompositeSheetExtrusionMachine#HDPE/PPT-GripSheetExtrusionMachine#HighPolymerCompositeWaterproofRollExtrusionLine#JwellExtrusionMachine#JwellMachinery#PEExtra-widthGeomembraneExtrusionMachine#Polymerwaterproofcoiledmaterialproductionline#PVCFloorLeatherExtrusionline#TPOWaterproofSheetExtrusionline#WaterproofRollExtrusionLine

2 notes

·

View notes

Text

Extrusion is one of the main manufacturing specializations of Custom Rubber Molded Products, who offer a myriad of extruded rubber products for their numerous uses, including seals, gaskets, hoses, profiles, and others.

0 notes

Text

0 notes

Text

What Are EPDM Extrusion Profiles Used For?

Recently, the extrusion generation has been advanced with the tool of Ethylene Propylene Diene Monomer (EPDM) profiles. High quality EPDM extrusion profiles are an example of advancement and development that promoted a wide range of uses in car, production, industrial, and other areas.

Enhanced Durability: These profiles are acknowledged to be environment friendly within the stability of the financial system. They proudly for the confrontation resistance of negative consequences from rather severe types of climate, high temperatures, chemicals, and UV radiation, thus maintaining durability.

Versatile Applications: The elastomeric-characterized EPDM extrusion profiles entails that the profile can be developed in a host of varied and specialized profile designs. This factor makes them suitable for use in window seals, door seals, gaskets and hoses in many industries.

Economic Viability: EPDM profiles strike a perfect balance of sturdiness and fee-effectiveness. They offer an excessive-overall performance, reliable answer without breaking the financial institution.

Advancements in EPDM extrusion profiles generation are yielding sturdy, adaptable, and least expensive profiles which might be enhancing myriad commercial programs.

Leading the Way: Stature of EPDM Rubber Profile Manufacturers in Today's Industry

In the commercial global, producers of ethylene propylene diene monomer or epdm rubber profiles are laying the foundations for increased great and tremendous durability. Industrial, automotive as well as production industries could not have a more remarkable indispensable contribution from them.

Unparalleled Quality: These manufacturers are synonymous with integrity and fine. Using superior era, those producers make sure the EPDM profiles have vast strength, UV resistance, and advanced weather ability that render lengthy-lasting overall performance.

Extensive Application: The versatility of the EPDM rubber profiles sees its wide application in car door and window sealing, cable and conduit installations and the insulation of windows and doors in residential and commercial homes.

EPDM rubber profile manufacturers play a paramount role in bolstering the economic realm with notable, versatile, and eco-friendly rubber answers.

Unmasking the Power of Extruded Rubber Seal Profiles

These profiles are the unsung heroes in a lot of sectors. Working seamlessly to make sure tight seals in applications starting from automotive, business equipment, to home appliances, those subtle components make our lives less difficult and more secure without a great deal fanfare.

Versatility: The innate strength that defines extruded rubber seal profiles is flexibility. In a customizable size and design it finds its uses in many places ranging from simply as barriers to doorways/ window to shielding gears/systems in highly chemical reactive places like industries.

Durability: These profiles are produced from first-class rubber material and thus they stand great stresses such as wear and tear, high temperature and unfavorable environment thus implying longevity.

Cost-Effectiveness: However, being a crucial component, the cost of these profiles is not heaped mainly on conventional mission charges. They are durable hence reducing the costs of replacement which makes them a capital power tool when considering the long-term.

It proves the adage that the seal is sealed tight when your packages are secure with those sturdy extruded rubber seal profiles.

Unraveling the Intricacies of Rubber Seal Profiles

Silent heroes are the rubber seals that seem to be unimportant all too often and are actually the backbones of many business plans. These tiny elements undertake the critical task of closing up a tight, airtight connection between different components of a machine; this prevents fluid or gases from leaking out and guarantees optimum rated machines’ performance.

Versatile Utility: Rubber seal profiles locations its software’s within various segments such as automobile, aerospace, electronics and upper. In the combustion chamber of a car engine or the hydraulic device of an aero plane, these seals perform a critical role of smooth running of machines.

Material Matters: The sort of rubber used in seal profiles, then, depends on the utility fully. The everyday materials include Silicone, Nitrile and EPDM, each of them has been selected for particular attributes such as temperature endurance, oil-progression, or elasticity.

Therefore, notwithstanding their unobtrusive presence, these profiles are unsung heroes in numerous industrial packages, warranting deeper expertise and appreciation.

Enhanced Home Security through Custom Door Seals

Each house deserves an add-on stage of safety and ease that can be easily attained through these seals. The differences between a basic door security and a personalized one are innumerable when you opt for the later.

Enhanced Security: Their design also ensures a better fit since they are made to order to be off the capacity access factors for the intruders. It does the same for your own home, thereby protecting you and those you care about.

Energy Efficiency: Custom Door Seals prevent air leakage, improving the power performance of your property. During winter, a terrific seal continues the cold air out; in the course of summer season, it keeps the conditioned air in.

Noise Reduction: Door seals can also lessen any undesirable noise from the out of doors, developing a nonviolent environment in the domestic.

Revolutionizing Sealing Solutions with T-Profile Rubber Seals

These Rubber seals are transforming the present day enterprise sealing requirements due to their precise layout and first-rate features.

Flexible Yet Robust: These seals are made from excessive-energy, strong rubber that makes them resilient to intense situations, but rather bendy to make sure a really perfect healthy.

Efficient Sealant: The T-Profile design gives remarkable sealing performance, stopping any ingress of liquids or dirt particles, surpassing traditional sealing strategies.

Versatile Use: Suitable for numerous industrial programs, those seals may be utilized in diverse regions along with automotive, aerospace, production and many extra.

T-Profile Rubber Seals combine durability with fantastic sealing performance. They can resist severe climate situations, resist chemical substances, and provide a green seal as a result making them a choicest choice throughout numerous industries requiring robust sealing answers. Explore the seal of the future with T-Profile rubber seals for a stable, leak-proof revel in!

Conclusion

Ethylene Propylene Diene Monomer (EPDM) profiles are a key component in the manufacturing of premium extrusion profiles, which find use in a variety of sectors, including automotive, manufacturing, and industrial. These profiles are renowned for their improved economic viability, durability, and adaptability. EPDM rubber profile producers are renowned for their dependability, excellence, and broad range of uses. Additionally, they are utilized in a number of industries, including household appliances, commercial equipment, and automobiles. Extruded rubber seal profiles are strong and adaptable, making them ideal for a range of uses, including insulation, cable and conduit installations, and door and window sealing. They are affordable and offer a long-term fix without going over budget. Custom door seals are a popular option for many businesses because they provide increased security, energy efficiency, and noise reduction.

Custom Rubber Extrusions offers specialised rubber extrusion solutions, designed to fit your precise wishes on your region. We interact with all involved stakeholders and verify the go back on investment to deliver most cost. Along with customizable capabilities, our offerings are aimed toward enhancing your business performance and industry effect.

Contact us nowadays at [email protected] or (213)-426-1030 to time table a session or speak your desire

#EPDM-extrusion-profiles#EPDM-rubber-profile-manufacturers#extruded-rubber-seal-profiles#Custom-Door-Seals

0 notes

Text

extruded rubber seals and customized silicone mould

Elevate your sealing solutions with our top-tier extruded rubber seals and customized silicone mould. Our expert craftsmen specialize in creating precision-engineered rubber seals, ensuring impeccable performance and durability. Additionally, we offer customized silicone molds tailored to your unique requirements. Whether you need seals for industrial applications or intricate silicone molds for creative projects, Krishani products guarantee superior quality and reliability. Experience seamless operations and unmatched creative freedom with us.

0 notes

Text

A Deep Dive into Micro Pump Sealing Technology | How TOPSFLO Chooses Rubber Seals

In both precision industrial and consumer devices, water pumps play an indispensable role, silently driving the flow of liquids. At the heart of this “engine,” lies a seemingly small yet crucial component — the sealing ring. As the primary sealing element in micro pumps, the sealing ring safeguards each stable operation with the unique charm of its material. Today, let’s delve into the world of micro pump sealing materials and uncover the secrets behind these smart material choices.

Micro pump sealing materials come in a wide variety, each with its own distinct characteristics and applications. In this article, we’ll explore the common rubber-based materials used in sealing elements.

Nitrile Butadiene Rubber (NBR)

NBR is a type of synthetic rubber copolymerized from acrylonitrile (ACN) and butadiene, primarily produced through a low-temperature emulsion polymerization process. The specific gravity of NBR is 1.5 ± 0.05g/cm³, with a tensile strength of ≥500 PSI or 3.5 MPa, an elongation of ≥350%, and a hardness of 65° ± 5° shore A.

NBR can have five different acrylonitrile (ACN) content percentages: 42-46%, 36-41%, 31-35%, 25-30%, and 18-24%. The higher the acrylonitrile content, the better the oil resistance, but the cold resistance decreases correspondingly. Besides its excellent oil resistance, NBR also possesses good abrasion resistance and aging resistance. Additionally, it has good gas tightness, effectively preventing the leakage of oil media and enduring the friction and wear during the operation of water pumps. It is often used in micro water pumps that need to transport oil media.

Advantages

1. Excellent Oil Resistance: Nitrile rubber exhibits outstanding resistance to various oils, fuels, and solvents, making it ideal for applications requiring protection against water or oil.

2. High Wear Resistance: It effectively reduces the wear rate of sealing components, thereby extending the lifespan of the seals.

3. Good Heat Resistance: Nitrile rubber maintains the stability of its physical and chemical properties even at high temperatures.

4. Excellent Processability: Nitrile rubber seals are easy to mold, extrude, and inject, offering high production efficiency and relatively low costs, providing a great balance of performance and value.

Ethylene-Propylene-Diene Monomer(EPDM)

Ethylene-Propylene-Diene Monomer (EPDM) is a copolymer of ethylene, propylene, and a small amount of non-conjugated diene, primarily produced through processes such as solution polymerization and suspension polymerization. Commercial production of this material began in the 1960s. Annually, the global consumption of EPDM is 800,000 tons.

The most prominent characteristic of EPDM is its superior resistance to oxidation, ozone, and corrosion. As EPDM belongs to the polyolefin (PO) family, it exhibits excellent vulcanization properties. Among all rubbers, EPDM has the lowest specific gravity and can absorb a large amount of fillers and oils without significantly affecting its properties, thus allowing for the production of cost-effective rubber compounds.

Advantages

1. Extremely high chemical stability: The main chain of EPDM rubber is composed of chemically stable saturated hydrocarbons, with unsaturated double bonds only in the side chains. This structure grants EPDM rubber extremely high chemical stability, enabling it to resist heat, light, oxygen, and especially ozone erosion.

2. Excellent aging resistance: Due to the saturation of its main chain, EPDM rubber exhibits outstanding aging resistance, including weather resistance, ozone resistance, sunlight resistance, heat resistance, water resistance, water vapor resistance, UV resistance, and radiation resistance. When used in combination with other unsaturated diene rubbers such as NR, SBR, BR, NBR, and CR, EPDM can function as a polymer antioxidant or antidegradant.

3. Cost-effective: EPDM rubber has a relatively low density, typically ranging from 0.860 to 0.870, making it the lightest commonly used rubber in terms of raw rubber density. This results in lighter products, which helps reduce costs. The raw rubber density is only 0.86 to 0.90g/cm3, and it can be filled with a large amount of material to reduce the cost of the rubber compound.

4. Excellent electrical insulation properties, with a volume resistivity of 1016Q·cm, a breakdown voltage of 30 to 40 MV/m, and a dielectric constant (at 1 kHz, 20°C) of 2.27.

In micro pumps, EPDM rubber is commonly used for sealing components in cooling fluid and water systems, as it maintains stability and durability under various environmental conditions.

Fluorinated Rubber(FKM)

FKM refers to a synthetic polymer elastomer containing fluorine atoms on the carbon atoms of its main chain or side chains. It is an irreplaceable key material in cutting-edge national defense industries. Since 1943, various types of fluorinated rubbers have been developed, including polyolefin-based fluorinated rubber, nitroso fluorinated rubber, tetrapropyl fluorinated rubber, phosphazene fluorinated rubber, and perfluoroether rubber.

The introduction of fluorine atoms provides the rubber with excellent heat resistance, antioxidant properties, oil resistance, corrosion resistance, and atmospheric aging resistance. It has been widely used in aerospace, aviation, automotive, petroleum, household appliances, and other fields.

Advantages:

1. Excellent Chemical Resistance: FKM seals are highly resistant to a wide range of corrosive liquids and gases, including oils, fuels, acids, and solvents.

2. High Temperature Stability: FKM seals are designed to withstand temperatures ranging from -40°C to 240°C.

3. Outstanding Resilience: They ensure long-term stable sealing performance, reducing the risk of leaks.

4. Good Mechanical Properties: FKM seals maintain sealing integrity even under harsh conditions, such as high pressure, vibration, and mechanical stress.

5. Wide Compatibility: FKM seals are compatible with a variety of fluids, including mineral oils, hydraulic oils, fuels, and chemicals.

6. Additional Features: FKM seals also offer excellent oil resistance, ozone resistance, strong resistance to permanent compression deformation, and high wear resistance.

Besides the rubber materials introduced above, there are also hydrogenated nitrile rubber (HNBR), silicone rubber (Q), fluorosilicone rubber (FVMQ), tetrapropylene fluorinated rubber (TFE/P), and perfluoro(ether) rubber (FFKM).

TOPSFLO adopts high-quality imported rubber materials, primarily EPDM rubber, which boasts high purity, excellent abrasion resistance, and the ability to withstand frequent startups and prolonged continuous operation. We can select the most suitable rubber components based on the type of liquid, such as NBR, FKM, or FFKM.

youtube

0 notes

Text

Anti Vibration Mounts, Manufacturer, Mumbai, India

Find here to get more details of Anti Vibration Mounts, We are manufacturer, supplier, dealer and best service provider of Anti Vibration Mounts in Mumbai, India.

#Rubber Products#Moulded Rubber Parts#Extruded Rubber Parts#Sponge Moulded Parts#Metal Bonded Parts#Manufacturers Of Rubber Components#Manufacturers Of Moulded Rubber Parts#Manufacturers Of Extruded Rubber Parts#Rubber Moulded Parts#'O' Rings#Oilseal#U Seal#V Seal#Chevron Packing For Pumps#Hydraulics Seal#Mechanical Seal#Neoprenen Rubber#Nitrile Rubber#Epdm Rubber#Hypalon Rubber#FKM Rubber#Natural Rubber#Polymers#Flourinated Rubber#Silicone Rubber#Polyurethane Rubber#Ethylene Propylene Terpolymers#Synthetic Rubber#Chemical Resistance#O Rings

0 notes

Text

Extruded Rubber Profiles Suppliers in Dubai, UAE

In search of trustworthy vendors of extruded rubber profiles in Dubai, UAE? We provide premium rubber gaskets and seals for a range of industries. Get in touch with us now! For more details, visit https://abaw.ae/metal.html

0 notes

Text

Shaping the Future: Exploring the World of Plastic Extrusion Profiles

From the intricate trim on your car to the robust window frames in your home, plastic extrusion profiles are ubiquitous in modern life. These versatile components, created through a fascinating manufacturing process, play a crucial role in countless applications across diverse industries. This blog post delves into the world of plastic extrusion profiles, exploring their creation, benefits, applications, and why partnering with a trusted supplier like PARK NON WOVEN can bring your projects to life.

What is Plastic Extrusion?

Plastic extrusion is a manufacturing process where molten plastic is forced through a die of a specific cross-section, creating a continuous profile. This profile can be simple, like a tube or a sheet, or complex, like a custom-designed shape. The extruded plastic is then cooled and cut to the desired length. This process allows for the efficient production of consistent and precise plastic parts.

Types of Plastic Extrusion:

Several variations of plastic extrusion cater to different needs:

Profile Extrusion: Produces shapes with complex cross-sections, like window frames, pipes, and seals.

Sheet Extrusion: Creates flat sheets of plastic, used for packaging, signage, and thermoforming.

Pipe Extrusion: Manufactures pipes and tubing for various applications.

Coating Extrusion: Applies a thin layer of plastic onto a substrate, like wire or cable.

Materials Used in Plastic Extrusion:

A wide range of thermoplastics can be used in plastic extrusion, each offering unique properties:

PVC (Polyvinyl Chloride): Durable, versatile, and cost-effective, used for pipes, window frames, and siding.

ABS (Acrylonitrile Butadiene Styrene): Impact-resistant and easy to process, used for automotive parts, toys, and appliance housings.

Polyethylene (PE): Flexible and lightweight, used for packaging, films, and pipes.

Polypropylene (PP): Strong and heat-resistant, used for automotive parts, containers, and fibers.

Thermoplastic Elastomers (TPEs): Flexible and rubber-like, used for seals, gaskets, and grips.

Benefits of Plastic Extrusion Profiles:

Plastic extrusion offers a variety of advantages:

Design Flexibility: Can create complex shapes and custom profiles.

Cost-Effective: Efficient manufacturing process, especially for large volumes.

Consistent Quality: Produces parts with uniform dimensions and properties.

Lightweight: Plastic profiles are often lighter than metal counterparts.

Corrosion Resistance: Many plastics are resistant to corrosion and weathering.

Versatility: Suitable for a wide range of applications.

Applications Across Industries:

Plastic extrusion profiles find applications in numerous sectors:

Construction: Window and door frames, siding, pipes, and trim.

Automotive: Interior and exterior trim, seals, and gaskets.

Packaging: Containers, bottles, and films.

Consumer Goods: Appliance housings, toys, and furniture components.

Medical: Tubing, catheters, and medical device components.

Electronics: Cable management, enclosures, and connectors.

Choosing the Right Plastic Extrusion Partner:

Selecting a reliable plastic extrusion partner is crucial for project success. Factors to consider include:

Experience and Expertise: A company with a proven track record in plastic extrusion.

Material Selection: Ability to work with a wide range of thermoplastics.

Customization Capabilities: Ability to design and manufacture custom profiles.

Quality Control: Rigorous quality assurance processes.

Production Capacity: Ability to meet your production volume requirements.

PARK NON WOVEN: Expanding Horizons Beyond Non-Wovens

While PARK NON WOVEN is known for its expertise in non-woven materials, we are also expanding our capabilities to serve a broader range of manufacturing needs. We are exploring opportunities in related fields like plastic extrusion profiles, leveraging our commitment to quality, innovation, and customer service. Stay tuned for updates on our expansion into this exciting area!

Why Partner with PARK NON WOVEN?

Commitment to Quality: We adhere to the highest quality standards in all our processes.

Customer Focus: We prioritize customer satisfaction and work closely with our clients.

Technical Expertise: Our team has the knowledge and experience to support your projects.

Innovation: We are constantly exploring new technologies and materials.

Contact PARK NON WOVEN Today!

For inquiries about our current product offerings and future ventures, please contact us.

[email protected] 0124-4816111 Corporate Office: Park Non Woven Pvt. Ltd., Gurugram, HR

#pet acoustic panel#non woven battery gaunlets#compressor felt#breather fabric#fiber glass felt#light weight insulation#pp + pet felt#plastic extrusion profile#high efficiency media#lint free wipes

0 notes

Text

Extruded Rubber Profile Manufacturers

In the realm of industrial applications, precision and durability are paramount, especially when it comes to extruded rubber profiles. Horiaki, a distinguished name in manufacturing, has carved a niche for itself as a leader among Extruded Rubber Profile Manufacturers, elevating the standards of quality, innovation, and customization.

Horiaki's extruded rubber profiles are a testament to the company's commitment to precision engineering. The extrusion process is a delicate art, and Horiaki excels in utilizing cutting-edge technologies and rigorous quality controls to produce profiles that meet the exacting demands of various industries. From intricate seals to complex gaskets, their profiles ensure optimal performance and longevity.

Versatility is a key strength of Horiaki in the realm of extruded rubber profiles. Understanding that different applications require unique solutions, the company offers a diverse range of profiles tailored to meet specific industry needs. Whether it's for automotive, construction, or electronics, Horiaki's flexibility in customization ensures that their profiles seamlessly integrate into various systems.

Innovation is ingrained in Horiaki's approach to manufacturing. The company invests in research and development to stay ahead of the curve, incorporating the latest advancements in rubber technology. This forward-thinking approach not only ensures that their extruded rubber profiles meet current industry standards but also positions Horiaki as a trailblazer in shaping the future of rubber applications.

Furthermore, Horiaki prioritizes sustainability in its manufacturing processes. Employing eco-friendly materials and efficient production practices, the company aligns its operations with global environmental standards, reflecting a responsible and forward-looking business ethos.

In conclusion, Horiaki stands as a beacon of excellence in the realm of Extruded Rubber Profile Manufacturers. With a focus on precision, versatility, innovation, and sustainability, Horiaki's profiles continue to be trusted components, seamlessly integrating into diverse industrial landscapes around the world.

#Rubber Product Manufacturers#O Ring Seals Manufacturers#Valve Seals Manufacturers#Extruded Rubber Profile Manufacturers#Thermal Conductive Materials Manufacturers

0 notes