#epe foam equipment

Text

Living Theory

as much as i want to say this is a crack theory, I do believe it

ill take the loss if I'm wrong but the proof is here

Generation loss theory

I don't think the cast is dead.

in fact

I don't think there were any deaths in TSE Ep 2

This theory that the cast is still alive has a few roots that range from really easy to stupid complex

we can start easy.

Easy:

The idea that showfall media can revive the dead needs to be questioned more. This run-down, abandoned mall with some camera equipment and brainwashed streamers having the power to raise the dead so easily that they will kill off characters, off-screen, legitimately. just in order to bring them back, doesn't make sense.

if we find out that showfall mall is some TADC rebuilt reality, fine.

but so long as we're working with real-world logic this is taking a step in a direction that's way too far from the rest of the story.

"well hetch talked about reviving the cast, Hetch said it was all real"

Hetch is an unreliable narrator. in generation loss, it's a very important (and horribly confusing) constant, that we have no reliable narrators.

Medium:

All the deaths in Ep. 2 are comedic and nonsensical. it's in a way that's clearly portrayed to us as fake, and portrayed to the characters as real.

while there's definitely some wiggle room for improvised show and trying to decipher what's supposed to be real or what is a prop, this is something that they do multiple times through the show where they aren't trying to convince US what's on screen is real, they just have to convince the CAST its real to get the proper reaction.

An example of this could be the wall in Ep 1 that was obviously fake but was treated as realistic until the right piece of dialogue came through before sneeg comments on how obviously fake it is.

In Ep 2 nikki dies with a comically long pistol, vinny gets crushed by a loony tunes anvil, ethan goes off screen with a rotating wall, the wall-crushing scene is powered by two rats slightly pushing sneeg and austin against a mostly empty room, and puzzler blows up leaving his shoes and slightly torn up chair wizard of oz style.

all these deaths are silly, goofy, comedic

not just that but since we know sneeg comes back to be in part of ep 3, it implies that austin and likely all the other equally goofy deaths weren't real either.

Hard:

ok

for this

just

hear me out.

at TFC - 20:40 and TSE 49:18 for Ep 1

ranboo picks up a cinderblock in order to slam it against sneegs cage lock.

as ranboo hits it against the lock, it doesn't work, and the block warps in his hand.

this is because the block is made out of foam, later on, sneeg actually throws the brick at ranboo during the evil snag fight.

both ranboo and sneeg comment on the block being real to them.

In TFC this scene of the block warping in ranboos hand is actually changed to have a different, debatably worse camera angle just looking behind ranboo and hiding the obvious prop behavior.

if the founder's cut is acknowledged by the founder and this is an imperfection that was corrected, then that in its own way is an acknowledgement in canon that the block is made out of foam.

Stick With Me

If the block is made of foam and sneeg throws the block at ranboo, causing ranboo to reel back, then that means that showfall can simulate the feeling of pain.

at what point other than this, would it be relevant that pain can be realistically but heavily simulated?

The Surgery Scene.

So let's swap the script. Let's say that during the surgery scene, charlie really was just there with a tub full of goop.

in this case, it would be *much easier* and *much more effective* to fake the gore instead of the slime by having a short, few-second-long period that charlie feels like he's being cut open and reacts appropriately then find a way to do it real.

and if the surgery is fake and its on screen its hardly a challenge to fake an off screen character death or 4.

I wont speak for all the deaths

but I have my eye on Ep 2

-Tophat

#fan theory#generation loss spoilers#genloss#ranboo#ranboo generation loss#generation loss#gl sneeg#sneegsnag#slimecicle#gl charlie

23 notes

·

View notes

Text

Defoamers in Wastewater Treatment - Mitigating Foam and Improving Processes

In the realm of wastewater treatment, foam can be a persistent nuisance, hindering efficiency and complicating operations. From excessive foaming in aeration tanks to foam buildup in clarifiers and digesters, foam-related issues can lead to process disruptions, increased maintenance costs, and compromised treatment performance. Fortunately, defoamers offer a practical solution for mitigating foam and improving processes in wastewater treatment plants. In this comprehensive guide, we explore the role of defoamers in wastewater treatment, their benefits, and the different types available from leading manufacturers in India.

Understanding Foam Formation in Wastewater Treatment

Foam formation in wastewater treatment processes can occur due to various factors, including:

Organic Matter: The presence of organic compounds in wastewater, such as proteins, fats, and surfactants, can contribute to foam formation by stabilizing air bubbles and increasing surface tension.

Microbial Activity: Microorganisms present in wastewater can produce extracellular polymeric substances (EPS) that promote foam stability and persistence.

Mechanical Agitation: Agitation caused by aeration, mixing, or pumping can introduce air into the wastewater, leading to foam formation.

Chemical Reactions: Certain chemical reactions, such as the release of gases during anaerobic digestion, can result in foam generation.

The Role of Defoamers in Wastewater Treatment

Defoamers, also known as antifoaming agents, are chemical additives designed to disrupt foam formation and promote foam collapse in wastewater treatment processes. By reducing surface tension and destabilizing foam bubbles, defoamers help prevent foam buildup and facilitate the smooth operation of treatment units. Some common applications of defoamers in wastewater treatment include:

Aeration tanks

Clarifiers and thickeners

Digesters

Filtration systems

Sludge dewatering processes

Types of Defoamers

Defoamers used in wastewater treatment are available in various formulations, each suited to specific applications and operating conditions. Some of the most common types of defoamers manufactured in India include:

Silicone-Based Defoamers:

Silicone-based defoamers are widely used in wastewater treatment due to their excellent foam-suppressing properties and chemical stability. These defoamers are effective across a wide pH range and can withstand high temperatures, making them suitable for diverse wastewater treatment applications.

Alcohol-Based Defoamers:

Alcohol-based defoamers contain alcohol compounds that disrupt foam formation and promote bubble coalescence. These defoamers are often used in wastewater treatment processes where silicone-based formulations may not be suitable due to compatibility issues with certain chemicals or materials.

Glycol-Based Defoamers:

Glycol-based defoamers utilize glycol compounds to combat foam formation in wastewater treatment. These defoamers are known for their fast-acting properties and low toxicity, making them suitable for use in environmentally sensitive applications.

Benefits of Using Defoamers in Wastewater Treatment

Improved Process Efficiency: By reducing foam buildup and preventing process disruptions, defoamers help wastewater treatment plants maintain optimal process efficiency and throughput.

Cost Savings: Defoamers help minimize downtime, reduce maintenance requirements, and enhance the performance of treatment equipment, resulting in cost savings for wastewater treatment plants.

Enhanced Treatment Performance: By mitigating foam-related issues, defoamers enable wastewater treatment plants to achieve better treatment outcomes, including improved effluent quality and compliance with regulatory standards.

Versatility: Defoamers are available in various formulations to suit different wastewater treatment applications, ensuring versatility and adaptability to specific process requirements.

Choosing the Right Defoamer Manufacturer in India

When selecting a defoamer manufacturer in India, it's essential to consider factors such as product quality, technical support, and reliability. Look for a manufacturer with a proven track record of supplying high-quality defoamers for wastewater treatment applications. Additionally, ensure that the manufacturer offers comprehensive technical support and assistance to help you select the right defoamer for your specific needs.

Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) – Your Trusted Defoamer Manufacturer in India

As a leading manufacturer of specialty chemicals in India, Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) offers a wide range of defoamers specifically designed for wastewater treatment applications. Our silicone-based, alcohol-based, and glycol-based defoamers are formulated to deliver exceptional performance, reliability, and cost-effectiveness.

With decades of experience in the chemical industry and a commitment to innovation and quality, ICPL is your trusted partner for all your defoamer needs. Whether you're operating a municipal wastewater treatment plant, an industrial wastewater facility, or a specialized treatment unit, we have the expertise and resources to provide customized defoamer solutions tailored to your requirements.

Conclusion

In conclusion, defoamers play a crucial role in mitigating foam and improving processes in wastewater treatment plants. Whether it's silicone-based, alcohol-based, or glycol-based formulations, defoamers offer effective solutions for combating foam-related issues and enhancing the efficiency and performance of treatment operations. By choosing the right defoamer manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. (ICPL), wastewater treatment plants can benefit from high-quality defoamers and comprehensive technical support to meet their foam control needs effectively.

#Glycol Based Defoamer Manufacturer in India#Alcohol Based Defoamer Manufacturer in India#Defoamer Manufacturer in India#Silicone Based Defoamer Manufacturer in India

4 notes

·

View notes

Text

Difficulties and Remedies in Reusing Styrofoam for Home Appliance Packaging

The packing of household appliances frequently uses Styrofoam. It can safeguard the security of household appliances while being transported and stored because of its superior cushioning, light weight, and impact resistance. But just as quickly as consumer gadgets and home appliances are becoming more and more in demand, so is the quantity of waste foam packaging produces. Because EPS is difficult to decompose, improper processing and recycling will result in significant environmental impact. The recycling problems with foam plastics found in household appliance packaging, as well as current recycling models and solutions, will be covered in this article.

Styrofoam is ineffective for storage and transportation because it is heavy despite being incredibly light. Due to its low density and light weight, foam requires more space and costs more to ship. Because recycling foam plastics has low economic rewards and large transportation expenses, many recyclers are not very enthused about it.

Despite its difficulty, styrofoam can be readily recycled provided the proper recycling tools are used. The most widely utilized piece of machinery in North America is the styrofoam densifier, which is mostly used to recycle the packaging from styrofoam appliances. The GREENMAX styrofoam densifier has a compression ratio of up to 90:1. The reason for this foam densifier's popularity is its increased compression ratio.Compression treatment is a basic first recycling step for large foam plastics. Compressing foam plastics with specialized equipment lowers their volume and lowers storage and shipping expenses. Reusing the foam plastic packaging used for household appliances is a crucial step in combating plastic pollution. With the aid of foam densifiers, legislative assistance, and technological advancement, it is possible to recycle foam despite the difficulties involved in doing so. Future foam plastic recycling rates can be greatly raised, environmental pollution can be decreased, and the circular economy can be fostered with the help of numerous parties working together.

0 notes

Text

Acknowledge a Few Facts Before Buying a Surfboard

Surfing is one of the most enjoyable sports activities that people with similar inclinations love to indulge in. However, buying a surfboard is tricky, as it is not just a board but keeps the entire body weight. This makes it difficult for first-timers as I was to determine which one is most appropriate for use. Some of the following are some aspects to consider when purchasing Hemp Surfboards.

Your height, weight and fitness

The right surfboard should depend on height, weight, and fitness levels. Thinner and lighter surfboards are ideal for skinny and lighter individuals, while thick and large ones are appropriate for more extensive and heavier individuals to make enough buoyancy. If you are bigger in size and weight, you should go for a longer and broader board for balance. An average-weight person can start with a 9-10-foot board and move to a 12-foot board after mastering basic techniques.

The kind of waves you will be surfing

Think about the general conditions that you usually encounter while surfing. Boards with more volume are recommended for smaller, less powerful waves, while thinner boards are better for more giant waves. Longboards are suitable for small waves as they help you catch waves easily. On the one hand, Shortboards are designed to handle steeper waves and are slightly more challenging to learn. Know your spot.

Surfboard Construction

Surfboards have varying types of foam cores covered with fibreglass and resin. Polyurethane or EPS foam, the core materials, vary in weight and flexibility. Also, the quantity of fibreglass used influences the material's density and response. A balance is best. The addition of more layers of glass results in a more robust but denser board. It is essential to consider the various options before making the purchase.

Rocker, Template as well as Fins

The rocker means the amount of curve on the bottom of the board from the nose to the tail. More rocker reduces the board’s smoothness, which is preferable for experienced surfers on steep waves since it provides more manoeuvrability and responsiveness. It also means for less rocker, there is more buoyancy, thus more stability for beginners, especially when it comes to catching mellower waves. The shape and fin set-up also affect the board's performance and should be suited to the rider's ability.

Used or New Board

For the first-timer, purchasing the used quality boards will be a wise decision as they help you cut costs. Look for any significant dents, pressure dents, or anything that has gone deep into the board’s material. Slight problems on the deck and other necessary modifications do not require significant changes. Purchase new means you have a fair chance of not being associated with a product that has had a string of previous owners and has been used roughly.

How much you are willing to spend

There are considerable variations in the prices of quality surfboards, from $200 for a second-hand board to over $1000 for high-performance short boards. For a beginner, it is advisable to go for good-conditioned boards costing less than $ 500. Remember that you will scratch and destroy your first board while practising! An investment will come later.

Try Before You Buy

Whenever you can, try to get a feel of the surfboard you want to buy by taking it for a trial run. You can test it in the ocean to feel the product's responsiveness, paddle power, stability, and handling. Find out how length, width, and volume apply to your current level of proficiency in terms of actual usage. You can agree with this assertion because demonstration is the only way to determine which surfboard suits a particular client.

The Conclusion

Selecting the proper Solidsurf will determine how you learn and how fast you progress in the sport. Just remember these seven tips. Remember that the basics come before high-performance equipment, and you’ll be carving up some waves quickly.

0 notes

Text

Mobil Gear EP 150: The Ideal Choice for Extreme Pressure Applications

Industrial machinery is the backbone of numerous sectors, from manufacturing and construction to mining and energy. The heart of this machinery often lies in its gearboxes, which are subjected to immense pressure, shock loads, and high temperatures. To ensure optimal performance and longevity of these critical components, selecting the right lubricant is paramount. This is where Mobil Gear EP 150, an ISO VG 150 gear oil, shines.

Understanding the Demands of Extreme Pressure Applications

Extreme pressure applications pose unique challenges for lubricants. These conditions demand a product that can withstand heavy loads, prevent wear, and protect against equipment failure. Gearboxes in industries such as mining, construction, and steel manufacturing often operate under these demanding circumstances.

Mobil Gear EP 150: A Solution for Extreme Challenges

Formulated with advanced technology, Mobil Gear EP 150 is specifically engineered to address the rigors of extreme pressure environments. This ISO VG 150 gear oil offers exceptional performance through:

Extreme Pressure (EP) Additives: These additives create a protective film on gear surfaces, reducing friction and preventing metal-to-metal contact. This significantly minimizes wear and tear, extending the life of your equipment.

High Viscosity Index: Maintaining consistent viscosity across a wide temperature range is crucial for optimal lubrication. Mobil Gear EP 150 excels in this area, ensuring reliable protection under varying conditions.

Shear Stability: Under extreme pressure, lubricants can break down, compromising their effectiveness. Mobil Gear EP 150 resists this breakdown, maintaining its protective film and safeguarding your gearboxes.

Anti-Foam and Rust Protection: Controlling foam and preventing corrosion are essential for gear health. Mobil Gear EP 150 incorporates additives to address both these issues.

Partnering with Sanjay Tools

To ensure you're getting the best product for your industrial needs, it's crucial to partner with a reliable distributor. Sanjay Tools is a trusted name in the industry, offering Mobil Gear EP 150 and other high-quality lubricants. Their expertise and commitment to customer satisfaction make them an ideal partner for your lubrication requirements.

Conclusion

Protecting your industrial machinery is essential for maintaining productivity and minimizing downtime. By choosing Mobil Gear EP 150 and partnering with Sanjay Tools, you're taking a proactive step towards optimizing your equipment's performance. This high-performance gear oil, combined with expert guidance from Sanjay Tools, will help you overcome the challenges of extreme pressure applications and ensure the longevity of your valuable assets.

Remember to include relevant images of industrial machinery and gearboxes to enhance the blog's visual appeal.

0 notes

Text

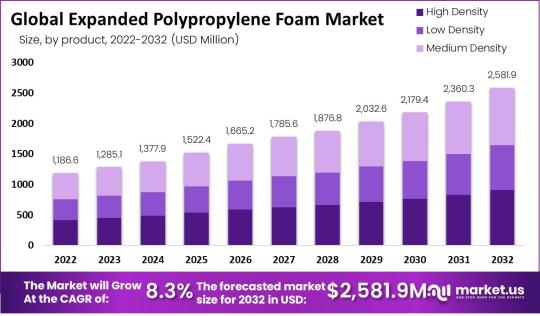

Expanded Polypropylene Foam: High-Density Segment Sees Surge in Automotive and Packaging Uses

Overview :

Expanded Polypropylene Foam Market was valued at USD 1,186.6 million and is expected to reach USD 2581.9 million in 2032. This market is estimated to register a CAGR of 8.3% between 2023 and 2032.

Get a Sample Copy with Graphs & List of Figures @ https://market.us/report/expanded-polypropylene-foam-market/request-sample/

Expanded polypropylene (EPP) foam is a versatile material known for its excellent impact resistance and lightweight properties. It is widely used in various industries due to its durability and cushioning ability. In consumer goods, EPP foam provides protection for sensitive electronics like computer equipment and circuit boards, where its shock-absorbing qualities help prevent damage during transport and use. Additionally, EPP foam's insulating properties make it valuable in packaging, building, and construction, where it contributes to energy efficiency and structural integrity.

Looking ahead, the demand for EPP foam is expected to grow, particularly in the toy and sports equipment sectors. As consumers become more health-conscious and seek products that offer better protection and safety, EPP foam's role in these areas is likely to expand. Its use in toys can provide safer play experiences for children, while in sporting goods, it can enhance comfort and injury prevention. This increasing awareness and preference for quality and safety are driving factors that will likely boost the global market for expanded polypropylene foam.

Key Market Segments

Based on Product

High Density

Low Density

Medium Density

Based on Application

Bumpers

Roof Pillars

Seat Bracing

Armrests

Other Applications

Based on End-User

Automotive

Packaging

Consumer goods

Appliances

Oil & Gas

Other End-Users

By Product Analysis:

The expanded polypropylene (EPP) foam market is segmented into high density, low density, and medium density, with high-density foams leading the market. In 2022, high-density EPP foams commanded over 42.0% of the market share, largely due to their use in automotive safety components and packaging.

By Application Analysis:

In terms of application, bumpers emerged as the leading segment, capturing over 42.0% of the market share in 2022. The increasing need for high-impact-resistant packaging for vehicle components drives this dominance, as EPP foam bumpers provide crucial safety features and impact absorption in automotive interiors and exteriors.

By End-Users Analysis:

The automotive sector is the primary end-user of expanded polypropylene foam, driven by its cost-effectiveness, mechanical strength, and moldability. EPP foam contributes to weight reduction in vehicles, enhancing fuel efficiency by up to 7% and lowering VOC emissions from interior components.

Key Players

JSP

BASF SE

Kaneka Corporation

DS Smith

Furukawa Electric Co., Ltd.

Hanwha Group

Sonoco Products

Knauf Industries

Izoblok

Dongshin Industry Incorporated

Clark Foam Products Corporation

Paracoat Products Ltd.

Molan-Pino South Africa

Signode Industrial Group LLC

Armacel

Furukawa Electric Co., Ltd.

Other Market Players

Drivers:

The expanding automotive industry is a major driver for the expanded polypropylene (EPP) foam market, as its lightweight and impact-resistant properties are ideal for components like bumpers and panels. Additionally, the growth of e-commerce and the increasing demand for sustainable packaging solutions are boosting the use of EPP foam in the packaging sector.

Restraints:

The high cost and price volatility of polypropylene, a key raw material, can impact profitability and increase finished product costs. EPP foam also faces competition from cheaper alternatives like expanded polystyrene (EPS) and may encounter challenges from emerging materials and technologies.

Opportunities:

There is significant growth potential in the automotive and packaging sectors, with emerging applications in building insulation and cushioning. The development of new uses, such as in toys and sports equipment, and advancements in manufacturing technology could reduce costs and broaden the material’s market reach.

Challenges:

Despite its advantages, EPP foam's market growth may be hampered by the development of new materials that could replace it in certain applications. Limited availability and higher costs associated with its recycling could also affect its overall market adoption and sustainability.

0 notes

Text

Insulation Foam Disposal Firm

An insulation foam disposal firm specializes in the responsible management of various types of insulation foam, including polyurethane, polyisocyanurate, and expanded polystyrene (EPS). These firms play a critical role in handling foam waste, which presents unique disposal challenges due to its chemical properties and environmental impact. The process typically begins with a thorough assessment, where the firm evaluates the type, quantity, and condition of the foam. This evaluation helps in developing a tailored disposal strategy that addresses specific needs and regulatory requirements.

Once the assessment is complete, the firm arranges for the collection of the foam insulation. This involves coordinating logistics to ensure efficient and safe removal from residential, commercial, or industrial sites. During collection, the firm employs specialized equipment and adheres to strict safety protocols to handle the foam properly and minimize any risk of contamination or exposure. Workers use personal protective equipment (PPE) such as gloves, masks, and goggles to safeguard against potential hazards.

The disposal methods used by the firm include recycling, landfilling, and waste-to-energy processes. Recycling is prioritized when feasible, as it helps to break down the foam into reusable components, thus reducing landfill waste and supporting sustainability. If recycling is not possible, the foam may be sent to a landfill or incinerated in waste-to-energy facilities, where it can be converted into energy while managing environmental impact.

#spray foam insulation removal#spray foam insulation#spray foam removal & equity release#spray foam insulation problems#spray foam removal#roof repairs service#spray foam removal services

0 notes

Text

Where Can Foam Inserts Be Found

Foam inserts are widely used across various industries for their versatility, cushioning properties, and protective qualities. They can be found in several places, catering to different needs and applications. Here are some of the most common sources where foam inserts can be found:

1. Packaging and Shipping Stores

Foam inserts are extensively used in packaging and shipping to protect fragile and valuable items. Stores specializing in packaging materials, such as Uline, Staples, and local packaging supply stores, often carry a variety of foam inserts. These stores offer different types of foam, including polyethylene, polyurethane, and expanded polystyrene (EPS) inserts, tailored to specific protection needs.

2. Custom Foam Manufacturers

For specific requirements, custom foam manufacturers provide tailored solutions. Companies like Foam Factory, MyCaseBuilder, and Pelican specialize in creating custom foam inserts designed to fit unique shapes and sizes. These manufacturers use advanced cutting technologies, such as CNC routing and waterjet cutting, to produce precise inserts that meet exact specifications.

3. Electronics and Appliance Stores

Electronics and appliance stores often use foam inserts to protect delicate items like televisions, computers and other electronic devices. Retailers like Best Buy, Apple, and other electronics stores include foam inserts in their packaging to ensure safe transportation of products. Additionally, these stores might sell protective cases with pre-cut foam inserts for various devices.

4. Tool and Hardware Stores

Foam inserts are commonly used in toolboxes and carrying cases to organize and protect tools. Stores like Home Depot, Lowe’s, and specialized tool retailers provide foam inserts for tool organization. These inserts can be custom-cut or pre-cut to fit specific tools, ensuring they remain secure and undamaged during transport and storage.

5. Outdoor and Sporting Goods Stores

Foam inserts play a crucial role in protecting equipment in outdoor and sporting activities. Stores like Cabela’s, Bass Pro Shops, and REI offer foam inserts for items such as firearms, cameras, and sporting gear. These inserts help secure and protect equipment from impacts and environmental elements.

6. Online Retailers

Online marketplaces like Amazon, eBay, and Alibaba offer a wide range of foam inserts for various applications. These platforms provide access to a broad selection of pre-made and customizable foam inserts, allowing consumers to find the perfect fit for their needs. Online retailers also offer reviews and ratings, helping buyers make informed decisions.

7. Medical and Scientific Equipment Suppliers

In the medical and scientific fields, foam insert sare used to protect sensitive instruments and equipment. Suppliers like Fisher Scientific and McKesson provide foam inserts for medical devices, laboratory equipment, and diagnostic tools, ensuring these critical items are safeguarded during transport and storage.

In summary, foam inserts are available in a wide range of places, each catering to specific needs. Whether for packaging, custom applications, electronics, tools, sporting goods, online purchases, or medical equipment, foam inserts provide essential protection and organization across various industries.

0 notes

Text

Expert Picks: Best Infant Car Seats for Safety and Comfort

Choosing the right infant car seat is paramount for the safety and comfort of your baby. With a myriad of options on the market, it can be challenging to determine which ones stand out in terms of safety features, ease of use, and overall comfort. To help you navigate this critical decision, we’ve compiled a list of expert picks for the best infant car seats based on top reviews and expert opinions.

Graco SnugRide 35 Lite LX

The Graco SnugRide 35 Lite LX is a popular choice among parents and experts alike. It’s celebrated for its lightweight design and robust safety features, making it a top contender in best baby car seat review.

Key Features:

Lightweight: Weighing just over 7 pounds, it’s easy to carry and transfer between the car and stroller.

Safety: It includes a five-point harness system and EPS energy-absorbing foam for effective impact management.

Ease of Installation: The seat is equipped with a straightforward LATCH system, making it easy to install correctly.

Reviews:

The Graco SnugRide 35 Lite LX infant car seat reviews highlight its user-friendly installation and comfortable design for newborns. Many parents appreciate the affordability without compromising on safety.

Chicco KeyFit 30

The Chicco KeyFit 30 is another top-rated infant car seat, known for its exceptional ease of use and comfort.

Key Features:

Installation: Its ReclineSure leveling foot and RideRight bubble level indicators ensure an accurate fit in a variety of vehicles.

Comfort: The seat features a newborn insert for added comfort and support for smaller babies.

Safety: It offers a five-point harness system and side-impact protection.

Reviews:

Chicco KeyFit 30 infant car seat reviews consistently praise its effortless installation process and snug fit for infants. It’s often recommended for first-time parents due to its intuitive design.

Chicco KeyFit 35

For parents seeking extended use, the Chicco KeyFit 35 offers higher weight and height limits compared to the KeyFit 30.

Key Features:

Extended Use: Accommodates infants up to 35 pounds and 32 inches tall.

Adjustable Base: The base includes an anti-rebound bar for added stability.

Safety: Features similar to the KeyFit 30, including side-impact protection and a five-point harness system.

Reviews:

Chicco KeyFit 35 infant car seat reviews highlight its extended usability and added safety features. Parents appreciate the extra room for growing babies and the enhanced stability of the anti-rebound bar.

Evenflo Shyft DualRide

The Evenflo Shyft DualRide stands out as a versatile option that combines an infant car seat with a stroller.

Key Features:

Versatility: Easily transitions from car seat to stroller without disturbing the baby.

Convenience: Ideal for on-the-go parents who need a quick and easy way to switch between driving and walking.

Reviews:

Evenflo Shyft DualRide infant car seat and stroller combo reviews highlight its practicality and convenience. Many parents find it a perfect solution for urban living and frequent travel.

Conclusion

When it comes to choosing the best infant car seat, consider your lifestyle, vehicle compatibility, and specific needs. Our expert picks like the Graco SnugRide 35 Lite LX, Chicco KeyFit 30 and 35, Evenflo Shyft DualRide, UPPAbaby Mesa V2, and Doona offer a range of options catering to various preferences and budgets.

1 note

·

View note

Text

The Importance of Helmet Durability and Crash Testing for Beginners

When embarking on the exhilarating journey of cycling or motorcycling, beginners often find themselves inundated with a plethora of gear and safety equipment options. Among these, one of the most crucial pieces is the helmet. However, not all helmets are created equal, and understanding the importance of helmet durability and crash testing can be a life-saving knowledge. This comprehensive guide will delve into why beginners must prioritize these factors when choosing a helmet.

Understanding Helmet Durability

Durability is the measure of how well a helmet can withstand wear, pressure, or damage. For beginners, investing in a durable helmet means investing in long-term safety and performance. A durable helmet is designed to endure multiple impacts without compromising its protective capabilities. This aspect is particularly important for beginners who are still mastering control and may be prone to falls and accidents.

The Role of Materials in Helmet Durability

The materials used in helmet construction significantly impact its durability. High-quality helmets typically use materials like polycarbonate, ABS plastic, carbon fiber, and EPS foam. Polycarbonate and ABS plastic are known for their strong impact resistance, while carbon fiber is prized for its lightweight yet incredibly strong properties. EPS foam, on the other hand, is excellent at absorbing shock, which is critical during a crash.

Our Socials:

https://www.facebook.com/motorcyclehelmetforbeginners/

https://twitter.com/helmetbeginners

https://www.tiktok.com/@helmetforbeginners

https://www.reddit.com/user/helmetforbeginners

https://www.pinterest.com/motorcyclehelmetforbeginners/

Why Crash Testing Matters

Crash testing is the process of evaluating a helmet’s performance under simulated crash conditions. This testing is essential to ensure that the helmet can provide adequate protection in real-world scenarios. For beginners, understanding the significance of crash testing can be the difference between a minor incident and a severe injury. Helmets that undergo rigorous crash testing are typically certified by safety standards organizations, providing an added layer of assurance.

Types of Helmet Safety Standards

There are several helmet safety standards worldwide, each with specific criteria for crash testing. Common standards include the DOT (Department of Transportation) for the United States, ECE (Economic Commission for Europe) for Europe, and Snell Memorial Foundation standards. Beginners should look for helmets that meet or exceed these standards to ensure optimal protection.

The Science Behind Helmet Design

The design of a helmet plays a pivotal role in its ability to protect the wearer. Modern helmets are designed with advanced aerodynamics, ventilation systems, and padding to enhance safety and comfort. For beginners, a well-designed helmet not only provides superior protection but also ensures comfort, which is essential for maintaining focus and control while riding.

The Impact of Helmet Fit on Safety

A helmet’s fit is crucial for its effectiveness. A helmet that is too loose or too tight can compromise safety. Beginners should ensure that their helmet fits snugly without causing discomfort. Most manufacturers provide sizing guides, and it's recommended to try on multiple helmets to find the perfect fit. A properly fitted helmet stays in place during a crash, ensuring that the protective features function as intended.

Maintenance and Lifespan of Helmets

To maintain a helmet’s durability and protective capabilities, regular maintenance is essential. Beginners should regularly inspect their helmets for signs of wear and damage, such as cracks, dents, or frayed straps. Additionally, helmets have a lifespan, typically ranging from three to five years. Even if a helmet appears undamaged, the materials can degrade over time, reducing its effectiveness. Replacing helmets periodically ensures continued safety.

The Psychological Benefits of Wearing a Tested Helmet

Wearing a helmet that has passed stringent durability and crash testing not only provides physical protection but also offers psychological benefits. For beginners, knowing that their helmet is capable of protecting them in an accident can significantly boost confidence and reduce anxiety. This mental assurance allows for better focus and enjoyment during rides, which is crucial for skill development.

Conclusion

For beginners stepping into the world of cycling or motorcycling, understanding the importance of helmet durability and crash testing is paramount. Durable helmets made from high-quality materials and those that have undergone rigorous crash testing offer the best protection against potential accidents. Adhering to recognized safety standards, ensuring a proper fit, and maintaining the helmet are critical practices for maximizing safety. Additionally, the psychological comfort provided by a reliable helmet can enhance a beginner's overall riding experience. Prioritizing these factors not only protects physical well-being but also fosters a safer and more enjoyable journey on the road. By making informed choices about helmet durability and crash testing, beginners can confidently embark on their riding adventures with peace of mind.

0 notes

Text

2032, Expanded Polystyrene (EPS) Recycling Market Growth and Research 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Expanded Polystyrene (EPS) Recycling Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Expanded Polystyrene (EPS) Recycling Market Size share, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Expanded Polystyrene (EPS) Recycling Market?

The expanded polystyrene (EPS) recycling market size reached US$ 19.7 Billion in 2023. Looking forward, Reports and Insights expects the market to reach US$ 36.5 Billion by 2032, exhibiting a growth rate (CAGR) of 6.7% during 2024-2032.

What are Expanded Polystyrene (EPS) Recycling?

EPS recycling is the practice of collecting, sorting, and processing EPS foam products to reclaim the material for reuse. EPS, also known as Styrofoam, is a lightweight and rigid plastic material utilized in packaging and insulation. The recycling process involves compressing the foam to reduce its size and then melting it down to create dense blocks or pellets suitable for manufacturing new products. EPS recycling contributes to environmental sustainability by diverting EPS waste from landfills and reducing the demand for new plastic production.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1775

What are the growth prospects and trends in the Expanded Polystyrene (EPS) Recycling industry?

The expanded polystyrene (EPS) recycling market growth is driven by various factors. The market for recycling expanded polystyrene (EPS) is expanding, fueled by growing environmental consciousness and regulatory measures promoting recycling practices. EPS, widely utilized in packaging and construction, significantly contributes to plastic waste. Recycling EPS involves collecting, cleaning, and processing it into reusable material for diverse applications. Market growth is propelled by increasing demand for recycled EPS in the construction and packaging sectors, driven by sustainability objectives and economic advantages. Moreover, technological advancements in EPS recycling and government support for recycling initiatives are further driving market growth. Hence, all these factors contribute to expanded polystyrene (EPS) recycling market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By EPS Waste Type:

Post-consumer EPS waste

Pre-consumer EPS waste

By EPS Recycling Process:

Mechanical recycling

Chemical recycling

Other recycling processes

By End-Use Industry:

Packaging

Construction

Electrical and Electronics

Automotive

Others

By Recycled EPS Product:

Packaging materials

Insulation boards

Molded products

Composite materials

Others

By Source of Collection:

Municipal recycling programs

Industrial and commercial collection

Retail collection

Other

By Recycling Equipment:

Shredders

Granulators

Densifiers

Extruders

Others

By Application:

Packaging

Building and construction

Insulation

Consumer goods

Others

By Distribution Channel:

Direct sales

Distributor sales

E-commerce

By Market Type:

Business to Business (B2B)

Business to Consumer (B2C)

Segmentation By Region:

North America:

United States

Canad

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Dart Container Corporation

NOVA Chemicals Corporation

ACH Foam Technologies, LLC

Ravago Recycling Group

Styro Recycle LLC

Total, Petrochemicals & Refining USA, Inc.

Alpek Polyester

Repsol S.A.

Vanden Recycling

Plasti-Fab Ltd.

NexKemia Petrochemicals Inc.

EPS Industry Alliance

Vita Group

FPC Foam Plastics Corporation

Winco Foam Industries Limited

View Full Report: https://www.reportsandinsights.com/report/Expanded Polystyrene (EPS) Recycling-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

#Expanded Polystyrene (EPS) Recycling Market share#Expanded Polystyrene (EPS) Recycling Market size#Expanded Polystyrene (EPS) Recycling Market trends

0 notes

Text

Is it possible to recycle EPS dust using an EPS densifier to efficiently reduce pollution?

Expanded polystyrene, or EPS for short, is a polymer that is frequently used in construction, packaging, and disposable dinnerware. Because EPS degrades slowly in nature, recycling material has become more crucial. Large foam blocks are typically disposed of as part of the primary EPS recycling process, but EPS dust—fine EPS particles produced during production or breakage—also has to be recycled effectively. Recycling EPS dust with an EPS densifier is a useful technique.

EPS densifiers typically recycle dust in this way.

EPS dust is being recycled using the GREENMAX EPS densifier; typically, EPS dust is recycled in conjunction with EPS blocs. Both are simultaneously added to the feeding bin, where they are heated, melted, and formed into dense ingots. In certain cases, crushing EPS dust is not necessary if you wish to recycle it separately; instead, you can pour it directly into the silo for hot melting. The two primary recycling status quos are as follows. Dense ingots are created when the amount of trash processed with GREENMAX EPS densifier is reduced to one-90th of its initial size.

Recycling EPS dust with a hot melt machine is a cost-effective and efficient way to treat trash. Hot melt technology can be intelligently applied to minimize the volume of EPS, increase recycling efficiency, and reuse resources. Reducing environmental impact and promoting sustainable development can be achieved through the use of effective recycling procedures and equipment management. A significant volume of EPS dust can be processed effectively and turned into recyclable products using the hot melt equipment. This lessens the environmental impact and increases recycling efficiency. Resource recycling is achieved by using recycled EPS that has undergone hot melt processing to create new goods or find other uses. This preserves raw materials while also lowering the amount of waste produced. Efficient recycling can lessen EPS dust's negative environmental effects. The environmental issues associated with landfilling and incineration can be lessened by turning garbage into reusable resources.

0 notes

Text

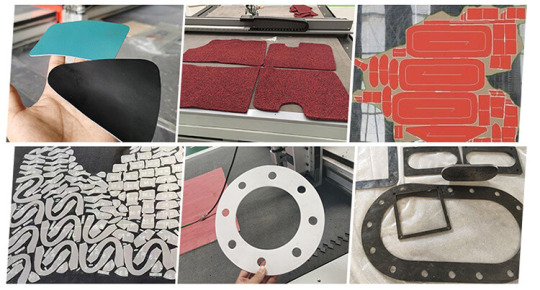

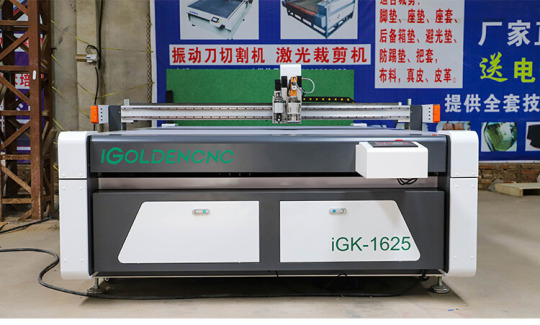

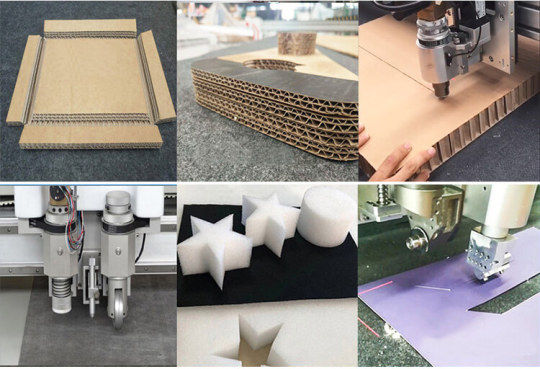

CNC Knife Cutter Machine for PE and EVA Foams

CNC knife cutter machines are widely used in industries such as packaging, textile, automotive, aerospace, and signage. They offer precise and efficient cutting capabilities, enabling the production of intricate shapes and patterns with minimal material waste.

Affordable cnc oscillating knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

CNC Knife Cutter Machine

A CNC knife cutter machine, also known as a CNC cutting machine or a CNC oscillating knife cutter, is a computer-controlled cutting system specifically designed for precision cutting of various materials. It utilizes a vibrating or oscillating knife, which moves rapidly up and down to cut through the material.

Affordable cnc oscillating knife machine have two types: ① CNC Router machine add oscillating knife cutting knife head (Knife together with spindle independent work, compatible with cnc router cotrol system, and running perfectly, Solve the processing needs of soft materials); ② Professional oscillating knife cutting machine ( Professional and efficient ). Accordding to functions: can be divided into oscillating knife cutting , round knife cutting, pneumatic knife cutting. you need to accordding to different material shapes cutting, choose different knives.

CNC can provide all kinds CNC Knife Cutter Machine for sale:

CCD camera series: automatic edge finding, automatic scanning, automatic imaging system.

CNC knife cutter machine table size:

CNC oscillating knife cutting machine for sale have model: 6090, 1390, 1410, 1610, 1325, 1530, 2030, and working table size 600*900mm, 900*1300mm, 1000*1400mm, 1000*1600mm, 1300*2500mm, 1500*3000mm, 2000*3000mm etc, maybe some regions describe cnc knife cutter machine table size with feet: 3*4, 3*5, 4*8, 5*10 etc. We also accept custom table sizes,to meet customer needs.

CNC Knife Cutter Machine Processing advantages

With the continuous development of numerical control technology, more and more customers choose to use smart cutting equipment instead of workers. It uses advanced oscillating knife cutting technology to select different tools according to material thickness and hardness. It can meet a variety of foam material cutting, such as EVA, EPE, sponge, EPS styrofoam and so on.

There are 6 advantages to using the CNC Knife Cutter Machine to cut the foam:

1. More flexible; EVA foam automatic cutting machine does not need a mold, just process the processing data (PLT, DXF, AI format) into the system to cut, and can modify the size and shape of the processing graphics arbitrarily;

2. Save materials; automatic nesting software can complete typesetting quickly and accurately without manual nesting. After actual testing, using an automatic cutting machine can save more than 10% of material compared to manual cutting;

3. Meet different foam cutting; can cut foam of different width, thickness, and material. High cutting precision and flat cutting to meet the cutting requirements of complex graphics.

4. The processing site is more humanized; AMOR EVA foam cutting machine adopts high-frequency oscillating knife cutting technology. Compared with laser cutting technology, the processing site has no soot, and the cutting speed is 3-4 times that of the laser. More environmentally friendly processing methods.

5. Different types of tools can be configured; customers can configure different processing tools according to the processing materials – round knife, pneumatic knife, punching knife, vibrating knife, and other cutter heads to configure freely to cut other materials except for foam;

6. Achieve higher cutting efficiency; AMOR EVA foam cutting machine adopts Japanese Mitsubishi servo motor with cutting speed of up to 2000mm/s. Customers can also choose dual-oscillating tools to cut at the same time, which doubles the processing efficiency.

CNC Knife cutter machine application

Affordable cnc Digital knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

Oscillating Knife Details

Cutting Capabilities

CNC knife cutter machine are versatile and can cut a wide range of materials, including but not limited to:

Soft materials: Foam, rubber, gaskets, textiles, carpets, felt, leather, etc.

Rigid materials: Cardboard, corrugated board, honeycomb board, thin plastics, composite materials, etc.

Other materials: Vinyl, paper, cork, magnetic sheets, adhesive-backed materials, and more.

The oscillating knife’s high-frequency motion allows for clean and precise cuts, even in intricate designs or complex patterns.

Additional Tool Option

In addition to the oscillating knife, CNC knife cutter machines can often accommodate other cutting tools or attachments, expanding their capabilities. Some common additional tools include:

Creasing wheels: Used for creating creases or scoring lines in materials like cardboard or paper, enabling easier folding or bending.

Perforation wheels: Used to create perforated lines for tear-off sections in materials like paper or cardboard.

Routing attachments: Used for cutting harder materials like acrylic or wood, where an oscillating knife may not be suitable.

The ability to interchange tools allows for more versatility in the types of materials and applications that can be handled by the machine.

High Precision and Repeatability

CNC knife cutter machines offer excellent precision and repeatability in cutting. The computer-controlled nature of the machine ensures accurate cutting paths, resulting in consistent and high-quality finished products. This is especially beneficial for industries that require precise fitting, such as packaging or automotive interior components.

Design Flexibility

With the help of specialized software, CNC knife cutter machines can process various design file formats, allowing for flexibility in design creation. Designs can be imported from computer-aided design (CAD) software or created directly within the cutting software. This flexibility enables customization, prototyping, and small-batch production with ease.

Production Efficiency

CNC knife cutter machines streamline the cutting process, reducing manual labor and increasing production efficiency. Once the cutting program is set up, the machine can autonomously execute the cutting tasks, optimizing material usage and minimizing waste. This automation also allows for faster turnaround times, enabling manufacturers to meet tight deadlines and handle larger production volumes.

Integration with Workflow

CNC knife cutter machine can be integrated into a larger production workflow, connecting with other equipment or systems. This integration facilitates seamless material handling, automated nesting (arranging shapes to minimize material waste), and data exchange, enhancing overall productivity and efficiency.

0 notes

Text

Chicago Fire Season 1 Ep. 21 "Retaliation Hit"

Detective Voight wants to collect on a favour from Dawson for helping her brother. Tara accuses Severide of sexual harassment. Casey falls back into old patterns in his personal life, reuniting with Hallie. Dawson, Herrmann and Otis become the proud owners of a neighbourhood bar as Molly's prepares for its grand opening.

If you want to watch the series for yourself, stop reading! This post contains spoilers to the storyline.

Severide goes to a hearing with a CFD ethics board about assault allegations against him by Tara Little. He thinks the charges are ridiculous, but Mouch helps him not to say more than he needs to. Either way, it's an ordeal that Severide doesn't like.

Casey and Hallie meet for coffee. Hallie talks about the firehouse gossip and says she's not seeing anyone. Casey says Curtis, who helped him execute the Voight sting, was murdered. Meanwhile, Voight has gotten out of prison.

Boden says that because of the allegations against Severide, the whole station must do sexual harassment training. Mills says he'll help, but the others think he's trying to impress Severide. Before they go on a call, Boden tells Casey that Voight is out of prison.

The firefighters arrive at the scene and find a car has driven through a convenience store wall, pinning the shop owner underneath. They lift the car to pull the owner out, then take the driver to the hospital.

Severide wants to meet his accuser, but Mouch says no. Dawson gets a call from Voight. She doesn't answer, but Voight wants to ask her for a favour. The firefighters don't take their sexual harassment training seriously.

In Chief Boden's office, Casey and Antonio discuss Voight's release from prison. Antonio says Voight is still dangerous and Casey should watch his back. Boden tells Casey not to fight with Voight.

Dawson tells Casey about the Voight call and Casey says she should avoid dealing with Voight alone.

Severide meets with Tara to discuss her sexual assault allegations. Tara says she'll drop the charges if he apologizes, but he refuses.

Meanwhile, Antonio says he'll take care of Voight.

At the scene of a big rig accident, the truck is leaking chemicals. Boden calls for a foam truck, and the Squad team rescues the driver. Severide tells his team to rig up a harness, but they aren't comfortable with the equipment. Mills rigs up a special harness, saving the day.

While the firehouse staff is training on sexual harassment, Squad member Hadley switches Mills' chili with dog food. Mills gets angry, and a fight almost breaks out in front of the training officer. Later, Boden transfers Hadley to another firehouse.

Antonio warns Voight to stay away from Dawson and Firehouse 51, but Voight doesn't seem intimidated.

At the courthouse, Mouch tells Severide that his meeting created more problems. The board is looking into Severide's history, including his short-lived relationships with Nikki.

Casey visits Hallie's new apartment. They drink wine and talk about the past. They end up in the bedroom, where they rekindle their romance.

On his way out of the courthouse, Severide meets Voight. Voight says he's back with the Chicago Police Department.

Nikki's father, Chief Rutkowski, comes to the station to tell Boden that he's testifying against Severide. Boden says their friendship is over. Shay and Dawson respond to a call where a snake owner has been bitten by his pet viper. Dawson overcomes her fear of snake to rescue the owner.

At the firehouse, Mouch tells Severide that his case is being reviewed by the state board. If they find the charges true, they'll press criminal charges against him. Severide tells Shay that she's the only person he can trust.

Later that night, the new bar is crowded and the patrons are happy. Casey arrives with Hallie on his arm, surprising Dawson. Voight shows up and offers to make amends with the firehouse. Antonio tells Dawson that Voight is in charge of his department. Nobody accepts Voight's apology.

0 notes

Text

EPS densifier can effectively solve the accumulation problem of foam beads, maintain the 5S on site, and help customers turn waste into treasure.

GREENMAX EPS densifier, affiliated with INTCO Recycling, can be customized according to the customer's EPS beads recycling needs, and add foam beads recycling equipment to the basic version. The EPS densifier developed by INTCO Recycling achieves foam volume reduction through the principle of high-temperature hot melting, with a compression ratio of 90:1. The EPS recycling machine can be equipped with additional pipes and fans to directly absorb the tiny EPS beads into the silo. Because the EPS beads are small in size, they do not need to be crushed and can be directly stored in the silo with other foam fragments. If the foam in the silo is full, the recycling staff can turn on the compaction function of the EPS densifier at any time.

The compacted foam can be remade into PS particles and returned to the production process of EPS boards to achieve resource reuse and save raw materials. Alternatively, the EPS beads compacted by the EPS densifier can be sold to downstream recyclers to manufacture various environmentally friendly products.

0 notes

Text

Luggage and backpacks with ACF material inserted in the lining, and airline cases, to protect valuables more safely.

Report Topic: ACF-CM series materials can effectively absorb 90% of the impact energy and protect valuables more effectively when inserted into the inner lining of suitcases, backpacks, and flight cases.

Introduction:

With the increase in the frequency of people's travel, luggage and backpacks, airline cases, precision instrument cases have become an indispensable part of our life and work. However, during traveling or carrying, valuables are easily damaged by external impacts, which brings unnecessary losses to people. In order to solve this problem, a new type of material, ACF-CM series material, has been developed. This report will introduce the characteristics and applications of this material in detail, in order to provide effective protection solutions for the majority of luggage manufacturers.

Abstracts:

ACF-CM soft series material is an innovative material with excellent impact absorption properties. It can effectively protect valuables from external impacts by placing it into the inner layer of luggage and backpacks, and airline cases. This report analyzes expert opinions, examples and data to illustrate the advantages of ACF-CM materials and their application prospects in the field of luggage and backpacks.

Body of the report:

I. Introduction of ACF-CM material

ACF-CM material is a unique new polymer metamaterial with high elasticity and toughness. After academician Wang Bowei's ACF laboratory of LinZhi science and technology research and development innovation, the material has a lightweight, soft and high toughness and other characteristics at the same time, can effectively absorb the impact energy, to reduce the risk of damage to the items under the action of external forces.

Advantages of ACF-CM material

1. more shockproof positioning: ACF-CM material can absorb up to 90% of the impact energy, efficient shock absorption of external impact, greatly superior to traditional EVA, EPE and other traditional foam sponge, more shockproof positioning, significantly reduce the risk of damage to valuables.

2. Lighter and softer: ACF-CM material is lightweight and soft, easy to cut and shape, compared to traditional shock absorbing materials for a variety of luggage and backpack design needs.

3. Stronger durability: ACF-CM material has excellent fatigue resistance, deformation rate <10%, and can maintain stable protection under repeated impacts.

4. Eco-friendly and non-polluting: ACF-CM materials are made of environmentally friendly raw materials, non-toxic and odorless, friendly to the environment and supportive of sustainable development policies.

Application Prospects of ACF-CM Materials

In recent years, consumers have put forward higher requirements for shock-absorbing and protective performance of luggage and backpacks, aviation cases, and cases for precision instruments, and the emergence of ACF-CM materials has provided new solutions for manufacturers of luggage and backpacks, aviation cases, and protective cases for precision instruments. According to market research organizations, in the next few years, the market size of luggage and backpacks, aviation cases equipped with ACF-CM materials will expand rapidly, and is expected to reach more than 1 billion U.S. dollars by 2025.

Conclusion

Science and technology is the driving force of the development of new quality productivity, Lin to technology company's ACF-CM soft series of materials with excellent impact absorption properties, will be placed into the luggage and backpacks, aviation cases, precision instruments within the inner layer, can effectively protect valuables. Catering to the consumer's demand for improved protection performance, expanding market share.

400-6543-699

www.acf.com

0 notes