#Defoamer Manufacturer in India

Explore tagged Tumblr posts

Text

Defoamers in Wastewater Treatment - Mitigating Foam and Improving Processes

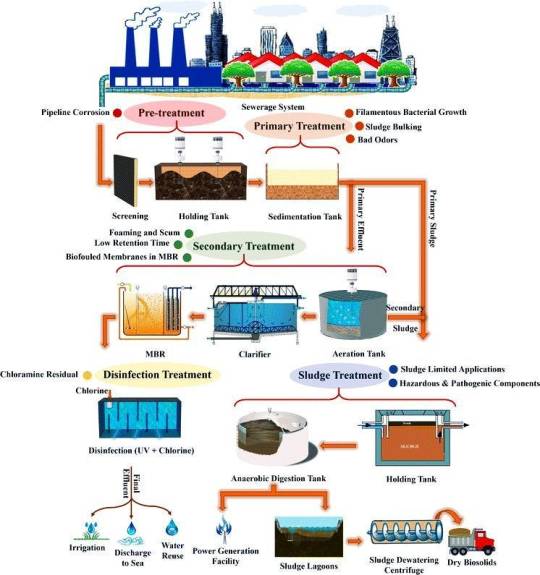

In the realm of wastewater treatment, foam can be a persistent nuisance, hindering efficiency and complicating operations. From excessive foaming in aeration tanks to foam buildup in clarifiers and digesters, foam-related issues can lead to process disruptions, increased maintenance costs, and compromised treatment performance. Fortunately, defoamers offer a practical solution for mitigating foam and improving processes in wastewater treatment plants. In this comprehensive guide, we explore the role of defoamers in wastewater treatment, their benefits, and the different types available from leading manufacturers in India.

Understanding Foam Formation in Wastewater Treatment

Foam formation in wastewater treatment processes can occur due to various factors, including:

Organic Matter: The presence of organic compounds in wastewater, such as proteins, fats, and surfactants, can contribute to foam formation by stabilizing air bubbles and increasing surface tension.

Microbial Activity: Microorganisms present in wastewater can produce extracellular polymeric substances (EPS) that promote foam stability and persistence.

Mechanical Agitation: Agitation caused by aeration, mixing, or pumping can introduce air into the wastewater, leading to foam formation.

Chemical Reactions: Certain chemical reactions, such as the release of gases during anaerobic digestion, can result in foam generation.

The Role of Defoamers in Wastewater Treatment

Defoamers, also known as antifoaming agents, are chemical additives designed to disrupt foam formation and promote foam collapse in wastewater treatment processes. By reducing surface tension and destabilizing foam bubbles, defoamers help prevent foam buildup and facilitate the smooth operation of treatment units. Some common applications of defoamers in wastewater treatment include:

Aeration tanks

Clarifiers and thickeners

Digesters

Filtration systems

Sludge dewatering processes

Types of Defoamers

Defoamers used in wastewater treatment are available in various formulations, each suited to specific applications and operating conditions. Some of the most common types of defoamers manufactured in India include:

Silicone-Based Defoamers:

Silicone-based defoamers are widely used in wastewater treatment due to their excellent foam-suppressing properties and chemical stability. These defoamers are effective across a wide pH range and can withstand high temperatures, making them suitable for diverse wastewater treatment applications.

Alcohol-Based Defoamers:

Alcohol-based defoamers contain alcohol compounds that disrupt foam formation and promote bubble coalescence. These defoamers are often used in wastewater treatment processes where silicone-based formulations may not be suitable due to compatibility issues with certain chemicals or materials.

Glycol-Based Defoamers:

Glycol-based defoamers utilize glycol compounds to combat foam formation in wastewater treatment. These defoamers are known for their fast-acting properties and low toxicity, making them suitable for use in environmentally sensitive applications.

Benefits of Using Defoamers in Wastewater Treatment

Improved Process Efficiency: By reducing foam buildup and preventing process disruptions, defoamers help wastewater treatment plants maintain optimal process efficiency and throughput.

Cost Savings: Defoamers help minimize downtime, reduce maintenance requirements, and enhance the performance of treatment equipment, resulting in cost savings for wastewater treatment plants.

Enhanced Treatment Performance: By mitigating foam-related issues, defoamers enable wastewater treatment plants to achieve better treatment outcomes, including improved effluent quality and compliance with regulatory standards.

Versatility: Defoamers are available in various formulations to suit different wastewater treatment applications, ensuring versatility and adaptability to specific process requirements.

Choosing the Right Defoamer Manufacturer in India

When selecting a defoamer manufacturer in India, it's essential to consider factors such as product quality, technical support, and reliability. Look for a manufacturer with a proven track record of supplying high-quality defoamers for wastewater treatment applications. Additionally, ensure that the manufacturer offers comprehensive technical support and assistance to help you select the right defoamer for your specific needs.

Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) – Your Trusted Defoamer Manufacturer in India

As a leading manufacturer of specialty chemicals in India, Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) offers a wide range of defoamers specifically designed for wastewater treatment applications. Our silicone-based, alcohol-based, and glycol-based defoamers are formulated to deliver exceptional performance, reliability, and cost-effectiveness.

With decades of experience in the chemical industry and a commitment to innovation and quality, ICPL is your trusted partner for all your defoamer needs. Whether you're operating a municipal wastewater treatment plant, an industrial wastewater facility, or a specialized treatment unit, we have the expertise and resources to provide customized defoamer solutions tailored to your requirements.

Conclusion

In conclusion, defoamers play a crucial role in mitigating foam and improving processes in wastewater treatment plants. Whether it's silicone-based, alcohol-based, or glycol-based formulations, defoamers offer effective solutions for combating foam-related issues and enhancing the efficiency and performance of treatment operations. By choosing the right defoamer manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. (ICPL), wastewater treatment plants can benefit from high-quality defoamers and comprehensive technical support to meet their foam control needs effectively.

#Glycol Based Defoamer Manufacturer in India#Alcohol Based Defoamer Manufacturer in India#Defoamer Manufacturer in India#Silicone Based Defoamer Manufacturer in India

4 notes

·

View notes

Photo

Types of Defoamer Chemicals

There are many types of defoamers are available in the market. They can also be used as fertilizer dust control. Everything you need to know about defoamers is right here.

#defoamers for phosphoric acid#oil-based defoamers#flotation agents for phosphate#defoamer chemical manufacturers in India#water-based defoamers

0 notes

Text

A Deep Dive into the Industrial Water Treatment Chemicals Market: Insights and Analysis

The global industrial water treatment chemicals market size is expected to reach USD 21.23 billion by 2030, registering a CAGR of 4.9% during the forecast period, according to Grand View Research, Inc. The growth is majorly driven by growing demand for freshwater and favorable regulatory support for water treatment.

High requirement for drinkable water across the world has surged demand for the chemicals that are utilized in cleaning. The environment is seriously endangered by company waste. Due to accelerating urbanization, a rising economy, and expanding industrial activity, freshwater is witnessing high demand.

The U.S. Environmental Protection Agency (EPA) establishes national standards to ensure that consumption by humans is safe while considering the country's available technology and associated costs. The Safe Drinking Water Act and its amendments set up the fundamental framework for safeguarding the solution used by public systems in the U.S. This law specifies the requirements for guaranteeing the security of the nation's municipal drinking supplies. Systems that regularly serve 25 or more people per day or that have at least 15 service connections are considered public drinking sources.

In response to COVID-19, the governments of the affected economies have resorted to lockdowns and social distancing that have impacted the global supply chains. Several manufacturing activities were suspended which in turn, to resulted in the decline in sales of oil & gas and other industrial products. Moreover, due to the supply disruption, the price of raw materials increased significantly which in turn, was followed by an increase in the cost of treatment chemicals.

Gather more insights about the market drivers, restrains and growth of the Industrial Water Treatment Chemicals Market

Industrial Water Treatment Chemicals Market Report Highlights

• Effluent water treatment application is expected to witness the fastest growth rate of 5.1% on account of stringent wastewater disposal limitations imposed by the major international as well as regional regulatory bodies

• Raw treatment is also estimated to witness a notable growth rate. Due to the presence of suspended particles and heavy metals, the demand for pretreated industrial water is anticipated to increase especially in key countries such as the U.S., China, India, the UK, Germany, and Brazil

• During the forecasted years, it is anticipated that the presence of manufacturing facilities in the chemical, pharmaceutical, food & beverage, and automotive sectors in the U.S. and Canada would play a significant role in driving up demand for treatment services, thus triggering demand in the North America region

• Key players in the market are engaged in R&D activities coupled with mergers & acquisitions to gain a higher share of the market. For instance, Ecolab purchased Purolite a purification and separation life science solution provider in October 2021

Industrial Water Treatment Chemicals Market Segmentation

Grand View Research has segmented the global industrial water treatment chemicals market report based on the application and region:

Industrial Water Treatment Chemicals Application Outlook (Revenue, USD Million; Volume, Kilotons; 2018 - 2030)

• Raw Water Treatment

o Deoiling Polyelectrolytes (DOPE)

o Organic Coagulants

o Flocculants

o Filtration Aids

o Dewatering Aids

o Others

• Water Desalination

o Biocides

o Cleaning Agents

o Carbonates

o Sulfates

o Metal Oxides

o Silica

o Chelating Agents incl. NaOH

o Biofilms

o Others

o Antiscalants

o Flocculants

o Defoaming Agents

o Others

• Cooling & Boilers

o Sludge Controllers

o Antifoams

o Antiscalants

o Oxygen Scavengers

o Others

• Effluent Water Treatment

o Deoiling Polyelectrolytes (DOPE)

o Organic Coagulants

o Flocculants

o Filtration Aids

o Dewatering Aids

o Others

• Others

Industrial Water Treatment Chemicals Regional Outlook (Revenue, USD Million; Volume, Kilotons; 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o UK

o France

o Italy

o Spain

o Belgium

o Sweden

o Austria

o Finland

o Poland

o Turkey

• Asia Pacific

o China

o Japan

o South Korea

o India

o Singapore

o Indonesia

o Thailand

o Vietnam

o Australia

o New Zealand

o CIS

o Indonesia

o Rest of Asia Pacific

• Latin America

o Brazil

o Argentina

o Chile

• Middle East & Africa

o South Africa

Order a free sample PDF of the Industrial Water Treatment Chemicals Market Intelligence Study, published by Grand View Research.

#Industrial Water Treatment Chemicals Market#Industrial Water Treatment Chemicals Market Size#Industrial Water Treatment Chemicals Market Share#Industrial Water Treatment Chemicals Market Analysis#Industrial Water Treatment Chemicals Market Growth

0 notes

Text

Industrial Waste Water Treatment Chemicals Market — Forecast(2025–2031)

Industrial Waste Water Treatment Overview

Industrial Waste Water Treatment Chemicals Market size is forecast to reach $8.5 billion by 2025, after growing at a CAGR of 4.58% during 2020–2025.

Request Sample :

Report Coverage

The report: “Industrial Waste Water Treatment Chemicals Market — Forecast (2020–2025)”, by IndustryARC, covers an in-depth analysis of the following segments of the Industrial Waste Water Treatment Chemicals industry.

By Type of Chemicals — Scale Inhibitors, Corrosion Inhibitors, Defoamer, Biocides, Organic Polymers, Oxygen Scavengers, Coagulants, Others.

By Geography — North America, South America, Europe, APAC, RoW.

Key Takeaways

Asia-Pacific dominates the Industrial Waste Water Treatment Chemicals market owing to larger water demand due to larger population.

Increasing water pollution and scarcity of water are major factors driving the waste water treatment services market.

Due to the covid 19 pandemic, the residential usage of water has increased due to which the Industrial waste water treatment chemicals market is growing.

One notable challenge for Industrial waste water treatment chemicals is that, it is considerably costly to set up.

Inquiry Before Buying :

Type of Chemicals — Segment Analysis

Organic Polymers segment holds the largest share in the Industrial Waste Water Treatment Chemicals market. Organic polymers consist of polyacrylamide, polyaluminium chloride among others. Organic polymers are used to purify low quality water either for drinking or industrial purposes. These are used in industrial waste water treatment process to inhibit the growth of harmful organisms and also to kill the existing ones. The efficiency of the industrial waste water treatment chemicals depends on dosage rate and duration of the additive’s presence in water. Industrial waste water treatment facilities are growing at a faster pace due to excess generation of wastewater from industrial sector. The soda ash industry is a part of the chemical industry, which is responsible for the production of sodium carbonate, calcium chloride, absorbent masses, evaporated wet salt, food salt, pickling salt or salt tablets. During manufacturing of those products, strongly alkaline wastewater is generated. Owing to this the Industrial Waste Water Treatment Chemicals market is growing.

Geography — Segment Analysis

APAC has dominated the Industrial Waste Water Treatment Chemicals market with a share of more than xx%, owing to high demand from the end-user industries, such as power, steel, and food & beverage. Countries such as India, China, Japan are the epicentre for the Industrial Waste Water Treatment Chemicals market, as these countries consist of large number of industries. The wastewaters from large-scale industries such as oil refineries, petrochemical plants, chemical plants, and natural gas processing plants commonly contain gross amounts of oil and suspended solids. Those industries use a device known as an API oil-water separator which is designed to separate the oil and suspended solids from their wastewater effluents.

Schedule A Call :

Industrial Waste Water Treatment Chemicals Market Drivers

Implementation of Stringent Government regulations

Implementation of Stringent Governments’ regulations and efforts to reuse water and wastewater treatment in industries, will further aid the market growth of Industrial Waste Water Treatment Chemicals market. The removal of impurities from wastewater, or sewage, before they reach aquifers or natural bodies of water such as rivers, lakes, estuaries, and oceans. Since pure water is not found in nature (i.e., outside chemical laboratories), any distinction between clean water and polluted water depends on the type and concentration of impurities found in the water as well as on its intended use.

Increasing demand for clean water

As demand for water increases across the globe, the availability of fresh water in many regions is likely to decrease because of climate change, as warns by latest edition of the United Nations’ World Water Development Report (WWDR4). It predicts that these pressures will exacerbate economic disparities between certain countries, as well as between sectors or regions within countries. So, the demand for fresh and clean water are increasing due to which the Industrial waste water treatment chemicals market will grow.

Industrial Waste Water Treatment Chemicals Market Challenges

Costly setting up of Equipment.

In manufacturing, setup cost is the cost incurred to get equipment ready to process a different batch of goods. Hence, setup cost is regarded as a batch-level cost in activity-based costing. Setup cost is considered to be a non-value-added cost that should be minimized. One notable hurdle of cooling water treatment chemicals market is that, it is considerably costly to set up. So, small industries are financially not that much strong to setup these equipments. So, they look to escape the installing of these equipments. Whereas Antifoams are chemical agents designed to control the wasteful formation of foam during industrial processes.

Buy Now :

Impact of COVID-19

The rapid spread of coronavirus has had a major impact on global markets as, major economies of the world are completely lockdown due to this pandemic. Because of this major lockdown, suddenly all the consumer market has started to show zero interest towards purchasing equipments regarding the IWTC. One of the major difficulties, market is facing are the shutdown of all kinds of International transportation. Global crisis for all sectors including manufacturing sector have slower down the demand of goods’ production and exports of effect pigments market.

Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the Industrial Waste Water Treatment Chemicals market. In 2019, the market of Industrial Waste Water Treatment Chemicals has been consolidated by the top five players accounting for xx% of the share. Major players in the Industrial Waste Water Treatment Chemicals Market are Akzo Nobel N.V., Angus Chemical Company, BASF SE, BWA Water Additives UK Ltd., Kemira OYJ, The Lubrizol Corporation, Tiarco Chemical, Shandong Taihe Water Treatment Co., Ltd, Kurita Water Industries Ltd, among others.

Acquisitions/Technology Launches

In April 2020, AkzoNobel has completed the acquisition of 100% of the shares of Mauvilac Industries Limited, a leading paints and coatings company in Mauritius.

For more information about Industrial Waste Water Treatment Chemicals Market click here

#WasteWaterTreatment#IndustrialChemicals#WaterManagement#Sustainability#EnvironmentalProtection#CleanWaterSolutions

0 notes

Text

Unlock the Power of Efficiency with Anti-Foaming Agents from Trckem

Foaming can be a significant challenge in industrial processes, often leading to inefficiency, equipment damage, and product quality issues. Trckem offers a range of high-quality anti-foaming agents that are designed to tackle foaming problems effectively. At Trckem, we provide the best anti-foaming agents online in India, ensuring superior performance and affordability for various industries.

What Are Anti-Foaming Agents?

Anti-foaming agents, also known as defoamers, are chemical additives that reduce or eliminate foam formation in liquids during industrial processes. Foam can arise due to the introduction of air or agitation in liquid solutions, causing disruptions in operations. Anti-foaming agents work by breaking down foam and preventing its reoccurrence, ensuring smooth and efficient workflows.

Applications of Anti-Foaming Agents

Trckem’s anti-foaming agents are widely used in multiple industries, including:

Food and Beverage Processing: Helps maintain hygiene and product consistency.

Water Treatment: Prevents foam-related issues in wastewater and industrial water systems.

Chemical Manufacturing: Reduces foam in chemical reactors, improving efficiency.

Paints and Coatings: Ensures smooth application by eliminating foam in formulations.

Pharmaceuticals: Enhances the quality of liquid medicines and ensures accurate processing.

Benefits of Trckem’s Anti-Foaming Agents

Efficient Foam Control: Quickly eliminates foam to enhance productivity.

Versatile Use: Suitable for water-based and oil-based systems.

Cost-Effective: Reduces waste and enhances the lifespan of equipment.

Eco-Friendly Options: We also offer environmentally safe anti-foaming agents.

Why Choose Trckem?

At Trckem, we are committed to delivering premium quality anti-foaming agents tailored to meet your industrial needs. With years of expertise, we ensure our products comply with industry standards and offer unmatched performance. Whether you are in manufacturing, agriculture, or any other sector, our anti-foaming solutions can optimize your processes while minimizing costs.

Order Online at Trckem.in

Shopping for anti-foaming agents has never been easier. Visit Trckem.in to explore our comprehensive range of anti-foaming agents available at the best price in India. We prioritize customer satisfaction with secure payments, reliable delivery, and exceptional support.

Experience seamless operations with Trckem.in top-notch anti-foaming agents. Let us help you take control of foam issues and achieve operational excellence!

0 notes

Text

Silicone Surfactant Market Growth Trends: Share, Size, and Industry Insights by 2031

Straits Research, a leading global market research firm, has released its latest research report on the silicone surfactant market, forecasting a steady growth trajectory in the coming years. The global silicone surfactant market was valued at USD 2.4 billion in 2023 and is expected to expand from USD 2.524 billion in 2024 to USD 4 billion by 2032, growing at a compound annual growth rate (CAGR) of 5.1% during the forecast period (2024–2032).

Market Definition

Silicone surfactants are a class of surfactants that are derived from silicone, a synthetic material that is known for its unique chemical structure and properties. These surfactants are used in various industrial applications to reduce surface tension, improve stability, and enhance the performance of other products. They find wide applications in industries such as personal care, agriculture, construction, paints and coatings, and textiles due to their superior performance in enhancing wetting, foaming, emulsification, defoaming, and dispersing properties.

Get a Full PDF Sample Copy of the Report @ https://straitsresearch.com/report/silicone-surfactant-market/request-sample

Market Dynamics

The silicone surfactant market is experiencing steady growth driven by several trends, market drivers, and emerging opportunities:

Key Trends:

Growing Demand for Sustainable Products: There is an increasing focus on sustainability and the need for environmentally friendly surfactants. Silicone surfactants are considered a greener alternative to conventional surfactants, as they are biodegradable and non-toxic, meeting the growing demand for eco-friendly solutions. This trend is propelling the adoption of silicone surfactants in various industries.

Technological Advancements in Silicone Chemistry: Recent technological advancements in silicone chemistry have led to the development of innovative and high-performance silicone surfactants. These innovations are enhancing the efficiency and effectiveness of silicone surfactants in diverse applications, including personal care, paints, and coatings, driving the market's growth.

Key Market Drivers:

Rising Demand from the Personal Care Industry: Silicone surfactants are increasingly being used in personal care products, such as shampoos, conditioners, and skincare products, due to their ability to enhance product performance. They are prized for their ability to provide superior conditioning, smooth texture, and long-lasting effects, making them a preferred choice for cosmetic manufacturers.

Expanding Agricultural Applications: Silicone surfactants are increasingly utilized in agriculture, particularly in agrochemical formulations, to improve the wetting, spreading, and absorption of pesticides and fertilizers. The growing need for efficient agricultural practices to boost crop yield and reduce environmental impact is driving the demand for silicone surfactants in this sector.

Key Market Opportunities:

Expansion in Emerging Economies: As industries in emerging economies such as India, China, and Brazil continue to grow, there is increasing demand for silicone surfactants across various sectors, including agriculture, construction, and textiles. These regions present significant opportunities for market expansion, with rising industrialization and awareness of product performance.

Increased Adoption in Green Technologies: With the global shift toward sustainability and the adoption of green technologies, silicone surfactants are well-positioned to capitalize on this trend. Their eco-friendly properties make them ideal for use in applications that focus on reducing environmental impact, presenting substantial growth opportunities for manufacturers.

Market Segmentation

The silicone surfactant market is segmented by application, end-use industry, and geography. Below are the key segments:

By Application:

Wetting Agents

Foaming Agents

Emulsifiers

Defoaming Agents

Dispersants

Others

By End-Use Industry:

Agriculture

Paints and Coatings

Construction

Textile

Personal Care

Others

For a detailed breakdown of the market segmentation, visit https://straitsresearch.com/report/silicone-surfactant-market/segmentation

Key Players

The silicone surfactant market features several key players who are dominating the global landscape. These players are focusing on expanding their product portfolios, developing innovative solutions, and capitalizing on emerging market opportunities:

Dow Inc.

Innospec

Momentive

Elkem Silicones

Shin-Etsu Chemical Co.Ltd.

Evonik Industries AG

Andisil

Supreme Silicones

Siltech Corporation

Silibase Silicone New Material Manufacturer Co. Ltd.

Jiangsu Maysta Chemical Co., Ltd.

Elkay Chemicals Pvt. Ltd.

Hangzhou Ruijiang Performance Material Science Co., Ltd.

Harcros Chemicals Inc.

SST Australia Pty Ltd

Dominated Region and Fastest Growing Region

Asia-Pacific dominates the silicone surfactant market, owing to its well-established industrial sectors, including textiles, paints and coatings, and personal care. The region's rapid industrialization, particularly in countries like China, India, and Japan, is a significant factor contributing to the market's dominance. Additionally, the increasing demand for high-performance products in emerging markets fuels growth in the region.

North America is the fastest-growing region in the silicone surfactant market, driven by strong demand from the personal care, paints and coatings, and construction industries. The region’s increasing focus on sustainable solutions and high-performing, eco-friendly chemicals is expected to drive further growth in the silicone surfactant market in North America.

Conclusion

The silicone surfactant market is expected to grow steadily over the next several years, driven by increasing demand for high-performance, sustainable surfactants across a variety of industries, including agriculture, personal care, paints and coatings, and textiles. Technological advancements, along with a rising focus on eco-friendly and innovative solutions, will continue to fuel the market's growth. With Asia-Pacific dominating the market and North America emerging as the fastest-growing region, the global silicone surfactant market is projected to reach USD 4 billion by 2032.

For more information, queries, or to customize the report before purchasing, visit https://straitsresearch.com/buy-now/silicone-surfactant-market

About Us:

StraitsResearch.com is a leading market research and market intelligence organization, specializing in research, analytics, and advisory services along with providing business insights & market research reports.

Contact Us:

Email: [email protected] Tel: +1 646 905 0080 (U.S.), +44 203 695 0070 (U.K.) Website: https://straitsresearch.com/

#Silicone Surfactant Market#Silicone Surfactant Market Share#Silicone Surfactant Market Size#Silicone Surfactant Market Research

0 notes

Text

Defoamer Surfactant Prices: Trend | Pricing | News | Price | Database

The market for defoamer surfactants has been witnessing significant dynamics in recent years, driven by a variety of factors influencing pricing trends and demand-supply equilibrium. Defoamers, essential in various industrial processes to reduce or eliminate foam, play a critical role in enhancing operational efficiency. These surfactants are widely utilized in industries such as paints and coatings, pulp and paper, water treatment, and oil and gas, where foam formation can hinder production processes and impact product quality. Consequently, the demand for defoamer surfactants continues to grow, albeit subject to fluctuations in raw material costs and regional market conditions.

One of the primary drivers of defoamer surfactant prices is the cost of raw materials. These surfactants are often derived from petrochemicals, silicones, or natural oils, whose prices are susceptible to fluctuations in crude oil markets, supply chain disruptions, and geopolitical tensions. For instance, any volatility in crude oil prices tends to cascade through the supply chain, impacting the cost of manufacturing defoamers. Additionally, the rising emphasis on sustainable and bio-based alternatives has led to increased research and development efforts, which, while promoting environmentally friendly products, may result in higher production costs that are subsequently reflected in market prices.

The growing demand for defoamer surfactants across diverse industries also contributes to pricing variations. In the pulp and paper sector, defoamers are indispensable in ensuring smooth paper production processes by minimizing foam-related interruptions. Similarly, in the paints and coatings industry, defoamers enhance the quality of finished products by preventing surface defects caused by trapped air. As these industries expand due to rising urbanization and infrastructural developments, the demand for high-performance defoamers is projected to rise, exerting upward pressure on prices. However, manufacturers are increasingly focused on achieving cost efficiency and developing innovative formulations to cater to industry-specific needs without significantly escalating costs.

Get Real time Prices for Defoamer Surfactant: https://www.chemanalyst.com/Pricing-data/defoamer-surfactant-1240

Regional market dynamics also play a pivotal role in shaping defoamer surfactant prices. For instance, in regions such as Asia-Pacific, where industrialization is rapidly advancing, the demand for defoamers is surging. Countries like China and India are significant contributors to this growth due to their robust manufacturing sectors and large-scale industrial activities. However, intense competition among regional manufacturers often leads to price wars, which can stabilize or even lower prices despite rising demand. Conversely, in developed regions such as North America and Europe, where stringent environmental regulations are prevalent, the focus on eco-friendly and compliant defoamer solutions may lead to higher costs due to the complexities involved in meeting regulatory standards.

Technological advancements and innovation have also influenced the pricing landscape of defoamer surfactants. Manufacturers are investing in the development of advanced defoamer formulations that offer enhanced efficiency, longer-lasting performance, and compatibility with a broader range of applications. These advancements cater to the evolving requirements of end-use industries but may come at a premium price. On the other hand, the adoption of advanced production technologies can improve manufacturing efficiency, thereby partially offsetting cost increases and providing a competitive edge in pricing.

The impact of global economic conditions cannot be overlooked when analyzing defoamer surfactant prices. Economic slowdowns, trade restrictions, and currency fluctuations can affect both demand and supply, leading to price volatility. For instance, during periods of economic downturn, industries may reduce production activities, thereby decreasing the demand for defoamers and putting downward pressure on prices. Conversely, economic recovery and growth spur industrial activities, increasing demand and potentially driving prices upward. Moreover, international trade dynamics and tariffs imposed on raw materials or finished products can directly influence the pricing structure within the global market.

Environmental concerns and regulatory frameworks are increasingly shaping the defoamer surfactant market, influencing not only product development but also pricing strategies. Governments and regulatory bodies worldwide are enforcing stricter environmental standards, prompting manufacturers to develop defoamers with lower volatile organic compound (VOC) content and minimal environmental impact. While these initiatives align with global sustainability goals, they often entail higher research, development, and production costs, which are eventually reflected in market prices. Furthermore, end-users are showing a growing preference for sustainable products, which is driving the demand for bio-based and eco-friendly defoamers despite their relatively higher costs.

The competitive landscape of the defoamer surfactant market also plays a significant role in price determination. Key players in the market are constantly striving to expand their product portfolios, enhance production capacities, and strengthen their distribution networks to capture larger market shares. This competitive environment encourages innovation and efficiency but may also lead to aggressive pricing strategies. Smaller players, on the other hand, often focus on niche markets or regional demands, which can lead to localized price variations.

Market trends indicate a growing emphasis on customization and application-specific defoamer solutions, which has implications for pricing. End-users are increasingly seeking defoamers tailored to their unique process requirements, such as compatibility with specific formulations or compliance with regulatory standards. While this trend enhances product value and user satisfaction, it also adds to production complexity and costs, contributing to price variations across different segments of the market. Furthermore, the rising adoption of digital tools and analytics in industrial processes is enabling manufacturers to optimize defoamer usage, potentially impacting demand patterns and pricing strategies in the long term.

In conclusion, the pricing landscape of defoamer surfactants is influenced by a complex interplay of factors, including raw material costs, regional dynamics, technological advancements, economic conditions, regulatory requirements, and market competition. As industries continue to evolve and prioritize sustainability, the demand for innovative and eco-friendly defoamer solutions is expected to rise, shaping future pricing trends. While challenges such as raw material volatility and regulatory compliance persist, the market remains resilient, driven by the essential role of defoamers in various industrial processes. Stakeholders in the defoamer surfactant market must navigate these dynamics strategically to capitalize on growth opportunities while addressing the evolving needs of end-use industries.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Defoamer Surfactant#Defoamer Surfactant Price#Defoamer Surfactant Prices#Defoamer Surfactant Pricing#Defoamer Surfactant News#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research

0 notes

Text

Industrial Waste Water Treatment Chemicals Market — Forecast(2024–2030)

Overview

With rise in the growing consumption for industrial waste water treatment chemicals is increasing due to increase in population, rapid urbanization and fresh water shortage, due to this the Industrial Waste Water Treatment Chemicals market is expected to grow in the forecast period. Growing governments implementation towards industrial waste water treatment will further enhance the overall market demand for Industrial Waste Water Treatment Chemicals during the forecast period.

Report Coverage

The report: “Industrial Waste Water Treatment Chemicals Market — Forecast (2020–2025)”, by IndustryARC, covers an in-depth analysis of the following segments of the Industrial Waste Water Treatment Chemicals industry.

By Type of Chemicals — Scale Inhibitors, Corrosion Inhibitors, Defoamer, Biocides, Organic Polymers, Oxygen Scavengers, Coagulants, Others.

By Geography — North America, South America, Europe, APAC, RoW.

Key Takeaways

Asia-Pacific dominates the Industrial Waste Water Treatment Chemicals market owing to larger water demand due to larger population.

Increasing water pollution and scarcity of water are major factors driving the waste water treatment services market.

Due to the covid 19 pandemic, the residential usage of water has increased due to which the Industrial waste water treatment chemicals market is growing.

One notable challenge for Industrial waste water treatment chemicals is that, it is considerably costly to set up.

Request Sample

Type of Chemicals — Segment Analysis

Organic Polymers segment holds the largest share in the Industrial Waste Water Treatment Chemicals market. Organic polymers consist of polyacrylamide, polyaluminium chloride among others. Organic polymers are used to purify low quality water either for drinking or industrial purposes. These are used in industrial waste water treatment process to inhibit the growth of harmful organisms and also to kill the existing ones. The efficiency of the industrial waste water treatment chemicals depends on dosage rate and duration of the additive’s presence in water. Industrial waste water treatment facilities are growing at a faster pace due to excess generation of wastewater from industrial sector. The soda ash industry is a part of the chemical industry, which is responsible for the production of sodium carbonate, calcium chloride, absorbent masses, evaporated wet salt, food salt, pickling salt or salt tablets. During manufacturing of those products, strongly alkaline wastewater is generated. Owing to this the Industrial Waste Water Treatment Chemicals market is growing.

Geography — Segment Analysis

APAC has dominated the Industrial Waste Water Treatment Chemicals market with a share of more than xx%, owing to high demand from the end-user industries, such as power, steel, and food & beverage. Countries such as India, China, Japan are the epicentre for the Industrial Waste Water Treatment Chemicals market, as these countries consist of large number of industries. The wastewaters from large-scale industries such as oil refineries, petrochemical plants, chemical plants, and natural gas processing plants commonly contain gross amounts of oil and suspended solids. Those industries use a device known as an API oil-water separator which is designed to separate the oil and suspended solids from their wastewater effluents.

Industrial Waste Water Treatment Chemicals Market Drivers

Implementation of Stringent Government regulations

Implementation of Stringent Governments’ regulations and efforts to reuse water and wastewater treatment in industries, will further aid the market growth of Industrial Waste Water Treatment Chemicals market. The removal of impurities from wastewater, or sewage, before they reach aquifers or natural bodies of water such as rivers, lakes, estuaries, and oceans. Since pure water is not found in nature (i.e., outside chemical laboratories), any distinction between clean water and polluted water depends on the type and concentration of impurities found in the water as well as on its intended use.

Increasing demand for clean water

As demand for water increases across the globe, the availability of fresh water in many regions is likely to decrease because of climate change, as warns by latest edition of the United Nations’ World Water Development Report (WWDR4). It predicts that these pressures will exacerbate economic disparities between certain countries, as well as between sectors or regions within countries. So, the demand for fresh and clean water are increasing due to which the Industrial waste water treatment chemicals market will grow.

Industrial Waste Water Treatment Chemicals Market Challenges

Costly setting up of Equipment.

In manufacturing, setup cost is the cost incurred to get equipment ready to process a different batch of goods. Hence, setup cost is regarded as a batch-level cost in activity-based costing. Setup cost is considered to be a non-value-added cost that should be minimized. One notable hurdle of cooling water treatment chemicals market is that, it is considerably costly to set up. So, small industries are financially not that much strong to setup these equipments. So, they look to escape the installing of these equipments. Whereas Antifoams are chemical agents designed to control the wasteful formation of foam during industrial processes.

Inquiry Before Buying

Impact of COVID-19

The rapid spread of coronavirus has had a major impact on global markets as, major economies of the world are completely lockdown due to this pandemic. Because of this major lockdown, suddenly all the consumer market has started to show zero interest towards purchasing equipments regarding the IWTC. One of the major difficulties, market is facing are the shutdown of all kinds of International transportation. Global crisis for all sectors including manufacturing sector have slower down the demand of goods’ production and exports of effect pigments market.

Buy Now

Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the Industrial Waste Water Treatment Chemicals market. In 2019, the market of Industrial Waste Water Treatment Chemicals has been consolidated by the top five players accounting for xx% of the share. Major players in the Industrial Waste Water Treatment Chemicals Market are Akzo Nobel N.V., Angus Chemical Company, BASF SE, BWA Water Additives UK Ltd., Kemira OYJ, The Lubrizol Corporation, Tiarco Chemical, Shandong Taihe Water Treatment Co., Ltd, Kurita Water Industries Ltd, among others.

0 notes

Text

We introduce ourselves as a manufacturer of Silicone based Products like Silicone Greases/Compound (SI/G-100 & SI/G/-200), Silicone Oil/Fluid, Silicone Heat sink Compound, Silicone Emulsion / Silicone Coolant Oil, Silicone Solution, Silicone DIE Coat, Defoamer Toluene, Silicone Rubber & other related Products, we are Vendors to many OEM companies.

1 note

·

View note

Text

Foaming Mastery Unleashed - Premier Water Foamer and Defoamer Manufacturer in Vadodara, Gujarat, and India

Imperialchem takes pride in being your trusted Water Foamer Producer in Vadodara and a leading Foamer Manufacturer in India. Elevate your processes with our high-quality Water Foamers and Defoamers, manufactured with precision and innovation. Choose Imperialchem for excellence in water foam control, setting the standard as the Water Foamer Manufacturer in Vadodara, Gujarat, and across India. Trust us to redefine your foaming needs with expertise that transcends expectations.

#Water Foamer Producer in Vadodara#Foamer Manufacturer in India#Water Foamer Manufacturer in Vadodara#Water Foamer Manufacturer in Gujarat#Defoamer Manufacturer in India#Chemicals#India#oil and gas industries

6 notes

·

View notes

Text

Angel Chem India: Taming the Foam Monsters in Your Industry

Foaming – it can be a beautiful spectacle in a latte, but a nightmarish enemy in countless industrial processes and Defoamer Chemicals Manufacturers. Enter Angel Chem India, the company armed with a chemical arsenal to conquer those pesky bubbles and ensure smooth operations across diverse industries.

From Water Treatment to Food Processing, Angel Chem Has a Defoamer for You:

Angel Chem India’s defoamer portfolio is as diverse as the industries they cater to. Whether you’re battling foam in your paint production, struggling with frothing in your pharmaceutical fermentation tanks, or facing bubbling woes in your wastewater treatment plant, Angel Chem has the defoamer solution. Here’s a glimpse into their arsenal:

Silicone Defoamers: Reliable workhorses, these defoamers excel in a wide range of applications, from paint and coatings to textiles and paper production. Their long-lasting effectiveness and heat resistance make them ideal for high-temperature processes and Defoamer Chemicals.

Polyethylene Glycol Defoamers: Gentler on the environment, these water-soluble defoamers are perfect for food processing and pharmaceutical applications. They break down foam effectively without leaving any residue, ensuring product safety and quality.

Antifoaming Agents: For those facing persistent foaming challenges, Angel Chem offers specialized antifoaming agents. These potent formulations prevent air bubbles from forming in the first place, offering a proactive approach to foam control.

Innovation Underpins Performance:

Angel Chem India doesn't believe in resting on its laurels. Their Research & Development team is constantly churning out new and improved defoamers, tailored to meet the evolving needs of their clients. Here are some of their innovative approaches:

Customizing for Specific Needs: No two foaming problems are identical. Angel Chem technical experts work closely with clients to understand their unique challenges and formulate customized defoamers for optimal performance.

Developing Eco-Friendly Solutions: Sustainability is at the forefront of Angel Chem agenda. They prioritize the development of biodegradable and non-toxic defoamers, minimizing their environmental impact while ensuring excellent functionality.

Investing in Cutting-Edge Technology: Angel Chem utilizes state-of-the-art manufacturing facilities and stringent quality control processes. This commitment to quality translates to consistent, reliable defoamers that clients can trust.

Beyond the Lab: Building Trust and Partnerships:

For Angel Chem India, defoamers are just the beginning. They believe in building strong relationships with their clients, offering comprehensive support and expertise alongside their products. Here’s how they go the extra mile:

Technical Assistance: Angel Chem’s team of specialists provides invaluable technical guidance, helping clients identify the right defoamer for their application and optimize its use for maximum effectiveness.

On-Site Support: For complex foaming challenges, Angel Chem offers customized on-site assistance. Their experts work directly with clients to analyze the problem and implement the most effective defoaming solution.

Continuous Improvement: Angel Chem actively fosters a culture of learning and feedback. They regularly engage with clients to understand their experiences and incorporate their insights into product development and service improvement.

Partnering for Foam-Free Success:

Choosing Angel Chem India is not just choosing a defoamer; it’s choosing a partner in ensuring efficient and hassle-free operations. Their diverse defoamer portfolio, commitment to innovation, and unwavering focus on customer satisfaction make them the ideal choice for companies across industries. So, next time foam threatens to disrupt your workflow, remember Angel Chem India – the foam tamers who can help you achieve smoother, more profitable operations.

0 notes

Text

Wood Coating Additives Market-Industry Forecast, 2024–2030

Wood Coating Additives Market Overview

Request Sample Report :

COVID-19 Impact

Various countries have declared a complete national lockdown as a result of the corona virus 2019 (COVID-19) outbreak. These decisions have restricted the movement of people and resulted in a complete shutdown of many businesses across many sectors. The construction industry, as a significant growth driver of the economy with no exception, has also been completely shut down. All the developments and projects were postponed until further notice. For instance, the construction output in Great Britain fell by a record 35.0% in Quarter 2 (Apr to June) 2020 compared with Quarter 1 (Jan to Mar) 2020. This value decline was due to the Corona Virus pandemic. With the decrease in building and construction operation, the demand for furniture has significantly fallen, which is having a major impact on the wood coating additives market.

Report Coverage

The report: “Wood Coating Additives Market — Forecast (2021–2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the wood coating additives Industry.

By Formulation: Water Based System, Solvent Based System, Radiation Cured System, and Others.

By Type: Dispersing Agents, Rheology Modifiers, Defoamers, Micronized Waxes, Emulsions, Wetting & Leveling Agents, Surface Modifiers, and Others.

By End-Use Industry: Food Industry (Trays, Pallets, and Others), Building and Infrastructure (Residential, Commercial, and Industrial), Furniture (Outdoor, and Indoor), and Others.

By Geography: North America (U.S., Canada, and Mexico), Europe (U.K, Germany, France, Italy, Netherland, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa).

Inquiry Before Buying:

Key Takeaways:

Asia-Pacific dominates the wood coating additives market, owing to the increasing building & infrastructure activities in the APAC due to various government initiatives such as “100 smart cities” and “Housing for all by 2022”.

The primary purpose of using coating additives in wood is to manufacture superior quality wood surfaces. Additives are often used in wood coatings for a variety of purposes such as better stabilization, hygiene, and decoration of wood.

The coating additives also add some extensive properties to the wooden material such as moisture-resistant, anti-bacterial solution, improved hardness, better appearance, and more. These enhanced properties of wood coating additives are projected to increase the market growth.

However, high regulation on coatings due to its high emission of volatile organic compounds and awareness on damage for deforestation is projected to hinder the growth of wood coatings, which indirectly affects the demand for wood coating additives.

Due to the Covid-19 pandemic, most of the countries have gone under lockdown, due to which various building and construction operations are disruptively stopped, which is hampering the wood coating additives market growth.

For More Details on This Report — Request for Sample

Wood Coating Additives Market Segment Analysis — By Formulation

The solvent based system segment held the largest share in the wood coating additives market in 2020 and is growing at a CAGR of 6% during 2021–2026. A solvent based wood coating additives system offers a liquid protective layer that is primarily composed of organic compounds and applied to a material’s surface to prevent corrosion. They are typically more resilient than water based wood coating additives system coatings during the curing time. These coatings have one major advantage over water based wood coating additives systems i.e. they are less susceptible to environmental conditions such as temperature and humidity during the curing phase. Humidity can prevent the water in a water-based system from evaporating, making them impractical in some climates. Thus, solvent based wood coating additives systems are preferred for applications in humid environments. All these superior properties of the solvent based system are the key factor anticipated to boost the demand for wood coating additives during the forecast period.

Wood Coating Additives Market Segment Analysis — By Type

The Rheology modifier segment held a significant share in the wood coating additives market in 2020. For the optimal application of coatings on wood, it is necessary to adjust the rheology profile of the coating with the help of rheology modifiers. This can be managed by using associative thickeners based on polyurethanes. Polyurethane thickeners can be used solely or in combination with each other as well as with other types of thickeners (e.g. polyacrylates or cellulose ethers). In addition, rheology modifiers enable formulators to adjust the flow behavior of coatings, owing to which the wood coatings benefit from improved viscosity. Furthermore, it reduces dripping and a spattering of paint during roller or brush application, which is the major driving factor for the Rheology modifier additives during the forecast period.

Schedule A Call:

Wood Coating Additives Market Segment Analysis — By End-Use Industry

The furniture segment held the largest share in the wood coating additives market in 2020 and is growing at a CAGR of 5% during 2021–2026, owing to the increasing usage of wood in the manufacturing of the furniture industry. This exceptionally versatile material is commonly used as a building material as it is a natural resource, which makes it readily available and economically feasible. It is remarkably strong in relation to its weight, provides good insulation from the cold, and can be fabricated into all kinds of shapes and sizes to fit practically any construction need. Pinewood and whatman filter paper are common substrates used in furniture fungal resistance. Also, wood is an environmentally sustainable product, biodegradable, renewable, and carries the lowest carbon footprint of any comparable building material. In addition, no high-energy fossil fuels are required to produce wood, unlike other common building materials such as brick, steel, or plastic owing to which wood is widely used in the manufacturing of furniture. And wood furniture requires preservation for which coating additives are extensively used over wood, which is the major factor driving the demand for wood coating additives in the furniture industry during the forecast period.

Wood Coating Additives Market Segment Analysis — By Geography

Asia-Pacific region held the largest share in the wood coating additives market in 2020 up to 36%, owing to the increasing demand for furniture in the region. The key factors driving the increase in demand for furniture are the growth of housing and commercial construction and also the increase in income levels that influence customers to adopt global lifestyle options, especially in urban affluent Indians. According to the Trade Promotion Council of India (TPCI), the Indian domestic furniture market is expected to expand at a CAGR of 12.91% from 2020 through 2024. It has been observed that for 2018 and from 2014–18, India’s furniture exports surged at CAGRs of 15% & 8.8% respectively, which is way higher than the world average. According to the United States Department of Agriculture (USDA), China remains the largest wood-based panel producer in the world, accounting for roughly half of global production. Production in 2019 was approximately 325 million meter cube, nine percent higher than in 2018 (299 million meter cube), driven by strong demand from decoration facilities. Thus, with an upsurge in the demand for furniture, the demand for wood coating additives will also subsequently increase to preserve the wooden furniture, which is anticipated to eventually drive the wood coating additives market in the APAC region during the forecast period.

Wood Coating Additives Market Drivers

Flourishing Food Industry

Products derived from wood are widely used in the packaging of food in the form of paper and cardboard. Paper is a very cheap, lightweight product with excellent printing capacity. Although it is very sensitive to moisture, it can be corrected with a combination of paper and other materials such as plastic or paraffin. The wooden packaging is specially designed for cooking or reheating in traditional ovens or microwave ovens. According to the International Trade Administration (ITA), there was an increase of 4.7% in food production in Russia. According to the United States Department of Agriculture (USDA), in 2018, the total value of all retail food and beverage sales in Japan was $479.29 billion (¥53,339 billion), an overall increase of 2.3 percent. According to the United States Department of Agriculture (USDA), China’s food processing industry continued to grow in 2017. Revenue climbed to $1.47 trillion, an increase of 6.3 percent compared with the previous year. The rising disposable income has resulted in the increasing demand for the food industry in various regions, which is further driving the growth of the food packaging industry market. And since additives improve or maintain the food’s nutritive value, make food last longer, make food stay fresh for much longer owing to which the demand for coating additives in wood-based food packaging is increasing. Thus, the expanding food industry acts as a driver for the liquid nitrogen market.

Buy Now :

Increasing Government Initiative Bolstering the Growth of building and infrastructure Industry In Various Regions

The building and construction industry is flourishing in countries such as India, and Singapore as governments are spending heavily on expanding the building and construction industry. The A government-wide program for a Circular Economy, aimed at developing a circular economy in the Netherlands by 2050 is boosting the construction sector in the country. The infrastructure sector has become the biggest focus area for the Government of India. India plans to spend US$ 1.4 trillion on infrastructure during 2019–23 to have a sustainable development of the country. The Government has suggested investment of Rs. 5,000,000 crore (US$ 750 billion) for railways infrastructure from 2018–30. And wood-based products such as furniture are often used in the construction industry. And these wood products to be durable and resistant require coating additives. Hence, with the increase in construction activities across the globe, the demand for wood coating additives will be foreseen to grow enormously. Thus, such government investments and initiatives in the construction industry act as a driver for the market.

Wood Coating Additives Market Segment Analysis Challenges

Presence of Other Substitute Materials

Most wood coatings are done either in a short-term artificial weathering chamber or long-term on an outdoor rack/fence. In both cases, the coatings are exposed to both ultraviolet radiation and water. As moisture is absorbed into the wood structure, the wood swells in proportion to the volume of water absorbed. As moisture is lost, the wood shrinks in proportion to the volume of the water lost. Thus, moisture in the wood end grain is responsible for coating failures. Also, the wood material may be too hard or rough for products like soft fruits, and therefore liners of soft material may be needed, which further increases the expenses owing to which polymeric materials are gaining popularity. Moreover, the continuous manufacturing of wooden-based products such as furniture, crates, pallets, containers, and more have put an extra claim on the natural forest resources, leading to deforestation. All these disadvantages of wood-based products are unlatching doors for other immediate substitute materials such as metal, polymer, composites, and more. Thus, the demand for wood may see a downfall, which may hinder the wood coating additives market growth during the forecast period.

Wood Coating Additives Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the wood coating additives market.

The Top 5 companies in the are: Wood coating additives market

BYK Additives & Instruments

Arkema S.A.

Sherwin-Williams Company

Akzo Nobel N.V.

PPG Industries, Inc.

Acquisitions/Technology Launches

In November 2019, AkzoNobel invested $55 million to transform its wood coatings facility in High Point, North Carolina, and further strengthen the company’s market position in North America.

In October 2019, BASF introduced a new silicone wetting agent-“Hydropalat® WE 3225”, which combines excellent substrate wetting with pronounced defoaming performance. It is designed for use in high-end water-based industrial and automotive coatings and especially wood coatings that require excellent wood grain accentuation.

In October 2019, BASF launched a new high molecular weight dispersing agent-“Dispex® Ultra PX 4290”. Dispex® Ultra PX 4290 in response to surging market demand for a dispersing agent, which enables broad applicability in both inorganic and organic pigments and fillers used in water-based automotive OEM and refinishes coatings, industrial coatings, and wood coatings.

For more Chemicals and Materials Market reports — Please click here

#WoodCoatings#WoodFinish#CoatingAdditives#WoodProtection#WoodCare#SurfaceFinishing#EcoFriendlyCoatings

0 notes

Text

Understanding Anti-Foaming Solutions: Benefits and Applications Across Industries

Foam formation is a common issue in various industrial processes, leading to inefficiencies, equipment malfunction, and reduced product quality. To tackle this problem, anti-foaming agents (also known as defoamers) are widely used across industries such as food processing, water treatment, oil and gas, and pharmaceuticals. Trckem offers high-performance anti foaming solutions online at competitive prices in India, ensuring that your industrial operations run smoothly without the disruption caused by unwanted foam. In this blog, we’ll explore the benefits of anti-foaming agents and their wide-ranging applications.

What Are Anti-Foaming Agents?

Anti-foaming agents are chemical additives that prevent or reduce foam formation in liquids. They work by breaking the surface tension of foam bubbles, causing them to collapse quickly. Foam can result from various factors such as agitation, aeration, and chemical reactions in liquids. Anti-foaming agents help maintain process efficiency by controlling foam levels in industrial systems.

Key Benefits of Anti-Foaming Solutions

Increased Operational Efficiency: Excessive foam can disrupt industrial processes, clog equipment, and slow down production. By using anti-foaming agents, you can maintain smooth operations, improving overall productivity.

Cost Savings: Foam can cause machinery damage and production delays, leading to higher maintenance costs and lost revenue. Anti-foaming solutions minimize these risks, reducing downtime and preventing unnecessary expenses.

Improved Product Quality: In industries such as food and beverage or pharmaceuticals, foam can negatively impact the quality of the end product. Anti-foaming agents help ensure the consistency and quality of the products by controlling foam formation during processing.

Versatility: Anti-foaming agents are suitable for a wide range of applications, including water treatment, chemical processing, paper and pulp manufacturing, and more. Their ability to adapt to different industries makes them a valuable asset for operational excellence.

Applications of Anti-Foaming Agents Across Industries

Water Treatment: Foam can interfere with filtration and aeration processes in wastewater treatment plants. Anti-foaming agents help improve efficiency and maintain water quality by controlling foam formation.

Food and Beverage: In food production, unwanted foam can affect both processing and packaging. Anti-foaming solutions are used to maintain product consistency without affecting taste or safety.

Oil and Gas: In oil drilling and refining operations, foam can reduce the efficiency of separation processes. Anti-foaming agents help enhance the performance of oil and gas systems, ensuring a smoother workflow.

Chemical Processing: Foam in chemical reactions can lead to contamination and

0 notes

Text

youtube

Know the Reasons Why Defoamer Chemical is Important | NAQ Global

NAQ Global is a multinational organization that provides specialized products and specialist technical services for fertilizer quality improvement. We are one of the best defoamer chemical suppliers and Filter aid powder manufacturers in Jaipur, India.

1 note

·

View note

Text

Agriculture Adjuvants Market Size and Share Analysis by Type, Application, Segmentation, Innovations, Solution and Services by 2032

Sales in the global agricultural adjuvants market are expected to grow at a steady 6.2% CAGR over the forecast period, reaching US$ 6.2 Bn by 2032.

Increasing industrialization and colonization across the globe is reducing cultivable land. To fulfil the rising demand for food, farmers are seeking effective ways to increase crop yield, which, in turn, is spurring demand for agricultural adjuvants.

Adjuvants are added to pesticides to improve spray retention and droplet drying. The reaction between herbicide adjuvants and herbicide activity depends on various factors like leaf surface, adjuvant type, herbicide chemical form and external weather conditions. Key players in the market are launching new variants by developing formulations to improve their efficacy to limit herbicide leaching in groundwater.

To remain ‘ahead’ of your competitors, request for @ https://www.futuremarketinsights.com/reports/sample/rep-gb-14281

Some types of agricultural adjuvants available in the market are surfactants, oils, compatibility agents, buffering and conditioning agents, defoaming agents, deposition agents, and drift control agents.

The availability of different types of adjuvants is expected to propel the demand for function-specific adjuvants in the market. Further, as adjuvants do not have any pesticide properties, their usage is not governed by the US Environmental Protection Agency regulations. This is expected to widen the scope of applications of agricultural adjuvants.

Further, rapid adoption of advanced technologies in agricultural industry such as precision farming is expected to boost the demand for agricultural adjuvants. As per FMI, North America is expected to emerge as the most lucrative market, followed by Europe and Asia Pacific.

“Rising awareness regarding wastage of pesticides and their negative environmental impact is spurring demand in the market. In addition to this, wide availability of target-based adjuvants will continue propelling sales over the assessment period,” says the FMI analyst.

Key Takeaways:

Based on the crop type, sales in the cereals segment are projected to increase at a 5.6% CAGR though 2032.

In terms of application, demand for herbicides adjuvants will gain traction at a considerable pace.

The U.S. will emerge as a lucrative market, accounting for 24% of the total market share over the forecast period.

Sales in the U.K. will account for a dominant share in the Europe agricultural adjuvants market through 2032.

Demand in the India agricultural adjuvants market will account for 18% of the total market share.

Competitive Landscape

Key manufacturers operating in the agricultural adjuvants are focusing on research & development to offer different effective formulations. Besides this, players are collaborating and investing in mergers and acquisitions to gain a competitive edge in the market. For instance:

BREAK-THRU® SD 260. is the first solid, water-soluble trisiloxane on the market is which is ideal for solid pesticide formulations (WP/WDG). It is used in biopesticide WP formulations, to simplify the manufacturing of solid pesticide formulations, makes trisiloxane available for solid pesticide and solid microbiological formulations, which can be used as a tank mix adjuvant.

Explore More Valuable Insights

Future Market Insights, in its new report, offers an impartial analysis of the global reduced fat butter market, presenting historical data (2017-2021) and estimation statistics for the forecast period of 2022-2032.

View Full Report@ https://www.futuremarketinsights.com/reports/agriculture-adjuvants-market

Agricultural Adjuvant Market by Category

By Product Type:

Activator Adjuvants

Oil Adjuvants

Surfactants

Utility Adjuvants

By Application:

Fungicide Adjuvants

Insecticide Adjuvants

Herbicide Adjuvants

Others

By Crop Type:

Cereals

Oilseeds

Fruits & Vegetables

Other Crops

By Region:

North America

Latin America

Europe

East Asia

South Asia

Oceania

MEA

About FMI Future Market Insights (ESOMAR certified market research organization and a member of Greater New York Chamber of Commerce) provides in-depth insights into governing factors elevating the demand in the market. It discloses opportunities that will favor the market growth in various segments on the basis of Source, Application, Sales Channel and End Use over the next 10-years.

0 notes

Text

Top Benefits of a Custom Oil Field Chemical Manufacturing in India

The benefits of a single source are provided to clients by specialized oilfield chemical manufacturing. A single site makes managing raw materials and completed goods simpler, lowering freight expenses and supplying more room for client activities. Custom oilfield chemical manufacturers complete the entire operating equation, which also provides packaging and logistics. Oil drilling has been a leader in manufacturing chemicals in various sectors. The manufacturers have a stellar track record in the natural gas and oil industries thanks to their Texas manufacturing facilities, rising to the challenges posed by harsh environments and rapidly evolving drilling equipment. Below you can see the benefits of custom oil field chemical manufacturing:

Cost

Oilfield companies look for a way to create new blends that are both affordable and effective. A new production line's construction and special equipment purchases can quickly add to a sizable expense. A return on investment can also take time to achieve. A leading industrial chemical supplier company is a contract chemical manufacturing company that can provide turnkey solutions for many oilfield chemicals while guaranteeing that every product is up to specifications.

Purchasing power and warehousing

For various industries, many sizable chemical producers produce a wide range of chemicals. Leading Oil Field Chemicals Manufacturers India focuses on the oil and natural gas industries. They are able to focus their purchasing power in these sectors, in addition to deepening their expertise in industries like the CASE market, construction, and the oilfield. Naturally, their ability to reduce the cost of acquiring raw materials translates into a better value proposition for their clients.

Additionally, businesses can store raw materials and finished goods before blending or shipping when they work with custom oilfield chemical manufacturers offering turnkey solutions. Since space is freed up for the customer company's more extensive operations, this benefit lowers freight costs overall.

Absolutely true

Optimized logistics and packing complete the turnkey operations equation. A top industrial chemical supply company can provide a competitive advantage in procurement streamlining and better logistics optimization by focusing on the unique needs of the oil and gas industry.

No matter how big the need, the company can accommodate it for bespoke packaging or labeling. The top businesses have an extensive global logistics network, which increases the return on investment for their clients. Through their connections with international carriers, they can offer their clients savings.

Control of risk

Risk control is crucial for suppliers and customers in the oil and gas industry. A company that provides custom oilfield chemical manufacturing services should adhere to a safety management program. It emphasizes developing site-specific elements like process safety information and hazard analysis, operating procedures, and applicator competency evaluation. It should also have a safety audit program to ensure that each requirement is met. Safety audits are conducted at the site to ensure that all safety-related procedures are followed. Fluid Loss Agents are relevant for drilling and completion fluids, fracturing fluids, and cement slurries.

Final thoughts

Thus those mentioned above are about the benefits of custom oil field chemical manufacturing. It will be the most affordable option and serve as a risk management tool if you require customized oil field manufacturing.

#Drilling fluids manufacturers#Oil field chemicals manufacturers india#Polymer and co -polymer#medium cloud point Glycol#Surfactant - Ionic & Non Ionic#Defoamer - Silicon Based & Alcohol Based

1 note

·

View note