#Industrial Water Treatment Chemicals Market Growth

Explore tagged Tumblr posts

Text

A Deep Dive into the Industrial Water Treatment Chemicals Market: Insights and Analysis

The global industrial water treatment chemicals market size is expected to reach USD 21.23 billion by 2030, registering a CAGR of 4.9% during the forecast period, according to Grand View Research, Inc. The growth is majorly driven by growing demand for freshwater and favorable regulatory support for water treatment.

High requirement for drinkable water across the world has surged demand for the chemicals that are utilized in cleaning. The environment is seriously endangered by company waste. Due to accelerating urbanization, a rising economy, and expanding industrial activity, freshwater is witnessing high demand.

The U.S. Environmental Protection Agency (EPA) establishes national standards to ensure that consumption by humans is safe while considering the country's available technology and associated costs. The Safe Drinking Water Act and its amendments set up the fundamental framework for safeguarding the solution used by public systems in the U.S. This law specifies the requirements for guaranteeing the security of the nation's municipal drinking supplies. Systems that regularly serve 25 or more people per day or that have at least 15 service connections are considered public drinking sources.

In response to COVID-19, the governments of the affected economies have resorted to lockdowns and social distancing that have impacted the global supply chains. Several manufacturing activities were suspended which in turn, to resulted in the decline in sales of oil & gas and other industrial products. Moreover, due to the supply disruption, the price of raw materials increased significantly which in turn, was followed by an increase in the cost of treatment chemicals.

Gather more insights about the market drivers, restrains and growth of the Industrial Water Treatment Chemicals Market

Industrial Water Treatment Chemicals Market Report Highlights

• Effluent water treatment application is expected to witness the fastest growth rate of 5.1% on account of stringent wastewater disposal limitations imposed by the major international as well as regional regulatory bodies

• Raw treatment is also estimated to witness a notable growth rate. Due to the presence of suspended particles and heavy metals, the demand for pretreated industrial water is anticipated to increase especially in key countries such as the U.S., China, India, the UK, Germany, and Brazil

• During the forecasted years, it is anticipated that the presence of manufacturing facilities in the chemical, pharmaceutical, food & beverage, and automotive sectors in the U.S. and Canada would play a significant role in driving up demand for treatment services, thus triggering demand in the North America region

• Key players in the market are engaged in R&D activities coupled with mergers & acquisitions to gain a higher share of the market. For instance, Ecolab purchased Purolite a purification and separation life science solution provider in October 2021

Industrial Water Treatment Chemicals Market Segmentation

Grand View Research has segmented the global industrial water treatment chemicals market report based on the application and region:

Industrial Water Treatment Chemicals Application Outlook (Revenue, USD Million; Volume, Kilotons; 2018 - 2030)

• Raw Water Treatment

o Deoiling Polyelectrolytes (DOPE)

o Organic Coagulants

o Flocculants

o Filtration Aids

o Dewatering Aids

o Others

• Water Desalination

o Biocides

o Cleaning Agents

o Carbonates

o Sulfates

o Metal Oxides

o Silica

o Chelating Agents incl. NaOH

o Biofilms

o Others

o Antiscalants

o Flocculants

o Defoaming Agents

o Others

• Cooling & Boilers

o Sludge Controllers

o Antifoams

o Antiscalants

o Oxygen Scavengers

o Others

• Effluent Water Treatment

o Deoiling Polyelectrolytes (DOPE)

o Organic Coagulants

o Flocculants

o Filtration Aids

o Dewatering Aids

o Others

• Others

Industrial Water Treatment Chemicals Regional Outlook (Revenue, USD Million; Volume, Kilotons; 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o UK

o France

o Italy

o Spain

o Belgium

o Sweden

o Austria

o Finland

o Poland

o Turkey

• Asia Pacific

o China

o Japan

o South Korea

o India

o Singapore

o Indonesia

o Thailand

o Vietnam

o Australia

o New Zealand

o CIS

o Indonesia

o Rest of Asia Pacific

• Latin America

o Brazil

o Argentina

o Chile

• Middle East & Africa

o South Africa

Order a free sample PDF of the Industrial Water Treatment Chemicals Market Intelligence Study, published by Grand View Research.

#Industrial Water Treatment Chemicals Market#Industrial Water Treatment Chemicals Market Size#Industrial Water Treatment Chemicals Market Share#Industrial Water Treatment Chemicals Market Analysis#Industrial Water Treatment Chemicals Market Growth

0 notes

Text

Industrial Water Treatment Chemicals Market Growth, Drivers, and Key Insights

The global industrial water treatment chemicals market is witnessing significant growth as industries across the globe emphasize water conservation, regulatory compliance, and environmental sustainability. According to SkyQuest Technology, the market is anticipated to reach USD 21.23 billion by 2031, growing at a CAGR of 4.9% from 2024 to 2031. The rising demand for clean and treated water in industrial processes is driving the adoption of advanced water treatment solutions worldwide.

Market Drivers: What’s Powering the Growth?

Several factors are contributing to the growth of the industrial water treatment chemicals market:

Stringent Environmental Regulations Governments worldwide are enforcing strict regulations to limit industrial discharge of untreated wastewater, increasing the adoption of water treatment chemicals to comply with these laws.

Increasing Industrialization Rapid industrial growth, especially in developing economies, has intensified the need for effective water treatment to ensure efficient processes and reduce operational costs.

Rising Water Scarcity Growing concerns about freshwater scarcity are encouraging industries to recycle and reuse water through advanced treatment processes, boosting the demand for chemicals such as flocculants and coagulants.

Focus on Sustainable Practices Companies are increasingly adopting eco-friendly and biodegradable treatment chemicals to align with global sustainability goals.

Request a Sample Report - https://www.skyquestt.com/sample-request/industrial-water-treatment-chemicals-market

Key Market Segments: Breaking Down the Industry

The industrial water treatment chemicals market is categorized based on product type, end-use industry, and region:

1. By Product Type

Coagulants and Flocculants: Widely used in primary water treatment for removing solids and impurities.

Corrosion and Scale Inhibitors: Essential for maintaining pipeline integrity and preventing scaling in industrial equipment.

Biocides and Disinfectants: Used for controlling microbial growth in water systems.

pH Adjusters and Stabilizers: Maintain optimal pH levels for efficient treatment processes.

Others: Include anti-foaming agents, chelating agents, and oxidants.

2. By End-Use Industry

Power Generation: High water usage in cooling towers and boilers drives significant demand.

Oil & Gas: Treatment chemicals are used for water injection and refining processes.

Chemicals and Petrochemicals: Require large volumes of treated water for manufacturing.

Food & Beverage: Ensures water used in production meets strict hygiene standards.

Textiles: Water treatment is critical for dyeing and finishing processes.

Others: Includes paper & pulp, pharmaceuticals, and mining industries.

Speak to an Analyst - https://www.skyquestt.com/speak-with-analyst/industrial-water-treatment-chemicals-market

Regional Insights: A Global Perspective

North America

The North American market is driven by stringent environmental regulations and the need for efficient water management systems in industries like oil & gas, power, and manufacturing.

Europe

Europe’s focus on sustainability and the adoption of green chemicals is propelling the market. Countries like Germany, France, and the UK are leading in industrial water treatment innovations.

Asia-Pacific

Asia-Pacific is the fastest-growing region, with rising industrialization in countries like China, India, and Southeast Asia driving demand. The region’s water scarcity issues further boost the adoption of advanced treatment chemicals.

Rest of the World

Regions such as the Middle East, Africa, and Latin America are witnessing growth due to expanding industries and increasing water reuse initiatives.

Top Companies in the Industrial Water Treatment Chemicals Market

The market is highly competitive, with leading companies focusing on innovation, sustainability, and strategic partnerships. Key players include:

Ecolab Inc.

BASF SE

Kemira Oyj

Suez S.A.

Kurita Water Industries Ltd.

The Dow Chemical Company

Solenis LLC

Ashland Global Holdings Inc.

Lonza Group AG

SNF Floerger

Buckman Laboratories International, Inc.

Veolia Water Technologies

AkzoNobel N.V.

GE Water & Process Technologies

NALCO (An Ecolab Company)

Make a Purchase Inquiry - https://www.skyquestt.com/buy-now/industrial-water-treatment-chemicals-market

Trends Shaping the Future of Water Treatment Chemicals

Development of Green Chemicals The industry is shifting towards biodegradable and sustainable water treatment chemicals to reduce environmental impact.

Automation and Digitization The adoption of IoT and AI in water treatment systems is enabling real-time monitoring and process optimization.

Focus on Water Reuse Growing investments in water recycling technologies are increasing the demand for advanced treatment chemicals.

Innovations in Chemical Formulations Companies are investing in R&D to develop multi-functional chemicals that offer enhanced performance.

The Road Ahead for Industrial Water Treatment Chemicals

The industrial water treatment chemicals market is poised for robust growth as industries continue to adopt sustainable practices and advanced technologies. With increasing water scarcity and stringent environmental norms, the demand for innovative treatment solutions will remain strong.

Leading companies are expected to focus on green innovations and strategic collaborations to meet the rising global demand for efficient water treatment chemicals.

Access the Full Report Here - https://www.skyquestt.com/report/industrial-water-treatment-chemicals-market

#Industrial Water Treatment Chemicals Market#Industrial Water Treatment Chemicals Market Size#Industrial Water Treatment Chemicals Market Share#Industrial Water Treatment Chemicals Market Trends#Industrial Water Treatment Chemicals Market Growth#Industrial Water Treatment Chemicals Market Outlook#Industrial Water Treatment Chemicals Market Overview#Industrial Water Treatment Chemicals Market Insights#Industrial Water Treatment Chemicals Market Forecast#Industrial Water Treatment Chemicals Market Analysis#Industrial Water Treatment Chemicals Market Statistics

0 notes

Text

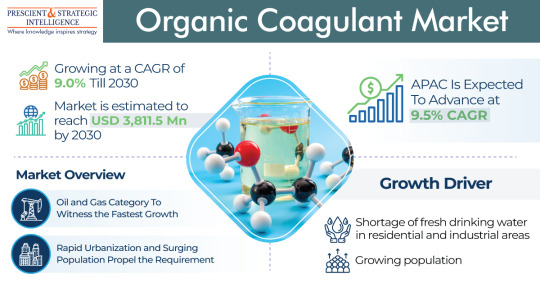

Harnessing Nature: Insights into the Organic Coagulant Market

The organic coagulant market is projected to reach at USD 3,811.5 million in 2030 with a CAGR of 9% in the years to come. The major reasons for this development of the industry are the scarcity of drinking and fresh water in residential and industrial areas along with the rising population, and urbanization.

And the rising demand for facilities like sewage treatment, industrial water treatment, fertilizer production, food & beverage industry, and paper manufacturing helps the demand for the chemical to grow.

And another major reason for the increasing demand is the growing population, which is creating an enormous demand for clean water and for which a need for advanced purification methods and also with the expansion of infrastructure for water treatment by government to meet the demand are all contributing the growth of eco-friendly water purification.

The oil & gas category will grow at a highest CAGR of 10% over the years, which is driven by the increasing use of organic chemicals with water at a required concentration for drilling and petroleum extraction purposes.

While, onshore and offshore operations both require different filtration processes as in onshore normal water is available, whereas offshore require advanced system to filter seawater. In addition, research and development activities are also contributing to the demand for organic coagulants, with eco-friendly solutions being explored for wastewater treatment.

Moreover, the increasing government focus to implement policies for water quality monitoring because of the increasing population all over the world. Strict regulations to prevent the direct release of harmful chemicals from industries and untreated sewage into water bodies.

APAC will grow the fastest in the organic coagulant market at a CAGR of 9.5% in the years to come due to the rapid urbanization and industrialization with rising population along with the rising investments in water treatment plant development and strict regulations on sewage disposal. Countries like India, China, South Korea, and Japan are expanding their contribution for the water treatment.

#organic coagulant#water treatment#wastewater treatment#coagulation solutions#eco-friendly chemicals#sustainable water treatment#natural coagulants#organic flocculants#water purification#organic coagulant applications#environmental sustainability#industrial water treatment#market growth#coagulation technology#organic chemicals

0 notes

Text

#Australia Water Treatment Chemicals Market#Australia Water Treatment Chemicals Market Size#Australia Water Treatment Chemicals Market Share#Australia Water Treatment Chemicals Market Analysis#Australia Water Treatment Chemicals Market Trends#Australia Water Treatment Chemicals Market Growth#Australia Water Treatment Chemicals Market Report#Australia Water Treatment Chemicals Market Research#Australia Water Treatment Chemicals Industry#Australia Water Treatment Chemicals Industry Report

0 notes

Text

The MEA Water & Waste Water Treatment Chemicals Market is projected to grow at around 5% CAGR during the forecast period, i.e., 2022-27. The growth of the market is likely to be driven by the rapidly increasing concerns over water contamination, improper treatment & disposal of waste from industries in water bodies, and the burgeoning demand for potable water by the rapidly growing population across the region.

#MEA Water & Waste Water Treatment Chemicals Market#MEA Water & Waste Water Treatment Chemicals Market growth#MEA Water & Waste Water Treatment Chemicals Market size#MEA Water & Waste Water Treatment Chemicals Market industry

0 notes

Text

The Future of Pumps Industry: Trends, Innovations, and Market Growth in 2024 and Beyond

The global pumps industry is experiencing significant growth, driven by rapid industrialization, urbanization, and infrastructure development. According to a report by MarketsandMarkets, the market is projected to expand from USD 61.32 billion in 2024 to USD 79.01 billion by 2029, reflecting a compound annual growth rate (CAGR) of 5.2%.

Key Market Drivers

Industrialization and Urbanization: Emerging economies, particularly in the Asia-Pacific region, are witnessing swift industrial growth and urban expansion. This surge necessitates efficient fluid handling systems across sectors such as water and wastewater treatment, oil and gas, chemicals, and power generation. The development of urban centers and large-scale infrastructure projects further amplifies the demand for advanced pump systems to ensure access to clean water and effective wastewater management.

Technological Advancements: The integration of Internet of Things (IoT) technology into pump systems has led to the emergence of smart pumps. These devices offer enhanced efficiency, predictive maintenance, and real-time monitoring, aligning with the industry’s move towards automation and energy conservation. Such innovations are particularly appealing to industries aiming to optimize operations and reduce energy consumption.

Environmental Regulations and Sustainability: Stringent environmental regulations and a global emphasis on sustainability are compelling industries to adopt energy-efficient and eco-friendly pumping solutions. This trend is driving the development and adoption of pumps that not only meet regulatory standards but also support organizations’ environmental goals.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=29873540

Regional Insights

The Asia-Pacific region holds the largest market share in the global pumps market. This dominance is attributed to rapid industrialization, urbanization, and substantial infrastructure investments in countries like China and India. The region’s focus on sectors such as water treatment, oil and gas, and chemicals further fuels the demand for advanced pumping solutions.

Top Companies in the Pumps Industry

Several key players are shaping the landscape of the pumps industry:

Grundfos Holding A/S

Xylem, KSB Limited

Flowserve Corporation

Sulzer Ltd

Grundfos Holding A/S

Grundfos Holding A/S is a global pump market leader that strongly adheres to the principles of energy efficiency, digitalization, and sustainability in its endeavours. The firm focuses on flexible solutions of innovative water and wastewater solutions, which cater to varied industries including water management, HVAC, industry, and energy. With a strong focus on advance technologies, Grundfos integrates IoT-enabled smart pumping solutions, which enhance the efficiency of the systems while building predictive maintenance capabilities into them, aligning with the increasing demand for energy-efficient solutions in both commercial and industrial sectors. For instance, its focus on strategic reduction of water and energy consumption with long-term investment in R&D and regional market expansion enhances its position as a core pumps company in the competitive modern global market.

Xylem Inc.

Xylem Inc. is one of the worldwide big players in the pumps market, recognized for its innovative water solutions that solve critical water and energy challenges. With a wide ranging product portfolio, Xylem is built on its expertise in providing advanced, energy-efficient pumping systems for industries that involve water utilities, industrial, residential, and commercial sectors. Offering the environment, digital transformation, and smart water management through IoT-enabled pumps and data-driven solutions, the company is capable of leading towards the reduction of water waste and the optimization of energy use. Xylem’s strategic acquisitions, R&D focus, and partnerships increase its competitive advantage by allowing it to expand its market presence globally while growing demand for efficient water management and environmental responsibility.

KSB Limited

KSB Limited is one of the world’s leading producers for high-performance pumps and valves, serving international markets in water, energy, mining, construction, and industrial applications. Being a part of the KSB group, the company sets up lines with the most modern technology and vast experience in engineering to supply energy efficient, reliable pumps specifically according to customer needs. KSB focuses on innovation in fluid handling and sustainable development, which means that IoT and smart pump technology will be implemented to optimize its client’s performance while keeping the operational costs at their lowest. With strategic expansion, strong positioning in customer focus, and a robust and efficient approach, the company can face the increased demands due to increasing competition in the global market.

Ask Sample Pages: https://www.marketsandmarkets.com/requestsampleNew.asp?id=29873540

Future Outlook

The pumps industry is poised for continued growth, driven by the increasing adoption of smart, IoT-enabled, and energy-efficient pumps. As industries advance towards automation and predictive maintenance, the demand for such innovative solutions is expected to rise. Additionally, government initiatives to enhance infrastructure in emerging economies present significant opportunities for market expansion. Industries such as oil and gas, chemicals, and construction are likely to contribute to the growing demand for advanced pumping solutions in the coming years.

0 notes

Text

Municipal Water Treatment Market Size, Trends, and Growth Forecast to 2025

The municipal water treatment market is experiencing significant growth, driven by increasing urbanization, stringent environmental regulations, and the rising demand for clean and safe water.

Get free sample copy @ https://www.statsandresearch.com/request-sample/30864-global-municipal-water-treatment-market

Market Overview:

Market Size and Growth: The global water and wastewater treatment market, which encompasses municipal water treatment, was valued at approximately USD 323.32 billion in 2023. It is projected to grow to USD 617.81 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 7.5% during the forecast period.

Key Market Insights:

Treatment Segmentation: The market is divided into municipal drinking water treatment and municipal wastewater treatment. Both segments are essential for ensuring public health and environmental protection.

Chemical Usage: Municipal water treatment processes utilize various chemicals, including coagulants, flocculants, corrosion inhibitors, and disinfectants, to ensure water quality and safety.

Get full report @ https://www.statsandresearch.com/report/30864-global-municipal-water-treatment-market/

Key Players:

The market features several prominent companies specializing in water treatment solutions:

Veolia Environnement S.A.: A global leader in optimized resource management, offering water, waste, and energy management solutions.

SUEZ: Provides water and waste management services, focusing on smart and sustainable resource management.

Xylem Inc.: Specializes in water solutions, including water and wastewater treatment, focusing on efficient and sustainable technologies.

Evoqua Water Technologies LLC: Offers a range of water and wastewater treatment solutions for municipal and industrial applications.

Pentair plc: Provides water treatment and sustainable solutions to residential, commercial, and industrial customers.

Challenges:

The municipal water treatment sector faces several challenges:

Aging Infrastructure: Many municipalities struggle with outdated water treatment facilities requiring significant investments for upgrades.

Emerging Contaminants: The detection of new pollutants, such as per- and polyfluoroalkyl substances (PFAS), necessitates advanced treatment technologies.

Regulatory Compliance: Adhering to evolving environmental regulations requires continuous monitoring and adaptation of treatment processes.

Regional Analysis:

North America: Dominates the market, accounting for a 38.67% share in 2023, driven by stringent environmental regulations and significant investments in water infrastructure.

Europe: Exhibits substantial growth due to strict water quality standards and a strong emphasis on sustainable water management practices.

Asia-Pacific: Anticipated to experience significant growth, propelled by rapid urbanization, industrialization, and increasing government initiatives to improve water infrastructure.

Get enquiry before buying @ https://www.statsandresearch.com/enquire-before/30864-global-municipal-water-treatment-market

0 notes

Text

Non-Woven - Industrial Membrane Market Research Report: Growth, Share, Value, Size, Industry Analsis and Forecast by 2030

"Non-Woven - Industrial Membrane Market Size And Forecast by 2030

The study also emphasizes the broader implications of the strategies employed by these companies on the Non-Woven - Industrial Membrane Market. Their innovations and market contributions not only shape the industry today but also pave the way for its future trajectory. By analyzing these companies, the report equips stakeholders with actionable insights to understand competitive positioning, identify growth opportunities, and devise strategies to thrive in this dynamic and evolving market landscape.

Data Bridge Market Research analyses that the global non-woven - industrial membrane market which was USD 1,423.65 million in 2022, is expected to reach USD 2,218.76 million by 2030, growing at a CAGR of 5.8% during the forecast period of 2023 to 2030.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-non-woven-industrial-membrane-market

Which are the top companies operating in the Non-Woven - Industrial Membrane Market?

The Top 10 Companies in Non-Woven - Industrial Membrane Market include leading firms. These companies are known for their strong market presence, innovative products, and ability to meet customer demands. They continue to drive growth in the industry through their commitment to quality and innovation, making them key players in the Non-Woven - Industrial Membrane Market.

**Segments**

- By Material Type: Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC), Polyester (PET), Others - By Technology: Microfiltration, Ultrafiltration, Reverse Osmosis, Nanofiltration - By End-Use Industry: Water & Wastewater Treatment, Food & Beverage, Pharmaceutical, Chemical Processing, Others

The global non-woven industrial membrane market is segmented based on material type, technology, and end-use industry. Material type includes polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polyester (PET), and others. Among these, polyethylene and polypropylene are widely used due to their cost-effectiveness and durability. Technology segments comprise microfiltration, ultrafiltration, reverse osmosis, and nanofiltration, with reverse osmosis witnessing significant growth owing to its efficiency in water purification processes. The end-use industry includes water & wastewater treatment, food & beverage, pharmaceutical, chemical processing, and others, with water & wastewater treatment being the dominant segment due to stringent regulations regarding water quality and increasing demand for clean water.

**Market Players**

- SUEZ Water Technologies & Solutions - Koch Membrane Systems - TORAY INDUSTRIES, INC. - Pentair plc - Alfa Laval - The 3M Company - GEA Group

Key market players in the global non-woven industrial membrane market include SUEZ Water Technologies & Solutions, Koch Membrane Systems, TORAY INDUSTRIES, INC., Pentair plc, Alfa Laval, The 3M Company, and GEA Group. These companies focus on research and development activities to enhance their product portfolios and meet the evolving demands of various industries such as water treatment, food & beverage, and pharmaceuticals. Strategic partnerships, mergers, and acquisitions are common strategies employed by these players to strengthen their market presence and expand their geographical reach.

The global non-woven industrial membrane market is witnessing significant growth driven by increasing demand from key end-use industries such as water & wastewater treatment, food & beverage, pharmaceutical, and chemical processing. The adoption of non-woven industrial membranes made from materials like polyethylene, polypropylene, polyvinyl chloride, polyester, and others is expected to continue rising due to their durability and cost-effectiveness. Polyethylene and polypropylene are particularly favored materials in this market segment. Technological advancements in microfiltration, ultrafiltration, reverse osmosis, and nanofiltration are enhancing the efficiency of water purification processes, with reverse osmosis emerging as a prominent technology due to its effectiveness.

In the competitive landscape of the non-woven industrial membrane market, key players such as SUEZ Water Technologies & Solutions, Koch Membrane Systems, TORAY INDUSTRIES, INC., and Pentair plc are investing heavily in research and development activities to innovate their product offerings and cater to the evolving needs of various industries. Collaborations, mergers, and acquisitions are common strategies being adopted by market players to enhance their market presence globally. Alfa Laval, The 3M Company, and GEA Group are also prominent companies driving market growth through strategic initiatives and a focus on expanding their product portfolios.

The water & wastewater treatment segment dominates the end-use industry category in the non-woven industrial membrane market due to stringent regulations regarding water quality and the increasing need for clean water. The food & beverage and pharmaceutical sectors are also significant contributors to market growth, driven by the need for advanced membrane technologies to ensure product safety and quality standards. With the rising emphasis on sustainability and environmental concerns, the demand for non-woven industrial membranes is expected to further increase as these membranes play a crucial role in water conservation and treatment processes.

Overall, the global non-woven industrial membrane market is poised for substantial growth in the coming years, fueled by technological advancements, increasing investment in research and development activities, and the expanding application scope across various industries. Market players will continue to focus on innovation and strategic collaborations to capitalize on emerging opportunities and maintain a competitive edge in the evolving market landscape.**Segments**

- **Module Type**: Spiral Wound, Hollow Fiber, Tubular, Plate and Frame - **Filtration Media**: Polyester, Aramid, PPS, Viscose, Rayon, Polypropylene, Nylon, Others - **Application**: Pharmaceutical and Medical, Water and Wastewater Treatment, Food and Beverage, Chemicals, Industrial Gas, Automotive

The Global Non-Woven Industrial Membrane Market is further segmented based on module type, filtration media, and application. Module types include Spiral Wound, Hollow Fiber, Tubular, and Plate and Frame, each offering unique benefits and suitable for various industrial applications. Filtration media consists of Polyester, Aramid, PPS, Viscose, Rayon, Polypropylene, Nylon, and others, catering to diverse filtration requirements across industries. Applications of non-woven industrial membranes span across Pharmaceutical and Medical, Water and Wastewater Treatment, Food and Beverage, Chemicals, Industrial Gas, and Automotive sectors, addressing specific filtration needs with efficiency and precision.

**Market Players**

- Sefar AG (Switzerland) - Ahlstrom-Munksjö (Finland) - Freudenberg Group (Germany) - Berry Global (U.S.) - Kimberly-Clark Corporation (U.S.) - DuPont (U.S.) - Toray Industries, Inc. (Japan) - Johns Manville (U.S.), LLC (U.S.) - Freudenberg Performance Materials (U.K)

Key players in the Global Non-Woven Industrial Membrane Market include Sefar AG, Ahlstrom-Munksjö, Freudenberg Group, Berry Global, Kimberly-Clark Corporation, DuPont, Toray Industries, Inc., Johns Manville, LLC, and Freudenberg Performance Materials. These companies are at the forefront of innovation, developing advanced membrane technologies to meet the evolving demands of industries like pharmaceuticals, water treatment, food and beverage, chemicals, industrial gas, and automotive. With a focus on product development, strategic collaborations, and market expansion, these players are poised to drive market growth and maintain a competitive edge in the dynamic landscape of non-woven industrial membranes.

The Global Non-Woven Industrial Membrane Market is witnessing substantial growth propelled by the increasing adoption of advanced filtration technologies in key industries. The diverse range of module types and filtration media options available cater to a wide spectrum of applications, ensuring efficient and reliable filtration performance. The pharmaceutical and medical sector, along with water and wastewater treatment, are significant sectors driving market expansion, buoyed by stringent quality standards and regulations. Additionally, the food and beverage, chemicals, industrial gas, and automotive industries are increasingly incorporating non-woven industrial membranes to enhance operational efficiency and product quality.

As the market continues to evolve, companies like Sefar AG, Ahlstrom-Munksjö, and Freudenberg Group are investing in research and development to introduce cutting-edge membrane solutions that address the specific needs of different industries. The strategic partnerships and acquisitions undertaken by key market players are aimed at strengthening their market presence and expanding their product portfolios to capture new growth opportunities. With a growing emphasis on sustainability and environmental responsibility, the demand for non-woven industrial membranes is expected to surge, driven by their crucial role in efficient filtration, water treatment, and resource conservation practices across various sectors.

Explore Further Details about This Research Non-Woven - Industrial Membrane Market Report https://www.databridgemarketresearch.com/reports/global-non-woven-industrial-membrane-market

Key Insights from the Global Non-Woven - Industrial Membrane Market :

Comprehensive Market Overview: The Non-Woven - Industrial Membrane Market is witnessing rapid expansion, fueled by increasing demand for advanced solutions and evolving consumer needs.

Industry Trends and Projections: The market is projected to grow at a CAGR of X%, with a notable shift towards digitalization and automation in the coming years.

Emerging Opportunities: There is a rising demand for eco-friendly products and services, creating new business avenues within the market.

Focus on R&D: Companies are prioritizing innovation and research to develop next-generation products and enhance competitive advantages.

Leading Player Profiles: Market leaders continue to drive growth through strategic acquisitions and product innovation.

Market Composition: The market is segmented by product type, region, and application, with a mix of both established and emerging players.

Revenue Growth: The market is experiencing significant revenue growth, attributed to increased consumer spending and the expansion of digital services.

Commercial Opportunities: There are substantial opportunities for expansion in untapped regions, particularly in developing economies where demand is rising.

Find Country based languages on reports:

https://www.databridgemarketresearch.com/jp/reports/global-non-woven-industrial-membrane-markethttps://www.databridgemarketresearch.com/zh/reports/global-non-woven-industrial-membrane-markethttps://www.databridgemarketresearch.com/ar/reports/global-non-woven-industrial-membrane-markethttps://www.databridgemarketresearch.com/pt/reports/global-non-woven-industrial-membrane-markethttps://www.databridgemarketresearch.com/de/reports/global-non-woven-industrial-membrane-markethttps://www.databridgemarketresearch.com/fr/reports/global-non-woven-industrial-membrane-markethttps://www.databridgemarketresearch.com/es/reports/global-non-woven-industrial-membrane-markethttps://www.databridgemarketresearch.com/ko/reports/global-non-woven-industrial-membrane-markethttps://www.databridgemarketresearch.com/ru/reports/global-non-woven-industrial-membrane-market

Data Bridge Market Research:

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]"

0 notes

Text

Magnesium Hydroxide Prices, News, Trend, Graph, Chart, Monitor and Forecast

The market for magnesium hydroxide has witnessed steady growth in recent years, driven by its wide range of applications across various industries, including water treatment, pharmaceuticals, and plastics. As a key chemical compound, magnesium hydroxide is utilized in numerous products, offering both environmental and economic advantages. The price trend of magnesium hydroxide is influenced by several factors, including raw material costs, production methods, and demand fluctuations in various end-use sectors. As the global demand for magnesium hydroxide increases, understanding the factors that impact its pricing becomes crucial for businesses involved in its production, distribution, and utilization.

Magnesium hydroxide is primarily produced by combining magnesium oxide with water, a process that can be influenced by factors such as energy costs and raw material availability. The price of magnesium hydroxide is inherently tied to the cost of magnesium oxide, as it forms the basis for its production. Magnesium oxide, which is derived from natural minerals like magnesite, dolomite, and serpentine, has experienced price fluctuations based on mining activities, transportation expenses, and global supply chain disruptions. These fluctuations can directly impact the price of magnesium hydroxide, making it essential for manufacturers to monitor trends in the raw material market.

Get Real time Prices for Magnesium Hydroxide: https://www.chemanalyst.com/Pricing-data/magnesium-hydroxide-1628

Another key factor influencing the price of magnesium hydroxide is the demand from its primary applications. In the water treatment industry, magnesium hydroxide is used as a flocculant to treat wastewater and remove heavy metals, making it an essential component in maintaining water quality. As environmental regulations tighten globally, the need for efficient water treatment solutions has increased, driving up the demand for magnesium hydroxide. Similarly, in the pharmaceutical sector, magnesium hydroxide is used as an antacid and laxative, further boosting its market value. The growth of the healthcare sector, especially in emerging economies, contributes to the rising demand for magnesium hydroxide-based products, thus impacting the overall price trend.

In the plastics industry, magnesium hydroxide is used as a flame retardant, replacing more toxic substances like brominated compounds. With the growing emphasis on eco-friendly alternatives and stricter environmental regulations, the demand for magnesium hydroxide as a flame retardant has seen significant growth. This shift toward environmentally conscious materials has driven up the price of magnesium hydroxide, as manufacturers seek sustainable solutions to meet regulatory standards. Additionally, the rise of the electric vehicle (EV) market, with its increasing need for fire-resistant materials, has further contributed to the upward pressure on magnesium hydroxide prices, as it is increasingly utilized in the production of EV batteries and components.

Geographical factors also play a significant role in shaping magnesium hydroxide prices. In regions with abundant magnesium mineral resources, such as China and parts of Europe, the price of magnesium hydroxide may be relatively lower due to the availability of raw materials and established production infrastructure. However, in regions where magnesium resources are less abundant or where transportation costs are higher, the price of magnesium hydroxide may be more volatile. Furthermore, international trade policies, tariffs, and regulations can also impact the pricing dynamics of magnesium hydroxide, especially in markets that rely on imports to meet demand.

In addition to supply and demand dynamics, technological advancements in production methods can also affect the price of magnesium hydroxide. Innovations that lead to more efficient and cost-effective production processes can help lower the overall cost of magnesium hydroxide, benefiting both manufacturers and consumers. For example, advancements in processing techniques that reduce energy consumption or optimize the use of raw materials can help mitigate the impact of fluctuating raw material prices. As the global market for magnesium hydroxide continues to evolve, producers who invest in research and development to improve production efficiency may gain a competitive edge in pricing and market share.

The global economic landscape is another factor that impacts magnesium hydroxide prices. Economic downturns, such as recessions or periods of low industrial activity, can reduce demand for magnesium hydroxide across various industries, leading to price reductions. Conversely, periods of economic expansion, coupled with increased industrial activity and infrastructure development, can lead to higher demand for magnesium hydroxide, driving prices upward. As magnesium hydroxide is used in a variety of industries, its price is often closely tied to the overall economic performance of key markets such as construction, automotive, and manufacturing.

In conclusion, magnesium hydroxide prices are shaped by a complex interplay of factors, including raw material costs, production methods, demand from various industries, and geopolitical and economic conditions. The growing emphasis on environmental sustainability and the increasing demand for eco-friendly materials are likely to continue driving the market for magnesium hydroxide, especially in sectors like water treatment, pharmaceuticals, and plastics. As businesses look to navigate the fluctuations in magnesium hydroxide prices, it is crucial to stay informed about market trends and anticipate shifts in demand. Ultimately, the price of magnesium hydroxide will continue to evolve in response to technological advancements, regulatory changes, and shifts in global economic conditions.

Get Real time Prices for Magnesium Hydroxide: https://www.chemanalyst.com/Pricing-data/magnesium-hydroxide-1628

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Magnesium Hydroxide#Magnesium Hydroxide Price#Magnesium Hydroxide News#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Industrial Wastewater Treatment Market to be Worth $206.81 Billion by 2031

Meticulous Research®—a leading global market research company, published a research report titled, ‘Industrial Wastewater Treatment Market by Offering (Treatment Technologies, Treatment Chemicals, Process Control & Automation, Design, Engineering, and Construction Services, Operation & Maintenance services), End User, and Geography - Global Forecast to 2031.’

According to this latest publication from Meticulous Research®, the global industrial wastewater treatment market is projected to reach $206.81 billion by 2031, at a CAGR of 6.1% from 2024–2031. The growth of the global industrial wastewater treatment market is driven by factors such as the lack of freshwater resources, government encouragement and the growing emphasis on corporate social responsibility, and the need for critical resource recovery from wastewater. However, the high installation, maintenance, and operating costs of wastewater treatment infrastructure restrain the growth of this market.

Furthermore, the growing demand for energy-efficient and advanced wastewater treatment technologies and the generation of green hydrogen from industrial wastewater are expected to provide growth opportunities for the players operating in this market. However, high energy consumption and expenses due to excess sludge production pose significant challenges to the market’s growth.

Meticulous Research® has segmented this market based on offering, end user, and geography for efficient analysis. The study also evaluates industry competitors and analyzes the market at country levels.

Downalod Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5170

Based on offering, the global industrial wastewater treatment market is segmented into operation & maintenance services, process control & automation, design, engineering, and construction services, treatment technologies, and treatment chemicals. In 2024, the operation & maintenance services segment is expected to account for the largest share of the global industrial wastewater treatment market. The large market share of this segment is attributed to the increasing need for meeting government-mandated quality standards for managing wastewater and companies’ rising focus on cost-effectiveness, efficiency, and reducing workforce requirements for monitoring and managing industrial wastewater.

Based on end user, the global industrial wastewater treatment market is segmented into power generation, semiconductor manufacturing, data centers, green hydrogen generation, chemical manufacturing, refining & petrochemicals, oil & gas, pulp & paper, food & beverage, pharmaceutical manufacturing, industrial manufacturing, and other end users. In 2024, the food & beverage segment is expected to account for the largest share of the global industrial wastewater treatment market. The large share of this segment is attributed to factors such as increasing volumes of sewage & wastewater generated during food production, the substantial utilization of water for food processing and cleaning in the food & beverage industry, and the growing need for wastewater reuse in the F&B industry to improve water efficiency and ensure reliable, and clean water sources for operations.

Based on geography, the industrial wastewater treatment market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2024, Asia-Pacific is expected to command the largest share of global industrial wastewater treatment. Asia-Pacific’s major market share is attributed to the rising demand for sustainable and advanced solutions due to significant water stress and environmental pollution. The key food & beverage sectors creating the highest investment opportunities in the region include dairy and beverages, especially in China and India.

Key Players:

The key players operating in the global industrial wastewater treatment market are Xylem Inc. (U.S.), SUEZ S.A. (France), Pentair plc (U.K.), Dow Inc. (U.S.), Veolia Environnement S.A. (France), BASF SE (Germany), PPU Umwelttechnik GmbH (Germany), DuPont de Nemours, Inc. (U.S.), Bio-Microbics (U.S.), Thermax Limited (India), Ecolab Inc. (U.S.), Kurita Water Industries, Ltd. (Japan), Kemira Oyj (Finland), GFL Environmental (Canada), 3M Company (U.S.), Kingspan Group plc (U.K.), Calgon Carbon Corporation (U.S.), Trojan Technologies (Canada), Clean TeQ Water Limited (Australia), SWA Water Australia Pty Limited (Australia), Adroit Associates Private Limited (India), Sauber Environmental Solutions (India), SEPC Limited (India), Golder Associates Inc. (Canada), Burns & McDonnell (U.S.), and WOG Technologies (India).

Compete Report Here : https://www.meticulousresearch.com/product/industrial-wastewater-treatment-market-5170

Key Questions Answered in the Report:

Which are the high-growth market segments in terms of offering, end user, and geography?

What is the historical market size of the global industrial wastewater treatment market?

What are the market forecasts and estimates for the period 2024–2031?

What are the major drivers, opportunities, and challenges in the global industrial wastewater treatment market?

Who are the major market players, and what shares do they hold in the global industrial wastewater treatment market?

What is the competitive landscape like?

What are the recent key developments in the global industrial wastewater treatment market?

What are the strategies adopted by major players in this market?

What are the key geographic trends and high-growth countries?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Industrial Wastewater Treatment Market#Effluent Treatment#Industrial Wastewater Treatment System#Water Treatment Technologies#Industrial Wastewater#Industrial Water Treatment#Wastewater Treatment#Industrial Wastewater Treatment Technologies

0 notes

Text

Boron Analyzer Market Expanding Rapidly With Innovations In Smart Monitoring And Automation Technologies

The boron analyzer market is expanding due to the rising need for precise boron measurement in industrial processes and environmental monitoring. Industries such as semiconductor manufacturing, water treatment, and power generation are adopting advanced boron analyzers to ensure compliance with strict regulatory standards. The demand for these analyzers is increasing as companies focus on improving efficiency, reducing contamination risks, and maintaining high-quality production standards. The market is also witnessing technological advancements, leading to the development of more accurate, efficient, and automated boron analyzers.

Market Size and Growth Trends

Increasing adoption of boron analyzers in industries requiring ultrapure water is boosting market expansion

Rising environmental concerns and regulatory mandates are driving market demand globally

Rapid industrialization in emerging economies is fueling the adoption of boron monitoring solutions

Advances in sensor technology and automation are enhancing the performance of modern boron analyzers

Growing research and development investments in water treatment and semiconductor industries are supporting market growth

Expansion of the power generation sector, particularly nuclear energy, is increasing the need for boron analyzers

High demand for portable and online monitoring solutions is shaping future market trends

Key Market Drivers

Stringent government regulations on water quality monitoring are accelerating boron analyzer adoption

The semiconductor industry’s requirement for precise boron detection in wafer manufacturing is boosting demand

Rising use of boron analyzers in pharmaceutical production for maintaining product purity standards

Increasing awareness of the effects of boron contamination in drinking water and industrial discharge

Growth in wastewater treatment facilities requiring continuous boron level monitoring

Power plants using boron analyzers for coolant system optimization and efficiency enhancement

Expanding applications in agriculture for monitoring boron concentration in irrigation water

Market Challenges

High cost of advanced boron analyzers limiting adoption in small and medium enterprises

Technical limitations in certain analytical methods affecting measurement accuracy and reliability

Lack of awareness in developing countries regarding the benefits of boron analyzers

Interference from other chemical compounds affecting boron detection accuracy

Need for frequent calibration and maintenance increasing operational costs for industries

Limited availability of skilled professionals for handling and interpreting boron analyzer data

Challenges in real-time boron monitoring in highly dynamic industrial processes

Opportunities in the Market

Development of AI-driven boron analyzers for enhanced real-time monitoring and predictive maintenance

Expansion of industrial automation integrating boron analyzers with IoT-enabled smart water management systems

Rising demand for compact and portable boron analyzers for field applications and on-site testing

Growth of the renewable energy sector increasing the need for boron monitoring in solar panel production

Emerging research on innovative boron detection methods improving analytical precision and efficiency

Increasing investments in smart infrastructure driving the need for advanced water quality monitoring solutions

Expansion of public-private partnerships for sustainable water management projects boosting market demand

Regional Market Analysis

North America – Strong presence of water treatment and semiconductor industries driving boron analyzer adoption

Europe – Strict environmental regulations promoting widespread use of boron analyzers in industrial applications

Asia-Pacific – Rapid industrial growth and rising investments in ultrapure water systems increasing market demand

Latin America – Growing focus on water pollution control encouraging the adoption of boron monitoring solutions

Middle East & Africa – Expansion of the mining and desalination industries creating new opportunities for boron analyzers

Technological Advancements

Development of real-time boron analyzers with advanced data analytics capabilities for industrial applications

Integration of boron analyzers with cloud-based monitoring platforms improving remote data accessibility

Advancements in sensor technology enhancing detection limits and measurement accuracy in boron analysis

Adoption of non-invasive and automated boron detection techniques reducing manual intervention and errors

Use of nanotechnology in boron sensors improving sensitivity and reducing energy consumption

AI-powered calibration systems optimizing analyzer performance and extending operational life

Introduction of multi-parameter analyzers capable of detecting multiple contaminants along with boron

Competitive Landscape

Leading market players investing in research and development to improve boron analyzer efficiency

Mergers and acquisitions among key companies expanding market reach and technological capabilities

Strategic collaborations with regulatory bodies ensuring compliance with evolving water quality standards

Increased focus on product innovation for cost-effective and user-friendly boron analyzer solutions

Expansion of distribution networks in emerging markets to cater to rising industrial demands

Growing emphasis on sustainability and eco-friendly analyzer designs reducing environmental impact

Competitive pricing strategies and customer-centric service models improving market penetration

Future Market Outlook

Rising adoption of automated boron analyzers in industries requiring continuous water quality assessment

Increased demand for smart monitoring solutions integrating AI and IoT for enhanced operational efficiency

Expansion of government-led water conservation initiatives increasing boron analyzer deployment

Development of cost-effective boron detection methods making analyzers more accessible to small industries

Advancements in portable boron analyzers improving on-site monitoring and real-time data collection

Strengthening global policies on water and environmental safety fostering market growth

Continuous technological innovations driving the development of next-generation boron analyzers

0 notes

Text

Ascorbic Acid Manufacturer in Delhi: Driving Quality and Innovation

Ascorbic acid, widely known as Vitamin C, is a crucial component with extensive applications in industries such as pharmaceuticals, food processing, cosmetics, and industrial manufacturing. A leading ascorbic acid manufacturer in Delhi addresses the ever-expanding demand by combining superior quality standards, innovative production methods, and eco-conscious practices.

The Significance of Ascorbic Acid

Ascorbic acid stands out for its remarkable versatility and benefits:

Health Benefits: Vital for boosting immunity, aiding collagen synthesis, and combating oxidative stress.

Food Applications: Preserves freshness and prevents discoloration in processed foods and beverages.

Cosmetic Uses: A core ingredient in skincare products, enhancing brightness and reducing signs of aging.

Industrial Applications: Functions as a reducing agent and stabilizer in diverse technical processes.

Why Delhi Manufacturers Stand Out

Delhi-based manufacturers have earned a reputation for delivering exceptional ascorbic acid products. Their strengths include:

Unmatched Quality: Products that comply with stringent pharmaceutical, food, and industrial-grade standards.

Customized Solutions: Tailor-made formulations to meet specific industry demands.

Technological Leadership: Advanced production facilities ensure precision and consistency.

Sustainability Focus: Environmentally responsible practices integrated throughout the production cycle.

Key Applications of Ascorbic Acid

Pharmaceuticals: Essential in immune boosters, multivitamins, and health supplements.

Food Industry: Maintains the quality and longevity of juices, canned goods, sauces, and baked items.

Cosmetics: A key component in skincare, improving texture, tone, and overall appearance.

Industrial Processes: Aiding chemical reactions, water treatment, and dyeing applications.

Benefits of Choosing a Delhi Manufacturer

Working with a Delhi-based manufacturer comes with multiple advantages:

Competitive Pricing: Superior quality products offered at affordable rates.

Reliable Supply Chains: Timely delivery ensured by robust logistics infrastructure.

Flexible Options: Bulk supplies, private labeling, and customizable packaging to meet diverse needs.

Commitment to Sustainability

Modern manufacturers in Delhi prioritize environmentally friendly practices:

Energy Efficiency: Incorporating advanced methods to reduce energy consumption.

Eco-Friendly Packaging: Utilizing recyclable and biodegradable materials to minimize environmental impact.

Waste Management: Reducing production waste to promote sustainability.

Conclusion

A trusted ascorbic acid manufacturer in Delhi plays a pivotal role in supplying high-quality Vitamin C to various industries. Their expertise in delivering reliable, customized solutions at competitive prices sets them apart as an ideal partner for businesses worldwide.

By prioritizing innovation, sustainability, and strict quality control, Delhi-based manufacturers ensure that their ascorbic acid meets the evolving demands of health, food, cosmetics, and industrial sectors. Choosing a reliable partner from Delhi guarantees access to top-tier products and services, fostering growth and success in a competitive market.

0 notes

Text

The GCC Water & Waste Water Treatment Chemicals Market is projected to grow at a CAGR of around 18.2% during the forecast period, i.e., 2023-2028, says MarkNtel Advisors. The market growth primarily attributes to the increasing issues of water contamination, burgeoning waste from industries, which gets discharged in water bodies, and mounting need for potable water due to rapid industrialization & expansion across the Gulf countries.

#GCC Water & Waste Water Treatment Chemicals Market#GCC Water & Waste Water Treatment Chemicals Market growth#GCC Water & Waste Water Treatment Chemicals Market size#GCC Water & Waste Water Treatment Chemicals Market industry

0 notes

Text

Exploring the Versatility of Polydimethylsiloxane Fluid in the Chemical Manufacturing Industry

In the realm of Chemical Manufacturing and Industrial Materials, Minmetals East stands out as a leader, particularly in the production of high-quality Silica Products and Adhesives. One of the remarkable offerings in their portfolio is polydimethylsiloxane fluid, known for its exceptional properties and versatility.

Polydimethylsiloxane fluid is widely used across various sectors, including Construction Materials and Water Treatment. Its unique characteristics, such as thermal stability, low viscosity, and excellent lubricating properties, make it an ideal choice for a multitude of applications. In the construction industry, it enhances the durability of materials, ensuring long-lasting performance.

Moreover, in water treatment processes, polydimethylsiloxane fluid contributes to improved efficiency, helping to achieve cleaner and safer water. Minmetals East's commitment to innovation and quality ensures that their products meet the highest industry standards, fostering a sustainable future for the chemical manufacturing sector.

By choosing Minmetals East and their polydimethylsiloxane fluid, businesses can benefit from reliable performance and a positive impact on their operations, paving the way for growth and success in a competitive market.

#industrial materials#lubricating properties#innovation#adhesives#quality#durability#sustainable future#polydimethylsiloxane

0 notes

Text

Borax Pentahydrate Prices, News, Trend, Graph, Chart, Monitor and Forecast

The Borax Pentahydrate market has experienced significant fluctuations over recent years due to various factors that impact its supply and demand. Borax Pentahydrate, a hydrated form of sodium borate, is widely used in industries such as glass manufacturing, ceramics, metallurgy, and cleaning products. Its unique properties make it a critical raw material in the production of borosilicate glass, which is commonly used in laboratory equipment and kitchenware, as well as in the manufacture of fiberglass and insulation materials. In addition, Borax Pentahydrate is utilized in the agriculture sector as a pesticide and herbicide, as well as in the production of flame retardants, water treatment chemicals, and detergent formulations. Consequently, any changes in the price of Borax Pentahydrate can have a ripple effect on these industries.

The prices of Borax Pentahydrate are influenced by a combination of global supply and demand dynamics, raw material costs, production levels, and geopolitical factors. As Borax is primarily mined from deposits in countries like the United States, Turkey, and Chile, the availability of the material can fluctuate based on mining operations, environmental regulations, and production constraints. For instance, disruptions in mining activities due to adverse weather conditions, labor strikes, or geopolitical tensions can lead to temporary shortages in supply, causing prices to rise. Additionally, fluctuations in fuel and energy prices, which are essential for the mining and transportation processes, can also contribute to price volatility.

Get Real time Prices for Borax Pentahydrate: https://www.chemanalyst.com/Pricing-data/borax-pentahydrate-1627

On the demand side, the growth of end-use industries such as glass manufacturing and construction has a direct impact on the price of Borax Pentahydrate. The demand for high-quality glass, driven by the expanding automotive and construction industries, has been a key factor in the increasing consumption of Borax. Furthermore, with the growing focus on sustainable building materials and energy-efficient products, the demand for fiberglass and insulation materials, which require Borax Pentahydrate, has surged. Similarly, the agricultural sector’s reliance on Borax Pentahydrate for its role in pesticide and herbicide formulations has contributed to its steady demand.

Another key factor influencing Borax Pentahydrate prices is the global economic climate. Economic slowdowns, particularly in major economies like China, India, and the United States, can result in decreased industrial activity and lower demand for Borax-related products. On the other hand, periods of economic growth often lead to higher demand, particularly in emerging markets where infrastructure development and industrialization are rapidly advancing. The ongoing global efforts to transition to green energy and sustainable manufacturing processes can also influence the demand for Borax Pentahydrate, especially in the production of lithium batteries and other green technologies.

The production of Borax Pentahydrate itself is energy-intensive and requires significant investment in specialized facilities and equipment. This means that any changes in energy prices or operational costs can directly affect the cost of production, which in turn impacts the overall market prices. For instance, the cost of electricity and natural gas has been known to rise due to fluctuations in global energy markets, which increases the cost of producing Borax Pentahydrate. Additionally, stricter environmental regulations in some countries, aimed at reducing pollution from mining and industrial activities, can add to the cost of production and, ultimately, lead to higher prices for consumers.

In recent years, there has been an increasing trend toward market consolidation in the Borax industry, with a few major players dominating global production and distribution. This concentration of market power can result in pricing pressure, as these large corporations may have the ability to influence market conditions and set prices. However, competition from smaller producers, particularly in emerging markets, continues to keep the market dynamic and responsive to changing demand patterns. As a result, the prices of Borax Pentahydrate often experience periods of volatility, driven by both local and global economic factors.

The export and import of Borax Pentahydrate also play a significant role in price determination. Countries that have abundant Borax reserves, such as Turkey and the United States, are major exporters of Borax Pentahydrate, while countries with high demand for the material, such as India and China, are large importers. Any changes in trade policies, tariffs, or shipping costs can disrupt the supply chain, leading to price fluctuations. For instance, trade disputes or tariff impositions between major producers and consumers can lead to supply chain disruptions, causing prices to rise.

Furthermore, the ongoing shift towards sustainability and the demand for greener alternatives in manufacturing processes could present both challenges and opportunities for the Borax Pentahydrate market. As industries become more conscious of their environmental impact, there is an increasing need for more sustainable and eco-friendly materials. This trend may drive the demand for Borax Pentahydrate in certain sectors while reducing the use of more harmful chemicals. At the same time, innovation in production technologies may lead to cost reductions and improved efficiency, potentially stabilizing prices over the long term.

In conclusion, the Borax Pentahydrate market is influenced by a variety of factors, ranging from supply and demand dynamics to geopolitical events and energy prices. The prices of Borax Pentahydrate are subject to fluctuations based on changes in industrial demand, production costs, and global economic conditions. As key end-use industries such as glass manufacturing, agriculture, and construction continue to expand, the demand for Borax Pentahydrate is expected to remain strong. However, the market's volatility requires industry players to remain agile and responsive to changes in supply and demand, ensuring that they can adapt to market shifts and maintain profitability. Despite these challenges, the Borax Pentahydrate market is poised for continued growth, driven by both traditional applications and emerging opportunities in sustainable technologies.

Get Real time Prices for Borax Pentahydrate: https://www.chemanalyst.com/Pricing-data/borax-pentahydrate-1627

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Borax Pentahydrate#Borax Pentahydrate Prices#Borax Pentahydrate Price#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Sendha Namak Manufacturer India Fueling the Growth of Rock Salt Production

India has emerged as a global leader in rock salt production, especially in the manufacturing of Sendha Namak and industrial salt. As a well-established Sendha namak manufacturer, the country’s abundant salt reserves, particularly in Rajasthan and Gujarat, play a pivotal role in its dominance in the salt industry. Sendha Namak, renowned for its mineral-rich composition, is highly sought after for both culinary and medicinal uses, preserving its natural properties through minimal processing. Meanwhile, industrial salt is critical for industries such as chemical production, water treatment, and food preservation. With an expanding production capacity, India continues to meet rising global demand and secure a strong position in the international salt market.

0 notes