#dustcollection

Explore tagged Tumblr posts

Text

The Vital Role of Dust Collector Manufacturers in Keeping Our Air Clean

Dust may seem like an insignificant nuisance, but it's anything but. Microscopic particles can wreak havoc on our health, environment, and industrial processes. Fortunately, unsung heroes stand sentinel against this silent threat: dust collector manufacturers. These companies play a crucial role in safeguarding our air quality, and Intech Bulk Handling Systems Pvt. Ltd., a leading chain conveyor manufacturers in India, stands out as a prime example.

Invisible Hazards, Tangible Impact:

Dust exposure poses significant health risks, triggering respiratory problems like asthma and allergies. In industrial settings, it can also compromise product quality, damage equipment, and even escalate fire hazards. Dust collectors combat these issues by capturing and filtering dust particles, ensuring cleaner air for workplaces and communities.

How Dust Collectors Work:

These unsung heroes come in various configurations, each suited to specific applications. Common mechanisms include:

Cyclones: Utilizing centrifugal force, they separate heavier dust particles from air.

Bag filters: Air passes through fabric bags, trapping dust while clean air exits.

Cartridge filters: Similar to bag filters, but with pleated cartridges offering higher efficiency.

Wet scrubbers: Water sprays capture dust, often ideal for sticky or hazardous materials.

Intech's Contribution to Cleaner Air:

Intech Bulk Handling Systems, while specializing in chain conveyors, also recognizes the importance of dust control. They offer a range of dust collection systems tailored to various industries, including:

Cement: High-efficiency bag filters capture fine dust particles, protecting workers and the environment.

Pharmaceuticals: Dust-free environments are crucial for product purity. Intech's systems ensure compliance with strict regulations.

Food processing: Preventing dust contamination safeguards product quality and consumer health. Intech provides solutions for both dry and wet ingredients.

Beyond Individual Companies:

The efforts of dust collector manufacturers reach far and wide. They contribute to:

Improved public health: By reducing dust exposure, they help prevent respiratory illnesses and promote overall well-being.

Environmental protection: Dust collectors control air pollution, contributing to cleaner air and mitigating climate change effects.

Enhanced industrial efficiency: Cleaner work environments and protected equipment lead to improved productivity and reduced maintenance costs.

Conclusion:

Dust collector manufacturers may not grab the headlines, but their work is essential for our health, environment, and industrial well-being. Companies like Intech Bulk Handling Systems, with their commitment to innovative solutions, exemplify the critical role this industry plays in keeping our air clean. As we strive for a healthier and more sustainable future, appreciating and supporting these silent guardians of clean air becomes ever more important.

#dust collector manufacturers#clean air#Intech Bulk Handling#dust emissions control#CleanAir#DustControl#IndustrialSafety#HealthAndSafety#EnvironmentalProtection#AirQuality#DustCollection#Manufacturing#PublicHealth#CleanerEnvironment#Sustainability#WorkplaceSafety#IntechBulkHandling#ChainConveyors#India

3 notes

·

View notes

Text

A Twin Lobe Roots Blower is a rotary compressor designed for high volume-low pressure applications, commonly used in wastewater treatment, pneumatic conveying, ash handling, and dust collection. Its reliable performance ensures efficient operation across various industrial processes.

For more details, visit- https://www.acmeairequipments.com/product/twin-lobe-roots-blower/

#AcmeAirEquipments#twinloberootsblower#EfficientOperations#WastewaterTreatment#rotarycompressor#DustCollection

0 notes

Text

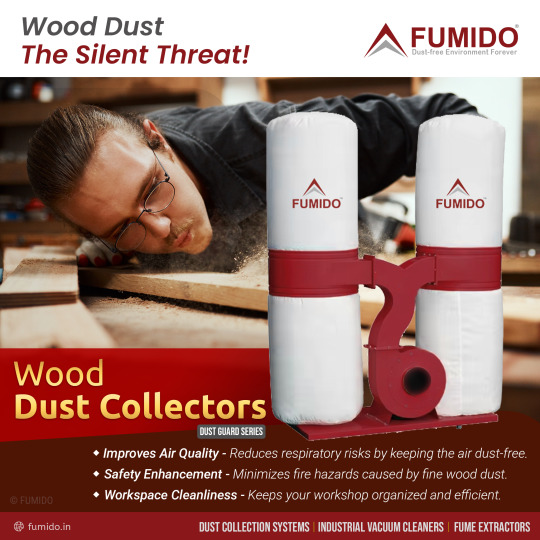

𝗪𝗼𝗼𝗱 𝗗𝘂𝘀𝘁 - 𝗧𝗵𝗲 𝗦𝗶𝗹𝗲𝗻𝘁 𝗧𝗵𝗿𝗲𝗮𝘁! 🌲

Wood dust isn’t just a mess - it’s a serious health and safety hazard! Fine wood particles can linger in the air, causing respiratory issues and increasing fire risks in your workshop.

✅ Improve Air Quality - Keep your workspace dust-free and breathable.

🔥 Enhance Safety - Minimize fire hazards caused by fine wood dust.

🛠️ Maintain Cleanliness - Organize your workshop efficiently.

𝑈𝑝𝑔𝑟𝑎𝑑𝑒 𝑡𝑜 𝐹𝑢𝑚𝑖𝑑𝑜’𝑠 𝑊𝑜𝑜𝑑 𝐷𝑢𝑠𝑡 𝐶𝑜𝑙𝑙𝑒𝑐𝑡𝑜𝑟𝑠 𝑎𝑛𝑑 𝑡𝑎𝑘𝑒 𝑐𝑜𝑛𝑡𝑟𝑜𝑙 𝑜𝑓 𝑦𝑜𝑢𝑟 𝑎𝑖𝑟 𝑞𝑢𝑎𝑙𝑖𝑡𝑦 𝑡𝑜𝑑𝑎𝑦! 💨🔧

📢 Say NO to airborne dust - Protect your health & workspace!

📧 [email protected] | 🌐 www.fumido.in

0 notes

Text

Harness the power of centrifugal force! Our centrifugal blowers for dust collection efficiently remove airborne particles, keeping your work operations safe and healthy.

🌐 www.yashblower.com ☎️ +91 9971006400

#yashblowers#centrifugalblower#AirBlower#dustcollection#airflow#industrialapplications#manufacturer#efficiency#EngineeringExcellence#mechanicalengineering

0 notes

Text

.V. Engineers: Your Partner for Top-Quality Extractor Fans and Blowers in South India

S.V. Engineers, a leading company in South India, is proud to offer a comprehensive range of extractor fans and blowers with exceptional technical specifications. We cater to all your ventilation needs, ensuring optimal airflow in various industrial and commercial settings.

Technical Details of Our Extractor Fans and Blowers:

Wide Variety: We offer a vast selection of extractor fans and blowers to suit diverse applications. Our range includes:

Centrifugal Blowers: High-pressure blowers ideal for dust collection, fume extraction, and material handling.

Axial Flow Fans: Efficient fans for general ventilation and air circulation.

Inline Fans: Compact and versatile fans perfect for ductwork installations.

Roof Extractor Fans: Powerful fans designed for removing heat, smoke, and fumes from buildings.

Durable Construction: Our extractor fans and blowers are manufactured using top-notch materials, ensuring long-lasting performance and resistance to harsh environments.

High Performance: Our products deliver exceptional airflow capacities and efficient operation, guaranteeing optimal ventilation results.

Quiet Operation: We understand the importance of noise reduction. Many of our extractor fans and blowers operate at low noise levels, creating a comfortable working environment.

Energy Efficiency: We offer energy-efficient models that help you save on electricity costs while maintaining optimal ventilation.

Sales and Service Expertise:

At S.V. Engineers, we go beyond just providing top-quality products. Our team of experienced professionals is dedicated to offering exceptional sales and service support throughout South India.

Expert Consultation: Our team can assist you in selecting the most suitable extractor fan or blower for your specific needs and application.

Prompt Delivery: We ensure timely delivery of your chosen extractor fans and blowers to your desired location.

Reliable Service: Our skilled technicians are available to provide after-sales support and ensure the smooth functioning of your equipment.

Visit Our Website for More Information:

For a detailed look at our comprehensive range of extractor fans and blowers, comprehensive technical specifications, and inquiries about sales or service in South India, please visit our website:

www.svblowers.in

Contact S.V. Engineers Today!

Let S.V. Engineers be your trusted partner for all your extractor fan and blower requirements. Contact us today and experience the difference of exceptional quality, unmatched expertise, and reliable service.

Velappar Nagar, Thiruverkadu, Chennai, Tamil Nadu, India

#ventilation#extractorfan#blower#industrialventilation#commercialventilation#ventilationequipment#airflow#airquality#dustcollection#fumeextraction

0 notes

Text

Best Bag Filter Systems Manufacturer in Maharashtra, India | Ph Engicon | 093706 85147

Best Bag Filter Systems Manufacturer in Maharashtra, India. Our advanced systems ensure a cleaner, safer work environment, enhancing productivity and compliance.Heavy Fabrication.

#phengicon#maharashtramanufacturing#industrialequipment#cleanairsolutions#engineeringexcellence#heavyfabrication#bag filter systems#industrialfiltration#manufacturer in maharashtra#india#AirFiltration#IndustrialAirQuality#PollutionControl#MaharashtraManufacturers#DustCollection#AirPollutionControl#FiltrationExperts#CleanAirTech#EngineeringSolutions#IndustrialEquipment

1 note

·

View note

Text

https://qr.ae/psmVYF

#BlastRoomSystem#SurfacePreparation#IndustrialEquipment#AbrasiveBlasting#Manufacturing#Efficiency#Automation#SafetyFirst#QualityFinishing#WorkplaceSafety#EquipmentDesign#DustCollection#PaintRemoval#MetalSurface#BlastingTechnology#IndustrialSolutions#MachineMaintenance#ProductionProcesses#EngineeringDesign#PerformanceEnhancement

0 notes

Text

Premier Bag Filter Manufacturer in India

Explore the top bag filter manufacturer in India, specializing in high-quality air filtration solutions for industrial applications. Our durable and efficient bag filters are designed to capture and remove dust and particulate matter, ensuring a cleaner and safer working environment. With a commitment to innovation and customer satisfaction, our bag filters offer exceptional performance and reliability. Discover our wide range of bag filters and enhance your air quality today!

#BagFilterManufacturer#AhmedabadFilterCompany#BagFiltersIndia#IndustrialFiltration#DustCollection#AirFiltration#FiltrationSolutions#FilterManufacturers#BagFilterSystem#AirQualityControl#IndustrialFilters#AhmedabadManufacturers#FilterProduction#PollutionControl#IndustrialHygiene#FiltrationTechnology#AirPurification#DustControl#BagFilterTechnology#CleanAirSolutions#FiltrationSystems#PollutionManagement#IndustrialAirQuality#FilterEngineering#AhmedabadIndustry#FilterExperts#AirPollutionControl#BagFilterSuppliers#IndustrialDustControl#FilterDesign

0 notes

Text

Dust collection system | Intelligent Edge

The Intelligent Edge Dust Collection System is a state-of-the-art solution designed to efficiently capture and manage airborne dust in industrial and commercial settings. Utilizing advanced filtration technology, this system ensures a cleaner and healthier work environment by effectively trapping dust particles at the source. With smart monitoring features, the Intelligent Edge system optimizes performance, reducing maintenance needs and operational downtime. Its robust and scalable design caters to various applications, from small workshops to large manufacturing facilities. Easy to install and operate, the Intelligent Edge Dust Collection System represents a significant advancement in workplace safety and air quality management.

1 note

·

View note

Text

Choosing The Right Benchtop Planer For Specific Woodworking Requirements

Are you looking for expert advice on the best benchtop planer for your specific woodworking needs? You've come to the right place. With so many types and models of planers available, it can be difficult to know where to start when making a purchase. In this article, we'll discuss some key factors that experts recommend considering when buying a benchtop planer, including: - Type of woodwork - Motor size - Number of knives - Ease of adjustment - Dust collection system - Portability - Safety features - Manufacturer's reputation Armed with this knowledge, you can make an informed decision about which planer is best suited for your project. So read on and get ready to make an educated purchase!

Key Takeaways

- Factors to consider when buying a benchtop planer include the type of woodwork, motor size, number of knives, ease of adjustment, dust collection system, portability, safety features, and manufacturer's reputation. - Evaluating needs is essential for choosing the right planer, taking into account factors such as type of woodwork, power, accuracy, and consistency. - Motor size should be chosen based on the bed width of the planer. - The number of knives affects the cutting quality of the planer.

Evaluate Your Needs

Evaluating your needs is essential if you want to ensure you get the perfect benchtop planer for your woodworking projects! When choosing a planer, it's important to consider the type of material you'll be working with and how often you'll need to sharpen the blades. Different woods require different types of blades, so selecting one that fits your material selection and blade sharpening needs is key. Also, consider whether or not the planer will need to handle harder woods like maple or walnut. If so, then look for a model that can accommodate them. Ultimately, by assessing your needs first, you can find the right benchtop planer for your specific project requirements. With this information in hand, you're ready to move on to researching other features and prices.

Consider the Type of Woodwork

When considering the type of woodwork you plan to do, think about how much power and material capacity you'll need from a planner. Roughing speed, noise level, accuracy, and consistency are key factors that should be taken into account. Here's a quick breakdown: - Roughing Speed – Look for a planer with a higher cutterhead speed for faster stock removal. - Noise Level – Consider the decibel rating of the machine when choosing one with lower sound levels. - Accuracy – Make sure your model has accurate depth adjustment settings for precise results on each project. - Consistency – A good benchtop planer will maintain consistent performance over time without compromising quality or safety. Whatever type of woodworking project you're looking to tackle, understanding what kind of planner is best suited for it can help ensure great results every time! Now let's move on to choosing the appropriate motor size...

Choose the Appropriate Motor Size

Choosing the right motor size for your project is essential to getting the desired results. The larger the bed width of your benchtop planer, the more powerful motor you'll need. A 12-inch bed width requires a minimum of 1 horsepower motor, while a 13-inch width requires at least 1.5 horsepower. Additionally, if you plan on using chip collection systems with your planer, you'll need an even more powerful motor - up to 3 horsepower is recommended in this case. Keep in mind that more powerful motors can be louder and can generate greater amounts of dust. Therefore, it's important to select an appropriately sized motor for all your woodworking needs.

Consider the Number of Knives

Carefully consider the number of knives your benchtop planer has - it's an important decision that could make all the difference in your project's success! The quality and sharpness of the blades will determine how well they cut, so look for a model with at least two knives: - For heavier cuts, more knives may be necessary. - A three-knife setup yields a smoother finish. - Having four or more knives is best for professional use. A single knife blade can cause tear out on some wood, leaving an uneven surface and compromising the quality of your work. Make sure to check knife quality and sharpness before purchase to ensure you get a smooth finish every time. Ease of adjustment is the next factor to consider when selecting a benchtop planer.

Look for Ease of Adjustment

Ease of adjustment is essential for successful woodworking - don't overlook it when selecting your planner! When looking at the power requirements, blade sharpening, and chip disposal capabilities, make sure to check that they're adjustable. This will allow you to customize your planer according to different types of wood and thicknesses and get better results. Adjustments should be easy to understand and apply without requiring too many tools or time. Moreover, ensure that the blades can be easily removed for sharpening or replacement. Finally, a good quality planer should offer adequate chip disposal options such as a dust collector connection or an integrated enclosure with minimal effort required. All in all, ease of adjustment is key when it comes to choosing the right benchtop planer for your needs; determine what works best for you before making your final decision!

Determine the Table Size

Consider the size of the table when selecting your planer - it will determine how much wood can be handled at once. Table size is important for two primary reasons: blade depth and stock thickness. Blade depth indicates how deep into the wood a cut can go, which affects the quality of the final product. A shallow blade depth requires multiple passes to get desired results, while a deeper blade allows for fewer passes but more powerful cuts. Stock thickness determines what type of material you can plane, from thin veneers to thick boards. Blade Depth Stock Thickness Shallow Thin Veneers Deep Thick Boards Choosing the right table size should take both factors into account; this way you can avoid making too many passes with shallow blades or overworking your machine with thicker boards than it was designed for. Moving on to consider dust collection systems is also an important factor in buying a benchtop planer that fits your needs.

Consider the Dust Collection System

Now that you've determined the table size for your benchtop planer, it's time to investigate the dust collection system. Investigate noise levels and compare brands - these are important considerations when choosing a planer. A high-quality dust collection system is essential, as dust can be hazardous to both your health and your woodworking projects. Make sure to look for one with a powerful motor and strong suction capabilities. If possible, try out different machines in person so you can get an idea of how noisy they are - that'll help you decide which one best meets your needs. Finally, when making your decision, consider the ease of maintenance and availability of replacement parts for the dust collection system; this could save you money in the long run! With all these factors in mind, you're ready to move on to considering portability.

Consider Portability

When selecting a benchtop planer, portability should be taken into account. Portability Benefits are an attractive option for those who need to move their tools around often, such as woodworking professionals or hobbyists who need multiple workshops. Investing in a benchtop planer with wheels and folding handles can make it easier to transport the device from one site to another. However, weight tradeoffs must also be considered; lightweight models may not offer the same level of performance when compared with heavier models. If portability is a priority, look for features like anti-vibration technology that'll help reduce noise and minimize movement while working. Be sure to balance the benefits of mobility against any potential drawbacks before making your purchase decision.

Check for Safety Features

It's essential to ensure that the benchtop planer you're looking at has safety features such as a guard to protect your hands from the blades and an emergency stop switch. Aside from these, here are 4 more safety features you should look for: - Noise reduction - Make sure the motor is quiet and won't annoy or disturb your neighbors. - Chip disposal - Look for a dust chute or bag that allows you to easily dispose of wood chips without making a mess. - Anti-kickback device - This important feature prevents boards from kicking back while being planned, ensuring your safety and accuracy of results. - Blade guard - A blade guard can help keep shavings away from your fingers, protecting them from harm when using the tool. No matter what type of benchtop planer you choose, it's important to research the manufacturer's reputation in terms of providing safe products with reliable customer service before making any purchase decisions.

Research the Manufacturer's Reputation

Do your homework and look into the manufacturer's reputation before deciding on a benchtop planer; it's essential to know you're getting a safe product with reliable customer service. Research online for reviews, reliability ratings, price points, and other factors to make sure the brand is reputable. If you can't find any information about them, take that as a warning sign and keep looking elsewhere. Also, check out their website for more details about their products, warranties, or after-sales support. By doing this research, you'll ensure you get a quality product from a reliable source that meets your woodworking needs. Ask around in woodworking forums or chatrooms if anyone has experience with the company's tools - they can provide valuable insight into how well they stand up over time. With these steps taken, you'll be able to buy the best benchtop planer for your specific needs with confidence!

Frequently Asked Questions

How much does a benchtop planer cost? Comparing prices is important when buying a benchtop planer. Safety should also be considered, as cheaper tools can increase the risk of injury. Prices vary, so shop around to get the best deal for your tool! How often should I sharpen the blades of my benchtop planer? You should hone your planer blades regularly, as per the manufacturer's instructions. Select blades that are suitable for your woodworking needs and ensure they are sharpened with the correct honing techniques. Are there any accessories I should consider purchasing with my benchtop planer? When buying a benchtop planer, consider purchasing precision blades and a dust collection system. This will help ensure the best results and make your woodworking projects easier to complete. How difficult is it to store and transport a benchtop planer? Storing and transporting your benchtop planer is easy - it's lightweight and space-saving. Its portability makes it a great choice for woodworkers on the go. What is the best way to clean and maintain a benchtop planer? To keep your benchtop planer in top condition, it's important to sharpen the blades regularly and use dust collection. Make sure to clean thoroughly after each use for best results.

Conclusion

You've done your research and considered all the important factors, and now you're ready to purchase the best benchtop planer for your needs. With so many options available, it can be difficult to choose one that will provide quality results. However, by evaluating your needs and considering the type of woodwork you want to do, choosing an appropriate motor size and number of knives, looking for ease of adjustment and a good dust collection system, as well as considering portability and safety features—all while researching the manufacturer's reputation—you can find a planer that will help you make beautiful woodworking projects with ease. Read the full article

#benchtopplaner#buyingguide#dustcollection#motorsize#numberofknives#safetyfeatures#woodworking#woodworkingtools

0 notes

Text

decorate my tree :)

thanks @angel-daydreams for the idea!! this is so cute

no pressure but would love for yall to help me decorate for the holidays <3

@velanavis @poetskings @drowninkystar @always-reading @playthatfunkymuzic @dustcollect @levelofyoureye @weasleytriplets @moutainrusing @my-castles-crumbling @stareggie @starslovechasers @sixlane @ecstarry @staringathesunbabe @quiethauntings @shamelesswolfstarshipper @arakhnee @aurorboros @ixekizumab (adding more people lol)

and even if I missed you but you still wanna join the festivities, please feel free !!! ✨🫶🏼

15 notes

·

View notes

Text

I’m going to tag some peeps but literally don’t feel pressured to respond unless you want to <3 (and you can send an ask if you do)

@velanavis @poetskings @always-reading @drowninkystar @weasleytriplets @sixlane @ecstarry @playthatfunkymuzic @dustcollect

(and reblog so I can send you one too if you want 😊)

7K notes

·

View notes

Text

Dust Collection Systems are essential for improving air quality and safety in African industries! 🌍💨 By controlling dust emissions, they enhance worker health, reduce equipment damage, and boost efficiency. A cleaner, safer workplace starts here!

Read more at - https://www.acmeairequipments.com/the-role-of-dust-collection-systems-in-african-industries/

0 notes

Text

I've been looking for this setup for a long time. Found it on marketplace for $100! Score!

#blastingcabinet #sandblaster #beadblaster #dustcollection @harborfreight #harborfreight #bauer #shoptools #garagetools #offroadendeavor #endeavor #doing

0 notes

Photo

DUST #dust #manurios #tequiero #elite #patrick #dustcollection https://www.instagram.com/p/CnJrgrmjV6U/?igshid=NGJjMDIxMWI=

10 notes

·

View notes

Text

https://surfaceinternational.blogspot.com/2024/06/maintaining-blast-room-systems-ensuring.html

#BlastRoomSystem#SurfacePreparation#IndustrialEquipment#AbrasiveBlasting#Manufacturing#Efficiency#Automation#SafetyFirst#QualityFinishing#WorkplaceSafety#EquipmentDesign#DustCollection#PaintRemoval#MetalSurface#BlastingTechnology#IndustrialSolutions#MachineMaintenance#ProductionProcesses#EngineeringDesign#PerformanceEnhancement

0 notes