#double regulating valves

Explore tagged Tumblr posts

Text

Flocontrol

FloControl offers a comprehensive range of valves, pipeline products, and highly engineered pre-assembled system solutions for fluid handling applications within the UK building services industry.

#butterfly valve#double regulating valves#drv valve#double regulating valve#picv valve for ahu#butterfly valves#fcu valve package#picv valve package

0 notes

Photo

FloControl offers the most comprehensive range of Double Regulating Valves, also known as Variable Orifice Double Regulating Valve or DRV Valve, to introduce a pre-set system resistance whilst offering the opportunity to isolate and return to the pre-set position. Traditional Globe Valve style Double Regulating Valves threaded from ½” – 2” and flanged 50mm – 600mm. Butterfly Valve style 65mm – 600mm Double Regulating Valve for applications with space limitations and cost effectiveness. Product Information: • WRAS-approved PN25 Variable Orifice Double Regulating Valve • Design in accordance to BS 7350 • Temperature range: -10°C to 130°C • Bronze Construction • ABS Hand-wheel operated • Numerical indicator • Characterised regulating disk • Supplied with two blank plugs as standard • Sizes: 1/2” – 2” with threaded end connections

0 notes

Text

The W-43 Saga: Oldsmobile’s Experimental 32-Valve 455 V8

Oldsmobile’s experimental W-43 engine is surrounded in myth, legend, and a tall tale or two. Let’s see if we can sort it all out.

Here at Mac’s Motor City Garage, we’re grateful to the World Wide Web for rediscovering so many wonderful stories in automotive history and bringing them to public attention. Still, we have to note that that often, the info isn’t always totally accurate—which is only natural, we suppose. After all, the internet could be described as the biggest and longest game of Telephone in history.

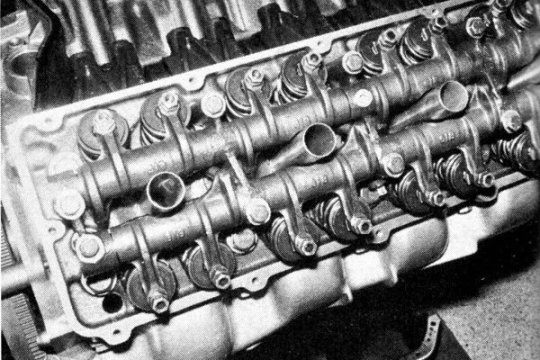

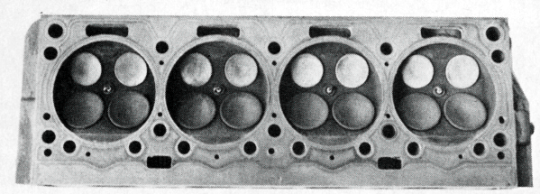

Take this fascinating engine, for instance: the Oldsmobile W-43, an experimental V8 developed in 1967-69. Various sources have described this engine as a hemi (it isn’t) or a Can-Am engine (that was never its purpose) or a double overhead-cam design (nope). In truth, the W-43 was a conventional overhead-valve, pushrod V8, in the classic Motor City style, but with special cylinder heads and valvetrain that provided four valves per cylinder.

To the average car enthusiast, a four-valve head with pushrod operation—that is, each rocker arm and pushrod operating a pair of valves—may seem like an outlandish setup, but in the diesel truck world it’s fairly commonplace (Cummins and Detroit, to name two). It looks cumbersome but it works just fine, especially where high engine speeds are not required.

The W-43 was indeed based on a standard 455 CID production block, but with some key modifications, including four-bolt main caps and special valve follower retainers that bolted into the lifter valley. The spark plugs were buried in tubes in the center of the valve covers, which no doubt fed the stories that the engine was a hemi. Bore, stroke, and other significant specs were identical to the production 455 CID V8. There was also an aluminum-block variant of the W-43 designated the OW-43, and the program eventually produced an experimental four-cam, 32-valve V8 based on the production engine’s architecture.

With four valves per cylinder, the combustion chambers of the W-43 were not hemispherical but rather a classic pentroof layout, utilizing shallow valve angles in the Cosworth style. Intake valves were 1.75 inches in diameter and 1.375 inches on the exhaust, providing 43 percent more intake valve area than the production 455 two-valve heads. According to a feature in the May 1971 issue of Hot Rod magazine, the W-43 was good for 440 horsepower at 4600 rpm in a relatively mild state of tune. And given the improved volumetric efficiency enabled by the far greater valve area, that figure seems downright conservative.

Reportedly, the W-43 V8 was at one point considered as an across the board replacement for the standard two-valve 455 CID V8, but as we know, that never happened. Various theories have been proposed to explain why, including stricter emissions regulations and corporate infighting with the far more powerful Chevrolet division at General Motors. But as we see it, the four-valve version’s considerably greater size, weight, and manufacturing cost would have been more than sufficient to kill the program. At least two W-43 prototype engines still exist, one of them incomplete, but their current whereabouts are unclear.

43 notes

·

View notes

Text

The Getty Villa, the museum built by oil tycoon J. Paul Getty and home to thousands of priceless antiquities, activated its emergency operations center in response to the fast-moving Palisades fire at 10:40 a.m. Tuesday. At 11:44 a.m., fire could be seen over the ridge, less than one mile away. By 12:27, flames had reached the property.

Fast-moving, wildly unpredictable and catastrophic in the damage it caused along a vast swath of prime coastline, the Palisades fire ultimately spared the Villa and its more than 44,000 objects, including many Roman, Greek and Etruscan relics dating from 6500 BC to AD 400.

J. Paul Getty Trust President and Chief Executive Katherine E. Fleming described for The Times the scene on the ground and how she and her staff worked from a conference center-turned-war room at the Getty Center in Brentwood, about 10 miles away — all while 16 staff members remained at the Villa to implement emergency protocols.

“We did get lucky in some ways, and people were rushing around,” Fleming said in an interview Wednesday evening after the most immediate danger had passed. “But there were also a lot of people who were really thoughtful about this over a long period of time, and I think that clearly paid off for us.”

Extensive brush-clearing over the last year, Fleming said, had been completed with the knowledge that fire is a way of life in Los Angeles, and that the region’s frequent periods of drought made a massively destructive fire inevitable. The museum had already pruned landscaping that might catch fire and made sure tree canopies were high off the ground. Low-lying brush had been significantly thinned. The grounds were irrigated Tuesday morning.

Fleming offered a riveting play-by-play of the day’s events. The staff members who remained at the Villa worked in emergency response, facilities, security and communications — each highly trained in emergency preparations. When the fire broke out, the biggest concern was protecting the collections from the damaging effects of smoke. The double-walled construction of the galleries provided significant protection, and at 10:45 a.m., the dampers — small valves that regulate airflow in a building’s HVAC system — were turned off, as was the air conditioning. The staff still smelled smoke, so the museum doors were sealed at 11:04 a.m. The smoke became overwhelming by 11:15, and at 11:20 the staff was sent an email alerting them that the Villa was closing.

About 20 minutes later, security swept the grounds to make sure only emergency staff was on site. Heat from the fire caused several cameras to fail to reboot. Ten minutes later, an aerial fire crew dropped water over the Villa’s ranch house, which Fleming said is at the perimeter of the property and most vulnerable to fire. (The ranch house was J. Paul Getty’s original residence and was not built with the same fire-resistant construction as the Villa.)

Fleming noted that communication between the two sites was difficult. Villa employees’ radios stopped transmitting when they were more than 100 feet away from one another. That meant staff in the Getty command center in Brentwood — about 15 people in total, sitting at a large conference table — had to relay pertinent information to each staffer at the Villa.

“We have cameras on pretty much every single conceivable part of the Villa property that you can zoom in with great specificity,” Fleming said. “There were instances where we would know something and have to relay it back to someone at the Villa.”

Over the course of the day and night, Fleming said, “we had all kinds of live video feed coming to us up at the Getty Center from the Villa.” When accumulating ash prevented the water from draining in the parking structure, a staff member was deployed to clear it.

At around 2:40 p.m., Fleming said, the perimeter wall behind the restaurant was in flames. Then, at close to 3:15 p.m., bushes directly above the outdoor classical theater caught fire. This was probably Fleming’s biggest moment of panic during the whole ordeal, she said, adding that it was “a total red herring.”

The fire came from a plant bed filled with rosemary.

“And lo and behold, just like if you sprinkle a bunch of rosemary on a pizza and put it under the broiler and it crackles and sparkles, and then very rapidly goes out,” Fleming said. “That happens ... and for someone like me, who doesn’t know a lot about how fires work, it looked really bright and fiery for a few moments.”

The wall flames died down on their own, but at 3:59 p.m., fire erupted at the museum’s pedestrian gate. Getty security put out the blaze with fire extinguishers in just six minutes. The Palisades fire grew large enough for staff at the Getty Center in Brentwood to see the flames by 5 p.m. At 6 p.m., museum officials made the decision to close that campus to help alleviate traffic in the area.

People on social media and news sites may have seen images of flames whipping next to a structure by the Getty Villa sign on Pacific Coast Highway. That structure was not the museum but rather Villa de Leon, a 35-room Italian Revival mansion that’s not affiliated with the museum.

Villa teams continued to monitor the fire threat throughout the night, and for now the Villa appears to be safe.

“A lot of what there was to burn has burned. The rosemary is gone. The low-level vegetation is gone,” said Fleming, who added that she was too superstitious to say the danger had completely passed.

#getty villa#la fires#palisades fire#los angeles#museums#ancient rome#my stuff#if you know how close that theater is to the main galleries it's like...😬

10 notes

·

View notes

Text

Inside the dash to save the Getty Villa from the Palisades fire: a timeline

"The Getty Villa, the museum built by oil tycoon J. Paul Getty and home to thousands of priceless antiquities, activated its emergency operations center in response to the fast-moving Palisades fire at 10:40 a.m. Tuesday. At 11:44 a.m., fire could be seen over the ridge, less than one mile away. By 12:27, flames had reached the property.

Fast-moving, wildly unpredictable and catastrophic in the damage it caused along a vast swath of prime coastline, the Palisades fire ultimately spared the Villa and its more than 44,000 objects, including many Roman, Greek and Etruscan relics dating from 6500 BC to AD 400.

J. Paul Getty Trust President and Chief Executive Katherine E. Fleming described for The Times the scene on the ground and how she and her staff worked from a conference center-turned-war room at the Getty Center in Brentwood, about 10 miles away — all while 16 staff members remained at the Villa to implement emergency protocols...

...Fleming offered a riveting play-by-play of the day’s events. The staff members who remained at the Villa worked in emergency response, facilities, security and communications — each highly trained in emergency preparations. When the fire broke out, the biggest concern was protecting the collections from the damaging effects of smoke. The double-walled construction of the galleries provided significant protection, and at 10:45 a.m., the dampers — small valves that regulate airflow in a building’s HVAC system — were turned off, as was the air conditioning. The staff still smelled smoke, so the museum doors were sealed at 11:04 a.m. The smoke became overwhelming by 11:15, and at 11:20 the staff was sent an email alerting them that the Villa was closing..." Keep Reading

#this article is so nerve-wracking and awesome#a wonderful example of a great emergency action plan and response too#even landscaping to help mitigate the spread of fire! preventive conservation at its finest 😤#museums#the getty villa#los angeles#california#news#history#anthropology#archaeology#art#culture#california wildfires

6 notes

·

View notes

Text

transforming soffits reorganizing keys formalizing immersion joints justifying kick extractors advising aggregates managing elbows recasting connectors achieving aluminum trowels officiating disks exhibiting absolute spigots progressing coil hydrants jerry-building reflectors informing casters inventing rubber hoists performing wrenches judging chalk adapters upgrading ignition paths

regrowing flashing recommending ratchets approving barriers sweeping impact fillers sewing mirrors detailing collectors enforcing measures distributing systems presenting plugs interwinding registers piloting ash diffusers gathering cranks supplying eave pockets undertaking scroll stops accelerating straps designing fittings protecting diamond boilers logging downspouts correlating shingles uniting mallets qualifying electrostatic lifts sharing clamps obtaining circular fluids ranking foundation gauges sensing miter brackets originating space networks translating drills regulating guards selecting gable padding utilizing pellet dowels reconciling artifacts altering pulleys shedding space filters determining vents representing mortar remaking flash rakers supporting funnels typecasting rotary chocks expressing junctures resetting auxiliary vises professing strip treads inlaying matter trowels questioning drivers forming edge fittings sketching blanks overshooting spark breakers rewriting controls playing tunnels inventorying buttons enduring joint handles effecting ratchet bibbs unwinding couplings forsaking vapor conduits defining sockets calculating heaters raising grids administering tiles measuring resources installing ignition remotes extracting corners manufacturing ventilators delegating consoles treating mounting stones enacting jig deflectors intensifying alleys improvising cargo pinpointing bobs prescribing arc masonry structuring metal chucks symbolizing lathes activating plumb kits adapting coatings fixing channels expediting cordage planning compressors enlisting hangers restructuring keyhole augers shearing ridge hardware collecting reciprocating bolts maintaining corrugated dimmers whetting hole collars conducting mandrels comparing assets compiling sealants completing paths composing equivocation wheels computing dampers conceiving electrostatic treatment ordering cotter grates organizing ties orienting ladders exceeding materials targeting thermocouples demonstrating emery stock expanding latch bases training wardrobe adhesives overcomming[sic] fasteners streamlining storm anchors navigating springs perfecting turnbuckles verifying gate pegs arbitrating arithmetic lifts negotiating outlets normalizing strips building surface foggers checking key torches knitting grinders mowing planers offsetting stencils acquiring bulbs adopting rivets observing avenues ascertaining coaxial grommets slinging wing winches instituting circuit generators instructing wicks integrating pry shutters interpreting immersion lumber clarifying coils classifying wood bits closing cogs cataloging matter strips charting holders conceptualizing push terminals stimulating supports overthrowing shaft spacers quick-freezing connectors unbinding ground hooks analyzing eyes anticipating gateways controlling proposition rollers converting power angles coordinating staples correcting benders counseling joist gaskets recording gutter pipes recruiting drains rehabilitating rafter tubes reinforcing washers reporting guard valves naming freize sprues nominating rings noting straps doubling nailers drafting circuit hoses dramatizing flanges splitting framing compounds refitting stems interweaving patch unions placing sillcocks sorting slot threads securing mode cutters diverting catharsis plates procuring load thresholds transferring syllogism twine directing switch nuts referring time spools diagnosing knobs discovering locks dispensing hinges displaying hasps resending arc binders retreading grooves retrofitting aesthetics portals seeking stocks shrinking wormholes assembling blocks assessing divers attaining lug boxes auditing nescience passages conserving strikes constructing braces contracting saw catches serving installation irons recognizing fluxes consolidating fuse calipers mapping shims reviewing chop groovers scheduling lag drives simplifying hoists engineering levels enhancing tack hollows establishing finishing blocks

21 notes

·

View notes

Text

Hydration on the Go: Tumblers with Straws for Fitness Enthusiasts

Hydration on the Go: Tumblers with Straws for Fitness Enthusiasts

Introduction

Staying hydrated is crucial for fitness success, and the right tumbler can make all the difference in your workout routine. Our premium gym tumbler with straw is designed to be the ultimate companion for athletes, gym-goers, and health-conscious individuals who demand peak performance and convenience.

Why Hydration Matters in Fitness

Proper hydration is essential for: - Maintaining optimal physical performance - Regulating body temperature - Supporting muscle function - Enhancing recovery - Preventing fatigue and improving endurance

Tumbler Specifications: Your Ultimate Hydration Companion

Technical Details - Capacity: 24 oz / 710 ml - Material: 18/8 Food-grade Stainless Steel - Insulation Type: Double-wall vacuum insulation - Temperature Retention: — Hot beverages: Up to 12 hours — Cold beverages: Up to 24 hours - Straw Material: BPA-free silicone - Lid Type: Leak-proof twist lid with quick-access straw - External Finish: Powder-coated for enhanced grip - Weight: 12.5 oz (355 grams) - Dimensions: — Height: 9.5 inches — Diameter: 3.2 inches - Color Options: — Matte Black — Steel Silver — Gym Blue — Crimson Red

Key Performance Features

1. Advanced Insulation Technology — Keeps drinks cold for 24 hours — Maintains hot beverages for 12 hours — No condensation on exterior

2. Ergonomic Design — Slim profile fits most car cup holders — Non-slip base — Comfortable grip coating

3. Straw Innovations — Removable silicone straw — Easy to clean — Flexible and durable — Bite-valve technology prevents leaks

Frequently Asked Questions (FAQs)

1. Is the tumbler dishwasher safe? Yes, both the tumbler body and lid are dishwasher safe. However, we recommend hand washing the silicone straw for optimal longevity.

2. Can I use this tumbler for both hot and cold beverages? Absolutely! The double-wall vacuum insulation is designed to maintain temperature for both hot coffee and ice-cold water, making it versatile for any drink.

3. How do I clean the straw? We include a specialized cleaning brush with each tumbler. For thorough cleaning, disassemble the straw and wash with mild soap and water, or use the provided brush to remove any residue.

4. Is the straw removable? Yes, the silicone straw can be easily removed for cleaning or replacement, ensuring maximum hygiene and convenience.

5. Will the tumbler fit in standard gym bag water bottle pockets? Our tumbler is designed with a slim profile to fit most standard gym bag water bottle compartments and car cup holders.

6. Is the exterior coating durable? The powder-coated finish is scratch-resistant and designed to withstand daily use in gym environments, providing both protection and style.

7. Does the tumbler come with a warranty? We offer a comprehensive 2-year warranty against manufacturing defects, demonstrating our confidence in product quality.

8. Can I customize the tumbler? We offer laser engraving services for personalization. Contact our customer service for custom order details.

9. Is the tumbler leak-proof? The twist lid with specialized sealing technology prevents leaks, making it perfect for gym bags, backpacks, and active lifestyles.

10. What makes this tumbler different from other gym water bottles? Our tumbler combines superior insulation, ergonomic design, innovative straw technology, and durability — specifically engineered for fitness enthusiasts.

Hydration Tips for Fitness Enthusiasts

- Drink water before, during, and after workouts - Calculate your personal hydration needs based on workout intensity - Use markings on the tumbler to track daily water intake - Clean your tumbler regularly to maintain hygiene

Conclusion

More than just a water bottle, our tumbler is a comprehensive hydration solution for serious fitness enthusiasts. Engineered with precision, designed for performance.

Hydrate Smarter. Train Harder.

Order Now and Transform Your Fitness Hydration!

#20 oz skinny tumbler#Stainless steel tumbler#Insulated straw tumbler#Double-wall tumbler#Vacuum insulated tumbler

2 notes

·

View notes

Text

Do you recall when America was energy independent? One must only think back a few short years before Joe Biden entered the White House and suppressed the nation’s ability to generate energy in the name of climate change. There were increased regulatory burdens, halts on new oil and gas leases, and a shift to funding renewables, but perhaps the deepest stab occurred when Biden terminated the Keystone XL Pipeline project that would have transported 830,000 barrels of crude daily from Alberta to Nebraska. Trump returning to the White House means that the project is back on the table.

Donald Trump has been pushing for Keystone since his first presidential bid in 2016. He took executive action in January 2017 by signing an executive order to invite TC Energy (previously TransCanada) to apply for a permit. The State Department issued a Record of Decision to approve the project in March 2017. Then in 2018, a US District Court judge prevented the pipeline due to “inadequate environmental reviews.” Obama had rejected the pipeline in 2015 under the premise of climate concerns, and this entire project became politically weaponized.

Still, Trump attempted to expedite the pipeline by repealing some regulations implemented by the National Environmental Policy Act (NEPA) in January 2020. Biden revoked all permits one year later.

Even Build Back Better poster boy Trudeau was “disappointed” by Biden’s actions. “No country would find 173 billion barrels of oil in the ground and just leave them there. The resource will be developed. Our job is to ensure that this is done responsibly, safely and sustainably,” Trudeau said back in 2017. In Canada, 1,000 workers were laid off by TC Energy when the project ceased. The Keystone XL pipeline was expected to contribute $2.4 billion to Canada’s GDP. Additionally, the project would have generated around $30 billion in tax and royalties over its lifetime.

Two years after Biden nuked the project, his own administration released a damaging report that highlighted the missed economic opportunities. The Department of Energy (DOE) claimed that Keystone XL could have created up to 59,000 new jobs and generation up to $9.6 billion. Americans watched as the price of gas doubled in one year. Yet, the US government and others simply blamed Russia especially after the Nord Stream pipelines to Europe were sabotaged in September 2022.

Trump may be able to prioritize the project, but it will not be as simple as turning on a valve. The original permits have been revoked and must be restored. TC Energy already begun disassembling portions of the pipeline and the company would need a large incentive to revive the deal. The climate zealots cling to the notion that renewable energy can completely replace fossil fuels and they will not relent. Every major action that Trump attempts will be met with extreme pushback.

3 notes

·

View notes

Text

Control valve supplier in Dubai

UAE Valves is one of the top Control Valve Supplier in Dubai. A control valve is a mechanical device used in various industrial processes to regulate the flow of fluids, such as gas, steam, or liquid, through a pipeline or duct. It achieves this regulation by adjusting the size of the flow passage according to signals received from a controller.

Control valves are crucial components in systems requiring precise control of flow rate, pressure, temperature, or liquid level. They are widely used in industries such as oil and gas, chemical processing, power generation, and water treatment.

Working Principle:

The working principle of a control valve is straightforward. In an industrial setting, a control valve adjusts the size of an opening to control the flow of fluid through a pipeline. When the valve is fully open, it allows maximum flow, and when fully closed, it stops the flow completely. Between these extremes, the valve can be precisely adjusted to allow a specific amount of fluid to pass through.

This adjustment is typically performed automatically based on signals from a controller, which monitors conditions such as pressure, temperature, or flow rate. Essentially, a control valve acts like a gatekeeper, regulating the flow of fluid to meet the system's requirements.

Parts of a Control Valve:

Valve Body: The main structure that contains the fluid and through which the fluid flows.

Actuator: A device that moves or controls the valve's mechanism, often powered by air, electricity, or hydraulic fluid.

Closure Element: The component that makes contact with the seat to restrict or allow flow.

Trim: Internal components such as the plug, seat, and stem that modulate the flow.

Seat: A surface against which the closure element seals to stop flow.

Positioner: A device that adjusts the valve actuator's position based on control signals.

Bonnet: The top part of the valve body that houses the stem and provides a seal.

Yoke: A support structure that holds the actuator in place and connects it to the valve body.

Stem: A rod that connects the actuator to the closure element and transmits motion.

Packing: Material that provides a seal around the stem to prevent fluid leakage.

Advantages:

Precisely controls the amount of fluid passing through a system.

Maintains the desired pressure levels within the system.

Helps maintain a stable temperature by regulating fluid flow.

Reduces energy consumption by optimizing fluid flow.

Enhances system performance by maintaining consistent operating conditions.

Prevents system overpressure and potential hazards.

Easily adjustable for various operating conditions.

Allows for control from a distance and integration into automated systems.

Designed for durability and ease of maintenance.

Ensures consistent production quality by maintaining optimal conditions.

Meets industry standards and regulatory requirements.

Industries Using Control Valves:

Control valves are used across numerous industries, including nuclear power, oil and gas, power generation, manufacturing and process industries, automotive, aerospace, mining and minerals processing, water treatment and distribution, pulp and paper, refining, marine, renewable energy, chemical and petrochemical, and steel and metal processing. These valves play a critical role in ensuring operational efficiency, safety, and compliance within these diverse sectors.

Types of Control Valves:

Three-way control valve

Cage type control valve

Double seat control valve

O type shutoff control valve

Single seat control valve

Water control valve

Globe control valve

Angle type control valve

We are a Control Valve Supplier in Dubai, supplying valves in the following descriptions:

Available Materials: Stainless Steel (SS316, SS304), Ductile Iron, Super Duplex (F51, F53, F55), Cast Iron (WCB, WCC, WC6), LCC, LCB

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Medium: Air, Water, Chemical, Steam, Oil

Operations: Electro Pneumatic Operated and Pneumatic Operated

Size: 1/2” – 24”

Ends: Butt Weld, Flanged, Threaded, Socket Weld

Electric Actuator Details:

Torque: 3 – 9 nm

Operating Pressure: 8 Bar

Port Connection: NPT 1.4”

Mounting Base: ISO 5211

Temperature: -20°C to +80°C

Configuration of a Pneumatic Actuator:

Torque: 3 – 9000 nm

Operating Pressure: 8 Bar

Port Connection: NPT 1.4”

Mounting Base: ISO 5211

Temperature: -20°C to +80°C

Temperature Ranges:

Standard: -4°F to 200°F (-20°C to 93°C)

Low: -40°F to 176°F (-40°C to 80°C)

High: 0°F to 300°F (-18°C to 149°C)

Visit us: https://www.uaevalves.com/product-category/control-valve/

3 notes

·

View notes

Note

we want some 18-inch blitz type 4's a 6-valve ptx chrome in take, double-injected Gunther regulators on the back 10 , and some neon on the undertow that flashes Morse code saying "check it out, beeeeeyotch"

Sir this is a Wendy's

5 notes

·

View notes

Text

Understanding Circuit Board Electronic Components: A Comprehensive Guide

In today's digital world, electronic devices have become an essential part of our daily lives. But what makes these devices tick? At the heart of every electronic device lies a circuit board—a masterpiece of tiny electronic components working together to perform complex tasks. In this article, we’ll dive deep into the fascinating world of circuit board electronic components, exploring each element’s role and how they contribute to the overall functionality of the device.

What is a Circuit Board?

A circuit board, often referred to as a PCB (Printed Circuit Board), is a flat board used to mechanically support and electrically connect various electronic components. These components work in unison to perform a specific task. Think of the circuit board as the skeleton and nervous system of an electronic device—it holds everything together and allows communication between parts.

Types of Circuit Boards

Single-sided PCB: Has one layer of conducting material.

Double-sided PCB: Contains two layers for components and connections.

Multi-layer PCB: Complex boards with multiple layers for advanced applications.

The Role of Electronic Components on a Circuit Board

Every electronic device you interact with is powered by a carefully designed circuit board filled with various components. These components might be tiny, but each one has a critical role in the operation of the device. Here's a breakdown of the most important electronic components you’ll find on a typical circuit board.

1. Resistors

Resistors are fundamental components that control the flow of electrical current. They resist the flow of electrons, hence the name "resistor." Their primary function is to reduce current flow, adjust signal levels, and divide voltages in a circuit. Without resistors, circuits would allow too much current to flow, potentially damaging other components.

Types of Resistors

Fixed resistors: Have a set resistance value.

Variable resistors: Allow adjustment of the resistance.

2. Capacitors

Capacitors store and release electrical energy in a circuit. They are often compared to small rechargeable batteries that quickly charge and discharge. Capacitors help smooth out fluctuations in voltage, filter noise, and store energy for future use.

Common Uses of Capacitors

Energy storage

Signal filtering

Voltage stabilization

3. Inductors

Inductors are components that store energy in a magnetic field when electrical current flows through them. They resist changes in current and are typically used in circuits to filter signals, manage power, and store energy.

Applications of Inductors

Power supplies

Radio frequency circuits

Noise suppression in circuits

4. Diodes

A diode is like a one-way valve for electricity, allowing current to flow in only one direction. They are vital in circuits to prevent reverse currents, which can damage components.

Types of Diodes

Light-emitting diodes (LEDs): Produce light when current flows through.

Zener diodes: Regulate voltage within a circuit.

5. Transistors

The transistor is a versatile component used to amplify or switch electronic signals. In essence, transistors are like tiny switches that turn signals on and off rapidly, making them essential in modern electronics.

Types of Transistors

NPN transistors: Allow current flow when a small voltage is applied to the base.

PNP transistors: Conduct when the base is negatively charged.

How Circuit Board Components Work Together

In a circuit, each component has a specific role, and together they form a cohesive system. For example:

Capacitors and resistors may work together to filter signals or smooth out voltage fluctuations.

Transistors and diodes ensure that signals are amplified or directed properly.

Integrated circuits handle the complex tasks, processing data, and controlling the overall system.

Choosing the Right Components for Your Circuit Board

When designing or repairing a circuit board, choosing the correct components is crucial. Some factors to consider include:

Voltage requirements

Power consumption

Signal type and frequency

Physical size and compatibility

Conclusion

Circuit boards are an integral part of any electronic device. The various components on the board each play a specific role in ensuring the device functions as intended. Understanding these components, from resistors to integrated circuits, is essential for anyone working with electronics, whether you're designing a new system or troubleshooting an existing one.

2 notes

·

View notes

Text

FloControlLtd

FloControl offers a comprehensive range of valves, pipeline products, and highly engineered pre-assembled system solutions for fluid handling applications within the UK building services industry. We provide the most innovative PICVs, ABVs, DPCVs, pre-assembled Valve Set arrangements, and Manifolds plus a full range of ancillary products, sourced from world-class manufacturers. Our products and solutions provide superior environmental comfort whilst reducing the capital, installation, commissioning, and running cost of heating and cooling systems as well as reducing a building’s carbon footprint.

#Commissioning Valve Set#Butterfly Valves#Actuated Butterfly Valve#PICV Installation#Valve Package for FCU#FCU Actuator Valve#AHU Valve Package#ABV Valve#Double Regulating Valves#PICV Valve#Automatic Balancing Valve#DRV Valve Function

0 notes

Text

The Ferengi keep using 'Hewman' as their byword for charity but like... who got that 'honor' before first Ferengi-Human contact?

I also wonder if contact with humans/the federation actually made the Ferengi like... double down?

Because it is an observed reality of history that the emergence and rise of communism/the USSR/etc actually made some capitalists... more capitalist. Groups that a generation before had been okay with some social safety nets, workplace comp, etc as a safety valve to control workers or just out of humanitarian interest, would actively start rejecting all forms of safety net, social warfare, regulation as being 'creeping communism'.

So maybe something loosely akin to that happened with the Ferengi?

5 notes

·

View notes

Text

TIL that my research advisor, the most scatterbrained person I know, is also somehow to only thing keeping the Environmental Studies scholarship department running. Last semester he was on sabbatical and they took several months to announce decisions - now that he's back I've been told I should hear back within a week. I don't know how he manages to be this good at project management and yet also forget his own meetings that he himself scheduled. Also today he found a pair of rubber stoppers he'd been looking for for weeks - they were in plain sight on top of the gas chromatograph, a place he walks by regularly. I love this man but his mind baffles me.

I don't have too much room to judge though because today I was messaging him in a panic that the GC was giving me error messages I'd never seen before (this machine costs more than a house, you'd panic too) - it said "fuel gas shutdown," but I'd already double and triple checked that the hydrogen tank was open. Well, I'd been checking the valve on the tank, but I forgot to check the regulator, which was closed. Duh. Maybe all scientists are a bit scatterbrained.

#hylian rambles#hylian does science#i really am extremely fond of this man#and he is the smartest person i know

4 notes

·

View notes

Text

Chemical Storage Tanks

Chemical storage tanks play a crucial role in various industries, including pharmaceuticals, agriculture, manufacturing, and waste management. They ensure the safe storage of hazardous and non-hazardous chemicals, preventing leaks, contamination, and environmental hazards. Choosing the right chemical storage tank is essential for operational efficiency, safety, and compliance with industry regulations.

At Sincro, we specialize in high-quality storage solutions, including water storage tanks, loft water storage tanks, and durable chemical storage tanks made from premium materials. In this guide, we will explore the key aspects of Chemical Storage Tanks, including types, materials, safety precautions, and maintenance tips.

Types of Chemical Storage Tanks

1. Polyethylene Storage Tanks

Polyethylene tanks are widely used for chemical storage due to their corrosion resistance and durability. These tanks are made from LLDPE rotomouldings powder, ensuring flexibility and strength. They are ideal for storing acids, alkalis, and other non-corrosive chemicals.

2. Stainless Steel Storage Tanks

Stainless steel tanks are preferred for highly reactive chemicals and food-grade storage. They offer excellent resistance to high temperatures and harsh substances.

3. Fiberglass Storage Tanks

Fiberglass tanks are lightweight, durable, and resistant to corrosion. They are often used in industries where chemical compatibility and structural strength are crucial.

4. Carbon Steel Tanks

Carbon steel tanks are commonly used in industrial applications for storing fuel, solvents, and other flammable chemicals. However, they require internal coatings to prevent rust and corrosion.

Key Factors to Consider When Choosing a Chemical Storage Tank

1. Chemical Compatibility

Not all tanks are suitable for every chemical. It is important to check the compatibility of the material with the chemical being stored. Sincro provides expert guidance on selecting the right tank based on chemical properties.

2. Tank Capacity and Size

The size of the storage tank depends on the quantity of chemicals needed for storage. Whether you need a small loft water storage tank or a large industrial tank, Sincro offers customizable solutions to meet your needs.

3. Environmental and Safety Regulations

Chemical storage must comply with safety standards such as EPA, OSHA, and local environmental laws. Proper labeling, secondary containment, and ventilation are crucial factors.

4. Temperature and Pressure Requirements

Some chemicals require specific temperature and pressure conditions. Insulated or double-walled tanks may be needed for temperature-sensitive substances.

Importance of Safe Chemical Storage

1. Preventing Leaks and Spills

Improper chemical storage can lead to hazardous spills, affecting human health and the environment. Tanks should be regularly inspected for leaks and cracks.

2. Fire and Explosion Protection

Certain chemicals are highly flammable. Fire-resistant coatings and grounding techniques should be used to prevent fire hazards.

3. Proper Waste Management

Safe storage contributes to efficient waste management by preventing contamination and ensuring proper disposal of residual chemicals.

4. Compliance with Industry Standards

Failure to meet safety regulations can result in heavy fines and legal penalties. Using high-quality LLDPE rotomouldings powder ensures tanks are durable and compliant with industry standards.

Maintenance Tips for Chemical Storage Tanks

1. Regular Inspections

Conduct periodic checks for cracks, leaks, or structural damage.

2. Cleaning and Decontamination

Use approved cleaning solutions to remove chemical residues and prevent contamination.

3. Monitoring System Installation

Install level indicators, pressure relief valves, and leak detection systems for enhanced safety.

4. Proper Ventilation

Ensure tanks have adequate ventilation to prevent the buildup of toxic fumes.

Why Choose Sincro for Chemical Storage Solutions?

At Sincro, we provide high-quality storage solutions designed for durability, safety, and efficiency. Whether you need a water storage tank, loft water storage tank, or a specialized chemical storage system, we offer a range of options made from top-grade materials like LLDPE rotomouldings powder. Our tanks ensure compliance with industry standards and provide long-lasting performance.

Conclusion

Investing in the right chemical storage tank is essential for operational safety, compliance, and efficiency. By choosing Sincro, you get reliable and durable solutions tailored to your needs. Whether for industrial or household use, our tanks ensure safe chemical storage with minimal environmental impact.For expert advice on selecting the best storage tank for your needs, contact Sincro today!

#chemical storage tank#Water Storage Tank#Waste Management#LLDPE Rotomouldings Powder#Loft Water Storage Tank

0 notes

Text

Vacuum Tanker UAE and Fuel Tank Manufacturers in UAE: A Comprehensive Guide

The industrial and commercial sectors in the UAE rely heavily on specialized equipment, including Vacuum Tanker UAE and fuel tanks. These essential components play a vital role in industries such as oil and gas, waste management, transportation, and construction. Whether for liquid waste disposal, fuel storage, or transportation, vacuum tankers and fuel tanks are indispensable.

In this article, we will explore the importance, uses, and key considerations when choosing vacuum tankers in the UAE, along with an overview of fuel tank manufacturers and their role in supporting various industries.

Understanding Vacuum Tankers in the UAE

What is a Vacuum Tanker?

A vacuum tanker is a specialized vehicle designed to collect, transport, and dispose of liquid waste, sludge, and other non-hazardous or hazardous materials. These tankers are commonly used in industries such as sewage management, oil refineries, and industrial cleaning.

Uses of Vacuum Tankers

Waste Management – Vacuum tankers are widely used for sewage and sludge removal, ensuring proper sanitation and hygiene.

Industrial Cleaning – Industries use vacuum tankers to clean tanks, pipelines, and hazardous material spills.

Oil and Gas Industry – Vacuum tankers help in transporting sludge, drilling mud, and other byproducts from oilfields and refineries.

Agriculture – They are also used for irrigation and liquid manure management in large-scale agricultural operations.

Key Features of a Vacuum Tanker

High Suction Power – Equipped with powerful pumps, vacuum tankers efficiently remove and transport waste.

Durability – Made from robust materials like stainless steel and reinforced carbon steel to withstand harsh conditions.

Safety Mechanisms – Features such as pressure relief valves and anti-spill technology ensure safe operation.

Capacity and Customization – Available in various sizes, from small tanks for municipal services to large-capacity tankers for industrial use.

Choosing the Right Vacuum Tanker in the UAE

When selecting a vacuum tanker, consider the following factors:

Type of Waste – Determine whether you need the tanker for hazardous or non-hazardous waste.

Tank Capacity – Choose the right size depending on the volume of waste to be transported.

Material and Durability – Ensure the tanker is made from high-quality, corrosion-resistant materials.

Compliance with UAE Regulations – The vacuum tanker should meet local safety and environmental standards.

Fuel Tank Manufacturers in UAE

Importance of Fuel Tanks

Fuel tanks are essential for storing and transporting petroleum products, diesel, and other fuels. They are widely used in industries such as construction, transportation, aviation, and power generation.

Types of Fuel Tanks

Above-Ground Fuel Tanks – Installed on the surface for easy access and maintenance. Ideal for gas stations, power plants, and industrial sites.

Underground Fuel Tanks – Used to store fuel discreetly, often found at fueling stations and emergency backup power systems.

Mobile Fuel Tanks – Designed for transportation and distribution, these tanks come in various sizes and are mounted on trucks or trailers.

Self-Bunded Fuel Tanks – Double-walled tanks that prevent leaks and provide extra safety.

Factors to Consider When Choosing a Fuel Tank Manufacturer in the UAE

Quality and Compliance – Ensure the manufacturer adheres to international safety and quality standards.

Customization Options – Choose a manufacturer that offers tailored solutions for different industries.

Material and Durability – Fuel tanks should be made from corrosion-resistant materials like stainless steel or reinforced steel.

Capacity and Scalability – Consider your fuel storage needs and opt for scalable solutions if required.

Safety Features – Look for tanks equipped with safety mechanisms such as leak detection, pressure relief valves, and fire-resistant coatings.

Industries That Rely on Fuel Tanks in the UAE

Oil & Gas – Fuel tanks support refineries, drilling operations, and fuel distribution networks.

Construction – Construction sites require fuel storage solutions for heavy machinery and generators.

Transportation – Logistics companies use fuel tanks for fleet fueling and fuel distribution.

Agriculture – Farms require fuel storage for tractors, irrigation systems, and backup generators.

Aviation – Airports and airlines depend on large-scale fuel storage for aircraft fueling.

Conclusion

Vacuum tankers and Fuel Tank Manufacturers In UAE are crucial assets in various industries across the UAE. Whether for waste management, industrial cleaning, fuel storage, or transportation, selecting the right equipment ensures efficiency, safety, and compliance with local regulations.

When choosing vacuum tankers, factors such as suction power, durability, and capacity should be considered. Similarly, when selecting a fuel tank manufacturer, quality, safety features, and customization options are essential criteria.

By making informed decisions, businesses can optimize operations, ensure regulatory compliance, and contribute to a more efficient industrial ecosystem in the UAE.

Oil Field Trailer UAE | Cement Silo Manufacturers UAE

0 notes