#dimensional measurement gauges

Explore tagged Tumblr posts

Text

Essential Dimensional Measurement Tools for Quality Control

In the manufacturing and engineering pulling process, Quality control (QC) plays a very significant role in that it is responsive to the standards and quality of the products to be manufactured. Emulsed within this process is dimensional measurement, which involves confirming the correct size, shape, and dimension of the various parts and components. Dimensional measurement tools are widely used in any industry that requires precision and quality, including aerospace, automotive, and electronics. This article will discuss some of the basic dimensional measurement instruments that help in sustaining quality standards.

1. Calipers Calipers are general-purpose instruments used for measuring thickness, width, depth, inside and outside diameters, and other dimensions with a fair degree of precision. There are three primary types of calipers: vernier, dial, and digital. Vernier calipers need a professional hand to read the measurements, which involves reading a scale. Dial calipers have a dial that has the measurements while the digital ones have an electronic display and can be switched between metric and imperial.

2. Micrometers Micrometers are other measuring instruments, which are widely used in the given field. They are suitable for use when taking measurements of small dimensions that need a lot of precision. A micrometer is an instrument that has a calibrated screw with a spindle that either slides towards or away from a stationary anvil. When the screw is rotated, the users can get very accurate readings normally with an error margin of about ± 0.001mm.

The different types of micrometers are outside micrometers for outside dimensions, inside micrometers for inside dimensions, and depth micrometers for depth. Digital micrometers have other advantages including an electronic readout and the capacity to store or transfer data. Micrometers are the most common choice where pieces need to be produced to very specific standards as in aerospace or medical fields.

3. Height Gauges Height gauges are employed for measuring the heights of objects and for scribing points on a workpiece at specific heights. Usually used in quality control and inspection departments, these are set on a granite surface plate to minimize any vibration. A height gauge is an instrument that has a sliding measuring head that can be slid up and down a vertical beam to get the height relative to the surface of the plate.

Modern height gauges may have digital readouts and can be set up to perform a particular quality control function. It is often utilized to measure the height, flatness, and perpendicularity of parts and therefore it is a very important tool in industries.

4. Coordinate Measuring Machines (CMMs) Coordinate measuring machines (CMMs) are sophisticated and fully automated instruments employed in industries that require high accuracy in the measurement of the geometric properties of an object. CMMs can be used in contact or non-contact form depending on the application. Contact CMMs employ a probe that comes into contact with the object to make the measurements while non-contact CMMs employ laser or optical scanning.

CMMs are used to measure any surface and geometry of an object and are very useful in measuring objects such as engine parts or turbine blades. Because of their accuracy and flexibility, CMMs are widely used in QC laboratories to offer precise 3D dimensions and dimensional control. Despite being more expensive than simple tools such as a caliper, CMMs have high accuracy and can record data to be reviewed later for quality assurance.

5. Surface Plates While surface plates themselves are not measuring instruments, they are used to improve the accuracy of dimensional measurement. Constructed from granite or cast iron, surface plates are flat and stable in temperature, and can support height gauges and CMMs. In quality control surface plates are used to check the flatness, squareness, and parallelism of the workpieces.

6. Optical Comparators Optical comparators are devices that are used to make a part image and project it on a screen so that the inspector can compare it with a master model. These devices are especially helpful for measuring the workpiece profile and edge of shapes such as gears and cams and other shaped workpieces or machined parts. Since the part is compared to a standard overlay, deviations are easily seen and therefore, optical comparators are suitable for quality control in production lines.

Conclusion Quality control across industries requires dimensional measurement tools. When it comes to using tools such as calipers and micrometers, CMMs, and optical comparators they are essential when it comes to determining the quality of products to be produced. This paper aims to establish that by choosing the right tools and ensuring that they are well-maintained, manufacturers can improve their quality control, minimize wastage, and produce quality products in the market.

#dimensional tools#dimensional inspection tools#dimensional measurement tools#dimensional measurement gauges#dimension measuring instruments#dimensional measurement equipment

0 notes

Text

Edward Nigma's Surprise

Batman: The Enemy Within ||| Edward Nigma/Danny Fenton ||| one-shot

POV Edward Nigma

After the events of episode one: The Enigma

Words: 1,057

The silence stretches between us, heavy and tense. Danny sits beside me, his hands clasped tightly in his lap, his fingers twisting nervously. I lean back against the couch, watching him, studying him. Whatever he’s about to say, I know it’s important. He has that look—the one he gets when he’s overthinking, calculating how to say something without dropping a bomb too abruptly.

“Danny,” I say, my voice calm but firm. “Whatever it is, just say it. You’re stalling, and it’s not helping either of us.”

He glances at me, his bright blue eyes flickering with something I can’t quite place. Fear? Guilt? Both? Then he exhales heavily, running a hand through his hair, and finally speaks.

“When I was a teenager,” he begins, his voice soft and hesitant, “I wasn’t just... normal. I wasn’t just Danny Fenton.”

I arch an eyebrow but don’t interrupt.

“I was a hero,” he continues. “Known as Phantom. It’s... a long story, but when I was fourteen, there was an accident. A lab accident.” He pauses, his gaze darting to me as if gauging my reaction. “It gave me powers. Ghost powers.”

Ghost powers? I blink, letting the words sink in, but I stay silent, motioning for him to keep going.

“The accident also opened a portal. A portal to another dimension called the Infinite Realms. It’s... hard to explain, but it’s where all deities and some ghosts reside. It’s this vast, endless place that connects to every world, every timeline. And...” He hesitates again, his fingers tightening around each other. “At one point, I had to fight the king of the Infinite Realms to protect my hometown. It was a whole thing. I won in single combat, which meant...”

His voice trails off, and he looks at me again, nervous and unsure.

“Which meant what?” I prompt, though I can already guess the answer.

“Which meant I became the prince of the Infinite Realms,” he says finally. “Until I decide to take the throne and become king.”

I stare at him. “You’re royalty.”

He winces. “Technically, yeah. But I never wanted to be king. I’ve spent years avoiding it because I didn’t want that kind of responsibility. I just wanted to live my life.”

I nod slowly, though my mind is already racing. Royalty. Dimensional royalty. Among gods. And he didn’t think to mention this sooner?

Danny takes another deep breath, and his voice lowers, growing more serious. “When you got shot with that poison dart, Ed... you died.”

The words hit me like a punch to the gut, but I don’t move. I don’t say anything. I let him finish.

“You died,” he repeats, his voice breaking slightly. “And I—I couldn’t... I couldn’t lose you. I couldn’t live in a world without you. So I made a deal with the council of the Infinite Realms. I agreed to be coronated as king—something I’ve been avoiding for years—on the condition that they bring you back.”

He stops, his hands trembling now. I can tell he’s waiting for me to say something, but I stay quiet, letting him squirm. I want him to feel the weight of what he’s just told me.

Finally, he looks at me, his expression pleading. “I’m sorry, Ed. I should’ve told you everything sooner. There’s no excuse for not telling you before now, but... I just didn’t know how. I didn’t want to lose you, and I didn’t want you to look at me differently because of... all of this.” He gestures vaguely, as if trying to encompass everything—his powers, his past, his royalty.

I stare at him for a long moment, my mind turning over everything he’s said. The part about him being a hero? Irrelevant. The part about him saving me? That’s... complicated. But the part about him being royalty among gods and not thinking it was worth mentioning? That sticks in my throat.

“So let me get this straight,” I say finally, my tone measured. “Not only have I been dating royalty for months without knowing it, but we’re talking about the royalty of an entire dimension filled with deities and ghosts?”

Danny winces again. “Pretty much... yeah.”

I lean forward, resting my elbows on my knees, and let out a long, slow breath. “You’ve been keeping this from me the entire time we’ve been together?”

“I wasn’t trying to keep it from you,” he says quickly. “I just... didn’t know how to bring it up. It’s not exactly easy to drop into casual conversation.”

“Oh, I don’t know,” I say, my voice laced with sarcasm. “‘Hey, Ed, did I mention I’m the prince of an interdimensional ghost kingdom?’ seems like a pretty solid opener.”

He groans, running a hand through his hair again. “I deserve that.”

“You do,” I reply bluntly. “I think I’m entitled to be a little upset about the fact that you’ve been royalty this whole time and didn’t think it was worth mentioning.”

He looks down at his hands, his shoulders slumping. “I know. And I’m sorry. I mean it, Ed. I should’ve told you sooner. You have every right to be upset.”

I watch him for a moment, my frustration still simmering beneath the surface, but... it’s hard to stay angry when he looks like that. Nervous, apologetic, vulnerable. I can tell this has been eating at him, and as much as I hate being kept in the dark, I know in my heart that this doesn’t change how I feel about him.

I sigh, leaning back against the couch. “Danny.”

He looks up, his blue eyes wide and uncertain.

“This doesn’t change the fact that I love you.”

Danny’s breath catches.

I reach out, curling a finger under his chin, tilting his face toward mine. “But,” I continue smoothly, “I am allowed to be upset that you neglected to mention you were royalty among deities, and that you traded a crown for my life without telling me.” My grip tightens slightly—not rough, but firm.

I hold his gaze a moment longer before sighing and releasing him, leaning back again.

“We’ll revisit that in a moment,” I say, my voice deceptively light. “For now—start at the beginning, love. No more secrets.”

Danny exhales heavily, but he nods.

Good.

I may not be a king, but I am still a man who hates being left in the dark.

#batman fandom#danny fenton#dc x dp#dcxdp#dp x dc#dpxdc#batman fanfiction#danny phantom#dc riddler#edward nigma#batman the enemy within#telltale riddler#fanfiction#fandom#fanfic#danny fenton x riddler#ghost king danny#telltale games#batman games#half right#Danny Fenton x Edward Nigma#edward nygma#danny phantom x dc crossover#dcu#dp fanfic#dp fandom#dc fanfic#dc fandom

34 notes

·

View notes

Note

Your "surely" comment at the end is wrong. The zero-dimensional measure of a single point is 1. The zero-dimensional measure is just counting. This viewpoint is completely standard and "obvious" in higher-dimensional geometry.

(A typical way to construct invariants of a space is by setting up some (eg) differential equation and looking at the space of solutions, which is some n-dimensional manifold, then integrating a differential form against it (or taking the homology cycle of the manifold and pairing it with some cohomology class, more generally). In these discussions an n=0-dimensional manifold is just a collection of (signed) points, and pairing with cohomology gives a (signed) count, giving numbers which associated to your space. This idea appears in gauge theory and enumerative geometry all over the place.)

(1/2)

2 notes

·

View notes

Note

hey! can you give any tips on shaping garments when knitting? i made a sweater i really love and i'm more confident in my skills now, but it's definitely boxy, even though the pattern included a little shaping. now that i know more about how things will fit me, do you have any advice on sort of freewheeling it to fit your body better? like how many decreases per round or how many rounds between decreases to make it look seamless, that kind of thing? thx!

hey! i can try to help :) thank u for asking !

i will say as a disclaimer that the customizations i have figured out are particular to what makes my body unique and distinct from "standard" sizing, and part of this process will be learning your own version of that ☺️ the good news is that i have only really been making garments since the summer of 2021, and i have only been modding them to my measurements for a little over a year! and i have already learned so so much. so you can do it!

there are a couple things that have really really helped me on this journey:

figure out the key features on your body that you want or need to mod for. mine are typically my bust, my short waist, and my muscular arms. it also helps to figure out what you want to enhance on your silhouette. i'm not like, a strict Kibbe types person, but i know i'm shaped like "elizabeth taylor if she was a powerlifter," and i can look at the things she wore as a guide to what i know will work on my shape.

learn your key measurements and pick pattern sizes accordingly. my waist is ~7" in smaller than my full bust, for example. most patterns that feature waist shaping have the waist 1-2" smaller than the bust. but i also typically choose sweater sizes based on my high bust (41") rather than full bust (43-44") measurement, because i find that the shoulders and neck fit me better on garments knit for my high bust measurement. it's usually easier to either add some extra size for the full bust (more on this in a moment) or simply deal with a couple inches of negative ease at the bust than it is to knit the size for my full bust and try to narrow the shoulders.

compare your measurements to the schematics from the pattern and note where you need to make changes. if possible, see if you can chop and screw the different pattern sizes together to something that suits you better. for example—the love magick sweater i made, with the big bell sleeves? i made the size M body, but i added stitches in the underarms to get it to the size L stitch count. i then decreased back down to the size M stitch count for the waist once i was past the bust. for my big biceps, i needed to make the sleeves between the XL and XXL. doing this was WAY easier than trying to do gauge math to figure it out for myself!! other folks do this differently—i saw a lady on reddit who knit the size M back of a sweater and the size XL for the front. the first time i chopped and screwed different pattern sizes was actually an accident—i cast on the M stitches when i wanted to make the L—but it worked so well that i seek out opportunities to do it now 🤑

try your shit on as you go and don't be afraid to rip back and make changes! i bought these pony bead cords on amz that easily slide onto the tips of needles up to size US 8 and allow me to easily try things on as i go, without having to transfer things to waste yarn or extra needles. this has been transformative! i realized when making my mini vee tee that my natural waist is only like... 5.5" under my arm? so i re-worked most of the body to space the increases closer together.

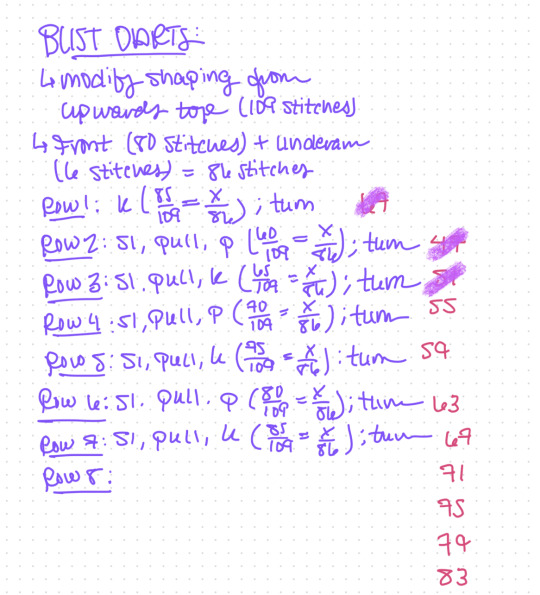

a word on bust darts: horizontal bust darts are my best friend!!!! the concept of horizontal bust darts is basically this: my boobs are so big and sit so far out on my chest that most shirts i wear rise up the front. horizontal darts add length and a bit of three dimensional room right where i need it, so that the hem sits straight on my waist!! adding darts helps me make my shirts long enough to wear to work without also having a bunch of excess fabric in the back, which is what happens if i knit something without them, like my first florence polo. i first learned how to add them when making the upwards top by lilykatemakes, which included really clear instruction on how to form the short rows that make up the darts. that top was knit in fingering weight, but the next thing i added them to (the love magick sweater) was DK weight. i did some literal 9th grade algebra to adapt it....:

bust darts cont.: ....and it worked great! because DK weight is longer, i ended up adding more length to the front of that sweater than i did on the upwards top, even though i stopped after just seven rows. this turned out fine, actually, because again—them boobies big! the upwards top was actually not enough darts for me 😅. but the lessons i learned doing this helped me to freehand them on my current wip (a second florence polo!)

a word on made-to-measure patterns: i also learned an absolute ton making patterns from oshenknits' made to measure collection. her patterns have big plug-and-play tables with stitch counts that correspond to your measurements, so it takes some of the scary part of the gauge math out. newwaveknitting also has a made-to-measure collection, and i have bought but not yet made the practically perfect raglan tee, a pattern that comes with a cool google doc for you to plug nearly a dozen measurements into to customize waist shaping and bust darts, as well as a standalone bust dart calculator. i would check it out if you're interested in shaping!

i hope this was helpful !!!

7 notes

·

View notes

Text

Once I'm made queen of video games, I'm going to create an open world RPG where you play as Emma Frost.

There's going to be a morality system, but you'll start the game at 75% evil, and every time you take a good action, we'll play a sound bit of Emma groaning in annoyance.

However, morality is actually going to be a 2 dimensional measure, with one axis being good/evil and the other being bisexuality/whatever's-going-on-between-you-and-jean-grey

As an example, you can chose to respond favorably to Kate's flirtations, and doing so will get you closer to embracing your bisexuality, but in doing so, you are also more likely to find a healthy resolution for your feelings towards Jean Grey.

OR!

You can "tastefully" imply that you support conversion therapy, thus making you more evil, and pushing you further into the closet, but also strengthening your desire to inflict homoerotic psychic torment on one Jean Elaine Grey.

In Duke Nukem Forever fashion, Emma also doesn't have a health bar, instead she has a "boredom" meter that increases when she's attacked or uses her powers. If it fills up, Emma decides that saving the world is beneath her; and leaves to get day drunk on mimosas on her private beach while shirtless men in diamond studded collars eat her out.

How do you get boredom to go down? By being a huge cunt of course. Steal candy from children, tell old people to kill themselves, loudly go "who's that cow?" when an obviously anorexic girl enters the room.

These are of course all morally neutral acts, cause again we're gauging this by Emma Frost standards.

Sidequests would include

Get cancelled on all major social media platforms

Find the man who took a picture of you while your wings were slightly uneven and make his family watch as he's tortured to death

Have a drunken hookup with S.H.I.E.L.D. commander Maria Hill, agree to never speak about it.

Don't bring up the fact that you're rich and therefore better than everyone else, just once.

Torment Jean Grey with increasingly homoerotic visions.

As for collectables, there's going to be both a good and an evil set. The evil set of course being abuse survivors who you can remind deserved everything that happened to them; while the good one is baristas you can chose to be nice to.

Like obviously you're not going to tip her or anything, but you won't point out that literally everyone here can tell she's secretly a man, cause she looks like a footballer who stole his 60 year old mom's lipstick, and that really shows how much you've grown as a person and Kate should be complimenting you.

4 notes

·

View notes

Text

ISO 17025 Accredited Calibration and NDT Calibration Services – MECL, UAE

Middle East Calibration Lab L.L.C. is a UAE-based ISO/IEC 17025:2017 accredited calibration laboratory recognized by the Emirates National Accreditation System (ENAS). MIDDLE EAST CALIBRATION LAB L.L.C is one of the leading organizations in the field of calibration and repair of measuring instruments, testing equipment and weighing systems.

ISO 17025 Accredited Calibration and NDT Calibration Services – MECL, UAE

Middle East Calibration Lab LLC (MECL) is a trusted provider of ISO 17025 Accredited Calibration Services in the UAE. As an accredited calibration laboratory, MECL offers reliable and traceable calibration solutions that meet international quality standards, supporting a wide range of industries in maintaining measurement accuracy and compliance.

ISO 17025 Accredited Calibration ISO 17025 is the international standard for competence in testing and calibration laboratories. MECL’s accreditation ensures that all calibration activities are performed with precision, using validated methods and traceable standards. Whether it is electrical, dimensional, thermal, or mechanical calibration, MECL delivers consistent and dependable results.

NDT Calibration Services MECL also specializes in NDT Calibration Services, providing calibration for equipment used in non-destructive testing processes. These services cover ultrasonic flaw detectors, thickness gauges, hardness testers, and other critical NDT instruments. With a focus on accuracy and repeatability, MECL supports industries such as oil and gas, aerospace, and manufacturing in maintaining their testing reliability.

Comprehensive Support and Traceability All calibration services provided by MECL come with detailed calibration certificates and are traceable to international standards. The lab uses advanced equipment and follows strict quality control procedures to ensure measurement integrity and compliance with industry regulations.

For more details, call us at +971 6 524 1472 or get in touch at [email protected].

0 notes

Text

hexagon cmm malaysia

Precision Measurement Tools Revolutionizing Malaysian Industries – From Digital Microscopes to Trimos Height Gauges

In today’s fast-paced industrial and manufacturing world, accuracy and efficiency are more critical than ever. Whether you're in automotive, aerospace, medical, or electronics manufacturing, ensuring the quality and precision of your components is key to maintaining competitiveness. This is where Takumiprecision.com.my steps in—your trusted partner in precision tools across Malaysia.

From digital microscopes and stereo microscopes to Trimos height gauges and Hexagon CMMs, Malaysian industries now have access to world-class measuring solutions that enhance productivity, quality, and reliability.

The Rise of Digital Microscope Technology in Malaysia

The evolution of microscopy has led to the advent of the digital microscope malaysia, a powerful tool that combines high-resolution imaging with advanced software to analyze the finest details of materials and components. In Malaysia, digital microscopes are gaining immense popularity due to their wide application across industries like electronics, metallurgy, and research labs.

Digital microscopes in Malaysia allow users to view, capture, and analyze images with ease. The benefits include:

High-definition live imaging

Real-time measurements

Documentation and reporting capabilities

Minimal operator training

Whether you are performing circuit board inspections or failure analysis, a digital microscope in Malaysia offers unmatched clarity and functionality, making it a must-have tool for precision-driven businesses.

Why Stereo Microscopes Still Matter in Modern Manufacturing

Despite the rise of digital alternatives, the stereo microscope remains an essential instrument for many hands-on tasks. These microscopes provide a three-dimensional view of a sample, offering depth perception that is especially useful in applications like soldering, dissection, and intricate assembly work.

At Takumiprecision.com.my, we offer stereo microscope Malaysia solutions that deliver clear optics, adjustable zoom levels, and ergonomic design. Our stereo microscopes are ideal for:

PCB inspection and rework

Biological dissection

Jewelry and watch repair

Quality control processes

In Malaysia, stereo microscopes are commonly used in educational institutions and industrial labs where close-up visual inspection is crucial.

Trimos Malaysia – Swiss Precision Meets Malaysian Innovation

Trimos is a globally renowned Swiss manufacturer known for its superior dimensional measuring instruments. As an authorized distributor of Trimos Malaysia, Takumiprecision.com.my brings you access to this world-class brand, ensuring you can measure with the utmost confidence and precision.

Trimos products are engineered for reliability and ease of use. Among the most popular Trimos products in Malaysia are:

Horizontal measuring instruments

Surface measuring systems

Roundness and form testers

What sets Trimos apart is its focus on innovation, user-friendly interfaces, and long-lasting precision. For manufacturers in Malaysia seeking dependable Swiss technology, Trimos Malaysia is the benchmark.

The Power of Trimos Height Gauge in Quality Control

A standout product in the Trimos line-up is the Trimos Height Gauge, a fundamental tool in every quality control lab. These gauges are designed for accurate vertical measurements, and they often serve as the reference standard for measuring the height, depth, and internal/external diameters of components.

At Takumiprecision.com.my, we offer a variety of Trimos height gauge models that are:

Digitally operated with touchscreen displays

Capable of storing measurement data

Built with Swiss precision for years of reliable service

The Trimos height gauge is indispensable in environments such as CNC workshops, inspection labs, and high-precision production lines across Malaysia. Its ergonomic design and intuitive interface make it ideal for both novice and experienced users.

Measuring to Microns with Hexagon CMM in Malaysia

When it comes to complex geometries and multi-axis parts, nothing beats the precision of a coordinate measuring machine (CMM). Among the leading CMM brands in the world is Hexagon, and we're proud to bring Hexagon CMM Malaysia solutions to our clients at Takumi Precision.

Hexagon CMM Malaysia systems deliver high-accuracy 3D measurement that is vital for:

Aerospace components

Medical device manufacturing

Mold and die inspection

Reverse engineering

These CMMs utilize touch-trigger and scanning probes, laser sensors, and automated systems to deliver data-rich analysis that supports smart manufacturing. Hexagon’s advanced software also enables real-time inspection and statistical process control, elevating the quality assurance game for manufacturers in Malaysia.

Why Choose Takumiprecision.com.my for Precision Equipment in Malaysia?

Takumiprecision.com.my is more than just a supplier—we are your strategic partner in quality assurance. We specialize in bringing the latest precision measurement tools to Malaysia, empowering industries to meet international standards and exceed client expectations.

Here’s why clients across Malaysia trust us:

Expert Consultation: We help you choose the right equipment for your specific application.

Certified Training & Support: Our team provides setup, training, and after-sales support to ensure smooth integration.

Latest Technology: We offer the newest models from globally respected brands like Trimos and Hexagon.

Local Presence: Being based in Malaysia, we understand local industry needs and deliver prompt, localized service.

Applications Across Diverse Industries

From semiconductor inspection with digital microscopes to dimensional validation with Hexagon CMMs, the equipment we provide serves a broad spectrum of industries:

Manufacturing and Machining

Electronics and Semiconductors

Aerospace and Automotive

Medical Device Manufacturing

Research and Education

Our goal is to help you enhance productivity, reduce rework, and deliver consistent quality—every time.

Conclusion

In the evolving world of industrial metrology and quality control, having the right tools makes all the difference. From digital microscopes Malaysia and stereo microscope Malaysia to world-class instruments like Trimos height gauges and Hexagon CMM Malaysia, Takumiprecision.com.my ensures you’re equipped for success.

0 notes

Text

Integration of ISO 17020 Consultants into Dimensional Checks Explained

When it comes to inspection and conformity assessment, specificity and uniformity are critical. This is especially the case with industries such as manufacturing, aerospace, automotive, and heavy engineering, where even the tiniest variance in dimensions can result in significant issues with quality or product failure. Dimensional checks and systematic evaluations to ensure that components meet predetermined specifications play a critical role in mitigating these risks.

Also, significant is compliance with ISO 17020, a widely-used global standard defining the competence of inspection bodies. It specifies requirements for deciding the competence of bodies performing inspection and for the impartiality and consistency of their inspection activities. However, it can be difficult to execute this standard effectively, in particular when dealing with technical domains, such as dimensional inspection. This is where the ISO 17020 Consultants come into play.

ISO consultants in UAE are the guiding stars who help manufacturing businesses to set the best dimensional inspection process that is compliant, accurate, and contributes towards operational excellence.

Understanding ISO 17020

What is ISO 17020?

ISO/IEC 17020:2012 is an international standard that specifies the criteria for the operation of different types of bodies performing inspections. It guarantees these bodies are disinterested, technically skilled, and systematic in their inspections.

Scope and Applicability

The standard applies to organizations that are engaging in:

In-process and final product inspection

First-article inspections

Client/regulatory third-party inspections

It is a yardstick of quality and assurance in inspection activities, designated applicable to all sectors.

Standard Key Requirements

Independence and Impartiality: Inspection bodies must not be subject to commercial, financial, or other pressures that may compromise their objectivity;

Technical Competence: However, inspectors need to have the right skills, training, and experience in dimensional checks and other checks.

Inspection Approach and Reporting: Each type of inspection requires adherence to clear procedures and methods, and results need to be reported consistently and transparently.

Quality Management Systems (QMS): Document control, internal audits, and corrective actions are essential parts of a QMS to ensure continuous improvement.

What Are Dimensional Checks?

Definition and Importance

K Dimensional checks are specific measurements taken of physical components to determine if the component is built to engineering specifications. These inspections are important for:

Ensuring product quality

Maintaining tolerance levels

Preventing rework and warranty claims

Back up compliance with rules and regulations

Dimensional Inspection Common Tools

Calipers, Micrometers, and Gauges: For manual measurements of lengths, diameters, and depths.

Coordinate Measuring Machines (CMMs): For 3D dimensional measurement with high accuracy.

Laser Measuring and Vision Systems: Used for non-contact inspections in an automated environment.

Role in Product Conformance

Dimensional checks work as a gatekeeper for quality (mainly in the case of mass production). They pick up deviations early and prevent defective goods from getting out to customers or causing downstream defects.

Why Are ISO 17020 Certification Consultants Responsible?

What do ISO 17020 Consultants Do?

These experts help organizations navigate the ISO 17020 Certification in UAE process. They are well versed at interpreting the clauses of the standard and a variety of technical environments where they can be applied, such as dimensional inspections.

Services Offered

Gap Analysis and Readiness Assessment: How current inspection practices compare to the requirements of the standard.

Documentation Support: Writing up inspection written procedures, quality manuals, and compliance reports.

Training and Competency Development: Staff training related to the principles and technical inspection methods.

Internal Audits and Mock Inspections: These involve aides with an internal audit system preparing for the audits that must be performed before each certification cycle to rectify issues and make necessary improvements.

Accreditation Assistance: Working with governing bodies to maintain accreditations and assist in formal audits.

Advantages of Getting a Consultant Involved

Knowledge: The ISO 17020 Certification Consultants in Dubai understand how the standard looks in practice.

Recognizing Change: They assist in the construction of systematic, repeatable, and standardized checking systems.

Improved Compliance: Their expertise reduces the chance of non-conformities during audits.

Risk Mitigation: Consultants spot deficiencies before they result in certification delays or failures.

Incorporating Consultants in Dimensional Inspection Processes

ISO 17020 Based Fitted Plan for Dimensional Checks

Note, however, that the certification does not prescribe how to perform inspections, only that those methods be validated, repeatable, and appropriate. Dimensional inspection practice is aligned with these principles by the consultants.

At a minimum, this has to go hand in hand with accreditation requirements

ISO 17020 Certification Consultants help to write SOPs (Standard Operating Procedures) that are well-defined, consistent, and traceable. They also make sure that records of inspections, calibration, and training are well-maintained, all of which are of key importance for successful accreditation.

Developing Traceable Systems

Traceability is required with the use of tools like CMMs or laser systems. Consultants help implement:

Calibration schedules

Evaluating uncertainty measurements

Standardized reporting formats.

Equipment calibration and operator competence

A dimensional check is only as good as the tool that is being used and the person performing the check. ISO 17020 Consultants in Abu Dhabi verify:

All measuring tools are traceable and properly calibrated to national/international standards

The competency of operators is trained and tested

Challenges and Solutions

Dimensional Inspections — Common��Issues

Document Shortcomings: Inadequate processes and absent checks.

Neglecting Measurement Uncertainty: Failing to properly compute or report measurement uncertainty.

Inconsistent Reporting: Different formats or auntency of results that makes it difficult to provide clarity to clients or auditors.

How Do Consultants Overcome These?

Structured Training Programs: They educate teams on the tenets of best practices, QMS requirements, and the principles of ISO 17020 Certification in UAE.

Process Optimization: Consultants tailor processes to best ensure efficiency and consistency by implementing a lean approach and process improvements through quality inspection steps.

Audit Preparation: Mock audits, as well as root cause analysis, aid in preempting external certification or surveillance visits.

Corrective Actions: Advice on finding root causes of non-conformities, making permanent corrections

The Main Point!!

When dimensional accuracy is mission-critical, precision inspections are vital to product quality. Without the guidance of ISO 17020 Consultants in UAE, organizations may struggle and take unnecessary measures in the process for effective dimensional checks. They may benefit from the guidance of ISO consultants to help organizations increase inspection outcomes more efficiently, reduce technical errors, and achieve accreditation effectively.

Consultants provide the blueprint of success from documentation to jobs, calibration to training, and compliance. They ensure that dimensional inspections are technically competent but also adhere to international quality standards.

If your organization is aiming to enhance inspection credibility, minimize errors, and ensure long-lasting quality improvements, enlist a consultant.

0 notes

Text

The Best Grinding Services in Delhi NCR

Finding the best grinding services in Delhi NCR can have a significant impact on the caliber and effectiveness of your operations when it comes to industrial and precise machining needs. In many industries, including manufacturing, construction, automotive, and aerospace, where exact material shape, finishing, and surface treatment are crucial, grinding services are indispensable. As a significant industrial center, Delhi NCR provides a variety of grinding service providers with state-of-the-art equipment and skilled workers to meet both small- and large-scale requirements.

The availability of cutting-edge equipment is one of the main reasons companies look for excellent grinding services in this area. The top grinding service providers in Delhi NCR have centerless grinders, cylindrical grinders, surface grinders, and CNC grinding machines that can process large amounts of material without sacrificing accuracy. These businesses constantly produce excellent results, whether it's mirror-finish surfaces or reaching precise tolerances.

The best grinding service providers in Delhi NCR are also distinguished by their proficiency with a variety of materials and components. Professional grinding companies can easily handle a wide range of material types, from carbon steel and stainless steel to exotic alloys, aluminum, and even ceramics. Whether it's for flat surface finishing, tool grinding, or gear grinding, they also offer customized solutions based on customer needs.

The legitimacy of these services is further increased by prompt delivery, quality control, and conformity to global standards such as ISO certifications. To guarantee dimensional accuracy and surface polish, many reputable businesses also provide in-house quality inspections utilizing sophisticated measuring tools, including height gauges, surface roughness testers, and CMMs (coordinate measuring machines).

0 notes

Text

Efficient Trapezoidal Screw Production Solutions: Techniques & Technologies

Trapezoidal screws, often used in linear motion systems and mechanical actuators, are critical components in a wide range of industries—from automotive to aerospace and industrial machinery. Known for their robust design and efficiency in converting rotary motion into linear motion, the demand for high-quality trapezoidal screws has significantly grown. As a result, manufacturers are constantly seeking optimized and scalable trapezoidal screw production solutions.

This article covers everything you need to know about producing trapezoidal screws, including materials, machining technologies, threading techniques, quality assurance, and automation trends in 2025.

1. What is a Trapezoidal Screw?

A trapezoidal screw is a type of lead screw with a trapezoid-shaped thread profile, typically conforming to standards like ISO or DIN. Unlike square threads, trapezoidal threads offer better load distribution and are easier to machine, making them ideal for high-load, low-speed applications.

Common Applications:

CNC machine beds

Linear actuators

Presses and lifting devices

Industrial automation systems

2. Choosing the Right Materials

Material selection is crucial for durability, precision, and resistance to wear. Common materials include:

Carbon Steel: Cost-effective and strong, often used with surface hardening.

Stainless Steel: Excellent corrosion resistance, preferred for medical and food-grade applications.

Bronze or Brass: Common for nuts paired with steel screws to reduce friction and galling.

Plastic or Polymer Composites: For low-load, high-speed applications, especially where lubrication is a concern.

Key Considerations:

Operating temperature

Load requirements

Corrosive environments

Maintenance cycles

3. Production Methods and Machining Solutions

a. Turning and Thread Cutting

Traditional lathes and modern CNC turning centers are used for cutting the trapezoidal thread profile.

Single-point threading on CNC lathes ensures precision but is time-intensive.

Thread rolling is a faster, deformation-based process ideal for high-volume production.

b. Thread Milling

Thread milling offers flexibility, especially for internal threads or difficult-to-machine materials. It reduces tool wear and produces cleaner finishes.

c. Grinding and Finishing

Post-threading, precision grinding improves surface quality and dimensional tolerance. Centerless and cylindrical grinding methods are popular for finishing the screw shaft.

4. Thread Standards and Tolerances

Global standards such as ISO 2904, DIN 103, and ANSI/ASME B1.5 define dimensions, tolerances, and profiles for trapezoidal screws. Precision is key, especially in applications where backlash or misalignment can impact performance.

Pitch accuracy and lead deviation must be tightly controlled.

Use of coordinate measuring machines (CMMs) and thread gauges ensures compliance.

5. Heat Treatment and Surface Coatings

To enhance durability and wear resistance, manufacturers often apply:

Case hardening or nitriding

Black oxide coating for mild corrosion resistance

Zinc or nickel plating

Teflon or PTFE coating for smooth motion

Each treatment is selected based on environmental conditions and expected wear cycles.

6. Quality Control and Inspection

Precision is everything. Key quality assurance practices include:

Microscopic inspection of threads

Surface roughness measurement

Load and torque testing

Dimensional accuracy checks with optical comparators

Modern facilities integrate inline sensors and AI-driven quality monitoring systems to flag defects in real-time.

7. Automation in Trapezoidal Screw Production

In 2025, smart manufacturing is transforming screw production. Here’s how:

a. CNC Automation

Automated lathes and thread milling machines minimize human error and increase consistency.

b. Robotic Handling

Collaborative robots (cobots) are used for part loading/unloading, inspection, and material movement.

c. MES Integration

Manufacturing Execution Systems (MES) streamline production planning, track progress, and optimize workflows.

d. Digital Twin Technology

Simulations of production lines and tool paths reduce setup time and improve first-pass yield.

8. Custom Screw Design Capabilities

Many industries require non-standard trapezoidal screws with customized:

Lengths

Thread profiles

Shaft features (flats, keyways, undercuts)

Nut assemblies (anti-backlash, split nuts)

Modern CAD/CAM software enables rapid prototyping and seamless CNC code generation, allowing quick design-to-production cycles.

9. Cost-Saving Strategies

To stay competitive, manufacturers implement the following strategies:

Batch production for economies of scale

Tool wear monitoring to avoid defects

Lean manufacturing principles to reduce waste

Local sourcing of raw materials to minimize delays and cost

10. Sustainability and Environmental Practices

Eco-conscious manufacturing is gaining ground. Companies are:

Using recyclable materials

Recycling cutting fluids and coolants

Installing energy-efficient CNC machines

Adopting green certifications like ISO 14001

Conclusion

The production of trapezoidal screws involves a blend of precision engineering, material science, and modern manufacturing technology. As industries demand more efficient, customizable, and high-performance lead screws, manufacturers must adopt advanced production methods and digital tools to stay ahead.

Whether you’re an established manufacturer or entering the lead screw industry, investing in optimized trapezoidal screw production solutions is key to meeting market expectations in 2025 and beyond.

0 notes

Text

How Instrument Calibration Affects Manufacturing Output

In manufacturing, precision is everything. The ability to produce consistent, high-quality products depends on accurate measurements, and that’s where instrument calibration plays a critical role. Without properly calibrated instruments, businesses risk errors, production inefficiencies, and non-compliance with industry standards. This article explores the impact of calibration on manufacturing output and why investing in professional Instrument Calibration Services is crucial.

The Role of Instrument Calibration in Manufacturing

Instrument calibration ensures that measuring devices provide accurate readings, reducing errors in production. Whether it’s pressure gauges, torque wrenches, temperature sensors, or industrial scales, calibration is vital for maintaining measurement integrity. When instruments deviate from their specified accuracy, even by a small margin, it can lead to faulty products, rework, and increased production costs.

Regular calibration also helps meet regulatory compliance requirements. Industries such as aerospace, pharmaceuticals, food processing, and automotive manufacturing must adhere to strict measurement tolerances. Inaccurate instruments can lead to product recalls, legal liabilities, and damage to a company’s reputation. Investing in Instrument Calibration Services helps manufacturers stay compliant with these regulations while maintaining operational efficiency.

The Impact of Calibration on Manufacturing Output

Enhancing Product Quality

Product quality is directly linked to measurement accuracy. If an instrument is out of calibration, even the smallest deviation can cause defects in the final product. For example, in the pharmaceutical industry, incorrect measurements of active ingredients can affect drug efficacy, leading to serious health risks. In metal fabrication, improper dimensional measurements can result in weak or improperly fitting parts. With reliable Instrument Calibration Services, manufacturers can ensure that all measurements are accurate, leading to consistent product quality and customer satisfaction.

Reducing Waste and Rework

Manufacturing defects often lead to material waste and rework, which can be costly and time-consuming. If a measuring instrument is not calibrated correctly, it may result in incorrect readings, causing an entire production batch to be off-spec. This can lead to expensive raw material wastage or require reworking defective products. Regular calibration ensures that all measurements are precise, reducing errors and minimizing unnecessary waste.

Improving Equipment Efficiency and Longevity

Manufacturing instruments and tools are significant investments, and proper maintenance extends their lifespan. Over time, all measuring instruments experience natural wear and tear, leading to drift in accuracy. Calibration identifies these deviations early, allowing for adjustments before they cause major operational issues. Reliable Instrument Calibration Services can help maintain equipment in optimal working condition, preventing unexpected breakdowns and costly repairs.

Ensuring Compliance with Industry Standards

Many industries require compliance with specific measurement standards, such as ISO 9001, FDA regulations, and ASTM standards. Calibration documentation is often required for audits and certifications. Failure to meet compliance standards can lead to regulatory fines, legal action, or loss of business opportunities. By scheduling routine calibrations, companies can ensure they meet industry regulations while demonstrating their commitment to quality and accuracy.

Enhancing Production Efficiency

Efficient manufacturing operations rely on precise measurements. When measurement tools are calibrated correctly, production processes run smoothly with minimal interruptions. Operators can trust the readings provided by their equipment, leading to fewer delays and better decision-making. If calibration is neglected, workers may need to perform additional checks or recalculations, slowing down production and reducing overall output. Investing in Instrument Calibration Services can significantly improve operational efficiency and streamline production workflows.

Signs That Your Instruments Need Calibration

Manufacturers should always be aware of when their instruments require calibration. Some common indicators include:

Frequent measurement inconsistencies or errors

Instruments that haven’t been calibrated in over a year

Physical wear and tear on measuring devices

Unusual product defects or increased rejection rates

Changes in environmental conditions affecting instrument performance

If any of these signs appear, it’s crucial to seek professional calibration services immediately. You can Find Out more about calibration best practices to ensure your equipment stays in peak condition.

Choosing the Right Instrument Calibration Services

When selecting a calibration service provider, manufacturers should look for key qualities such as:

Accreditation: Choose a provider that follows national and international calibration standards.

Experience and Expertise: Look for companies with industry-specific calibration experience.

Traceability: Ensure that calibration results are traceable to national or international measurement standards.

On-Site and Laboratory Services: Some providers offer both on-site and laboratory calibration, depending on your needs.

Detailed Reporting: Comprehensive calibration certificates with measurement data and accuracy specifications are essential for compliance.

By partnering with a trusted calibration provider like Industrial Scale & Measurement, manufacturers can Get More Information on maintaining measurement accuracy and improving production efficiency.

Conclusion

Instrument calibration is a fundamental aspect of manufacturing that directly impacts product quality, waste reduction, equipment longevity, compliance, and overall efficiency. Companies that prioritize regular calibration benefit from more consistent production, fewer defects, and improved profitability. Investing in professional Instrument Calibration Services ensures that all measurement tools perform at their best, ultimately leading to better manufacturing outcomes.

If you want to ensure precision and compliance in your manufacturing operations, you could check here for reliable calibration services. Don’t wait until inaccurate measurements affect your production—go right here to learn more about professional calibration solutions today.

Original Sources: https://industrialscalemeasurement.blogspot.com/2025/04/how-instrument-calibration-affects.html

0 notes

Text

The Essential Guide To Pet Bottle Testing Instruments

Source of info: https://www.perfectgroupindia.co.in/the-essential-guide-to-pet-bottle-testing-instruments.php

Pet bottles, also known as polyethylene terephthalate bottles, have become commonplace in our daily life. PET bottles are commonly used for packaging a variety of beverages and liquids, ranging from water bottles to soda cans. However, ensuring the quality and safety of these bottles is of utmost importance, and this is where PET bottle testing instruments play a crucial role. In this essential guide, we will explore the significance of PET bottle testing and the key instruments involved in the process.

Why PET Bottle Testing is Essential

PET bottles are preferred for packaging due to their lightweight, transparency, and recyclability. However, various factors, like as material faults, manufacturing abnormalities, and environmental factors, might have an impact on the quality and safety of these bottles. Testing is essential to identify and rectify these issues, ensuring that the bottles meet the required standards and regulations. Here are some reasons why PET bottle testing is crucial:

Material Integrity:

PET bottles should have consistent material properties to withstand the pressure and conditions during packaging, transportation, and storage.

Barrier Properties:

PET bottles are frequently used to keep beverages, and they must have adequate barrier qualities to prevent gas and other external substance infiltration.

Dimensional Stability:

The dimensional accuracy of PET bottles is vital to ensure compatibility with filling and capping equipment, preventing leakage and spillage.

Transparency and Clarity:

PET bottles should be transparent and clear, allowing customers to view the contents. Testing guarantees that the bottles' optical qualities are preserved.

Closure Compatibility:

PET bottles are sealed with closures, and testing ensures that the bottle and closure combination provides a secure and leak-proof seal.

Key PET Bottle Testing Instruments

Several instruments are used in the testing process to assess different aspects of PET bottles. Here are some essential PET bottle testing instruments:

1. Bottle Burst Tester:

Purpose: Determines the burst strength of PET bottles. How it works: The bottle is inflated till it bursts. The pressure at which this occurs reveals the burst strength of the bottle.

2. Bottle CapTorque Tester:

Purpose: Measures the torque required to open or close bottle closures. How it works: Rotates the closure and measures the force applied, ensuring proper sealing and easy opening for consumers.

3. Vacuum Leak Tester:

Purpose: Detects leaks in PET bottles under vacuum conditions. How it works: The bottle is placed in a vacuum chamber, and any leaks cause a pressure shift, indicating a flaw.

4. Top Load Tester:

Purpose: Evaluates the vertical load-bearing capacity of PET bottles. How it works: To test the bottle's resistance to deformation, apply a compressive weight from the top.

5. Wall Thickness Gauge:

Purpose: Measures the thickness of PET bottle walls. How it works: Wall thickness is measured using ultrasonic or infrared technology to ensure uniformity and strength.

6. Melt Flow Index Tester:

Purpose: During the manufacturing process, the flow properties of the PET material are evaluated. How it works: Measures the rate of extrusion of molten PET under standardized conditions.

Conclusion

Product quality and safety are critical in the PET bottle manufacturing industry. To discover and correct deviations from standards, modern testing devices must be used. From burst strength to wall thickness, each parameter plays a crucial role in determining the overall integrity of PET bottles.

Manufacturers and quality control professionals must invest in state-of-the-art PET bottle testing instruments to meet industry standards, regulatory requirements, and consumer expectations. They not only ensure the dependability and safety of their products, but they also contribute to sustainable packaging methods by using recyclable materials.

In conclusion, the essential guide to PET bottle testing instruments emphasizes the importance of a comprehensive testing process in the production of PET bottles. This commitment to quality assurance benefits producers as well as customers by assuring them that the PET bottles they use are dependable, safe, and environmentally friendly.

0 notes

Text

APPEARANCE!

APPEARANCE!

1 Samuel 16:7

In a culture and generation where looks seem to define everything, and beauty holds great importance—evident in the thriving beauty industry—it appears we are still making the same mistake as Prophet Samuel: judging by outward appearance alone.

What does "appearance" mean?

Appearance refers to the way someone or something looks, the impression given by someone or something, an act of participating in a public event, or the act of arriving or becoming visible.

What does appearance look like today according to these definitions?

For most people, personal appearance is everything. It matters in almost every aspect of life. But should it? According to God, appearances do matter, but His perspective is vastly different from popular culture's focus. In Matthew 7:20, the Bible emphasizes that how we look on the inside matters far more to God than our outward appearance. What truly counts is how we reflect Jesus, not how we strive for popularity or validation from people.

Man often focuses on the physical, but God looks beyond appearance.

For example, Saul was tall, handsome, and an impressive-looking man. When Samuel was seeking Israel’s next king, he may have been inclined to choose someone resembling Saul. However, God warned him against judging by appearances alone. Judging people by outward appearance often leads us to overlook individuals who lack society's admired physical qualities. But appearance doesn't reveal a person's true character or value.

Is appearance a form of identification?

Yes, appearance often serves as a form of identification. For instance, uniforms identify police officers, medical personnel, and other professionals.

We’ve all heard the saying, “Don’t judge a book by its cover.” But what does it really mean?

Can we accurately determine someone's character based on their appearance, how they dress, act, or speak? Sometimes, yes, but often, no. For example, people with tattoos, piercings, dyed hair, or unconventional clothing are sometimes unfairly labeled as bad, hooligans, criminals, or no-good individuals. How do you judge others—by their physical appearance, the content of their heart, or their character?

Fortunately, God judges by faith and character, not by appearances. Since only God can see the heart, only He can judge accurately. While most people spend hours maintaining their outward appearance, they should dedicate even more time to developing their inner character. Everyone sees your face, but only you and God know what your heart looks like. Which part of you is truly more attractive?

We categorize people as beautiful, handsome, good-looking, well-dressed, rich, or well-to-do. We naturally gravitate toward these individuals, often without considering their character, attitude, or behavior. Conversely, we dismiss and disregard those who don't meet these superficial standards, as though they hold no importance or value.

However, 1 Peter 3:3–4 reminds us that what truly matters is not outer appearance—like hairstyles, jewelry, or clothing—but our inner disposition. We are called to cultivate inner beauty, the gentle and gracious kind that delights God.

Sadly, many people today judge others based on brands, styles, and the cost of their attire, using these to gauge someone's worth or value. Yet, in Matthew 23:28, Jesus warns: "Outwardly you look like righteous people, but inwardly your hearts are filled with hypocrisy and lawlessness."

Appearance can be deceiving. Proverbs 31:30 tells us: "Charm can be deceiving, and beauty fades away, but a woman who honors the Lord deserves to be praised."

In the last decade, there has been a troubling shift in how we measure and judge others—a shift that is one-dimensional and ungodly. We must strive to see as God sees, rather than conform to society's shallow programming.

PRAYER: Father, help me to me godly-minded and discerning so that I don’t judge people based on the flesh in Jesus’ name, amen.

Shalom

WOMEN OF LIGHT INT’L PRAYER MIN.

#spotify#devotional#christianpost#women's ministry#biblestudy#biblestudy christianpost women's ministry#biblestudy christianpost 'women's ministry#conference#prayer meeting#family

0 notes

Text

How CMM Measurement Enhances Efficiency in Metal Fabrication

In the fast-paced world of metal fabrication, precision and efficiency are crucial for maintaining high-quality standards and reducing production costs. Coordinate Measuring Machines (CMMs) have revolutionized the industry by providing accurate and automated measurement solutions. These advanced systems help manufacturers maintain tight tolerances, improve workflow efficiency, and reduce material waste.

For businesses looking to optimize their manufacturing processes, investing in reliable CMM measurement manufacturers in Bangalore can significantly enhance production capabilities. In this blog, we will explore how CMM measurement enhances efficiency in metal fabrication and why it has become an essential tool in modern manufacturing.

The Role of CMMs in Metal Fabrication

Metal fabrication involves cutting, bending, welding, and assembling metal parts to create final products. Accuracy in every stage of the process is vital to ensure that components fit together seamlessly and meet industry specifications. CMMs play a crucial role in verifying the dimensional accuracy of fabricated parts by using advanced probes and sensors to measure complex geometries with high precision.

CMM measurement ensures that each component meets the required specifications before proceeding to the next stage, reducing the likelihood of defects and costly rework. This quality control process enhances the overall efficiency of metal fabrication operations.

Key Benefits of CMM Measurement in Metal Fabrication

1. Improved Accuracy and Precision

Traditional measurement methods, such as manual calipers and gauges, are prone to human error, leading to inconsistencies in part dimensions. CMMs, on the other hand, provide highly precise measurements with minimal variation. By using advanced scanning technology and touch probes, CMMs can detect even the smallest deviations from design specifications, ensuring consistent quality in metal fabrication.

2. Faster Inspection and Reduced Downtime

One of the major advantages of using CMMs is their ability to automate the inspection process. Traditional manual measurements can be time-consuming and may require multiple steps to validate part accuracy. CMMs streamline this process by quickly scanning and verifying parts, significantly reducing inspection times.

With automated measurement systems, manufacturers can conduct real-time quality checks, identify potential defects early, and prevent costly delays in production. This improved efficiency helps manufacturers meet tight deadlines without compromising on quality.

3. Enhanced Productivity and Workflow Optimization

CMMs help metal fabrication companies optimize their workflows by integrating measurement data into manufacturing processes. By using software-driven inspection reports, manufacturers can analyze trends, identify areas for improvement, and fine-tune their production techniques.

Additionally, CMMs can be integrated with CNC machines and other automated systems, allowing real-time feedback and adjustments during the fabrication process. This seamless integration improves productivity and reduces the risk of material waste caused by incorrect machining.

4. Minimized Material Waste and Cost Savings

Material waste is a significant concern in metal fabrication, as errors in measurement and cutting can lead to excessive scrap. CMM measurement helps reduce waste by ensuring that components are manufactured correctly the first time. By identifying deviations early in the process, manufacturers can take corrective actions before costly materials are wasted.

Investing in high-quality CMM measurement manufacturers in Bangalore can help businesses reduce material waste and achieve significant cost savings over time.

5. Compliance with Industry Standards

The metal fabrication industry must adhere to strict quality control standards, including ISO, ASME, and GD&T (Geometric Dimensioning and Tolerancing) guidelines. CMMs ensure compliance by providing highly detailed measurement reports that verify product accuracy against industry standards.

By maintaining high-quality standards, manufacturers can enhance their reputation, reduce the risk of defects, and improve customer satisfaction.

Choosing the Right CMM Measurement Manufacturer

When selecting a CMM measurement solution, it is essential to choose a reputable manufacturer with experience in the metal fabrication industry. Here are a few key factors to consider:

1. Advanced Technology and Equipment

Look for manufacturers that offer cutting-edge CMM machines equipped with multi-sensor technology, laser scanning, and software integration capabilities.

2. Customization and Application Support

Each metal fabrication process has unique requirements. A good manufacturer should provide customized solutions tailored to specific production needs.

3. Training and Technical Support

Investing in CMM measurement technology is only beneficial if operators are trained to use it effectively. Choose manufacturers that offer training programs and ongoing technical support.

4. Accuracy and Calibration Services

Regular calibration is essential to maintain the accuracy of CMM measurements. Opt for manufacturers that provide calibration and maintenance services.

Conclusion

CMM measurement has become an indispensable tool in metal fabrication, improving accuracy, efficiency, and overall productivity. By automating the inspection process, reducing material waste, and ensuring compliance with industry standards, CMMs help manufacturers produce high-quality components with greater reliability.

For businesses looking to enhance their manufacturing capabilities, partnering with trusted CMM measurement manufacturers in Bangalore is a smart investment. With the right technology and expertise, companies can achieve superior precision, faster production times, and cost-effective solutions in metal fabrication.

0 notes

Text

Electrolytic Polished Stainless Steel Capillary Tube

SD-Steel is a leading provider of high-quality electrolytic polished stainless steel capillary tubes, designed to meet the most stringent requirements in various industries. Our capillary tubes are meticulously crafted using advanced electrolytic polishing techniques to ensure exceptional surface finish and dimensional accuracy. This product is ideal for applications requiring precise fluid control and durability, such as medical devices, aerospace components, and precision instruments.

Product Description

Our electrolytic polished stainless steel capillary tubes offer unparalleled performance and reliability. The electrolytic polishing process results in a smooth, corrosion-resistant surface that enhances the longevity and functionality of the tubes. These tubes are known for their superior strength and resistance to wear and tear, making them suitable for demanding environments where precision and reliability are paramount.

Material

The primary material used in our capillary tubes is 316L stainless steel, renowned for its excellent corrosion resistance and mechanical properties. The 316L grade ensures optimal performance in corrosive environments and high-pressure applications.

Specifications & Dimensions

| Diameter (mm) | Wall Thickness (mm) | Length (m) |

|------------------|-----------------------|---------------|

| 1.0 | 0.1 | Customizable |

| 1.5 | 0.2 | Customizable |

| 2.0 | 0.3 | Customizable |

Usage Scenarios

These capillary tubes are widely used in:

Medical Devices: For applications requiring sterile conditions and high precision.

Aerospace Industry: Ideal for fuel lines and hydraulic systems.

Precision Instruments: Used in sensors and gauges due to their consistent bore and outer diameter tolerances.

Company Strengths

With over two decades of experience in the steel industry, SD-Steel has established itself as a trusted supplier for clients globally. We pride ourselves on our commitment to quality and customization, ensuring each tube meets the highest standards of performance and safety.

Application Scenarios

Medical Equipment: Used in syringes, catheters, and other medical devices.

Automotive Industry: Essential for fuel delivery systems and instrumentation.

Chemical Processing: Suitable for transferring corrosive fluids and gases.

Food & Beverage: Perfect for food processing equipment where hygiene and durability are critical.

Pharmaceutical Industry: Critical for drug delivery systems and biotech applications.

Industrial Machinery: Integral in manufacturing machinery parts that require high precision and reliability.

FAQs

Q: What are the key benefits of your capillary tubes?

A: Our tubes provide a seamless, clean inner surface, reducing contamination risks and ensuring smooth flow without clogging.

Q: Can you customize the length and diameter?

A: Yes, we offer custom lengths and diameters to meet specific project requirements.

Q: How do I place an order?

A: Contact us at +65 83016969 for any inquiries or custom orders.

Why Choose SD-Steel?

Customization: We offer tailored solutions to meet unique project needs.

Quality Assurance: Every batch undergoes rigorous testing to guarantee consistency and reliability.

Delivery: Fast turnaround times with global shipping capabilities.

Contact us at +65 83016969 for specialized applications.

Key Features

High Precision: Ensures accurate measurements and reliable performance.

Durability: Designed to withstand harsh conditions.

Versatility: Suitable for a wide range of industrial applications.

Technical Support

For more information or custom specifications, reach out to our team for expert advice and support.

Conclusion

Choose SD-Steel for unmatched quality and service. Call us today at +65 83016969 for all your needs.

Stainless Steel Capillary Tube

Stainless steel bar

0 notes

Text

Financing Sustainable Transition: Key Insights for Investors

Introduction

Financial institutions face challenges financing essential industries hindered by significant ESG transition barriers. Hard-to-abate sectors like steel, cement, chemicals, aviation, and shipping, as well as labor-intensive manufacturing, need targeted strategies to improve ethical practices and ensure regulatory compliance. Transition finance is crucial in supporting these industries' decarbonization and ESG improvements, driving progress while managing risks and investment opportunities.

Evaluating Transitionary Trends

At Inrate, four key themes guide sustainable transition evaluation:

Sustainable development

A low-carbon economy

Restoring biodiversity

An inclusive society

Macro Perspective: Sector Classification for Sustainable Transition

Sustainable transition requires restructuring the economy, favoring industries contributing to essential societal needs. Instead of traditional classifications, sectors can be defined by the key services they provide, like grouping all transportation modes under one sector. Inrate's ESG Impact Ratings apply absolute measurements, comparing companies across different sectors.

Micro Perspective: Company-Level Transition Evaluation

Assessing transition at the micro level focuses on individual companies' sustainability performance. Investors prioritize companies producing goods and services sustainably, excluding those relying on unsustainable methods. Key parameters help refine evaluations, highlighting variations in execution that influence a company's impact score.

Tracking Change Over Time

To gauge genuine transformation, investors should analyze a company's business activities over time. Real progress is determined by shifts in revenue streams and investment priorities. By tracking these changes, investors can distinguish between companies making tangible progress and those merely signaling intent.

Driving Meaningful Sustainability Transitions

Achieving sustainable transition requires a multi-dimensional approach:

Macro Perspective: Redefine sector classification based on societal needs.

Micro Perspective: Distinguish companies by how they operate within their sectors.

Change Over Time: Measure transition by tangible shifts in activities and revenue streams.

By leveraging these perspectives, investors can allocate capital to companies driving real, measurable progress, ensuring sustainability assessments focus on tangible action and impact.

Read more: https://inrate.com/blogs/financing-sustainable-transition-insights/

0 notes