#diesel engine fire pump

Explore tagged Tumblr posts

Text

Diesel Engine Fire Pump

A diesel engine fire pump is a type of fire pump that uses a diesel engine rather than electricity or another source of power. Fire pumps are key components of fire protection systems that are designed to deliver a consistent high-pressure water supply to firefighting sprinkler systems, standpipes, or fire hydrants.

0 notes

Text

So,

I just heard something on a programme I am watching, Do Americans, leave their car engine running when they fill up with petrol/diesel? This man said he does it everytime! Running your engine while pumping petrol/diesel increases the risk of fire because your engine produces not only heat, but also static electricity while running.

28 notes

·

View notes

Text

2024-12-05: Oklahoma (Hex 5)

Dry forests of pine and oak are scattered across the prairie as it gives way to more hilly terrain. The way to the southwest, northwest, north, and southeast are craggy and prone to delays.

Notable Feature: Natural Landmark

A river in a shallow gorge winds its way through the landscape on both sides of the road; several lakes formed by the river's path are visible out to the horizon.

Secret: A Man And His Horses

A nomadic herder named Johnny Burns (which may or may not be his real name) grazes his herd of horses illegally on private property throughout the state and has somehow never been caught. His horses are prized for their racing ability and fetch an incredible price at auction, but he is only known to show up once a year with a single horse for sale at the Oklahoma Jockey Association. No one knows how to find or contact him, not even the people who regularly travel these mystical roads.

Johnny is intentionally difficult to find, as he has perfected a type of ritual that functions like a more powerful version of the Pass Without Trace spell. This spell keeps him and his herd hidden until they have left an area, but it does have one important limitation: it only obfuscates creatures from searchers on the ground. Flying a plane over the area will make it obvious where Johnny is.

If Johnny is ever found, he will offer to teach the finder(s) a ritual version of Pass Without Trace on the condition that they do not reveal his location and agree to swear a blood oath affirming this. The blood oath functions similarly to an explosive Glyph of Warding cast on a person's hand though it is not subject to the 10 foot distance limitation of the spell. The glyph explodes with fire damage and no saving throw if Johnny's secret is ever revealed to anyone who does not already know it, and it will completely obliterate the arm of whoever revealed the secret (if it doesn't outright kill them).

Service Station: Sooner Municipal Airfield

It's basically a strip of asphalt and a tiny shack where the radio operator (middle-aged man named Walker Bradley) works and other people pop in to escape the elements between flights. A corrugated metal hangar holds 1d4+2 single engine aircraft that crop dusters and aviation enthusiasts have left parked here. There are four pumps here that are spread out quite far from each other: three dispense aviation fuel and the fourth dispenses diesel.

The small-engine aircraft that launch from here have engines that use a very high octane form of leaded gasoline. It's a bit overkill for automotive engines, but regular cars of the era can use it without any trouble. The lone diesel pump is for fueling up the heavy equipment that tow planes, grade the airstrip, and keep the facility operational; but it's not uncommon for people to fill up their personal diesel vehicles here.

As long as someone gives Walker the radio operator at least a token tip, he'll conveniently forget he saw anyone filling up their vehicle. Failure to pay up means he'll take note of the offending license plate and notify both the police and any airborne pilots in the area. There's also a 1-in-6 chance that a plane will begin following the gas thief's vehicle and try to stop them long enough for the police to arrive if they don't decide to pursue vigilante justice first.

Items From Other Hexes

To be added later from Hex 26. I know what hexes are linked together with quests and secrets, but exactly what is going to be shared between those hexes has yet to be determined. This will be updated later with whatever the hidden feature is.

-----------

Apparently aviation fuel for small aircraft can actually IRL be used to fuel cars of the era because it used leaded gasoline. Modern cars that require fuel without tetraethyl lead in them can't use it, though. I am taking this information from classic car restoration forums and didn't fact check it beyond that, so if you attempt to use avgas in your vehicle, you're doing so at your own risk!

4 notes

·

View notes

Note

As a Guy who Fixes Machines for a living, but unfortunately doesn't have Much experience with engines, *but* has read a Ton about them: please tell me about steam engines and/or their Repair Quirks and Logistics. Infodump Away :chinhands:

I'm going to be honest with you - this is one of the most flattering asks I've ever received in my 14+ years on this website.

Steam locomotives seem pretty overwhelming at first because, as you'd expect, there's a lot of moving parts, and they're actually huge. Like many large animals, people often don't realize how big they can actually get until they're in the presence of one. The one I drove, Strasburg #90, weighs in at 212,000 lbs - and she's smaller than a lot of the active steam locomotives operating today. 106 tons is nothing to sneeze at, and she's still considered smaller.

You probably don't need this in layman's terms, but I'm going to try to keep the explanations easy to understand in case anyone who doesn't work with machines reads this.

How do the beasts run?

Continuing the metaphor of these things basically being really large animals, you have to feed and water them. Early steam locomotives ran on wood, but as time went on the most common fuels became coal and oil, and today some can even run clean on vegetable oil or torrefied biomass. The fact that they need to be fed and watered fairly regularly is why there's always at least two people in the locomotive cab - you've got an engineer driving and a fireman keeping the beast fed and monitoring the water levels in the boiler.

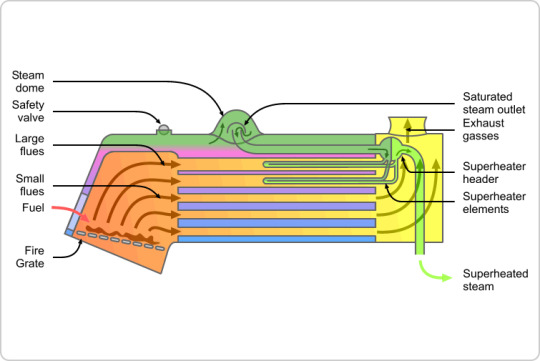

This is a diagram of a fire tube boiler from Wikipedia. Steam locomotives generally use this type of boiler, which gives them their familiar shape. The fuel is thrown into the firebox on the left of the diagram, and the heat from the fire flows up to the tubes in the boiler. The water in the boiler becomes steam (specifically what's called "wet steam" because it's saturated). The steam rises to the highest point in the boiler, the steam dome at the top. From here, the steam is sent down into a superheater, which dries it out and produces superheated steam, and that's what's directed down to the cylinders to get everything moving. The smokestack on the right of the diagram is where the exhaust gasses are released, giving off that plume of smoke everyone expects to see.

Now that the steam is at the cylinders, the pistons can start pumping and moving the driving rods on the driving wheels (the big ones). Here's an animated gif of that process, again from Wikipedia.

At this point, it's basically like any other engine with pistons - the pistons get pumping and the machine starts operating. This whole section of the locomotive is referred to as the running gear, and includes the valve gear, connecting rods, brake gear, wheelsets, axleboxes, and springing.

Essentially, it's a steam engine with wheels that is capable of pulling incredible amounts of weight if everything is done correctly. Your average steam locomotive is still stronger than your average diesel or electric locomotive is. Depending on what you needed your steam locomotive to do, the size of the driving wheels would differ - locomotives built for high speed tend to have really large drive wheels, whilst locomotives designed to go slower but pull more weight have smaller drivers for better adhesion and traction.

Maintenance?

As expected, since they have a lot of moving parts, steam locomotives need a lot of active maintenance. They're checked frequently, have mandated annual inspections, and are required by the Federal Railroad Administration in the United States to have a more thorough inspection every 1,472 days of active service - so it's basically 15 years or 1,472 days of operation, whichever comes first. 90, the locomotive I drove at Strasburg, is currently undergoing her 1,472-day inspection as I write this post and she'll hopefully be back in operation for her 100th birthday next year.

One of the things that's unique about steam locomotive maintenance is that the boiler regularly has to be cleaned out, which is why the boilerplate on the front has hinges - that thing's a door! This job was more dangerous historically because boilers were often insulated with asbestos, but pretty much anything operating today has had any asbestos removed or wasn't built with it in the first place. This website has a really good explanation of the process of cleaning out and fixing up a locomotive boiler for a 1,472 day inspection, complete with photos!

In terms of steam locomotive shops, I'm biased towards Strasburg because I grew up going there all the time, but they really do perform incredible work. Late last year, one of their locomotives, #475, had a run-in with a crane left on the track due to a misthrown switch, and her smokebox took some damage. Fortunately, the damage was minor, and they were able to get her repaired in a mere 96 hours.

She now looks like this:

They opted to braze weld her and didn't smooth it out as a reminder to crews to stay vigilant, so she now has some really cool battle scars.

I'm not as well-versed in repair since I don't have hands-on experience with it (yet), but once I can start volunteering I'll hopefully have some more stuff to talk about since I'm hoping to learn to work with these machines more closely! (And drive. Drive all the time. Drive forever.)

40 notes

·

View notes

Text

So the switch to E10 petrol happened several years ago, and as annoyed as I was at the time about it, it's taken this long to start really seeing the toll ethanol takes on small engines, and how inappropriate it is for machines that are used sporadically.

With the old E5 grade fuel, we left things sitting for months at a time to no major effect; our tolerant old Honda-powered pump fired up after over a year no problem.

E10 goes off at around the 5–6 week mark. This is not in keeping with the literature posted about the stuff at the time of the switchover, but it's what we've experienced.

We've had to take off and clean the carbs after this miserably tiny window has passed on the following machines:

The chipper

The stump grinder

The skidsteer

The chainsaw (despite premix and despite being run virtually empty)

Both Scorpas

I discovered the Scorpa problem this weekend, although tbf I was braced for it after this many stupid unnecessary failures. A problem with my bike's registration took most of this year to resolve, so we missed the whole riding season waiting for it to be reliably road-legal. There was no way this shite fuel was going to survive the glacial pace of the DVLA.

Sad dead bae after I managed to get it started, only for its float to get stuck and flood the airbox with fuel 🙃

Here's the gelatinous crap this fuel produces as it putrifies. Looks almost like fish eggs. I couldn't photograph the clagged-up jets, they're just too delicate for my phone camera to get the detail, but all the fine holes were clogged to shit.

I cleaned this out with carb cleaner and the compressor.

We only have one nearby petrol station, and it doesn't supply E5. I'm not impressed — partly for my own sake, and the extra work this stupid policy has dumped in our laps, but also for the sheer number of good petrol domestic machines that are going to be wrecked by this policy. For stupidity, I rank it up there with the abrupt removal of red diesel.

2 notes

·

View notes

Text

There's a developing story in german railroads that I need to share with you all because it has become a meme at this point. It concerns this type of vehicle:

Source: Falk2 on Wikimedia commons, CC-BY-SA

This is the class 711.1 overhead line maintenance car, one of several different types of similar vehicles. It is designed to fix any problems that may develop with the overhead lines. It's diesel-powered, obviously, and it has a big workshop on the inside full of all sorts of copper equipment, and on the top, a special pantograph for checking wire alignment and a working platform from where you can actually touch and work on the wires.

The official nickname for them when they were introduced was Hubarbeitsbühnen-Instandhaltungsfahrzeug für Oberleitungsanlagen (lift working platform maintenance vehicle for overhead line equipment), or in short HIOB, the german spelling of the biblical Job, which was definitely not a bad omen at all.

22 of these were built between 2002 and 2004, and they (as well as other similar vehicles) are stationed all over Germany to react quickly to any issues with overhead lines, as well as do various forms of regular checks and maintenance. The 711.1 is special, though: It keeps catching on fire.

Picture by fire brigade Bienenbüttel, found at https://www.az-online.de/uelzen/bienenbuettel/flammen-bahn-1605363.html

The first one burned down in 2012. Nobody got hurt (in any of the following incidents), and it was treated like a freak accident. Specifically, the investigation revealed that it's related to how the train functions. Normally, for a diesel train, you either have a direct mechanical connection from the motor to the driven wheels (sometimes including something like the torque converter in an automatic gearbox), or sometimes the diesel engine drives an electric generator and electric motors at the wheels drive the train. This, on the other hand, has a hydrostatic transmission: The main engine drives a pump that creates pressure in an oil system, and this high-pressure oil is then used in motors at the wheels to drive the train.

The good thing about this arrangement is that the train can run both fast (up to 160 km/h or 100 mph) to quickly reach the place where it's needed, but also really slowly, walking pace or slower, so someone standing on the roof working platform can check every part of the wires carefully.

The bad thing about this arrangement is that the oil in the system is flammable. If there's a leak, it sprays out, and if that spray hits something hot, it can ignite. That's what happened here. Okay, gotta do better maintenance, alright.

Then it happened again, in July 2020.

Source: German Federal Police, via official accident investigation report

The cause was pretty much the same, but the effect was much more noticeable. The train was underway on a training run when it came to a stop for no clear reason. The staff activated the parking brake, got out, and noticed that their train was on fire. As they were calling firefighters, however, the train suddenly started to move. The engineer actually climbed back on board and tried to activate every braking system the train had, and it had a lot of them; this one was specifically equipped for more mountainous railway lines. But none of it worked, and the engineer jumped back out at still low speeds (no reported injuries).

It kept rolling downhill for 22 kilometres (about 14 miles). Station staff tried to stop it by putting signals on red and hoping for the automatic train control system to stop it, but train control systems can't do anything if there are no brakes. Others tried to put wheel chocks on the rails, but those are for parked trains, fast trains will just throw them to the say. So on it went, burning more and more. In the end the railway decided to find a nice save spot where nothing important was around and firefighters would have easy access, and let it derail there. That's what the picture above shows.

What happened? Well, the same as before, but this time with an additional twist. The fire had destroyed all normal braking systems. It hadn't destroyed the parking brake, but on this train, the parking brake is electrically controlled. You don't need to electricity for it to stay active, but you need it to activate or deactivate it. The fire had already destroyed the relevant electrical lines when the engineer thought they activated the parking brake.

Two trains of the same type burning down for the same reason is scary and warrants action, even if it's eight years apart, and the accident investigation report lists a number of steps already taken and others that were planned, like more checks for leaks, new procedures for leaving the train so it doesn't roll away, perhaps changing some equipment out.

And it seems to me personally that these changes had an effect. Of sorts.

youtube

You can ignore the narration (which consistently calls it an engine even though it's a rail car), just admire these pictures of a driverless burning train coming towards you. Yes, in January 2023, another of these trains caught fire, it rolled away again, and got derailed on purpose again. We don't have an official accident investigation report yet, so who knows what happened here, but, like, it's not exactly hard to make a guess.

Just to really hammer the point home, let's go to February 2023, just a month later, and this time we see the same thing in Dresden.

Picture: Credited to "Firefighters", from https://bahnblogstelle.com/198726/erneut-brand-von-instandhaltungsfahrzeug-diesmal-in-dresden/

This time it didn't run away! My understanding is that the train drivers, well aware of the history of this type, placed wheel chocks in front of the wheels before it had the chance to do anything crazy.

Which brings us to last month. You won't believe what happened June 13th, 2024:

Picture: Firefighters Haan, via https://rp-online.de/nrw/staedte/haan/triebwagen-brennt-auf-der-bahnstrecke-gruiten-hochdahl_aid-114420335

So as the Wikipedia infobox helpfully says,

that's five out of 22 burned down. I gotta say, if your train's Wikipedia article has a "train burned down" counter and a section of fires that's nearly a third of the whole article, that's an issue.

(Ironically, it is actually not the most-burned-down german train by percentage. That dubious honour goes to the MaK DE 1024, an experimental heavy diesel locomotive. Three were built, two of them burned down eventually. The sole survivor was, in the numbering scheme of its last and longest owner, number 13.)

As of right now, DB has decided that these trains can't be trusted with engines, so for now they will all have to be pulled by locomotives. To me that sounds like it should fix the issue, for some value of "fix".

It's definitely notable that during the first 18 years of this type's use, they suffered two fires, and after they implemented all sorts of fixes after the second, three more burned down in just four years. I don't want to say the fixes made it worse, maybe it's just age starting to show, but it doesn't seem to have helped any.

Anyway, I hope that they either manage to fix or replace these trains before more burn down, but I have to admit that it's also very funny to open social media (mostly Bluesky for me these days, I haven't yet decided on a Mastodon server) and see the rail bubble shout because yet another of these machines has burned down.

6 notes

·

View notes

Text

Postcards from Snagglepuss

So who was O. Winston Link, anyway?

O. WINSTON LINK MUSEUM, ROANOKE, VA: Outside of railfans (especially such fond of the Norfolk and Western Railway, which has long had a presence in Roanoke, one continuing in its contemporary form as Norfolk Southern) and students of photography, the name O. Winston Link (1914-2001) probably doesn't ring quite a bell.

But in the Blue Ridge country, his photography of tne Norfolk and Western Railway as it was preparing to make the transition from steam to diesel locomotion in the late 1950's is something of the stuff of legend. Especially a two-year initiative of his during 1955 and 1956 in particular, which featured plenty of night scenes of steam draped against backdrops rural, semi-urban and urban ... the sort, you might say, bound to strike the fascination of Super Snooper and Blabbermouse. Who, for some reason, decided to join our own party of vagabonds in Roanoke's former Norfolk and Western station, as houses the Roanoke Historical Museum, of which the O. Winston Link such is a part and parcel.

"It just seems particularly fascinating, Blab," Snoop could be heard remarking, "how one could situate a hotshot freight train in the background of a drive-in movie theater, with the inevitable pair of lovers kissing away in the foreground."

"And wondering what to pay the more attention to--the movie or the train," remarked I. (Which, you might like to know, was taken in the summer of 1956 in Iaeger, West Virginia.)

"It just gets me here, Snoop," Blabbermouse was quick to note on seeing a picture of a coal train passing through a small West Virginia town in the proverbial wee small hours of the night as the late shift waitress was being picked up from her shift at the local cafe. Like sentiment was directed at a nighttime wedge shot out of Luray, Virginia as the engine was preparing to take on water.

Crazy Claws was quick to chime in as well: "And you wonder how many flash bulbs he went through just to get the shot, to begin with!" (As a matter of fact, Link and his assistant, George Thom, relied on the asynchronous firing of no less than 42 #2 flashbulbs and one #0 flashbulb just to get that shot at the Iaeger drive-in. As Link himself famously explained that penchant of his for night photography in that project of N&W steam in its twilight, "I can't move the sun — and it's always in the wrong place — and I can't even move the tracks, so I had to create my own environment through lighting.")

Breathe in, then, such sentiment for times long past, bringing in a sense of moodiness in a landscape doubtless much changed. Yet it makes you wonder, especially as moi, Huck, Snoop and Blab took note of one shot of a gravity-feed gas pump at the local store in Vesuvius, Virgina as the N&W's premier overnight train, the Pocahontas, passed by at close range ... in the middle of a power outage affecting the village!

*************

@warnerbrosentertainment @groovybribri @jellystone-enjoyer @ultrakeencollectionbreadfan @zodiacfan32 @artistic-octopus @archive-archives @thylordshipofbutts @thebigdingle @themineralyoucrave @screamingtoosoftly @warnerbros-blog1 @iheartgod175 @indigo-corvus @theweekenddigest @funtasticworld @warnerbrosent-blog

#hanna barbera#fanfic#fanfiction#road trip#postcards from snagglepuss#huckleberry hound#unlikely crossovers#super snooper and blabbermouse#o. winston link#o. winston link museum#night photography#night photoshoot#rail photography#norfolk and western railway#steam's twilight#hannabarberaforever

3 notes

·

View notes

Text

Welded Steel Tanks for Crude Oil and Petroleum Storage

Welded Steel Tanks for Crude Oil and Petroleum Storage

As the world increasingly relies on petroleum products for energy and industrial applications, efficient and secure storage solutions for crude oil and refined petroleum are more critical than ever. Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) proudly offers industry-leading welded steel tanks, providing robust and reliable storage solutions for the oil and gas industry.

Unparalleled Quality and Engineering Expertise

At Center Enamel, our welded steel tanks are meticulously designed and fabricated to meet the highest international standards, including API 650, AWWA D100, and OSHA requirements. With decades of experience in the industry, we have refined our processes to deliver tanks that combine exceptional durability with superior performance, making them ideal for the demanding environments of crude oil and petroleum storage.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Applications in the Oil and Gas Industry

Welded steel tanks are indispensable in various stages of oil and gas operations, including:

Crude Oil Storage: Storing unrefined crude oil at exploration sites, refineries, and terminals.

Refined Petroleum Storage: Safely housing gasoline, diesel, jet fuel, and other refined products.

Strategic Reserves: Acting as a buffer during supply chain disruptions or emergencies.

Blending and Distribution: Supporting blending processes and serving as intermediate storage for distribution networks.

Features and Benefits of Our Welded Steel Tanks

Customizable Designs:

Our tanks are fully customizable to meet specific project requirements, including size, capacity, and configurations. This ensures optimal compatibility with your operational needs.

Superior Material Selection:

We use high-grade carbon steel and stainless steel to fabricate tanks capable of withstanding harsh environmental conditions and corrosive materials.

Advanced Anti-Corrosion Technology:

Each tank undergoes surface treatments and coatings to ensure long-lasting resistance to corrosion, reducing maintenance costs and extending service life.

Compliance with Safety Standards:

Our welded steel tanks are designed with safety as a priority, adhering to stringent international standards for pressure containment and fire resistance.

Thermal Insulation and Heating Options:

For crude oil storage in colder climates, our tanks can be equipped with insulation and heating systems to maintain optimal storage temperatures.

Ease of Integration:

Our tanks are compatible with modern monitoring systems, including level gauges, pressure sensors, and automated controls, ensuring seamless integration with existing infrastructure.

Proven Track Record in Global Projects

Center Enamel’s welded steel tanks have been successfully deployed in numerous oil and gas projects worldwide. From crude oil terminals in remote regions to high-capacity storage facilities in bustling refineries, our tanks have consistently demonstrated their reliability and efficiency.

One notable example is their proven ability to withstand extreme environmental conditions, including seismic activities, thanks to robust structural designs and quality manufacturing processes. This makes our tanks a trusted choice for storage solutions in both standard and challenging environments.

Comprehensive After-Sales Support

At Center Enamel, our commitment to excellence extends beyond product delivery. We provide comprehensive after-sales support, including installation guidance, routine maintenance services, and expert consultations. Our team of professionals is always ready to ensure the continued optimal performance of your storage tanks.

Why Choose Center Enamel for Your Crude Oil and Petroleum Storage Needs?

Proven Expertise: Over three decades of experience in the tank manufacturing industry.

Global Reach: Trusted by clients in more than 100 countries worldwide.

Innovation-Driven: A dedicated R&D team to ensure continuous product improvement.

Certifications: ISO 9001, API 650, AWWA, and other international standards.

Contact Us for Your Storage Solution

As the most experienced bolted and welded steel tank manufacturer in Asia, Center Enamel is your trusted partner for crude oil and petroleum storage solutions. Contact us today to learn more about our welded steel tanks and how we can meet your specific project requirements. Together, we can ensure safe, reliable, and efficient storage for your valuable resources.

0 notes

Text

The Importance of Fire Pumps

Fire pumps play a critical role in fire protection systems and are essential for the safety of buildings, industries, and communities. Learn some key reasons why fire pumps are important.

#fire pump system#fire fighting pump#diesel fire pump#electric fire pump#diesel engine fire pump#fire water pump

0 notes

Text

Diesel Dredge Safety: Tips for a Risk-Free Operation

Operating diesel-powered dredge requires a strong focus on safety to prevent accidents and ensure efficient performance. This guide highlights essential safety tips to mitigate risks during dredging operations. From regular equipment inspections and proper maintenance of diesel engines to ensuring adequate ventilation and fire prevention, adherence to safety protocols is critical. It also emphasizes the importance of personal protective equipment (PPE), training for operators, and following emergency procedures. Monitoring fuel systems for leaks, reducing exposure to hazardous emissions, and maintaining a clear communication system on-site are equally vital. By implementing these practices, operators can minimize hazards and maintain a safe, risk-free environment, ensuring both the safety of personnel and the longevity of the equipment.

Introduction to Diesel Dredge: A Vital Tool for Marine Excavation

Diesel dredge are essential machines in the marine and construction industries, widely used for excavating and transporting sediment. Equipped with powerful diesel engines, these dredge offer unmatched efficiency and reliability in challenging aquatic environments. Understanding their purpose and functionality is crucial for industries relying on dredging for land reclamation, harbor deepening, and environmental restoration.

How Diesel Dredge Work: Powering Efficient Sediment Removal

Diesel dredge operate through a robust system powered by diesel engines. The engines provide the energy required to drive pumps, cutters, and suction mechanisms. These components work together to remove underwater sediments, transferring them through pipelines to designated locations. Their high-power output makes them suitable for handling dense and abrasive materials in various water bodies.

Key Features of Diesel Dredge: Durability and Performance

Diesel dredge are designed with features that prioritize durability and performance. The diesel engines are built to withstand heavy-duty operations, while the hulls and components are corrosion-resistant to endure prolonged exposure to water. Advanced control systems and automation enhance operational efficiency, enabling precise dredging even in harsh marine conditions.

Applications of Diesel Dredge: From Harbors to Environmental Restoration

Diesel dredge are versatile, supporting a range of applications:

Port and Harbor Maintenance: Ensuring navigational channels remain clear for vessels.

Land Reclamation: Transforming underwater areas into usable land.

Environmental Projects: Removing pollutants and restoring aquatic ecosystems. Their adaptability makes them invaluable in both commercial and environmental projects.

Advantages of Using Diesel Dredge Over Electric Alternatives

While electric dredge have their place, diesel dredge offer several advantages:

Higher Mobility: Diesel-powered dredge can operate in remote areas without relying on power grids.

Greater Power Output: Diesel engines provide the torque needed for heavy-duty dredging.

Cost-Effectiveness: In regions with limited electricity access, diesel dredge can reduce operational costs.

Maintenance and Challenges of Diesel Dredge

Maintaining diesel dredge involves regular engine servicing, monitoring fuel consumption, and inspecting components for wear. Challenges include high fuel costs, emissions regulations, and the environmental impact of diesel operations. Adopting eco-friendly practices, such as using cleaner fuels or hybrid systems, can mitigate these issues.

Future Trends in Diesel Dredging Technology

As industries strive for sustainability, advancements in diesel dredging technology are emerging. Hybrid diesel-electric systems, low-emission engines, and smart automation are shaping the future of diesel dredge. These innovations aim to enhance efficiency while minimizing environmental footprints, ensuring diesel dredge remain relevant in modern dredging projects.

Conclusion

Diesel dredge are indispensable tools in marine excavation, offering unmatched power and versatility. Their ability to handle complex dredging tasks makes them vital across various industries. However, addressing environmental concerns and embracing technological advancements will be crucial for ensuring their sustainability in the future.

0 notes

Text

Understanding Fire Pump Control Systems

A fire pump control system is a critical component of fire protection infrastructure, designed to ensure the reliable operation of fire pumps during emergencies. These systems play a pivotal role in delivering water at high pressure to firefighting equipment, safeguarding lives and property. Their importance lies in their ability to activate automatically during a fire event, ensuring a consistent water supply when it is most needed.

Fire pump control system are typically integrated into fire sprinkler or standpipe systems and are essential for maintaining the required water pressure in buildings where municipal water supply is insufficient. They manage the operation of fire pumps, which may be powered by electric motors, diesel engines, or steam turbines, depending on the facility’s requirements and regulatory standards.

At the heart of the fire pump control system is the fire pump controller, a device that monitors system pressure and activates the fire pump when pressure drops below a predefined threshold, often caused by the activation of a sprinkler head or firefighting hose. The controller is equipped with features like manual and automatic operation modes, alarm functions, and status indicators. It also includes safeguards to prevent overheating, overloading, and other operational hazards, ensuring the system remains functional under duress.

Modern fire pump controllers are designed to comply with stringent standards set by organizations such as the National Fire Protection Association (NFPA). NFPA 20, for instance, outlines requirements for the installation and operation of fire pump systems, ensuring reliability and performance. Advanced controllers may also include digital interfaces, remote monitoring capabilities, and data logging features, allowing operators to track system performance and quickly address potential issues.

The components of a fire pump control system include pressure-sensing devices, such as pressure switches or transducers, that detect changes in water pressure. These devices send signals to the controller, which then initiates the pump's operation. Additional elements like transfer switches ensure a seamless power supply by switching to backup generators or alternative power sources if the primary supply fails.

Proper installation, maintenance, and testing of Firetrol Fire Pump Control are vital to their effectiveness. Routine inspections help identify wear and tear, electrical issues, or mechanical malfunctions that could impair performance. Testing protocols, including churn tests, flow tests, and pressure tests, verify the system’s ability to meet operational demands during an emergency. Adherence to these procedures not only ensures compliance with safety standards but also reinforces the reliability of the system when lives and property are at stake.

0 notes

Text

Top Diesel Testing Services Offered by Labs in Ajman | +971 554747210

Diesel fuel plays a vital role in powering industries, transportation fleets, and backup systems across Ajman. Ensuring its quality is critical for maintaining engine performance, meeting environmental standards, and safeguarding equipment. Diesel testing labs in Ajman offer a variety of specialized services to address these needs. These labs help businesses identify impurities, comply with regulatory standards, and optimize fuel efficiency.

In this blog, we’ll explore the top diesel testing services provided by labs in Ajman and how they contribute to operational excellence and sustainability.

Why Diesel Testing is Essential

Diesel quality directly impacts the performance and longevity of diesel-powered engines and machinery. Low-quality diesel or contaminated fuel can result in:

Increased Maintenance Costs: Impurities in diesel can clog filters, damage injectors, and cause engine wear, leading to frequent repairs.

Regulatory Non-Compliance: Failing to meet UAE fuel quality and emissions standards can result in fines or penalties.

Reduced Efficiency: Poor-quality diesel results in incomplete combustion, leading to higher fuel consumption and operational costs.

Environmental Damage: Contaminated diesel contributes to higher emissions of harmful pollutants.

By leveraging diesel testing services, businesses can mitigate these risks and maintain the highest standards of fuel quality.

Top Diesel Testing Services Offered by Labs in Ajman

1. Sulfur Content Testing

Sulfur is a significant component in diesel that can harm engines and increase emissions. Testing labs analyze sulfur levels to ensure compliance with Ultra-Low Sulfur Diesel (ULSD) standards, which are critical for reducing air pollution and adhering to environmental regulations.

2. Cetane Number Testing

The cetane number indicates the combustion quality of diesel fuel. A higher cetane number ensures smoother ignition and efficient engine operation. Diesel testing lab assess this parameter to help businesses optimize engine performance and reduce wear and tear.

3. Density and Viscosity Analysis

Density and viscosity affect how diesel flows and combusts within an engine. Labs measure these properties to ensure that the fuel meets the specifications required for optimal engine performance.

4. Water and Sediment Testing

Water and sediment contamination in diesel can lead to severe engine damage and reduced efficiency. Testing labs in Ajman use advanced techniques to detect and quantify these impurities, helping businesses avoid costly repairs.

5. Flash Point Testing

Flash point is the lowest temperature at which diesel vapors ignite. Ensuring an appropriate flash point is essential for safe storage and transportation. Testing labs evaluate this parameter to minimize fire risks.

6. Oxidation Stability Testing

Diesel fuel can degrade over time due to oxidation, leading to sludge formation and reduced fuel quality. Labs test for oxidation stability to determine the shelf life of diesel and recommend storage solutions for long-term use.

7. Cold Flow Properties Testing

In colder conditions, diesel can form wax crystals, leading to fuel filter blockages and engine failure. Cold flow testing evaluates properties like cloud point and pour point to ensure diesel performs efficiently in low-temperature environments.

8. Lubricity Testing

Diesel fuel must provide adequate lubrication to prevent wear on engine components such as fuel pumps and injectors. Testing labs analyze the lubricity of diesel to ensure it meets the required standards for engine protection.

9. Microbial Contamination Testing

Diesel storage tanks are susceptible to microbial growth, which can cause corrosion and clogging. Labs in Ajman offer microbial testing to detect bacteria and fungi, enabling businesses to take preventive measures.

10. Additive Analysis

Diesel often contains additives to improve performance and stability. Testing labs evaluate these additives to ensure they are present in the right proportions and delivering the intended benefits.

Industries That Benefit from Diesel Testing Services in Ajman

1. Transportation and Logistics

Diesel testing labs support fleet operators by ensuring high-quality fuel for vehicles, which translates to lower maintenance costs and compliance with emission standards.

2. Construction and Infrastructure

Heavy machinery and equipment used in construction projects rely on diesel fuel. Testing ensures optimal performance, minimizing downtime and enhancing project efficiency.

3. Marine Industry

Diesel-powered vessels need to meet strict maritime fuel standards. Testing labs ensure compliance while helping maintain engine reliability and fuel efficiency.

4. Manufacturing and Power Generation

Industries that use diesel for backup generators and machinery benefit from testing services by ensuring a consistent fuel supply that supports uninterrupted operations.

Advantages of Using Diesel Testing Services in Ajman

1. Regulatory Compliance

Ajman, like the rest of the UAE, enforces strict fuel quality and environmental standards. Testing labs help businesses stay compliant with regulations, avoiding fines and reputational damage.

2. Operational Efficiency

High-quality diesel verified by testing labs reduces engine wear, improves fuel efficiency, and minimizes downtime, ensuring smooth operations.

3. Cost Savings

Preventing engine damage and optimizing fuel efficiency translates to significant cost savings for businesses. Testing services help identify and eliminate potential issues before they escalate.

4. Environmental Responsibility

Testing labs help businesses reduce emissions by ensuring fuel meets ULSD standards and other environmental benchmarks. This supports sustainability initiatives and enhances corporate social responsibility.

5. Enhanced Safety

By testing critical parameters such as flash point and microbial contamination, labs help businesses minimize risks associated with fuel storage and transportation.

Key Features of Diesel Testing Labs in Ajman

1. ISO Accreditation

Most reputable diesel testing labs in Ajman are ISO/IEC 17025 accredited, ensuring they meet international standards for testing accuracy and reliability.

2. State-of-the-Art Equipment

These labs use advanced equipment and methodologies to deliver precise results, enabling businesses to make informed decisions about fuel quality.

3. Experienced Professionals

Certified chemists and engineers in these labs ensure thorough analysis and accurate reporting.

4. Comprehensive Reporting

Labs provide detailed reports on diesel quality, helping businesses identify issues and implement corrective actions.

5. Customized Solutions

Diesel testing labs in Ajman offer tailored services to meet the specific needs of different industries, ensuring businesses receive the most relevant insights.

How to Choose the Right Diesel Testing Lab in Ajman

When selecting a diesel testing lab, consider the following:

ISO Accreditation: Ensure the lab meets ISO standards for quality and reliability.

Range of Services: Opt for a lab that offers comprehensive testing solutions.

Reputation: Choose a lab with a proven track record and positive client reviews.

Timely Reporting: Look for labs that provide fast and detailed results.

Customer Support: Select a lab that offers excellent customer service and guidance.

Conclusion

Diesel testing labs in Ajman play a crucial role in maintaining fuel quality, ensuring regulatory compliance, and supporting operational efficiency across various industries. With services like sulfur content analysis, microbial contamination testing, and cold flow properties evaluation, these labs provide businesses with the insights needed to optimize diesel performance and minimize risks.

By partnering with a reputable diesel testing lab, businesses in Ajman can achieve significant cost savings, enhance environmental responsibility, and ensure the longevity of their equipment. As fuel quality standards evolve, the role of diesel testing labs will remain indispensable in promoting sustainability and operational excellence.

0 notes

Text

0 notes

Text

USA Fire Truck Food Truck Hire Big Bold and Beautiful. (Or Big Ugly F**cker) depending on your point of view. Whether you love the look or hate it, there is no denying that this fire truck food truck makes a statement. A BIG statement. Named ENG9INE and built onto a custom fabricated American firetruck, this is unique in the UK. It is also louder than Donald Trump. Twin air horns, an electronic two tone siren, and a Federal Signals 127db Q siren mean you hear this coming long before you see it. The bottom deck cooking facilities are designed for smaller events upto perhaps 1000 guests. If you need high capacity then the top deck opens up hydraulically giving you an extra 128 sq ft of kitchen. Spartan Monarch Firetruck For the geeks out there, this is built onto a 1992 Spartan Monarch custom built firetruck chassis. It originally served with Evansville, Indiana's fire department. It was fitted out by KME fire body builders It has a 1250 GPM Hale pto driven pump It has a Detroit Diesel 6V92TA two stroke, turbocharged aftercooled diesel engine set to 350HP, and affectionately known as a "screaming Jimmy" It carries the name of John W Sanders II after a young firefighter who was killed in 1991 aged just 33.Our fire service theme continues with things such as aprons upcycled from fire fighter uniforms, and condiment dispensers made from pipe fittings. Specification This has the following; On board 25kw generator system with a 250 litre fuel tank 250 litre fresh water tank 100 litre waste water tank 2 metres x 1 metre LED advertising screen 3 metre rain canopy On board gas system for cooking appliances Multiple electric outlets for cooking facilities and accessories Optional matching support trailer with on board freezer system 4 speaker hifi sound system Digital Menu BoardsPromotional Tours The fire truck food truck lends itself to corporate promotional tours. With massive cooking facilities, acres of body work for wrapping and advertising, a number of digital display screens and a huge 2x1 metre video screen you are sure to get your message across. If you need a street food truck than firetruck food truck hire is the way to go. We can work with you to add the facilities you need such as drinks pumps and chillers, pizza ovens, chip fryers etcWhat area's do you cover? The full UK and Europe. Are there additional transport costs? Unfortunately yes, due to the single digit fuel consumption What food can you serve? Anything except hog roast. Fire Truck Food Truck Hire in Yorkshire, Lancashire, Nottinghamshire, The North East, Midlands, London and the full UK. Read the full article

0 notes

Text

Emergency and Backup Systems: Ebara Pumps

Emergency and backup systems are essential components of any commercial building, industrial facility, or municipal infrastructure. When unexpected events occur—whether fires, power outages, or natural disasters—reliable water management can mean the difference between swift recovery and significant damage. Ebara’s emergency and backup pump solutions are designed to perform under pressure, ensuring critical water delivery, drainage, and pressure management when standard systems are compromised. With robust construction, quick activation, and energy-efficient features, Ebara’s pumps deliver peace of mind in emergency preparedness.

Critical Needs in Emergency and Backup Systems

Fire Protection and Rapid Water Access

Fire suppression systems require reliable, high-pressure water delivery in emergencies, often facilitated by dedicated fire pumps that activate automatically to provide swift water supply.

Power Outage Resilience

Facilities with water management needs must maintain system functionality during power outages, necessitating backup pumps with independent power sources like diesel engines or battery systems.

Flood and Stormwater Control

Flooding from heavy rain, snowmelt, or storm surge can threaten building integrity and safety. Effective emergency drainage systems prevent flooding, protecting assets and maintaining accessibility.

Sanitary and Wastewater Management

Emergency pumps for wastewater management ensure that sewage and greywater continue to be safely handled, preventing backups that could lead to health hazards or environmental issues.

Minimal Maintenance and High Durability

Emergency pumps must be low-maintenance yet highly durable, able to remain idle for long periods and perform reliably on demand with minimal intervention.

Ebara Pump Solutions for Emergency and Backup Systems

Fire Pumps for Rapid Water Supply

High-Pressure Delivery: Ebara’s fire pumps provide the high-pressure water required for effective fire suppression, quickly delivering water to sprinklers, hydrants, and hoses throughout the building.

Automatic Activation: These pumps feature automatic start-up capabilities, activating instantly upon fire detection, ensuring rapid water access and reducing response time in emergencies.

Diesel-Powered Backup Pumps for Power Outages

Independent Power Source: Ebara’s diesel-powered pumps are ideal for facilities requiring continued water flow during power outages, providing reliable performance without dependence on electricity.

Portable Options for Flexibility: For additional versatility, portable diesel-powered pumps can be moved to various locations on-site as needed, giving operators flexibility during emergencies.

Submersible Pumps for Flood Control and Stormwater Management

High-Flow Capacity: Ebara’s submersible pumps are designed for quick water removal, helping to control floodwaters, prevent basement flooding, and protect valuable equipment from water damage.

Corrosion-Resistant Materials: Built to endure harsh conditions, Ebara’s submersible pumps handle muddy and debris-laden stormwater, delivering long-lasting performance in demanding applications.

Battery-Operated and Portable Pumps for Quick Deployment

Ideal for Temporary Emergencies: Battery-powered portable pumps are quick to deploy and provide instant response in small-scale emergencies where immediate water removal or pressure relief is necessary.

User-Friendly Design: Lightweight and compact, these pumps are easy to handle, enabling quick setup in unexpected situations where rapid water management is needed.

Wastewater and Sewage Backup Pumps

Reliable Sewage Handling: Ebara’s emergency wastewater pumps are designed to handle high volumes of sewage, ensuring continued operation of waste management systems even in power-loss scenarios.

Preventing Backup and Contamination: By preventing sewage backups, these pumps help facilities avoid contamination, uphold sanitary conditions, and comply with environmental regulations.

Smart Monitoring and Remote Operation

Remote System Control: Ebara’s pumps can be connected to monitoring systems, allowing operators to oversee pump activity remotely, quickly identify issues, and activate pumps if needed.

Predictive Maintenance and Alerts: Smart systems offer predictive maintenance alerts, ensuring that backup pumps are always operational and in top condition for emergencies.

Applications of Ebara Pumps in Emergency and Backup Systems

Fire Protection Systems

Ebara’s fire pumps are essential for buildings where fire suppression is critical, such as hospitals, warehouses, high-rise buildings, and schools, ensuring compliance with fire safety codes and protection of lives and assets.

Flood Prevention in Basements and Underground Areas

Submersible pumps help protect basements, parking garages, and underground equipment rooms from water intrusion, minimizing downtime and potential damage.

Power Outage Resilience in Critical Infrastructure

Diesel and battery-powered pumps are critical for maintaining water management in critical infrastructure, such as data centers, manufacturing facilities, and healthcare institutions, where uninterrupted service is vital.

Wastewater Management in Emergency Conditions

Backup wastewater pumps ensure that sewage and waste continue to flow during emergencies, preventing dangerous overflows and maintaining sanitary conditions for facility occupants.

Agricultural and Industrial Emergency Response

In agricultural settings, emergency pumps help prevent crop damage from unexpected flooding, while in industrial environments, they manage water flow to prevent equipment damage or contamination.

Benefits of Ebara’s Emergency and Backup Pump Solutions

Reliable Performance Under Pressure

Ebara’s emergency pumps are built for challenging conditions, delivering dependable performance during high-stress situations, including fires, floods, and power outages.

Energy-Efficient Options with Low Operating Costs

Energy-efficient motors, optimized flow rates, and high-quality components minimize operating costs and conserve fuel, supporting sustainable operations without compromising on reliability.

User-Friendly Operation and Easy Maintenance

Designed for ease of use, Ebara’s pumps are straightforward to deploy, requiring minimal training and enabling quick response in emergency situations.

Enhanced Safety and Compliance

Ebara pumps meet stringent safety standards, ensuring that facilities comply with fire and safety codes, while also contributing to a safer environment for occupants.

Long-Lasting Durability in Harsh Conditions

Ebara’s emergency pumps are made from corrosion-resistant and abrasion-resistant materials, ensuring they can withstand extended idle periods as well as harsh operating conditions when activated.

Scalable Solutions for Various Facility Needs

Ebara’s extensive range of pumps can be tailored to fit the unique requirements of different facilities, whether small office buildings, expansive industrial sites, or multi-story commercial properties.

In the face of emergencies, effective water management is critical to safety, property protection, and continuity of operations. Ebara’s emergency and backup pumps provide reliable, durable, and efficient solutions for a variety of scenarios, from fire suppression to flood control and wastewater management. With energy-efficient options, robust construction, and user-friendly designs, Ebara’s pumps offer invaluable support for facilities looking to prepare for the unexpected, ensuring that water management systems are ready to perform when they are needed most. For more info contact Ebara Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

China Welded Steel Tanks Fuel Storage Tanks Manufacturer: Excellence in Fuel Storage Solutions

Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) is a leading manufacturer of welded steel tanks and fuel storage tanks, renowned for its exceptional product quality, innovative engineering, and extensive global reach. With a proven track record of delivering reliable storage solutions across diverse industries, Center Enamel continues to set benchmarks for excellence in the fuel storage sector.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Specialized in Welded Steel Tanks for Fuel Storage

Our welded steel tanks are expertly designed to meet the specific needs of fuel storage. Whether for diesel, gasoline, aviation fuel, or other refined products, our tanks are engineered to provide:

High-Strength Materials: Fabricated using premium-grade carbon steel, stainless steel, and other alloys for enhanced durability and performance.

Corrosion Resistance: Protective coatings and linings ensure longevity in harsh environments.

Customizable Designs: Tailored configurations to accommodate specific storage capacities and operational requirements.

Leak-Proof Construction: Precision welding and strict quality control guarantee safe and reliable storage.

Applications Across the Fuel Industry

Center Enamel’s welded steel tanks are versatile and widely used in:

Diesel Storage: Providing safe and efficient storage for transportation and industrial use.

Gasoline Storage: Supporting refineries and fuel distribution networks with reliable containment solutions.

Aviation Fuel Storage: Ensuring secure storage for aviation operations.

Marine Fuel Storage: Designed to withstand the challenges of coastal and offshore environments.

Emergency Fuel Reserves: Serving as a critical resource for disaster preparedness and energy security.

Manufactured to Meet International Standards

We ensure our welded steel tanks comply with the most stringent global standards, delivering the highest quality and safety to our clients:

API 650 and API 620: Standards for the design and construction of large, welded steel tanks for fuel storage.

AWWA Standards: Ensuring water-tightness and structural integrity.

ISO 9001: Certification for quality management systems.

NFPA 30: Compliance for flammable and combustible liquid storage.

OSHA Standards: Prioritizing safety during tank construction and operation.

Global Projects and Proven Success

Our welded steel fuel storage tanks have been deployed in various landmark projects worldwide. These include:

Middle East Fuel Terminals: Supplied high-capacity diesel and gasoline tanks with advanced corrosion-resistant coatings.

African Aviation Fuel Depot: Provided welded steel tanks for secure aviation fuel storage and handling.

Southeast Asia Marine Fuel Facility: Delivered customized storage solutions for marine fuels.

Why Choose Center Enamel?

As a trusted partner for fuel storage solutions, Center Enamel offers:

Comprehensive Expertise: Decades of experience in tank design, fabrication, and installation.

Customized Solutions: Tailored storage systems to meet unique project specifications.

Global Reach: A strong presence in over 100 countries, supporting clients with localized expertise.

Proven Quality: Adherence to international standards and rigorous quality control measures.

Innovative Technology: Continuous investment in R&D to stay ahead in storage innovation.

Commitment to Sustainability

Center Enamel is dedicated to sustainability, designing tanks that minimize environmental impact through durable materials, efficient construction methods, and eco-friendly coatings. Our commitment ensures that our solutions support both operational and environmental goals.

Partner with the Industry Leader

For welded steel tanks and fuel storage solutions that combine quality, reliability, and innovation, trust Center Enamel. Contact us today to discuss your storage needs and explore how our expertise can elevate your project to new heights.

0 notes