#cut and sew jeans manufacturer

Explore tagged Tumblr posts

Text

Unlock Your Creativity: Design and Make Your Own Jeans with China-Jeans

With China-Jeans, you have the opportunity to make your own jeans, tailored specifically to your style and preferences. Imagine having a pair of jeans that perfectly fit your body shape and reflect your individuality. Whether you prefer a classic straight leg, trendy skinny fit, or relaxed bootcut, our expert team will guide you through the process of creating your dream pair.

0 notes

Note

All your settings are crazy interesting to think about and currently I've been taur-brained. sorry if you've already answered this somewhere else, but who are the ones manufacturing their clothes? Or their mane and hoof care products, etc? Would it be humans who were already making similar stuff for normal horses, or are there some centaurs also in the business making more specialized and informed products (like shoes or horse-pants????) Surely there's an economic power imbalance in there somewhere between whoevers making the necessities and who's got to buy them.

(either way, being good at diy is probably a plus for them )

I mentioned it a little bit in the first clothing post i made but the examples given (aside from the classical dress) are all modern - basically, small tailor shops in Ironwall will bulk-order horse blankets from wholesale (usually international) retailers and modify them on-site for resale to centaurs, sometimes doing a same-day custom job for someone if they need it. this is considered kinda cheap, and not in the realm of formalwear/barely business casual. think t-shirt and jeans level stuff. but like you said, in a lot of cases centaurs would buy their own horse rugs to modify at home (basically you need longer straps that articulate at a different part of the body than stock). these specific alteration shops are usually some of the first businesses to pop up in cities/towns outside Ironwall whenever emmigrant centaurs have a decent presence, alongside herbivore food shops.

so yeah absolutely as a marker of class & a requirement for formal occasions, there is bespoke tailor-made clothing made to fit their bodies from the start and it is EXPENSIVE. especially the big classical style gowns, there's a lot of fabric there and it has to be cut well so that it doesn't entangle the legs or restrict the torso, and have enough petticoat/underskirt/etc so that there'll be no accidental flashing on a windy day. now modern commercialism/capitalism hit Ironwall in a very strange way - many centaurs remember the exact moment the first mcdonalds opened in ironwall in the 90s, as human resident % had gone up and suddenly Ironwall was a market and a consumer base.

(this one got so long that even I will concede to a readmore)

most people unable to afford the tailored stuff in the early 20th century would buy big cuts of curtain fabric and sew their own gowns for formal occasions/serving on a budget and those gowns would see use for decades. companies saw the potential to offer factory/sweatshop produced off the rack centaur fast fashion that resembled the very intricate classical gowns without any of the tailored properties/thick skirts/flexibility in the torso/etc. this is landfill junk and wears out quickly. in many cases it's a cheap human bodice/t-shirt/etc sewn to the bottom gown bit, which means there's a weak seam right at a point of great articulation, and the clothes will catch/snag in odd places because the muscles underneath are different too. in terms of the economic power imbalance - yep. it's a market but a small one, without much competition, and multinationals can easily outcompete the centaur tailors who offer services at middle or low price brackets.

and of course. there's always poverty tourism. you can buy fully bespoke, made-for-centaurs, designer... rebadged horse blankets, for the athleisure/sports-luxe fans

because centaurs as a market share are not very prominent still (that is changing tho), most of their own businesses are small and dynastic - one group running the same mane oil business since the 1700s, churning out the same basic product for a small but dedicated audience. these types of businesses rarely advertise and if they do it's by putting a tiny text-only ad into the paper with their phone number inserted. they are woefully ill-prepared to compete with external businesses turning their eye to Ironwall in search of new markets. but what they have that large multinationals don't is parochialism and loyalty to a brand, and access to a more readily exploited centaur work force. many will turn around and do a little song and dance "don't you want to support small centaur businesses? we'll go under if we have to comply with modern labour laws!"

because at the heart of centaur businesses is that old purifying work ethic, and because ironwall is 1. conservative and 2. largely self-governing, their labour laws are antiquated. they still have workhouses. and there has always been a lack of interest from the wider country's government to intervene because ehh it's the Ironwall culture to work hard, isn't it? and do we really want to insert ourselves into centaur business? humans actively seeking work in ironwall, then, make up two broad groups - those who seek to exploit these relaxed labour laws by opening a business, and those who know that 'poor' in other places is 'middle class disposable income' in Ironwall (like first worlders becoming 'expats' or 'digital nomads' in places with cheaper costs of living than their wealthy home nation - easily leading to gentrification).

Anyway so that's all the modern perspective; all of this applies for the other beastmen as well like the harpies and so on, though they have to live with the additional layer of most of their laws and products being about horses.

Historically centaur clothing was made by hand in the home, usually by the women in a social group, and made robust enough to last several generations of wear (with repairs). Because clothing would be passed down from mother to daughter, this resulted in colt bachelor bands being so fucking naked all the time. In traditional enclaves and pre-Florian settlements, a stallion who was accepted into his new herd would be gifted handmade kinetic clothing (bells, ribbons, feathers, anything that enhances the movement) by his new wives and his ability to keep his gifts looking nice would be judged for a set period of time (if you lose a bell that's bad luck buddy), after which he was supposed to return the favour by hand-carving them beautiful tail ornaments (as discussed in my historical clothing post - the ornaments would appear similar to welsh lovespoons in design)

this tradition got trampled over with the introduction of Florian's penal laws because tail ornaments could not be worn when the tail was fully covered and attempts at kinetic fashion fell flat when your nice trot is all hidden up by what's basically a giant tablecloth. but there does remain a custom of women giving men gifts to test their commitment (to heterosexuality), with the expectation that it'll be paid back with something nice and handmade. but commercialism comes for us all eventually.

finally on the topic of shoes, iron shoes are not super common anymore but in the victorian era, rope shoes were manufactured in the city to cut down on noise levels when streets were becoming full paved/cobbled.

they were not very good for the feet and required regular replacement because the rope would wear down, but that meant business for farriers was booming and became almost guaranteed when the famously and hilariously corrupt high councillors and lord protector began to pass increasingly strict anti noise pollution laws.

40 notes

·

View notes

Text

Star Player - 5

A time jump and a reunion between Carl and Caleb.

1 | 2 | 3 | 4 (Previous)

---

“So it’s like, a harness.”

“No, no that’d be rude, that would never sell. It’s more of a…” Dwayne searched among motes of floating dust for the words, “support system.”

Carl, standing in the middle of Dwayne’s makeshift studio, shot a look of mild amusement at his friend turned business partner. It had been eight months since Henri’s (and Marc’s) non-appearance at the exhibition match and much had changed in all their lives. But at this moment, Carl was sporting what looked like an array of straps and elastic bands that curved taut around his perfectly round cheeks, holding them steadfastly in place.

“It looks like you went overboard with a jockstrap,” he said, turning to one of the mirrors to get a better look at his backside.

“I did, sort of,” said Dwayne, with a wave of his hand. “Same concept, with added reinforcements for men with a lot of jiggle. It’s supposed to be paired with the slacks in the business casual line.”

“Oh there’s a business casual line, now?” replied Carl, cocking his eyebrow.

“Well I was thinking with your fancy new office job, you would need something business casual, and then I figured we might as well include it in the catalog. Professional, yet flattering.”

“I think this ass does all of its own flattering. But I don’t hate the idea.”

After graduation, Carl had kept his diner gig until eventually landing a data entry job at a local nonprofit. He was thrilled to trade it in the hustle and bustle of the service industry for a boring cubicle, not to mention his regulars at the diner were getting a little too familiar with his shift schedule and a little too comfortable with the wagon he’s draggin’. So he was settling into office life, and while Dwayne knew how to get the fit just right for his slacks, his ass still had a mind of its own, threatening every stitch and seam through the workday.

The pair had gone into business together making menswear intended for GluteMax cases. Dwayne the designer and seamstress, with Carl handling operations and, obviously, modeling. After the end of wrestling season, Carl had finally stopped taking the supplement and had started to cut now that he no longer needed the bulk. He had thinned somewhat into an athletic, lean muscled appearance, except of course, for his massive ass. That, to his chagrin, looked somehow even more pronounced since he had slimmed down, but due to Dwayne’s sewing genius, proved a boon to their nascent business.

Turns out there was a demonstrable demand for well fitting pants, shorts, slacks, jeans, underwear, swimwear, and more from men with Carl’s predicament. And there were quite a few. GluteMax hadn’t been all that well known outside of bodybuilding and body mod circles, but after the exhibition match, when Henri, with Marc’s encouragement, revealed that his ridiculous glute gains were in fact due to being ‘maxxed,’ the supplement entered the mainstream. Demand skyrocketed beyond what the manufacturer could supply and all manner of amateur fitness models to social media influencers to curious consumers jumped on the trend. With increased attention came increased scrutiny, along with an uptick of rare, extreme cases of men who had monster booties far beyond what they had expected or been promised. Not to mention the odd side effects and second hand impacts. Between the federal investigation and class action lawsuit, production was put on pause for the time being, but the damage was done. And suddenly, there was a market for which Dwayne and Carl were uniquely prepared. While things were going well early on, that didn’t mean Carl wouldn’t have reservations about Dwayne’s new ideas.

“Yeah, yeah,” said Dwayne. “Just tell me how it feels. How’s the fit?”

“Honestly?” Carl took a few seconds to move around in the new piece, getting accustomed to how it shifted and stretched across his round bottom, even going so far as to bend over, lunge, and settle into a deep squat. “It’s great! I forgot what it was like to not have to worry about turning one way and my ass going the other.”

“Fantastique!” exclaimed Dwayne with a clap of his hands. He was excited to start rolling out this new product, but also relieved for his friend. While Carl had gotten used to walking around with a comically large ass, it still came with its peculiar set of ongoing frustrations, and Dwayne liked finding ways to support him, literally and metaphorically. Besides, this was much better than his previous experiment, which was little more than a sewn in spandex cage. “Now get dressed, we have a client coming any minute now.”

“A client? Since when do we take appointments?” asked Carl, interrupted by a slow, intentional knock on their door.

“Someone had an issue with some of our compression shorts and I couldn’t figure out what the problem was over email, so I figured he could just stop by,” answered Dwayne in a brisk walk through their living room. “You go throw something on, I’ll keep him busy in the studio.”

Carl hustled to his bedroom, not bothering to take off Dwayne’s new contraption. Truth be told, it was quickly growing on him. Once you got used to it, it was surprisingly comfortable. And kind of hot, he thought to himself, getting a look at his mega booty as he hiked a pair of stretchy shorts over his cheeks. They were visibly perkier and more firm, and would probably look fantastic in their new line of slacks. He was settling into visions of photoshoots, marketing, and a seasonal soft launch when he remembered why he had rushed to get dressed in the first place. He headed back into their makeshift studio while throwing a short sleeve button down around his shoulders. Not the most professional entrance, but whatever works, he thought, looking up to see a blast from the past: Caleb.

He hadn’t seen his old teammate in months. Not since he quit towards the end of wrestling season. Or quit wasn’t exactly the word, maybe something like took a leave of absence, as their coach had told them curtly before practice one day. Since they had faced each other in that fateful practice match that still lived rent free in Carl’s head, Caleb’s prodigious schlong had transformed from an oddity to a nuisance to a problem through the rest of the season. It had become almost impossible to hide in his skin tight singlet, much to his chagrin. Oddly enough, it did give them somewhat of an edge by setting the other teams completely off guard. Carl’s monster glutes were an ace in the hole, but as it turned out so was Caleb’s super dick.

That is, until, in a particularly heated bout, Caleb found himself pinned to the mat, his opponent showing no intention of letting go of his full body hold. Caleb, using his surprisingly strong legs, executed a switch that brought them around 180 degrees, face to face with him in the advantageous position and his opponent left wide eyed in shock. Except, as he quickly realized, that expression wasn’t because of Caleb’s unexpected skills but actually the inches of rock hard cock jutting out of the left leg of his singlet.

“Oh shit,” he whispered, as his opponent subtly shifted position to make sure Caleb’s faux pas stayed hidden from view, giving him time to quickly rearrange his manhood back into the spandex and nestled along the outside curvature of his leg. As they ended the match, with Caleb eking out a win on a technicality, his bulge was deemed too obscene to continue, looking unreal in the tight, stretchy fabric. He fought the decision in his usual matter of fact tone, his seriousness belied by his not so subtle attempts to cover up the ridiculous pipe running across his quads.

As the league decided how to handle Caleb’s distracting problem, he took a break from the team. And of course, word had spread like wildfire about his serious endowment, leading him to keep an even lower profile than usual. He refused to be caught dead in anything remotely form fitting.

So it was a surprise in more than one way when Carl got a chance to look him over after all these months, dressed in nothing other than their own line of stretchy summer slim fit joggers.

“Hey, you!” exclaimed Carl, trying and failing to act like he wasn’t mildly detached from reality over the fact that this man he’d been fantasizing about for the better part of a year had manifested in his living room. In the clothes that he had marketed, no less–the olive green is such a good color on him, came a fleeting thought in the back of his mind.

“Oh, uh, hi,” said Caleb, giving a shy wave to his old teammate, his eyes flitting to meet Carl’s, before returning to whatever it was that Dwayne held tenderly in his hands.

“Do you two know each other?” asked Dwayne, before cutting himself off with a sudden lack of interest. “Oh, right. Wrestling or whatever.”

“Yes, wrestling or whatever,” repeated Carl, delicately placing each word as if he’d been practicing the phrase for weeks, bright smile still plastered on his face. “Wait, oh, you’re the appointment! What brings you here?”

“Compression shorts gave out,” answered Dwayne, almost to himself, eyes still studying the fabric in his hands, his right incisor visible as it chewed on his lower lip. Carl had known him long enough to know that this meant a particularly complex problem needed to be solved.

“Ok, so, can’t we just…” he drifted off mid sentence as Caleb adjusted his sitting position, giving an unconscious pull on his joggers, his eyes still focused on Dwayne in mid thought. “I see,” he muttered, as what he thought was a fold in the fabric of Caleb’s pants turned out to more accurately portray a kielbasa running down Caleb’s inner thigh, approaching the bend of his knee. He came to the chilling realization that Caleb’s growth must have continued for quite some time as the supplement’s lasting impacts dissipated.

“Oh, sorry,” said Caleb, catching Carl’s dumbfounded stare. “I forgot I wasn’t wearing the compression shorts. They’re super comfortable by the way, it’s like I forget they’re there.”

“Oh thanks,” said Dwayne, a polite half smile crossing his lips that Carl knew was actually an immensely satisfied mental high five about his handiwork.

“N-no problem,” stuttered Carl. “Nothing I haven’t seen before right? Well I guess it’s even more than I’ve seen before,” he continued with a nervous laugh.

Dwayne shot him a mildly exasperated keep it in your pants glare before turning back to Caleb with a reassuring smile on his face. “I think I know how to fix this, but I’ll need a little bit of time.”

“Oh wow, thanks,” said Caleb with uncharacteristic enthusiasm. “I was really starting to depend on these. Nothing else has been able to keep all this under control.”

“Of course,” Carl jumped in, finally regaining his professional composure. “That’s why we’re here!”

—

Carl was usually pretty hands off when it came to Dwayne working his creative magic. He knew better than to rush the process. But over the next few days that didn’t stop him from checking on this particular compression short adjustment a little too incessantly.

“Your wrestling team crush isn’t going anywhere,” said Dwayne, putting the final touches on this impromptu rush job. “At least not without these.” He prided himself on a high quality, deliberate process, but was tired of his friend breathing down his neck. “Why didn’t you just ask him out?”

“Hm. I guess that was an option,” said Carl, his lips twisting in thought. “Don’t worry about postage, I’ll hand deliver!” He picked up the package that Dwayne had just sealed with the shorts safely inside, tossing it into his cross-shoulder bag as he bounded to the door.

“Now, hold on!” exclaimed Dwayne.

“What? It’s called good service,” responded Carl, hand resting indignantly on his hip. “We go above and beyond for our customers.”

“I think you’re a little below and beyond,” said Dwayne, using his index finger to draw attention to the fact that other than the short sleeve button up, shoulder bag, and carefully chosen snapback, Carl was wearing nothing but a lavender thong below the waist, his bulbous butt sitting proud, framed by the half open doorway.

“...Right.”

Just under an hour later, Caleb opened the door to find Carl intently staring down at him, package in hand and clad in a pair of just the joggers that Caleb loved so much. And the snugness with which they hugged his ample curves certainly didn’t hurt.

“Oh,” said Caleb, a look of surprise replaced with one of his curt greetings. “I thought you would just mail it.”

“Nope!” Carl replied. “We wanted to make sure you got it safe, sound, and to your liking.”

“Well yeah, I guess I could just try them on now, make sure they fit. Come on in.”

“Oh, that’s not what I…” stammered Carl, as Caleb gingerly lifted the package out of his hands and turned to walk back into his apartment, his tight, perky backside swishing back and forth in his sweats.

“It’s kind of sparse, but make yourself at home,” Caleb yelled over his shoulder as he headed back to his room to change. “There might still be beer in the fridge from the move.”

Carl, heart aflutter, thought he might as well verify that the product performs as promised, stepping into Caleb’s very modern, recently renovated, but mainly empty apartment. From the loose boxes mixed with packing supplies and small furniture arranged haphazardly in the space, Carl guessed he must have just moved recently, and it looks like it was a big upgrade. Reminder to self to ask what he does now, thought Carl. What was his major, again?

He found the second to last beer and settled onto a stool next to the kitchen island, his ass cheeks smothering the metal seat.

Caleb re-entered a couple minutes later still wearing a tank top, but having traded out his sweats for the recently mended compression shorts. And nothing on top of them. Carl was surprised to see a beaming smile on his face, hands splayed wide as he did a quick turn. He caught a brief glimpse of his perfect bubble butt before his pipe came into view, looking like it may run the length of the compression shorts if he didn’t have it curved around his right upper thigh.

“They’re great!” he said. “Even better than before, feels really secure. You two are kind of a dream team.”

“I, um, well, it’s-it’s mainly Dwayne, I just run operations.”

“And delivery?” Caleb chuckled. “Let me go change back into my sweats, if you don’t mind? Don’t like keeping things compressed when I don’t have to. You know how it is,” referring with a hand gesture to the comfortable joggers caressing Carl’s round, oversized bottom.

“Yeah yeah, totally fine,” said Carl, regaining his composure. He reasoned that he must be about to wake from some sort of fever dream, picking up his bag as he got ready to dutifully leave Caleb’s place, having confirmed that the product was, in fact, a good fit. Before he could reach the door, Caleb re-entered in his original sweats, massive manhood still unmistakable but maybe less intense.

“You haven’t finished your beer,” he said. “No rush.”

Carl returned to the kitchen island to nurse his IPA, which led to Caleb deciding to finish off the last one, which led to Carl politely not wanting to leave before Caleb finished his beer, which led to Caleb mentioning that he had just found the box with a mix of gin, mezcal, and a variety of high shelf liqueurs and mixers that his ex had left behind months ago after an amicable, yet frustrating break up. And this led to Carl letting slip that he had developed a skill with cocktails from working the late shifts at the Tuesday Diner, which led to him throwing together some sort of concoction he called a Pretty Boi, insisting that the i in Boi was essential, which led to them sitting comfortably, drinks in hand, on the couch.

Not exactly the fantasy date Dwayne had been alluding to, but Carl was having a great time. Caleb did in fact land a consulting gig that not only paid well but allowed him to set his own work from home hours. Carl got into his struggle to balance his new nonprofit gig with the side hustle with Dwayne that was taking off faster than they expected, leaving him with tragically little social or romantic space. Which of course led Caleb to reflect on his recent breakup. Without getting into too much detail–and without needing to–Caleb’s growth had not only put quite a strain on their sex life, but the supplement sparked some secondary effects in his partner that changed the dynamic, so to speak. By their second round of pretty bois, they were well into the aggravation of navigating the local dating scene as overworked young professionals, especially whenever someone found out they were maxxed, which, for them both, was virtually impossible to hide. They hadn’t made it through the third round of Carl’s cocktail–which Caleb loved–before they had passed out right there on the sofa, Carl’s head resting heavy on Caleb’s chest, with Caleb’s hand lightly caressing the curvature of Carl’s bubble booty.

Carl was woken up the next morning by something long and hot running rock hard between them, and it didn’t take long for him to figure out what it was. Especially since it impatiently throbbed in sync with the beat of Caleb’s heart. This is his morning wood? he thought incredulously, shifting slightly to get a better idea of Caleb’s unbelievable dimensions.

In response, Caleb, just starting the process of emerging from sleep, let out a soft moan, thrusting his hips sensually into Carl’s crotch. As he opened his eyes, he realized that this wasn’t in fact a dream but a real live person meeting his mega dick up close and personal.

“Oh shit, I’m so sorry,” he said, still bleary eyed. He attempted to wrestle his cock out of the way, but the friction of his sweats against his sensitive head produced a visible shiver of pleasure.

“No, it’s cool,” said Carl. “Nothing I haven’t seen before, right?”

“I don’t think you remember it quite like this,” laughed Caleb, one hand covering half his face in faux embarrassment.

“Well I’m down for an update,” responded Carl, leaning in to nuzzle the scruff of Caleb’s chin, which Caleb eagerly returned as a kiss.

They fooled around the early morning sun, Caleb grabbing handfuls of Carl’s ridiculous donk while his dick extended even further down his leg, finally reaching full mast. With Caleb’s tank top long gone, Carl moved down his torso, planting tender kisses along the trail of fur that led to Caleb’s waistband.

“Is this ok?” he asked, looking up at Caleb as he played tentatively with the elastic.

“More than ok,” Caleb replied, already starting to breathe heavily. It had been a while.

Carl slowly pulled down his friend’s sweats, taking his time to savor the sight of more, and more, and more dick. In the soft light, his full erection was majestic. Carl took a moment to taste the precum leaking out of Caleb’s massive purple head, before letting it go and watching it give a wet slap to Caleb’s chest, flinging even more pre onto his chin. Carl traced the veins along the underside of Caleb’s prodigious cock, marveling at the fact that as he reached the head, they were practically face to face. He could probably suck himself off, he thought. This is a beast.

He spent some time ministrating on Caleb’s painfully sensitive cock head–Caleb practically writhing in orgasmic bliss–before finally opening his jaw and taking as many inches as he could. And he could take quite a few, having had plenty of practice with Brian over the past several months.

“Oh my god,” grunted Caleb. “No one’s…no one’s ever…aughhhhhhh!”

Caleb’s brain practically short circuited as he shot volley after volley of gooey jizz into Carl’s throat, then mouth, then face as it plopped free, still shooting for what seemed like an eternity, Carl eagerly lapping up as much as he could.

“Oh, shit,” said Caleb, slowly coming to. “I’m sorry. It’s been a while since anyone’s been willing to try that.”

“It’s cool,” said Carl, smile beaming through the streaks of jizz covering his mouth and chin. “Good morning, but I really should be going.”

Caleb did convince him to at least let him clean him off in the shower after covering him in spunk. And he threw in a bonus while soaping up Carl’s massive ass, leaning in to bury his face between the cheeks before eagerly eating him out, working his juicy nuts from the back until Carl shot his ropes of jizz onto the tile.

Before finally heading out, Carl leaned against the door frame of the entrance. “So packaged safely delivered? Quality assured?” he asked.

“Five out of five stars,” said Caleb. “But you’ve got some explaining to do to your roommate.”

“Ugh, I’ll never hear the end of it. Yesterday he, um, said to just ask you out. Ya know, if you’re–”

“Yes,” Caleb cut him off, reaching up to give Carl a deep kiss. “What are you up to this weekend?”

17 notes

·

View notes

Text

I will do an honest review of mother jeans since clearly no one else is doing one….

No no no no no no no no no no no.

Here’s the deal:

When you call your brand “mother” you may want to make sure they’re cut for most women. Not just Asian men. (& women with very narrow hips and tiny buttockses buttock-i? I dunno… you get the gist …🤷♀️🤣)

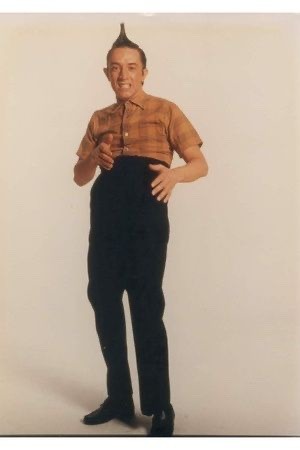

I wear a size 6 normally now. I used to be a solid 4, but I have sized up. And I admit that. But when I wear 4 different sizes within the same brand, that’s some ass manufacturing. There is absolutely no continuity whatsoever from one pair to another. Very. Cheaply. Made!!!!! I fit in 28s with the cut that has more give, great. Some 28s in the mother jeans were even too big, and I had to roll them on top to fit my waist. But then in another style jean by them I’m a solid 29. Fine. I can even accept that. But when I keep buying these orange leopard jeans and I end up in a size f’n 30 and STILL can’t sausage into them and when I finally paint them on I get the tight crotch that don’t accommodate my thighs BUT they did leave room, however, for my nonexistent peep. I mean, a whole 3 inches of dead air, cause I have woman’s hips and not a peep to put in there and I have a purse and wallet so I don’t need that much space in my crotch to keep my keys and my lipstick, ok?! and then the a ten foot crotch that is most unflattering, it’s longer than my torso rise, making me look like Ed Grimley, not to mention the muffin edges I get on the very top of these jeans, no. Just no. How can you name yourself “mother” when it’s for tween boys and some women with no hips?

This is Ed Grimley. (See below)

No. I’m now forever calling mother jeans, “tiny hipped, no ass, long crotch, man jeans and yes, Asian men do fit that bill, so call me a racist if you will but I’m not one so go scratch with that! Cause one time I saw a literal Asian man in drag modeling a pair of jeans (full disclosure: may not have been mother jeans) as if i wouldn’t notice!

So, am I still trying to lose weight? Always and No! And I shouldn’t have to! Their job is to make bigger sizes so I can fit my bigger self inside the pants to clothe me! And yes I do try to be healthy even though I don’t have to justify my weight to anyone, but a lot of times I fluctuate in weight like a lot of other human beings. The fact that I usually wear a size 6 bottoms, and 28 inch jeans this is unacceptable. What about ladies who are bigger than me? Should we wear a tarp, or sew two pairs of your jeans together to make a Normal cut for my ass?! No! Ain’t nobody got time for that!

So ladies, if you have any kind of curves like me, steer waaaaaaaaayyyy clear of the mother brand. And if you are shaped like them, then they’ll be perfect. I’m pissed, cause I now have to find another brand, and since I’m not in the know, I have to look online for a new brand, and I hate that. Pft! Caca fitting jeans! I’m sticking to leggings until I figure out a better brand to invest in.

9 notes

·

View notes

Text

60 hours from pattern to completed product for those pants with fittings and they're lined, is completely reasonable depending on seam finishing and any hand hemming. Plus, all that pressing. (Ugh the pressing!)

Good on you, OP. They look great!

Good on you for knowing your worth.

Fashion designer here who has seen an actual fashion business costing sheet. (And have done costing for small parts manufacturing.) We were discussing the negative impact of fast fashion back in the early 2000s, and nothing err, was done about it at all. So, it's now infinitely worse between the design theft and the fabric/water waste/desert dumping etc.

Talking about costing under a read more for the curious:

In fashion, every zip, every button, every pocket, and every seam/stitch line like quilting ups the cost.

Stores go by price bracket. Prices are pre-determined, and your design better fit into them. If you think your 80 dollar jeans aren't the same quality from 10 years ago but still cost 80 dollars, that's why. That jean cost was decided years ago. It doesn't move. Everything has to accommodate it. For every store price bracket, you are allowed so many details like that. There is a top limit.

then the materials are added up. manufactures buy in thousands to millions of units which brings the cost down a lot. Your 9.99 item generally costs .25 cents or less material wise. (Walmart could pay as low as 2 cents a yard.) Private fabric sellers like Mood selling overstock are making a killing on "Fashion designer fabrics."

Then there's a test done where the manufacturer has a room of employees who cut and sew the test garment and they're timed. Each section is timed from side seams to zippers. Your fashion item might go through half a dozen hands depending on styling. There's a set rate of pay for each section. Time multiplied by that rate: That's labor.

Then there is the added cost of tags from another manufacturer, sometimes buttons are put in with a totally different factory, plus packaging and shipping which you got to get it all into the USA before it hits quota limit. All in all, wholesale, your 9.99 item might cost... 99 cents. Sometimes, this will even include store overhead like electric and payroll.

They will cut costs in fabric first. Styling details second. Labor third. You want pockets. That's a styling detail of extra fabric. Two strikes. Plus the labor to put it in. Bye bye pockets. (Also blame Calvin Klein super tight jeans. A designer suggested not having actual pockets and the idea snowballed.)

All of this is paid in advance through a factor system, meaning the designer is in debt to fashion factors before anything hits shelves. They're often sponsored by big fashion corporations like LVMH or Fendi who are willing to take on this debt b/c in they won't see a profit for 5 to 10 years, but after it could be millions if not billions of dollars in business. Pattern making and model fittings are on the designer, not the manufacturer. There's also services like pattern sizing, (which is different than model fitting) but many manufacturers are skipping that part so that's why many garments can be so ill fitting. They're relying on computers, not trained people (because those trained people cost hundreds of thousands of dollars in pay. Last I knew, there was like 6 trained pattern sizers. Ready to Wear gets first dibs.)

The reason so many clothes manufacturers were moved to other countries out of the USA is Greedy Corps shut down shops entirely b/c they didn't want to pay people and moved shops overseas to exploit labor there, (which they shouldn't be able to do) in order to "cut costs." The Ladies Garment Union was/is one of the strongest unions in the country and made it so their shops would remain union shops across state lines. Corps didn't like that, blamed the workers instead of their own greed, and they've been chasing the cheapest labor from country to country ever since. Other industries followed suit once they saw the fashion industry get away with it.

Many people today are so distanced from how anything is made from raw material to final product, they cannot gauge prices. My father refuses to let my mother sell her crocheting and knitting b/c she cannot get what it is worth. FYI, he's also done costing. He was the guy who did all the quotes in the shop.

I never pursued a career in fashion. Though I still design at times for fun. I had plenty of good reasons.

Use a costing sheet. Know your worth. Charge appropriately.

still thinking about the brainrot that fast fashion has caused in people, like i made this pair of pants that are black and white with a cool flowery design, and an acquaintance saw them and said "wow i'd pay like 20 dollars for you to make me a pair" and i could barely think with how utterly horrified i was at that; i told them that 20 dollars wouldn't even cover the materials, let alone the hours of work that went into cutting, sewing, ironing, hemming, altering, etc. they just had this look on their face when i told them that, when i said i wouldn't make them a pair for even 100 dollars because that was still way too low of an amount, a look that said "you're crazy for thinking that those cost 100 dollars" and maybe i am crazy but holy shit, 20 dollars for a pair of handmade, durable, lined pants fitted specifically to your measurements? 20 dollars for upwards of 60 hours of work? 20 dollars for several yards of high-quality fabric, thread, and buttons? 20 dollars???

91K notes

·

View notes

Text

Jeans Manufacturing Process: Crafting the Perfect Pair

Introduction The jeans manufacturing process transforms raw materials into one of the most popular and versatile garments in the world. This article outlines the various stages involved in producing jeans, emphasizing quality, efficiency, and sustainability in denim manufacturing. Brands like Silksage Textiles are leading the way in ensuring excellence in the denim fabric process.

1. Material Sourcing

The journey of jeans begins with sourcing high-quality cotton. Cotton is the primary fabric used in jeans, known for its breathability, comfort, and durability. Sustainable sourcing practices, such as using organic cotton, have become increasingly important in the denim manufacturing industry.

How is denim fabric made

2. Yarn Spinning

Once the cotton is sourced, it is processed into yarn. This involves cleaning, carding, and spinning the cotton fibers into yarn. The thickness and quality of the yarn will ultimately affect the feel and durability of the final jeans.

Denim fabric manufacturing process

3. Indigo Dyeing

After spinning, the yarn is dyed using indigo dye, which gives jeans their characteristic blue color. The dyeing process can involve multiple dips in indigo vats, allowing the fabric to develop a unique fading pattern over time. This step is crucial in achieving the distinctive look of denim.

Denim Manufacturing Process

4. Weaving the Fabric

The dyed yarn is then woven into denim fabric, typically using a twill weave pattern. This technique creates the diagonal ribbing characteristic of denim. Different types of weaving machines, including shuttle looms for selvage denim, can be used to create various denim styles.

Denim making process

5. Cutting and Sewing

Once the denim fabric is ready, it is cut into the desired patterns for jeans. Skilled workers then sew the pieces together using industrial sewing machines, incorporating elements such as pockets, zippers, and rivets. This stage requires precision to ensure a perfect fit and finish.

6. Washing and Finishing

After sewing, the jeans undergo several washing and finishing processes. This can include stone-washing, acid-washing, or enzyme-washing to create different textures and looks. These finishes not only enhance the appearance of the jeans but also soften the fabric for comfort.

Denim production

7. Quality Control and Packaging

Before reaching consumers, each pair of jeans undergoes rigorous quality control checks to ensure they meet industry standards. After passing inspection, the jeans are packaged for distribution, ready to be sold in stores worldwide.

Conclusion

The jeans manufacturing process is a fascinating blend of tradition and technology, culminating in a garment that is both functional and fashionable. By understanding each step, from material sourcing to quality control, consumers can appreciate the craftsmanship that goes into every pair of jeans. Brands like Silksage Textiles continue to innovate, ensuring that their products meet high standards of quality and sustainability.

0 notes

Text

Garments Manufacturer In Bangladesh

Garments Manufacturer in Bangladesh: Power Ark Apparel

Power Ark Apparel is a leading garment manufacturer in Bangladesh, renowned for its commitment to quality, sustainability, and ethical practices. With years of industry experience and a dedicated team of professionals, we have established ourselves as a trusted partner for global brands and retailers.

Our Expertise and Capabilities

Wide Range of Products: We specialize in manufacturing a diverse range of garments, including:

T-shirts and polos

Denim jeans and jackets

Knitwear and sweaters

Activewear and sportswear

Workwear and uniforms

Corporate apparel

Customization and Flexibility: We offer comprehensive customization options to meet your specific requirements, from fabric selection and design to labeling and packaging. Our agile manufacturing processes allow us to adapt quickly to changing trends and demands.

State-of-the-Art Facilities: Our modern manufacturing facilities are equipped with the latest technology and machinery, ensuring efficient production and high-quality output. We adhere to strict quality control standards to deliver products that exceed customer expectations.

Ethical and Sustainable Practices: We are committed to ethical and sustainable manufacturing practices. We prioritize the well-being of our workers, ensuring fair wages, safe working conditions, and compliance with labor laws. Additionally, we implement eco-friendly initiatives to minimize our environmental impact.

Why Choose Power Ark Apparel?

Quality Assurance: Our commitment to quality is unwavering. We employ stringent quality control measures throughout the production process to deliver garments that meet the highest standards.

Competitive Pricing: We offer competitive pricing without compromising on quality. Our efficient operations and cost-effective sourcing enable us to provide value for money.

On-Time Delivery: We understand the importance of timely delivery. Our streamlined supply chain and reliable logistics ensure that your orders are shipped promptly.

Customer Satisfaction: We prioritize customer satisfaction and build long-term partnerships based on trust and mutual respect.

Ethical and Sustainable Manufacturing: We are dedicated to ethical and sustainable practices, ensuring a positive impact on both our workers and the environment.

Our Manufacturing Process

Sample Development: We work closely with our customers to develop samples that meet their exact specifications.

Fabric Sourcing: We source high-quality fabrics from trusted suppliers, ensuring the durability and comfort of our garments.

Cutting and Sewing: Our skilled workers utilize advanced cutting and sewing techniques to create garments with precision and attention to detail.

Quality Control: Rigorous quality checks are conducted at various stages of production to identify and rectify any defects.

Finishing and Packaging: The garments undergo finishing processes such as embroidery, printing, and labeling before being carefully packaged for shipment.

Our Commitment to Sustainability

Eco-Friendly Materials: We prioritize the use of sustainable and eco-friendly materials whenever possible.

Waste Reduction: We implement measures to minimize waste generation and promote recycling.

Energy Efficiency: We invest in energy-efficient equipment and practices to reduce our carbon footprint.

Social Responsibility: We support initiatives that promote social and environmental well-being.

Power Ark Apparel is your trusted partner for high-quality, ethically produced garments. With our expertise, commitment to sustainability, and customer-centric approach, we are confident in our ability to meet your manufacturing needs. Contact us today to discuss your project and explore how we can collaborate to create exceptional garments.

1 note

·

View note

Text

"Everyone makes all their clothes at home" is also largely ahistorical. Especially pre-sewing machine. Patterns for home sewers didn't become popular on the level they are today until the 20th c.

Like, yes, ~back~in~ye~olde~thymes~ it was more common for people to know how to mend their clothes, and do basic alterations (at least for those who couldn't afford to have staff to do that for them). But even before off-the-rack clothes and mail-order clothing catalogues took off as concepts in the 19th c, relatively unfitted garments like shirts and shifts could be purchased pre-made.

I don't know as much about non-western clothing history, but in Europe and the USA, until the mid 19th c, the vast majority of people acquired the vast majority of their clothing by purchasing the fabric and then taking it to a tailor or dressmaker.

And even now, the hard divide between "hand made clothes" and "industrially made clothes" is pretty fake. There's no machine you can toss denim into and have it spit out pairs of jeans. Somebody has to cut the fabric. Somebody has to sew it together.

Mass production of garments is not in and of itself the issue, and never has been. It's mistreatment and erasure of the people doing the labor. It's no care being given by the manufacturers for the environmental impacts. It's the deliberate reduction of quality to the point clothes are basically disposable now. It's fashion cycles moving faster and faster to sweep people further up into mindless overconsumption, and normalizing the idea that it's better to have 100 outfits that fall apart after a few wears than to have just a few outfits that fit well and are of good quality.

i need to start a collection of Takes About Alienation From The Material Conditions Of Production That Only Make Sense If You Yourself Are Alienated From The Material Conditions Of Production

4K notes

·

View notes

Text

"Hoodie"

"We are manufacturer and Supplier of all types of American Football, Baseball, Basketball, Boxing, Soccer, Karate, BJJ uniforms, Fashion, Fitness, Gym wears, and accessories with full customization (designs, logos, labels, packaging).

We're based in Sialkot-Pakistan.

Quality is everything🙏🏻

Quality is our first priority⚜️

No one will give you Quality like this 💯

Bet!

📦Orders going out Customizations we offer🙏🏻Printing (Vinyl Transfer, Screen Printing, Silicone 💯 Screen Printing, 3D Printing)

📩Inbox to get started with your merch!"🙌🏻

Pr

📌Build your BRAND with us.

Best Customized Quality Products and Another 💯 BET!

Custom Products Available Here d

✅Responsible Prices

✅Fastest Delivery &

✅DM for More info and inquiry's #marsiq_enterprises

Our aim Provided to all customer satisfaction and according to customer demands,

Show us your Desired Products Picture we will Prepare According to your illustrations or Mockups 🙌🏻

💯 We Know Better Quality than Others.

We do offers;

✅Custom Design (Pattern)

✅Custom Sizing (Cut & Sew)

✅Custom Rhinestone

✅Custom Embossing

✅Custom Poly Packaging

✅Custom Chinelle Embroidery

✅Custom Puff/Screen Printing

✅Custom Sublimation Printing

✅Custom DTF/Reflective Sticker

✅Embroidery (Normal, 3D, Applique)

✅Custom Woven Labels & Swing Tags

✅Screen Printing (Standard, Injection Moulded)

V.Acid wash

🙌🏻Shipping worldwide (through DHL, FedEx, UPS, DPD..)

Secure Payment

🪡Low MOQ (minimum order quantity)

🪢Sample will be provided for quality checking 💯

Please feel free to contact us in any queries and We should of course provide you with good quality products with the best prices.

Waiting for your kind reply soon.

Gmail: [email protected]

What's app link: https://wa.me/message/Q7I5QT5SFH5ZI1

Thanks and regards,

"Marsiq Enterprises"

#hoodie #bhfyp #streetstyle #mensfashion #bajumurah #clothes #streetwear #tshirt #jeans #clothing #brand #baju #shirt #sweater #jacket #kaos #hoodie #kaosmurah #kemeja #apparel #tshirts

0 notes

Text

What Factors to Consider Before Selecting Garment Equipment?

It therefore becomes very important for any textile factory to choose the right garment equipment for its undertaking. Whether it is a brand new facility or modification of an existing one, the type of machinery is determinant to the effectiveness, degree of quality, and therefore the returns on investment. In this blog, basic guidelines which one should go through before purchasing the garment equipment will be elaborated with more emphasis on how your textile factory machines can turn out to be the best.

Understanding Your Requirements

Now, let us focus on garment equipment; however, the specific requirements of your production must be recognized first. It is understood that different textile factories require a different set of equipment depending on the sort of garments that are manufactured, size of the factory, and the processes done. Here are some key questions to help you define your requirements:Here are some key questions to help you define your requirements:

Which kinds of clothes are you manufacturing?

If it is a simple dress then it can be sewed with the help of a hand sewing machine while for other dresses one has to use an industrial sewing machine. For instance, the process of making t-shirts may require more machinery than making jeans or jackets.

Are you large or small scale producers?

A high volume production may require more specialised machinery while low volume production may require a more flexible machinery.

What is your budget?

Availability of funds will have a close correlation with the kind of machinery which you will be in a position to purchase. The major challenge is that one has to consider the cost factor while at the same time incorporating the features that can help in the construction of quality structures.

What are your quality policies and procedures?

The level of precision and quality of the product that one wants to produce will determine the kind of equipment to use.

What space do you have?

Your factory’s physical layout will define the scale and layout of the equipment you have in terms of spatial requirements.

Types of Garment Equipment

Garment equipment is of different classifications and these are used for different processes in the production line. Everyone’s opinion will be of great help in exercising the right decision making of these categories.

1. Cutting Machines

Sewing is the last operation in the manufacturing process of garments; cutting is the initial process of manufacturing garments. High levels of accuracy and speed of cutting also allows for no wastage and fashioning of desirable pieces.

Manual Cutting Machines: Recommended for small scale production of juices, concentrates and other comparable food products.

Automatic Cutting Machines: Suitable for mass uses because there is usually accuracy and time factor that goes with its use.

Laser Cutting Machines: Give high accuracy and they are suitable for complex patterns.

2. Sewing Machines

Sewing machines are the core of any garment factory in the sense that the operation of the factory largely depends on their functionality. It completely depends on the kind of apparel that is being manufactured and the particular sewing operations.

Single-Needle Machines: Plano machines for straight line sewing.

Overlock Machines: Applied in the trimming of edges.

Coverstitch Machines: Suitable for pick stitching, hemming, and many other mirror stitchings.

Embroidery Machines: They can put extra ornaments on the clothes.

3. Finishing Machines

They finalise the garments so that they can be sold in the market by finishing machines.

Pressing Machines: It is used to Iron and remove wrinkles.

Steaming Machines: For the last treatment of garments before they are ready for sale.

Packaging Machines: Of this amount, 30 percent is used for packing the finished products.

4. Quality Control Machines

Quality is one of the major considerations in garment production and hence must be kept high. The quality control machines help in checking or monitoring sections to ensure that the right quality has been attained.

Inspection Machines: To examine the quality of the fabric and garments produced, or garments that have been finished.

Testing Machines: Basically, for testing the strength and the durability of the fabric that has been produced.

Key Factors to Consider

1. Quality and Durability

Textile factories understand the importance of right investment, especially high quality machines that will last longer. Though there is a possibility that high-quality machines might be expensive in the beginning, yet these machines will have a better performing capability as compared to low quality machines, less time will be required for repair and maintenance and these machines also have a longer life expectancy and thus are definitely cheaper in the long run.

2. Automation and Technology

Automation and use of advanced technology in the construction and organisation of your garment equipment can greatly boost production. Automated machines eliminate the need of manpower, lessen the rate of error making and speed up the rate of production. Hire newer machinery that integrates advanced technologies including on the computerised controls as well as integration of IoT.

3. Energy Efficiency

Efficient, cost-effective machinery supports cutting down the expenses and diminishing the hazardous effects of your manufacturing plant. This is where you should find machines with features that help to save energy and badges that denote lower energy use.

4. Maintenance and Support

Hence, periodic servicing is significant for the adequate operation of garment equipment. Select machines from reputable manufacturers such as Weavetech to ensure you are served with reliable after sale service, spare parts for the machines are readily available. This helps in that any complications can be solved in good time so that the disruption of business is as little as possible.

5. Flexibility and Versatility

As market conditions shift one has to be in a position to make certain changes in one’s production cycles. Choose machinery that provides the possibility to work simultaneously in different styles of the garments and production technologies with the least possible adjustments.

6. Space and Layout Considerations

Another factor that will determine the equipment you choose is the available layout of your factory and space. Make sure that the end choice in the machines that you opt for can easily fit into your workspace and also the workflow. This means the placing of machines should accommodate the comforts of the workers to allow optimum productivity.

7. Cost and Return on Investment (ROI)

While cost is a critical factor, it should not be the sole determinant. Evaluate the total cost of ownership, including maintenance, energy consumption, and potential downtime. Calculate the expected ROI based on the machine’s efficiency, productivity, and lifespan. Investing in slightly more expensive but more efficient machines can pay off significantly over time.

8. Compliance with Standards

Ensure that the equipment you choose complies with industry standards and regulations. This includes safety standards, environmental regulations, and quality certifications. Non-compliance can lead to legal issues and damage your brand’s reputation.

9. Scalability

Consider the future growth of your business when selecting garment equipment. Opt for machines that can be easily scaled up or integrated with additional units as your production volume increases. Scalability ensures that your investment remains viable as your business expands.

10. Training and Ease of Use

The ease of use and the level of training required for operating the machines are important factors. Choose machines that are user-friendly and come with comprehensive training programs for your staff. Well-trained operators can maximize the efficiency and lifespan of the equipment.

Why Choose Weavetech for Your Textile Factory Machines?

Weavetech is a renowned name in the textile machinery industry, offering a wide range of high-quality garment equipment. Here’s why Weavetech is the preferred choice for many textile factories:

Innovation and Technology

Weavetech is at the forefront of innovation, constantly integrating the latest technology into their machines. Their state-of-the-art equipment ensures high productivity, precision, and efficiency.

Quality and Reliability

Weavetech machines are known for their durability and reliability. Built with high-quality materials and advanced engineering, these machines are designed to withstand the rigours of continuous production.

Comprehensive Support

Weavetech provides excellent after-sales support, including maintenance services, spare parts availability, and technical assistance. Their customer service ensures that any issues are promptly addressed, minimising downtime.

Custom Solutions

Understanding that every textile factory has unique needs, Weavetech offers customized solutions tailored to specific requirements. Whether it’s a small-scale operation or a large manufacturing facility, Weavetech has the right equipment to meet your needs.

Energy Efficiency

Weavetech machines are designed with energy efficiency in mind, helping you reduce operational costs and adhere to environmental standards. Their energy-saving features contribute to sustainable manufacturing practices.

Conclusion

Selecting the right garment equipment is a critical decision that can significantly impact the success of your textile factory. By considering factors such as quality, automation, energy efficiency, maintenance, flexibility, and cost, you can make informed choices that enhance your production capabilities and profitability. Weavetech, a leading textile factory machine provider, offers innovative, reliable, and efficient solutions to meet all your garment manufacturing needs.

Investing in the right machinery today will set the foundation for a successful and sustainable future in the garment industry. Ensure your equipment choices align with your business goals and operational requirements, and watch your textile factory thrive.

This blog is originally posted here: What Factors to Consider Before Selecting Garment Equipment?

0 notes

Text

JIMJEANS - The Best Jeans Manufacturer in China

As one of the Best Jeans Manufacturers in China, USA, and UK. JIMJEANS offers you a manufacturing facility to create personalized and stylized jeans, We are not only the leading jeans supplier that can provide premium quality custom jeans at factory costs, but also we are an excellent leader in contract cut and sew jeans, the full package manufacturing services. For more detail and info visit us: https://www.jimjeans.com/

0 notes

Text

Tank Tops for Men: Embracing Comfort and Style

In the realm of men's fashion, the tank top holds a unique position. It's more than just a piece of clothing; it's a statement of comfort, style, and versatility. From casual outings to intense workouts, tank tops offer men the freedom to express themselves while staying cool and comfortable. This article delves deep into the world of men's tank tops, exploring their history, styling tips, and why they're a must-have in every man's wardrobe.

I. The Evolution of Tank Tops for Men:

Historical origins: Tracing back to athletic wear in the early 20th century.

From utilitarian to fashionable: How tank tops have transcended their athletic roots to become a fashion staple.

Influence of pop culture: Celebrities, athletes, and influencers shaping the popularity of tank tops in modern times.

II. The Anatomy of a Tank Top:

Fabric choices: Cotton, polyester blends, and performance fabrics.

Fit and cut: Classic, slim fit, and muscle fit styles cater to different body types.

Neckline variations: Crew neck, scoop neck, and racerback designs add diversity to the tank top landscape.

III. Styling Tips for Men's Tank Tops:

Casual looks: Pairing tank tops with shorts, jeans, or chinos for a laid-back vibe.

Layering options: Incorporating tank tops into layered outfits with shirts, jackets, or sweaters.

Dressing up: Elevating the tank top with tailored trousers and blazers for a smart-casual ensemble.

Accessorizing: Adding sunglasses, hats, or watches to enhance the overall look.

IV. Tank Tops for Every Occasion:

Beachwear: Lightweight and breathable tank tops perfect for a day by the water.

Gym attire: Moisture-wicking tank tops designed to keep you cool during intense workouts.

Outdoor adventures: Sleeveless shirts ideal for hiking, camping, or other outdoor activities.

Casual outings: Versatile tank tops suitable for running errands, grabbing coffee, or meeting friends.

V. Embracing Body Positivity:

Breaking stereotypes: Tank tops for men of all shapes and sizes, promoting body positivity and self-confidence.

Overcoming stigma: Encouraging men to embrace sleeveless styles without fear of judgment or scrutiny.

Celebrating diversity: Recognizing that every body is different and that all bodies deserve to feel comfortable and stylish.

VI. Trends in Men's Tank Tops:

Graphic prints: Bold designs, logos, and patterns adding flair to traditional tank tops.

Retro revival: Vintage-inspired tank tops making a comeback with nostalgic prints and colors.

Sustainable options: Eco-friendly materials and ethical manufacturing practices gaining popularity among conscious consumers.

VII. Care and Maintenance:

Washing instructions: Tips for prolonging the life of tank tops through proper laundering techniques.

Storage solutions: Storing tank tops in a cool, dry place to prevent wrinkles and maintain shape.

Repairing minor damages: Sewing loose seams or patching small holes to extend the lifespan of tank tops.

VIII. Conclusion: Tank tops for men are more than just articles of clothing; they're symbols of comfort, style, and confidence. Whether you're hitting the gym, lounging at home, or stepping out for a night on the town, there's a tank top to suit every occasion and every personality. By embracing tank tops, men can express themselves freely while staying cool, comfortable, and undeniably stylish. So why wait? Embrace the versatility of tank tops and elevate your wardrobe to new heights of fashion and comfort.

#tank top#clothing#menswear#cloth#men's fashion#men's style#men's clothing#men's t shirts#men's tank top

0 notes

Text

Sustainable Style: 5 Eco-Friendly Ways to Breathe New Life into Grey Cotton Fabric

In a world where sustainability is paramount, Sri Shakthi Tex Erode brings you eco-conscious solutions for your home decor needs. Harnessing the natural and biodegradable properties of grey cotton fabric, here are five DIY projects that not only add style to your living space but also contribute to a greener planet:With Sri Shakthi Tex Erode’s grey cotton fabric, you can elevate your home decor while reducing your environmental footprint. Embrace sustainable style and make a positive impact on the planet with these eco-friendly DIY projects.

1. Upcycled Denim Throw Blankets: Give old jeans a new lease on life! Cut them into squares, sew them together, and add a touch of personality with contrasting fabrics or patches. This warm and cozy throw is perfect for chilly nights and adds a unique touch to your living room.

2. Reusable Grocery Bags: Ditch the plastic! Cut recycled grey cotton sheets into tote bags, adding pockets or embellishments for functionality and style. These sturdy bags are eco-friendly alternatives for shopping trips, reducing waste and supporting a sustainable lifestyle.

3. Natural Cleaning Cloths: Ditch the harsh chemicals! Cut grey cotton into squares and sew them together for reusable cleaning cloths. These gentle cloths are perfect for wiping surfaces, dusting furniture, and even tackling spills, all while minimizing your reliance on disposable cleaning wipes.

4. DIY Pillow Covers: Spruce up your pillows with a touch of grey! Repurpose old grey cotton shirts or curtains into new pillow covers. Mix and match patterns, add buttons or embroidery for a personalized touch, and instantly refresh your bedroom or living room décor.

5. Fabric Wall Art: Unleash your creativity! Use grey cotton scraps to create stunning wall art pieces. Experiment with weaving, collage techniques, or even fabric painting to create unique and eco-conscious artwork that reflects your style and personality.

Embrace the Sri Shakthi Tex Difference:

At Sri Shakthi Tex, we understand the importance of sustainable practices. We are committed to using ethically sourced cotton and responsible manufacturing processes. By choosing Sri Shakthi Tex grey cotton fabric, you’re not just investing in your home, but also in a greener future.

Embrace Sustainability, Embrace Style:

These are just a few ideas to get you started. With a little creativity and Sri Shakthi Tex’s eco-friendly fabrics, you can transform your home into a haven of sustainable style.

We are manufacturer and supplier of various 100% cotton and polycotton fabrics such as plain, drill, duck, canvas and stain fabrics, Eco friendly bag materials, white shirting,pyjama and kurti materials, white karate uniform fabrics, bedding linens, bedsheets, white dhotis, cradle cloth and cotton tapes.

#fabric collection erode#cotton bedspreads india#handloom textiles india#sri shakthi tex#fabric manufacturers in erode#srishakthitex#handloommagic#organic cotton textiles india#textile manufacturers india

0 notes

Text

The Ultimate Jeans Sewing Pattern: Make Your Own Jeans with Stitch Perfect

In a world dominated by mass-produced fashion, the quest for individuality propels many to explore unique avenues of self-expression. Designing your own men’s jeans is a remarkable opportunity to showcase your style, and at Stitch Perfect, we elevate this experience by offering tailored denim creations that resonate with your uniqueness.

Choosing the Right Fabric:

As a jeans manufacturer, Stitch Perfect takes pride in the quality of denim used in every pair of jeans. Denim comes in various weights, weaves, and compositions, each contributing to the overall look and feel of the final product. Whether you prefer a classic, heavier weight for durability and warmth or a lighter weight for a more casual vibe, our extensive range caters to diverse preferences.

The Fitting Process:

Precision is paramount when it comes to creating a pair of jeans that fits like a second skin. Our skilled artisans at Stitch Perfect emphasize the importance of accurate measurements for the waist, hips, inseam, and thighs. For a truly bespoke experience, we encourage you to consult with our professional tailors or follow our detailed online guides for self-measurement. If crafting jeans as a gift or for someone else, effective communication about body shape and style preferences ensures a tailored fit that aligns seamlessly with the wearer’s unique style.

The Crafting Process:

For those less experienced in the art of crafting, our online customization services offer a seamless process. Submit your design, measurements, and fabric choices, and let our professionals handle the rest. DIY enthusiasts can also find a wealth of resources, tutorials, and patterns online, empowering them to take on the challenge of creating jeans that tell their unique story.

Let’s present those customization options in a varied way

Pockets: Opt for a personalized pocket arrangement — whether it’s adding coin pockets for functionality or embracing a sleek look with fewer pockets.

Button-Fly: Make a style statement by choosing between the timeless button-fly for a classic touch or the modern convenience of a zipper closure.

Stitch Craft: Infuse personality into your jeans with a play of contrasting or harmonious stitching. Consider a double or triple stitch for both durability and a dash of flair.

Metalworking: You can add a touch of sophistication to your jeans by opting for custom metal finishes for buttons and rivets. You can choose from brass, copper, or silver to complement your jeans’ overall aesthetic.

Distressing: Tailor the level of distressing or fading to suit your taste. Whether it’s a pristine pair or a vintage, worn-in look, this customization adds a unique character to your jeans.

Feel free to mix and match these options to create jeans that truly reflect your style! If you have any more questions or need further assistance, let me know.

Stitch Perfect stands as your go-to jeans manufacturer and wholesale jeans supplier in Mumbai, India. Our commitment to quality, customization, and sustainable practices makes us the preferred choice for B2C businesses seeking distinctive denim creations. From crafting your own jeans to exploring our wholesale jean jackets collection, Stitch Perfect is your partner in fashioning a wardrobe that speaks volumes about your style.

At Stitch Perfect, we redefine denim fashion by providing cutting-edge designs that resonate with the latest trends in the market. Our commitment to innovation ensures that each pair of denim jeans tells a unique story, blending contemporary aesthetics with timeless comfort. Discover the perfect blend of style and substance with our trendy denim designs that set you apart in the fashion landscape.

For more details visit our website https://stitchperfect.co.in/

0 notes

Text

Advancements Reshaping the USA Apparel Sector

Introduction

The USA apparel industry stands at the forefront of global fashion, driven by a dynamic ecosystem of manufacturers. From renowned denim manufacturers crafting iconic jeans to sportswear manufacturers delivering cutting-edge athletic gear, the landscape is brimming with innovation and creativity. In this exploration of the advancements reshaping the sector, we delve into the pivotal role played by USA clothing manufacturers, also known as clothing manufacturers in USA. These entities have become epicenters of progress, driving the industry forward with their commitment to quality, sustainability, and technological integration.

As the demand for ethically-produced, sustainable fashion rises, American clothing manufacturers have been swift to respond. They’ve embraced eco-friendly practices and implemented state-of-the-art technologies to redefine the production process. This shift towards sustainability not only reflects a deeper understanding of environmental responsibility but also showcases the adaptability and forward-thinking approach of these manufacturers.

we will dissect the pivotal technological advancements, sustainable initiatives, and consumer-driven strategies that are currently revolutionizing the USA apparel sector. By shedding light on the efforts of apparel manufacturers, including denim manufacturers and sportswear manufacturers, we aim to provide a comprehensive understanding of how the industry is evolving to meet the demands of a conscious and ever-evolving market.

Technological Innovations in Apparel Manufacturing

In the competitive realm of apparel production, staying at the cutting edge of technology is paramount. USA clothing manufacturers, often hailed as pioneers in the industry, have been quick to adopt and integrate the latest technological advancements. From automated stitching systems to sophisticated fabric-cutting machinery, these manufacturers are revolutionizing the way garments are crafted.

One of the breakthroughs in recent years has been the integration of Computer-Aided Design (CAD) software. This allows designers and manufacturers to create intricate patterns and designs with precision and speed. Designs can be visualized in 3D, enabling a more accurate representation of the final product. This not only expedites the design process but also minimizes material wastage.

Additionally, advancements in robotics and automation have significantly enhanced production efficiency. Automated sewing machines, for example, are capable of stitching complex patterns at a pace unmatched by manual labor. This not only accelerates production but also maintains a consistent level of quality across batches. Such technological strides are redefining the capabilities of apparel manufacturers in USA, enabling them to produce high-quality garments on a larger scale.

RFID (Radio-Frequency Identification) technology is yet another game-changer. By tagging each garment with a unique identifier, manufacturers can track its progress throughout the production process. This level of traceability not only aids in quality control but also facilitates supply chain management, allowing for real-time updates on inventory levels.

Moreover, advancements in smart textiles are opening up a realm of possibilities. Fabrics embedded with sensors can monitor vital signs, track movement, and even respond to environmental conditions. This innovation is particularly relevant in the sportswear sector, where athletes can benefit from apparel that adapts to their needs.

Technological innovations are propelling USA clothing manufacturers to new heights of efficiency and creativity. By embracing these advancements, manufacturers are not only meeting the demands of a rapidly evolving market but also setting the standard for the global apparel industry.

Sustainability Initiatives by American Clothing Manufacturers

In an era where conscious consumerism is paramount, American clothing manufacturers have emerged as pioneers in sustainable practices. Renowned as some of the best clothing manufacturers in USA, these industry leaders are driving the shift towards eco-conscious production. They’re actively redefining the narrative of fashion by prioritizing ethical sourcing, reducing waste, and embracing eco-friendly materials.

One prominent initiative involves the use of organic and recycled fabrics. Manufacturers in America are increasingly turning to materials that have minimal environmental impact. Organic cotton, for instance, eliminates the use of harmful pesticides and conserves water, making it an eco-friendly alternative to conventional cotton. Similarly, recycled polyester and nylon are finding their way into garments, diverting plastic waste from landfills.

Furthermore, the adoption of closed-loop production processes is becoming commonplace among sustainable clothing manufacturers. This approach minimizes waste by recycling and reusing water, chemicals, and textiles throughout the manufacturing process. It’s a testament to the industry’s dedication to reducing its ecological footprint.

American clothing manufacturers are also actively engaged in responsible sourcing and ethical labor practices. They seek out suppliers who adhere to fair labor standards, ensuring safe working conditions and fair wages for workers. By fostering transparent and accountable supply chains, these manufacturers are contributing to a more equitable global fashion industry.

By championing these sustainability initiatives, clothing manufacturers in America are not only meeting the demands of an increasingly eco-conscious market but also setting a standard for the global fashion industry. They exemplify how fashion can be both stylish and environmentally responsible, proving that ethical practices can coexist with high-quality, fashionable apparel.

The dedication of American clothing manufacturers to sustainability is reshaping the industry’s landscape. Their commitment to ethical sourcing, eco-friendly materials, and responsible production processes positions them as leaders in the movement toward a more sustainable and environmentally-conscious fashion future.

Data-Driven Insights and Consumer Preferences

In the fast-paced world of fashion, understanding and meeting consumer demands is paramount. Clothing manufacturers in the USA, known for their agility and innovation, are leveraging data-driven insights to stay ahead of trends and ensure their offerings resonate with their target audience. This strategic approach involves the systematic collection and analysis of consumer behavior, purchase patterns, and trend forecasts.

By harnessing advanced analytics and AI algorithms, apparel manufacturers gain valuable insights into evolving consumer preferences. These technologies enable them to decipher which styles, colors, and designs are gaining traction, allowing for informed decisions throughout the design and production process. Additionally, they can optimize inventory levels to match actual demand, reducing excess stock and minimizing waste.

Clothing manufacturers in India, while also making strides in this field, look to their American counterparts for guidance on implementing robust data-driven strategies. The adoption of these technologies represents a paradigm shift in how the fashion industry operates, ultimately leading to more efficient and responsive production cycles.

American clothing manufacturers, with their deep understanding of consumer data, are able to create products that not only meet current demands but also anticipate future trends. This foresight allows them to stay relevant and competitive in a rapidly evolving market. Moreover, by tailoring their offerings to align with consumer preferences, they foster stronger brand loyalty and customer satisfaction.

The integration of data-driven insights is revolutionizing the practices of clothing manufacturers, both in the USA and globally. This innovative approach not only enhances the agility and responsiveness of manufacturers but also ensures that the fashion industry remains dynamic and attuned to the ever-changing desires of consumers.

Supply Chain Transformations in the USA Apparel Industry