#custom cnc plastic

Explore tagged Tumblr posts

Text

Make Custom CNC Plastic Parts with Great Accuracy

Precision and customization have become very important in the ever-changing world of production. Custom CNC plastic parts have become a key part of creation because they let businesses bring their own unique designs to life with a level of accuracy that is unmatched. As a pioneering one-stop solution provider, RM Mold is at the head of this change. Please visit us: https://dribbble.com/shots/22934673-Make-Custom-CNC-Plastic-Parts-with-Great-Accuracy

0 notes

Text

Transparent CNC custom plastic parts

#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#cnc machining service#cnc machining parts#cnc plastic#cnc plastic part#plastic machining#plastic cnc machining#cnc plastic machining#cnc transparent parts#custom cnc machining#oem cnc parts

1 note

·

View note

Video

youtube

We specialize in rapid, professional prototyping services, utilizing advanced technologies to deliver high-quality results. Whether you're looking for functional prototypes or appearance samples, we can meet your needs with precision.

Simply upload your 2D and 3D drawings, specify the materials, surface finishes, and quantities, and we will promptly provide you with a free quote.

Contact us today—we look forward to your inquiry!

📞 Contact us: [email protected] 🌐 Visit our website: www.kd-cncmachining.com

#youtube#Prototype parts manufacturing#Rapid prototyping#Functional prototypes#Appearance prototypes#CNC prototyping services#3D printing prototypes#Prototype machining#Custom prototype parts#Prototype development#Low-volume production#Precision prototyping#Prototype design and fabrication#Plastic prototype parts#Metal prototype parts#2D/3D CAD prototypes#Surface finish prototyping#Prototype assembly#Prototype testing#Free prototype quote

0 notes

Text

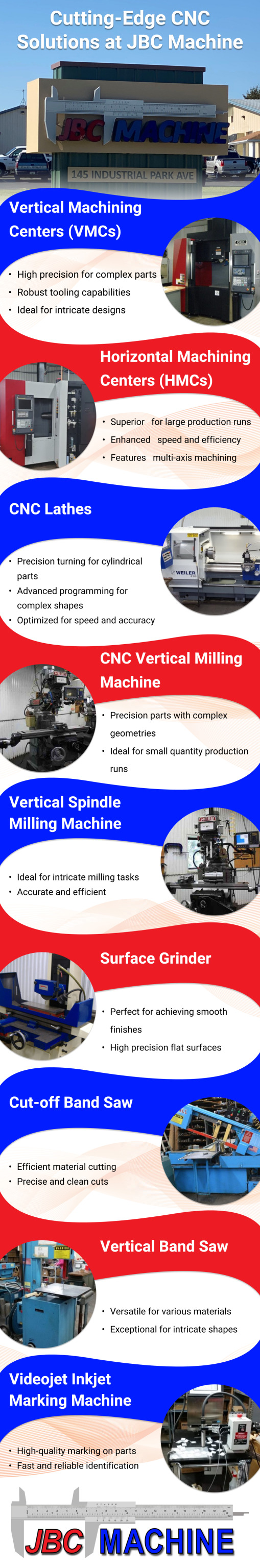

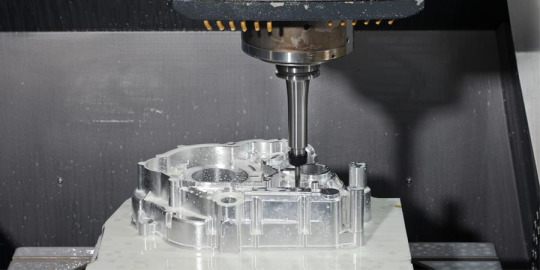

Precision CNC Machining & Custom Engineering Solutions at JBC Machine

https://jbcmachine.com/ - JBC Machine, Inc. offers advanced machining solutions with Vertical and Horizontal Machining Centers for precision and complex designs, ideal for intricate parts and large runs. Our CNC Lathes and Milling Machines excel in turning and milling precision parts, optimized for speed and accuracy. The facility also includes a Surface Grinder, Cut-off, and Vertical Band Saws for precise finishes and shapes, alongside a Videojet Inkjet Marking Machine for fast, reliable part identification. Call JBC Machine Inc. at 920-779-4075 for custom machining services.

JBC Machine, Inc.

145 Industrial Park Avenue, Hortonville, WI 54944

Phone: (920) 779-4075

E-mail: [email protected]

https://jbcmachine.com/

#CNC Plastic Machining#Plastic Machining#Aluminum Machining Custom Machine Shop#CNC Shaft Machining#Custom Machine Shop#CNC Drilling#CNC Drilling Services

0 notes

Text

A Buyer's Guide to Choosing Custom CNC Machined Parts Manufacturers

In today's market, the demand for custom CNC machined parts is soaring across industries, including aluminum CNC turning parts. Selecting the perfect CNC machined components manufacturer is essential for quality and value. This article offers a concise guide to help you make an informed choice for your project.

Material Selection: Custom machined parts can be crafted from a variety of materials, including aluminum for CNC turning parts. Choose the right material based on your project's needs, properties, and cost, consulting your CNC machining parts factory for the best fit.

Assess Supplier Capabilities: Not all CNC machined components manufacturers are equal. Evaluate their expertise, experience, and equipment for the required machining processes and complexity, especially for aluminum CNC turning parts. Check their track record and references for reliability and quality.

Quality Control and Assurance: Ensure your chosen CNC machined components manufacturer follows stringent quality control processes, such as ISO 9001 certification, to guarantee precision and quality in your aluminum CNC turning parts.

Lead Time Management: Custom parts often have longer lead times. Understand your CNC machining parts factory's lead times to meet your project deadlines with effective communication & planning.

Pricing and Value: Compare quotes from multiple CNC machined components manufacturers, considering material and machining costs, along with additional services for aluminum CNC turning parts. Prioritize overall value and reliability over the cheapest option.

Effective Communication: Opt for a CNC machining parts manufacturer with strong communication skills. Clear and timely communication is vital for addressing questions or issues during production.

Post-Processing Services: Check if the manufacturer offers post-processing services such as deburring, polishing, anodizing, or painting, especially for aluminum CNC turning parts. Consolidating these services with one vendor can save time and effort.

Packaging and Shipping: Ensure the CNC machining parts factory can package and ship your parts securely to prevent transit damage, including your aluminum CNC turning parts. Confirm they can meet your specific shipping requirements.

Intellectual Property Protection: If your custom CNC machined parts involve proprietary designs or technology, ensure the manufacturer has policies to protect your intellectual property.

The right CNC machined parts manufacturer, including aluminum CNC turning parts, is crucial for your project's success. Considering these factors, you can make an informed decision and establish a productive partnership with a CNC machining parts factory that meets your quality, service, and value requirements.

#custom cnc turning parts#cnc parts manufacturer#cnc turned parts manufacturer#cnc machining parts manufacturer#small batch cnc machining#low volume cnc machining#machining components#machined plastic parts#aluminum parts machining#custom aluminum parts#prototype cnc machining#cnc precision parts

0 notes

Text

Elevating Precision Manufacturing: The Role of Mekalite’s CNC Machining Service

In today’s competitive manufacturing landscape, precision, efficiency, and adaptability are key to staying ahead. CNC machining has emerged as a vital technology, enabling manufacturers to produce complex and high-precision parts consistently. At Mekalite, we are redefining excellence in CNC machining services by combining advanced technology, a skilled workforce, and a commitment to quality.

https://mekalite.com/

What is CNC Machining?

CNC (Computer Numerical Control) machining is a process that uses computerized controls to operate machinery and tools with high accuracy. This enables the production of intricate parts from a variety of materials, including metals and plastics, while maintaining tight tolerances. CNC machining is critical in industries such as aerospace, automotive, medical devices, and electronics.

Why Choose Mekalite for CNC Machining?

Mekalite sets itself apart by offering a comprehensive approach to CNC machining, ensuring every project is handled with precision and care.

Advanced Machinery and Capabilities Our cutting-edge, multi-axis CNC machines allow us to handle even the most complex designs with precision and consistency. Whether you need rapid prototyping, low-volume manufacturing, or full-scale production, Mekalite’s technology enables us to meet your unique needs.

Customized Solutions We understand that every project is different. Mekalite works closely with each client to understand their specific requirements, delivering tailored solutions that align with their design and functionality goals.

Strict Quality Assurance At Mekalite, quality is our top priority. Our rigorous quality control protocols cover every step of the production process, from material selection to final inspection. This commitment ensures every part meets the industry’s highest standards.

Industries Served by Mekalite

Mekalite’s CNC machining services support a diverse range of industries, including:

Aerospace: High-precision components for engines, structural parts, and aircraft interiors.

Automotive: Custom engine parts, suspension components, and detailed bodywork.

Medical: Surgical instruments, implants, and diagnostic equipment requiring tight tolerances.

Electronics: Housing frames, connectors, and precision parts for delicate devices.

Benefits of Partnering with Mekalite

Choosing Mekalite as your CNC machining service provider offers numerous advantages:

High Precision and Accuracy Our state-of-the-art CNC machines, combined with skilled operators, enable us to achieve exceptional accuracy and repeatability across all projects.

Wide Range of Materials Mekalite’s expertise spans across various materials, from metals like stainless steel and aluminum to specialized plastics. This flexibility allows for innovative product designs and customized applications.

Cost Efficiency and Scalability With automated processes and minimal manual intervention, CNC machining reduces labor costs while enhancing efficiency. Whether you need a single prototype or a large production run, Mekalite’s scalable services can adapt to your requirements.

Timely Deliveries Time is crucial in manufacturing. Our efficient workflows and commitment to meeting deadlines ensure that your projects are completed on schedule, every time.

Looking Ahead: Mekalite’s Commitment to Innovation

Mekalite is committed to staying ahead of industry trends and technological advancements. By continually investing in the latest CNC machinery and refining our processes, we aim to provide even more innovative and reliable solutions to our clients. Our vision is to be a trusted partner in helping businesses achieve new levels of success through precision manufacturing.

Conclusion

CNC machining is revolutionizing the manufacturing industry, and Mekalite is at the forefront of this transformation. Our combination of cutting-edge technology, tailored solutions, and a dedication to quality makes us a preferred partner for businesses across various sectors.

If you’re looking for a reliable CNC machining service provider that delivers precision and value, Mekalite is here to help. Contact us today to discuss your next project!

https://mekalite.com/

2 notes

·

View notes

Text

Rotary CNC Router Machine

At GK Laser Enterprises, we pride ourselves on delivering cutting-edge solutions to meet the evolving needs of the manufacturing and fabrication industries. One such innovation that has gained popularity for its versatility and precision is the Rotary CNC Router Machine. As a leader in CNC technologies, we offer a range of advanced CNC machines, and today we dive deep into how a rotary CNC router machine can revolutionize your operations.

What is a Rotary CNC Router Machine? A Rotary CNC Router Machine is a computer-controlled cutting machine that uses rotary tools to carve, cut, or engrave materials in three dimensions. The term “rotary” refers to its ability to rotate the material around an axis while it works, providing access to all sides of the material. This capability enables intricate detailing, sculpting, and shaping of cylindrical or irregularly shaped materials.

Unlike traditional CNC routers that work on flat surfaces, rotary CNC routers can handle 3D shapes, making them ideal for creating complex, multi-faceted designs.

How Does a Rotary CNC Router Machine Work? The Rotary CNC Router works by rotating the material, typically using a rotary axis attachment, while the cutting tool precisely follows the programmed paths. Here’s a breakdown of the process:

Material Preparation: A workpiece, such as wood, metal, or plastic, is mounted on the rotary axis, which allows it to rotate. Programming: A computer-aided design (CAD) program creates a digital blueprint of the desired outcome. This is then converted into machine-readable code using computer-aided manufacturing (CAM) software. Cutting Process: The router uses its rotary axis to rotate the material while the cutting tool moves along the X, Y, and Z axes to carve, cut, or engrave the material into the desired shape. Finishing: Once the operation is complete, the workpiece is inspected and may require minimal finishing, thanks to the machine’s precision.

Key Features of a Rotary CNC Router Machine High Precision and Accuracy: Rotary CNC routers are known for their precision in handling complex designs, offering high accuracy even in detailed cuts and engravings. Versatility: Whether you’re working with wood, metal, plastic, or composites, the rotary CNC router can handle a wide range of materials. This versatility makes it invaluable for industries such as furniture design, sculpture, and sign-making. 3D Carving and Engraving: With the ability to rotate the material, rotary CNC routers are ideal for creating 3D objects like sculptures, chair legs, moldings, and even complex cylindrical designs. Automation and Efficiency: The CNC aspect automates the cutting process, ensuring uniformity in production and reducing the need for manual labor. This enhances efficiency and speeds up production time.

Why Choose a Rotary CNC Router Machine for Your Business? If your business requires precision, complexity, and scalability, a rotary CNC router is a wise investment. At GK Laser Enterprises, we emphasize the value it can bring to industries like:

Furniture Manufacturing: Intricate 3D carvings and details for chair legs, columns, and sculptures can be easily achieved using rotary CNC routers. Sign Making and Woodworking: From large signs to ornate wood designs, rotary CNC routers deliver exceptional precision that elevates your craftsmanship. Sculpture and Artwork Creation: Artists and designers benefit from the ability to craft complex shapes and details, providing unmatched creativity. Metal and Plastic Fabrication: Industrial manufacturers who work with metals and plastics can create custom parts, components, and molds with great precision.

Benefits of Using a Rotary CNC Router Machine Enhanced Productivity: With automated processes, your business can take on more projects with faster turnaround times, maximizing profitability. Cost Efficiency: Despite the upfront investment, the long-term savings on labor, material waste, and improved product quality make it a highly cost-effective solution. Precision and Consistency: The automation ensures that each piece you produce is identical in quality and detail, improving overall consistency. Flexibility: Whether you’re producing one-of-a-kind custom pieces or bulk products, the rotary CNC router offers the flexibility to handle both with ease. Lower Material Waste: Precision machining ensures that there is minimal waste, reducing the cost of raw materials and promoting sustainable practices.

Why Buy From GK Laser Enterprises? At GK Laser Enterprises, we provide high-quality rotary CNC router machines tailored to meet the unique needs of businesses across industries. With our deep industry expertise, we ensure that you get the most suitable machine for your applications, ensuring optimal performance and cost-efficiency.

We also offer:

Comprehensive Training and Support: Our team will provide full training on how to operate and maintain your CNC router machine. Maintenance Services: Regular servicing to keep your machine running smoothly, ensuring minimal downtime and maximum output. Custom Solutions: We understand that every business has different requirements, so we provide customized solutions that best fit your needs.

Conclusion The Rotary CNC Router Machine offers unparalleled precision and flexibility, making it an essential tool for businesses involved in woodworking, metalworking, and creative design. At GK Laser Enterprises, we’re committed to providing top-tier CNC solutions that enhance productivity and reduce costs. By investing in a rotary CNC router, your business can stay ahead of the competition while delivering superior quality products. Contact us today to learn more about our CNC machines and how they can benefit your operations!

2 notes

·

View notes

Text

Rapid Prototyping Services Revolutionizes Innovation

Rapid prototyping is a process that uses three-dimensional computer-aided design (CAD) data to quickly produce a scale replica of a physical item or assembly. The intention is to provide engineers and designers the opportunity to assess a design's shape, fit, and functionality before mass production. The procedure allows for rapid prototype, which cuts down on the development cycle's duration and expense.

Important Elements of Services for Rapid Prototyping

3D Manufacturing

3D printing is one of the most popular methods for fast prototyping. It entails the layer-by-layer deposition of material from a computer design to produce a tangible item. The versatility of materials, such as metals, ceramics, and plastics, allows for the flexible prototyping of a wide range of items.

CNC Machining: CNC machining is a type of subtractive manufacturing in which a machine tool controlled by a computer removes material from a solid block to mold it into the desired shape. Prototypes may be made with this technique using a variety of materials, including metals and polymers.

Molding by Injection

High-volume prototypes are produced by the rapid prototyping manufacturer using injection molding. The prototype is created by pouring molten material into a mold cavity, where it hardens. Larger production runs result in lower per-unit costs, notwithstanding the greater initial tooling cost.

Advantages of Services for Rapid Prototyping

Accelerated Product Development: From concept to final design, the time it takes to produce a product is greatly decreased by rapid prototyping. Businesses can gain a competitive edge by bringing items to market faster because of this speed.

Savings: When adjustments are needed, traditional prototyping techniques may be costly. Quick modifications are made possible by rapid prototyping, which lowers tooling costs and development costs overall.

Iterative Design Process: An iterative design process is supported by the capacity to swiftly create and test prototypes. Designers can quickly retest, make changes, and get feedback, which results in a better and more optimized final product.

Customization & Complexity: Using Chinese rapid prototyping services makes it feasible to produce extremely intricate and personalized designs that would be difficult or impossible to produce using conventional manufacturing techniques. In sectors including consumer electronics, healthcare, and aerospace, this capacity is very useful.

#Chinese Rapid Prototyping Services#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Rapid Prototype

4 notes

·

View notes

Text

UHMWPE lining sheet,road mats,soccer rebounder board.plastic cut to size....

Dezhou New Origin Rubber&Plastic CO.,Ltd. is located at the China polyethylene engineering plastic products intensive center, Dezhou City, close to Beijing and Tianjin City. We are engaging in the engineering plastics from 1996.

Kelly Wei

Sales Manager

Email:[email protected]

Cell:+86 17705445030

Whatsapp: +86 17705445030

Website:www.dz-neworigin.com

Our plastic products cover a full range from semi-finished sheets to various machined parts, including CNC machining parts, injection molding parts, marine fender pads, lining sheet, temporary road mats, outrigger pads, synthetic ice rink, curling lanes, cutting board,soccer rebounder boards, as well as plastic irregular machinery parts, which are widely used in marine system, mining, construction, events and projects, sports, food and machinery industries. Which have been exported to United States, United Arab Emirates, India, Russia, Australia, Ukraine, Lithuania, Peru, Germany, Spain Saudi Arabia, South Africa etc. All the customers give good appreciation to our products.

2 notes

·

View notes

Text

Shaping the Road Ahead: 30 kW Lasers in Automotive Innovation

In recent years, 30 kW fiber laser cutting machines have emerged as a revolutionary technology in the automotive manufacturing industry. These machines utilize advanced fiber laser technology to achieve high-power cutting capabilities, enabling precise and efficient fabrication of automotive components. The impact of these machines on the industry has been profound, leading to improved productivity, cost-saving benefits, and enhanced customization opportunities.

Understanding Fiber Laser Cutting Machines

Fiber laser cutting machines are state-of-the-art tools that use fiber lasers to cut through various materials, including metals, with remarkable precision. The core of these machines is the fiber laser source, which generates an intense laser beam guided through an optical fiber. This highly focused and coherent laser beam is then directed onto the material to be cut, melting and vaporizing it with exceptional accuracy.

Advantages of fiber laser cutting machines over traditional cutting methods are numerous. Firstly, they offer higher cutting speeds and increased productivity, making them ideal for mass production in the automotive industry. Secondly, fiber lasers consume significantly less energy compared to CO2 lasers, reducing operating costs and environmental impact. Additionally, these machines are known for their excellent beam quality, resulting in smooth, burr-free cuts and minimizing post-processing requirements.

The key components of a fiber laser cutting machine include the laser source, optical fiber, cutting head, and CNC (Computer Numerical Control) system. The CNC system allows for precise control of the cutting process, ensuring accurate and repeatable results. The machine's software plays a crucial role in generating cutting patterns and nesting layouts to optimize material usage and minimize waste.

Transformation

The adoption of 30 kW fiber laser cutting machines has brought about a transformative impact on automotive manufacturing processes. One of the most significant advantages is the improved precision and speed of cutting operations. These machines can cut complex shapes and intricate patterns with unparalleled accuracy, leading to tighter tolerances and higher quality components. The enhanced speed allows for faster production cycles, reducing lead times and increasing overall manufacturing efficiency.

Moreover, fiber laser cutting machines offer exceptional versatility, capable of cutting a wide range of materials used in automotive manufacturing. From steel and aluminum to composites and plastics, these machines can handle various automotive-grade materials with ease, expanding the possibilities for design and innovation.

youtube

Benefits for Automotive Manufacturers

The utilization of 30 kW fiber laser cutting machines provides several compelling benefits for automotive manufacturers. One of the most notable advantages is cost-saving. Due to their high cutting speeds and reduced energy consumption, these machines lead to lower production costs, making them cost-effective for large-scale manufacturing.

Furthermore, fiber laser cutting machines result in minimal material waste. Their precise cutting abilities allow for optimized nesting layouts, maximizing material utilization and minimizing scrap. This reduction in waste not only saves costs but also contributes to a more sustainable and environmentally-friendly manufacturing process.

Another advantage is the level of customization and flexibility these machines offer. With their ability to cut intricate shapes and patterns, automotive manufacturers can cater to customer demands more effectively. Additionally, the adaptability of these machines enables rapid prototyping and quick design iterations, accelerating the product development cycle.

Several leading automotive manufacturers have successfully implemented 30 kW fiber laser cutting machines in their production processes. Hyundai Motor Company for instance, increased their production output by 40% after integrating fiber laser cutting machines into their assembly line. This efficiency gain allowed them to meet rising market demands while maintaining high product quality.

Another example is Volkswagen Group, which achieved significant cost savings by minimizing material waste through precise cutting patterns generated by fiber laser cutting machines. This reduced their overall material expenses and made their operations more sustainable.

In conclusion, 30 kW fiber laser cutting machines have revolutionized automotive manufacturing, offering increased precision, speed, and material versatility. These machines are driving the industry towards enhanced productivity, cost-effectiveness, and customization opportunities, making them a pivotal technology for automotive manufacturers in the 21st century.

2 notes

·

View notes

Text

Best CNC laser cutting services providers in Manesar

CNC laser cutting services refer to the professional cutting services provided by companies equipped with CNC (Computer Numerical Control) laser cutting machines. These services offer precise and efficient cutting of various materials using laser technology.

Here are some key aspects of CNC laser cutting services:

Material Versatility: CNC laser cutting services can handle a wide range of materials, including metals (such as steel, stainless steel, aluminum, brass, copper), plastics, acrylics, wood, fabric, leather, and more. Different types and thicknesses of materials can be accommodated.

Precision and Accuracy: CNC laser cutting machines are known for their high precision and accuracy. They can create intricate and detailed cuts with tight tolerances, allowing for complex shapes and designs. The use of computer-controlled systems ensures consistency and repeatability in the cutting process.

Speed and Efficiency: Laser cutting is a fast and efficient cutting method. CNC laser cutting machines can rapidly cut through materials, reducing production time and increasing productivity. The automation capabilities of these machines enable high-speed cutting while maintaining accuracy.

Customization and Flexibility: CNC laser cutting services offer customization options to meet specific client requirements. They can work with designs provided by clients or assist in creating custom designs. This flexibility allows for the production of unique and tailored products.

Minimal Material Waste: CNC laser cutting machines have narrow kerf widths, resulting in minimal material waste. The precise cuts and tight nesting of parts optimize material utilization, reducing costs and minimizing environmental impact.

Prototyping and Production: CNC laser cutting services cater to both prototyping and large-scale production needs. Whether you need a single prototype or a large batch of parts, these services can accommodate varying order sizes.

Additional Services: Some CNC laser cutting service providers offer additional services such as design assistance, material sourcing, finishing (deburring, polishing), and assembly. This can provide a comprehensive solution for your cutting and fabrication needs.

When looking for CNC laser cutting services, consider factors such as the company's experience, expertise, equipment capabilities, turnaround time, pricing, and customer reviews. It's important to communicate your specific project requirements and ensure that the service provider can deliver the desired results.

4 notes

·

View notes

Text

JWZ-BM05D/12D/20D Double Station Blow Molding Machine

Performance and advantages 1. Suitable for producing 1-5L different size of gear oil bottle, lubrication oil bottle, cooling water tank etc. 2. Optional multi-layer co-extrusion. 3. Optional view strip line system. 4. According to the product size,select different cavity of die head. 5. According to the different material,optional JW-DB single station hydraulic screen-exchanger system. 6. According to customer's requirement,optional auto-deflashing on line,scrap conveying on line,finished product conveying on line. Technical Parameters Model Unit BM05D BM12D BM20D Max product volume L 5 12 20 Dry cycle Pc/h 700*2 600*2 600*2 Die head structure Continuous type Main screw diameter mm 75 90 90 Max plasticizing capacity (PE) kg/h 90 160 160 Driving motor Kw 30 45 45 Oil pump motor power Kw 11 15 15 Clamping force KN 70 120 160 Space between platen mm 150-510 240-640 280-680 Platen size W*H mm 350*400 450*500 500*520 Max.mould size mm 360*400 500*520 560*520 Platen moving stroke mm 450/520 600/650 650 Heating power of die head Kw 7.5 10 12.5 Machine dimension L*W*H m 3.7*3.1*2.7 4.2*3.2*3.0 4.3*3.2*3.1 Machine weight T 8.5 12 14 Total power Kw 60 90 93 Note: Informations listed above are for reference only, the production line can be designed by customer’s requirements. Product image display JWELL Co., Ltd. was founded in 1978, the Chinese biggest plastic extrusion machinery manufacturers with over 24 years in extrusion industry .Now we have 6 production base , more than 3000 employees, having a strong technical & after sales service team for serving more than 150 countries. Core components: screw and barrel, mold, roller, all processed by us. jwell group has 16 professional branches, each of which produces different products, You can get all the plastic extrusion equipments you need in jwell company and provide you with one-stop service. Our processing equipment is all CNC imported from Japan and Europe. The steel used in our machine is superior to our peers. For the same equipment, the lifetime of jwell company's equipment is generally two or three times longer than our peers. The electrical components used in our equipment are imported brands or Chinese famous brands, and they are specially optimized and designed according to the requirements of jwell company, which can well match our equipment. Other companies do not have such strength and influence. There is an old saying in China:You get what you pay for! Read the full article

2 notes

·

View notes

Text

Expert mechanical design engineering company offering services such as 3D moulding products design, plastic mould design, 2D drafting DFM for mould manufacturing CNC programming for machines

Thiram is capable of providing product development and design. Our three decades of experience in the engineering field have helped us develop unmatched expertise in the market. Our strong material technology has helped us serve time and distance for the customers.

2 notes

·

View notes

Text

CNC Machining - Everything You Need to Know

CNC machining is a very broad category of possible operations and processes. Among CNC machining operations, drilling, milling, and turning are the most common.

DRILLING

Drilling processes use bits with a diameter the same size as the diameter of the desired hole. The machining equipment inserts the spinning drill bit perpendicularly into the workpiece until it drills a hole of a predetermined length. More complex equipment can produce angular holes, and drilling tools can provide capabilities such as:

MILLING

The milling process removes cuts of material from the workpiece by moving the material against a spinning cutting edge. The tools have multiple cutting points, and each tool spins to provide a sharp cutting surface with a different length and shape. When the workpiece is pressed against milling tools, thin strips or cuts of material are removed from the existing edge. This can create shallow cuts, wide cuts, or flat-bottom cavities to shape the part. Peripheral milling processes may cut deeper to create slots or threads into the piece’s general shape.

TURNING

Turning processes turn the workpiece instead of the cutting tool. They include cutting processes such as boring, grooving, and facing. They cut excess material off of a workpiece by using single-point cutting tools precisely applied to the rotating workpiece. Turning creates cylindrical parts that have a specified diameter. Turning can create linear features both inside and on the exterior edge of the parts. These features include:

ADVANTAGES OF CNC MACHINING

Many manufacturers prefer machining processes because they create parts or components from a single workpiece. CNC machining has several additional advantages. These include:

Increased productivity. Facilities with CNC machining can produce parts 24/7. The machines may run continuously with little-to-no human intervention. The machines also require less space than workstations or manual machining setups, so a facility with a set square footage can have more machines running simultaneously.

A high degree of accuracy. CNC machining uses highly detailed programming operations. The machines follow these instructions without allowing any unwanted variation or human error. The parts will be high-quality, precise, and identical. CNC machining can also produce parts with intricate, complex designs.

Faster project completion. Every CNC machining process starts with a CAD design, so the prototyping process will be much faster. The software catches or prevents many possible design flaws or potential risks with different materials. When the prototyping and testing processes are shortened, products can go from design into production faster. CNC machining instructions can also be modified or replaced quickly, so there is little delay between changes in production runs.

Cost-effectiveness. CAD file designs and reduced risks of manufacturing errors reduce the per-unit cost of production. CNC machining also requires less human labor, which further reduces the price of manufacturing the products.

For customers seeking a complete manufacturing solution, Pro-Type Industries, Incorporated offers a level of value and process flexibility that is unmatched in the industry. We operate a state-of-the-art facility that is equipped with some of the most advanced CNC machining systems available.

With our experienced skillful engineers team, we providing high quality custom CNC metal and plastic parts to world wide clients in many industries field. We are always appreciated by high tolerance quality and one-stop service of multiple processes. We are now working for clients partners from USA, Euro, Mid-East, Asian, supporting clients’ projects by excellent quality, bottom cost and quick lead-time.

3 notes

·

View notes

Link

🌍 IMA Schelling Group: Pioneering the Future of Precision Manufacturing 🚀

At IMA Schelling, we’re more than just a machinery manufacturer – we’re transforming industries! From woodworking to metalworking and plastics, our cutting-edge machinery is setting new standards in precision, efficiency, and innovation.

🔹 CNC machining centers 🔹 Panel saws 🔹 Edge banding machines 🔹 Automated material handling systems

With 18 global offices, 24/7 support, and a spotlight at the Ligna 2024 Trade Fair, we are empowering manufacturers worldwide to push boundaries and elevate their production processes.

🚀 Join us in shaping the future of manufacturing.

🔗 Discover more about our solutions

0 notes

Text

What distinguishes top CNC laser cutting machine manufacturers?

The industrial industry has changed because of CNC laser cutting technology, which offers accuracy and efficiency in material processing. It enables precise cuts and sophisticated patterns by directing a beam toward materials like plastic, metal, and wood using computer numerical control. Electronics, aerospace, and, therefore, the industry all depend upon this technology. However, the manufacturer selected will determine how successful this technology is. Reputable manufacturers must supply dependable maintenance, support, and high-performance equipment. To ensure the simplest possible manufacturing results, factors including expertise, technical prowess, and client feedback should be taken into consideration. Gaining an understanding of those factors helps guarantee that the investment produces the simplest possible results.

Understanding CNC Laser Cutting Machines

High-powered devices called CNC laser cutting machines are utilised in a spread of industries for precise cutting of materials, including electronics, metals, plastics, wood, and, therefore, the automotive and aerospace sectors. They work by guiding the beam using computer controls and optics, enabling precise and sophisticated patterns. They're extensively employed within the fields of electronics, automotive, aerospace, and manufacturing for both production and prototyping, as well as in art and signs for the creation of intricate patterns and graphics. High accuracy, repeatability, the capacity to chop intricate forms and patterns, and quicker production periods than traditional methods are some benefits of utilising CNC laser cutting technology.

Criteria for Evaluating CNC Laser Cutting Machine Manufacturers

CNC Laser Cutting Machine Manufacturer are evaluated by a variety of things, like the standard of their equipment and technology, industry standards and customer feedback, customer support and repair, warranty and maintenance services, and therefore, the manufacturer's dedication to machine capabilities and technological advancement. Examining proof of current research projects and merchandise upgrades that improve operational effectiveness is a component of this.

Leading CNC Laser Cutting Machine Manufacturers

Manufacturers provide a spread of laser cutting solutions. They're a specialist in high-performance systems and automation, a pioneer in cutting-edge laser technology, and among the leading producers of CNC laser cutting machines. The company is well-known across the planet for its dependability, quality, creativity, and customer service.

Key Features That Differentiate Manufacturers

Innovative technology and style advances, such as intelligent laser systems with integrated software, user-friendly interfaces, and modular designs, are created by manufacturers. Offering high-speed cutting with less waste, optimum energy consumption and cycle times, and continuous precision and repeatability in production, they supply tailored solutions to support the stress of individual customers. Additionally, these improvements enable modification to satisfy specific operating needs.

Price Comparison and Value Proposition

An outline of pricing policies among top manufacturers is given during this section, emphasising differences in costs consistent with machine capabilities and specifications. It weighs extra expenses like maintenance and support when comparing entry-level and high-end devices. TheThe first investment, possible productivity increases, operating efficiency, and output quality are all taken into consideration when buying high-quality machinery. Long-term savings, decreased downtime, repair expenses, energy efficiency, and increased resale value are all benefits of high-quality machinery.

Future Trends in CNC Laser Cutting Technology

Automation and AI (AI) are going to be used in CNC laser cutting technology in the future to extend accuracy, speed, and material compatibility. It'sIt's also anticipated that software innovations will improve workflow management and style. Adoption is anticipated to rise with hybrid systems that combine laser cutting with other technologies. With applications rising in sectors like aerospace and automotive, there's an increasing need for small-batch and customised manufacturing capabilities. Manufacturers are focused on sustainability and environmentally friendly practices, investing in R&D, working with tech businesses, and adjusting to changes within the market.

Tips for selecting the proper CNC Laser Cutting Machine Manufacturer

This section compares entry-level and high-end models, takes maintenance and support expenses under consideration, and offers a radical examination of price structures among leading manufacturers. When it involves long-term savings, less downtime, repair costs, energy efficiency, and increased resale value, it emphasises the analysis of investing in high-quality machinery.

Conclusion

For CNC laser cutting technology to supply the intended outcomes in industrial processes, choosing the right manufacturer is important. The calibre of the equipment and support services strongly impacts productivity and cost-effectiveness. For your operations to achieve success and sustainability, carefully consider your alternatives and make wise choices.

1 note

·

View note