#cr coils

Text

Learn more about cold rolled CR coils at www.jindalstainless.com.

0 notes

Text

How to choose the Best Quality Cold rolled coils?

Cold rolled coilsare a type of coil made from a very thin sheet of metal that has been cold rolled. Cold rolling is a process where the metal is heated to a very high temperature and then slowly rolled into a coil. This process makes the metal much thinner and less likely to break.

What is the quality of cold rolled coils?

The best qualitycold rolled coilsare usually the thinnest and have the least defects. The coils should also be brightly colored and have a smooth surface. When choosing the best quality, cold rolled coils. It is important to consider both the quality of the coil itself and the manufacturing process. Here are some tips for finding high-quality coils:

Look for a company with a good reputation. A reputable manufacturer will have a long history of producing high-quality coils, so you can be sure that their products will meet your standards.

Inspect the coil for defects and inconsistencies. Avoid purchasing that coil if there are noticeable flaws, such as cracks or bumps in the metal.

Consider the size of the coil. The size of a coil will impact how much you’ll need to vape it. If you’re new to vaping, start small and work your way up to bigger coils if you want more significant clouds.

Check the design. The design of a coil will further impact how much you will need to vape it. If you don’t like the look of a specific color, you can always choose a different one.

Consider the material used to make the coil. The material used to make the coil will impact how much you need to vape it. For example, choose one made from stainless steel if you’re looking for a longer-lasting coil.

How is Cold Rolled Steel made?

Steel is a metal that is made from iron and other elements. It is a strong metal that can be used to make products like cars and bridges.

To make steel, you start by heating iron ore in a furnace. Next, the ore is heated until it is a hot, molten metal. Then, you pour the molten metal into a rolling mill. The rolling mill uses a series of rollers to crush the metal into tiny pieces. The tiny pieces are then cooled and shaped into sheets.

The steel sheets are then heated up again and rolled into thin sheets. The thin sheets are then cut into pieces and finished.

What to look for in a quality cold rolled coil?

It is important to look for a quality product regardingcold rolled coils. There are a few things to consider when shopping for cold rolled coils, including material quality, coil diameter, and coil shape.

Material quality is essential when purchasingcold rolled coils.To ensure durability and reliability, the coils should be made of high-quality metal, such as copper or stainless steel. The diameter of the coils should also be considered; as smaller coils are typically less expensive than larger coils.

Coil shape is also essential.Cold rolled coilscan be in the form of rounds, squares, or hexagons, and each has its advantages and disadvantages. Rounded coils are typically more durable than square or hexagonal coils, but they are also less flexible. On the other hand, square and hexagonal coils are more flexible but less durable.

Finally, it is important to consider the price when shopping forcold rolled coils.It is important to find a product that is affordable but also of high quality.

Conclusion If you are looking for high quality cold rolled coils,shree venktesh wires and steels pvt. ltd. is the best option. Their coils are of excellent quality and they offer a wide range of products, so you’re sure to find what you’re looking for. So if you’re in the market for quality coils, be sure to check out shree venktesh wires and steels pvt. ltd.

0 notes

Photo

Monster Popularity Contest– Kaldheim

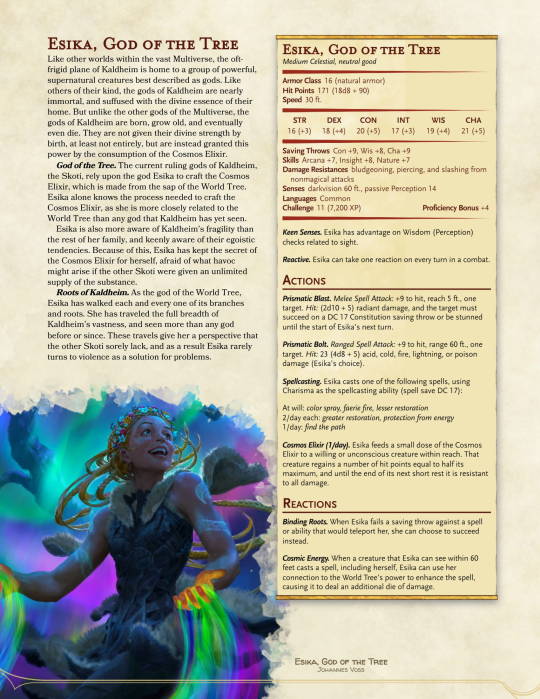

Esika, God of the Tree

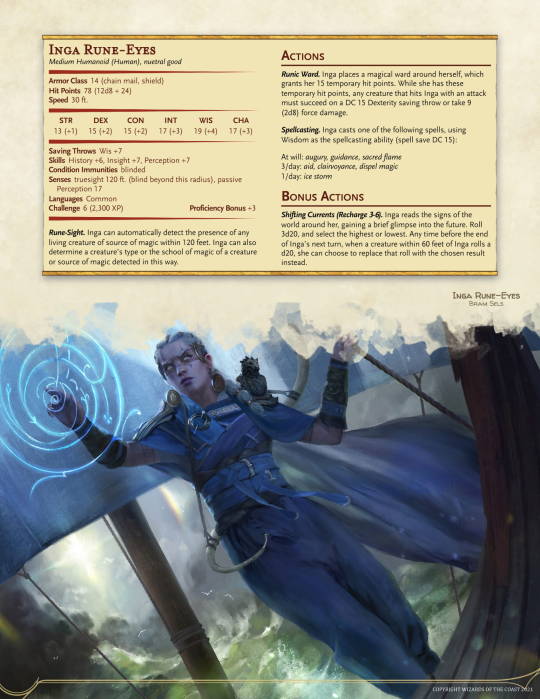

Inga Rune-Eyes

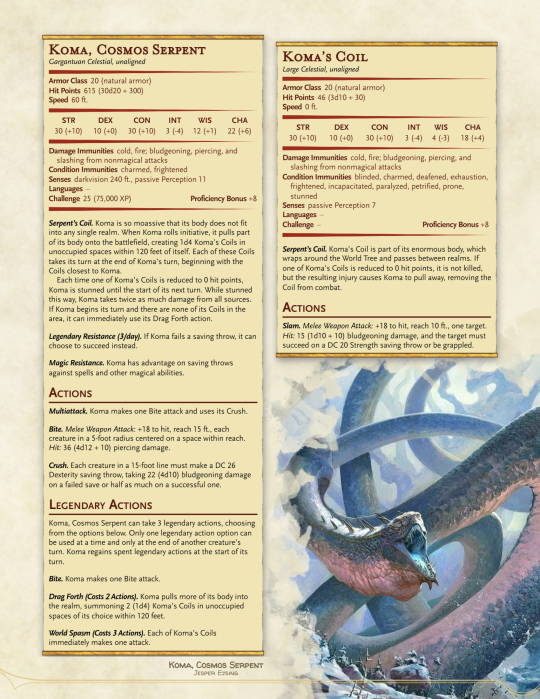

Koma, Cosmos Serpent

Alright, after a quick and easy month-long break to decompress after Arcanatober, I’m back at it again. On my Patreon, I do weekly patron-exclusive polls, and the first poll of each month is the Monster Popularity Contest. This month, to celebrate the upcoming arrival of Winter, I’m also doing exclusively winter-themed homebrews! This, of course, means a visit to the coldest MtG plane of all, Kaldheim

#dnd#dnd 5e#mtg#dnd homebrew#magic the gathering#kaldheim#monster#cr 11#celestial#cr 6#humanoid#cr 25#esika#god of the tree#inga rune-eyes#koma#cosmos serpent#koma's coil

111 notes

·

View notes

Text

Stainless Steel CR Coil Prices Trend | Pricing | Database | Index | News | Chart

Stainless Steel CR Coil Prices have been a subject of significant attention in the global market, given their importance in various industries such as automotive, construction, and appliances. The pricing of stainless steel CR coils is influenced by a myriad of factors, including raw material costs, supply and demand dynamics, global economic conditions, and technological advancements in production processes. As the demand for high-quality and durable materials grows, understanding the fluctuations in stainless steel CR coil prices becomes crucial for manufacturers, suppliers, and end-users alike.

The primary driver of stainless steel CR coil prices is the cost of raw materials, particularly nickel, chromium, and iron. Nickel is a key component in stainless steel production, and its price volatility directly impacts the cost of stainless steel products. When nickel prices surge due to supply constraints or increased demand from other industries, stainless steel CR coil prices typically follow suit. Similarly, chromium, which imparts corrosion resistance to stainless steel, also plays a crucial role. Fluctuations in the availability and pricing of these elements significantly affect the overall cost of stainless steel CR coils.

Get Real Time Prices of Stainless Steel CR Coil: https://www.chemanalyst.com/Pricing-data/stainless-steel-cr-coil-1369

Supply and demand dynamics are another critical factor influencing stainless steel CR coil prices. On the supply side, the production capacity of stainless steel mills, technological advancements, and geopolitical factors can lead to shifts in output levels. For instance, disruptions in production due to maintenance or upgrades at major mills can tighten supply and drive prices up. Conversely, an oversupply situation, where production outpaces demand, can lead to a decrease in prices. On the demand side, economic growth in key markets such as construction, automotive, and industrial manufacturing can spur demand for stainless steel CR coils, thereby increasing prices. For example, a boom in the construction industry often leads to higher demand for stainless steel products used in structural applications, consequently driving up prices.

Global economic conditions also play a significant role in determining stainless steel CR coil prices. Economic stability and growth foster industrial activities, boosting the demand for stainless steel products. Conversely, economic downturns or recessions can lead to reduced industrial output and lower demand, causing prices to fall. Additionally, trade policies and tariffs imposed by major economies can impact the flow of stainless steel products across borders, influencing prices. For instance, tariffs on imported steel can lead to higher domestic prices as supply becomes constrained.

Technological advancements in the production processes of stainless steel CR coils have also contributed to price fluctuations. Innovations that enhance production efficiency, reduce waste, and improve product quality can lower production costs, which may translate to lower prices for end consumers. However, the initial investment in new technologies and the transition period can temporarily increase costs, affecting prices. The adoption of sustainable and environmentally friendly production practices, driven by regulatory pressures and consumer preferences, also plays a role in shaping the cost structure of stainless steel CR coils.

Moreover, energy costs are a significant component of stainless steel production. The energy-intensive nature of steel manufacturing means that fluctuations in energy prices, particularly electricity and natural gas, can have a direct impact on production costs. Rising energy prices increase the cost of production, which can lead to higher prices for stainless steel CR coils. Conversely, a decrease in energy costs can help reduce production expenses and potentially lower prices.

Market sentiment and speculation can also influence stainless steel CR coil prices. Traders and investors often react to news and forecasts about the supply-demand balance, raw material prices, and economic indicators. Positive news about economic growth or an anticipated increase in demand can lead to speculative buying, driving prices up. Conversely, negative news such as economic slowdowns or geopolitical tensions can lead to speculative selling, causing prices to drop.

In conclusion, stainless steel CR coil prices are influenced by a complex interplay of factors including raw material costs, supply and demand dynamics, global economic conditions, technological advancements, energy costs, and market sentiment. Stakeholders in the stainless steel industry must continuously monitor these variables to make informed decisions. As industries that rely on stainless steel CR coils continue to grow and evolve, understanding the underlying factors that drive price fluctuations remains essential for maintaining competitiveness and managing costs effectively. The dynamic nature of the stainless steel market requires a proactive approach to stay ahead of trends and mitigate risks associated with price volatility.

Get Real Time Prices of Stainless Steel CR Coil: https://www.chemanalyst.com/Pricing-data/stainless-steel-cr-coil-1369

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Stainless Steel CR Coil#Stainless Steel CR Coil Price#Stainless Steel CR Coil Prices#Stainless Steel CR Coil Pricing

0 notes

Text

Incoloy 901 Plate Supplier in Mumbai - Renine Metalloy

We at Renine Metalloys, supplies high quality Incoloy 901 Plate at a very competitive price. Check out price list, and more. Contact us at +91-22- 67437353.

#UNS N09901 2B Finish#DIN 2.4662 Ring#UNS N09901 Sheets#DIN 2.4662 CR Sheet#DIN 2.4662 Coil#Incoloy 901 Flats#Incoloy 901 Plain Sheet#UNS N09901 Clad Plate#Incoloy 901 Perforated Sheets#DIN 2.4662 Plate#UNS N09901 Rolls#UNS N09901 Foil Sheet#Incoloy 901 Circle#DIN 2.4662 Hot Rolled Sheet#Incoloy 901 Shims.

0 notes

Text

Stainless Steel CR Coil Prices Trend, Monitor, News & Forecast | ChemAnalyst

Stainless steel CR coil prices have exhibited notable fluctuations influenced by a variety of factors encompassing global market dynamics, industrial demand, and production costs. Comprehending these price shifts requires a thorough analysis of supply and demand dynamics, technological advancements, and macroeconomic indicators.

One of the primary drivers impacting stainless steel CR coil prices is the equilibrium between supply and demand within the stainless steel industry. Stainless steel CR (cold-rolled) coils, renowned for their corrosion resistance and versatility, are manufactured through cold-rolling processes from stainless steel sheets or strips. Any disruptions in the supply chain, such as fluctuations in raw material prices, energy costs, or trade policies, can affect the production costs of stainless steel CR coils, thereby influencing their market prices.

Industrial demand plays a pivotal role in determining stainless steel CR coil prices. These coils find extensive applications across various sectors including automotive, construction, appliances, and machinery. Fluctuations in demand from these sectors, influenced by factors like economic conditions, infrastructure projects, and technological advancements, can lead to price volatility for stainless steel CR coils. For instance, increased construction activities during economic booms can drive up demand and consequently prices.

Raw material costs significantly impact stainless steel CR coil prices. The price of raw materials such as nickel, chromium, and molybdenum, which are crucial alloying elements in stainless steel production, can fluctuate due to changes in global supply and demand dynamics, geopolitical tensions, and currency fluctuations. Any substantial increase in raw material costs can translate into higher production costs for stainless steel CR coils, thereby exerting upward pressure on prices.

Get Real Time Stainless Steel CR Coil Prices: https://www.chemanalyst.com/Pricing-data/stainless-steel-cr-coil-1369

Macroeconomic indicators, such as GDP growth, inflation rates, and currency exchange rates, indirectly influence stainless steel CR coil prices by affecting overall industrial activity and consumer demand. Economic downturns or currency devaluations in major stainless steel-consuming regions may lead to decreased demand and downward pressure on prices. Conversely, robust economic growth and stable currencies can support higher stainless steel CR coil prices by stimulating industrial production and infrastructure investments.

Geopolitical factors also contribute to price volatility in the stainless steel CR coil market. Trade tensions, tariffs, and political instability in major stainless steel-producing regions can disrupt supply chains and lead to price fluctuations. For example, trade disputes between major economies may result in tariffs on stainless steel imports, impacting the availability and cost of stainless steel CR coils in global markets.

Technological advancements and innovation influence stainless steel CR coil prices by enhancing manufacturing efficiency and product quality. Advanced production techniques and automation can lead to cost savings in the manufacturing process, potentially mitigating price increases resulting from higher raw material costs or external factors.

Looking ahead, several factors are expected to continue shaping stainless steel CR coil prices. Continued infrastructure development, urbanization, and industrialization in emerging economies are likely to drive sustained demand for stainless steel CR coils. Moreover, advancements in materials science and engineering could lead to the development of new grades of stainless steel with improved properties, further influencing demand and price levels.

In conclusion, stainless steel CR coil prices are subject to a complex interplay of factors including supply and demand dynamics, industrial trends, raw material costs, macroeconomic indicators, geopolitical developments, and technological advancements. Stakeholders in the stainless steel industry must closely monitor these factors to anticipate price movements and make informed decisions. As the global economy evolves and technologies advance, navigating the dynamic landscape of stainless steel CR coil pricing will remain a key challenge for industry participants.

Get Real Time Stainless Steel CR Coil Prices: https://www.chemanalyst.com/Pricing-data/stainless-steel-cr-coil-1369

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

CR Coil

CR Coil, developed by Infrakeys Technologies, is an innovative component designed to optimize the efficiency and performance of various industrial applications. This cutting-edge coil is crafted with precision and advanced materials, ensuring durability and reliability in demanding environments.

The CR Coil is engineered to provide exceptional conductivity and thermal stability, making it ideal for use in a wide range of systems such as power transmission, telecommunications, and automotive industries. Its compact design and seamless integration capabilities make it a versatile solution for enhancing the functionality of equipment and machinery.

In addition to its technical prowess, the CR Coil boasts a user-friendly interface, allowing for easy installation and maintenance. With its superior performance and robust construction, this coil stands as a testament to Infrakeys Technologies' commitment to innovation and excellence in the field of industrial technology."

0 notes

Text

Shree Mahalaxmi Steel Industries, the Premier CR Coil Manufacturer in India

Introduction:

The demand for high-quality Cold Rolled (CR) coils and sheets continues to soar in the dynamic landscape of the steel industry. As businesses seek reliable and efficient solutions for their diverse industrial applications, the role of CR coil manufacturers becomes pivotal. Among the frontrunners in this domain is its distinguished name, synonymous with excellence and innovation in producing CR coils and sheets.

Shree Mahalaxmi Steel Industries: A Beacon of Quality and Reliability

It has emerged as a leading CR coil manufacturer, catering to the evolving needs of industries across India. Renowned for its commitment to quality and customer satisfaction, the company stands out as a trusted partner in the supply chain of cold-rolled steel products.

CR Coil Manufacturing Excellence: Setting Industry Standards

Cold Rolled Coil Producer:

It takes pride in being a premier cold-rolled coil producer. The company leverages cutting-edge technology and a state-of-the-art manufacturing facility to ensure the production of CR coils that meet the highest industry standards. “Cold Rolled Coil Producer” perfectly encapsulates the company’s dedication to delivering precision-engineered coils with a superior surface finish.

Industrial CR Coil Supplier:

As a reliable Industrial CR Coil Supplier, it plays a crucial role in meeting the diverse requirements of industrial sectors. The company’s commitment to maintaining a robust supply chain ensures that clients receive CR coils promptly, adhering to the stringent timelines of modern manufacturing processes.

CR Coil Manufacturers in India: Pioneering Progress

In the realm of CR coil manufacturing, it is one of India’s most prominent CR Coil Manufacturers. The company’s unwavering focus on quality and customer-centric approach has earned it a distinguished reputation in the domestic market. With a vast distribution network, it ensures that its high-quality CR coils reach every corner of the country.

Cold-Rolled Steel Sheet Manufacturer: Crafting Excellence

Industrial CR Sheet Supplier:

It extends its expertise beyond coils to include the production of Cold-Rolled Steel Sheets. As an Industrial CR Sheet Supplier, the company caters to the specific needs of industries that rely on flat and durable steel sheets for various applications. The precision and durability of these sheets make them a preferred choice in sectors ranging from automotive to construction.

A Commitment to Sustainability

In addition to its prowess in CR coil manufacturing, it strongly emphasizes sustainability. The company adopts eco-friendly practices in its manufacturing processes, ensuring a minimal environmental footprint. This commitment aligns with the global shift towards sustainable and responsible industrial practices.

Conclusion:

In the competitive realm of CR coil manufacturing, it stands out as a beacon of quality, reliability, and innovation. As a Cold Rolled Coil producer, Industrial CR Coil Supplier, and CR Coil Manufacturers in India, the company has carved a niche by consistently exceeding customer expectations.

Whether you are searching for high-quality CR coils or Cold-Rolled Steel Sheets, it emerges as the go-to partner. With a commitment to excellence and a vision for a sustainable future, the company continues to shape the landscape of the steel industry in India and beyond. Shree Mahalaxmi Steel Industries is where quality meets precision, and innovation meets reliability.

0 notes

Text

Cut to Length Line Machine Manufacturer

About PrecisionCut Industries:

PrecisionCut Industries is a leading manufacturer of high-quality Cut to Length Line Machines, catering to various industries such as automotive, construction, metal processing, and more. With a strong commitment to innovation, reliability, and customer satisfaction, PrecisionCut Industries has established itself as a trusted name in the metal fabrication equipment industry.

Cut to Length Line Machines:

PrecisionCut Industries designs and manufactures a wide range of Cut to Length Line Machines, tailored to meet the specific needs of its diverse clientele. These machines are essential for transforming large metal coils into precise and accurate flat sheets of various lengths. Whether you require precision cuts for small-scale applications or heavy-duty processing for industrial projects, PrecisionCut Industries has the perfect solution to streamline your production process.

Key Features:

1. Precision Cutting: The Cut to Length Line Machines by PrecisionCut Industries are equipped with advanced cutting technology, ensuring precise and uniform cuts throughout the entire length of the metal coil.

2. High-Speed Processing: To maximize efficiency and productivity, these machines are designed to handle high-speed processing, enabling rapid conversion of metal coils into flat sheets.

3. Customizable Solutions: PrecisionCut Industries understands that each client's requirements may vary. Therefore, their Cut to Length Line Machines can be customized to accommodate different coil widths, thicknesses, and processing speeds.

4. Automated Control System: These machines come equipped with a state-of-the-art automated control system, allowing for easy operation and reducing the likelihood of errors during the production process.

5. Durability and Reliability: PrecisionCut Industries uses top-quality materials and components in their manufacturing process, ensuring the durability and longevity of their machines even under heavy-duty usage.

6. Safety Features: Safety is a top priority at PrecisionCut Industries. Their machines are designed with multiple safety features to protect operators and prevent accidents in the production environment.

#cr slitting line#manufaturinginindia#coil slitting machine#coil slitting line#steel coil slitting line#steel coil slitting machine#manufaturing

0 notes

Text

Looking for a reliable and trustworthy brand for your cold-rolled steel needs? Look no further than Steelium Super! Our extensive range of product and service offerings is designed to help fabricators gain a competitive advantage in the retail market. Choose Steelium Super for your next project and experience the difference!

#cold rolled steel channel#cold rolled steel sheet#cold rolled coil#cold rolled steel#cold rolled sheet#cr sheet#cr steel#tata steel#steelium super

0 notes

Text

In the US market, the Stainless Steel CR Coil prices showcased a downswing in the price momentum in the first quarter of 2023 owing to the falling raw material prices amidst the reduced buying sentiments. The number of stocks available in the spot market increased significantly in January. In February, certain Stainless-Steel products saw an increase in imports as high US prices made lower-cost imports more appealing. Companies in Europe and the US frequently rely on imports from Asia to meet their needs, as mills in these regions are often uninterested in large-scale production of grades. Service centers are concerned about rising Stainless Steel CR Coil prices amid the flurry of announcements, but most market participants believe the uptrend will end in the first quarter due to interest rate hikes and pressure on the US economy. Manufacturing output in the United States fell in March due to lower demand, production, and employment. Multiple buyers are concerned that pricing will peak and then fall off in the late second quarter and into the second half of the year. The SS-304 CR plate (6 mm) prices for Ex Florida (USA) settled at USD 6528/MT.

0 notes

Text

The Different Types of CR Sheets and Coils and How to Choose the Right One for Your Needs - AMNS India

Cold-rolled (CR) sheets and coils are widely used in various industrial and commercial applications. They offer several advantages, such as a smooth finish, excellent strength and durability, and superior surface quality. However, choosing the right type of CR sheet or coil for your specific needs is important. Here are some of the different types of CR sheets and coils and how to choose the right one:

Standard CR sheets and coils:

Standard CR sheets and coils are the most common type of CR products. They are used in various applications, such as construction, automotive, and electrical components. These sheets and coils are available in various thicknesses, ranging from 0.4 mm to 3.2 mm, and widths up to 1,500 mm.

Drawing quality (DQ) CR sheets and coils:

Drawing quality CR sheets and coils are used in applications that require deep drawings, such as automotive parts and kitchen utensils. These sheets and coils have excellent surface quality, uniform thickness, and good mechanical properties. The thickness of DQ CR sheets and coils ranges from 0.4 mm to 2.5 mm.

Deep drawing quality (DDQ) CR sheets and coils:

Deep drawing quality CR sheets and coils are used in applications that require even deeper drawing, such as automotive components and home appliances. These sheets and coils have superior surface quality and uniform thickness, which ensures high formability and excellent deep drawing characteristics. The thickness of DDQ CR sheets and coils ranges from 0.4 mm to 2 mm.

Extra deep drawing quality (EDDQ) CR sheets and coils:

Extra deep drawing quality CR sheets and coils are used in applications that require the highest level of deep drawing, such as automotive components and household appliances. These sheets and coils have the highest formability and excellent deep drawing properties. The thickness of EDDQ CR sheets and coils ranges from 0.4 mm to 1.5 mm.

How to choose the right CR sheet or coil for your needs:

Choosing the right type of CR sheet or coil for your needs involves considering several factors. These include:

The specific application: Determine the requirements of your project, such as the level of formability, the thickness, and the width needed.

Surface quality: Consider the surface quality required for your project, as different CR products have varying levels of surface finish.

Mechanical properties: Check the mechanical properties of the CR sheet or coil, such as tensile strength, yield strength, and elongation, to ensure they meet your project's requirements.

Cost: Consider the cost of the CR sheet or coil, as different CR products have varying prices.

Conclusion:

CR sheets and coils offer several industrial and commercial applications advantages. By understanding the different types of CR products and how to choose the right one for your needs, you can maximize the potential of cold-rolled steel plates in your next project.

0 notes

Text

Stainless Steel CR Coil Prices Trend, Database, Chart, Index, Forecast

Stainless steel CR coil prices play a pivotal role in various industries, dictating production costs and impacting market dynamics. As a sought-after commodity, stainless steel coils undergo continuous fluctuations influenced by factors like demand-supply dynamics, raw material costs, and global economic trends. Understanding these fluctuations is crucial for stakeholders in sectors ranging from automotive to construction. In recent years, the stainless steel market has witnessed notable volatility, attributed to geopolitical tensions, trade policies, and shifts in consumer preferences. Despite this volatility, stainless steel remains a preferred material due to its corrosion resistance, durability, and aesthetic appeal.

The pricing of stainless steel CR coils is intricately linked to the prices of nickel, chromium, and other alloying elements. Nickel, in particular, holds significant sway over stainless steel prices due to its substantial presence in most stainless steel grades. Fluctuations in nickel prices, driven by factors such as mining disruptions, trade disputes, and economic indicators, directly impact the cost of stainless steel production. Similarly, chromium, an essential component in stainless steel, influences prices based on its availability and demand in various industries.

Get Real Time Prices of Stainless Steel CR Coil: https://www.chemanalyst.com/Pricing-data/stainless-steel-cr-coil-1369

Global economic conditions also exert a considerable influence on stainless steel CR coil prices. Economic growth or recession in major consuming regions like China, the United States, and Europe can lead to shifts in demand for stainless steel products, thereby affecting prices. Moreover, currency exchange rates play a crucial role, as fluctuations can either boost or dampen demand for stainless steel in export-oriented markets.

Trade policies and tariffs further complicate the pricing dynamics of stainless steel CR coils. Imposition of tariffs, anti-dumping duties, or trade restrictions by key producing countries can disrupt supply chains and lead to price fluctuations. Moreover, trade agreements and geopolitical tensions can create uncertainty, impacting investment decisions and market sentiments.

Environmental regulations and sustainability initiatives also influence stainless steel prices. As industries strive to reduce their carbon footprint and adopt eco-friendly practices, the demand for sustainable materials like stainless steel may increase. This trend can drive up prices, especially if the production processes involve higher costs for emissions reduction or recycling.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

ERP Software for CR Steel Coil

Ease your CR Steel Coil, Galvanized & Color Coated Sheet Products Manufacturing Process WIth Lighthouse India Integrated ERP Software. Request a quote NOW

#CR Steel Coil ERP Software#ERP Software for CR Steel Coil#ERP Solutions for CR Steel Coil#Best erp for Galvanized colour coated sheets ERP#ERP for Galvanized colour coated sheets

0 notes