#container yard depot

Explore tagged Tumblr posts

Text

Shipping containers depot | LOTUS Containers

Our shipping container depots offer a diverse range of containers for storage and transportation. Conveniently situated, they provide easy access to a range of containers, ensuring you find the ideal logistics solution for your specific needs. Contact LOTUS Containers to simplify your logistics and shipping services and optimize your supply chain.

0 notes

Text

i’m so deeply sad at the moment that i’m surrounding myself in fluffy fluffy fics and just hoping for a soft landing for myself but when i try to write it’s just either a) minimal effort or b) so fucking sad

like i’m trying to write a retail hell au with the tf141 boys but yeah. anyway have some notes under the cut about where i’ve stuck the boys so far.

so imagine with me that for whatever reason tf141 end up working in B&Q (home depot for those of you over the pond)

gaz works in the kitchens, bathrooms and bedroom department as a designer/consultant. why? because he’s pretty and can charm anyone into an upsell. oh you came in to get a quote on cheap sanitary ware (toilet, sink, bathtub/shower)? suddenly the customer (“client, they’re always clients. sounds better y’know?”) walking out with a £2000 order containing new tiles, a waterfall shower head, walk in shower array, £120 basin taps, a new towel warmer and a beautiful mirrored cabinet. you love watching him work because he’s just so charming and personable. always shoots you a wink from behind the computer too.

simon works stockflow. he’s in the warehouse or yard exclusively. smashes through deliveries and stock at a rapid pace and then stands in the yard smoking. no he doesn’t need any help, fuck off. leave it alone you’re going to fuck up his system. incredibly territorial over the yard/warehouse and only lets john, soap, gaz in. has a hand written sign pinned by the doors “NO ENTRY UNDER ANY CIRCUMSTANCES. ESPECIALLY FOR YOU.” the store a manager takes it down periodically. simon puts it back up. nods at you when you pass the entrance to the warehouse but doesn’t speak. coincidentally he seems to be by the entrance shuffling delivery notes or paperwork whenever you walk past.

soap technically works the interior decorating department. technically. he loves working on the paint mixing desk and flirting with all the women that come up looking for just the right shade of whatever trendy colour has been advertised in home and gardens this season but will absolutely wander off to go bother price/gaz/simon/you whenever he feels like it. constantly being called for on the tannoy system “this is a staff announcement could john mactavish please return to the paint desk, customers waiting. that’s john mactavish to the paint desk. thank you”. you’re positive he ignores the first tannoy call just so he can hear you get more exasperated on the second and third call you put out for him.

price is the hardware, electrical and plumbing supervisor and technically the stockflow supervisor. barely ever steps foot in the warehouse aside from a quick check in because he knows simon has it covered. hates management meetings and always finds himself something time critical/difficult to put down when he knows there’s one coming up. a constant presence on the shop floor. always the first supervisor to respond to the tannoy when a customer is kicking up a fuss at the customer service desk. always seems to know where you are, whether that’s on the customer service desk, serving customers on the checkouts or putting away go backs in various aisles. checks in frequently with a little smile and a “alright love?” before moving on to whatever task he can do to keep him out of the store manager’s sights. reminds everyone to take their breaks regardless of whether or not they’re technically part of his department.

#pfh rambles#retail hell au#kyle gaz garrick#cod fic#please excuse the typos i’m tired and sad#captain john price#john soap mactavish#simon ghost riley#sr#jm#jp#kg

119 notes

·

View notes

Text

This 1922 home in Los Angeles, California started out as a power substation. It closed down and was professionally remodeled in the 1990s. Since then, it was a home, an art gallery, and a show dog kennel. It has 3bd, 4ba, & is listed for $7M. It was also the backdrop for several horror films.

This entrance looks like it was an art gallery. It looks like it hasn't been painted or cleaned since then, and the look in this area is very industrial.

Looks like a a game room in this corner. There's a TV and chairs, but there's also a game table and pool table.

There's a catwalk above this area, and you can see through the two glass windows, the separate living quarters.

That glass structure is interesting. This is definitely still an art gallery.

Now, we're in the residence and this the living room. The style is modern and industrial. It's an interesting building.

It certainly is roomy. The dining room easily accommodates this large table with upholstered chairs. Display shelving is in the window, probably from the gallery.

The kitchen is very industrial. It even looks like a factory kitchen. It doesn't have a warm atmosphere.

Isn't this an interesting bedroom?

Look at the size of that counter. Why did they only give it one sink, though.

The main bedroom is a completely different and unique style.

There's a walk-in closet/dressing room.

Plus this very compact and sleek en-suite.

There are several patio areas behind the building.

Weird looking roof.

Even though it's in Los Angeles, this is a terrible area, so I don't think it's worth $7M. Can you imagine sitting all alone at night, lucky to have a few trees, next to a semi truck depot, a highway, across which, is a shipping container yard.

124 notes

·

View notes

Text

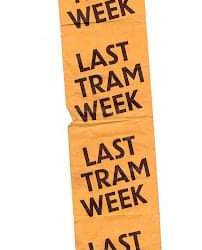

On November 16th 1956 the last of the original trams ran in Edinburgh.

Sixty five years ago this evening, thousands turned out to wave an emotional goodbye to the city’s original tram system before it was scrapped.

Trams had been falling out of favour across the country since the end of the Second World War. Cities were expanding, and the rail-and-wire-bound trams of yesteryear could not compete with the flexibility and cost-effectiveness of the modern motor bus. Municipal tramways up and down the country faced the heavy axe of progress.

The decision to decommission Edinburgh’s tram network arose in 1952, its 47 miles taking just four years to dismantle.

In the last week, a special service painted handsomely in white and gold livery was laid on to tour what was left of the old network.

All ordinary tram passengers were issued with a bright yellow “Last Tram Week” ticket; a masterstroke by Edinburgh Corporation which did a “roaring trade” in the final seven days.

The last hurrah arrived on Friday, November 16; a suitably cold, grey and miserable day. That evening, a procession of tramcars made its way from the Braids terminus to Shrubhill depot, taking in much of the original 1871 route. Ten trams were laid on due to the demand – one car containing the very city councillors who had consigned the trams to the history books in the first place.

It seemed that the entire city was out in force that night; throngs of people lined the pavements and eager spectators hung out of tenement windows to catch a glimpse of the historic procession.

Motor cars and buses added to the atmosphere by tooting their horns.

At the Mound and Hanover Street, an enormous crowd reaching 60 or 70 yards up the road gathered to wave goodbye to the last cars.

Police, mounted and on foot, kept the mass of spectators from pressing against the vehicles. Souvenir-hungry “boys and youths” armed with screwdrivers were reported aboard the final convoy, keen to secure their own little bit of history from the inside of the cabins.

Regardless of whether you lamented their passing or were glad to see them vanish, it was certainly the end of an era. From the earliest horse-drawn trams and cable cars of the turn of the century, to the electric system implemented in the 1920s, tramcars had been present in the Capital, in one form or another, for generations.

Eighty-five years of municipal tram history, which at its height had carried around 200 million passengers a year on routes covering Corstorphine to Levenhall, and just about everywhere in between, had been consigned for good to the great catenary wire in the sky... or so we all thought.

17 notes

·

View notes

Note

Hi! I was lurking through the reblogs on a post and you mentioned something about mosquito repellent plants? Can I pleeeeease hear you infodumb about that I'm so tired of them

This is all from memory so may be a little inaccurate and I will not be citing sources, but I have written a paper on this (in high school so it’s not in any databases) and all my sources had to be from peer reviewed journals so this IS academically informed.

Okay

SO first off: most mosquito-repellent plants work by releasing chemical agents that may smell good to US but smell very bad to the mosquitoes. The problem with this is that these oils tend to be released as globules that cling to the plants with fairly high surface tension, so unless the plants are disturbed somehow (wind or animals/humans) the oil isn’t released into the air and it does fuck all to actually repel mosquitoes.

That said, the best accessible mosquito-repelling plant is a plant called LEMONGRASS. If you live in the states then Home Depot sells this usually. If you don’t live in the states then idk, check your local garden center. I live in Texas and our lemongrass dies every winter but tends to come back on its own in the spring, and it smells really good to humans. You can also throw the dead grass into the yard and mow over it to release extra scent.

The most EFFECTIVE mosquito-repellent plant is something called lemon-eucalyptus which is a lab-created crossbreed produced somewhere in either Australia or New Zealand. I don’t remember which I just remember being super mad that I couldn’t get my hands on it for experiments. Anyway there’s a special compound in the oil this plant produces that lemongrass shares. I don’t remember the name of it but mosquitoes hate it. Plant lemongrass :)

If you can’t get your hands on lemongrass, rosemary will also repel mosquitoes, though there’s not much academic literature about this one and various mom-blogs all contradict each other about its effectiveness. It’s pretty smelly (good to humans bad to bugs!) and will repel a variety of insects.

Citronella contains a compound used in current commercial bug repellent, so it is also good to plant! I could never get mine to be very big though. You can also buy torches (like decorative tiki torches) with citronella oil in them which are designed to repel bugs by releasing the oil in the smoke.

Mint will also repel insects and mice though I could never narrow down if mosquitoes were among the list of insects that mint repels! Pro tip: PLANT MINT IN POTS. DO NOT PLANT MINT DIRECTLY IN THE GROUND. It will take over everything <3

Lastly, basil and thyme are reported to be insect repellents! I have not tested these myself (I tried but there were Circumstances) but a variety of home-blogs say that these work. I found basil in an academically sourced list but found no proof of thyme working. I despair at the lack of academic literature on this topic. Anyway.

Also, did you know you can purchase mosquito larvae on Amazon? It’s about $10 USD for 100 larvae.

If you choose to disturb your plants yourself to release the oils then be ready to have very strong smelling hands. Also, if you get your hands on cheesecloth (lightweight) you can see simple sleeves and boil one of these plants, then dip the cloth in the boiled water. The oil from the plant will soak in and the cloth will smell like it once dry. Idk how long these last because I never properly tested them, but I kept some in a drawer for a year and they were still pretty smelly. If you wore them out and about they would probably last about a month before the small wore off. Cheesecloth is extremely light so it shouldn’t be much of a bother in the summer, however idk how well they would hold the oil if you got sweat on them.

It’s also important to note that different hormones are capable of attracting or repelling bugs, so some plants may not be strong enough to get the job done if you’re particularly bug-attractive (I am rip). Also if you’ve ever noticed that you get a ton of bug bites but a friend doesn’t then may not be random. They may be repellent, and you may be attractive. This fact blew my mind when I learned it. Go forth and repel bugs!!!!

#the Circumstances that meant I couldn’t test thyme were:#I only had 2 weeks to get my testing done#and my mosquitoes were LATE in the mail. arrived to late to do any testing… I had to pivot QUICK#mosquito repellent plants#herbal repellent#herbal mosquito repellent#bug repellent#herbal bug repellent#mosquitoes#mosquito repellent#arbitrary answers#thanks birdsquidd!

9 notes

·

View notes

Text

A More Complete History of America

Section 1 - When to Begin?

Folsom, Clovis and The First Debate

Part 2 - Clovis

There is some dispute on the true type site of the predecessor of Folsom. The Type Site, the first site to be formally described to a scientific audience, often dictates naming rights. This leads to some academic saltiness and state rivalry. In the interest of fairness, we’ll actually start in Colorado.

Along the South Platte River, southwest of the small town of Milliken, Colorado once stood the Dent Railroad Depot. In 1932, strong Spring rains exposed several very large bones in a sandstone gully west of the tracks.

The son of the Depot’s manager informed his geology professor, Jesuit priest Conrad Bilgery. He took some of his students to the site in September of that year, where Father Bilgery determined the bones were that of a mammoth and contacted Jesse D. Figgins.

Yes. The same Figgins that was the Director of the Colorado Museum of Natural History.

Figgens sent a museum staff member to excavate the remains, though Father Bilgery and his students were allowed to assist. In the end, 13 partial skeletons from 5 adult females and 8 young mammoths were sent to Denver, along with two intact stone points.

Figgins published the find in the Proceedings of the CMNH in 1933 - the museum bulletin essentially - describing the points as belonging to a Late Ice Age culture.

Sadly, internal museum publications don’t count. I don’t make the rules.

In 1929, EB Howard was part of Alden Mason’s Southwestern Expeditions as a representative of the University Museum of Philadelphia. They had come to the Guadalupe Mountains west of Carlsbad, NM to search for archaeological sites, and were quickly directed by local Bill Burnet to a cave locally known for its artifacts.

It's unclear how long the predominantly white local population had known about the cave. Burnet reported it had once been sealed, but he and his brother had busted through the stacked stone wall. At some point, they had dug 3 or 4 holes,each about a yard deep. Beads, pieces of sandals, hide, and several baskets, one containing charred bones (which may have been human remains as cremation was practiced in the region at various times in the past) were all removed.

Still, the site was relatively intact. The pits had been dug straight down, and, aside from stones and debris being moved at the surface, most of the ground appeared undisturbed.

Excavations began in 1930. As Howard and the team had hoped, by the time their trench hit that 3 ft deep mark, they were in undisturbed soils. Like most caves and rock shelters, Burnet had little stratigraphy, or distinct soil layers, to go off of and they were about 30 years from widespread radiometric dating, so they attempted to date the cave using the common method of the day: identifying Cultural Horizons.

This meant, quite simply, looking at whatever turned up in their trench and trying to identify the age of that layer by the artifacts it contained. More baskets, sandals and bags found in those between about 1.5 and 3ft down indicated a Basketmaker Culture (an uncreatively named Pueblo precursor). They found several burials, which were likely the reason the cave had been sealed.

Above the Basketmaker layers were no distinctive artifacts beyond what had been scattered near the surface by looting. Again, the fact that the cave had been closed off to all but pack rats and other rodents had stopped later people from using it.

It was about 2 feet below the burials, however, that EB Howard made a more unexpected discovery. Among the bones of bison and musk-ox, some of them charred, were thick lenses of ash and charcoal. Hearths. Along one of these rested a fluted stone point that Howard described as Folsom-like. Several bone awls for sewing hides or making beads were also recovered.

Howard was very careful in his initial report of the site in 1931. He made a point of describing the interior of the cave, its geology, condition, and included multiple sketches of the layout. He reiterated that the cave had been sealed, hiding it for generations. He discussed how pack rats could have gotten in and built nests and middens at the surface, but that there was no evidence of burrowing or middens near the remains or below them. It was doubtful, Howard expressed, that the stone point or awls could have been deposited so deep by rodents.

EB Howard took that point to the 1931 Pecos Conference. Among the people he showed it to was Frank Roberts of the Smithsonian.

Cannon AFB was once a small local airstrip. By the early 1930s, it had been named the Clovis Air Field and was expanding. Some of the gravel for the new road construction came from nearby Black Water Draw, a seasonally dry valley crossed by small channels from the infrequent rains located along the Llano Estacado Plateau. The Dustbowl had already stripped away some of the surface layers, and while quarrying workmen revealed, you guessed it, large animal bones. They also turned up a large tooth and a stone point.

In 1932, as he was finishing work at Burnet Cave, it came to the attention of EB Howard that points like those at Folsom had been found in the area. He and his team swung by Clovis to look around, guided by locals AW Anderson and George Roberts, who themselves had taken a keen interest in the site.

The first point had been found by a workman with the gravel company, along with a mammoth tooth, when they had first reached the blue-gray layer at the gravel pit. This was the point that George Roberts had notified Howard about. Roberts had secured the point from the workman and shown it to Howard when he arrived in Clovis.

“The workman, whose honesty I do not question, showed me the spot where he had ploughed up the tooth and this artifact, and there is no doubt in my own mind that they both came from the blue sand on the west side of the gravel pit.” EB Howard

The point itself had been broken long ago, before the workman had uncovered it, as evidenced by the lime crust and was similar to the points from Folsom and about 4 inches long and 2 ¼ in wide, and “extraordinarily thin - ⅛ in at its maximum thickness”.

The summer field season was almost over, but Howard had the opportunity to explore Black Water Draw and view some of the artifacts and bones that had been found. That fall, machinery uncovered another mass of bones in a layer of blue-gray sands below the gravel layers.

Like at Burnet Cave, Howard made detailed notes of the site and its surroundings. Black Water Draw as a whole was dotted by the remains of ancient lakes, ponds and channels. On its western edge and near the Texas border, there were still a few alkali spring ponds. Likely, the Draw had once been a tributary of the nearby Brazos River, or at least drained into it. Where the gravel pits had been dug revealed a clear view of the geologic layers or strata to well below the bone bearing layers.

The bone layers, blue-gray sandy clay, were near, but not at the top. These were water deposited and held many species of diatoms, tiny water dwelling animals, which still live in fresh and saline waters. These diatoms, and the bones of the mammoths and bison, allowed Howard and his team to determine that the blue-gray sands had been deposited in the late Pleistocene, near the end of the Ice Age.

Howard could not begin a full excavation until the summer field season of 1933 and spent the next 4 years in Clovis. On the east side of the gravel pit a flint scraper and charcoal, presumably from a campfire, were among the bones of extinct bison, the first in situ objects found. More scrapers and knives were uncovered near the pit. In a section of Blackwater Draw Howard named the Anderson Lakes, a thick lense-shaped layer of charcoal contained the charred bones of bison (found all over the Lakes), small mammals and birds and a selection of blades and shapers. None of the Anderson Lakes artifacts appeared to be of the “Folsom-type”, even though they came from the same deposits of blue-gray sands.

No mention of a new “Clovis-type” appears in Howard's 1935 report. Instead it included a great deal of discussion of the geology, such as the diatom studies, and theories of how such a site could have come to be. It's here that Howard relays a story from Prentiss Gray, who had studied bison and in 1887 had observed a herd of some 4000 attempt to cross the South Platte River when it was low. “Soon the leaders were stuck in the mud, those behind, pressed forward by the herd, trampled over their struggling companions until the whole bed of the river a half mile wide was filled with dead and dying buffalo. This habit of stampeding was a habit of the wild buffalo.” Howard also shared similar accounts of antelopes in the Congo and Guanacos in Patagonia who had trampled each other or become trapped in frozen mud.

Howard also devoted part of his report to explaining honestly that he, his team and even the other prominent scientists they had brought to Clovis or otherwise consulted, can't say for certain that there had been no mixing of artifacts and layers at the site. Firstly, at and near the windblown surface, were scattered Yuma style points. These were known to be old - no contemporary peoples were known to use points quite like them, but they were from long after the Ice Age. Other points, some Yuma, some of other styles but all of that same old but still recent manufacture, and some pot sherds had been recovered from layers above and within the blue-gray sands. While never found directly alongside the older, unidentified and Folsom-like tools, these finds cast a shadow of doubt as to the antiquity of the flints.

It was in 1937 that JL Cotter, Howard's primary partner on the excavation, published the final report on the The Occurrence of Flints and Extinct Animals in Pluvial Deposits near Clovis, NM (part IV). Though he did not formally classify the points as a new type, this is where they start being referred to as a distinct style that had only been reported before from the Dent Site and Burnet Cave.

By the 1950s, the fluted points had become called Clovis Points and their style and method of manufacture was known to be a precursor to Folsom technology. Radiometric dating, though it would need future calibration and refinement, would first be done in the 1950-60s, returning dates of nearly 10,000 years before present, well within the known range of the late Ice Age.

Hrdlicka died in 1943, and would never accept the findings at Folsom, Clovis or anywhere else.

Sources and further reading/listening:

“THE INITIAL RESEARCH AT CLOVIS, NEW MEXICO: 1932-1937.” Plains Anthropologist 35, no. 130 (1990): 1–20. http://www.jstor.org/stable/25668959.

Cotter J. L. 1937 The Occurrence of Flints and Extinct Animals in Pluvial Deposits near Clovis, New Mexico, Part IV: Report on the Excavations at the Gravel Pit in 1936, Proceedings of the Academy of Natural Sciences of Philadelphia, 89, pp. 1–16

Jesse D. Figgins, “A Further Contribution to the Antiquity of Man in America,” Proceedings of the Colorado Museum of Natural History 12, no. 2 (1933).

Brunswig, R. (2016) The Dent Site: A Late Ice Age Encounter on the South Platte River

for the online Colorado Encyclopedia

Steeves, P. F.C. (2022) The Indigenous Paleolithic of the Western Hemisphere University Press Audiobooks

Meltzer, D.J. (2011) First Peoples in A New World: Colonizing Ice Age America University Press Audiobooks

Adovadio, J.M., Page, J., (2022) The First Americans: In Pursuit of Archaeology’s Greatest Mystery Tantor Audio

Hamalainen, P. (2022) Indigenous Continent: The Epic Contest for North America

Howard, Edgar B.. "Burnet Cave." The Museum Journal XXIV, no. 2-3 (June, 1935): 62-79. Accessed March 13, 2024. https://www.penn.museum/sites/journal/9515/

#archaeology#paleolithic#clovis#prehistory#history#found the format buttons#still need to stop doing this on phone

3 notes

·

View notes

Text

So my brother got these bacon gumballs at a yard sale that are from the year I was born. These ancient gumballs are all misshapen and stuck together like they've been trapped in a hot car for years. I tried one and it tastes like the smell of Home Depot times one thousand. They contain so much liquid smoke that they have the taste of a cremated pig. They also have a weird latexy-bean thing going on and I'm not here for it. They also have a weirdly familiar taste to them that could only be experienced in a sleep paralysis dream. Horrible.

2 notes

·

View notes

Text

Monday 10th July 2023

Kamloops wouldn't be our first choice for a holiday, but as a stopover location it is practical. Kamloops is a mining town; copper and gold, with the largest open cast mine operation in Canada just 30km out of town, and underground mining in town. Logging and sawmills seem popular here too. Kamloops is expanding apparently with people from Vancouver; now 115,000 population with many first nation folk living here. We were collected from our hotels yawningly early at 7.10am; required to leave suitcases in the room to be transferred by road to our hotels in Vancouver. Hopefully. A 22 coach train does not fit well into a standard station platform so we were delivered to the extended train parked in the Rocky Mountaineer depot at one side of the marshalling yards. Yards that are filling up with freight containers, stacking due to the freight operator strike. This eased our passage to Vancouver since we didn't need to pull into sidings so often to allow freight to pass. The journey began by crossing the Thompson River, through downtown with the smokestack of the pulp mill pluming upwards on the edge of town, moved by popular demand away from housing due to the smell.

The landscape was gradually changing to semi-arid desert like conditions, sun bleached hillsides and pastures: home to bald eagles, ospreys and long horn sheep. The temperature today was predicted to hit 35° which would be ideal for its growing wine industry. The baron landscape has been the setting for XFiles, The A Team, Battlestar Galactica and no doubt many more films and TV shows. As the train snaked its way along the course of the Thompson River we spotted bald eagle and osprey nests, some of the latter being up to 100 years old mainly built on manmade structures. Parent ospreys must from time to time have the conversation; one day son, all this will be yours! This is a big country, the home of ballads such as crooned by the likes of John Denver, Cowboy and Indian films, Luis Armstrong wafting over the sound system singing Wonderful World seemed to sum up the general feeling.

Thompson River soon merged with Fraser River just before lunch. The Fraser soon to be busy with salmon. The topography changing now reverting to pine forest and mountains as we headed south towards Hope and Vancouver.

It is a thing most strange that we have travelled hundreds of miles into the Rockies without meeting any English people until boarding the Rocky Mountaineer. Now all on our carriage are English or occasionally Scottish, all Radio 4 of an age. Is it only the Anglo Saxons that appreciate the permanent way? We are all practically on Christmas card terms by now, but of course all that will be forgotten by December.

The train seemed to pick up speed by the time we reached Hope where we were a fortnight ago. We were travelling a good 50mph towards Vancouver. I think the driver needed to be home by tea time. Then he really put his foot down.

And so it was we finally made it into Vancouver crossing the swing bridge. It was a very agreeable way of returning to the great metropolis of the city.

Remarkably, we were able to step off the train and onto a waiting coach which was able to take us directly to our hotel for the following two nights. What was even more remarkable, our suitcases actually made it to the coach!

We have a couple of days to enjoy ourselves in Vancouver before travelling home on Wednesday. Well didn't that go quickly.

2 notes

·

View notes

Text

Top 10 Reasons Why Envision GTOS Leads the Container Terminal Operating System Market

In an era characterized by unruly growth of worldwide commerce, the efficiency of seaports, inland terminals, and cargo depots has been the factor ensuring that international trade stands on its weak legs. It would have been very much in demand right now while cargo volumes kept surging for smarter, more scalable, and technologically advanced solutions. Enter GTOS or General Terminal Operating System-a digital framework that aims to evolve the ways in which the terminals operate.

Leading the way in this transformation is the Envision GTOS platform-it is said to be the platform of the future by Envision Enterprise Solutions. In this in-depth blog post, we will dissect the GTOS concept; we shall state why it matters, go into the details of Envision GTOS's features, and explain how it stands taller than traditional systems. We'll also cover how Envision's commitment to smart integration and digital transformation continues to reshape the future of terminal management.

What is GTOS?

GTOS (General Terminal Operating System) is a software system used to manage and optimize the daily operations of cargo terminals. It serves as the digital brain behind terminal logistics, orchestrating processes such as:

• Cargo intake and dispatch

• Gate operations

• Yard management

• Equipment control

• Vessel planning

• Documentation and invoicing

• Real-time tracking and tracing of containers

This system, therefore, applies to container as well as general cargo, breakbulk, Ro-Ro, and bulk terminals. Its main objective is to automate manual processes, reduce operational errors, and improve throughput. The flexibility of GTOS allows it to be used in a variety of terminal environments, adjusting to regional and cargo-type-specific needs.

The modern GTOS is evolving to handle the intricacies of hybrid cargo types, multiple modes of transport (rail, road, and sea), and rapid digitization demands from customs and regulatory authorities. It also facilitates seamless integration with external systems like ERP platforms, shipping lines, and government portals, making it the hub of smart terminal ecosystems.

Importance of GTOS in Cargo and Terminal Management

1. Operational Efficiency

A robust GTOS minimizes manual data entry and speeds up cargo movements, helping terminals handle higher volumes without increasing overhead. This is crucial in today's environment where terminal congestion can delay entire supply chains. With precise control over gate, yard, and berth operations, GTOS reduces downtime and improves cargo turnover rates.

2. Real-Time Visibility

This GTOS platform acts as a brain by providing a set of interfaces giving one real-time information about cargo location, equipment status, and venue schedule. This visibility is crucial in making operational decisions swiftly, deterring demurrage, and improving customer satisfaction. It also supports instant exception handling and performance monitoring.

3. Standardization & Compliance

Having an inbuilt integration for customs, billing, and safety protocol applications, GTOS enables terminals to effortlessly observe some regulations. Documentation is generated automatically, stored, and made traceable for the purpose of customs clearance and audits.Terminals can configure regional rules and port-specific compliance requirements, reducing legal and financial risks.

4. Data-Driven Insights

Modern GTOS platforms offer advanced analytics to evaluate KPIs like berth productivity, truck turnaround time, and equipment utilization. These kinds of insights assist in long-range planning, Predictive maintenance, and short-term adjustments on an operational level. These predictive algorithms can identify bottlenecks as they begin and also provide excellent forecasting tools.

5. Scalability and Flexibility

As terminal volumes grow, GTOS platforms can scale through modular upgrades. Whether it’s expanding yard space or integrating new technologies, GTOS provides the necessary backbone. Its modular architecture supports future extensions without interrupting live operations. Additionally, cloud-based systems enable global access and updates.

Who Uses GTOS?

GTOS solutions are used by a wide array of stakeholders in the global logistics chain:

Seaports and Terminals: To manage inbound and outbound container traffic, bulk handling, and equipment scheduling.

Inland Container Depots (ICDs): For handling hinterland cargo flows, customs clearance, and road/rail interface.

Container Freight Stations (CFS): To manage less-than-container-load (LCL) and de-stuffing operations.

Bulk Cargo Handlers: For managing grain, coal, and ore cargoes through conveyors, silos, and hoppers.

Shipping Lines & Freight Forwarders: For digital visibility, pre-arrival documentation, and EDI.

Customs and Port Agencies: For digital inspection clearance, security checks, and regulatory control.

Private Logistics Parks: For freight forwarding, warehousing, and integrated operations spanning trucking.

Essentially, implementing a GTOS might be of great advantage to any organization that manages large cargo volumes or demands efficiency, traceability, and regulatory compliance.

Core Features of a Normal GTOS

A standard or traditional GTOS includes the following features:

Gate Automation

Utilizes OCR (Optical Character Recognition), RFID (Radio-Frequency Identification), and ANPR (Automatic Number Plate Recognition) technologies to automate vehicle entry and exit processes. It reduces human involvement and accelerates truck turnaround time.

Yard Management

Optimizes the placement of containers and general cargo. Assigns space dynamically, schedules equipment, and ensures optimal yard utilization. It prevents mishandling and streamlines stacking and retrieval processes.

Vessel Planning

Allocates berths, schedules quay cranes, and manages stowage planning based on vessel arrival times and cargo manifests. Efficient vessel turnaround enhances port reputation and throughput.

Cargo Handling

Manages the loading and unloading process, ensuring minimal damage, efficient use of cranes and forklifts, and faster truck turnarounds. Smart task allocation and job execution tracking boost productivity and safety.

Billing & Invoicing

Tracks all chargeable activities—such as storage, handling, and demurrage—and generates automated invoices. Integrates with accounting systems for audit-ready documentation. Multi-currency and tax logic are often included.

Reporting Tools

Provides dashboards and reports for analyzing operational metrics. Often used by managers to evaluate performance and make data-backed decisions. Advanced systems can export data for machine learning models and predictive algorithms.

Benefits of GTOS in Terminal Operations

Higher Throughput

By automating repetitive tasks and optimizing cargo flows, GTOS enables terminals to handle more cargo in less time. This makes it easier to handle peak season volumes without service degradation.

Lower Operational Costs

Less dependency on manual labor and better utilization of equipment leads to significant cost savings. Resource optimization reduces energy consumption and maintenance overheads.

Improved Customer Service

Faster processing and real-time updates improve customer satisfaction. Terminals can provide clients with live tracking, automatic alerts, and digital documentation.

Enhanced Safety

Automated systems reduce human involvement in hazardous areas, lowering the risk of accidents. Integrated safety compliance ensures secure cargo movement. Risk assessments and safety drills can also be managed through GTOS.

Environmental Benefits

Efficient terminal operations reduce fuel consumption and emissions, supporting green port initiatives. Energy-efficient equipment scheduling and paperless documentation also contribute. Sustainability dashboards allow ports to monitor and improve their carbon footprint.

Envision GTOS: Redefining Terminal Efficiency

Envision GTOS is designed with a future-ready architecture that incorporates AI, IoT, and cloud computing to deliver next-level efficiency. Here’s how it surpasses traditional GTOS systems:

AI-Powered Decision Making

Predictive analytics and machine learning algorithms optimize berth planning, equipment usage, and yard allocation. AI-driven recommendations ensure proactive management and faster cycle times.

Real-Time IoT Integration

Integrates with smart sensors and IoT devices to provide real-time data on container conditions, equipment health, and yard congestion. It supports real-time alerts and automated escalation.

Cloud-Native and Mobile First

Accessible from anywhere, Envision GTOS supports mobile devices for on-the-go monitoring, approvals, and task management. It supports hybrid cloud environments and multi-terminal operations.

Blockchain for Document Security

Utilizes blockchain for secure, immutable documentation and transparent cargo movement records. This enhances stakeholder trust and compliance.

Low-Code Configuration

Allows users to customize workflows without writing complex code, reducing deployment time and cost. Terminal operators can easily define rules, triggers, and alerts.

Envision GTOS Smart Integrations

Envision GTOS brings together a suite of intelligent integrations that enhance performance:

Automated Gate System: Reduces gate congestion and enables rapid in/out processing.

Container Tracking Software: Provides real-time container location and movement history.

Yard Truck Management System: Tracks and schedules internal container transportation.

Container Freight Station (CFS) Software: Manages LCL cargoes, documentation, and cargo splitting.

Depot Management System (DMS): Controls empty container repairs, storage, and dispatch.

Vessel Planning and Optimization: Automates berth and stowage planning with smart algorithms.

Digital Twin Integration: Simulates real-world operations for training, planning, and risk evaluation.

Smart Maintenance System: Predicts equipment failure and schedules proactive maintenance.

About Envision Enterprise Solutions

Envision Enterprise Solutions is a global leader in enterprise-grade digital platforms for the port and logistics industry. With over two decades of domain expertise, Envision’s platforms serve terminals, depots, CFS units, ICDs, and logistics parks across Asia, Africa, and the Middle East.

The company’s mission is to enable smarter, safer, and more sustainable logistics operations through intelligent, modular, and cloud-native solutions. Envision's platforms have helped digitize and automate operations at some of the world’s busiest and most complex port facilities.

Envision’s Achievements

Successfully deployed Envision GTOS at over 10 major terminals globally

Reduced truck turnaround times by up to 40% in high-volume ports

Achieved 99.9% system uptime across all customer installations

Named among the Top 10 Smart Port Technology Providers by LogisticsTech Magazine

Partnered with government customs agencies to build next-gen port community systems

Delivered smart yard automation using IoT in Africa's largest inland terminal

Recognized for innovation in AI and predictive analytics in the maritime sector

Conclusion

A General Terminal Operating System (GTOS) is no longer a luxury—it is a necessity for terminal operators aiming to thrive in the digital age. On the one hand, we say that the traditional systems are the first starting point; however, Envision GTOS promises intelligence, scalability, and flexibility for the future.

By placing AI, IoT, blockchain, and cloud technologies inside the picture, Envision GTOS ensures that the operations meet the needs of today while preparing the terminals for the challenges of tomorrow. Whether you are operating an inland depot or a large container terminal, Envision GTOS leads you to operate smarter, faster, and greener.

With intelligent modules, real-time integration, low-code customization, and global success stories, Envision GTOS is redefining the future of cargo and terminal operations. It’s time to embrace a connected, data-driven, and automated future with Envision GTOS.

Get in touch to schedule a demo of Envision GTOS orExplore our services to see how Envision GTOS can transform your terminal.

Download

#artificial intelligence#container#terminals#operating systems#software engineering#operation#Envision GTOS#general cargo

0 notes

Text

Revolutionizing Terminal Efficiency with Envision CTOS: The Future of Smart Container Terminal Operations

In the hyper connected economy of today, the seamless functioning of container terminals is crucial for economic momentum, trade, and logistics. From inland depots to giant international ports, cargo movement both in terms of quantity and complexity has grown manifold.

In the midst of these issues, Envision Enterprise Solutions brings forth a revolution in products: Envision CTOS — a next-generation Container Terminal Operating System (CTOS) designed to integrate intelligent automation, real-time visibility of containers, and automated terminal orchestration.

@EnvisionEnterpriseSolutions

This blog explores the full potential of Envision CTOS, explains its technological framework, breaks down core features, and offers a comprehensive competitor analysis. It also answers the most common questions about terminal operations and highlights why Envision CTOS stands out in the market.

What is a Container Terminal Operating System (CTOS)?

A Container Terminal Operating System (CTOS) is an electronic system that controls and automates the complex processes in seaports, inland terminals, and depots. Its function extends to scheduling, container transport, resource allocation, documentation, and performance monitoring.

The key subsystems of a modern CTOS include:

Container Yard Management System

Depot Management System (DMS)

Container Freight Station (CFS) Software

Automated Gate System

Yard Truck Management System

Vessel Planning and Optimization

Container Tracking Software

Without a central CTOS, terminals will experience congestion, manual mistakes, poor resource utilization, and low profitability. Real-time visibility, intelligent scheduling, and active exception handling are no longer discretionary items in today's logistics universe; they are essential for survival in competition.

What is Envision CTOS?

Envision CTOS is a next-generation Container Terminal Operating System developed by Envision Enterprise Solutions. Created for the changing needs of container logistics, Envision CTOS combines real-time visibility, smart automation, and mobile-first design into one powerful platform.

With modular flexibility, it can serve both large global ports and small inland container depots (ICDs), allowing for fast digital transformation without regard to terminal size or complexity. With an emphasis on configuration over customization, the solution enables faster deployments and significantly reduces the total cost of ownership.

Core Features of Envision CTOS

1. Container Yard Management System

The container yard management system in Envision CTOS utilizes AI and rule-based automation to manage yard storage space and container allocation. It optimizes space usage and positions containers in a way that reduces rehandling and dwell time.

Yard visualization technology offers a heatmap view of container density, enabling planners to make informed decisions based on data.Real-time updates also allow for rapid response to vessel schedule changes and truck arrival fluctuations.

2. Depot Management System (DMS)

The integrated depot management system (DMS) simplifies operations for empty container depots, managing inspection, repair, release, and repositioning. Real-time inventory updates improve coordination with carriers and leasing companies.

It also provides mobile functionality for surveyors to capture repair images and upload damage reports directly from their handheld devices.

3. Container Freight Station (CFS) Software

The CFS software in Envision CTOS streamlines operations for both LCL and FCL cargo. Automated invoicing, electronic documentation, and cargo tracking reduce paperwork, delays, and customer complaints.

It also integrates with customs clearance systems to ensure faster regulatory processing, thus reducing detention charges and improving cargo turnover.

4. Automated Gate System

Envision’s automated gate system uses OCR and RFID to reduce gate wait times and eliminate manual checks. Integration with weighbridges and container scanners ensures compliance and security.

Self-service kiosks and appointment scheduling features help reduce congestion and improve customer satisfaction.

5. Container Tracking Software

Live dashboards powered by GPS and IoT form the backbone of Envision’s container tracking software, helping operators trace containers across their journey—from vessel to yard, depot, or consignee.

Alerts, geofencing, and ETA predictions ensure better coordination among stakeholders.

6. Yard Truck Management System

The yard truck management system in Envision CTOS optimizes internal truck movements with real-time task assignments, reducing idle time and fuel usage. It includes performance metrics and geofencing alerts.

Fleet operators receive detailed insights into driver productivity, turnaround times, and equipment maintenance schedules.

7. Vessel Planning and Optimization

Terminal efficiency begins with smart vessel planning. Envision CTOS ensures optimal crane split, berth scheduling, and stowage planning, powered by analytics for continuous improvement.

The module supports real-time updates on vessel ETAs and prioritizes container discharging and loading based on delivery windows and truck arrivals.

Mobile Accessibility: Work from Anywhere

Envision CTOS is built with mobile-first architecture. Supervisors, truck drivers, equipment operators, and depot staff can access real-time updates, assign or accept tasks, and monitor KPIs on smartphones or tablets.

Mobile Highlights:

Mobile dashboards for yard operations

Task approvals, maintenance logs, and checklists

E-token generation for gate-in/out processes

Offline support for operations in low-connectivity zones

Whether in the yard, on a crane, or at a remote depot, Envision’s mobile capability ensures no user is disconnected from operations.

Integration Capabilities of Envision CTOS

Envision CTOS is designed to integrate effortlessly into your terminal’s digital ecosystem.

Supported Integrations:

ERP Systems: SAP, Oracle, Microsoft Dynamics

PCS Systems: Port Community Systems for stakeholder coordination

Customs Portals: Auto-submission of import/export documents

Shipping Line Interfaces: EDI/API-based communications

IoT Sensors: Temperature, weight, GPS, vibration, and tamper sensors

These integrations help terminals eliminate silos, accelerate customs clearance, and improve transparency across the logistics chain.

Frequently Asked Questions About Envision CTOS

Q1: Is Envision CTOS cost-effective for mid-sized operators?

Yes. Envision CTOS offers modular deployment and competitive pricing. It can be tailored to your terminal’s size and complexity without incurring excessive costs.

Q2: How long does implementation take?

Typical implementation takes 8–12 weeks for mid-sized terminals. Larger, more complex environments may require phased rollouts.

Q3: What technologies power Envision CTOS?

The platform is powered by cloud-native architecture, AI-driven algorithms, microservices, and real-time analytics. It’s designed for high availability, redundancy, and global scalability.

Real-World Use Cases of Envision CTOS

Inland Container Depot (ICD) Transformation

A leading ICD in South Asia adopted Envision CTOS and witnessed a 38% improvement in gate throughput and 25% increase in yard utilization. The depot management system (DMS) module automated container maintenance scheduling, eliminating paper-based workflows.

Coastal Port Automation

A regional coastal port implemented Envision’s full CTOS suite, integrating vessel planning and optimization, yard truck management, and automated gate system modules. Result: a 40% reduction in vessel turnaround time and 50% faster gate processing.

Dry Port Efficiency Boost

A dry port handling over 300,000 TEUs per year deployed Envision CTOS and reduced container misplacements by 70% using the container tracking software and real-time yard mapping. Stakeholders praised the improvement in turnaround and transparency.

Competitor Analysis: Where Envision CTOS Stands Out

1. Navis N4

Strengths: Feature-rich, widely adopted.

Weaknesses: High licensing costs, slower deployment.

Envision CTOS Advantage: Lower TCO, faster go-live, better for hybrid cloud.

2. Tideworks Technology

Strengths: Modular tools.

Weaknesses: Limited flexibility in emerging markets.

Envision CTOS Advantage: Agile customization and mobile-enabled workflows.

3. CyberLogitec OPUS Terminal

Strengths: Strong documentation workflows.

Weaknesses: Limited support in South America, Africa.

Envision CTOS Advantage: Global 24/7 support and adaptable localization.

4. RBS TOPS

Strengths: Good for small terminals.

Weaknesses: Outdated UX, scaling issues.

Envision CTOS Advantage: Intuitive interface, scalable cloud deployment.

Envision CTOS is purpose-built for terminals seeking enterprise-grade functionality with startup-like agility.

Why Choose Envision CTOS?

Envision CTOS is more than a system—it’s a growth enabler.

Key Benefits:

Unified Platform: Integrates yard, gate, vessel, and depot operations.

Mobile and Cloud-First: Built for modern workflows.

Data-Driven Decision-Making: Advanced reporting and predictive analytics.

AI-Powered Automation: From crane scheduling to truck routing.

Enterprise-Grade Security: GDPR, ISO, and SOC compliance.

Faster ROI: Deploy, train, and gain within weeks—not months.

The Future of Container Terminal Automation

As the maritime logistics landscape embraces container terminal automation, stakeholders demand smarter, faster, and leaner solutions. Terminals must transition from fragmented software environments to integrated ecosystems. Envision CTOS helps operators do just that—by unifying key terminal processes in a future-ready platform.

The push toward sustainable, green port operations also underscores the value of digital solutions like Envision CTOS. Fewer truck idling times, better resource utilization, and paperless documentation contribute to environmental targets and regulatory compliance.

Conclusion: Embrace the Intelligent Terminal with Envision CTOS

Whether you manage a container freight station (CFS), operate a busy inland container depot (ICD), or run a complex coastal port, Envision CTOS transforms operations from reactive to proactive. It offers unmatched functionality across container yard management, vessel planning, tracking, and terminal automation — all while being scalable, secure, and mobile-ready.

If your goal is to modernize operations, increase throughput, reduce delays, and gain full control of terminal logistics, Envision CTOS is the strategic solution for you.

Take the Next Step Toward Terminal Excellence

Contact Envision Enterprise Solutions today to book a demo, schedule a consultation, or explore how Envision CTOS can become the foundation of your digital terminal transformation.

Envision CTOS – Automate Intelligently. Operate Efficiently. Grow Sustainably.

#ai powered port management#artificial intelligence#ports#ai powered automation#management#maritime#logistics#container#smartports#envision#CTOS#envision CTOS

0 notes

Text

Container depot | LOTUS Containers

A container depot is crucial for storing, maintaining, and repairing containers before they enter circulation again. The ports are located near major transport hubs, which ensures effective container management. These facilities consist of inspection, cleaning, and refurbishing to increase the container's lifespan. Contact LOTUS Containers to get access to major container depots and simplify your logistics.

0 notes

Text

Envision CTOS: The Future of Smart Container Terminal Operations

In the hyper connected economy of today, the seamless functioning of container terminals is crucial for economic momentum, trade, and logistics. From inland depots to giant international ports, cargo movement both in terms of quantity and complexity has grown manifold.

In the midst of these issues, Envision Enterprise Solutions brings forth a revolution in products: Envision CTOS — a next-generation Container Terminal Operating System (CTOS) designed to integrate intelligent automation, real-time visibility of containers, and automated terminal orchestration.

This blog explores the full potential of Envision CTOS, explains its technological framework, breaks down core features, and offers a comprehensive competitor analysis. It also answers the most common questions about terminal operations and highlights why Envision CTOS stands out in the market.

What is a Container Terminal Operating System (CTOS)?

A Container Terminal Operating System (CTOS) is an electronic system that controls and automates the complex processes in seaports, inland terminals, and depots. Its function extends to scheduling, container transport, resource allocation, documentation, and performance monitoring.

The key subsystems of a modern CTOS include:

Container Yard Management System

Depot Management System (DMS)

Container Freight Station (CFS) Software

Automated Gate System

Yard Truck Management System

Vessel Planning and Optimization

Container Tracking Software

Without a central CTOS, terminals will experience congestion, manual mistakes, poor resource utilization, and low profitability. Real-time visibility, intelligent scheduling, and active exception handling are no longer discretionary items in today's logistics universe; they are essential for survival in competition.

What is Envision CTOS?

Envision CTOS is a next-generation Container Terminal Operating System developed by Envision Enterprise Solutions. Created for the changing needs of container logistics, Envision CTOS combines real-time visibility, smart automation, and mobile-first design into one powerful platform.

With modular flexibility, it can serve both large global ports and small inland container depots (ICDs), allowing for fast digital transformation without regard to terminal size or complexity. With an emphasis on configuration over customization, the solution enables faster deployments and significantly reduces the total cost of ownership.

Core Features of Envision CTOS

1. Container Yard Management System

The container yard management system in Envision CTOS utilizes AI and rule-based automation to manage yard storage space and container allocation. It optimizes space usage and positions containers in a way that reduces rehandling and dwell time.

Yard visualization technology offers a heatmap view of container density, enabling planners to make informed decisions based on data.Real-time updates also allow for rapid response to vessel schedule changes and truck arrival fluctuations.

2. Depot Management System (DMS)

The integrated depot management system (DMS) simplifies operations for empty container depots, managing inspection, repair, release, and repositioning. Real-time inventory updates improve coordination with carriers and leasing companies.

It also provides mobile functionality for surveyors to capture repair images and upload damage reports directly from their handheld devices.

3. Container Freight Station (CFS) Software

The CFS software in Envision CTOS streamlines operations for both LCL and FCL cargo. Automated invoicing, electronic documentation, and cargo tracking reduce paperwork, delays, and customer complaints.

It also integrates with customs clearance systems to ensure faster regulatory processing, thus reducing detention charges and improving cargo turnover.

4. Automated Gate System

Envision’s automated gate system uses OCR and RFID to reduce gate wait times and eliminate manual checks. Integration with weighbridges and container scanners ensures compliance and security.

Self-service kiosks and appointment scheduling features help reduce congestion and improve customer satisfaction.

5. Container Tracking Software

Live dashboards powered by GPS and IoT form the backbone of Envision’s container tracking software, helping operators trace containers across their journey—from vessel to yard, depot, or consignee.

Alerts, geofencing, and ETA predictions ensure better coordination among stakeholders.

6. Yard Truck Management System

The yard truck management system in Envision CTOS optimizes internal truck movements with real-time task assignments, reducing idle time and fuel usage. It includes performance metrics and geofencing alerts.

Fleet operators receive detailed insights into driver productivity, turnaround times, and equipment maintenance schedules.

7. Vessel Planning and Optimization

Terminal efficiency begins with smart vessel planning. Envision CTOS ensures optimal crane split, berth scheduling, and stowage planning, powered by analytics for continuous improvement.

The module supports real-time updates on vessel ETAs and prioritizes container discharging and loading based on delivery windows and truck arrivals.

Mobile Accessibility: Work from Anywhere

Envision CTOS is built with mobile-first architecture. Supervisors, truck drivers, equipment operators, and depot staff can access real-time updates, assign or accept tasks, and monitor KPIs on smartphones or tablets.

Mobile Highlights:

Mobile dashboards for yard operations

Task approvals, maintenance logs, and checklists

E-token generation for gate-in/out processes

Offline support for operations in low-connectivity zones

Whether in the yard, on a crane, or at a remote depot, Envision’s mobile capability ensures no user is disconnected from operations.

Integration Capabilities of Envision CTOS

Envision CTOS is designed to integrate effortlessly into your terminal’s digital ecosystem.

Supported Integrations:

ERP Systems: SAP, Oracle, Microsoft Dynamics

PCS Systems: Port Community Systems for stakeholder coordination

Customs Portals: Auto-submission of import/export documents

Shipping Line Interfaces: EDI/API-based communications

IoT Sensors: Temperature, weight, GPS, vibration, and tamper sensors

These integrations help terminals eliminate silos, accelerate customs clearance, and improve transparency across the logistics chain.

Frequently Asked Questions About Envision CTOS

Q1: Is Envision CTOS cost-effective for mid-sized operators?

Yes. Envision CTOS offers modular deployment and competitive pricing. It can be tailored to your terminal’s size and complexity without incurring excessive costs.

Q2: How long does implementation take?

Typical implementation takes 8–12 weeks for mid-sized terminals. Larger, more complex environments may require phased rollouts.

Q3: What technologies power Envision CTOS?

The platform is powered by cloud-native architecture, AI-driven algorithms, microservices, and real-time analytics. It’s designed for high availability, redundancy, and global scalability.

Real-World Use Cases of Envision CTOS

Inland Container Depot (ICD) Transformation

A leading ICD in South Asia adopted Envision CTOS and witnessed a 38% improvement in gate throughput and 25% increase in yard utilization. The depot management system (DMS) module automated container maintenance scheduling, eliminating paper-based workflows.

Coastal Port Automation

A regional coastal port implemented Envision’s full CTOS suite, integrating vessel planning and optimization, yard truck management, and automated gate system modules. Result: a 40% reduction in vessel turnaround time and 50% faster gate processing.

Dry Port Efficiency Boost

A dry port handling over 300,000 TEUs per year deployed Envision CTOS and reduced container misplacements by 70% using the container tracking software and real-time yard mapping. Stakeholders praised the improvement in turnaround and transparency.

Competitor Analysis: Where Envision CTOS Stands Out

1. Navis N4

Strengths: Feature-rich, widely adopted.

Weaknesses: High licensing costs, slower deployment.

Envision CTOS Advantage: Lower TCO, faster go-live, better for hybrid cloud.

2. Tideworks Technology

Strengths: Modular tools.

Weaknesses: Limited flexibility in emerging markets.

Envision CTOS Advantage: Agile customization and mobile-enabled workflows.

3. CyberLogitec OPUS Terminal

Strengths: Strong documentation workflows.

Weaknesses: Limited support in South America, Africa.

Envision CTOS Advantage: Global 24/7 support and adaptable localization.

4. RBS TOPS

Strengths: Good for small terminals.

Weaknesses: Outdated UX, scaling issues.

Envision CTOS Advantage: Intuitive interface, scalable cloud deployment.

Envision CTOS is purpose-built for terminals seeking enterprise-grade functionality with startup-like agility.

Why Choose Envision CTOS?

Envision CTOS is more than a system—it’s a growth enabler.

Key Benefits:

Unified Platform: Integrates yard, gate, vessel, and depot operations.

Mobile and Cloud-First: Built for modern workflows.

Data-Driven Decision-Making: Advanced reporting and predictive analytics.

AI-Powered Automation: From crane scheduling to truck routing.

Enterprise-Grade Security: GDPR, ISO, and SOC compliance.

Faster ROI: Deploy, train, and gain within weeks—not months.

The Future of Container Terminal Automation

As the maritime logistics landscape embraces container terminal automation, stakeholders demand smarter, faster, and leaner solutions. Terminals must transition from fragmented software environments to integrated ecosystems. Envision CTOS helps operators do just that—by unifying key terminal processes in a future-ready platform.

The push toward sustainable, green port operations also underscores the value of digital solutions like Envision CTOS. Fewer truck idling times, better resource utilization, and paperless documentation contribute to environmental targets and regulatory compliance.

Conclusion: Embrace the Intelligent Terminal with Envision CTOS

Whether you manage a container freight station (CFS), operate a busy inland container depot (ICD), or run a complex coastal port, Envision CTOS transforms operations from reactive to proactive. It offers unmatched functionality across container yard management, vessel planning, tracking, and terminal automation — all while being scalable, secure, and mobile-ready.

If your goal is to modernize operations, increase throughput, reduce delays, and gain full control of terminal logistics, Envision CTOS is the strategic solution for you.

Take the Next Step Toward Terminal Excellence

Contact Envision Enterprise Solutions today to book a demo, schedule a consultation, or explore how Envision CTOS can become the foundation of your digital terminal transformation.

Envision CTOS – Automate Intelligently. Operate Efficiently. Grow Sustainably.

#ai powered solutions#container#ctos#envision#operating systems#terminals#artificial intelligence#envision CTOS

0 notes

Text

Envision CTOS: A Next-Generation Container Terminal Operating System Transforming Port Operations

Introduction: The Urgency of Digital Transformation in Terminal Operations

Global seaports and inland terminals are at a strategic crossroads. Faced with increasing trade volumes, vessel mega-sizing, and a demand for faster throughput, traditional container terminal operations are being stretched beyond their limits. Manual processes, legacy software, and siloed data models are no longer sufficient to sustain the agility and efficiency required by today’s logistics ecosystem.

Enter Envision CTOS — a next-generation, AI-driven Container Terminal Operating System (CTOS) that transforms the way ports, inland container depots (ICDs), and container freight stations (CFSs) operate. More than just a tool for automation, Envision CTOS is a strategic platform built to empower intelligent decisions, unify multi-terminal operations, and drive measurable ROI.

In this in-depth blog, we explore how Envision CTOS is redefining container logistics through advanced technology integration, digital twin modeling, data intelligence, and seamless interoperability. Whether you’re a port authority, private terminal operator, or a logistics conglomerate managing multiple facilities, Envision CTOS provides the tools to lead in the era of smart ports.

Understanding Envision CTOS: An Overview

What is Envision CTOS?

Envision CTOS is a cloud-ready, modular, and highly scalable Container Terminal Operating System designed to manage and optimize the entire container terminal lifecycle. It goes far beyond the traditional scope of a TOS by incorporating:

AI & machine learning algorithms for dynamic decision-making

Digital twin simulation for planning and risk-free testing

Integrated mobility for remote and on-site task execution

Multi-terminal coordination for centralized control

Predictive analytics for anticipatory operations

Why Envision CTOS Matters

As the global logistics chain becomes increasingly digitized, real-time container tracking and tracing, intelligent container yard optimization, and integrated inland container depot (ICD) automation are essential. Envision CTOS is designed to address the complexity and scale of modern port environments while ensuring full transparency, traceability, and flexibility.

Core Functional Modules: How Envision CTOS Powers Smart Terminals

1. Vessel Planning and Berth Optimization

Efficient vessel planning is crucial for reducing port congestion and maximizing quay crane productivity. Envision CTOS Vessel Scheduler features:

AI-driven berth window recommendations

Real-time coordination with pilotage and tug services

Simulation of quay crane allocations

Scenario planning for delayed or out-of-window arrivals

This ensures optimal berth occupancy and reduces vessel idle time, supporting higher throughput during peak seasons.

2. Smart Yard Planning and Container Lifecycle Management

Yard management is the nerve center of terminal operations. Envision CTOS introduces dynamic yard allocation algorithms that:

Predict yard congestion

Suggest optimal stacking strategies

Integrate container priority based on export/import urgency

Auto-link with RTG, RMG, and reach stacker assignments

With live heatmaps and inventory snapshots, yard managers can reduce re-handling, minimize traffic paths, and improve container yard optimization and flow.

3. Gate and Truck Turnaround Automation

Gate operations are often a chokepoint. Envision CTOS integrates GateOps+, a module built for automated, secure, and speedy gate processing:

OCR for container number recognition

RFID-enabled driver check-ins

Pre-scheduled appointment systems

Queue management and dynamic rerouting

Combined, these innovations reduce average truck turnaround time by up to 35%, improving customer satisfaction and reducing pollution from idling vehicles. It also enhances container drayage management through real-time coordination.

4. Crane Productivity Monitoring and Control

Crane operations often determine the overall speed of vessel servicing. Envision CTOS offers:

Real-time crane performance dashboards

Automatic move counting and analytics

Crane clash detection and crane-to-vessel mapping

Shift-wise KPIs and utilization alerts

This module enables crane operators and supervisors to maintain optimal productivity while ensuring safety and alignment with operational goals.

The Role of AI and Machine Learning in Envision CTOS

Envision CTOS is not a static tool; it’s a continuously learning platform. It uses historical and real-time data to power predictive models, including:

Vessel arrival delay prediction based on port congestion and sea traffic

Container dwell time forecasting using shipment profiles and port activity

Labor demand modeling to ensure cost-effective shift planning

Predictive maintenance for yard and handling equipment

These intelligent forecasts allow for pre-emptive resource allocation, better decision-making, and a shift from reactive to proactive terminal management. AI also enhances container tracking and tracing accuracy and operational efficiency.

Digital Twin Technology: Simulation-Driven Optimization

One of the most unique aspects of Envision CTOS is its Digital Twin Engine — a real-time simulation of the terminal’s operational and spatial layout. Terminal operators can simulate:

New container flow strategies

Equipment layout changes

Emergency evacuation scenarios

High-traffic conditions and peak-day planning

This allows management to experiment without disrupting real operations, increasing innovation and reducing risk. It plays a critical role in achieving empty container depot management efficiency.

Interconnectivity Across the Logistics Chain

In today’s fragmented logistics networks, a unified view across seaports, inland container depots (ICDs), and container freight stations (CFSs) is essential. Envision CTOS enables:

Real-time data exchange between facilities

Intermodal scheduling (rail-truck-container coordination)

Shared visibility on cargo movement and inventory

Customs clearance integration across nodes

This integrated architecture supports end-to-end import/export container logistics, reducing handoff delays and enhancing supply chain predictability.

Container Tracking and Tracing Capabilities

The SmartChain Tracker module in Envision CTOS ensures full visibility into container locations, status, and condition:

GPS and IoT-based real-time container tracking

Integration with shipping line EDI systems

Alerts for exceptions (e.g., lost, damaged, or misrouted containers)

Historical traceability for compliance and audits

This leads to better empty container depot management, lowers demurrage, and enhances customer trust through robust container tracking and tracing.

CFS and ICD Automation: Total Logistics Synchronization

For terminals with affiliated CFS and ICD operations, Envision CTOS brings specific modules that include:

Bonded cargo tracking and audit control

LCL/FCL split & merge management

Inspection, fumigation, and documentation status

Container drayage management and delivery scheduling

These features ensure holistic container freight station (CFS) management software capability and seamless inland container depot (ICD) automation, enabling terminals to eliminate silos and reduce overhead costs.

Smart Port Integration and IoT Enablement

Envision CTOS supports IoT integration to connect cranes, reach stackers, trucks, and sensors throughout the terminal. Features include:

Equipment telemetry and fault diagnostics

Condition-based asset monitoring

Smart lighting and energy management systems

Automated gate barriers and weighbridges

These integrations enable ports to transition into fully smart terminals with real-time responsiveness and system-wide optimization. This also enhances real-time container tracking and tracing and ensures better performance visibility.

Sustainability and ESG Compliance

Modern ports are increasingly judged on their environmental performance. Envision CTOS offers tools that support:

Monitoring of equipment fuel consumption and emissions

Real-time carbon footprint reporting

Optimization suggestions for green logistics practices

Support for electric and hybrid handling equipment integration

This helps terminals meet ESG targets and regulatory mandates without compromising performance. It also supports green initiatives in container depot software environments.

Multi-Terminal and Multi-Country Management

Large logistics companies operating across countries can deploy Envision CTOS MultiPort, a command and control tower to:

Benchmark performance across terminals

Transfer best practices between facilities

Standardize data reporting formats

Share assets (e.g., cranes, containers) for cost savings

This enables geographically distributed terminals to operate in synergy, maximizing the value of depot management system (DMS) and digital transformation across borders.

Envision CTOS in Numbers: Proven Benefits

Real-world deployments of Envision CTOS have delivered measurable results, including:

35–45% improvement in truck turnaround time

25–30% increase in crane productivity

30–50% reduction in manual documentation errors

70%+ visibility in real-time container location

50% faster response to operational disruptions

These metrics highlight how Envision CTOS and its integrated container depot software are proven drivers of operational excellence and competitive advantage.

Future-Ready Capabilities in Development

Envision CTOS is built with forward compatibility, and several cutting-edge features are in active development:

Drone integration for container scanning and yard surveillance

Blockchain-enabled digital handshakes for cargo milestones

AI-based co-pilot assistants for operations planners

Digital collaboration tools for shipping lines and customs agents

These advancements ensure that Envision CTOS evolves with industry trends, keeping your terminal ahead of the curve in depot management system (DMS) deployment and digital logistics.

Why Choose Envision CTOS?

In a world where container terminals are expected to operate with speed, precision, and transparency, Envision CTOS stands as a holistic solution that combines:

Deep domain expertise in port operations

Advanced technology architecture

Proven scalability for small to mega terminals

Local and global compliance readiness

24/7 support and rapid deployment capabilities

From onboarding to ROI realization, Envision CTOS is a partner in transformation, not just a technology vendor. It’s your ideal platform for modern container depot software, ICD automation, CFS management, and container yard optimization.

About Envision Enterprise Solutions

Envision Enterprise Solutions Pvt. Ltd. is a pioneer in port and logistics automation. With over two decades of expertise in deploying advanced systems for seaports, ICDs, and CFSs, Envision is recognized for:

Cutting-edge products like Envision CTOS

Specialized modules for depot management system (DMS), container yard optimization, and predictive logistics

Global clientele spanning Africa, Asia-Pacific, and the Middle East

Strong partnerships with terminal operators, shipping lines, and government bodies

Envision continues to push the boundaries of what’s possible in smart logistics with next-gen container depot software and container tracking and tracing solutions.

Final Thoughts: Embrace the Future with Envision CTOS

As the global economy becomes more interconnected and digitized, container terminals need more than operational tools — they need strategic enablers. Envision CTOS is that enabler. With intelligent automation, real-time insights, full lifecycle tracking, and integrated inland logistics, it represents the future of port operations.

For terminal operators seeking to increase productivity, reduce costs, and deliver superior service, the journey to intelligent logistics begins with Envision CTOS.

Ready to transform your terminal operations? Contact Envision today or request a personalized demo of Envision CTOS to see how we can power your digital port transformation.

#artificial intelligence#container#ports#terminals#logistics#envision#freight#manufacturing#iotsolutions#ctos

0 notes

Text