#conductive fabric

Explore tagged Tumblr posts

Text

Know About the Conductive and Metal Fibre Fabric

Conductive Fabric are materials that can transfer electricity. These textiles are employed in a variety of industrial applications, primarily to reduce static and protect against electromagnetic interference. Conductive textiles can be made by inserting conductive additives or threads, or by applying various conductive coatings. Conductive textiles are textile constructions capable of conducting…

View On WordPress

1 note

·

View note

Text

Silver Fiber vs. Nickel Copper Fabric: A Comparative Analysis of Conductive Textiles

In the world of innovative textiles, conductive fabrics have gained significant attention due to their ability to integrate electronics and enhance functionality. Among the various conductive fabrics available, silver fiber fabric and nickel-copper fabric are two popular choices. In this blog post, we will compare these two materials and explore their characteristics, applications, and benefits.

Silver fiber fabric, as the name suggests, is a textile infused with silver fibers. Silver, being an excellent conductor of electricity, imparts conductive properties to the fabric. The silver fibers are either blended with other fibers or woven into the fabric to create a conductive pathway. This unique composition allows for the efficient transmission of electrical signals and currents across the fabric surface.

On the other hand, nickel-copper fabric consists of a blend of nickel and copper fibers. Nickel provides excellent corrosion resistance and durability, while copper offers high electrical conductivity. This combination makes nickel-copper fabric an ideal choice for applications where longevity and conductivity are crucial.

When comparing these two materials, several factors come into play:

Conductivity: Both silver fiber fabric and nickel-copper fabric exhibit excellent electrical conductivity. However, silver is known for its highest electrical conductivity among all metals. This gives silver fiber fabric an edge in terms of overall performance in conducting electricity.

Durability: Nickel copper fabric is renowned for its exceptional durability and resistance to corrosion. It can withstand harsh environmental conditions, making it suitable for applications where longevity is important. Silver fiber fabric, although less durable than nickel copper fabric, still maintains good overall durability.

Cost: Silver is a precious metal, and consequently, silver fiber fabric tends to be more expensive compared to nickel-copper fabric. The cost factor is an important consideration for large-scale production and cost-sensitive applications.

Applications: Both silver fiber fabric and nickel-copper fabric find applications in various industries. Silver fiber fabric is commonly used in wearable technology, smart textiles, and electromagnetic shielding. Its high electrical conductivity and antimicrobial properties make it suitable for applications such as medical garments and electronic accessories. Nickel copper fabric is often employed in applications that require robust grounding or electromagnetic interference (EMI) shielding, such as protective clothing, aerospace, and military equipment.

One notable application worth mentioning is the grounding recovery bag, which is used for electromagnetic radiation protection during electronic device usage. This bag utilizes conductive textiles to create a Faraday cage-like enclosure, effectively blocking external electromagnetic signals. Both silver fiber fabric and nickel-copper fabric can be used for this purpose, depending on the specific requirements of the application.

In summary, silver fiber fabric and nickel copper fabric are two types of conductive textiles that offer unique advantages and applications. While silver fiber fabric boasts superior electrical conductivity, nickel-copper fabric excels in terms of durability and cost-effectiveness. The choice between these materials ultimately depends on the specific requirements of the intended application.

As technology continues to advance, conductive textiles like silver fiber fabric and nickel-copper fabric will play an increasingly significant role in enhancing the functionality and performance of various products. Whether it's wearable technology, medical garments, or electromagnetic shielding, these conductive fabrics open up a world of possibilities for innovative and integrated solutions.

0 notes

Text

I wonder if there's a way to like. Weave fine copper wire or some other metal into a knit fabric to make a thermally conductive stretch fabric. Sort of like a zigzag stitch but with that super fine copper wire they use for brush contacts

#its fucking freezing at work and i am once again musing over the possibilty of heated gloves#if i could have thermally conductive strips in the fabric then i could use fewer heating elements#and keeo them from being super bulky and impractical#if only my hands actually had blood in them >:(

2 notes

·

View notes

Text

Help I'm Having creation ideas beyond my skill level

#iron widow#im going to cosplay as wu zetian in her conduction suit and jacket#and. sigh#i just got a full time job so my time is limited. so a relatively simple modified morph suit is ideal for me rn#but i want to make it a tranforming piece so bad!#I was thinking like a reversible jacket. maybe the easiest way to do that right now is to make the inside red and feathery#with fabric wings that i can raise with my arms

6 notes

·

View notes

Text

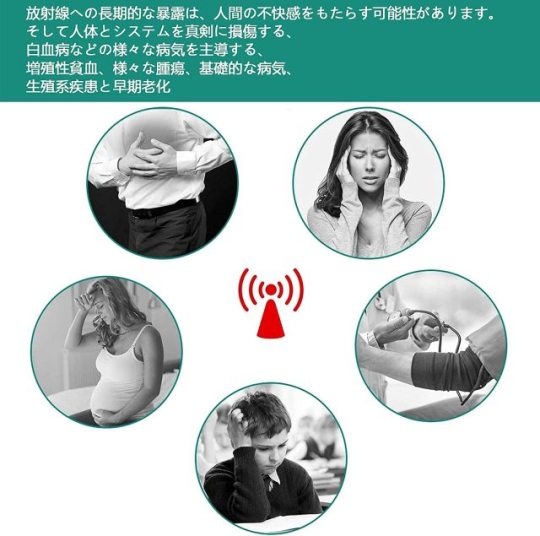

Shielding cloth can really prevent radiation damage!

In fact, many electrical appliances around our room contain radiation, and the shielding cloth can prevent the damage caused by radiation.

For example: refrigerators, ovens, etc. contain radiation. The long-term damage caused by radiation will endanger human health, so the shielding cloth can be used to isolate it.

1 note

·

View note

Text

FIBC Jumbo Bags

Commercial Syn Bags Ltd specializes in manufacturing FIBC Jumbo Bags (Flexible Intermediate Bulk Containers). These bags are designed for the safe and efficient storage and transportation of bulk materials such as chemicals, agricultural products, construction materials, and more. Known for their durability and high strength, FIBC Jumbo Bags from Commercial Syn Bags Ltd come in various designs like U-panel, circular, and 4-panel, catering to different industries. The company ensures quality control and offers customizable options to meet specific customer needs, providing eco-friendly and cost-effective packaging solutions.

For more info visit our website:

#FIBC#Big Bags and Food Grade FIBC (BRC & ISO 22000 Certified)#Pond Liner#Tarpaulin#BOPP Bags#PP Fabric#PP Woven Sacks#Conductive Bags#Conductive Liners#Baffle Liners

0 notes

Text

The fabric could reach 100 dB in the shielding effectiveness and 0.005-0.008O/sq in the surface resistivity, and this is the lowest resistivity fabric in the JINAN.

Website: http://www.emishielding.com.cn

Tel: 86-531-81901321

Fax: 86-531-81901321

Email: [email protected]

Add: 1-301,XINGFULIANCHENG LASER PARK, KEJIA ROAD, JINAN, CHINA

0 notes

Text

PCB Manufacturing Process: All You Need to Know

Creating a printed circuit board (PCB) is a systematic process that begins with meticulous design and material selection, crucial for ensuring functionality and durability. The initial steps involve the application of a thin layer of copper over a substrate material, typically a fiberglass substrate reinforced with epoxy resin and glass fiber, which provides the necessary rigidity and electrical insulation. This copper layer is then patterned to form conductive areas that will eventually carry electrical signals.

The layout design process utilizes advanced CAD software for precision, ensuring that the conductive paths and component placement areas are accurately defined. Once the design is finalized, it's transferred onto the PCB using photo reactive chemicals and UV exposure, a process known as outer layer imaging. This method allows for the precise alignment of layers and the creation of intricate circuit patterns.

After the design transfer, the excess copper is removed through a careful etching process, leaving behind the copper traces that form the circuitry. The PCB then undergoes a laminating process to apply a solder mask, a protective layer that covers the entire board while exposing the areas where components will be soldered. This solder mask application is crucial for preventing short circuits and ensuring the longevity of the PCB.

Following the application of the solder mask, a silkscreen printing process adds labels and markings to the PCB, aiding in component placement and board identification. The final step in the fabrication processes involves applying a surface finish, such as tin plating, to protect the exposed copper and ensure a reliable soldering surface. Other surface finishes like HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold) are also used depending on the application requirements.

Throughout the PCB manufacturing process, precision is maintained through the use of technologies like CNC machines for accurate drilling of holes that will accommodate electronic components. Each part of the PCB fabrication process, from the initial design to the final surface finish, is critical to enhancing the PCB's electrical performance and longevity.

The final stages of assembly involve the placement of components onto the PCB, often by a contract manufacturer specializing in PCB assembly. This is followed by soldering, which can be done through various methods, to securely attach the components to the board.

Rigorous electrical tests are conducted to validate the PCB's performance, ensuring that it meets stringent quality standards before integration into electronic devices. These tests verify the integrity of the conductive paths, the correct orientation of components, and the overall functionality of the PCB.

This holistic approach underscores the importance of meticulous craftsmanship and thorough quality assurance in producing reliable PCBs that power our modern gadgets effectively. Each step, from the initial plating process to the final surface finishing, contributes to enhancing the PCB's electrical performance and longevity, making it a vital component in the electronics industry.

To read more please visit:

Reachemical chemicals

16479857177

600 Matheson Blvd W Unit 5, Mississauga, Ontario ,ON L5R 4C1.

#thin layer of copper#plating process#excess copper#laminating process#tin plating#fabrication processes#substrate material#exposed copper#solder mask application#circuit board manufacturing process#conductive areas#surface finish#layer alignment#outer layer imaging#parts of the pcb fabrication process#epoxy resin and glass fiber#contract manufacturer#outer layers#electrical tests#photo reactive chemicals

0 notes

Text

Innovative EMF Blocking Fabrics and Conductive Materials: Pioneering Health and Safety Solutions

In an era dominated by technological advancements, our daily lives are increasingly intertwined with electronic devices and wireless communication. While these innovations bring convenience, they also expose us to electromagnetic fields (EMFs), which can have potential health implications. Enter conductive materials and fabrics, designed to mitigate EMF exposure and enhance our well-being. At the forefront of this innovation is Conductive-Fabric.com, offering a range of advanced products including nickel-copper plated fabrics, conductive goat leather, and conductive silver fiber anti-virus masks.

EMF Blocking Fabric Nickel-Copper Plated

One of the standout offerings from Conductive-Fabric.com is the nickel-copper plated fabric. This material is engineered to block EMFs effectively, providing a shield against the electromagnetic radiation emitted by various electronic devices. The fabric is made by plating a base textile with a thin layer of nickel and copper, creating a conductive barrier that deflects and absorbs EMFs.

Key Features:

High Conductivity: The nickel-copper combination ensures excellent conductivity, making it highly effective in blocking EMFs.

Durability: The plating process enhances the fabric’s durability, allowing it to withstand regular use and washing without losing its protective properties.

Versatility: This fabric can be used in various applications, from protective clothing to lining for electronic device cases.

Conductive Goat Leather

Another innovative product is the conductive goat leather, which combines the natural benefits of leather with advanced conductivity. This material is particularly useful in applications where flexibility and durability are crucial, such as wearable technology and protective gear.

Key Features:

Natural Comfort: Goat leather is known for its softness and comfort, making it ideal for wearable applications.

Enhanced Conductivity: Infused with conductive materials, this leather offers effective EMF protection while maintaining its natural properties.

Durability: The robust nature of goat leather ensures longevity and resistance to wear and tear.

Conductive Silver Fiber Anti-Virus Mask

In the wake of the global pandemic, face masks have become essential. Conductive-Fabric.com has taken this necessity a step further with their conductive silver fiber anti-virus masks. These masks are not only effective in blocking viruses but also offer EMF protection.

Key Features:

Antiviral Properties: Silver fibers are known for their natural antibacterial and antiviral properties, making the mask highly effective in preventing the spread of viruses.

Washable and Reusable: Unlike disposable masks, these can be washed and reused, making them an environmentally friendly option.

EMF Protection: The conductive nature of the silver fibers adds an extra layer of protection against electromagnetic radiation.

Applications and Benefits

The products from Conductive-Fabric.com cater to a wide range of applications, from personal health and safety to industrial uses. Here are some key benefits:

Personal Health: EMF blocking fabrics and conductive masks help reduce exposure to potentially harmful electromagnetic radiation, contributing to better overall health.

Enhanced Safety: For professionals working in high-EMF environments, such as technicians and engineers, these products offer essential protection.

Environmental Sustainability: Reusable products like the conductive silver fiber masks help reduce waste, supporting environmental sustainability efforts.

Conclusion

As we continue to navigate a world filled with electronic devices and wireless communication, the need for effective EMF protection becomes increasingly important. Conductive-Fabric.com is at the forefront of this movement, offering innovative solutions such as nickel-copper plated fabrics, conductive goat leather, and conductive silver fiber masks. These products not only provide essential protection against EMFs but also offer additional health benefits, paving the way for a safer and healthier future.

#EMF Blocking Fabric Nickel-Copper Plated#Conductive Goat Leather#Conductive Silver Fiber Anti-Virus Mask#China Emf shielding fabric Manufacturers#V

0 notes

Text

0 notes

Text

Enhance Your Events with LED Video Wall Rental Services in Gurgaon

Are you planning an event in Gurgaon and looking for a way to make a lasting impression on your audience? Consider renting a LED video wall to elevate the visual experience and create a memorable atmosphere. LED video walls are a popular choice for events of all kinds, including corporate meetings, conferences, trade shows, concerts, weddings, and more. With their stunning visuals and versatility, LED video walls can enhance any event and leave a lasting impact on attendees.

At Jvevenz, we specialize in providing high-quality LED video wall rental services in Gurgaon and the surrounding areas. Whether you need a small screen for a private event or a large video wall for a corporate conference, we have the perfect solution for you. Our LED video walls are available in a variety of sizes and configurations to suit your specific needs, and our team of experienced professionals will work with you every step of the way to ensure that your event is a success.

One of the key benefits of renting a LED video wall for your event is the flexibility it offers. Unlike traditional projection screens, LED video walls can be easily customized to fit any space and can display high-resolution images and videos with stunning clarity. Whether you want to showcase promotional videos, live presentations, or dynamic visual effects, a LED video wall provides the perfect platform to captivate your audience and deliver your message effectively.

In addition to their visual impact, LED video walls also offer practical advantages for event organizers. LED technology is energy-efficient and produces bright, vibrant colors that are visible even in well-lit environments, making them ideal for use in indoor and outdoor settings alike. Our LED video walls are also easy to set up and operate, allowing you to focus on other aspects of your event without worrying about technical issues.

When you choose Jvevenz for your LED video wall rental needs in Gurgaon, you can trust that you're getting the best quality equipment and service available. Our team is dedicated to providing exceptional customer service and ensuring that your event is a success from start to finish. Whether you need assistance with installation, content creation, or technical support, we're here to help every step of the way.

Don't settle for a mediocre visual experience at your next event. Elevate your event with a LED video wall rental from Jvevenz and create an immersive atmosphere that will leave a lasting impression on your audience. Contact us today to learn more about our rental options and how we can help make your event a success.

#Corporate conference organiser Delhi#conducting seminars Delhi#conducting seminars Gurgaon#Corporate conference organisers Noida#conducting seminars Noida#Av equipment on rent Delhi#Led video wall on rent Gurgaon#Av equipment on rent Gurgaon#Led video wall on rent in Noida#led screen on rent Noida#Av equipment on rent Noida#Av equipment on rent#Event stage setup and fabrication in Delhi#Event stage setup and fabrication in Gurgaon#Event stage setup and fabrication in Noida#Event stage setup fabrication

0 notes

Text

Versatility Meets Innovation In Fiber Fabric

Metal fiber fabric is made using complex procedures that combine textile manufacturing and metallurgy. Using sophisticated technology, fine metal filaments which are often manufactured from alloys like copper, aluminum, or stainless steel are spun with other fibers like cotton, silk, or synthetic materials. After that, the composite yarn is woven into the fabric using either conventional weaving techniques or creative ways like knitting or braiding.

Qualities and Features

Conductivity: The electrical conductivity of metal fiber fabric is one of its most remarkable qualities. This characteristic creates opportunities for wearable technology, smart fabrics, and electromagnetic shielding applications.

Strength and Durability: The addition of metal strands to fabric increases its tensile strength and resilience against tearing, abrasion, and deformation. Applications in industrial environments, protective apparel, and high-performance athletics benefit greatly from its durability.

Thermal Regulation: Good heat dissipation is made possible by the exceptional thermal conductivity of metal fibers. Because of this characteristic, metal fiber fabric or Conductive Fabric is appropriate for uses that call for temperature control, including outdoor activity wear or insulation under harsh conditions.

Aesthetic Appeal: Metal fiber cloth has a distinct aesthetic appeal that goes beyond its practical uses. Fashion ensembles and home design items are given a sophisticated touch by the interplay of metallic sheen and textile textures.

Utilizations in All Sectors

Clothing and Style

Metal fiber fabric provides designers with a new creative medium in the field of fashion. Clothes made of this futuristic material, from avant-garde streetwear to high couture, stand out on the catwalk. The choices are unlimited whether it comes to metallic embellishments, conductive threads for lighted patterns, or futuristic materials for avant-garde clothing.

Technical Cloths

Metal fiber fabric is a material of choice in technical textiles, where utility is paramount. Because of its conductive qualities, it is perfect for use in medical textiles, wearable electronics, and protective gear for personnel in hazardous or electromagnetic radiation-exposed areas.

Applications in Industry and Engineering

Metal Fiber Fabric is used in filtration systems, gaskets, seals, and reinforcing materials in the industrial and technical industries. Because of its durability and superior thermal and electrical conductivity, it is a useful tool in difficult settings where dependability and performance are critical.

1 note

·

View note

Text

nickel copper fabric

Looking for nickel-copper fabric? Look no further than conductive-fabric.com! Our high-quality conductive fabric is perfect for various applications, from shielding and grounding to heating and sensing. Our nickel copper fabric is made with the highest standards of quality & durability, ensuring that your project will be a success. Visit our website today to learn more and place your order.

#nickel copper fabric#conductive fabric#fabric over foam#EMI shielding fabric#silver fiber fabric#anti radiation fabric

0 notes

Text

Quick reminder, despite how much transphobes complain about "shoving it in their faces", shove it in everyone's faces. You don't need to tell people you're trans, but if nobody is loud and gets people's attention directed at a problem, nobody will know about it.

Long part comes now with the example

My best example is poly mc (a Minecraft launcher) vs fabric (a Minecraft mod loader) both have had huge transphobia issues with the owners blocking/removing changes and removing people's access to editing the projects because they were trans. The difference is how people found out, initially when poly mc did these things, they were sudden, its been described as a hostile takeover where one person removed the code of conduct along with all maintainers. Because of how sudden this was people initially thought it was hacked, this immediately got every user and beyond to pay attention because it could pose a risk to them and as a hacker could install malware. When they explained they weren't hacked and were just a bigot, it didn't take long for a fork to be made that to my knowledge is much larger than poly mc is. Fabric, on the other hand, is still probably the most popular mod loader, despite a fork being made before the poly mc thing even happened, why? Because most people don't know that anything happened, there was never a big event to grab people's attention, and I only recently found out. Looking online, most people don't even really know what quilt (the fabric fork) is and why it exists. A lot of people don't see it as trying to replace fabric, but as another loader that makes modding more complicated.

#complain loudly#let people know#another factor in the examples is that fabrics issues are “less”#the primary thing I have heard is the owner refused to cut ties with the person who took care of community stuff#and they are extremely bigoted#compare that to suddenly removing a code of conduct and all contributers#and you can kinda see why prism mc (the fork) still warns that poly mc might install malware#but that doesnt make one form of bigotry acceptable#tw bigotry#tw transphobes#its honestly suprising just how quickly people seemed to switch to prism launcher#but quilt is still mostly unused#so most mods you use are from the fact that it is backwards compatible with fabric#prism mc#quilt mod loader#prism launcher

0 notes

Text

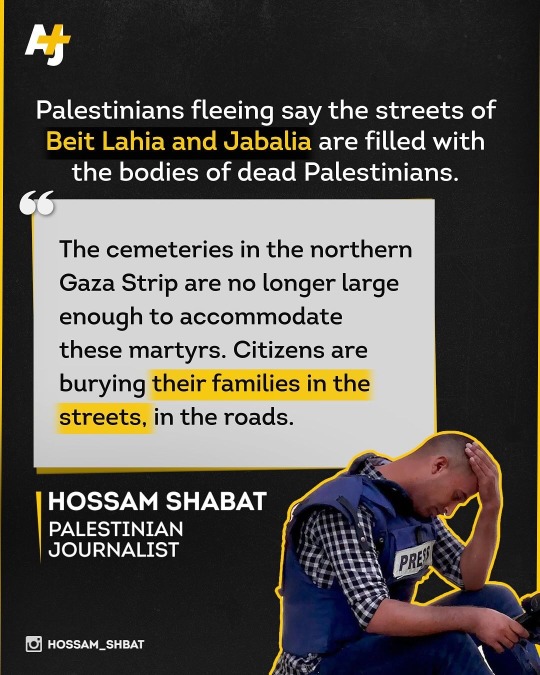

Israel is conducting massacres and mass arrests as it decimates northern Gaza. With journalists and social media activists increasingly targeted and detained, less and less footage is getting out of Israel’s ethnic cleansing campaign.

Israel has killed at least 175 journalists since the start of its genocide. Now, it has labeled six Al Jazeera journalists as “terrorists,” which the network denied, calling Israel’s claims “fabricated accusations as a blatant attempt to silence the few remaining journalists in the region.”

The Committee to Protect Journalists said on X, “Israel has repeatedly made similar unproven claims without producing credible evidence.”

As it silences journalists, Israel has leveled over 10 residential buildings in Jabalia and stormed the north’s only remaining hospital, threatening the lives of about 200 patients trapped inside and conducting mass arrests.

One of the journalists targeted by Israel, Anas al-Sharif, wrote, “North Gaza is being wiped out.”

Journalist Bisan Owda reacted to the attacks in Jabalia, saying: “No civil defense to grab the people from under the rubble. Nothing. Even journalists. No one to cover this massacre ... the world is complicit in this, is silent on this.”

#Gaza #Jabalia #BeitLahia #Palestine #Palestinian #JournalismIsNotACrime #Journalist #Israel #Hospital

#palestine#human rights#free palestine#gaza#israel#free gaza#gaza genocide#beit lahia#jabalia#journalism#gaza journalists#north gaza#journalists#israel is committing genocide#israel is a terrorist state#israeli war crimes#news#kamal adwan hospital

2K notes

·

View notes

Text

Unleashing the Potential of Oxygen-Free Copper: Revolutionizing High-Performance Applications

Oxygen-free high-conductivity copper is another name for oxygen-free copper. A class of wrought copper alloys known as oxygen-free copper is refined using an electrolytic process and exhibits excellent conductivity. In particular, electrolytic refining is required to reduce the oxygen concentration to or below 0.001%. Makers are focused on item testing to make sure that production programs,…

View On WordPress

#advanced metal#aerospace industry#automotive applications#circuit boards#conductivity#copper alloys#corrosion resistance#electrical industry#Electronics#heat exchangers#high-performance materials#market trends#metal fabrication#oxygen-free copper#power transmission#reliability#renewable energy#telecommunications

0 notes