#concrete slurry cleaner

Text

When You Know the Proper Concrete Slurry Clean Up – These 5 Ordeals Can Be Avoided

Concrete slurry clean up would appear ordinary and pointless if one does not have a knowledge of the reasons why it is necessary. Read more: https://www.advancecutting.com.au/2022/03/16/concrete-slurry-clean-up/

#concrete cutting slurry conctrol#concrete slurry clean up#concrete slurry control#concrete slurry cleaner

0 notes

Text

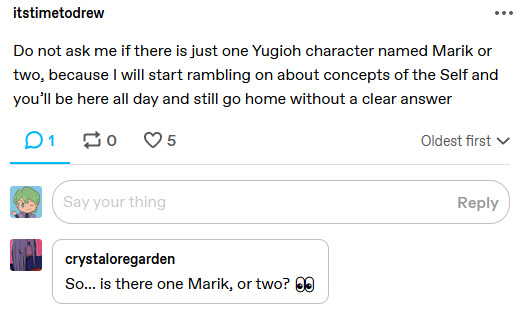

alright I'm taking the bait @crystaloregarden, rolling up my sleeves...

Short Answer: 2, if you want to keep it simple from a narrative or marketing perspective (thank god for their differences in design netting us 2 kotobukiya figures...blessed are the Marik fans getting to spend double money 🙏)

Long Answer: I'm read more-ing this shit

(tw for mentions of abuse and death and suicide)

Summarizing sections from a 17-page google doc I have on him involving topics like this teehee

Anyway! I feel like there really isn't a definitive answer. Just what exactly Yami Marik 'is' isn't 100% clear. Is he a stereotypical and negative portrayal of something like DID? Is it a case of possession, and if so, how much personality does this spirit have of its own? If you see Yami Marik as a separate character, does he begin his own existence when created by Marik, or is it not until he gains a more physical and tangible form? If you don't consider him his own character, what would it take for him to become an entity in his own right, or is it impossible because of his beginning? So many cool questions, no concrete answers!

I think in that sense, people arrive at different answers depending on their view. I think canon shows them more as separate people, or at least for Yami Marik to be a separate Entity, to keep the story cleaner. He is the personification of moral and emotional faults and failings, generational trauma, of being abused, and wanting to abuse others, just to name a few. In a story where he is a villain for an arc for a franchise pushing card game sales, we have to put a nice bow on it all! Marik is bad, but this Other Marik is worse, so we just kill him to redeem the 'good' one and dust our hands off before the next villain comes in.

I can see how that notion can be either inspirational or uncomfortable for people. If you could separate all the qualities of yourself that you dislike and banish them, would you? On one hand, Marik overcoming his 'darker half' shows that what's important is to always work to become better, and no one is too far gone. It's hope and change that drive us forward. Conversely, ironically... that message rings hollow if you see Yami Marik in another light. Why is it fine to portray him as a monster (literally, as he fuses with Ra) and use his death as a benefit for others? We don't get much more character growth for Marik after this, he mostly joins Ishizu in dumping some lore about ancient ceremonies, so we just know he's 'better off' now. (Again, I'm not complaining Marik should have gotten more focus, because his time in the story was up and Millennium World was rushed enough as is without expanded Keeping Up with the Ishtars tidbits. I just love him as a character so much, it's an interesting conclusion for him canonically!)

For my personal take on The Lore, I think what we know as Yami Marik began as the culmination of millennia worth of trauma going back to Kul Elna. A slurry of souls, now voiceless and faceless, only wanting to exact retribution. They gain power and influence being passed from one generation to the next via the Tombkeeper's initiation until we hit Marik, where finally there's enough built up for a more solid Form to emerge. Not something totally new, though. He still uses Marik's name, identifies Marik's siblings as his own (interestingly enough not Marik's father though, IMO showing continued dissociation from the abuse he faced), but has clear quirks and preferences of his own. And none of this is going into the relationship they have with each other, both trying to kill the other/themself but having a purpose rooted in self-preservation. They reflect one another and share a common base, so where does the 'self' end and the 'other' begin?

Idk, all I know is it's Yugioh and my head hurts.

#i want to keep writing but its late and I'd just recreate my doc here skdfj#MARIK IS SOOOOOOOOOOOOOOOOOOOOO COOL!!! I LOVE THE MARIKS!!!!#i am Fascinated with characters that tackle themes of Inner Self Become Manifest...so cool so cool......

5 notes

·

View notes

Text

Short Construction Period Enamel Tanks as Biogas Digester Tanks

Short Construction Period Enamel Tanks as Biogas Digester Tanks

Center Enamel stands out as a leading provider of premium enamel tanks, offering top-notch solutions for biogas digester applications. Center Enamel's enamel tanks are at the forefront of innovation in biogas digester technology, offering durability, gas-tight seals, customization, easy maintenance, and eco-friendliness. As a trusted provider in the industry, Center Enamel's tanks contribute significantly to sustainable waste-to-energy solutions, supporting a cleaner and greener future.

When selecting enamel tanks for biogas digester applications, consider Center Enamel's expertise, reputation, tank capacity options, compatibility with biogas systems, insulation features, safety standards, and customer support. Partnering with Center Enamel ensures reliable, efficient, and high-performance biogas digester tanks.

The Need for Efficient Biogas Digester Tanks

Biogas, a renewable energy source, is generated through the anaerobic digestion of organic matter, such as agricultural waste, manure, and sewage sludge. Biogas digester tanks are the core infrastructure where this process occurs. These tanks facilitate the breakdown of organic material by microorganisms in an oxygen-free environment, leading to the production of biogas—a mixture primarily composed of methane and carbon dioxide.

Efficient biogas production requires well-designed digester tanks that can withstand various environmental conditions, maintain optimal temperature and pH levels, and minimize gas leakage. Additionally, the construction of such tanks should be cost-effective and time-efficient to ensure the viability of biogas projects, especially for small-scale installations.

As a leading storage tank manufacturer in China. Center Enamel can provide GFS Tanks, SS Tanks, Epoxy Coated Bolted Steel Tanks, Galvanized Tank, Aluminum Dome Roofs, Wastewater and Biogas Project Equipments for global customers.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Advantages of Enamel Tanks for Biogas Digesters

Rapid Construction: Bolted steel tanks can be assembled quickly, significantly reducing construction time compared to concrete or welded steel tanks. This rapid deployment is particularly advantageous for biogas projects aiming for swift implementation and commissioning.

Cost-Effectiveness: The simplified construction process of bolted steel tanks translates to lower labor costs and fewer logistical expenses. Moreover, the durable nature of steel ensures long-term reliability, reducing maintenance and replacement costs over the tank's lifespan.

Versatility: Bolted steel tanks offer versatility in terms of size, shape, and configuration, allowing for customization according to specific project requirements. This flexibility enables biogas plant designers to optimize tank design for efficient biogas production and storage.

Durability and Corrosion Resistance: Steel is inherently robust and resistant to corrosion, ensuring the longevity and structural integrity of biogas digester tanks even in harsh environments. Additionally, modern coating technologies further enhance corrosion resistance, prolonging the tank's service life.

Ease of Maintenance: Bolted steel tanks are designed for easy maintenance and repair, with individual panels being replaceable without the need for extensive dismantling. This feature minimizes downtime and ensures continuous operation of biogas plants.

Center Enamel combines the excellent performance of various tanks to provide customers with solutions composed of diverse equipment combinations. This approach allows us to flexibly meet the needs and requirements of different application fields. Throughout the project construction process, the teams at Center Enamel collaborate closely, actively coordinate, and prioritize each step, conducting rigorous checks at every level to ensure the smooth completion of projects.

From being a leader in the Global GFS tank industry to becoming a diversified environmental equipment smart manufacturer in China, Center Enamel utilizes crucial core technologies to continuously iterate and upgrade equipment in research and development. This drives the sustained high-quality development of the company in the face of new challenges. Leveraging existing brand advantages, technological strengths, and team capabilities, the company will continue to focus on cutting-edge industry technologies. Adhering to a diversified development strategy, Center Enamel aims to elevate environmental business to new heights while jointly creating a beautiful picture of green hills and clear waters.

0 notes

Text

Experience the robust performance of the Husqvarna W70P, an industrial vacuum cleaner specifically engineered for challenging tasks in wet and slurry settings. Crafted with durable stainless steel components and equipped with a unique filter and float system, this vacuum ensures the motor remains safeguarded from potential damage, even during the cleanup of messy or hazardous substances. The W70P excels in handling a diverse range of liquids, including concrete slurry, oils, and machining coolants, while also effectively capturing solids like dust, dirt, and debris. Contact Rentalex at (813) 971-9990 today to secure your rental of the Husqvarna W70P Slurry Vacuum!

See the Husqvarna W70P Slurry Vacuum here: https://www.rentalex.com/rental_equipment/tampa-floor-wall-finishing/vacuum-slurry-1-6hp-w70p-hq/

#husqvarna#husqvarnaW70P#W70P#k3000#slurryvacuum#husqvarnavacuum#husqvarnatools#rentalex#husqvarnaequipment

0 notes

Text

Polished Concrete Countertop

You can polish concrete countertops to create a smooth, hard surface that is easy to clean and maintain. Polishing is done after the countertop has cured for several days.

Start with a coarse grit, such as 50 or 60, and lightly go over the whole surface. As you move to higher grits, the surface will become smoother.

Aesthetics

Concrete countertops are becoming increasingly popular in homes, as they offer a unique alternative to traditional materials like granite and marble. They can be customized to fit your specific style and color preferences, and they are durable and stain-resistant when properly sealed.

Once the counters are fabricated, they can be ground and polished to achieve the desired look. This can be done with a variety of finishes, including matte and glossy. It is also possible to add designs and embeds to the countertop, such as crushed glass or metal.

The smooth surface of a polished concrete countertop reflects light and makes it appear bright, which can make your kitchen seem more spacious. It is also hygienic and easy to clean. It can withstand heat, which is an advantage if you often cook or bake. Moreover, it can withstand scratches from dishes and silverware. If you want to repair these scratches, you can use a special slurry that contains cement, fine sand, water, and pigment.

Durability

Concrete is durable and strong on its own, but when a protective coating is applied, it can be even stronger and more resistant to staining. It can be sealed with a glossy or matte finish.

A countertop made with a special mix designed for polished concrete, like Quikrete’s Countertop Mix, has smaller aggregate pieces and super-plasticizer additives that create a dense, smooth surface that can be ground and polished to a high sheen without developing miniscule cracks. The countertop must be allowed to cure fully before it is finished and sealed.

When polishing the concrete, it’s important to use water as a lubricant to prevent causing any damage or scratching the surface. You should also wear the appropriate safety equipment, including goggles and ear protection. Start by polishing with a coarse grit pad and progress to the finer pads. Be sure to complete a full pass over the entire countertop with each grit, including vertical surfaces.

Easy maintenance

Concrete countertops are durable and can be polished to a high gloss. They are also an eco-friendly choice. However, like other counters, they require regular maintenance. You should use a pH-neutral, non-abrasive cleaner. Avoid acidic cleaners, such as vinegar, and harsh cleansers, which can damage the countertop’s sealer or cause etching and physical damage to the concrete itself.

If you prefer a rougher finish, you can expose the aggregate in the concrete mix during polishing. This finish is attractive and holds stains better than smooth polish. To achieve this look, you’ll need a hand-held wet concrete polisher with pads ranging from 50 grit to 3000 grit.

Ensure the countertops have cured for at least 10 days before polishing. Concrete younger than this will be too soft and may not polish well. You’ll also need a patching slurry to fill in small blemishes and holes. These slurries are usually color-matched to the counter and can be mixed with different additives to create veining.

Safety

Concrete countertops are an eco-friendly, durable choice for kitchens. They are also food-safe and stain-resistant if they are sealed. They are also highly customizable. You can choose from a wide range of additives and colors to create a unique look.

The concrete used in these counters is usually a mix that includes rock aggregate and sand. Cement alone is brittle, but when mixed with aggregate and sand, a matrix forms that strengthens the mix. It’s important to use a quality mix that has the right additives, such as accelerators and superplasticizers, for best results.

Once the countertop is poured and cured, it can be polished to a high sheen. It is important to use a concrete polisher that uses water as a form of lubrication, and to wear appropriate safety equipment. It is also important to let the concrete cure for a minimum of ten days before polishing. Concrete that is younger than this will be too soft to polish well.

source https://sydneypolishedconcrete35734287.wordpress.com/2023/06/25/polished-concrete-countertop/

0 notes

Text

youtube

Dirt EATER Heavy Duty Cyclonic Industrial Vacuum Cleaner for Concrete Slurry Concrete Cutting.

Call Today on 0426 291 402 Or Toll free 1800 438 822 or Email Us On [email protected].

Concrete #Cutting, #Concrete #Slurry #Cyclonic #Industrial #Vacuum #Cleaner #CleaningMachines #Cleaning

0 notes

Text

How to Clean Victorian Tiles Without Using Much Water

The restoration of this Victorian Tiled hallway floor at a property in Glasgow’s West End proved to be quite a challenge. It had seen a long life and over that time it had numerous so called repair work carried out on it which basically resulted in bits of problematic floor being ripped out and back filled with concrete.

The current owner fully appreciated the value a fully restored period feature like an original tiled floor can add to a property so we were asked to pop round and provide a quote. Having restored numerous floors in the area I was happy to take on the job and provide a quote for the work. With the quote accepted and a date agreed I set about sourcing replacement tiles to match the existing.

Repairing a Victorian Tiled Hallway Floor

The first job was to lift all the tiles that were damaged or loose and move them to one side. This was followed by carefully knocking out all the areas of concrete back fill and screed from the original repairs. With the rubble cleared those areas were then levelled off with a mixture of cement board and self-levelling compound until the floor was level with the base of the original tiles.

While the repairs to the subfloor were setting the focus work moved on to salvaging as many of the original tiles as possible by grinding down the sides and backs to remove the old adhesive and cement. Once the tiles were cleaned and the sub floor had dried it was time to lay the tiles to match the original pattern. Many of the original tiles were unusable so a mixture of original and new reproduction Victorian tiles were used. Most of the tiles had to be hand cut down to size to fit.

The floor was then left to set and then re-grouted before moving on to the next step of restorative cleaning and sealing.

Restorative Cleaning and Sealing of an Original Victorian Hallway Floor

Old Victorian floors like this one do not have a damp proof membrane are as such are very susceptible to Efflorescent salt issues, so because of this I opted to go with a low moisture cleaning method.

This involved cleaned the tiles using a Tile Doctor Acid Gel which was worked in initially with a 100-grit diamond pad and then a 200-grit diamond pads fitted to a weighted rotary bonnet machine. This was carried out several times with all the slurry extracted using a wet vacuum. The advantages of Acid Gel is that an acidic cleaner will neutralise and alkaline salt, being a gel its very easy to control and finally its good at removing grout smears left over from tiling.

After a final inspection the floor was left to dry out overnight with the help of a fan to assist the drying before we could return to seal the tiles.

Sealing a Victorian Tiled Hallway Floor

I returned the following day to seal the floor checking first that it had dried using a damp meter. Once I was satisfied, three coats of Tile Doctor Colour Grow were applied to the tiles to enhance their appearance and protect then going forward.

I chose Colour Grow mainly because it’s a fully breathable sealer that will allow moisture to rise through the tile and evaporate at the surface. Use of a non-breathable sealer can lead to moisture becoming trapped under the floor where it could spread into the walls leading to rising damp.

The hallway was completely transformed by the time we had finished and as you can imagine our client was more than happy. So much so they even recommended us for another job and went to the extent of inviting them round to view the work.

Source: Victorian Tile Restoration Contractor in Glasgow

#Acid Gel#Adhesive Removal#Carpet Glue#Clean and Restore#Colour Grow#Glasgow#Gripper Rod#Hallway Floor#Paint Splashes#tile cleaning#victorian floor#West End

1 note

·

View note

Text

Meet Me Halfway- Chapter 5

Sorry again for the short chapter- longer with Liquidator POV next time, promise! Summary: Bushroot has Liquidator back at his apartment- now he just needs a plan to get him out of his concrete full-body prison.

Notes: Short chapter is short. Sorry >~<"

-First Chapter-

To Bushroot’s surprise, getting Liquidator to his apartment was the EASY part.

Granted, getting a solid concrete statue up two flights of stairs without making a ton of noise was difficult, but he’d had to move a wooden dresser on his own before and the concept was pretty similar- wrap it in towels to avoid scuffing or breaking, tie it to a piece of cardboard so it slides easily, then just tie something to the thickest part and drag it until you reach your destination. After that was done, he drove the truck out to the outskirts of town, thoroughly cleaned it with a portable vacuum cleaner and some wet wipes to make sure he didn’t leave any evidence behind, and then caught a cab back into town once he was close enough. By the time he got home it was a little past two in the morning, and he was so exhausted that he passed out on the couch next to where he’d left Liquidator’s statue in the living room.

The HARD part, however, was figuring out how to get his friend out of his petrified state.

It was a weekend, so thankfully he had plenty of time away from work to do his research and form a plan. Another thing he was thankful for was that, while the university itself was closed on the weekend, the library was still open for students and faculty who wanted to study or check out reading material.

Bushroot had some experience with chemistry when it came to how certain chemicals affected the biology of plants and animals, but it wasn’t his main field of study, so that meant that he had to do A LOT of research to figure out the best ways to separate water from concrete besides giving it months to evaporate out. It took almost all day hunched over a series of books and scribbling notes and formulas but, finally, he’d found a method that seemed feasible: If he could break the concrete down into small enough pieces, then there was a pair of chemical compounds he could use- one for softening the concrete down into its base minerals and liquids and one to separate and purify water from the denser minerals that should, theoretically, work to separate Liquidator from the concrete mixture.

With that in mind, Bushroot used his faculty keys to “borrow” a few supplies. Namely a hammer, a chisel, and the necessary chemicals he would need for his plan to work. He was lucky that no one saw him take anything off-campus as he rushed back to his apartment, as he would have looked odd (and suspicious) carrying around implements that had NOTHING to do with botany.

Dawning a pair of protective gloves, goggles, and a face mask, Bushroot spent the remaining hours of his weekend working around the clock to break the concrete statue into pieces (wincing and apologizing every time he broke another piece off) and setting everything up in his bathtub. Once he had all the pieces broken down into small enough bits, he started adding the softening solution to further break the solid chunks down and mixed the whole batch with extra water from the tap for good measure. After giving the pseudo-slurry some time to set, he added in the chemical compound used to separate the minerals from the water, which in itself was a lengthy process that involved repeatedly stirring the liquid to agitate and bond the denser minerals together before scooping out the resulting sludge and sediments to keep them from mixing back together.

By the time the water was more than 75% clear, the exhausted duck’s eyes had trouble staying open. A distant part of his brain wondered if it was from not sleeping or eating since he started everything earlier that day (or was it the other day by now? The hours kind of blurred together since there wasn’t a window in his bathroom..), or if it was from breathing in the stuffy, contaminated air that smelled funny even through the mask.

Bushroot sat on the floor, his head and left shoulder leaning against the wall by the tub with his right hand idling on the rim as he watched the water and waited for a chance to pull out more of the sludge in the hopes that what he was doing was actually helping and not just making everything worse.

His eyelids fluttered and the world began to grown dimmer and dimmer with each attempt at opening them, until he succumbed to his exhaustion with one last thought:

‘Please come back to me- I need you.’

<-Previous Chapter Next Chapter->

End Notes: Sorry again for the short chapter- longer with Liquidator POV next time, promise!

16 notes

·

View notes

Text

How to Increase Your Vehicle Utilizing a Jack

These days you have to wait-list some do-it-yourself projects simply because of cost. But fixing the parts of your property with shifted or uneven concrete shouldn't need to be one of them. With the innovative, cost-effective way of mud jacking, you can get to underneath of concrete settling problems once and for many and level off the uneven areas around your property or office.

It's some of those harsh realities of home maintenance: Concrete can settle and slope over time, turning your once beautiful walkway or patio into an unsightly and hazardous part of your property. What's not true, however, is the requirement for entirely new concrete construction in these cases. Because of an easy process called mud jacking or تعمیر جک درب اتوماتیک slab jacking, you are able to permanently restore your home's buckled concrete work to its original smooth grade. On top of that, you can make the mandatory repairs for approximately one-third to one-half of the price of putting in a brand new slab.

That's right. Done properly, mud jacking may be the affordable answer to all the settled and shifting concrete slabs through your property, including: Mud jacking functions getting to the source of the sub-grade problems and supporting the settled slab from underneath. Two small holes, not much larger when compared to a quarter, are drilled into the sloping slab. An assortment of insoluble materials is then pumped through these holes and to the underlying area of the slab. As this slurry mix enters the room beneath, it helps to release any pent-up water and air and firm up any loose subsoils, slowly lifting the slab back again to its original grade level.

According to what type of construction you need restored, slab jacking can save you as much as one-third to one-half the expense of replacing the entire concrete slab. Mud jacking can be the smart environmental choice over a new concrete driveway or decking. Rather than breaking up your settled slab and hauling it to the landfill, repairing the issue with mud jacking uses not as concrete and eliminates the requirement for many that waste.

Brake repair can often be an accidental side effectation of rusty rotors. Invest the a close look at any car that's partially exposed rotors, you're likely to see a lot of buildup. A similar thing is probably happening to your personal car, whether you can see them or not. It's not a serious problem, but it could lead to presenting premature brake repair problems if you don't take at the least a couple of measure to prevent it. Here are a few ways to accomplish just that.

Leaving your vehicle parked for long intervals will really subscribe to rust building on the rotors. You don't want to take you car in for brake repair if you aren't even utilizing it, so move out there and drive your car every so often, even although you don't actually need to. A car doesn't do well when simply sitting, unattended to. It will cause your battery to drain with time, for one thing. If you keep your car moving on a typical basis, the brake pads building a regular link with the rotors will do a good job of keeping rust from forming.

Cleaning your rotors on a steady basis is another simple method to help keep the rust monster away. When you yourself have the means to do this, jack up your car or truck on safety platforms and eliminate the wheels to have easy access to the rotors. They sell inexpensive cleaners that spray out in a aerosol can to assist you do the cleaning. Not that it was mentioned, but remember to avoid spraying almost any compressed air in to the parts themselves. This is because most brakes systems are filled up with asbestos, and this substance can cause a whole host of problems with your lungs that you truly don't desire to mess with.

If you are having trouble keeping rust from forming, you might want to think about replacing the rotors altogether with an alternative type of metal. Rotors covered in a zinc plating are especially great at resisting rust damage.

Finally, take your car in the local brake repair center and question them what you can certainly do to prevent rust buildup. They might be able to recommend some different solutions they came across inside their years of experience. Obviously, you've to find a shop you are able to trust. This can be done by seeking out the recommendations of your pals, or by looking online to see who in your town has received the right ratings and reviews.

1 note

·

View note

Text

Concrete Cutting Sydney – Dry vs. Wet

There are many types of concrete cutting, but diamond cutting using a diamond saw blade is considered one of the most efficient techniques. This is because it offers less fracture to cutting surfaces and cleaner overall cuts. There are two primary techniques for diamond cutting: dry and wet.

Concrete cutting Sydney uses both of these methods depending on the project. Both techniques are very efficient and offer high-quality cuts, but they have certain differences. Read on to learn each technique's pros and cons to determine which is the right choice for your specific project.

Dry Concrete Cutting

Dry concrete cutting, as the name suggests, does not use water. This technique is typically handheld, and it is used intermittently.

Following are the advantages of dry concrete cutting:

• No water source is needed on site.

• No electrical hazards from water coming into direct contact with equipment used for cutting concrete.

• It results in a cleaner job site, and you don't have to worry about messy wet slurry.

Here are the downsides of dry concrete cutting:

• It is suitable only for straight, shallow cuts.

• Since no water is used, dust accumulation at the job site is a problem. You may need to use dust extractors and other methods to mitigate dust-related health concerns.

• Overheating problems may arise since no water is used to cool and lubricate the concrete cutting blades.

Generally, dry concrete cutting is suitable for indoor jobs where you want to make straight, precise cuts at a shallow depth and you wish to keep the job site dry.

Wet Concrete Cutting

Unlike dry concrete cutting, wet cutting involves the use of water. There are certain key advantages of this, but there are also some downsides.

Following are the advantages of wet concrete cutting:

• Water cools and lubricates the cutting blades. It makes the blades last longer.

• Wet cutting is efficient for handling relatively larger jobs.

• It delivers more precise cuts.

• It minimizes the amount of concrete dust generated during the operation.

Here are the downsides of wet concrete cutting:

• A constant supply of water is required. It can be a hassle if a water supply isn't available on site.

• Using water increases the risk of electrical hazards on the job site.

• Wet concrete cutting leads to a messier job site as the mixture of water and concrete dust forms a slurry.

Wet concrete cutting is generally suitable for creating more precise, deeper cuts in concrete. Therefore, it is applicable in large-scale construction.

Conclusion – Which One is Better?

Which concrete cutting technique you choose should depend entirely on your specific project requirements. Both techniques offer clean cuts, and they are exceptional at their work. However, both have their unique advantages and drawbacks.

Choosing the right equipment and technique for each job to improve the tool and operator safety and manage any environmental impacts is crucial. If you are not sure which technique would be the best for your project, then it is recommended that you consult with your local concrete cutting Sydney for assistance.

0 notes

Text

The Husqvarna W70P is a powerful industrial vacuum cleaner designed for tough jobs in wet and slurry environments. Its stainless steel components and combination filter and float system protect the motor from damage, even when cleaning up messy or hazardous materials. The W70P can handle a wide variety of liquids, including concrete slurry, oils, and machining coolants. It is also capable of picking up solids, such as dust, dirt, and debris. To rent the Husqvarna W70P Slurry Vacuum from Rentalex, please call (813)971-9990 today!

See the Husqvarna W70P Slurry Vacuum here: https://www.rentalex.com/rental_equipment/tampa-floor-wall-finishing/vacuum-slurry-1-6hp-w70p-hq/

#husqvarna#husqvarnaW70P#W70P#slurryvacuum#husqvarnavacuum#husqvarnatools#rentalex#husqvarnaequipment

0 notes

Text

Dirt EATER Heavy Duty Cyclonic Industrial Vacuum Cleaner for Concrete Slurry Concrete Cutting.

Product Demo https://www.youtube.com/watch?v=dMwJGf0OH1Q

Call Today on 0426 291 402 Or Toll free 1800 438 822 or Email Us On [email protected].

Concrete #Cutting, #Concrete #Slurry #Cyclonic #Industrial #Vacuum #Cleaner #CleaningMachines #Cleaning

1 note

·

View note

Text

Oxfordshire Stone Floor Professional Details Renovation of Victorian Hallway Floor

This is a Victorian hallway floor laid in a classic Black and White diamond pattern at a property in the Oxford suburb of Headington. I suspect the floor is original and dates to 1890 when the house was built. Unfortunately, at some point in its recent past it was damaged during the installation of heating pipes and then backfilled with cement.

Here at Tile Doctor, we see this happen time and time again and have been brough into to restore many period floors such as this example. Gas and heating pipes are the most common reasons for digging up a floor but often the homeowner doesn’t know what to do to restore it so they either live with the defaced floor or more usually cover it with carpet or vinyl.

In this case the property had recently changed hands and the new owner was keen to have the floor restored to its original condition. Fortunately, here at Tile Doctor we are in contact with various companies that make reproduction tiles, so it is not a problem finding matching replacements. In this case I managed to find suitable replacements with a company called Original Features who specialise in reproductions. We visited site to have a look at the job and gave the owners a quote for the work which they were happy to accept.

Cleaning and Repairing a Victorian Tiled Hallway Floor

The first day was spent restoring the damaged floor by carefully cutting out the old cement backfill and replacing to a level that was just deep enough for the replacement tiles to fit. I then made up a concrete adhesive mix and smoothed this in the hole and laid the tiles making sure they were level with the original floor. This was then left to set overnight.

Day two’s focus was cleaning the floor, however given the age of the property I knew it would not have a damp proof membrane, so I was concerned about the use of too much water. Not wishing to exacerbate any damp issues I decided to go with a low moisture cleaning approach.

To do this a gel cleaner known as Tile Doctor Acid Gel was applied to half the floor and then scrubbed into the tiles using a rotary floor machine fitted with a coarse 100-grit diamond pad. Once done this was repeated on the other half of the floor. The tiles were then rinsed with minimal water and the soil extracted with the wet vacuum.

A 200-grit diamond pad was then fitted to the rotary machine, and this was used to further refine the appearance of the tiles using some water for lubrication. This was then followed by a series of Tile Doctor burnishing diamond pads with just water to rinse, clean and force a natural sheen on the floor, again a wet vacuum was employed to vacuum up the slurry. Last step before leaving for the day was to mop the floor with Tile Doctor Neutral Floor Cleaner and left the floor to dry.

Sealing a Victorian Tiled Hallway Floor

Returning on the final day, I set about sealing the Victorian tiles with Tile Doctor X-Tra Seal which is an oil-based sealer that enhances the Black and White colours in the tile. This sealer can also be used externally so it will cope happily with any damp issues that can occur on old floors.

Two coasts were applied allowing each one to dry before applying the next. When the seal was dry, I buffed the floor with a 3000-grit diamond pad to leave a hard-wearing natural sheen. The floor looked great, fully restored, and gave the homeowners a traditional welcoming hallway.

Source: Headington Stone Floor Cleaning and Sealing Service

#Acid Gel#Burnishing Pads#Floor Repair#Floor Tiles#hallway#Hallway Restoration#Headington#Neutral Tile Cleaner#Originalfeaturesuk#oxford#Replacement Tiles#restoration#Victorian Floor Tiles#X-Tra Seal

0 notes

Text

A Beginner's Guide To Concrete Walkway

Confined Alternatives: Given that they’re colored with pure clays, bricks have a lot more limited colour possibilities. They’re commonly rectangular in form and only can be found in a handful of sizes.

This decorative concrete walkway was established for El Cortez Resort & On line casino in downtown Las Vegas. 21,000 square feet of concrete were being poured foremost as many as the doorway with the lodge. The concrete was stamped and colored. Rollers and sprayers were being applied to use acid stains.

With decorative concrete, you retain amazing longevity with no sacrificing elegance. If your community necessitates you sustain a sidewalk that you think that is surely an eyesore, decorative concrete is a great concept to help keep up with area ordinances and completely transform the dull space into excess curb attractiveness.

Increase fashion and framework for your outside space devoid of breaking the bank Using these DIY walkway Tips to DIY ahead of summer months commences!

Discover the top stainless steel cleaner to really brighten up the chrome steel through your kitchen area! Preserve 25% with coupon MYHAUS25.

It could be combined with exposed aggregate finishes or incorporate a border to reinforce the glance of a specific pattern.

Pour a thin layer of slurry over a two-foot part of your concrete, then scoop mortar on top of it which has a shovel. Distribute the mortar to your one-inch thickness. The slurry functions as being a binding agent among the concrete along with the mortar.

We've got a sloped driveway that’s deteriorating. It’s a concrete driveway that a preceding proprietor chose to place a stamped concrete over leading of it. Lucky us-not. Now the stamped layer is crumbling and we’re checking out some enhancement selections.

Keep the Resource as flat as possible so You do not seal the floor, you would like the very best of the concrete to show plenty of air holes When you are concluded Along with the bull float. A bull float is often 4 toes vast so you need to go from side to side from the get rid of walkway.

On the subject of installing or restoring concrete walkways, Hello-tech Concrete is nearly as good as it receives. Adhering to are some great benefits of picking us to build your walkways.

action 1 Safety Retaining matters Safe and sound when working with concrete is essential. The acids in cement are irritating into the skin and eyes. It is a short define of the safety safety measures you must just take when dealing with concrete.

This household walkway was designed utilizing many styles to stamp the concrete; a seamless Italian slate texture and ribbons stamped utilizing a London cobblestone. The concrete was coloured using a cream beige hardened and contrasting walnut release. See additional pictures from this contractor >>

youtube

Spray it periodically with drinking water to avoid it from cracking. Leave it moist for the following 5 to 7 times before using or stepping on it. Repeat the methods 2 to 4 as required.

Inspite of simplicity of set up, concrete slab walkways demanded routine maintenance as you’ll need to seal them on a regular basis to maintain water out and become diligent about getting rid of concrete stains as It is just a porous content.

0 notes

Text

12 Helpful Tips For Doing Color Correcting Stamped Concrete

Labor is A part of this concrete leveling or slab jacking estimate. Value accounts for pumping slurry into drilled holes to boost volume of sunken concrete slab and stabilize subsoil. Further cost for pouring new concrete, concrete elimination, concrete demolition, or tree removal.

"I had been so amazed Along with the kindness and professionalism in the crew. Whenever we had inquiries or problems, they answered and handled them to our pleasure whenever. The finished product or service is beautiful. We Unquestionably like our stamped concrete patio!"

The color on the patch need to match the color with the stamped colored concrete precisely or no less than be as near as you possibly can. If the crack is a little bit tiny, a intently relevant color will not be as noticeable, but when the crack is massive, it may well demand a precise match in an effort to conceal the repair.

Mark Sisco As a previous service veteran of our army, Mark proceeds to provide his customers While using the same enthusiasm and zeal for offering a first-class product or service and service towards the people of Colorado Springs and surrounding communities. Mark and his crew consider good delight in giving a myriad of very affordable options and solutions to clientele in beautifying their indoor and outside dwelling regions.

These are all superior arguments for applying tinted liquid release in lieu of powder. It really is undoubtedly more quickly and cleaner, and in the event the liquid evaporates There may be powdered antiquing release left pooled from the minimal places.

Homeowners enjoy The reality that they might restore their earthquake damaged concrete with no cost, and more so, the disruption that is a result of a complete removal and replacement. Just like all crack repairs, we are unable to guarantee that over time (especially in metropolitan areas like Christchurch exactly where earthquakes are an everyday risk) substrate motion or tree roots, to call several examples, could probably open up the cracks or develop new types.

Stamped colored concrete might develop cracks after the stamping process or soon after lengthy exposure to site visitors along with other exterior things.

Remark: We have a six' tall garden stage patio below our back again deck. At present We've rock beneath the patio, which fits together the back of your house concerning the home and also the yard. We have an interest in ideas with regards to how we can easily far better make use of this space.

Posted: May 6, 2019 Just take your out of doors living spaces to another standard of design, comfort and ease, and durability with our concrete services. Concrete patios are ideal for homeowners who want to build or improve their out of doors living and entertaining places. E & J Concrete has many different patio stamped concrete patterns and textures to remodel your normal concrete slab patio into a stunning and sturdy surface area wherever family and friends can gather safely.

Opt for a Key, integral color for The bottom mix then "flash" or dry-shake a colored, powdered hardener to the area from the concrete in 4 or five different accent colors.

Upon washing and sealing, the primary difference in color among the fundamental concrete as well as the release generates a visually beautiful, antiqued glimpse into the concrete. The added color presents the appearance of depth.

youtube

A well-liked texture particularly when utilised with brick or tile grout traces. An integral color working with a rather darker green or grey release powder to accentuate the pattern would be very result Wooden Grain

Before you begin an real job, consider basic color schemes. "I use a color wheel continuously," says Lee Levig, operator of Concrete Is effective from the San Francisco Bay region, to determine colors for picks ranging from monochromatic and break up complementary to complementary and analogous.

The completed microtopping surface is always sealed the moment finished to shield the floor and lock while in the colour.

0 notes

Text

Slab Raising, Do It Yourself

A section is a location regarding 10 x 12 ft. that is defined by the existing control joints. Prior to starting, power laundry the whole surface area and brush it with a tight mop and a cleaner/degreaser concentrate offered from the equipment shop. Nevertheless, even newer driveways can have bad foundations. After a number of years of rain, snow, and also hundreds of lots worth of automobiles driving over it, foundations can start to wear.

Why is my concrete driveway flaking?

Mudjacking can last for long periods, but it is inherently less reliable and usually does need to be replaced. The injected materials are extremely heavy (30-50 times heavier than their polyurethane equivalent) and can cause a new round of soil compression (and foundation sinking) beneath the slab.

If necessary.You can also include shades or patterns if you so desire, the work can be done across several different days. If your residence driveway, service car park or other surface shows indications of aging, do not automatically think that concrete elimination is your only choice. Resurfacing is promptly spilling right into the mainstream forever reason. When you can resurface it for a fraction of the expense, there is no sense in paying for a totally new driveway or vehicle parking great deal. To bond efficiently, an overlay requires a tidy surface area.

What you NEED to Learn About Concrete Lifting Foams.

Can you pour new concrete over old cracked concrete?

Concrete resurfacer is a very strong product, rated for a compressive strength of about 4,500 psi. This is actually stronger than the slab itself, so properly applied, resurfacing layers can be very durable.

Be sure when you buy excellent hardware shop C-clamps that are heavy duty, not those from Harbor Freight or a 'Made In China' tool shop. A buddy that has apartment buildings had a slab-jacking company pump in broadening foam. Yet this Foamular is actually designed to be installed under concrete. It is made use of in new building to insulate floors and also walls! Don't try this on your own unless you have correct tools as well as take safety precautions.

What is the best concrete adhesive?

Driveway resurfacing, however, can solve widespread damage without digging up the driveway, foundations and all. Resurfacing is when new asphalt is poured over the old layer. If your driveway has bigger holes or cracks in a small area, you may be able to patch it yourself.

Increase slab HIGH SUFFICIENT to glide in the foam Concrete Driveways in manageable items. No need to cover the whole location underneath the piece with foam - covering regarding 1/2 of the area or even more will certainly suffice. Safeguard the existing growth splits with weather condition removing. They're an indispensable part of your driveway's structure.

After several hrs, the coating will certainly support foot web traffic. Allow the product set up and also use a 2nd layer later in the day if the pits still show.

Prior to you include your new concrete, take a large brush and also dip it right into the bonding slurry.

Mix up a stiff batch of resurfacer, making use of just enough water for a practical uniformity.

Think it or not, that's all it requires to restore the look of your driveway for the life of the concrete piece.

Similar to driveway resurfacing, you'll require to take a look at the cracks. If they are wider than a fifty percent inch as well as several inches deep, it's time to do something about it. These are as well big to secure well and recommend a loosened, failing structure.

Does foam jacking last?

youtube

Unlike other cement products, it is designed to be applied in very thin coats (no more than 1/2 inch thick), and its additives provide good adhesion to an existing slab. Concrete resurfacer is a very strong product, rated for a compressive strength of about 4,500 psi.

The concrete requirements to be solid.Any damaged materials need to be gotten rid of from the edges of cracks and also loosened concrete broke away with a little hammer and also carve. This assists patching materials remain in location to maintain the cracks from redeveloping. A degreaser or meal cleaning agent used with water and also permitted to remain on the concrete surface for thirty minutes before washing and also drying provides a clean surface area to begin the task. The majority of the time, however, you can anticipate the new surface area to be prepared for foot web traffic in about six hrs. Resilience ranks high amongst the numerous reasons to choose concrete as a driveway emerging material.

But you can quit with one coat if it offers excellent protection. Press the squeegee onward under moderate pressure to function the resurfacer into the concrete and compel it into matches and pores.

Will Great Stuff foam lift concrete?

Remove large chunks of broken concrete and sweep out the hole with a stiff broom; flush it thoroughly with water from a garden hose. Then remove standing water with a sponge. Mix ready-mix concrete according to the manufacturer's instructions; use sand mix for small holes and gravel mix for large or deep ones.

On the other hand, replacing the driveway is a complete overhaul. Driveway resurfacing, however, can fix extensive damages without excavating up the driveway, foundations and also all. Make no mistake ... there are certain circumstances when it's finest to tear out existing concrete and rebound by soaking a compacted rock or sand base.

Load Cracks http://dominickeayv027.unblog.fr/2020/04/30/3-signs-its-time-to-change-your-concrete-driveway/ and Holes

For instance, if you have large working splits in your slab and the concrete has actually worked out to the point that it's at a number of different levels, you should remove it. Similarly, if tree roots are creating your existing concrete to heave, after that it's best to remove the concrete, resolve the origin issues, and also start fresh. Possibly door limits or stair riser heights are a problem as well as you just can't pour any kind of greater without developing troubles. Any one of these are great reasons to get rid of the existing concrete and also go back to square one. In hot, dry weather, it's an excellent suggestion to haze the hard surface area; maintaining it damp longer will allow the resurfacer to fully harden.

0 notes