#compound fertilizer equipment

Explore tagged Tumblr posts

Text

youtube

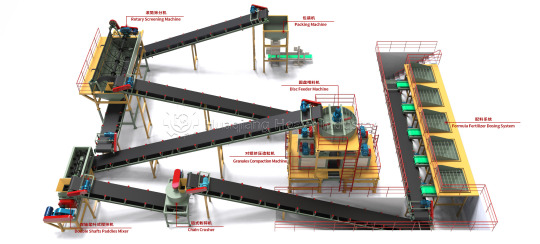

NPK compound fertilizer granulator supporting device, fertilizer making machine, Granulation device.

Hello Everyone, welcome to our Zhejiang Tongli Heavy Machinery Co., Ltd Official Channel, In this video we will Introduce the supporting device of the granulator as well as the rotary drum cooler supporting device and rotary drum dryer supporting device and rotary drum coating machine supporting device.

website: https://www.cementl.com

Email: [email protected]

whatsapp: +86 15988878668

#compound fertilizer production line#youtube#ballmill#compound fertilizer equipment#fertilizer production equipment#fertilizer#fertilizer production plant#fertilizer manufacturing equiptment#fertilizer plant equiptment#fertilizer plant machinery#metalcasting#foundry#npk fertilizer production#zhejiang tongli#fertilizermanufacturingequiptment#fertilizerplantequiptment#fertilizerplantmachinery#tongli zhejiang#zhejiang tongli heavy machinery manufacturing#Youtube

0 notes

Text

NPK Manufacturing Machines & Fertilizer Cooling Equipment | NPK Fertilizer Solutions

Discover high-quality NPK manufacturing machines and fertilizer cooling equipment at NPK Fertilizer Solutions. We specialize in advanced NPK fertilizer equipment, designed for efficient production processes. Our solutions include cutting-edge machines for NPK fertilizer production, cooling, and processing, ensuring high-performance and optimal yields. We also offer specialized palm fiber crushing production lines for enhanced fertilizer manufacturing. Visit us today to explore reliable, cost-effective machinery for your fertilizer production needs. Click to Know More -

0 notes

Text

CLASSIFIED OPERATION SUMMARY

DRC, Planning & Evaluation Office, Logistics & Infrastructure Division

Date Initiated: [REDACTED]

From: Assistant Director [REDACTED], Logistics & Infrastructure Division

To: Director [REDACTED]

Subject: Operation Overdue

Background

Paternity Compound 110 exceeded maximum capacity due to an influx of high-multiparity surrogates and operational delays due to the ongoing [REDACTED] in the Philadelphia metropolitan area. Overcrowding led to strained medical staff and diminished care standards.

Operation Overdue was launched to mitigate these risks. It was a cross-country air transport initiative intended to distribute surrogates to Paternity Compound 133 in Portland, far below occupancy capacity. This initiative required covert execution to avoid public attention and ensure all surrogates reached their destination intact.

Paternity Compound 110 (Philadelphia)

Paternity Compound 110 is an aging and overcrowded facility located in a repurposed commercial structure in Philadelphia. Designed to house a maximum of [REDACTED] surrogates, it currently holds over [REDACTED] (20% over capacity), leading to severe resource strain and cramped conditions. Despite its deteriorating infrastructure, the compound remains operational due to its proximity to a high-fertility urban population, ensuring a steady influx of conscripts.

Paternity Compound 133 (Portland)

Paternity Compound 133 is a modern, state-of-the-art facility in a remote area outside Portland. It is designed to accommodate up to 1,000 surrogates and boasts cutting-edge medical technology and advanced monitoring systems. However, its location in a region with a lower urban population has led to concerns about underutilization, with only a sporadic influx of conscripts to fill its capacity.

Transport Details

Stage 1: Ground Transfer

Surrogates were loaded into climate-controlled transport vehicles with hydraulic lifts to accommodate limited mobility.

Vehicles were disguised as commercial cargo containers to minimize civilian interference.

Stage 2: Cross-Country Airlift

[REDACTED] cargo planes were requisitioned from [REDACTED] for the operation. Each aircraft was retrofitted with cushioned flat beds, oxygen units, and onboard medical stations.

Medical personnel monitored surrogates for complications, administering sedatives to those exhibiting distress or restlessness.

“Flying cargo is one thing. Flying this cargo? Another beast entirely. I could hear the medical staff scrambling in the back every time we hit turbulence. It wasn’t until we touched down that I realized how close we came to disaster.” - [REDACTED], Pilot

Stage 3: Arrival & Integration at Compound 133

Surrogates were offloaded and delivered to their assigned wards, where medical personnel assessed their condition.

Immediate hormonal stabilizers were administered to counteract the physical strain caused by altitude changes and prolonged immobility.

Mobility & Transport Constraints

Issue

Many surrogates, especially those late term (+25 days), were unable to walk or sit upright due to the size and weight of their pregnancies. The average weight of surrogates and supporting equipment was over [REDACTED] lbs, +300 lbs average surrogate weight, 489 lbs max weight transported.

Solution

Specialized equipment, such as reinforced stretchers, forklifts for heavier surrogates, and bariatric wheelchairs, was employed to move surrogates from Compound 110 onto the planes. Stretchers were secured in a palletized format inside the aircraft to maximize space.

“The forklift crew had a hell of a time loading the bigger ones. You’d think they were moving industrial machinery, not people. One was so massive they had to be rolled onto the stretcher like a beached whale. It wasn’t pretty.” - Anonymous Ground Technician

Issue

While the standard [REDACTED]-type plane has a cargo capacity of approximately [REDACTED] lbs and an internal volume of [REDACTED] cubic feet, the vehicles needed retrofitting to accommodate the unique needs of heavily pregnant surrogates. This included safety measures for turbulence and environmental controls to maintain appropriate temperature and pressure levels.

Solution

The [REDACTED]-class plane could transport [REDACTED] surrogates per flight with DRC modifications.

Planes were equipped with mobile dividers so that if surrogates suffered complications, they could be rapidly isolated from view for treatment or birth. Climate control systems were enhanced to maintain a stable environment and portable restroom facilities were added for staff use (surrogates were catheterized to avoid the need for movement).

“They told me this was for my own good, but I can barely breathe in here. Every bump in the air made it feel like my belly was going to burst. I just want this to end—I don’t care where we’re going.” - Surrogate S110-523-Q

Key Incidents

Mid-Transport Medical Emergency

During the flight, Surrogate S110-399-Q, pregnant with septendecuplets (17), began exhibiting severe respiratory distress. Initial symptoms included difficulty breathing, chest tightness, and visible [REDACTED]. Onboard medical personnel swiftly administered oxygen and sedatives to stabilize, but within minutes, signs of early labor emerged, prompting the emergency medical team to prepare for an in-flight delivery.

The medical team worked tirelessly to assist the surrogate as he delivered all 17 fetuses before arrival in Portland. Each newborn was immediately evaluated for viability and determined to be stable. As expected, the surrogate's vital signs rapidly declined following the final birth, and he succumbed to [REDACTED] failure.

"I’ve never seen anyone that big in my life. I couldn’t stop staring. His belly was so massive it looked like it was about to split open. When he started struggling to breathe, the medical staff was all over him, but the sounds he made… it was like he was suffocating under his own weight..." - Surrogate S110-403-I, Observed Situation

Public Visibility Concerns

Several bystanders filmed the convoy and uploaded clips online during the ground transfer stage. DRC Cyber Security immediately intervened, scrubbing social media platforms and issuing cease-and-desist orders to content creators.

Surrogate Stuck in Chair

One surrogate, pregnant with octodecuplets (18), experienced significant growth during the flight, reportedly due to hormonal surges and fluid retention. Upon landing, the crew discovered that the surrogate had become physically wedged in his reinforced seat due to his expanded abdomen and swollen extremities. Extraction required the partial disassembly of the seat and the use of specialized equipment to free him.

“I wasn’t even surprised anymore. His belly was literally spilling over the armrests. That’s when you realize these missions aren’t just logistical—they’re borderline impossible.” - Anonymous Transport Specialist

Behavioral Issues

Three surrogates attempted to resist boarding at Paternity Compound 110, citing fears about the unknown destination and poor treatment. They were sedated on-site and securely transported.

Post-Operation Notes

Total Surrogates Transported: [REDACTED]

Surrogates Expired En Route: [REDACTED]

Fetuses Delivered During Operation: [REDACTED]

While operational challenges were anticipated, the results align with DRC efficiency standards. The use of modified cargo planes and specialized medical protocols ensured the safe delivery of most surrogates despite several complications during transit.

Additional safeguards are required to manage the physical strain of long-term pregnancy during extended transport. Enhancing hormonal regulation pre-flight may mitigate extreme growth events.

Stronger sedation measures, particularly during boarding, will reduce incidents of resistance and streamline pre-departure logistics.

Transport plans must minimize exposure to the public. Future operations should prioritize routes and timing to limit interaction with civilian populations.

Conclusion

Operation Overdue underscores the complexities of large-scale surrogate relocation efforts and demonstrates the DRC’s capacity to execute such operations precisely and adaptively. Lessons learned during this mission will inform future strategies, ensuring the continued success of critical population sustainability initiatives.

----------------

Click Here to return to DRC Report Archives

#mpreg#mpregkink#malepregnancy#mpregbelly#pregnantman#mpregmorph#mpregcaption#mpregstory#mpregbirth#mpregart#mpregnancy#aimpreg#mpregroleplay#malepregnant#caucasianmpreg

70 notes

·

View notes

Text

Weird idea I sent someone else but is now putting on my blog to add on to,

The Primes are kinda weird being literally demigod, and one of the weirdness is their interface equipment to ensure successful breeding, cuming twice from the spike in overload, first with normal transfluid rich with nanites and other things for sparking up a nice healthy forge, second with a thicker, more viscous transfluid that harden quickly to keep the first nice and sealed in the forge, incidentally hardening into a slightly bigger plug because it mold around the spike while it's still inside and filling in the mold. The plug dissolve by itself to become extra material for the forge but it's a slow process, VERY slow. Something Sentinel is very intimate with.

Sentinel having to go about his day with his forge swollen with transfluid and valve stretched and full, plugged up with one of the Primes hardened transfluid in roughly the shape of their own spike but slightly bigger. Sentinel has a slight bump on his lower stomach due to it, spending days to weeks unconsciously squeezing around it, milking it like a real spike. There is no moment his valve is empty because the moment the plug dissolves enough, a spike sheath is kissing his valve lips again.

It has gotten to the point where Sentinel's body is so prime for sparking, his belly swell out a bit making him look low-key gravid because his forge is HEAVY with material, making the Primes even crazier about him, if they are not putting their spike in him, they put their mouths and hands on him.

Unfortunately for the Primes, Sentinel is not keen on having a sparkling so they are going to have to use their imagination, it's not that hard with that beautiful fertile bump.

The Primes' valves are design to completely milk and drain a spike until it physically can't, like, big, plush lips just suctioned to the spike housing, it doesn't matter what size the spike, it's not leaving until that transfluid reserve is not only empty but also temporary shutting down from overwork. The electro magnet in their valve is so strong that it keep the spike constantly erect as long as there is still something in that transfluid reserve.

It work better than any chastity safeguard because afterward that spike is Done.

Additionally, the mating plug can actually be melt away from compound found in the Primes' saliva. So when someone wants to rut their spike into Sentinel's hot fertile body when the plug is still there, they give him At Least an hour of head before they can get to that nice breeding frag, with some deep Frenching to make sure all that extra material stay inside, they don't need to go that long they just wanted eat some valve

Sentinel is constantly in a weird zen where his spike is just I Done My Job and his valve is just uncontrollably clenching around a plug bigger than the spike of the Prime it belong to, the tip holding open but sealing the entrance to his heavy, transfluid stuffed forge, it's a miracle he manage to walk muchless do his job.

At this point in their (onesided) relationship, the Primes are so down with the idea of conjunxing him and just having a consort suit for him so they could just come frag him until he pops open his spark chamber so they could put a sparkling in him

Sentinel, on the other hand, is so focus on his job and mildly addle from overloading his processor out all the time that he is completely obvious that his bosses want to whisk him away to a life of leisure stuffed with their spikes, ocassionally getting his spike put out of commission from sheer usage

43 notes

·

View notes

Text

Uncovering the unreleased Far Cry 5 in-game Encyclopedia

The almost complete but unused in-game encyclopedia, reconstructed thanks to the oasisstrings file.

Please note that it’s still cut content, so some information might not be relevant anymore.

You can read the oasisstrings file here. Pictures from this encyclopedia were also extracted and posted by @xbaebsae here.

Part 2: Locations - Holland Valley

Gardenview Packing Facility

The last facility added to the Hadlers' apple empire. They shipped their apples throughout Hope County and beyond. When the cult went red state, the Hadlers stopped their legal threats and resorted to violence.

Silver Lake Trailer Park

A community of people just trying to do their best.

Gardenview Orchards

A part of Doug and Debbie Hadler’s apple empire. After their ciderworks facility, they expanded to a second, larger orchard: Gardenview Orchards. Then they opened the Gardenview Packing Facility.

Rae-Rae's Pumpkin Farm

Fiery matriarch Rae-Rae Bouthillier cares about two things: Prize-winning pumpkins and her dog Boomer.

Gardenview Ciderworks

The first major facility owned by Doug and Debbie Hadler. Ten years ago, they had a dream: an empire made of apples. They nearly achieved it too, until the cult forcibly took over everything they had worked for.

Bridge of Tears

It was called the Mišihrew Bridge when the railroad was still active. It’s now a rickety old train bridge and John Seed's ideal location to send a warning message to all sinners.

Frobisher's Cave

In 1970, a cougar, named "Frobisher" by the locals, killed the star pitcher of a rival baseball team. The Hope County Silver Foxes won that year and changed their name to the Cougars in Frobisher's honor.

Howard Cabin

Home of Niesha Howard, an extreme rock climber from Canada who moved to Montana to be a prepper.

Copperhead Rail Yard

Copperhead Rail was created in the late 1800s by Emmet Reaves. It was shut down in the early 70s and a lot got left behind. It became a place for kids to get drunk or bums to find shelter, then the cult bought it.

Lincoln Lookout Tower

It’s the last working fire tower in the county. A man who worked here promised to help the Strickland family fight off the cult if ever their farm was under attack.

Sergey’s Place

A hobo historian calls this place home. Nobody's seen him in a while though.

Boyd Residence

Will Boyd lives here, or at least he did. No one in the valley talks about him. And for good reason.

Strickland Farm

Property owned by the Strickland family of farmers. No friends to Eden’s Gate.

U.S. Auto

A scrap yard containing trashed cars, broken farm equipment, and even a few busted planes. Eden's Gate uses the garage to build and maintain their convoys.

Doverspike Compound

Les Doverspike was a militia nut and he built himself a bunker. Nobody in the prepper community liked him. Despite that, he was anti-cult and pro-Resistance.

Harris Residence

Mike and Deb Harris were preppers with a cunning plan to keep themselves fed after the end of the world.

Reservoir Construction Yard

Deep North Water wanted to build a new reservoir for the Holland Valley. The company ran out of funding and was chased away by Eden’s Gate.

Dodd’s Dumps

Colin Dodd used to run garbage disposal for the whole Holland Valley, and his business lot shows it. The cult intimidated him into leaving but has yet to sort through all he left behind.

Davenport Farm

The remains of a run-down farm. Local farmers let their cows graze here. Can't let good land go to waste.

Hilgard Electric Power Station

The Holland Valley's power supply is reliant on this transformer station which is controlled by Eden's Gate.

Golden Valley Gas

Once the kind of gas station that gave out free bubble gum to kids, Golden Valley is now a strategic point of gasoline and auto maintenance for the Project at Eden's Gate.

Green-Busch Fertilizer Co.

Facing a decline in business, the Green-Busch family said “yes” and sold the place to John Seed on the condition that locals could keep their jobs and work alongside Eden's Gate.

St. Isidore School

Once a religious boarding school, it was forced to close its doors by Eden's Gate.

Dodd Residence

Home of Colin Dodd, hoarder and DIY enthusiast. He never throws anything out. His granddaughter Nadine's been known to lurk here.

Roberts Cabin

Home of Joe Roberts, a hunter. He's gone missing. He loved hunting deer above all else.

Hope County Clinic

Dr. Kim Patterson provides medical services to Hope County's farmers and low-income residents, many of whom would never receive care in such a remote area.

Holland Valley Station

In the days that it was up and running, Copperhead Rail used to stop here. Eden’s Gate uses this station to catch people who try to escape the region.

Grain Elevator

As the farmlands started to collapse, the grain elevator was the first casualty. Too expensive to maintain.

Henbane River Rail Bridge

Copperhead Rail was created in the 1880s during a mining boom, and shut down in the early 70s after the industry collapsed.

Flatiron Stockyards

Bobby Budell established the stock yards in 1946, and has proudly provided farm and ranch auction services since. The economic and community base employed over 25 people at its height.

Fillmore Residence

Home of Doug Fillmore. Not much is known about him.

Dupree Residence

Home of Tommy Dupree, an idiot who used to work at Green-Busch Fertilizer Co. He got fired by Eden's Gate because he was as dumb as the crap he bagged.

Catamount Mines

Fall’s End owes its existence to the gold Orville Fall discovered here in 1865. The mine brought a generation of prosperity to the region until a suspicious accident entombed 100 men within it, forcing its closure in 1912.

Sunrise Farm

Sunrise Farm was going under, so owners Mike and Chandra Dunagan reluctantly sold it to Eden's Gate. Big mistake.

Deep North Irrigation Reservoir

Originally designed to irrigate farms, the reservoir became a liability when the cult began putting Bliss in the water supply. The Resistance sealed it up to buy themselves time.

Red’s Farm Supply

The Redler family has run this place for 4 generations, and earned a reputation for honest business. Wendell did his best to keep it out of cult hands.

Purpletop Telecom Tower

In the 1950s, Purpletop Telecom built this tower, blessing people with the wonders of AM radio. As time and technology marched forward, they were also given the American splendor of a local TV station.

Woodson Pig Farm

This place has been in the Woodson family since 1943. Current owners Andrew and Frances Woodson used their wealth to try to stand up to John Seed and fight him in court. They lost, and joined the Resistance.

Sawyer Residence

Don Sawyer came from out of town to join the Project at Eden's Gate. He restores canoes, but isn't very good at it. Visitors have sworn they've heard him swearing in Russian over those boats.

Hyde Barn

Kenny Hyde's a poor man in Holland Valley, but that doesn't stop him from loving deep fried balls. He's the proud keeper of Fall’s End Testy Festy decorations, stashing them at his barn until they're needed.

Kupka Ranch

Zip Kupka's the only one who really knows what's going on in the Holland Valley.

John’s Gate

A missile silo long decommissioned and abandoned. The locals used to call it "Area 68." Eden's Gate bought it in secret and turned it into a bunker that is in John Seed's safekeeping until the Collapse.

Security Gate

Formerly the entrance to the missile silo, it's now the gateway to John Seed's bunker. Everything taken in the Reaping passes through this checkpoint.

Steele Farm

The Steele family managed to get their kids out of Hope County, but stayed behind to try and defend their home from Eden's Gate.

Lamb of God Church

A Lutheran church. Its elderly priest was overshadowed by Pastor Jerome’s charismatic sermons. John once asked the priest to say “yes.” Not a chance. Then, the priest was gone. He had taken a “long vacation.”

Lamb of God Sacristy

The Project at Eden's Gate has turned the Lamb of God Church's sacristy into a holding place for everything they need to baptize people at the water's edge.

Armstrong Residence

The Project at Eden's Gate targeted the Armstrong family early, burning their home to the ground when Grace Armstrong refused to devote her sharpshooting skills to the Father's cause.

Bradbury Tractor Shed

A shed for tractors.

Hope County Jail Bus

Prisoners hijacked this bus but were run off the road. The wreck was left to rot in the woods. When Eden's Gate brought prohibition to Hope County, some enterprising moonshiners set up shop behind the cult’s back.

Parker Laboratories

Home and workshop of Dr. Laurence Parker, and the origin of many mysterious noise complaints.

Seed Ranch

The power of yes gave John Seed this dream ranch overlooking the Holland Valley. it has commanding views, a private air strip, and secluded soundproofed rooms for his most invigorating religious pursuits.

Bradbury Farm

The home of the Bradbury family, hay farmers for generations. The strange pattern of dead hay in the field does not impact the quality of the final product. That's the Bradbury guarantee.

Bradbury Hay Field

Bradbury Farm's hay is baled and stored here before being sold to clients looking to feed their livestock with quality hay.

Laurel Residence

Laurel family honey was a local market favorite until their bee colony collapsed and jeopardized the business. It also spooked the Laurels who sunk money into a bunker and became preppers overnight.

Eden’s Gate Greenhouse

Bliss plants are found throughout the Henbane River, but they're also found here. John Seed takes the flowers he receives by boat from the east and plants them in his greenhouse.

Seed Boat Launch

Once a favorite spot for summer frolickers, this boat launch is used by John Seed for receiving shipments of Bliss and other supplies from elsewhere in Hope County.

Rye & Sons Aviation

This plot of land was first settled in 1920 by Willard Rye. He started a crop dusting business. His sons inherited both and it now belongs to the current generation of Ryes: Nick & Kim.

Kellett Cattle Co.

The Kellett family supplied beef for 3 generations. These proud Republicans thought they recognized the American spirit in Eden’s Gate, but when John Seed asked them to serve the Project, they said “no.”

Fall’s End

After prospector Orville Fall struck gold, his small mining camp quickly grew. Decades later, his rival, rail baron Emmett Reaves, shot him dead in the streets, giving the town its official name.

Old Silo

Welcome to the middle of it.

Kay-Nine Kennels

The owner, Kay Wheeler, loved her dogs more than life itself. She bred and trained hunting and guard dogs. When Eden’s Gate showed up, the local demand for guard dogs tripled. John Seed noticed and took action.

Sunrise Threshing

A silo and shed complex attached to Sunrise Farm. Rumor has it that Mike Dunagan's stashed a lot of cool shit around here somewhere.

Redler Residence

Home of Wendell Redler, local businessman and Vietnam veteran.

Adams Ranch

Jules Adams lost her husband in an "accident" after saying no to John Seed. Her family's struggled to keep the cattle ranch out of cult hands ever since.

Miller Residence

Despite financial hardship, the Miller family refused the cult’s invitations, prepping for doomsday all on their own. When the reaping came, Jerry Miller was out working.

Wellington Residence

The Wellington family mine is an urban legend, supposedly stuffed with gold, explosives, or both depending who you ask. Generations of Wellingtons (possibly inbred) have tried and failed to strike it rich here.

#far cry 5#hope county#holland valley#boomer#wendell redler#kenny hide#zip kupka#john seed#jerome jeffries#grace armstrong#larry parker#nick rye#kim rye#far cry absolution#will boyd

111 notes

·

View notes

Text

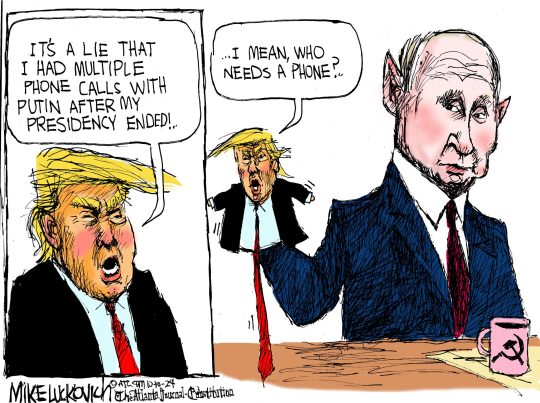

Mike Luckovich

* * * *

“It’s lies all the way down.”

October 9, 2024

Robert B. Hubbell

Oct 10, 2024

“It’s lies all the way down.”

An apocryphal story tells of a skeptical audience member who challenged a 19th-century astronomer after a lecture in which the astronomer asserted that the Earth is round and suspended in space. The skeptic told the astronomer that the Earth rests on the back of a giant turtle (a myth with an ancient heritage). The astronomer patiently pushed back, asking, “On what does the giant turtle stand?” The skeptic replied, “On another giant turtle.” The astronomer persisted, “And on what does the second turtle stand?” The skeptic responded, “You aren’t going to trick me! It’s turtles all the way down!”

So, too, with Trump world’s cascade of lies. It’s lies all the way down. It is impossible to disprove lies that disappear into a bottomless cesspool of falsehoods. Trump’s self-replicating lies are a virus compounded by the absolute lack of shame or remorse when the liar is caught in the lie. The last forty-eight hours have given us the textbook example of Trump's “respond to disproven lies with bigger lies” strategy.

On Tuesday, multiple outlets reported that Trump sent Vladimir Putin an early Covid testing machine. Putin instructed Trump to keep the transaction secret because it would prove embarrassing to Trump. (In fact, as noted below, the transfer was probably illegal.)

The story of the Covid testing machine gift to Putin was met with a furious, unequivocal denial by Trump and his spokesperson. Trump told ABC News, “That’s false. He [Bob Woodward] is a storyteller. A bad one. And he's lost his marbles.

Trump's shameless campaign spokesperson, Steven Cheung, dismissed the stories, saying,

None of these made-up stories by Bob Woodward are true and are the work of a truly demented and deranged man who suffers from a debilitating case of Trump Derangement Syndrome.

On Thursday, a Kremlin spokesperson made a liar out of Trump, confirming that Trump did send a Covid testing machine to Putin during the early days of the pandemic. See Axios, Kremlin refutes Trump denial on sending Putin COVID testing equipment. The original report of the Kremlin statement is here, behind a paywall: Bloomberg, US Elections: Kremlin Confirms Trump Sent Putin Covid Tests While President.

To recap: Trump and his campaign issued a flat-out denial of Woodward’s report. The Kremlin confirmed the report, proving that Trump was lying about a matter that posed the risk of blackmail by the Kremlin.

How can this man be president?

And, just as importantly, why is the story of this blatant lie not the leading story on every newspaper and website, accompanied by a red-flashing siren graphic? But as of Thursday evening, that outrage—or even news coverage—was missing from major media.

This isn’t just any lie. It is a lie about an action by Trump that likely violated the US sanctions embargo in effect at the time. See Lucian K. Truscott IV, Kremlin confirms that Trump sent COVID testing equipment to Putin (substack.com). (“Russia was under strict sanctions by 2020, which were imposed under the Obama administration after Moscow invaded and seized the Crimean peninsula from Ukraine.”)

The media is reporting that Trump has been caught lying. But those stories lack the analysis of “So what?” and “Why does it matter?” No other candidate caught in such a lie would survive the press firestorm that would follow.

But here, the response is “crickets.” Nothing. Nada. Zip. The press spilled tankers of ink over whether Tim Walz and his wife used “IVF��� versus “fertility treatments” twenty years ago. I hope that major editorial boards are furiously working on opinion articles that say, “Trump is a liar who is unfit to be president.”

The second part of Woodward’s story will likely prove true, as well. On Wednesday, JD Vance said, “I haven’t talked to Trump about this, but even if he did talk to Putin, what’s the big deal?” See HuffPo, JD Vance Scorched For ‘Grotesque’ Defense Of Trump’s Reported Chats With Putin.

In case you missed the point, Vance’s comments are a set-up for the revelation that Trump did, in fact, speak to Putin on a half-dozen occasions after leaving office—in direct contradiction to Trump's denials.

Why do those conversations matter? Because the DOJ has accused Russian interests of actively interfering in the 2024 presidential election. The fact that Trump is holding secret discussions with Putin at the very moment that Russia is interfering in our elections creates the strong implication that Trump and Putin are coordinating those efforts. The burden lies on Trump to rebut that logical inference.

The problem with Trump's constant lies is that they are not limited to his treachery. He lies about immigrants, elections, the economy, and natural disasters. Trump has managed to create distrust between victims and first responders. He has encouraged potential victims to ignore evacuation warnings because they wrongly believe FEMA will seize their homes if they leave. He has caused his followers to believe that the government can control and direct the weather to “red states” or “red counties” in purple states.

Marjorie Taylor Green tweeted that hurricanes are striking “red” states because “they” control the weather. She also famously claimed that wildfires in California were caused by “Jewish space lasers.” It is always only one step from any conspiracy theory to antisemitism. (Josh Marshall of Talking Points Memo has an important story about antisemitic texts being sent to Florida voters connecting disaster relief lies and US support for Israel. See TPM, The Text Campaign Underworld and the Florida Anti-Semitism You Can Find There. This article may be behind a paywall.)

It has become so bad that President Biden took to the airwaves on Wednesday to deny that the US government controls the weather. See Talking Points Memo, Biden Forced To Remind Everyone He Doesn’t Control The Weather.

When the media ridiculed Marjorie Taylor Greene’s ludicrous lie, her response was to double down with more lies. See The Independent, Marjorie Taylor Greene doubles down on weather control conspiracy theory despite experts rubbishing ‘hurricane modification’.

Marjorie Taylor Greene expounded,

“Everyone keeps asking, ‘who is they?’ Well, some of them are listed on NOAA, as well as most of the ways weather can be modified . . .” Greene also attached screenshots of “weather modification project reports” from the National Oceanic and Atmospheric Administration [NOAA] website.

Marjorie Taylor Greene’s attack on NOAA is consistent with the goals of Project 2025. Project 2025 proposes the “commercialization” (read: privatization) of NOAA’s weather forecasting function.

Per PBS, Project 2025 “describes NOAA as a primary component “of the climate change alarm industry” and said it “should be broken up and downsized.”

Republicans are institutionalizing lies. For example, in Florida, Governor Ron DeSantis signed a bill in May that removes the term “climate change” from state law and “deprioritizes” efforts to fight global warming. See NPR Florida Gov. DeSantis signs bill that deletes climate change from state law. DeSantis said when he signed the bill that “I am not a global warming guy,” but 90% of Floridians believe climate change is happening now. After Hurricane Milton, that percentage is likely to increase.

The attack on NOAA and the institutionalized lies in Florida bring us full circle to Hurricane Milton and Trump's “lies all the way down” strategy of undermining trust in the government. That strategy seeks to reduce the size and presence of the federal government in our lives. However, Hurricanes Helene and Milton highlight the federal government's irreplaceable role in natural disasters that quickly overwhelm the resources of any individual state.

Trump's lies matter. It should be big news when he lies, not a collective yawn in the media and among elected officials. Lying about the federal government's response to natural disasters and his own violations of US embargo sanctions against Russia are disqualifying for the presidency. The media needs to say so. As do we—with an overwhelming repudiation of Trump at the polls.

[Robert B. Hubbell Newsletter]

#Robert B. Hubbell#Robert B. Hubbell Newsletter#lies all the way down#turtles all the way down#NOAA#weather#the big lie#lies#MAGA lies#climate science#climate change#Russia#Putin#Bob Woodward#Mike Luckovich

12 notes

·

View notes

Text

Lawns and Variation

Lawns most often consist of grasses and clover kept short by mowing. For decades in the United States of America, they were an important aspect of conformity. To this day, lawn maintenance is a key focus of many Homeowner Associations (HOAs). Through media and HOA policies, lawns grown out of control are associated with neglected land and poverty.

A short, well-kept lawn can be very aesthetically pleasing. It also reduces concerns about ticks and other pests. Maintaining one through regular mowing can provide homeowners a reason to spend time outside, and be part of important routines that help people keep their lives on track. Additionally, a short lawn is ideal for outside activities for pets, children, and adults. Of course, not maintaining one’s lawn can also lead to fines if part of an HOA.

The negatives of monoculture lawns, however, far outweigh the potential benefits.

The Negatives

Reducing biodiversity is the best-known way in which typical lawns cause damage. Persistent mowing keeps many species of plants from succeeding. Low biodiversity directly contributes to low ecosystem resilience1. For example, when a pest or fungus comes along that wipes out one type of plant, an entire field or dozens of fields will be wiped out because they are all the same plant. That leaves the land susceptible to erosion, flooding, and desertification (i.e arid land).

Low biodiversity means worse conditions for other forms of life, as well. Regular mowing to keep the grass short and uniform also keeps different floral plants from growing, thus reducing resources for pollinators1.

Persistent mowing also acts as an unnecessary addition to greenhouse gas production. Gas-powered lawn equipment contributes significantly to CO2, NOx, and volatile organic compound (VOC) emissions3. The amount of carbon equivalent pollution from lawn mowing and fertilizer use more than negates the benefit of carbon sequestration (CO2 kept out of the atmosphere) in grass yards2.

For many, yard maintenance also involves fertilizer and pesticide use. Fertilizer use contaminates waterways, primarily through rainfall, and causes algal blooms and decreased oxygenation in waterways. Pesticides can also pollute waterways. In fact, a majority of applied pesticides end up in soil, water, and air, and end up entering the food chain where they negatively affect a wide range of animals, including humans5. Pesticide contamination in humans has been linked to conditions like cancers, neurological issues, obesity, and neurological issues, to name a few5.

Lastly, lawns can need excessive amounts of water. On average, about 9 billion gallons of water goes to watering lawns in the U.S.A. every day6. This is made worse by poor watering practices, causing much of that water to be lost to evaporation and runoff. Water is considered a renewable resource, but that is contingent on proper maintenance and management.

Grass lawns around the world consume an abundance of resources and toxic materials to maintain. Maintaining a grass lawn is ecologically harmful because of pesticides, fertilizers, petroleum pollution, low biodiversity, erosion, and water use.

Cultivating native flora instead nullifies the need for these measures. Native plants are physiologically adapted to the local climate and conditions, and thus need less, if any, watering7. They are less likely to need pesticides or fertilizers, and their deeper root systems decrease soil erosion8. The reduced use of lawn equipment vastly improves air quality, and provides a much more interesting view than a monoculture yard8.

Clover

Transitioning a lawn from short, uniform grasses into a more biodiverse, environmentally healthy yard can be very difficult, and potentially impossible for some people. It doesn’t have to be all or nothing, though. Fostering the growth of clovers instead of grasses, for example, can be a good step for your soil.

Clovers include about 300 species with native varieties in many parts of the world, including Europe, central Asia, North America, and Africa. Clovers generally need minimal maintenance and, if allowed to flower, provide valuable resources for native pollinators9. Clover is also esteemed for its nitrogen-fixing properties. Like many legumes, clover species pull nitrogen from the atmosphere and increase nitrogen availability in soil10.

Converting grass lawns into areas for various native flora has many benefits for the environment and the land-owner, who can enjoy beautiful flowers and bushes while improving air and water quality. While a clover lawn is not as beneficial in these aspects, they can still be an important way for people to start improving their lawn. Fortunately, many more websites now exist to guide land-owners in cultivating native plants. There is always something you can do to help.

Additional Resources

1. https://besjournals.onlinelibrary.wiley.com/doi/pdf/10.1111/1365-2664.13542

2. https://link.springer.com/article/10.1007/s00267-012-9967-6

3. https://www.epa.gov/sites/default/files/2015-09/documents/banks.pdf

4. https://www.ctahr.hawaii.edu/kaufmana/downloads/Kaufman%20Lawn.pdf

5. https://link.springer.com/article/10.1007/s40726-018-0092-x

6. https://19january2017snapshot.epa.gov/www3/watersense/pubs/outdoor.html

7.https://www.montvillenj.org/DocumentCenter/View/155/Choose-Plants-That-Are-Native-to-the-Area-That-Are-Drought-Resistant-PDF?bidId=#

8. https://archive.epa.gov/greenacres/web/html/index.html#

9. https://www.oneearth.org/the-various-advantages-of-clover/

10. https://onlinelibrary.wiley.com/doi/pdf/10.1002/its2.19

11. https://www.sciencedirect.com/science/article/pii/S1618866715000436

#monoculture#lawns#suburban lawns#grass#clover#flowers#flora#climate change#environment#resources#research#article#soil erosion#runoff#pesticides#fertilizer#planting#garden#biodiversity#ecological resistance

10 notes

·

View notes

Text

Marty: Сhinga tu madre! Why the fuck did you go in there without a respirator?! Ash: So should we have left Danny there to die?

Ricky: Guys, look! The equipment is the same as in the room where the scientist was. And it's all new!

Marty: Mi corazón, you breathed in that much of that shit? These devices are everywhere. Ash: Fuck, I'm gonna puke.

Ricky: I don't think we can go any further without the hazmat suits. This fucking gas is blocking the next level.

I carried Danny to the couch in the recreation room. I didn't think I'd say this, but I'd rather see him smile maniacally and listen to his bullshit than hold his unconscious body and check his pulse every few minutes.

Danny: You are my light. If you leave me, I'll die. Ash: Shh. It's okay. I'll never leave you.

We went through all the files in Larsen's office. Subject #17 responds positively to third injection of compound… All subjects are highly active… Fuck, they're not even people, they're subjects! After the second injection, the fingers atrophy… Immunity is high, the cells of the microorganism destroy all known viruses… The subjects show signs of mental communication with each other…

Ash: Marty, did you realize what they were trying to do here? Marty: In simple terms… So, they thought they could improve fertility in women to reduce the risk of disease in the fetus… What came from outer space is some kind of chingado parasite!

Marty: I don't understand exactly what it does, but THIS controls all the infected like a fucking puppeteer! Ricky: What are the chances that if we destroy the parasite, all infected people will survive and get better? Marty: I think we need to find a way to at least temporarily block his influence on people. We're only going to get one chance to kick his ass.

Previous // Next

#ts4 story#strangerville syndrome#ts4#the sims 4#ts4 simblr#sims 4#simblr#ts4 gameplay#OC Ash#OC Danny#OC Marty#OC Ricky#ts4 screenshot#sims story#long post

2 notes

·

View notes

Text

The Comprehensive Compilation of Adverse Reactions Associated with Cabergoline 0.25mg

Cabergoline 0.25mg is a frequently given prescription for many medical disorders. However, it is important for users to be aware of the possible negative effects that may accompany its usage, as is the case with any pharmaceutical. This page provides an extensive list of side effects linked to Cabergoline 0.25mg, including both typical responses and more severe cautions and long-term concerns. Through comprehending these adverse consequences and acquiring the knowledge to handle them, people may make well-informed choices about their therapy and overall state of health.

Cabergoline is a medication used to treat medical conditions such as hyperprolactinemia and Parkinson's disease

Cabergoline is a pharmaceutical compound classified as a dopamine agonist. It is often used in the treatment of disorders such as hyperprolactinemia, which may result in complications such as infertility, irregular menstruation, and lactation in both males and females.

Medical uses of Cabergoline 0.25mg

Cabergoline 0.25mg is often used for the treatment of hyperprolactinemia, a medical disorder defined by elevated levels of prolactin in the bloodstream. This medicine effectively reduces prolactin levels and effectively manages symptoms such as infertility, decreased libido, and irregular menstruation.

Adverse effects on the digestive system

Typical gastrointestinal adverse effects of Cabergoline 0.25mg may include nausea, emesis, constipation, and stomach discomfort. To reduce side effects, it is crucial to consume this drug with meals.

Neurological Adverse Reactions

Individuals using Cabergoline 0.25mg may encounter symptoms such as vertigo, somnolence, or cephalalgia. It is recommended to refrain from driving or operating heavy equipment until you are aware of the impact of this drug on your abilities.

Adverse effects on the cardiovascular system

Certain people may encounter alterations in blood pressure or heart rate while consuming Cabergoline 0.25mg. Regularly monitoring these measures and promptly reporting any major changes to your healthcare professional is essential.

Cabergoline 0.25mg is used to treat a variety of illnesses that arise from excessive production of the hormone prolactin. It may be used to treat pituitary prolactinomas, which are tumors of the pituitary gland, as well as certain menstruation issues and issues with fertility in both sexes.

Possible cardiac valve impairment

An important concern connected with Cabergoline is the possibility of cardiac valve injury, especially in those who are prescribed greater dosages for a prolonged duration. Consistent monitoring of the heart is crucial in order to promptly identify any anomalies in the valves.

Potential for Fibrotic Reactions

The use of Cabergoline has been associated with the emergence of fibrotic responses in diverse tissues, such as the cardiac, pulmonary, and abdominal tissues. If you encounter symptoms such as respiratory distress or edema in the limbs, it is advisable to promptly seek medical assistance.

Potential for the Development of Tolerance

Prolonged usage of Cabergoline might result in the development of tolerance, necessitating greater dosages to get the same therapeutic outcome. It is essential to adhere to the recommendations of your healthcare practitioner and refrain from altering your dose without seeking their advice.

Effect on Hepatic Function

Cabergoline has the potential to impact liver function in some people, resulting in increased levels of liver enzymes. It is advisable to undergo regular liver function tests while taking this drug in order to monitor any changes and avoid any problems.

Controlling and Reducing Side Effects

If you are encountering adverse reactions as a result of consuming Cabergoline 0.25mg, do not worry; there are strategies to address them. Here is a method to effectively control and reduce undesired consequences.

Titration and Surveillance of Dosage

Seek guidance from your healthcare professional about the possibility of modifying your Cabergoline dose. Regular surveillance may aid in monitoring the body's response to the medicine.

Implementing lifestyle modifications to mitigate adverse effects

Modest lifestyle adjustments may significantly alleviate adverse effects. To promote your general well-being, it is important to ensure that you stay well hydrated, follow a balanced diet, and make regular exercise a priority.

Drug Interactions

It is essential to be aware of the potential interactions between Cabergoline and other drugs for your safety and well-being. Now, let's explore the possible interactions and contraindications that need to be monitored.

Important Drug Interactions to Be Mindful Of

Cabergoline may have adverse interactions with some drugs. Ensure that you regularly update your healthcare practitioner about all the drugs you are currently taking in order to prevent any possible drug interactions.

Interactions with Specific Medications

Certain drugs should be avoided while using Cabergoline owing to the potential for adverse interactions. Take note of these contraindications to avoid any potential consequences.

Specific considerations for certain demographics

Customized strategies may be necessary for administering Cabergoline to various groups. Below are important factors to consider for pregnant or nursing women and geriatric patients.

Cabergoline is used to treat hyperprolactinemia (high levels of prolactin, a natural substance that helps breast-feeding women produce milk but can cause symptoms such as infertility, sexual problems, and bone loss in women who are not breast-feeding or men). Cabergoline is in a class of medications called dopamine receptor agonists. It works by decreasing the amount of prolactin in the body.

Women who are currently pregnant or breastfeeding

When you are pregnant or breastfeeding, it is crucial to have a conversation with your healthcare professional about the potential advantages and disadvantages of using Cabergoline. The utmost importance should be placed on ensuring the well-being of both you and your kid.

Geriatric Patients

Cabergoline may need special care for elderly people. Close surveillance and possible dose modifications may be required to guarantee the safety and efficacy of the medication.

Summary and Concluding Remarks

Understanding and addressing the possible side effects, interactions, and concerns of Cabergoline 0.25mg may seem challenging, but with enough information and help, you can successfully handle them. It is important to constantly seek advice from your healthcare professional for specialized assistance that is specifically targeted to your individual requirements.

Ultimately, it is essential for both patients and healthcare practitioners to have a thorough understanding of the potential adverse effects of Cabergoline 0.25mg. By being knowledgeable about the possible hazards, closely monitoring for any worrisome symptoms, and seeking advice from a healthcare expert as necessary, people may manage their course of treatment with more assurance and security. It is important to emphasize that taking a proactive approach to managing and maintaining open lines of communication are crucial in achieving the most favorable results while using Cabergoline 0.25mg.

1 note

·

View note

Text

youtube

Working Principle of NPK Compound fertilizer Granulator. NPK compound fertilizer production line.

Hello Everyone, welcome to our Zhejiang Tongli Heavy Machinery Co., Ltd Official Channel, should of done this video before, but anyways. In this video we will walk you through the working principle of the granulator.

website: https://www.cementl.com

Email: [email protected]

whatsapp: +86 15988878668

#fertilizerproductionmachine#fertilizermanufacturingequiptment#fertilizerplantmachinery#fertilizerplantequiptment#fertilizerproductionequiptment#fertilizer#fertilizer machine#npk fertilizer production line#compound fertilizer production line#fertilizer machinery#fertilizer equipment supplier#fertilizer industry#compound fertilizer equipment#Youtube

0 notes

Text

Agriculture Drone Market Dynamics, Analysis, Growth Insights, Key Players, Size Value and Latest Trends By 2033

The agriculture drone market (農業用ドローン市場) is poised for substantial growth, with a projected valuation of US$ 3,807.0 million by 2023. It is anticipated to exhibit a robust compound annual growth rate (CAGR) of 14.1%, ultimately reaching US$ 14,237.6 million by 2033.

In 2023, the global drone market is expected to encompass approximately 7.6 million unit shipments, experiencing a notable growth rate of 15.3% CAGR. This surge can be attributed to significant technological advancements within the agriculture industry, leading to substantial investments in drone deployment. As of the conclusion of 2022, the sales of agriculture drones had already secured an impressive 11% share within the broader global drone market.

Download a Sample Copy of This Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=5417

Precision Farming at its Best

Traditionally, farming has been a labor-intensive and time-consuming endeavor. However, the advent of agriculture drones has changed the game completely. These high-tech machines equipped with advanced sensors and imaging technology can collect a wealth of data from the air, providing farmers with invaluable insights into their crops.

One of the primary benefits of agriculture drones is their ability to perform precise crop monitoring. Drones can fly over vast fields and capture detailed images and data about crop health, soil conditions, and pest infestations. This data can be used to identify trouble spots, allowing farmers to take targeted actions to optimize crop yields. This level of precision has the potential to reduce resource wastage, such as water and pesticides, ultimately leading to more sustainable farming practices.

Efficiency and Productivity Soar

The use of agriculture drones also significantly improves the efficiency and productivity of farming operations. Drones can cover large areas in a short amount of time, which would be a daunting task for human labor alone. This means that tasks like crop scouting, which used to take days or even weeks, can now be completed in a matter of hours.

Additionally, drones can be programmed to perform specific tasks autonomously, such as spraying crops, planting seeds, or even harvesting. This automation not only saves time but also reduces the need for manual labor, which can be a significant cost savings for farmers.

Data-Driven Decision Making

The data collected by agriculture drones is a goldmine for farmers looking to make informed decisions. Through the use of data analytics and machine learning algorithms, farmers can gain deeper insights into crop performance and trends. This enables them to adjust irrigation schedules, optimize fertilization, and take proactive measures to prevent disease outbreaks or pest infestations.

Furthermore, the data can be used to create detailed maps of fields, allowing for precise planning and management of resources. Farmers can identify areas that require specific attention and tailor their actions accordingly. This level of data-driven decision-making can lead to higher yields and better overall farm management.

Competitive Landscape

Agriculture drone manufacturers in this rapidly evolving industry landscape include 3D Robotics, AgEagle Aerial Systems Inc, Asteria Aerospace, ATMOS UAV, Autel Robotics, Ayaan Autonomous Systems Pvt. Ltd., Delair SAS, and DJI.

These manufacturers are actively employing diverse marketing strategies, such as offering competitive pricing for their products, establishing strategic partnerships with retailers, launching endorsement programs, and harnessing new technologies to create cutting-edge products. These tactics are geared towards staying competitive within the sports equipment industry.

In April 2021, AgEagle Aerial Systems Inc., a well-established U.S.-based drone technology firm with over a decade of experience, made a significant move. The company announced its acquisition of Measure Global Inc., a renowned provider of aerial intelligence solutions. This acquisition was structured as a combination of cash and stock transactions valued at approximately US$45 million, further solidifying AgEagle's position in the market.

Segmentation of Agriculture drone Industry Research

By Offerings :

Fixed Wing

Rotary Wing

Hybrid Wing

By End Users :

Consumer / Civil

Commercial

By Coverage Distance :

Below 3 Km

3-6 Km

6-9 Km

Above 9 Km

By Application :

Precision Agriculture

Livestock Monitoring

Surveying & Mapping

Irrigation

Precision Fish Farming

Fertilization & Spraying

Aerial Imaging

By Payload Capacity :

Below 5 Kg

5-10 Kg

10-15 Kg

15-20 Kg

Above 20 Kg

By Region :

North America

Latin America

Europe

East Asia

South Asia & Oceania

MEA

Challenges and the Future

While agriculture drones hold immense promise, there are challenges that need to be addressed. These include regulatory hurdles, data security concerns, and the cost of acquiring and maintaining drone technology. However, as the technology continues to advance and become more accessible, these challenges are gradually being overcome.

𝐂𝐡𝐞𝐜𝐤 𝐎𝐮𝐭 𝐌𝐨𝐫𝐞 𝐑𝐞𝐥𝐚𝐭𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

Vacuum Degreaser Market Vacuum Excavator Market Molded Case Circuit Breaker (MCCB) Market

Contact: US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

CONFIDENTIAL MEMORANDUM

DRC, Black Ops Command, Covert Acquisition Unit

To: Director [REDACTED]

From: Administrator [REDACTED], Covert Acquisition Unit

Date: [REDACTED]

Subject: Surrogate Recruitment via Social Media Application

Executive Summary

This memorandum summarizes the initial pilot testing of "Broodr," a mobile dating application developed by the DRC Covert Acquisition Unit as an identification and capture tool of viable surrogate candidates within the Los Angeles metropolitan region.

The Broodr pilot program aims to:

Test effectiveness in luring suitable surrogate candidates aged 18-25.

Assess the app’s capability to profile and locate high-fertility individuals discretely.

Evaluate the overall success rate of transitioning online interactions into physical capture operations.

Operational Procedure

Broodr was launched covertly through standard digital app distribution channels. It is marketed as a casual social/dating application targeted at young, romantically single men. Four other apps in the market were also disrupted to reduce competition and increase public awareness. The application utilizes advanced profile analytics to identify users displaying surrogate-compatible traits based on fertility indicators such as age, athletic status, height, genetic background, and health metrics.

Once identified, candidates receive targeted messaging from AI bots and doctored profiles using altered photos of athletes and models designed to entice them to designated physical meeting locations. These meeting spots are strategically placed within zones easily secured by DRC rapid response capture teams.

Initial Test Results

Since the pilot launch [REDACTED] weeks ago, Broodr has attracted over [REDACTED] registered users within the target demographic.

[REDACTED]% of identified high-value targets initiated interactions leading to physical meetings.

Capture success rate currently stands at [REDACTED]%, exceeding initial operational goals.

Captured surrogates demonstrate above-average fertility rates, with an average fetal load of 12-16 embryos upon initial insemination.

Key Incident

On [REDACTED], Broodr successfully identified, seduced, and facilitated the capture of a high-profile fitness celebrity at our DRC detainment site in [REDACTED], Beverly Hills.

Mr. [REDACTED], a 23-year-old fitness influencer known for his muscular physique, extensive social following, and endorsements of health products, was identified as a prime surrogacy candidate due to exceptional fertility markers (5'11", 174 lbs pre-pregnancy, optimal athletic conditioning).

Four real profiles and 28 tailored AI-generated profiles initially contacted him, depicting attractive, athletic personas that closely matched his profile's interests. This sophisticated digital interaction rapidly evolved into sexually graphic exchanges, successfully convincing him to attend what he believed to be a home address for a physical engagement.

“Hey, handsome ;) Hott as fuck! A stud like you promising an unforgettable night got me seriously curious. What are you into? I would love to work out all your kinks, physical and sexy!” - Copy of Chat Log

Upon arrival at the designated location, a rapid response team swiftly and discreetly apprehended Mr. [REDACTED]. Upon completion of on-site insemination, secured transport protocols were immediately enacted, moving Mr. [REDACTED] to the nearby Paternity Compound 141, best equipped for his subsequent gestation, birth, and expiration. Mr. [REDACTED] was assigned the surrogate ID S-141-548-P (which will be used henceforth to identify the surrogate).

Post evaluations confirmed highly successful insemination, resulting in an exceptionally high fetal load of sexdecuplets (16 embryos), and in under 33 days, S-141-548-P's weight jumped to 534 lbs (+360 lbs) with an abdominal circumference of 96 inches (+64 inches), rendering the surrogate wholly bedridden and dependent on continuous medical supervision. Despite his extreme size and rapidly declining mobility, regular medical evaluations confirmed that S-141-548-P's health remained within acceptable operational parameters.

"I can barely process what's happened—my body’s unrecognizable. I used to flex these abs for millions online, and now they're buried beneath a mound of babies. I'm so enormous and heavy that breathing feels like a workout! I never thought I'd feel this helpless—or this big." - S-141-548-P, Gestation Day 21

Labor commenced on day 33 of gestation, and over 22 hours, all 16 fetuses were successfully delivered. Upon completion of delivery, vital signs deteriorated rapidly, culminating in S-141-548-P’s expiration approximately [REDACTED] minutes after the last fetus was expelled. Post-mortem assessments indicated complete [REDACTED] shutdown, extensive [REDACTED] to the [REDACTED] and [REDACTED] system.

"I can't stop it! They’re coming! Everything's ripping apart, and every contraction feels like my belly's splitting open. Oh God—I can’t move, I can't breathe, but my body... I'm just so... fat…" - S-141-548-P, Gestation Day 33

Of particular note is that S-141-548-P was well known on social media channels for exemplifying his abdominal muscles, mainly using the moniker “All Core, No Compromise.” The primary cause of expiration was confirmed to be the macroscopic tearing and rupture of all abdominal muscles, a typical result for surrogates subjected to such high fetal loads.

Recommendations

The capture and subsequent pregnancy of such a notable public figure not only significantly boosted internal operational morale but also underscored the strategic efficacy of Broodr as an unprecedented method of securing high-value surrogate candidates. This incident has provided robust proof-of-concept evidence, strongly supporting further investment and nationwide deployment of the Broodr initiative.

Based on the Los Angeles pilot:

Expand Broodr's implementation to additional high-density urban areas (e.g., New York City, [REDACTED], San Francisco).

Increase application analytics capabilities to enhance fertility trait profiling.

Implement additional security protocols to ensure continued operational secrecy.

Conclusion

The pilot deployment of Broodr in the Los Angeles metro area confirms the application's high efficacy as a discreet surrogate recruitment and capture tool. Expansion into additional metropolitan zones is recommended to bolster surrogate conscription efforts further nationwide.

Prepared by: Assistant Director [REDACTED]

DRC, Black Ops Command, Covert Acquisition Unit

----------------

Click Here to return to DRC Report Archives

#mpreg#mpregkink#malepregnancy#mpregbelly#pregnantman#mpregmorph#mpregcaption#mpregstory#mpregbirth#mpregart#mpregnancy#aimpreg#mpregroleplay#malepregnant#latinompreg

40 notes

·

View notes

Text

Fertilizer Granulation Equipment: Which One Fits Your Line?

In fertilizer production, choosing the right granulation equipment is crucial for product quality and production efficiency. Disc granulators, rotary drum granulators, and drum granulators each have unique features. This article provides a detailed comparison to help you make an informed decision.

1. Disc Granulator Machine

Working Principle:

Material rolls into balls under centrifugal force and gravity on a tilted rotating disc, with binder spray assisting granulation.

Key Advantages:

High granulation rate (85-95%)

Excellent particle roundness

Low energy consumption, easy operation

Ideal for small batch multi-formula production

Best For:

Medium-small scale organic fertilizer, bio-fertilizer, and NPK compound fertilizer production, especially when frequent formula changes are needed.

1. Rotary Drum Granulator

Working Principle:

Material forms granules through rolling, agglomeration and compaction in a slowly rotating large drum.

Key Advantages:

High capacity (up to 50 tons/hour)

Suitable for high-moisture materials

High particle strength

Continuous production

Best For:

Large-scale NPK compound fertilizer, organic-inorganic compound fertilizer, and applications requiring high-strength granules.

3. Drum Granulator

Working Principle:

Combines drum rotation and extrusion principles, forming granules through both mechanical pressure and rolling action.

Key Advantages:

High particle density

Low moisture content

Minimal dust pollution

Strong adaptability

Best For:

Specialty fertilizers, micronutrient fertilizers, and applications requiring low moisture content and high-density granules.

0 notes

Text

Disc Granulator: The Universal Solution for Fertilizer Production?

In the field of fertilizer production, disc granulators have become the preferred equipment for many manufacturers due to their unique advantages. But what types of fertilizer production are most suitable for disc granulators? What tangible benefits can they bring? This article will answer these questions one by one.

1. Application Scope: Which Fertilizer Productions Suit disc Granulators?

The disc granulator production line, featuring a rotating inclined pan for agglomerating materials, differs from traditional fertilizer production lines primarily in its granulation mechanism. While traditional lines often use extrusion or compaction methods, disc granulators employ a gentle tumbling action that creates more spherical, uniform pellets with lower energy consumption. This method is particularly effective for organic fertilizers, allowing better control over particle size distribution and producing less dust compared to conventional granulation systems.

disc granulator production lines are particularly suitable for the following types of fertilizer production:

Organic-Inorganic Compound Fertilizers: Effectively handles the granulation of mixtures containing both organic and inorganic materials

Bio-Organic Fertilizers: Can granulate temperature-sensitive biological agents under mild conditions

NPK Compound Fertilizers: Especially meets the needs of small and medium-sized compound fertilizer producers

Micronutrient Fertilizers: Allows precise control of micronutrient addition ratios

Special Formula Fertilizers: Easy to adjust formulas for customized production needs

2. Core Advantages: Why Choose disc Granulators?

3. Practical Value: Economic Benefits of disc Granulators

According to actual production case studies, disc granulator production lines can bring the following economic benefits:

Quick ROI: Typically recovers equipment investment within 1-2 years

Low Production Costs: 15-30% lower comprehensive production costs than traditional granulation methods

Stable Product Quality: Uniform particle size with moderate strength, highly accepted by the market

Significant Environmental Benefits: Lower energy consumption and reduced emissions

References:

[1] Fertilizer Production Technology and Equipment Manual, Chemical Industry Press, 2018

[2] Research Progress in Modern Fertilizer Granulation Technology, Transactions of the Chinese Society of Agricultural Engineering, 2020

0 notes

Text

Daily Fertilizer Production Knowledge: Horizontal Mixer

Function of Horizontal Mixers

The horizontal mixer plays a critical role in fertilizer production lines by ensuring uniform blending of raw materials. In organic fertilizer production processes, it thoroughly mixes composted organic matter with additives like biochar or microbial inoculants. This equipment's robust design handles fibrous organic materials while preventing segregation, which is essential for creating homogeneous organic fertilizers with consistent nutrient distribution.

The horizontal mixer serves as the core mixing equipment in fertilizer production lines. With its horizontally mounted mixing shaft and specially designed blades, it achieves homogeneous blending of powdered, granular, or viscous materials. Its unique horizontal structure delivers exceptional performance in mixing uniformity, processing capacity, and operational stability[1].

Why Choose Horizontal Mixers?

Compared to vertical mixers, horizontal mixers offer distinct advantages:

High Mixing Efficiency: Creates complex material movement patterns, reducing mixing time by 30-50%

Large Capacity: Single-unit capacity up to 20m³, ideal for large-scale continuous production

Low Residue: Unique discharge design ensures residue rates below 0.5%, minimizing cross-contamination

Material Versatility: Handles everything from powders to viscous pastes

Typical Applications:

Premixing of compound fertilizer ingredients

Final blending of organic-inorganic fertilizers

Uniform dispersion of micronutrient additives

Mixing of high-viscosity materials

Role in Fertilizer Production Lines

In modern fertilizer production, horizontal mixers are typically positioned between raw material preparation and granulation sections, playing a critical role in ensuring formula accuracy and product uniformity. For complex compound fertilizers with diverse ingredients, horizontal mixers become indispensable[2].

Selection Guidelines

Key considerations when selecting horizontal mixers:

Material characteristics (particle size, density, viscosity)

Production scale (batch or continuous)

Required mixing uniformity

Ease of cleaning and maintenance

For high-value specialty fertilizer production, consider models equipped with liquid addition systems and online monitoring devices[3].

References:

[1] "Fertilizer Production Equipment and Technology Manual", China Agricultural Press, 2019

[2] Smith, J. "Mixing Technology in Fertilizer Production", IFDC Technical Bulletin, 2020

[3] European Fertilizer Equipment Manufacturers Association (EFEMA) Technical Standards, 2021 Edition

0 notes

Text

What Key Equipment is Needed for Fertilizer Production Lines?

Modern fertilizer production integrates both general-purpose equipment and specialized machinery, with granulation technology being particularly critical. Drum granulators utilize a rotating cylinder to form spherical granules through a combination of agglomeration and layering mechanisms, ideal for high-capacity NPK production. Disc granulators employ an inclined rotating pan to produce uniform granules via a controlled cascading motion, offering precise particle size control. These core granulation units work in conjunction with auxiliary systems including:

Precision batching systems for raw material formulation

Thermal processing units for drying/cooling

Surface coating systems for enhanced product performance

Automated packaging lines for final product handling

Proper equipment selection directly impacts production efficiency, product quality, and operational costs in fertilizer manufacturing.

General Equipment in Fertilizer Production

All fertilizer production lines share certain fundamental equipment that handles the basic processing stages:

Specialized Fertilizer Equipment

Beyond general equipment, specialized fertilizer production requires additional machinery tailored to specific product types:

Global Fertilizer Production by Type (2022)

Selecting the Right Equipment

Choosing appropriate equipment depends on several factors:

Production capacity: Small (1-5 tons/hour), medium (5-20 tons/hour), or large-scale (20+ tons/hour)

Fertilizer type: Organic, inorganic, compound, or specialty fertilizers

Automation level: Manual, semi-automatic, or fully automatic systems

Budget: Initial investment versus long-term operational costs

Modern fertilizer production lines increasingly incorporate smart technologies such as IoT sensors for real-time monitoring and AI-driven optimization systems to improve efficiency and product consistency [1].

[1] Data from International Fertilizer Association 2022 Report

Note: Equipment specifications may vary by manufacturer and application requirements.

0 notes