#cnc fiber laser market

Explore tagged Tumblr posts

Link

Increasing adoption of automation technologies to boost the CNC Fiber Laser Industry...

#market research future#cnc fiber laser market#cnc fiber laser#fiber laser cutting machine#laser cutting machines market

1 note

·

View note

Text

Advanced Cutting Solutions in the UAE: Fiber Lasers, CNC Plasma, and Plasma Tables

The UAE’s industrial and manufacturing sectors are booming, and with this growth comes the demand for precise, efficient, and reliable cutting technology. Businesses in the region are turning to advanced equipment to meet these needs, including fiber laser cutting machines, CNC plasma systems, and plasma cutting tables. These cutting-edge tools offer unparalleled accuracy and productivity, making them essential for industries ranging from construction to automotive.

The Power of Fiber Laser Cutting Machines

For companies seeking top-tier cutting performance, fiber laser cutting machines are a game-changer. Their ability to deliver incredibly precise cuts on various materials has revolutionized the manufacturing process.

Here’s why these machines stand out:

Speed and Efficiency: Fiber lasers operate faster than traditional cutting methods, enabling high-volume production without compromising quality.

Versatility: From stainless steel to aluminum, these machines handle a wide range of materials with ease.

Low Maintenance: The solid-state design of fiber lasers reduces wear and tear, ensuring long-lasting reliability.

For businesses in the UAE, investing in a fiber laser cutting machine for sale isn’t just about acquiring equipment—it’s about gaining a competitive edge in the market.

CNC Plasma Cutting: Precision Meets Versatility

Another essential tool for industrial cutting needs is the CNC plasma cutting machine. These machines are known for their ability to cut through thick and tough materials with unparalleled precision.

Advantages of CNC plasma systems include:

Enhanced Accuracy: Computer-controlled operation ensures every cut is precise, reducing waste and material costs.

Adaptability: Ideal for cutting steel, brass, copper, and other conductive metals, making it a versatile choice for various industries.

Cost-Effective Performance: These machines provide high-quality results without the hefty price tag of other advanced cutting methods.

Finding the right CNC plasma cutting machine for sale in UAE can transform your production process, helping you deliver superior results with every project.

Reliable Plasma Cutting Tables for Every Business

The foundation of any efficient cutting operation is a dependable plasma cutting table. These tables provide the stability and support needed for accurate and efficient cutting processes.

What makes a high-quality plasma cutting table essential?

Sturdy Construction: A robust frame ensures durability and long-term performance.

Customizable Options: Available in various sizes and configurations to meet the specific needs of your workspace.

Seamless Integration: Designed to work perfectly with plasma cutting machines for optimal results.

When choosing plasma cutting table suppliers in the UAE, it’s essential to look for providers who offer durable products and exceptional after-sales support to keep your operations running smoothly.

Why Cutting-Edge Technology Matters

Investing in advanced cutting equipment isn’t just about meeting today’s needs—it’s about preparing for tomorrow’s challenges. With fiber lasers, CNC plasma machines, and reliable plasma cutting tables, UAE businesses can enhance productivity, reduce downtime, and improve overall efficiency.

As the demand for high-quality cutting solutions grows, choosing the right equipment and suppliers becomes critical. Look for trusted providers offering innovative technology, comprehensive support, and tailored solutions to suit your specific requirements.

Conclusion

Whether you’re in construction, manufacturing, or any industry that requires precision cutting, the UAE offers a wealth of options to meet your needs. Explore fiber laser cutting machines for sale, invest in a CNC plasma cutting machine, and partner with reliable plasma cutting table suppliers to stay ahead of the competition. With the right tools and expertise, your business can achieve new heights of success in today’s fast-paced industrial landscape.

Contact us...

0 notes

Text

How to Choose the Best CNC Laser Cutting Machine in Canada for Your Business

If More Info Visit -

In this guide, we will explore how to choose the best CNC laser cutting machine in Canada for your business, discussing key considerations such as machine features, cost, and where to source them. Whether you’re based in Toronto or another part of Canada, this guide is designed to help you make an informed decision.

1. Understand Your Cutting Requirements

Before you start shopping for a CNC laser cutting machine, it’s essential to understand the specific cutting needs of your business. Ask yourself the following questions:

What materials will you be cutting? CNC laser machines can cut a wide variety of materials, including plastics, wood, metals, and more. The type of material you plan to work with will influence the machine you need.

What thicknesses will you be cutting? Different machines are designed to handle varying material thicknesses. Ensure the machine you choose can handle the maximum thickness you expect to cut regularly.

What level of precision is required? CNC laser cutting machines are known for their precision, but some models offer higher tolerances than others. If you’re working in industries like automotive, aerospace, or electronics, you may need a machine with superior precision capabilities.

How large are the workpieces? The size of the work area on a CNC laser cutting machine is a critical factor. Make sure the machine can accommodate the dimensions of the materials you’ll be working with.

2. Types of CNC Laser Cutting Machines

There are different types of CNC laser cutting machines available on the market, each designed for specific purposes. Understanding the differences between these machines can help you choose the best one for your business.

a) CO2 Laser Cutting Machines

CO2 laser cutting machines are some of the most popular options for cutting non-metallic materials like plastics, wood, and textiles. They are highly efficient, easy to use, and affordable compared to other types of CNC laser cutters. For businesses that work primarily with plastics or organic materials, a CO2 laser machine may be the ideal solution.

b) Fiber Laser Cutting Machines

Fiber laser cutting machines are designed for high-speed cutting of metals such as stainless steel, aluminum, and brass. They are energy-efficient and require less maintenance than CO2 lasers. If your business focuses on metal fabrication, a fiber laser cutting machine is an excellent choice.

c) Hybrid Laser Cutting Machines

Some machines combine the capabilities of both CO2 and fiber lasers. These hybrid machines are versatile and can handle a wide range of materials, making them a good option for businesses that work with both metals and non-metals.

3. Evaluating Machine Features

When looking for the best CNC laser cutting machine in Canada, it’s essential to evaluate the features of each model to ensure it meets your business needs. Some important features to consider include:

a) Power Output

The power of the laser determines its cutting ability. Higher-wattage lasers can cut through thicker materials more quickly but may be overkill for thinner materials. Choose a machine with the right power output for the materials you’ll be cutting regularly.

b) Cutting Speed

The speed at which the machine can cut materials will impact your overall productivity. Look for machines with adjustable cutting speeds, so you can optimize performance based on the material type and thickness.

c) Work Area Size

The size of the cutting bed is crucial for handling larger workpieces. Ensure the CNC laser cutting machine you choose has a work area that fits your typical material dimensions. Machines with larger work areas offer more flexibility, but they also take up more space in your facility.

d) Software Compatibility

Most CNC laser cutting machines come with proprietary software for design and cutting control. It’s important to check if the machine’s software is compatible with your existing CAD (computer-aided design) systems or if it requires additional training and support. The best software should offer user-friendly interfaces and allow for complex designs.

e) Maintenance and Support

Regular maintenance is essential for keeping your CNC laser cutting machine in top condition. Check the availability of local support and replacement parts in Canada. Machines from reputable brands often come with excellent customer support, which can be invaluable if your machine requires servicing or technical assistance.

4. Budget Considerations

The cost of a CNC laser cutting machine can vary significantly depending on its features, power, and brand. While it’s tempting to go for the cheapest option, investing in a high-quality machine will pay off in the long run through improved performance, reliability, and longevity.

Initial Costs: Higher-end models may cost more upfront, but they typically offer better precision, speed, and durability.

Operating Costs: Consider energy consumption, the cost of consumables (such as laser tubes), and maintenance costs when calculating your budget.

Financing Options: Many suppliers offer financing options for businesses looking to invest in CNC laser cutting equipment. This can help spread out the cost over time, making it easier to afford the best machine for your needs.

5. Find a Reliable Supplier in Canada

When looking for the best CNC laser cutting machine in Canada, choosing a reputable supplier is essential. A reliable supplier can provide expert guidance, high-quality machines, and ongoing support.

For businesses in Toronto, Plastics Source is a trusted provider of CNC cutting services. They offer a range of CNC solutions tailored to different industries. Whether you need custom laser cutting for plastics or other materials, their expertise and cutting-edge machinery ensure high-quality results. To learn more about their CNC cutting services in Toronto, you can visit their website at CNC Cutting Toronto.

Additionally, Plastics Source offers comprehensive support, ensuring that your CNC laser cutting machine continues to perform at its best. Contact them at (416) 650–0976 or via email at [email protected] to discuss your CNC cutting needs.

6. Location and Shipping

If you are in Toronto or the surrounding areas, it’s beneficial to choose a supplier that offers local support. This ensures faster delivery, installation, and maintenance services. For those outside Toronto, many Canadian suppliers offer nationwide shipping and service packages to ensure that your CNC laser cutting machine is delivered and installed professionally.

Plastics Source, located at 622 Magnetic Dr, North York, ON M3J 3J2, Canada, offers CNC cutting services and can assist you in finding the best machine for your business. Their extensive experience in the field ensures that you get the right machine with the best technical support available in Canada.

7. Future-Proof Your Investment

When selecting a CNC laser cutting machine, consider how your business may grow in the future. Choosing a machine that can scale with your production needs or be upgraded will save you from having to purchase new equipment down the line. Look for machines with modular designs or upgradeable components, which allow for flexibility as your business evolves.

Conclusion

Choosing the best CNC laser cutting machine in Canada for your business involves understanding your cutting requirements, evaluating machine features, and finding a reliable supplier like Plastics Source. By taking into account factors such as power, precision, and cost, you can make an informed decision that will enhance your business’s capabilities.

For businesses in Toronto and beyond, Plastics Source provides expert CNC cutting services and support. Visit their website at CNC Cutting Toronto or contact them at (416) 650–0976 to learn more about how they can help meet your CNC laser cutting needs.

0 notes

Text

Precision CNC Fiber Laser Cutting Machine Manufacturers in India

The universe of assembling has gone through a huge change with the appearance of CNC (Computer Numerical Control) laser cutting technology. These high level machines have changed enterprises by giving high accuracy, proficiency, and flexibility in cutting different kinds of metals. India, a developing center point for mechanical advancements, is home to probably the most respectable CNC fiber laser cutting machine manufacturers, especially in districts like Gujarat and Ahmedabad. This blog dives into the significance of CNC laser cutting machines and the job of Indian manufacturers in this always advancing industry.

The Meaning of CNC Laser Cutting Machines

CNC laser cutting machines have become vital in the assembling area, offering unrivaled precision and speed. These machines utilize powerful lasers controlled by CNC frameworks to slice through metals like treated steel, aluminum, and other amalgams. The degree of accuracy accomplished by CNC laser cutting technology is infinitely better to conventional cutting techniques, pursuing it a favored decision for businesses, for example, auto, aviation, hardware, and development.

The reception of CNC fiber laser cutting machines has been a unique advantage for some manufacturers. Fiber lasers utilize optical fibers to intensify the laser pillar, giving quicker and more energy-productive cutting arrangements contrasted with CO2 lasers. This technology guarantees that even the most perplexing shapes and examples can be cut easily and accuracy, essentially further developing creation processes.

CNC Laser Cutting Machine Manufacturers in India

India has arisen as a central member in the worldwide assembling scene, with a few organizations spend significant time in CNC laser cutting technology. CNC laser cutting machine manufacturers in India are known for delivering cutting-edge machines that satisfy worldwide guidelines. These manufacturers give many machines intended for different industrial applications, guaranteeing that organizations can upgrade their creation capacities while keeping up with cost effectiveness.

The Indian market for CNC laser cutting machines is assorted, taking care of both enormous scope industrial activities and more modest ventures. Manufacturers offer machines furnished with cutting edge elements like computerized material taking care of, fast cutting, and negligible upkeep prerequisites. These machines are intended to deal with high creation volumes while keeping up with the accuracy required for mind boggling plans.

CNC Laser Cutting Machine Manufacturers in Gujarat

Gujarat is quite possibly of the most industrialized state in India and has turned into a significant center for CNC laser cutting machine manufacturers. The state is home to a few famous organizations that produce great laser cutting machines for different businesses. CNC laser cutting machine manufacturers in Gujarat center around conveying creative arrangements that assist organizations with working on their efficiency and effectiveness.

These manufacturers have some expertise in CNC fiber laser cutting machines, which offer a few benefits, including quicker cutting paces, lower functional expenses, and more prominent energy productivity. Many organizations in Gujarat additionally give modified machines to meet the particular requirements of their clients, guaranteeing that organizations can advance their creation processes. Gujarat's standing as a forerunner in assembling is additionally reinforced by its obligation to delivering mechanically progressed CNC laser cutting machines.

CNC Laser Cutting Machine Manufacturers in Ahmedabad

As the biggest city in Gujarat, Ahmedabad has laid down a good foundation for itself as a central participant in the assembling area. The city is known for its gifted labor force, mechanical ability, and solid industrial base. CNC laser cutting machine manufacturers in Ahmedabad have gained notoriety for creating elite execution machines that take special care of many businesses.

Manufacturers in Ahmedabad offer machines that are intended for both accuracy and effectiveness. These machines are great for enterprises that require high exactness in cutting, for example, car, aviation, and gadgets. CNC fiber laser cutting machines created by Ahmedabad-based manufacturers are known for their sturdiness, usability, and negligible support necessities, going with them a famous decision for organizations hoping to put resources into long haul arrangements.

Benefits of CNC Fiber Laser Cutting Machines

High Accuracy: One of the essential purposes behind the prevalence of CNC laser cutting machines is their capacity to convey high accuracy. Fiber lasers can cut metals with outrageous exactness, guaranteeing clean edges and insignificant material wastage.

Speed and Effectiveness: CNC fiber laser cutting machines are known for their high cutting velocities, which essentially diminish creation times. This effectiveness permits manufacturers to build their result without settling on quality.

Practical: CNC fiber laser cutting machines are more energy-proficient than customary cutting strategies, bringing about lower functional expenses. Moreover, these machines require less consumables, further decreasing costs.

Flexibility: These machines can cut a great many metals, including hardened steel, aluminum, metal, and copper. This flexibility makes them appropriate for different industrial applications, from car parts to complex aviation parts.

Low Support: CNC fiber laser cutting machines have less moving parts contrasted with other cutting advancements, which means lower upkeep prerequisites and longer machine life expectancies.

CNC Laser Cutting Technology in India's Industrial Scene

The fast development of CNC laser cutting machine manufacturers in India mirrors the nation's rising spotlight on modernizing its assembling framework. These manufacturers assume an essential part in driving development and guaranteeing that Indian businesses can contend on a worldwide scale. The capacity to create machines that offer both accuracy and cost effectiveness has gone with Indian manufacturers a favored decision for organizations hoping to embrace CNC laser cutting technology.

With progressions in CNC technology, CNC fiber laser cutting machine manufacturers in India are pushing the limits of what is conceivable in metal cutting. The interest for these machines keeps on developing, especially in businesses that require elevated degrees of precision and speed. Subsequently, CNC laser cutting technology has turned into a foundation of India's industrial turn of events, assisting organizations with remaining cutthroat in an undeniably globalized market.

End

The ascent of CNC laser cutting machine manufacturers in India, particularly in Gujarat and Ahmedabad, features the country's obligation to embracing progressed producing advancements. CNC fiber laser cutting machines have turned into a fundamental apparatus for ventures that require high accuracy, proficiency, and adaptability in their creation processes. As the interest for these machines keeps on developing, Indian manufacturers are ready to lead the manner in which in giving creative arrangements that meet the advancing requirements of the worldwide assembling industry.

Organizations hoping to put resources into CNC laser cutting machines can depend on the skill of India's top manufacturers to convey cutting-edge technology that improves efficiency while diminishing expenses. Whether you're in the car, aviation, or metal manufacture industry, CNC laser cutting machines offer the accuracy and productivity expected to remain serious in the present speedy industrial scene.

#fiberlasercuttingmachine#fiberlasercuttingmachinemanufacturer#metweld#cncfiberlasercuttingmachine#industrialcncfiberlasercutter#manufacturer#fiberlasercutter

0 notes

Text

Benefits of Fiber Laser Cutting Machine in Sheet Metal Cutting

A fiber laser cutting machine has many benefits over a standard fiber laser cutter, including high precision and processing flexibility. However, given the doubts surrounding a fiber laser cutting machine, the question mentioned earlier is still making its way through the industry and has some importance.

The practical, time-consuming ways should be replaced with something quick and efficient as a result of technological advances over time. Therefore, the loss of market share for CNC punching machines and shearing equipment is not surprising. Additionally, a CO2 laser cutting machine is a more recent addition to this list of options. This was because it was time-consuming, expensive, included additional overhead, and the output's quality was lower to the power input.

The rate of efficiency for processing reflective mediums, such as carbon and stainless steel, has increased by 200% through advancements in power laser cutting machines and the introduction of fiber laser cutters.

Additionally, constant developments in fiber technology resulted in a fiber laser with rapid and simple laser spot size transformation. Regarding cutting quality, the feeding fiber's range is three times more accurate than average, and it operates at different speeds without experiencing any problems.

This fiber laser cutting machine has made it easier to design tools and promoted more optimised cutting that can handle different metal thicknesses. Also, the output of fiber laser beams can be adjusted within a range of around 100 µm to 300 µm. The fact that these highly advanced fiber lasers have shorter transition times and quick beam change is a benefit of using them. Because of this, these fiber lasers can run continuously at maximum power without experiencing an index change, and they can do so without having to switch off or blank the laser beam in order to change its shape. This feature selects and initiates the usage of the best beam characteristics for each cutting working without limiting the beam's capacity to cut a given material with a certain thickness.

However, the processing of thick steel cutting often commands the majority of the market for general metal cutting. compared to conventional laser cutting systems, giber lasers also provide a variety of special advantages in terms of edge quality and maximum thickness for cutting thick metal sheets. With a fixed optic cutting head that has a 1.5x magnification and sufficient oxygen support, this machine can handle any type of metal sheet. Compared to traditional fiber laser cutters, these highly evolved fiber lasers can deliver greater edge quality and three times less roughness, regardless of the sample size, even for the tiniest 0.25-inch sample.

0 notes

Text

Pressure Washer Market Size, Share, Price, Trends, Growth, Analysis, and Forecast 2024-2031

The Pressure Washer Market research report provides an in-depth analysis of market drivers, restraints, emerging opportunities, technological advancements, and current trends. This report is a valuable resource for established players and new entrants looking to navigate the evolving landscape of the pressure washer market.

The pressure washer market is witnessing significant growth, driven by governments involved in improvement of infrastructure and increasing number of commercial and residential construction projects. These powerful cleaning machines are increasingly being used for various applications, including vehicle washing, exterior cleaning of buildings, and maintaining outdoor spaces. The shift toward environmentally friendly and efficient cleaning solutions is further boosting the adoption of pressure washers, with innovations in technology enhancing their functionality and performance.

Request for the Sample Report of the Pressure Washer Market: https://www.snsinsider.com/sample-request/1307

Competitive Analysis

The Pressure Washer Market report offers a comprehensive analysis of key industry players, detailing their product portfolios, market share, financial performance, geographic presence, segment revenue, SWOT analysis, and strategic initiatives such as mergers and acquisitions, product developments, and partnerships. Recent developments from these leading companies are also highlighted to provide insights into the competitive landscape.

Key Players Included Are:

Generac Power Systems, Inc.

Snow Joe LLC.

SIMPSON

Campbell Hausfeld

Alfred Kärcher UK

Landa Karcher Group

DEWALT

Sears Brands, LLC.

Sunrise Global Marketing LLC.

Revive Powerwashing Inc.

Karcher

Dewalt

Stanley Black & Decker Ltd.

Generac Power System Inc.

AR North America

Simpson

SunJoe

Ryobi

Craftsman

Market Segmentation

This report provides a detailed segmentation analysis to help both existing and new market participants understand industry needs, market size, and competitiveness. Utilizing robust research methodologies, the report presents graphical forecasts for the upcoming years.

By Type

Portable

Non-Portable

By Power Source

Electric

Gas

Battery

By Component

Water Pump

Electric Motor/Gas Engine

High-pressure Hose

Nozzle

By Water Operation

Hot Water

Cold Water

By Application

Residential

Commercial

Industrial

Regional Analysis

The global pressure washer market research study examines key regions, analyzing revenue, sales, market share, and growth rates to provide a comprehensive view of the market landscape.

North America

USA

Canada

Mexico

Europe

Germany

UK

France

Italy

Spain

The Netherlands

Rest of Europe

Asia-Pacific

Japan

south Korea

China

India

Australia

Rest of Asia-Pacific

The Middle East & Africa

Israel

UAE

South Africa

Rest of Middle East & Africa

Latin America

Brazil

Argentina

Rest of Latin America

Enquiry Before Buying: https://www.snsinsider.com/enquiry/1307

Frequently Asked Questions (FAQ)

What is the current size of the pressure washer market?

What are the main factors driving the growth of the pressure washer market?

Which regions are expected to see the highest growth in the pressure washer market?

Who are the key players in the pressure washer market?

Related Report:

CNC Fiber Laser Market Size

Mid Wave Infrared MWIR Sensors Market Size

Thermal Control Devices Market Size

PNP Transistor Market Size

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company’s aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Akash Anand - Head of Business Development & Strategy

Email: [email protected]

Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

#Pressure Washer Market Size#Pressure Washer Market Share#Pressure Washer Market Forecast#Pressure Washer Market Growth#Pressure Washer Market Analysis

0 notes

Text

Best CNC Laser Cutting Machine in India

Identifying the best CNC laser cutting machine in India involves more than just looking at specifications; it requires an understanding of the market dynamics, application needs, and technological advancements that define modern manufacturing. Among the top contenders, the MSB CNC Fiber Laser Cutting Machine stands out due to its exceptional precision and versatility. Designed for various materials such as metal, wood, and acrylic, this machine utilizes advanced fiber laser technology that not only enhances cutting speed but also reduces operational costs. Its user-friendly interface allows operators, even those with minimal training, to engage with the sophisticated software that controls the cutting process, ensuring accuracy and repeatability.

The robust build quality is matched by the safety features integrated into the design, such as automatic shut-off in case of malfunction, making it suitable for both small workshops and large-scale industrial applications. Furthermore, with the relevance of sustainability in manufacturing today, the MSB machine operates with lower energy consumption compared to traditional cutting machines, aligning with eco-friendly practices that many businesses are now adopting.

The support and after-sales service offered by manufacturers are equally crucial in solidifying customer trust. Companies that provide training, maintenance packages, and readily available spare parts often receive positive feedback from users looking to maximize uptime and machine longevity. When evaluating the best CNC laser cutting machines, it is essential to consider not just the initial investment but also the total cost of ownership, including maintenance, consumables, and the potential for technology upgrades.

Another key player in the Indian market is the HSG LASER cutting machine, known for its exceptional cutting quality and high-speed operation. This machine excels in industries where precision is paramount, such as automotive and aerospace, and features an intelligent control system that optimizes cutting paths and reduces waste material, ultimately increasing productivity. Customers have praised its reliability and performance, especially for intricate designs that require meticulous attention to detail.

Price is often a decisive factor; hence it is essential for prospective buyers to evaluate machines within their budget while also considering the potential return on investment based on their production needs. Entry-level models are available for smaller operations, while high-end machines cater to large manufacturing setups demanding high throughput and versatility.

Recent advancements in technology also mean that businesses can explore additional functionalities, such as 3D laser cutting and engraving capabilities, which can further enhance their service offerings and market competitiveness. Vendors that offer customization options for their CNC laser cutting machines are often seen as more appealing, as they allow businesses to tailor features according to specific operational requirements.

In conclusion, while the MSB CNC Fiber Laser Cutting Machine and HSG LASER stand out for their performance and customer support, selecting the best CNC laser cutting machine in India ultimately depends on the unique needs of the buyer. Focus on assessing machine specifications, total ownership costs, supplier service quality, and technological advancements in laser cutting is critical in making an informed decision. The right choice not only optimizes workflow efficiency but also positions a business for long-term growth in a competitive landscape, making the investment in a quality CNC laser cutting machine a strategic move rather than just a financial expenditure.

Email :- [email protected]

For More Info Visit Us At :- https://sawantgroup.co.in/

Mobile No :- +91 98810 66175

#best cnc bending services india#best mig welding machine#best spot welding services in pune#pre-treatment for surface preparation in pune#cnc bending#best tube#best ss fabrication services in india#cnc punching services in pune#machinery#cnc punching

0 notes

Text

Global Top 15 Companies Accounted for 58% of total Carbon and Graphite Felt market (QYResearch, 2021)

Felts are soft, flexible, high temperature refractory insulation materials, typically used in vacuum and protected atmosphere environments up to a temperature of 3000°C. Carbon and Graphite Felts are two main types of felt used in industries. They are produced when fibres are pressed, matted and condensed together. The firing temperature of carbon felt is usually about 800°C. After high temperature above 2000 ℃ in the vacuum or inert atmosphere, the carbon felt turned into graphite fiber felt. The carbon content is much higher than carbon felt, its 99% min.

According to the new market research report “Global Carbon and Graphite Felt Market Report 2023-2029”, published by QYResearch, the global Carbon and Graphite Felt market size is projected to reach USD 0.38 billion by 2029, at a CAGR of 10.8% during the forecast period.

Figure. Global Carbon and Graphite Felt Market Size (US$ Million), 2018-2029

Figure. Global Carbon and Graphite Felt Top 15 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Carbon and Graphite Felt include Gansu Haoshi Carbon Fiber, SGL Carbon, Kureha, Morgan Specialty Graphite, Chemshine Carbon, Mersen, Nippon Carbon, Sinotek Materials, AvCarb, Shenzhen Goldstone Technology, etc. In 2022, the global top five players had a share approximately 58.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

The Future of Laser Welding: Innovations and Trends in Indian Manufacturing

Laser welding is revolutionizing the manufacturing landscape in India, promising precision, efficiency, and a leap into the future. This blog post will uncover the latest innovations and trends in laser welding, demonstrating why this technology is essential for anyone looking to buy a laser welding machine in India or partner with a CNC laser welding machine manufacturer in India.

Introduction to Laser Welding

Laser welding uses a concentrated beam of light to join materials, often metals. Unlike traditional welding methods, laser welding offers unmatched precision and speed, making it ideal for complex manufacturing processes. This introduction aims to familiarize you with the basics and set the stage for exploring its future in India.

The Growth of Laser Welding in Indian Manufacturing

Manufacturing in India is booming, and with it, the demand for advanced technology. Laser welding is at the forefront, enabling manufacturers to enhance production capabilities and meet global standards. This section explores how laser welding is becoming integral to the manufacturing sector in India.

Why Choose Laser Welding

Laser welding stands out for several reasons:

Precision: Achieve cleaner, more accurate welds.

Speed: Faster welding process reduces production time.

Versatility suitable for various materials and thicknesses.

These attributes make it a go-to choice for industries seeking efficiency and quality.

Innovations in Laser Welding Technology

The technology behind laser welding is continually evolving. Innovations include:

Fiber lasers offer higher efficiency and better control.

Hybrid Laser Welding: Combining laser welding with other methods for enhanced results.

Automation: Integrating AI and robotics for seamless operations.

These advancements are pushing the boundaries of what's possible in manufacturing.

Benefits for Indian Manufacturers

Adopting laser welding technology offers numerous benefits, including:

Cost Reduction: Lower operational costs due to faster production times.

Improved Quality: Higher consistency and fewer defects.

Environmental Impact: Reduced waste and energy consumption.

These benefits make a compelling case for investing in laser welding machines in India.

Key Markets for Laser Welding in India

Several industries are recognizing the advantages of laser welding.

Automotive: Precision welding of components enhances vehicle safety and performance.

Electronics: Miniaturization of parts requires extremely accurate welding.

Aerospace: High-strength, lightweight materials benefit from advanced welding techniques.

Understanding these markets can help businesses identify where laser welding can have the most significant impact.

Trends Shaping the Future of Laser Welding

Several trends are emerging in the world of laser welding:

Customization: Custom laser welding solutions tailored to specific industry needs.

Sustainability is becoming a priority.

Continual Innovation: Ongoing development of new technologies and applications.

Businesses may remain ahead of the curve by keeping an eye on these developments.

Choosing the Right Laser Welding Machine

When looking to buy laser welding machine in India, consider:

Machine Specifications: Ensure it meets your production requirements.

Manufacturer Reputation: Partner with a reliable CNC laser welding machine manufacturer in India.

Support and Training: Availability of technical support and operator training.

Making an informed choice can significantly impact your manufacturing efficiency and product quality.

Collaborating with CNC Laser Welding Machine Manufacturers

Working with experienced CNC laser welding machine manufacturer in India offers several advantages:

Expertise: Access to specialized knowledge and experience.

Customization: Machines tailored to your specific production needs.

After-Sales Support: Ongoing maintenance and troubleshooting support.

These collaborations can provide a significant edge in a competitive market.

Real-World Applications in Indian Industry

Laser Welding Machine is making waves across various sectors.

Jewelry: Precision welding for intricate designs.

Medical Devices: High-quality welds for critical components.

Machinery: Durable and precise welding for industrial machinery.

These applications showcase the versatility and importance of laser welding in modern manufacturing.

Overcoming Challenges with Laser Welding

Implementing laser welding technology isn't without challenges.

Initial Investment: High upfront costs can be a barrier.

Skill Gap: Requires trained operators and technicians.

Integration: Adapting existing production lines to incorporate new technology.

Addressing these challenges is crucial for successful adoption.

The Future of Laser Welding in India

The future looks bright for laser welding in India. Continued advancements in technology, coupled with increasing demand for high-quality manufacturing, will drive growth. By staying informed and adapting to new trends, businesses can harness the full potential of laser welding.

0 notes

Text

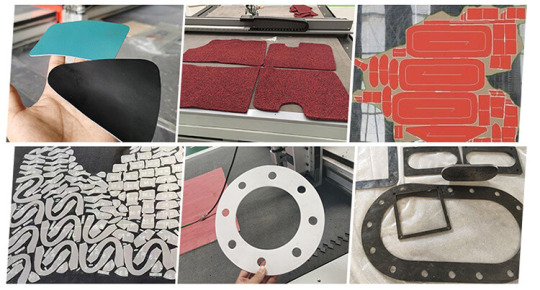

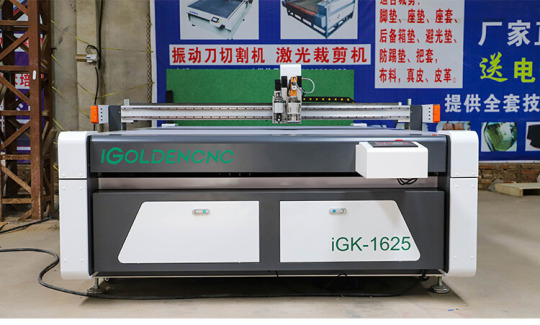

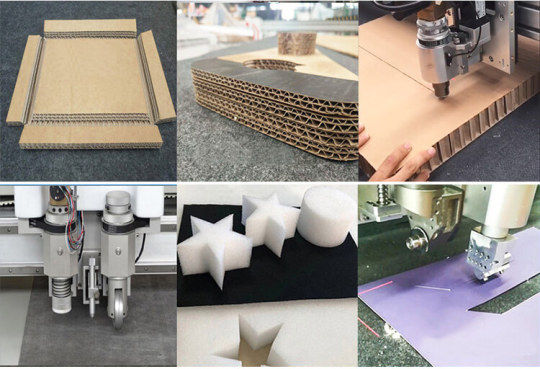

CNC Knife Cutter Machine for PE and EVA Foams

CNC knife cutter machines are widely used in industries such as packaging, textile, automotive, aerospace, and signage. They offer precise and efficient cutting capabilities, enabling the production of intricate shapes and patterns with minimal material waste.

Affordable cnc oscillating knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

CNC Knife Cutter Machine

A CNC knife cutter machine, also known as a CNC cutting machine or a CNC oscillating knife cutter, is a computer-controlled cutting system specifically designed for precision cutting of various materials. It utilizes a vibrating or oscillating knife, which moves rapidly up and down to cut through the material.

Affordable cnc oscillating knife machine have two types: ① CNC Router machine add oscillating knife cutting knife head (Knife together with spindle independent work, compatible with cnc router cotrol system, and running perfectly, Solve the processing needs of soft materials); ② Professional oscillating knife cutting machine ( Professional and efficient ). Accordding to functions: can be divided into oscillating knife cutting , round knife cutting, pneumatic knife cutting. you need to accordding to different material shapes cutting, choose different knives.

CNC can provide all kinds CNC Knife Cutter Machine for sale:

CCD camera series: automatic edge finding, automatic scanning, automatic imaging system.

CNC knife cutter machine table size:

CNC oscillating knife cutting machine for sale have model: 6090, 1390, 1410, 1610, 1325, 1530, 2030, and working table size 600*900mm, 900*1300mm, 1000*1400mm, 1000*1600mm, 1300*2500mm, 1500*3000mm, 2000*3000mm etc, maybe some regions describe cnc knife cutter machine table size with feet: 3*4, 3*5, 4*8, 5*10 etc. We also accept custom table sizes,to meet customer needs.

CNC Knife Cutter Machine Processing advantages

With the continuous development of numerical control technology, more and more customers choose to use smart cutting equipment instead of workers. It uses advanced oscillating knife cutting technology to select different tools according to material thickness and hardness. It can meet a variety of foam material cutting, such as EVA, EPE, sponge, EPS styrofoam and so on.

There are 6 advantages to using the CNC Knife Cutter Machine to cut the foam:

1. More flexible; EVA foam automatic cutting machine does not need a mold, just process the processing data (PLT, DXF, AI format) into the system to cut, and can modify the size and shape of the processing graphics arbitrarily;

2. Save materials; automatic nesting software can complete typesetting quickly and accurately without manual nesting. After actual testing, using an automatic cutting machine can save more than 10% of material compared to manual cutting;

3. Meet different foam cutting; can cut foam of different width, thickness, and material. High cutting precision and flat cutting to meet the cutting requirements of complex graphics.

4. The processing site is more humanized; AMOR EVA foam cutting machine adopts high-frequency oscillating knife cutting technology. Compared with laser cutting technology, the processing site has no soot, and the cutting speed is 3-4 times that of the laser. More environmentally friendly processing methods.

5. Different types of tools can be configured; customers can configure different processing tools according to the processing materials – round knife, pneumatic knife, punching knife, vibrating knife, and other cutter heads to configure freely to cut other materials except for foam;

6. Achieve higher cutting efficiency; AMOR EVA foam cutting machine adopts Japanese Mitsubishi servo motor with cutting speed of up to 2000mm/s. Customers can also choose dual-oscillating tools to cut at the same time, which doubles the processing efficiency.

CNC Knife cutter machine application

Affordable cnc Digital knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

Oscillating Knife Details

Cutting Capabilities

CNC knife cutter machine are versatile and can cut a wide range of materials, including but not limited to:

Soft materials: Foam, rubber, gaskets, textiles, carpets, felt, leather, etc.

Rigid materials: Cardboard, corrugated board, honeycomb board, thin plastics, composite materials, etc.

Other materials: Vinyl, paper, cork, magnetic sheets, adhesive-backed materials, and more.

The oscillating knife’s high-frequency motion allows for clean and precise cuts, even in intricate designs or complex patterns.

Additional Tool Option

In addition to the oscillating knife, CNC knife cutter machines can often accommodate other cutting tools or attachments, expanding their capabilities. Some common additional tools include:

Creasing wheels: Used for creating creases or scoring lines in materials like cardboard or paper, enabling easier folding or bending.

Perforation wheels: Used to create perforated lines for tear-off sections in materials like paper or cardboard.

Routing attachments: Used for cutting harder materials like acrylic or wood, where an oscillating knife may not be suitable.

The ability to interchange tools allows for more versatility in the types of materials and applications that can be handled by the machine.

High Precision and Repeatability

CNC knife cutter machines offer excellent precision and repeatability in cutting. The computer-controlled nature of the machine ensures accurate cutting paths, resulting in consistent and high-quality finished products. This is especially beneficial for industries that require precise fitting, such as packaging or automotive interior components.

Design Flexibility

With the help of specialized software, CNC knife cutter machines can process various design file formats, allowing for flexibility in design creation. Designs can be imported from computer-aided design (CAD) software or created directly within the cutting software. This flexibility enables customization, prototyping, and small-batch production with ease.

Production Efficiency

CNC knife cutter machines streamline the cutting process, reducing manual labor and increasing production efficiency. Once the cutting program is set up, the machine can autonomously execute the cutting tasks, optimizing material usage and minimizing waste. This automation also allows for faster turnaround times, enabling manufacturers to meet tight deadlines and handle larger production volumes.

Integration with Workflow

CNC knife cutter machine can be integrated into a larger production workflow, connecting with other equipment or systems. This integration facilitates seamless material handling, automated nesting (arranging shapes to minimize material waste), and data exchange, enhancing overall productivity and efficiency.

0 notes

Text

CNC Metal Cutting Machine Tools Market to Exhibit 6.7% CAGR by 2027 - Report by Market Research Future (MRFR)

CNC Metal Cutting Machine Tools Market Overview: According to a comprehensive research report by Market Research Future (MRFR), “CNC Metal Cutting Machine Tools Market Research Report, Product Type, By Application and By Region - Forecast Till 2027” the market is expected to expand at a CAGR of 6.7% from 2020 to 2027 (forecast period).

Market Analysis

CNC metal cutting machining is a manufacturing process that uses computer software that has been pre-programmed to control the movement of factory machines and equipment. The approach is used to control a wide range of complex devices, including metal cutting, broaching, grinders, lathes, and others. These machines are frequently used in metal cutting operations to obtain the desired cutting of the metal workpiece. Metal cutting machines currently on the market include plasma cutters, laser cutting devices, and fiber cutters.

0 notes

Text

Frequently Asked Questions About Sheet Metal Fabrication

What is Sheet Metal Fabrication?

At its core, sheet metal fabrication is a term that actually references a few different types of processes. While they may differ in technique, all of them have the same basic goal: to alter the original shape of metal to create new parts, products, and other items.

There are a few different types of metals that one might work with during the sheet metal fabrication process. Perhaps the most commonly used is stainless steel. This is often chosen for applications that require strength and durability, among other properties. Stainless steel is often a desired option for tasks that require high levels of corrosive resistance, too. Note that this should not be confused with regular steel, which is not corrosive resistant.

Another common type of metal used during this process is aluminum. Despite the fact that it is known for its high strength, it is also lighter than a lot of the other options.

Some applications may require copper fabrication. Copper is great for projects that require high levels of both heat and electrical conductivity. It is also "softer" than other types of metal, thus making it more versatile as well.

Finally, bronze can also be used during the sheet metal fabrication process. The major advantage of bronze is that it has a low melting point.

When choosing a laser cutting company, make sure you pick a partner who is willing to go over all the differences with you in great detail, helping to select the right one given your project's requirements.

What is Sheet Metal Laser Cutting?

Sheet metal laser cutting is one of the aforementioned types of sheet metal fabrication that are available. It's also one of the most widely used thanks to the plethora of different benefits it brings with it.

Here, a powerful beam of light (the laser) is used to cut sheets of metal through machines that are leveraging both optics and CNC (computer numerical control) technology. It is by far the most accurate and efficient of the sheet metal fabrication processes.

Depending on the laser cutting services provider you're working with, they may use one or even a few different types of lasers during this time. The first are fiber lasers, which are the most common. In addition to working with metal, they can also work with materials like alloy and even glass.

Another type of laser that you may have heard of is called the CO2 laser – indeed, it is one of the most widely used lasers in the industry. It can only cut non-metals, with plastics being a prime example. It produces its laser by transmitting electricity through a specialized tube that has been filled with carbon dioxide, helium, and nitrogen.

Finally, you have fiber optic laser. These are known for, among other things, their high efficiency. They are also lightweight and movable, allowing them to be used in very flexible working positions. They’re known for being a cost-effective way to achieve high-quality and consistent cutting, regardless of the complexity of the project.

What Other Benefits Does Sheet Metal Fabrication Have to Offer?

In addition to helping create finished parts and products, sheet metal fabrication is also great for assisting with the prototyping stage of any projects.

Using sample parts that have already been created using stamped metal, a team of engineers like those at Yarder Manufacturing can then bring it to life. Sheet metal fabrication allows for a great deal of experimentation, helping to find the best qualities like form and fit. Parts can then be tested in small batches to make sure that they achieve the intended result, all before then moving onto the mass production phase.

The ends results of this are that it almost always leads to faster production, which in turn leads to a faster time-to-market for the finished product as well. During this process you can learn about what works in your design and, more importantly, what doesn't. That gives you the chance to reinforce those good qualities by getting rid of the negatives before spending a lot of money to find them out the hard way. Design flaws can be eliminated now while they're still in their nascent stages, all before they have a chance to become much bigger (and potentially more expensive) issues down the road.

If you have any additional questions about sheet metal fabrication that you'd like to see answered, or if you'd just like to talk about the specifics of your next project in more detail, please don't hesitate to contact the team at Yarder Manufacturing today.

Source URL:- https://americanassit.com/frequently-asked-questions-about-sheet-metal-fabrication/

0 notes

Text

How Fiber Laser Cutting Machines Enhance Manufacturing Processes

In today's fast-paced manufacturing landscape, efficiency and precision are paramount. Businesses are constantly seeking cutting-edge technologies to streamline their processes and stay ahead of the competition. One such innovation that has revolutionised manufacturing is the fiber laser cutting machine. Let's explore how these machines, particularly the ones offered by MadBytes, are enhancing manufacturing processes across industries.

Fiber Laser Machine: The Backbone of Modern Manufacturing

Fiber laser cutting machines have emerged as the go-to solution for precision cutting in various materials, including metals, plastics, and composites. Unlike traditional cutting methods, such as mechanical or plasma cutting, fiber lasers offer unmatched speed, accuracy, and versatility.

MadBytes, a leader in CNC machinery, offers state-of-the-art fiber laser machines designed to meet the evolving needs of manufacturers. These machines utilise advanced fiber laser technology to deliver superior cutting performance, whether it's intricate designs or large-scale production runs.

Flatbed Nesting CNC: Optimising Material Usage

One of the key features of MadBytes' fiber laser machines is their compatibility with flatbed nesting CNC systems. This integration allows manufacturers to maximise material utilisation by nesting multiple parts on a single sheet, thereby reducing waste and minimising production costs.

Auto-Nesting CNC Machine: Streamlining Workflow

MadBytes takes efficiency to the next level with their auto-nesting CNC machines. These automated systems intelligently arrange parts on the cutting bed, optimising cutting paths and minimising idle time. By automating the nesting process, manufacturers can significantly improve throughput without compromising quality.

Fiber Laser Cutting Machine: Precision Redefined

At the heart of MadBytes' manufacturing solutions lies the fiber laser cutting machine. These machines deliver unparalleled precision, thanks to their high-powered fiber lasers and advanced motion control systems. Whether it's intricate patterns or complex geometries, MadBytes' fiber laser cutting machines ensure precise cuts with minimal material distortion.

Benefits Across Industries

The benefits of MadBytes' fiber laser cutting machines extend across a wide range of industries. From automotive and aerospace to electronics and signage, manufacturers are leveraging these cutting-edge technologies to stay competitive in today's market. With faster turnaround times, reduced waste, and superior quality, businesses can meet the demands of their customers while maximising profitability.

Future Outlook:

As technology continues to evolve, the role of fiber laser cutting machines in manufacturing will only grow. MadBytes remains at the forefront of innovation, continuously refining their machines to meet the evolving needs of the industry. With a focus on reliability, performance, and customer satisfaction, MadBytes is empowering manufacturers to thrive in an increasingly competitive landscape.

In conclusion, the fiber laser cutting machines offered by MadBytes are revolutionising manufacturing processes worldwide. From precision cutting to material optimisation, these machines are driving efficiency and productivity across industries. With MadBytes' commitment to innovation and excellence, the future of manufacturing looks brighter than ever.

0 notes

Text

Industrial Laser Solutions Decoded

In the realm of precision manufacturing, detailed laser cutting systems play a crucial role in revolutionizing industrial processes. As businesses strive for efficiency and quality in material processing, the complexities of industrial laser solutions take center stage. Understanding these cutting-edge systems isn't just about technology but a strategic necessity for companies aiming to lead in a competitive market. This article delves into the significance of details laser cutting systems in industrial settings, unveiling the transformative power of these advanced technologies.

Key Takeaways

Laser cutting systems crucial for precision manufacturing in automotive, aerospace, electronics, and medical industries.

Components like laser source, CNC systems, focusing optics, and cooling systems are essential for detailed laser cutting.

Efficiency enhancements include automation, stable temperatures, parameter optimization, and regular maintenance for top performance.

Achieves intricate designs, minimal material wastage, versatile cutting, and precise cuts with advanced laser cutting systems.

Understanding Industrial Laser Solutions

Industrial laser solutions play a pivotal role in various industries, offering precise and efficient cutting capabilities that revolutionize manufacturing processes. One of the key applications of industrial laser solutions is in the automotive industry, where laser cutting is used for shaping and forming various components with unmatched precision. The aerospace sector also heavily relies on laser technology for cutting materials like titanium and composites due to its ability to produce intricate designs while maintaining structural integrity.

Additionally, the electronics industry benefits from industrial laser solutions for precise micromachining processes, enabling the creation of intricate circuit boards and electronic components. In the medical field, laser cutting is essential for manufacturing medical devices and implants with high precision and minimal thermal damage to the surrounding tissues. The versatility of industrial laser solutions extends to the textile industry as well, where lasers are used for cutting fabrics with precision and sealing edges to prevent fraying.

Exploring Detailed Laser Cutting Systems

Delving into the intricacies of laser cutting systems reveals a complex web of precision engineering and advanced technology. Laser cutting systems are at the forefront of industrial manufacturing processes, offering unmatched precision and efficiency. These systems utilize high-powered lasers to cut through materials with incredible accuracy, making them essential tools in various industries such as automotive, aerospace, and electronics.

One key component of laser cutting systems is the laser source itself, which can vary from fiber lasers to CO2 lasers, each with its unique characteristics and applications. These lasers are guided by sophisticated CNC systems that dictate the cutting path with exceptional detail, ensuring precise and consistent results.

Additionally, the focusing optics play an important role in determining the spot size and intensity of the laser beam, directly impacting the cutting quality and speed. Additionally, advanced cooling systems are employed to maintain the best operating temperature of the laser source, ensuring long-term reliability and performance.

Advantages of Precision Laser Cutting

Exploring the efficiency gains and unmatched precision provided by precision laser cutting reveals a multitude of advantages in industrial manufacturing processes. Precision laser cutting offers several benefits that contribute to enhancing productivity and quality in manufacturing settings:

Critical Precision: Laser cutting systems can achieve incredibly precise and intricate cuts, ensuring accuracy and repeatability in the production process.

Versatility: Laser cutting technology can be used on a wide range of materials, including metals, plastics, wood, and ceramics, making it a versatile solution for various industries.

Minimal Material Waste: The precision of laser cutting results in minimal material wastage, optimizing resource utilization and reducing overall production costs.

Increased Efficiency: Laser cutting is a fast and efficient process, allowing for rapid prototyping, short lead times, and streamlined production workflows.

These advantages showcase how precision laser cutting systems play a crucial role in modern industrial manufacturing by enabling high-quality, cost-effective production processes.

Key Components in Laser Cutting Systems

Key components in laser cutting systems work in tandem to guarantee precise and efficient material processing. The laser source emits a high-powered beam focused and directed by mirrors and lenses. These optical components control the laser beam's intensity and accuracy.

The cutting head, with a focusing lens and nozzle, determines the spot size and delivers laser energy to the workpiece. The CNC controller translates design specifications into precise movements of the laser beam. The motion system, with servomotors and drive systems, ensures proper positioning and speed during cutting operations.

The assist gas system provides necessary support, like oxygen or nitrogen, to aid in the cutting process by blowing away molten material. The machine frame provides stability and support for all components, contributing to the accuracy and reliability of the system.

Enhancing Efficiency in Laser Cutting

To optimize the operational performance of laser cutting systems, efficiency enhancements can be strategically implemented through targeted modifications and process refinements. When aiming to enhance efficiency in laser cutting, the following strategies can be utilized:

Implementing Automation: Introducing automation in loading/unloading processes can greatly reduce downtime and increase overall productivity.

Utilizing Advanced Cooling Systems: Efficient cooling systems help maintain stable operating temperatures, preventing overheating and ensuring consistent cutting quality.

Optimizing Cutting Parameters: Fine-tuning parameters such as laser power, cutting speed, and focal length can lead to improved precision and reduced material waste.

Regular Maintenance and Calibration: Scheduled maintenance checks and calibration of the laser cutting system components are essential to ensure top performance and longevity.

Future Trends in Laser Cutting Technology

Advancements in laser cutting technology are shaping the future landscape of industrial manufacturing processes. As industries aim for increased efficiency and precision, laser cutting technology continues to evolve to meet these demands. One of the future trends in laser cutting is the development of even more powerful and precise laser systems. These systems will enable manufacturers to cut through thicker materials at faster speeds while maintaining high levels of accuracy.

Another trend on the horizon is the integration of artificial intelligence (AI) and machine learning algorithms into laser cutting systems. This integration will allow for real-time adjustments based on various factors such as material properties, cutting patterns, and environmental conditions. By leveraging AI, laser cutting machines can optimize parameters on the fly, resulting in improved efficiency and quality of cuts.

Additionally, the trend towards environmentally friendly practices is also influencing laser cutting technology. Manufacturers are increasingly looking for sustainable solutions, leading to the development of laser systems that minimize energy consumption and waste generation. These advancements in laser cutting technology signify a promising future for the manufacturing industry, where efficiency, precision, and sustainability are paramount.

Frequently Asked Questions

Can Laser Cutting Systems Be Used for Materials Other Than Metal?

Laser cutting systems have versatile applications beyond metal materials. They are also used for cutting various non-metal materials like wood, acrylic, plastic, fabric, and more. The precision and efficiency of laser cutting make it a popular choice across different industries.

How Do Laser Cutting Systems Compare to Traditional Cutting Methods?

Laser cutting systems offer unparalleled precision, speed, and versatility compared to traditional cutting methods. They excel in intricate designs, minimize material waste, and provide cleaner cuts. These systems are highly efficient for various industries seeking cutting-edge solutions.

Are There Safety Precautions That Need to Be Taken When Operating Laser Cutting Systems?

Safety precautions are crucial when operating laser cutting systems. Prioritize proper training, wear protective gear, and maintain a clean workspace. Implement safety protocols, guarantee proper ventilation, and regularly inspect equipment for any signs of wear or malfunction to prevent accidents.

What Maintenance Is Required for Laser Cutting Systems to Ensure Optimal Performance?

Maintenance for laser cutting systems is important for best performance. Regularly clean lenses, mirrors, and cutting bed. Check for wear on components like nozzles and focus lenses. Calibration should be done periodically. Make sure proper ventilation and cooling.

How Customizable Are Laser Cutting Systems for Specific Cutting Needs?

Laser cutting systems offer high levels of customization to meet specific cutting needs. Variable parameters like power, speed, and focal length can be adjusted to optimize performance for different materials and thicknesses, ensuring precise and efficient cutting processes.

Conclusion

To sum up, the detailed laser cutting systems discussed in this article play a pivotal role in advancing industrial processes by enabling precision and efficiency in material processing. Through the utilization of advanced technologies, businesses can optimize production efficiencies and achieve high levels of quality in manufacturing. The evolution of laser cutting technology continues to shape the future of industrial sectors, driving innovation and productivity in the domain of fabrication and manufacturing.

0 notes

Text

Fiber Laser Cutting Reduces Production Time

Fiber Laser Cutting Reduces Production Time:

As industries strive to meet increasing demands while maintaining high-quality standards, innovations in technology play a pivotal role in streamlining production processes. One such innovation that has transformed the landscape of manufacturing is fiber laser cutting. By harnessing the power of concentrated laser beams, fiber laser cutting has emerged as a game-changer, significantly reducing production time and enhancing overall productivity. Let's explore how fiber laser cutting achieves these efficiencies and its impact on various industries.

Speed and Precision: One of the primary reasons fiber laser cutting reduces production time is its unparalleled speed and accuracy. Traditional cutting methods can be slow and prone to wear. Fiber lasers deliver concentrated beams of light that can cut through materials with incredible speed and accuracy. The high cutting speeds of fiber lasers allow manufacturers to complete jobs in a fraction of the time, thereby reducing overall production time significantly.

Minimal Setup and Tooling: Another factor contributes to the time-saving capabilities of fiber laser cutting. Traditional cutting methods often involve extensive setup times, including the installation of specialized tools, fixtures, and templates. In contrast, fiber laser cutting is a non-contact process. It eliminates the need for physical tooling and reduces setup times. This flexibility enables manufacturers to respond quickly to changing production requirements and optimize workflow efficiency.

Versatility in Material Handling: Best CNC laser sheet cutting machine in India offers unparalleled creativity in material handling. It allows manufacturers to process a wide range of materials with ease. Whether it's metals like steel, aluminum, copper, or non-metallic materials, fiber lasers can cut through them with accuracy and consistency. This creativity eliminates the need for multiple cutting processes and pieces of equipment.

Integration with Automation: The integration of fiber laser cutting technology with automation systems enhances overall productivity by optimizing workflow efficiency and reducing labor costs. Automated material handling, loading, and unloading systems enable continuous operation and minimize downtime between jobs. Additionally, advanced software solutions and intelligent control systems automate process monitoring and optimization. It ensures optimal cutting parameters for each job and minimizes errors and rework.

Impact Across Industries: The time-saving benefits of fiber laser cutting have a profound impact across various industries, from automotive and aerospace to electronics and consumer goods. In automotive manufacturing, for example, fiber laser cutting speeds up the manufacture of structural components, body panels, and engine parts, allowing for faster turnaround times and improved production capacity. Similarly, in aerospace engineering, fiber lasers speed up the fabrication of complex components like turbine blades and structural elements.

In the electronics industry, CNC fiber laser cutting machine manufacturer facilitates the rapid prototyping and production of circuit boards, enclosures, and other electronic components, enabling faster time-to-market for new products. Moreover, in the consumer goods sector, fiber laser cutting enables manufacturers to quickly iterate designs and produce custom products with short lead times.

Future Outlook: As fiber laser cutting technology continues to evolve, we can expect further advancements that will drive even greater efficiencies and productivity gains. Prolonged research and development efforts focused on increasing laser power, improving beam quality, and enhancing automation capabilities will speed up production procedures and expand the scope of fiber laser cutting's uses across sectors. Additionally, innovations in software solutions and data analytics will enable manufacturers to optimize cutting parameters, predict and prevent errors, and maximize overall equipment effectiveness.

Application of the Fiber Laser Cutting Machine:

1. Automotive Industry

2. Aerospace Industry

3. Electronics Industry

4. Medical Equipment Manufacturing

5. Architectural and Interior Design

6. Textiles and Apparel

7. Jewelry Making

8. Tool and Die Making

9. Shipbuilding and Offshore Industries

10. Signage and Advertising

We can expect even more accuracy, speed, and adaptability from this incredible equipment as technology develops.

0 notes

Text

Enhance Productivity with Fiber Laser Cutters

In today's manufacturing landscape, businesses are increasingly turning to cutting-edge solutions to boost productivity, and Fiber Laser Cutting Machines are at the forefront of this revolution. As a leading Fiber Laser Cutting Machine Manufacturer, we understand the pivotal role these machines play in precision cutting and efficiency. Our state-of-the-art technology ensures that businesses stay competitive by delivering unparalleled accuracy and speed in metal cutting processes.

Not only are Fiber Laser Cutting Machines an integral part of enhancing productivity, but they also represent a commitment to quality and innovation. As a trusted CNC Plasma Cutting Machine Manufacturer, we provide versatile solutions that cater to diverse industrial needs. Our cutting-edge CNC Plasma Cutting Machines offer a perfect blend of precision and cost-effectiveness, empowering businesses to achieve remarkable results in metal fabrication.

Investing in Fiber Laser Cutting Machines from a reputable Fiber Laser Cutting Machine Manufacturer is a strategic move that aligns with the evolving needs of modern manufacturing. By incorporating these advanced technologies, businesses can streamline their production processes, reduce material waste, and ultimately, achieve higher levels of productivity. Stay ahead in the competitive market by choosing cutting-edge solutions that redefine the standards of efficiency and precision.

#fiberlasercuttingmachine#fiberlasercuttingmachinemanufacturer#industrialmetal#industrialmanufacturer#metweld#industrialproducts#industrialequipment

0 notes