#chequered plate

Explore tagged Tumblr posts

Text

Chequered Plate Prices, News, Trend, Graph, Chart, Forecast and Historical

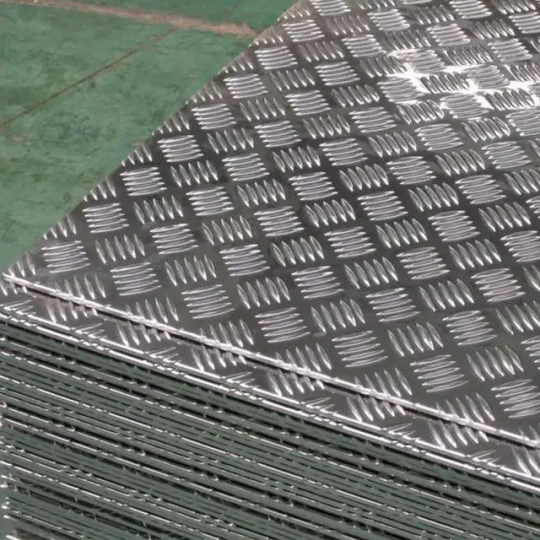

Chequered Plate prices have been experiencing fluctuations over the years due to various market dynamics, including raw material costs, supply-demand imbalances, and global economic conditions. As a key component in industries such as construction, transportation, and manufacturing, the price of chequered plates plays a crucial role in determining the overall costs of projects involving flooring, industrial applications, and safety equipment. The chequered plate, also known as diamond plate or tread plate, is a flat metal sheet featuring a raised pattern of diamonds or lines, providing excellent traction and durability. These plates are predominantly made from materials like steel, aluminum, and stainless steel, each of which influences the final price due to its specific properties and production processes.

The demand for chequered plates is often tied to the performance of industries such as construction, automotive, and mining. These sectors require durable, non-slip surfaces for various applications, which has led to a steady demand for chequered plates. However, the price of raw materials used in manufacturing chequered plates, such as steel and aluminum, plays a significant role in shaping the overall cost. Steel prices, for instance, are largely influenced by global factors such as the cost of iron ore, energy prices, and transportation expenses. Similarly, the aluminum market is susceptible to changes in the global supply chain, geopolitical tensions, and shifts in demand from industries like aerospace and electronics. As such, chequered plate prices often follow trends in the broader metal market, experiencing periodic increases or decreases based on fluctuations in material costs.

Get Real time Prices for Chequered Plate: https://www.chemanalyst.com/Pricing-data/chequered-plate-1490

In addition to raw material costs, the manufacturing process itself contributes to the overall pricing of chequered plates. The production of chequered plates involves several stages, including the rolling, pattern embossing, and cutting of metal sheets. These processes require specialized machinery, skilled labor, and energy, all of which add to the production cost. For instance, the cost of electricity and fuel can significantly impact the final price of chequered plates, especially in regions where energy prices are volatile. Furthermore, advancements in production technologies, such as automated machinery and enhanced quality control measures, can help reduce manufacturing costs over time, potentially leading to more competitive pricing in the market.

Another factor influencing chequered plate prices is regional demand and supply conditions. Different regions may experience varying levels of demand based on local construction activities, infrastructure development, and industrial growth. For example, countries undergoing rapid urbanization or infrastructural development often see a surge in the demand for chequered plates for use in flooring, staircases, and walkways. Conversely, in regions where construction activity slows down, the demand for chequered plates may dip, causing a decrease in prices. Additionally, regional supply chains and the availability of raw materials play a critical role in shaping pricing trends. Countries with abundant natural resources and well-established manufacturing capabilities tend to offer more competitive pricing, while regions dependent on imports may face higher prices due to logistics costs and tariffs.

The global economic climate also has a profound impact on chequered plate prices. Economic slowdowns, inflation, and shifts in trade policies can all affect the cost of materials and manufacturing. For instance, during periods of economic uncertainty, demand for construction and industrial products may decrease, leading to a reduction in the need for chequered plates. This lower demand can result in price stabilization or even a drop in prices. On the other hand, during economic booms, when demand for infrastructure and manufacturing materials is high, chequered plate prices may rise due to increased competition for limited supplies of raw materials. Moreover, inflationary pressures in the broader economy can drive up production costs, which are often passed on to consumers in the form of higher prices for chequered plates.

The pricing of chequered plates is also influenced by trade policies and tariffs, particularly in regions with high levels of import and export activity. For example, if a country imposes tariffs on imported steel or aluminum, the cost of these raw materials can increase, thereby pushing up the price of chequered plates manufactured locally. Additionally, fluctuations in currency exchange rates can impact the affordability of imported chequered plates. When the local currency depreciates against foreign currencies, the cost of imports increases, potentially leading to higher prices for chequered plates.

The availability of alternative materials and technologies can also influence the market price of chequered plates. As industries increasingly look for cost-effective and sustainable solutions, alternative materials like composite plates or non-metallic chequered plates may gain popularity, affecting the demand for traditional metal-based chequered plates. These alternative materials often come with their own set of benefits, such as reduced weight or enhanced corrosion resistance, which can make them more attractive to certain industries. As a result, the demand for traditional chequered plates may decrease, putting downward pressure on prices.

Looking ahead, the chequered plate market is expected to remain influenced by the ongoing development of the global economy, raw material costs, and technological advancements in manufacturing. While price volatility is expected to continue, the increasing use of chequered plates in various industries and applications will likely ensure a stable level of demand. Manufacturers may focus on improving the efficiency of their production processes to mitigate rising material costs, while consumers may seek out more affordable alternatives as the market becomes more competitive. As such, stakeholders in the chequered plate industry must stay informed of market trends, raw material price movements, and technological innovations to navigate the ever-evolving landscape of chequered plate pricing.

Get Real time Prices for Chequered Plate: https://www.chemanalyst.com/Pricing-data/chequered-plate-1490

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Chequered Plate#Chequered Plate Price#Chequered Plate Prices#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

What are the uses of MS chequered plates?

MS chequered plates, also known as mild steel checkered plates, are versatile materials with a wide range of applications across various industries. Some common uses of MS chequered plates include:

Flooring and Walkways: MS chequered plates are often used as flooring materials in industrial and commercial buildings, as well as in areas where slip resistance is essential, such as walkways, ramps, stair treads, and platforms.

Vehicle Flooring: In the automotive industry, MS chequered plates are used as flooring materials for trucks, trailers, and other vehicles to provide traction and durability, especially in heavy-duty applications.

Structural Components: MS chequered plates are utilized in the construction of structural components such as bridges, beams, columns, and support structures, where their strength and durability help ensure the stability and integrity of the structure.

Decorative Applications: MS chequered plates are also used in decorative applications such as architectural accents, interior design elements, and exterior cladding, adding texture and visual interest to surfaces.

Industrial Machinery: MS chequered plates are incorporated into industrial machinery and equipment to provide stable and secure footing for operators, as well as to protect surfaces from wear and tear.

Storage Systems: MS chequered plates are used in the construction of storage systems such as shelving, racks, and pallets, providing a sturdy and durable surface for storing heavy items.

Overall, MS chequered plates offer strength, durability, and slip resistance, making them suitable for a wide range of applications in various industries.

Whether for vehicle flooring, decorative accents, or industrial machinery, trust SteelonCall to deliver top-notch MS chequered plates directly to your project site, eliminating middlemen and ensuring quality at every step.

0 notes

Text

Chequered Plate - Infrakeys Technologies

Chequered Plate by Infrakeys Technologies is an innovative solution designed to enhance security and access control in diverse environments. It integrates advanced technology with robust construction to provide reliable performance in various applications. The Chequered Plate system features a unique combination of features, including biometric authentication, RFID access control, and video surveillance capabilities, all seamlessly integrated into a sleek and modern design.

At its core, Chequered Plate utilizes cutting-edge biometric recognition technology to ensure secure and accurate identification of individuals. Whether it's fingerprint, facial recognition, or iris scanning, users can access controlled areas with confidence, knowing that their identity is verified with precision.

In addition to biometric authentication, Chequered Plate incorporates RFID technology for streamlined access control. Authorized personnel can gain entry with a simple swipe or tap of their RFID-enabled credentials, reducing wait times and improving overall efficiency.

Furthermore, Chequered Plate is equipped with comprehensive video surveillance features, including high-definition cameras and intelligent analytics. This enables real-time monitoring of access points, allowing security personnel to respond swiftly to any unauthorized activities or breaches.

The design of Chequered Plate is both aesthetically pleasing and highly functional, seamlessly blending into various architectural environments. Its durable construction ensures long-term reliability, making it suitable for indoor and outdoor installations alike.

Infrakeys Technologies has engineered Chequered Plate to meet the evolving security needs of modern facilities, providing a versatile and effective solution for access control and surveillance challenges. With its advanced features and user-friendly interface, Chequered Plate sets a new standard for security excellence.

0 notes

Text

Strength in Steel: Trusted Structural Steel Services in UAE by Mechden Steel Fabrication LLC

When it comes to building the future of infrastructure in the UAE, one name that stands out in the industry is Mechden Steel Fabrication LLC. Known for its precision engineering, quality craftsmanship, and commitment to safety, Mechden has become a trusted partner in Structural Steel Services in UAE. From metal work to the supply and installation of Trench Chequered Plates, the company is redefining the standards of modern construction.

0 notes

Text

Key Benefits of Using Hot Dip Galvanized Chequered Plates in Construction

A chequered plate or checker plate is the type of metal plate with a raised diamond pattern to enhance grip and traction. The alloy is often prepared of steel but is sometimes manufactured in various other metals also like aluminum, stainless steel, etc. The checkered version is referred to as a Galvanized checkered plate wherein one or both the sides of plates are covered under the zinc oxide as the coating via the galvanization method which is usually hot dipped. The result is a steel checker plate that is more resistant to corrosion and wear, making it ideal for use in environments prone to harsh weather and heavy traffic.

1. Enhanced Durability and Corrosion Resistance

The foremost advantage of having a galvanized checker plate sheet is enhanced durability. It protects the steel due to the galvanized zinc coating, from the moisture, air, and other factors causing rust and corrosion. Thus, the chequered plate proves ideal for outdoors or areas of high humidity, such as construction sites, factories, and warehouses.

In construction, using a galvanized chequered plate ensures that structures become safe and reliable for a very long time where the safety of workers is an utmost priority. The galvanized layer acts as a barrier, a protective layer over the chequered plate providing a long life against the roughest environmental conditions.

2. Improved Safety and Anti-Slip Properties

The raised pattern of a checker plate not only gives aesthetic appeal to the surface but also greatly enhances safety. The design of the steel checker plate creates friction, reducing the likelihood of slipping. This makes it suitable for stair treads, walkways, and industrial flooring. This is very important in construction zones, where workers are usually required to work in challenging conditions.

Whether it is installed on a floor, staircase, or platform, the chequered plate sheet with its anti-slip properties offers a safe working environment and allows personnel to move safely and comfortably across surfaces without the risk of accidents caused by slippery floors.

3. Cost-Effectiveness

Though some construction materials can be quite expensive, hot dip galvanized chequered plates do not cost a fortune without affecting the quality and safety standards. The base steel plate from which checker plates are made is widely available, and the galvanization process is relatively cheap compared to other corrosion protection processes. Thus, long-term protection through hot dip galvanized chequered plates makes it a feasible choice.

Furthermore, the galvanized coating prolongs the life of the material, meaning that less maintenance and fewer replacements are needed. This reduces long-term costs for construction companies and ensures that investments in materials like steel checker plate provide excellent value over time.

3. Safety

Hot-dip galvanized steel has a life expectancy greater than 50 years within any environment, making it fit to be used for integral structural components of stainless-steel cable trays and earthing systems.

4. Versatility in Application

The versatility of hot dip galvanized chequered plates in construction is another key advantage. Hot Dip Galvanized Checker plates can be used for industrial, commercial, or residential construction. They can be used for multiple purposes, such as:

Flooring: Suitable for high-traffic areas like factory floors, warehouses, and garages.

Stair Treads: Provides grip and durability on both indoor and outdoor stairs.

Platforms: Offers a strong, slip-resistant surface for either temporary or permanent platforms.

Ramps: Helps prevent slipping on ramps which can become slippery and wet.

Walkways: Maintains safe and durable surfaces on pedestrian paths.

Apart from construction, checker plate sheets are also widely used for other purposes, such as vehicle loading ramps and protective coverings for machinery, thus showing their wide utility.

5. Easy Installation and Maintenance

Another major advantage of hot dip galvanized chequered plates is that they are easy to install. The steel base plate is relatively light in weight compared to other materials, hence easier to handle and install. Moreover, the galvanized coating ensures that the plates are resistant to rust and wear, thus reducing the need for constant maintenance.Since Hot Dip Galvanized checker plate sheets are quite resistant to weathering and corrosion, they will not degrade even when exposed to the elements. This means once the plates are installed, there is little to no upkeep required. This makes it an ideal solution for construction projects where quality and low-maintenance solutions are demanded.

6. Environmental Sustainability

Increasing pressure to adopt more environment friendly methods for the construction industry has resulted in galvanized checker plates becoming one of the popular options. In the application of zinc coating using a hot dip galvanizing process, corrosion is effectively repelled, and also, this is considered as safe for the environment. Zinc is naturally occurring metal and galvanized zinc coating applied to steel checker plates is easily recyclable.

In addition, the longer durability of galvanized materials minimizes the resources needed to be used for replacement and repairs. This also saves waste in construction and helps build more sustainably. Using hot dip galvanized chequered plates falls in line with the construction industry’s current trends toward sustainability.

7. Strength and Load-Bearing Capacity

Steel checker plates are known for their strength and load-bearing capacity. This makes them ideal for heavy-duty applications, such as industrial floors and platforms, where significant weight is placed on the surface. The raised pattern of a chequered plate adds strength, distributing the weight evenly across the surface. When properly installed, these plates can withstand heavy equipment, machinery, and foot traffic.

It is for such reasons that steel base plates are widely applied in the implementation of critical infrastructure projects, as the integrity of the construction has to be upheld in these projects.

8. High Aesthetic Appeal

Apart from the functional benefits, hot dip galvanized chequered plates are also aesthetically pleasing. The raised pattern gives a textured and visual appearance to surfaces, making them not only safe and functional but also attractive. This is very beneficial in areas where the appearance of the structure is important, such as in commercial buildings, modern architecture, and public spaces.

Undeniably, the construction benefits and attributes of using hot dip galvanized chequered plates are undeniable. Such plates provide enhanced durability and corrosion resistance yet deliver far more with anti-slip properties and ease of installation. We at Parco Engineers intend to provide high quality Hot Dip Galvanized steel checker plates, whereby the standards of each product would satisfy the criteria of the high and stringent demands of modern construction.

Whether it is flooring, stair treads, platforms, galvanized checker plates are versatile, durable, and cost-effective. Long-lasting performance and environmental sustainability make them a staple in the construction industry.For the best hot dip galvanized chequered plates, Parco Engineers continues to lead the way with innovative and reliable products that ensure the success of every construction project.

0 notes

Text

Steel Plates P-20 Suppliers in Delhi | MS Circular Plates Suppliers in Delhi | Chequered Plate Suppliers in Delhi – GM Goel Steel Impex

Trusted Steel Plate Suppliers in Delhi – GM Goel Steel Impex

GM Goel Steel Impex is a renowned name in the steel industry, providing high-quality steel plates and allied products to meet diverse industrial requirements. As leading Steel Plates P-20 Suppliers in Delhi, MS Circular Plates Suppliers in Delhi, and Chequered Plate Suppliers in Delhi, we cater to the demands of various industries, including automotive, construction, manufacturing, and heavy engineering.

With years of experience and expertise, we ensure that our clients receive superior-grade steel products that comply with international quality standards. Whether you need P-20 steel plates, mild steel circular plates, or chequered plates, we offer the best solutions tailored to your needs.

Steel Plates P-20 Suppliers in Delhi

P-20 Steel Plates are widely used in the tooling and die-making industries due to their excellent machinability, high strength, and resistance to wear. GM Goel Steel Impex is a trusted P-20 Steel Plates Suppliers in Delhi, offering premium-quality plates suitable for mold-making applications.

Key Features of P-20 Steel Plates:

High Hardness & Toughness – Ideal for molds and dies.

Excellent Machinability – Easy to cut, weld, and fabricate.

Corrosion & Wear Resistance – Ensures durability and longevity.

Uniform Surface Finish – Reduces the need for additional machining.

Applications of P-20 Steel Plates:

Plastic Injection Molds

Die-Casting Tools

Forging Dies

Industrial Machine Parts

Structural Components

At GM Goel Steel Impex, we offer custom sizes and specifications of P-20 steel plates to meet our clients' requirements. Our commitment to quality ensures that you get the best product at competitive prices.

MS Circular Plates Suppliers in Delhi

Mild Steel (MS) Circular Plates are widely used in structural and industrial applications due to their high strength, versatility, and durability. As one of the most reliable MS Circular Plates Suppliers in Delhi, GM Goel Steel Impex provides top-quality circular steel plates for diverse industrial and engineering applications.

Key Features of MS Circular Plates:

High Tensile Strength – Suitable for heavy-duty applications.

Excellent Weldability – Easily weldable for fabrication purposes.

Corrosion Resistant – Long-lasting and durable.

Cost-Effective Solution – Affordable and reliable for multiple applications.

Applications of MS Circular Plates:

Pressure Vessels

Boilers & Heat Exchangers

Machinery Components

Structural Engineering

Industrial Fabrication

Our MS circular plates are available in different thicknesses, diameters, and grades to meet the exact needs of our customers. We ensure precise cutting and finishing to provide ready-to-use circular steel plates.

Chequered Plate Suppliers in Delhi

Chequered Plates, also known as tread plates or diamond plates, are used in construction, transportation, and industrial flooring due to their anti-slip surface. As one of the leading Chequered Plate Suppliers in Delhi, GM Goel Steel Impex provides durable and high-strength chequered plates suitable for various applications.

Key Features of Chequered Plates:

Anti-Skid Surface – Ideal for flooring and staircases.

High Durability – Withstands heavy loads and pressure.

Corrosion & Weather Resistance – Long-lasting performance.

Available in Various Thicknesses – Customizable as per client needs.

Applications of Chequered Plates:

Industrial Flooring & Staircases

Automobile & Railway Platforms

Ramps & Walkways

Structural Fabrication

Heavy Equipment Manufacturing

Our chequered plates are manufactured using high-quality raw materials, ensuring superior strength and longevity. Whether you need standard sizes or custom specifications, GM Goel Steel Impex provides the best solutions at competitive prices.

Why Choose GM Goel Steel Impex?

As a trusted name in the steel industry, GM Goel Steel Impex stands out as one of the best steel suppliers in Delhi. Here’s why our clients prefer us:

Premium Quality Products – We supply only the finest steel plates that meet international standards.

Competitive Pricing – Get the best rates without compromising on quality.

Wide Range of Products – From P-20 steel plates to MS circular and chequered plates, we have it all.

Customized Solutions – Tailored sizes and specifications to match industry requirements.

Timely Delivery – Efficient logistics ensure prompt supply and delivery.

Experienced Team – Expertise in steel trading and supply chain management.

Contact Us – Get the Best Steel Plates in Delhi

Looking for high-quality Steel Plates P-20, MS Circular Plates, or Chequered Plates in Delhi? GM Goel Steel Impex is your go-to supplier for all types of steel plates. get in touch with us today for the best deals on steel plates in Delhi. Let us provide you with high-quality, durable, and cost-effective steel solutions for your industrial and construction needs.

Conclusion

GM Goel Steel Impex is the top supplier of Steel Plates P-20, MS Circular Plates, and Chequered Plates in Delhi. With our commitment to quality, customer satisfaction, and competitive pricing, we ensure that you get the best steel products for your projects. Whether you need P-20 plates for tooling, MS circular plates for fabrication, or chequered plates for flooring, we have the right solutions for you.

#Steel Plates P-20 Suppliers in Delhi#MS Circular Plates Suppliers in Delhi#Chequered Plate Suppliers in Delhi

0 notes

Text

inconel alloy 625 chequered plate manufacturers in Uae | Mehta Metals

Mehta Metals is a leading manufacturer and supplier of Inconel Alloy 625 chequered plates, renowned for their exceptional strength, corrosion resistance, and durability. Our chequered plates are meticulously crafted to meet the stringent demands of industries such as offshore oil drilling, power generation, petrochemicals, gas processing, specialty chemicals, pharmaceuticals, and seawater equipment. With a commitment to quality and precision, we ensure that each plate adheres to international standards, providing reliable performance in challenging environments. Our state-of-the-art manufacturing facilities and experienced team enable us to deliver products that not only meet but exceed client expectations. Choose Mehta Metals for your Inconel Alloy 625 chequered plate needs and experience unparalleled service and product excellence.

0 notes

Text

Understanding Chequered Plates: Features, Uses, and Benefits

Chequered Plates are an essential material in various industries due to their durability, anti-slip properties, and versatility. These metal plates have a raised pattern on one side, making them ideal for applications where grip and safety are crucial. This article will explore the features, uses, and benefits of Chequered Plates in different industries.

What Are Chequered Plates?

Chequered Plates are metal sheets with a raised surface pattern that provides better traction. The patterns commonly include diamonds, lines, or other geometric shapes. They are made from different metals such as steel, aluminum, and stainless steel, each offering unique properties for specific applications.

Features of Chequered Plates

Anti-Slip Surface – The raised pattern provides excellent grip, making Chequered Plates a perfect choice for flooring, ramps, and staircases.

Durability – Made from strong metals, these plates can withstand heavy loads and harsh environmental conditions.

Corrosion Resistance – Depending on the metal used, Chequered Plates can resist rust and corrosion, making them suitable for outdoor and marine applications.

Lightweight Option Available – Aluminum Chequered Plates are lighter compared to steel ones, making them easier to handle without compromising strength.

Aesthetic Appeal – The patterns on Chequered Plates add a stylish touch, which is why they are used in interior and architectural designs.

Common Applications of Chequered Plates

Due to their unique properties, Chequered Plates are widely used in different industries. Some of the most common applications include:

1. Construction Industry

Chequered Plates are used in construction for staircases, walkways, and flooring to prevent slipping. They are also used in scaffolding for extra safety.

2. Automotive Industry

In vehicles, Chequered Plates are commonly used for footrests, truck beds, and interior flooring to provide better grip and durability.

3. Industrial Flooring

Factories and warehouses use Chequered Plates to enhance workplace safety by reducing the risk of slips and falls.

4. Marine and Shipbuilding

Due to their resistance to corrosion, Chequered Plates are used on ship decks, docks, and offshore platforms.

5. Decorative and Architectural Uses

Modern buildings and interior designs incorporate Chequered Plates for their stylish and functional appeal, especially in commercial spaces and staircases.

Benefits of Using Chequered Plates

Enhanced Safety – The anti-slip surface reduces accidents in workplaces and public areas.

Long Lifespan – High-quality Chequered Plates are designed to last for years, even in harsh environments.

Low Maintenance – They require minimal maintenance, making them a cost-effective choice.

Versatility – Chequered Plates can be used in various industries, from construction to decorative applications.

Conclusion

Chequered Plates are a valuable material in many industries, offering safety, durability, and aesthetic appeal. Whether for industrial flooring, vehicle interiors, or marine applications, their unique features make them an excellent choice. If you are looking for a reliable, long-lasting, and slip-resistant material, Chequered Plates are a perfect solution.

This article is written in simple English and focuses solely on Chequered Plates, ensuring clarity and readability while maintaining originality. Let me know if you need any modifications!

0 notes

Text

Differences Between Aluminium 6061 Chequered Plates and Flat Plates

Aluminium 6061 is a versatile alloy known for its excellent mechanical properties and widespread use across various industries. Two common forms of this alloy are chequered plates and flat plates. While both are made from the same base material, their distinct forms serve different purposes and have unique characteristics. This blog explores the key differences between Aluminium 6061 chequered and flat plates, helping you understand which is best suited for your needs.

What Are Aluminium 6061 Chequered Plates?

Aluminium 6061 chequered plates are distinguished by their textured surface featuring a raised pattern. This pattern typically consists of diamond-shaped or linear designs, which provide a unique combination of strength, traction, and aesthetic appeal. The raised pattern increases the surface friction, making these plates ideal for applications requiring slip resistance.

Applications:

Flooring: Commonly used in industrial and commercial flooring where slip resistance is crucial.

Vehicle Platforms: These are often found in trailers and service vehicles to enhance grip.

Decorative Uses: Employed in architectural elements for its distinctive look.

What Are Aluminium 6061 Flat Plates?

Aluminium 6061 flat plates are smooth and even with no texturing on their surface. These plates are plain and unembellished, offering a uniform surface suitable for various applications requiring precision machining and smooth finishes.

Applications:

Structural Components: Used for beams, supports, and other structural elements in construction.

Machining: Ideal for creating custom parts and components that must be shaped and finished precisely.

Enclosures: These are commonly used for electronic and mechanical enclosures where a smooth surface is needed.

Key Differences Between Chequered Plates and Flat Plates

1. Surface Texture

The most apparent difference between chequered and flat plates is their surface texture. Chequered plates feature a textured surface that provides enhanced grip and traction, making them suitable for applications where slip resistance is essential. On the other hand, flat plates have a smooth surface that is ideal for applications requiring precision and uniformity.

2. Strength and Durability

Both types of plates are made from Aluminium 6061, known for its excellent strength-to-weight ratio. However, the textured surface of chequered plates can add additional strength in terms of resistance to wear and tear, especially in high-traffic areas. Flat plates, being smooth, are typically used where uniform strength and load distribution are more critical.

3. Aesthetic and Functional Features

Chequered plates offer aesthetic appeal with their distinctive patterns, making them a popular choice for architectural applications and decorative purposes. The raised pattern also serves a functional purpose by increasing traction. Flat plates, being plain, are chosen for their clean appearance and suitability for applications where the surface finish is paramount.

4. Ease of Fabrication

Flat plates are generally easier to machine and fabricate due to their smooth surface. They can be cut, drilled, and welded precisely, making them ideal for custom manufacturing. While still machinable, chequered plates may present some challenges due to their textured surface, which can affect cutting and welding processes.

5. Cost and Availability

The cost of chequered plates can be slightly higher than flat plates due to the additional manufacturing processes required to create the textured surface. Both types of plates are widely available, but prices may vary depending on the pattern complexity and plate dimensions.

Choosing the Right Plate for Your Needs

When deciding between Aluminium 6061 chequered plates and flat plates, consider the specific requirements of your application. Chequered plates are likely the better choice if you need a durable, slip-resistant surface. Flat plates are more suitable for applications requiring precise machining and a smooth finish.

Check out this website for the finest quality Aluminium 6061 Chequered Plates.

Conclusion

understanding the differences between these two types of plates can help you make an informed decision based on your project's needs. Whether you require the functional benefits of chequered plates or the versatility of flat plates, Aluminium 6061 offers exceptional properties that cater to a wide range of applications.

0 notes

Text

Guide to Different Types and Applications of Chequered Plates!

Want to know about Different Types and Applications of Chequered Plates? Here, we shares all info on What is Chequered Plates, MS chequered plate, Types of Chequered Plates, Applications of Chequered Plates, etc. For MS chequered plate supplier in Vadodara & order,, contact us!

#MS steel product supplier in Vadodara#mild steel plate supplier in Vadodara#MS chequered plate supplier in Vadodara#Types of Chequered Plates#Applications of Chequered Plates

0 notes

Text

Aluminium 6082 Chequered Plates: Strength, Versatility, and Applications

Aluminium 6082 chequered plates, also known as tread plates or diamond plates, are renowned for their strength, lightweight nature, and corrosion resistance. This blog explores the properties, applications, and benefits of Aluminium 6082 chequered plates, emphasizing their importance in construction, transportation, and manufacturing sectors.

Properties of Aluminium 6082 Chequered Plates

Aluminium 6082 chequered plates offer several key properties that make them suitable for diverse applications:

High Strength: Provides excellent structural integrity and load-bearing capacity, ideal for heavy-duty applications.

Lightweight: Aluminium's low density makes 6082 chequered plates easy to handle and install, reducing overall structural weight.

Corrosion Resistance: Resistant to corrosion and weathering, ensuring durability in outdoor and marine environments.

Skid-Resistance: Patterned surface design enhances grip and reduces slipping, making them ideal for flooring and stair treads.

Machinability: Easy to fabricate and machine, allowing for precise cutting and shaping in manufacturing processes.

Recyclability: Fully recyclable without loss of properties, supporting sustainability efforts in construction and manufacturing.

Applications of Aluminium 6082 Chequered Plates

Aluminium 6082 chequered plates find extensive use across various industries and applications:

Transportation: Used in truck beds, trailers, and marine vessels for their durability and skid-resistant properties.

Construction: Ideal for flooring, stair treads, and walkways in commercial buildings, industrial facilities, and outdoor structures.

Manufacturing: Utilized as protective and decorative elements in machinery, equipment, and architectural applications.

Decorative Purposes: Applied in interior design and architectural projects for their aesthetic appeal and functional benefits.

Safety Applications: Employed in industrial settings and public spaces to enhance safety by reducing the risk of slips and falls.

Benefits of Aluminium 6082 Chequered Plates

Aluminium 6082 chequered plates offer several advantages, making them a preferred choice in various applications:

Enhanced Safety: Provides a secure, non-slip surface, improving safety in high-traffic areas and industrial environments.

Longevity: Resistant to corrosion, abrasion, and wear, ensuring extended service life with minimal maintenance.

Versatility: Available in different patterns, thicknesses, and sizes to suit specific application requirements.

Cost-Effectiveness: Lower installation and maintenance costs compared to alternative materials, contributing to overall project savings.

Environmental Sustainability: Fully recyclable and energy-efficient during production, supporting green building initiatives.

Conclusion

Aluminium 6082 chequered plates are essential in industries where safety, durability, and aesthetics are paramount. Their unique patterned surface and robust properties make them versatile for various applications in transportation, construction, manufacturing, and decorative uses. Understanding the properties and benefits of Aluminium 6082 chequered plates underscores their significance in enhancing safety, efficiency, and sustainability across diverse sectors.

#Aluminium 6082 Chequered Plates#Tread Plates#Diamond Plates#Skid-Resistance#Construction Applications#Transportation Industry

0 notes

Text

Chequered Plate Price | Prices | Pricing | News | Database | Chart

In the second quarter of 2024, Chequered Plate prices in North America showed a strong upward trend, driven by a combination of factors that bolstered market dynamics. This period saw significant price growth due to supply chain constraints, strong demand from sectors like construction and automotive, and rising raw material costs, particularly for zinc and nickel. Additionally, maintenance outages at major steel mills, including Acerinox and Outokumpu’s Calvert facility, further tightened supply, pushing prices higher. In the U.S., prices saw the most notable increases, fueled by bullish market sentiment. Demand from the automotive and HVAC sectors for galvanized and value-added steel products contributed to the steady rise in prices. Despite a slowdown in overall manufacturing indices, construction and manufacturing activities continued to support the price surge. Compared to the previous quarter, prices rose by 14%, highlighting the strength of the market. By the end of the quarter, the price of SS Chequered Plate (6 mm) in Texas reached USD 4,641/MT, reflecting a period of significant price growth and market resilience in response to both supply constraints and growing demand.

In contrast, the second quarter of 2024 saw a negative pricing environment for Chequered Plates in the APAC region. The market faced a downturn, largely driven by weak demand from the construction and automotive sectors, alongside high raw material costs, particularly for nickel. Despite elevated production costs, market prices failed to rise due to sluggish demand, and seasonal slowdowns further exacerbated the oversupply issue. China, the key player in the region, experienced the sharpest price declines. Weak demand from the property sector and reduced infrastructure investments led to a steady downward trend, especially after the post-Labour Day period when downstream consumption dropped. Despite high production costs, the lack of strong end-user demand resulted in a bearish market. Prices in China fell by 1% compared to the previous quarter, with SS Chequered Plate (304-6 mm) Ex Tangshan closing at USD 2,179/MT. Overall, the market remained weak, marked by excess supply and low demand, with no major plant disruptions reported.

In Q2 2024, the European Chequered Plate market experienced a significant rise in prices, driven by various key factors. Rising alloy surcharges, increasing energy costs, and regulatory impacts from the EU Critical Raw Materials Act (CRMA), which focuses on securing strategic raw material supplies, all contributed to the upward price trajectory. Additionally, strong demand from the automotive sector, despite broader manufacturing slowdowns, supported the price increases, while the spring construction season further boosted demand for steel products. Germany saw the most pronounced price changes in the region, with robust demand from the automotive sector and favorable economic conditions, including an ECB interest rate cut. Energy costs, particularly for gas and CO2 emissions, had a strong correlation with metal prices, while geopolitical disruptions around the Suez Canal led to additional shipping surcharges, further driving up prices. Compared to the previous quarter, prices in Germany rose by 14%, with SS Chequered Plate (304-5mm) Ex Ruhr closing at USD 3,847/MT. This period was marked by positive market dynamics, with regulatory, economic, and seasonal factors all contributing to the price surge. No significant plant shutdowns were reported during this time.

Get Real Time Prices for Chequered Plate: https://www.chemanalyst.com/Pricing-data/chequered-plate-1490

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Chequered Plate#Chequered Plate Price#Chequered Plate Prices#Chequered Plate Pricing#Chequered Plate News#Chequered Plate Price Monitor

0 notes

Text

Mild Steel Chequered Plates in Tamil Nadu: Quality and Durability You Can Trust

Looking for reliable and durable mild steel chequered plates in Tamil Nadu? Our guide provides you with everything you need to know about sourcing high-quality chequered plates in the region. Whether for industrial flooring, staircases, or decorative applications, discover top suppliers, product specifications, and the benefits of using mild steel chequered plates. Ensure safety, durability, and aesthetic appeal with the best options available in Tamil Nadu.

0 notes

Text

Premium Structural Steel Services in UAE by Mechden Steel Fabrication LLC

When it comes to superior steel solutions in the UAE, Mechden Steel Fabrication LLC stands out as a trusted name in the industry. From high-end infrastructure projects to customized metal fabrications, Mechden brings decades of expertise and precision to every job. Specializing in Structural Steel Services in UAE, we cater to diverse industries including construction, oil and gas, transportation, and architecture.

Read more: https://mechdensteelfabricationllc.hashnode.dev/premium-structural-steel-services-in-uae-by-mechden-steel-fabrication-llc

0 notes

Text

Hot-Dip Galvanized Earthing Flats: Ensuring Safety and Longevity ?

In today’s world, where safety, reliability, and durability are paramount, hot-dip galvanized earthing flats emerge as an indispensable component in ensuring the safety of electrical systems and infrastructure. From industrial setups to residential complexes, these galvanized components are designed to offer optimal performance, corrosion resistance, and an extended lifespan.

What Are Hot-Dip Galvanized Earthing Flats?

Hot-dip galvanized earthing flats, also known as earthing GI strips or earthing patti, are flat steel components coated with a protective layer of zinc through the hot-dip galvanization process. The hot-dip galvanization process ensures that the steel is resistant to environmental factors such as moisture, heat, and chemicals, making it ideal for electrical grounding and earthing systems.

The earthing system plays a critical role in protecting electrical installations by providing a safe path for excess electrical energy to safely drain into the ground. Use of galvanized components such as galvanized beams, galvanized steel beams, and galvanized c channels ensures that these systems are durable and efficient.

Benefits of Hot-Dip Galvanizing for Earthing Flats

The hot-dip galvanization process provides various benefits for earthing flats, including:

1. Corrosion Resistance

One of the most significant advantages of hot-dip galvanizing is its ability to resist corrosion. The zinc coating acts as a barrier, protecting the underlying steel from rust, even in harsh environmental conditions. This ensures the galvanized steel grating and earthing flats maintain their integrity for decades.

2. Cost-Effectiveness

Although the initial investment for hot-dip galvanized products may be more compared to non-galvanized options, reduced maintenance and replacement costs make them a cost-effective solution in the long run.

Steel and zinc have a high recycling rate. Once galvanized iron or steel has served its lifetime, it can be collected, melted, and then reused. This makes such construction projects an eco-friendly method.

3. Safety

Hot-dip galvanized steel has a life expectancy greater than 50 years within any environment, making it fit to be used for integral structural components of stainless-steel cable trays and earthing systems.

Uses of Galvanized Earthing Flats

Galvanized earthing flats are one of the most versatile and commonly utilised products in many industries with wide applications, including:

1. Industrial Plants

Factories and processing plants require reliable earthing systems to protect the machinery and personnel. In addition to earthing flats, there are components such as galvanized c channels and chequered plates that are applied to ensure an all-rounded safety solution.

2. Power Transmission

Power generation and distribution requires reliable earthing systems to avoid faults and guarantee smooth running. Galvanized steel beams and earthing flats are the pillars of these systems.

3. Renewable Energy Systems

Solar farms and wind turbines necessitate efficient grounding systems to protect against lightning or electrical surges. Stainless steel cable trays and galvanized checker plates along with earthing GI strips enhance the durability of these systems.

4. Infrastructure Projects

Large construction projects involving bridges and buildings make use of hot-dip galvanized earthing components for safety and structural stability.

Hot-Dip Galvanized Earthing Flats’ Contribution to Sustainability

Sustainability is one of the growing concerns in modern construction and manufacturing. Hot-dip galvanization is an eco-friendly process that supports sustainable practices in the following ways:

1. Recyclability

Galvanized steel, including chequered plates and earthing strips, is 100% recyclable, which reduces waste and conserves resources.

2. Reduced Maintenance

The long life of galvanized products means less frequent replacement, saving resources and energy in the manufacturing process.

3. Energy Efficiency

Hot-dip galvanized earthing flats reduce the probability of system failures, thus avoiding downtime and saving energy in industrial processes.

Comparison with Other Coating Methods

Hot-dip galvanization is compared to other coating methods, for example, paint or electroplating, on the following grounds:

1. Durable

Paint may only offer a temporary protective covering, but it is not as durable as that of a galvanized zinc coating, especially in demanding environments.

2. Thorough Coverage

The galvanization process ensures full coverage of the steel surface, including corners and edges, which are often missed by other coating methods.

3. Low Maintenance

Unlike paint, which may require frequent touch-ups, the galvanized coating remains intact for decades, offering superior performance with minimal upkeep.

Why Choose Parco Engineers?

At Parco Engineers, we are committed to meeting the highest industry standards, and our hot-dip galvanized products are of good quality. Our product categories include galvanized steel beams, galvanized steel gratings, and checkered plates, all designed for safety, durability, and performance.

1. Galvanization Expertise

With years of experience and expertise, Parco Engineers mastered the art of galvanization, providing good quality products which are long-lasting.

2. Extensive Product Line

From stainless steel cable trays to galvanized c channels, we provide a wide variety of products to suit different applications.

3. Sustainability

Through our practice of sustainable manufacturing, we are contributing to a greener future while still producing top-quality products.

Galvanized earthing flats, a part of the modern system used for safety, efficiency, and durability, are indeed widely used in many other areas like power transmission or renewable energy. Hot-dip galvanized earthing components from Parco Engineers have the right durability and are cost-effective, sustainable products that can serve your purposes. Depend on Parco Engineers for innovative products that would pass the test of time and assure the safety and efficiency of your systems.

#hot-dip galvanized earthing flats#earthing GI strips#galvanized beams#galvanized c channels#galvanized steel grating#hot-dip galvanized#chequered plates#stainless steel cable trays

0 notes

Text

Stainless Steel 310H Coils Suppliers

#Stainless Steel 310H Coils Manufacturers#Stainless Steel 310H Coils Exporters#Stainless Steel 310H Coils Suppliers#Stainless Steel 310H Coils Importers#Stainless Steel 310H Coils Stockists#Stainless Steel 310H Coils Manufacturers in Mumbai#Stainless Steel 310H Coils Exporters in Mumbai#Stainless Steel 310H Coils Suppliers in Mumbai#Stainless Steel 310H Coils Importers in Mumbai#Stainless Steel 310H Coils Stockists in Mumbai#Stainless Steel 310H Coils Manufacturers in India#Stainless Steel 310H Coils Exporters in India#Stainless Steel 310H Coils Suppliers in India#Stainless Steel 310H Coils Importers in India#Stainless Steel 310H Coils Stockists in India#SS 310H Coils#SS 310H Circle#310H SS Chequered Plate Exporter

0 notes