#chapati making machines

Explore tagged Tumblr posts

Text

Flour Machine: Chapati Making Machines – Health and Safety Considerations

When it comes to setting up a food business focused on Indian cuisine, particularly one that involves making chapatis, investing in the right equipment is crucial. Chapati making machines, also known as flour machines or roti makers, are indispensable tools for efficiently producing high-quality chapatis. However, as with any food processing equipment, it's essential to prioritize health and safety considerations to ensure a safe working environment and maintain product quality.

#Chapati making machine manufacturers#chapatti making machine suppliers#Chapati making machines#chapati making#chapati machine manufacturers#chapati machine suppliers#chapati

0 notes

Text

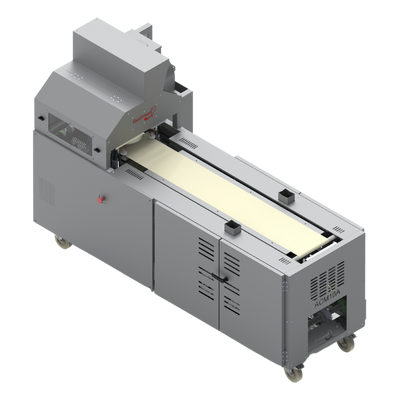

A chapati making machine is a device used to make chapatis in bulk. It is designed to mix, knead, roll, and cook chapatis automatically, making it easier and faster to produce large quantities of chapatis.

#chapati making machine#chapati making machines#automatic chapati making machine#automatic roti maker machine#automatic roti making machine#roti making machine

0 notes

Text

Happy Republic Day

Republic Day is a time to reflect on the values that make our nation great. At Sunshine Industries, we salute the brave hearts who fought for the freedom and democracy we cherish today. As we celebrate this special occasion, we reaffirm our commitment to driving progress, sustainability, and innovation in everything we do. We believe in a future where every individual, community, and business can thrive, and we take immense pride in contributing to this vision. Let’s continue to work towards a future that’s bright, inclusive, and prosperous for all. Happy Republic Day from Sunshine Industries!

0 notes

Text

Benefits of Using an Automatic Roti Maker

For those who enjoy freshly produced rotis but find the traditional approach labor-intensive and time-consuming, the automatic roti maker machine is a game-changer. Here, we go over the many advantages of using an automatic roti maker machine over more conventional techniques.

The ease that the automatic roti maker machine provides is among its biggest benefits. Kneading the dough, rolling it into flat discs, and frying each roti separately on a tawa (griddle) are all phases in the traditional roti-making process. You just need to put the dough into an automatic roti maker machine, and it will take care of the rest. For busy people and families, this hands-off approach is perfect because it saves time and effort.

The automated roti maker machine is made to be efficient. In a fraction of the time required to prepare them by hand, it can produce several rotis. This is particularly useful for big parties or events where a lot of rotis must be consumed fast. Every roti is cooked uniformly and flawlessly because of the machine's reliable operation, which does away with the uncertainty and guesswork involved in using conventional techniques.

Using an automatic roti maker machine ensures that each roti is of consistent size, thickness, and texture. This uniformity is challenging to achieve with manual methods, where variations in dough rolling and cooking time can lead to inconsistent results. The machine's precise controls guarantee that every roti is cooked to perfection, providing a superior dining experience.

Even someone with no prior cooking knowledge can easily use the automatic roti maker machine. Usually, the equipment has easy-to-follow instructions and needs little setup. After you get the hang of it, preparing rotis is simple and stress-free. Because of its simplicity, more people are enjoying homemade rotis without the trouble of more conventional ways.

Making rotis the old-fashioned way may be untidy, with dough and flour sometimes spilling onto floors and countertops. By keeping the mess inside the machine, the automatic roti maker machine contributes to a cleaner kitchen. With detachable sections that can be cleaned independently, the machine is very simple to maintain a clean and hygienic cooking area.

You have control over the ingredients that go into your rotis when you use an automatic roti maker machine. Whole wheat flour, multigrain flour, or gluten-free substitutes are healthier options. Because store-bought rotis may contain preservatives and other additives, this level of control isn't always achievable. An automatic roti maker machine produces healthier, fresher, and chemical-free homemade rotis.

Long-term cost savings may result from purchasing an automatic roti maker machine even though the first purchase might seem like a big outlay, the money saved on store-bought rotis and the decreased need to eat out soon add up. Additionally, the machine saves time and effort when making rotis by hand, freeing you up to concentrate on other activities or duties.

Moreover, investing in automatic Roti Making Machines can be a significant decision for any household. Here, we evaluate the cost-effectiveness of investing in Roti Making Machines compared to other kitchen appliances, along with safety considerations.

Machines for making roti require little upkeep. To keep them in good operating order, regular cleaning, and sporadic servicing are usually enough. Reliability and durability are features of high-quality models. Automatic Roti Making Machines can be a more enduring investment than other kitchen appliances that might need to be repaired or replaced more frequently.

With the help of roti-making machines, consumers may regulate the ingredients used to make healthy rotis. To steer clear of the preservatives and additives frequently found in store-bought rotis, you can use whole wheat, multigrain, or gluten-free flour. You can enjoy healthier meals and better dietary management by preparing fresh rotis at home.

The brand, model, and characteristics of roti-making machines affect their original cost. Advanced models with greater features can cost more, while some simple variants are reasonably priced. The initial cost of a roti-making machine may appear more than that of other household appliances like mixers, grinders, or toasters. But the advantages they provide outweigh this expense.

Machines for making roti require little upkeep. To keep them in good operating order, regular cleaning, and sporadic servicing are usually enough. Reliability and durability are features of high-quality models. Roti Making Machines can be a more enduring investment than other kitchen appliances that might need to be repaired or replaced more frequently. Numerous benefits, like time savings, consistent quality, health benefits, energy efficiency, convenience of use, safety, and durability, are revealed when evaluating the cost-effectiveness of investing in roti-making machines. The long-term advantages of Roti Making Machines outweigh the initial cost, which may be more than those of some other kitchen gadgets. These devices can improve your culinary experience and support a healthier lifestyle by making the process of producing fresh rotis easier.

0 notes

Text

#Commercial Kitchen Equipments#Sink unit and kitchen equipments#Commercial Refrigeration Equipments#Commercial Chapati Making Machine#Cooking equipments

0 notes

Text

#Papad Making Machine Manufacturer in Ahmedabad#pani puri making machine in Ahmedabad#chapati Making Machine Manufacturer in Ahmedabad

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description Rico All-In-One flour kneading machine can help in atta mixer , Roti Mekar, Food Chopper ,Salad Maker Vegetable Cutter. Its a new way to make roti , chapati , naan more quickly and easily. Rico automatic electric dough kneader comes with multiple detachable sharp stainless steel chopping blades .The strong and unbreakable Atta kneading blade is used to make dough in a minutes. This Dough Maker Electric Machine comes with 2 speed setting for maximum control. For best results, use the low speed setting (speed 1) to whip cream, beat eggs, create pastries and bread dough. It comes with powerful 400 watts long lasting copper motor. Unbreakable food processing bowl made up of transparent poly-carbonate material with 800 ml capacity. This Dough Maker Machine includes 1 Kneader Blade For Aata Kneader, 1 Food Processor 800 ml Bowl, 1 Citrus Juicer Attachment, 1 Slicer Blade For Slicing Vegetables, 1 Chopper Blade, 1 Shredder Blade [ad_2]

2 notes

·

View notes

Text

How the Roti Maker Machine is Changing Traditional Cooking Forever

For centuries, the process of making rotis has been an integral part of traditional cooking, especially in households across South Asia. However, the advent of modern technology has brought forth innovations that are transforming age-old practices. Among these, the roti maker machine stands out as a groundbreaking invention. This revolutionary device is not only simplifying the process but also redefining the way we perceive home cooking. In this article, we delve into how the roti maker machine is changing traditional cooking forever, highlighting its features, benefits, and impact on modern lifestyles.

What is a Roti Maker Machine?

A roti maker machine is an automated or semi-automated device designed to prepare rotis quickly and efficiently. It eliminates the need for manual rolling and cooking, offering a seamless experience for users. These machines come equipped with advanced heating elements and precision controls to ensure perfectly cooked rotis every time.

Key Features of Modern Roti Makers

Non-Stick Surface: Ensures that the dough doesn’t stick, making cleanup easy.

Adjustable Temperature Settings: Allows customization for different types of flatbreads.

Compact Design: Saves kitchen space while being portable.

Energy Efficiency: Consumes minimal electricity, making it economical.

Multi-Functionality: Some models can prepare other flatbreads, such as tortillas and chapatis.

Benefits of Using a Roti Maker Machine

1. Time-Saving Convenience

Traditional roti-making can be time-consuming, requiring skillful rolling and careful attention during cooking. A roti maker machine automates these steps, reducing preparation time significantly. This convenience is especially beneficial for working professionals and busy households.

2. Consistent Quality

Achieving uniform thickness and texture in rotis manually can be challenging. Roti makers ensure consistent results by maintaining even pressure and heat distribution, leading to perfectly round and evenly cooked rotis.

3. Health Benefits

With precise temperature control, these machines prevent overcooking or burning, preserving the nutritional value of the ingredients. Additionally, the non-stick surface requires minimal oil, promoting healthier eating habits.

4. User-Friendly Operation

Most modern roti makers are designed with simplicity in mind. Even individuals with little or no cooking experience can operate these devices effortlessly, thanks to intuitive controls and clear instructions.

5. Cost Efficiency

While the initial investment might seem significant, the long-term savings on energy and effort make roti makers a cost-effective addition to any kitchen.

How Roti Makers Are Impacting Traditional Cooking Practices

Preserving Traditions with a Modern Twist

While traditional cooking methods carry cultural and emotional significance, incorporating technology like roti makers doesn’t diminish these values. Instead, it complements them by providing a modern alternative that aligns with today’s fast-paced lifestyles.

Empowering Non-Cooks

For individuals who struggle with cooking or have never learned the art of making rotis, these machines serve as a game-changer. They democratize the process, allowing anyone to enjoy fresh, homemade flatbreads without relying on external help.

Encouraging Healthy Eating

Fast food and processed meals often dominate busy households. The ease and speed of preparing fresh rotis with a roti maker encourage healthier home-cooked meals, promoting better dietary habits.

Choosing the Right Roti Maker Machine

When selecting a roti maker, it’s essential to consider the following factors:

Size and Capacity: Choose a model that fits your household’s needs.

Build Quality: Opt for durable materials that ensure longevity.

Brand Reputation: Established brands often provide better warranties and customer support.

Additional Features: Look for added functionalities like automatic dough feeders or multi-purpose cooking capabilities.

Price: Compare models to find the best value for your budget.

Tips for Using a Roti Maker Effectively

Prepare the Dough Correctly: The dough’s consistency plays a crucial role in achieving the best results. It should be soft and pliable.

Preheat the Machine: Allow the machine to reach the optimal temperature before placing the dough.

Use the Right Amount of Dough: Ensure the dough balls are uniform in size to maintain consistency.

Clean Regularly: Keep the non-stick surface clean to prolong the machine’s life.

Follow the Instructions: Adhere to the user manual for optimal performance and safety.

The Future of Roti Making

As technology continues to evolve, we can expect even more advanced iterations of roti makers. Features like AI integration, app-based controls, and energy-efficient designs are likely to become standard. These innovations will further enhance the device’s appeal, making it an indispensable tool in modern kitchens worldwide.

Conclusion: Embracing the Change

The roti maker machine is more than just a kitchen appliance; it’s a symbol of how technology can seamlessly blend with tradition to create something extraordinary. By simplifying the art of roti making, it empowers individuals, saves time, and promotes healthier eating habits. As we embrace this change, the future of cooking looks brighter than ever.

0 notes

Text

0 notes

Text

Paratha making machine fully automatic - Grisham Industry

Paratha is one of the most popular and traditional foods of the Indian Subcontinent. They are also known as soft, unleavened flatbread made from whole wheat in thick layers, unlike chapati which is thinner. Parathas are typically cooked on a griddle with ghee or oil, resulting in a golden, crispy exterior and a soft, flavourful interior.

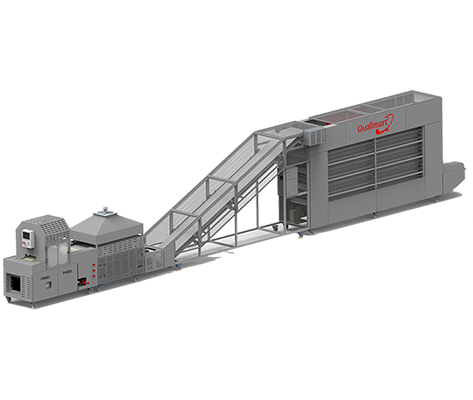

Introducing the Automatic Paratha Making Machine – a revolutionary innovation designed to transform the traditional art of paratha preparation in industrial kitchens. This cutting-edge machine organizes and automates the entire Paratha-making process, from kneading the unleavened dough to the final flatbread. Parathas, being a staple food in Indian households, are characterized by their thin, flaky layers and rich, flavourful fillings.

As a result, this innovation not only benefits businesses in terms of efficiency and cost-effectiveness but also contributes to the preservation and popularization of traditional culinary delights on a larger scale. The fully automatic paratha-making machine stands as a testament to the fusion of technology and gastronomy, making the joy of relishing authentic parathas accessible to all.

For more details please visit our website: https://grishamindustry.com/semi-automatic-half-cooked-paratha-making-machine-manufacturer-coimbatore-kerala-tamilnadu-india/

0 notes

Text

Stainless Steel Puri Maker Press Machine with Handle

Faverito Manual Stainless Steel Puri Press Machine (6.5 inches) Features Useful for flattening or pressing puri in kitchen.This puri machine is of large size and having a working diameter of nearly 6.5 inches.This puri presser is provided with an anti-skid/slip sole that does not lets the presser machine move when you press the machine.

Useful for flattening or pressing puri in kitchen. It is helpful for SMALL ROTI PRESSING. This puri machine is of large size and having working diameter of nearly 7 inches. If you want, take any cover and cut into round shape for the bottom and upper part of the plate means 2 pieces we need to cut, Put a dough in the centre of that cover by applying some oil to that dough, cover the top with one more round shape cover piece and close the pruri press and press.

Move the cover to left and press again same move the cover to right and press. This process will make some big and thin puri for you. If you want to know the better usage of chapati press please refer some videos.

0 notes

Text

Case Studies: Successful Implementation of Chapati-Making Machines

The food industry continuously seeks innovations to streamline processes and improve efficiency. One such innovation is the chapati-making machine, which has revolutionized the preparation of this staple food in many commercial kitchens. Here, we explore a few case studies highlighting the successful implementation of chapati-making machines by leading chapati making machine manufacturers.

Case Study 1: Catering Services in Delhi

To satisfy the enormous demands of weddings and events, a well-known catering firm in Delhi looked to improve its chapati production. They added a completely automatic chapati-making machine to their operations by collaborating with chapati-making machine manufacturers. The outcome of this implementation was:

A 50% boost in output capability.

Chapatis of uniform size and quality.

Substantial decrease in the cost of manual labor.

The caterer stated that they were able to serve big groups of people with ease and maintain a high level of customer satisfaction because of the machine's dependability and effectiveness, which were supplied by the chapati-making machine manufacturers.

Case Study 2: Restaurant Chain in Mumbai

During peak hours, a well-known restaurant chain in Mumbai struggled to maintain the uniformity and speed of chapati preparation. They placed semi-automatic chapati-making machines throughout their locations after speaking with a reliable chapati-making machine manufacturer. The outcomes were striking:

40% less time was spent on preparation.

Chapatis that are all the same thickness and size.

Increased productivity in the kitchen.

The restaurant business admitted that the chapati-making machine's manufacturer knowledge and assistance were essential to attaining these advancements.

Case Study 3: Industrial Canteen in Bangalore

To meet the tremendous demand for chapatis, an industrial cafeteria in Bangalore that serves thousands of meals every day sought a solution. They adopted a high-capacity chapati-making machine in partnership with a forward-thinking chapati-making machine manufacturer. As a result of the implementation:

More than 2,000 chapatis are produced per hour.

Despite large volumes, quality remains constant.

Enhanced cleanliness and hygienic conditions throughout production.

The chapati-making machine manufacturers were commended by the canteen management for their innovative technology and smooth integration, which significantly increased their operating efficiency.

These case studies demonstrate the transformative impact of chapati-making machines in various commercial and institutional settings. The expertise and advanced technology provided by chapati-making machine manufacturers have enabled businesses to increase efficiency, maintain consistent quality, and reduce labor costs. Whether in catering services, restaurants, industrial canteens, school meal programs, or luxury hotels, the role of a reliable chapati-making machine manufacturer is crucial in achieving these successes. The continued innovation and support from these manufacturers ensure that chapati-making machines remain an integral part of modern food preparation.

The landscape of kitchen technology is ever-evolving, and chapati-making machines are no exception. With the growing demand for automation and efficiency in food preparation, chapati-making machine manufacturers are continuously innovating to meet these needs.

The combination of advanced automation and artificial intelligence (AI) is one of the most important trends. Chapati-making machine manufacturers are creating devices that can instantly modify settings in response to climatic conditions and the consistency of the dough. With little assistance from humans, AI-powered devices can ensure flawless chapatis by learning from previous experiences to increase productivity and consistency.

Chapati-making machine manufacturers will provide more personalization in their future designs. To meet particular needs, consumers will be able to modify characteristics like size, thickness, and cooking time using machines. Because of their adaptability, chapati machines can be used in a wide range of settings, from small homes to expansive commercial kitchens.

The rise of the smart kitchen means that chapati-making machine manufacturers are developing models that can connect with other smart appliances. These machines will be able to sync with kitchen management systems, providing real-time data and enhancing overall kitchen efficiency.

Sustainability is a growing concern in all industries, and chapati-making machine manufacturers are no exception. Future designs will incorporate eco-friendly materials and manufacturing processes, reducing the environmental impact of these machines.

As commercial kitchen space becomes more valuable, chapati-making machines, fully automatic designs will become more compact and space-efficient. These new models will be designed to fit seamlessly into various kitchen layouts without compromising on their output capacity or functionality.

When designing kitchen equipment, safety is still of utmost importance. Chapati-making machines fully automatic would have sophisticated safety features like temperature control, automatic shut-off, and integrated sensors to identify problems. In crowded kitchen settings, these characteristics will guarantee safe operation and lower the possibility of mishaps.

With so many improvements in the works, the future of completely chapati-making machines fully automatic is bright. Among the themes influencing this developing technology are increased automation, the integration of artificial intelligence, greater customization, enhanced energy efficiency, user-friendly interfaces, small designs, sophisticated safety measures, integration of smart kitchens, expanded manufacturing capabilities, and sustainability. Chapati-making machines fully automatic will be essential in revolutionizing the production of chapatis as they develop further, improving its consistency, efficiency, and usability in both home and commercial kitchens.

#Chapati making machine manufacturer#Chapati making machine#chapati maker#Chapati making machine fully automatic

0 notes

Text

#Commercial Chapati Making Machine#Cooking equipments#Mobile equipments#Kitchen Trolleys#Bar equipments#Pantery Equipments

0 notes

Text

Commercial Atta Chakki in Delhi - Sonar Appliances

Are you in the market for a commercial atta chakki in Delhi? If so, you're probably aware that choosing the right one can be a game changer for your business. In bustling cities like Delhi, where the demand for fresh, quality flour is always on the rise, having a reliable atta chakki is essential. Sonar Appliances has been making waves in this arena, offering top-notch solutions for businesses of all sizes. Let's dive into why Sonar Appliances is the go-to choice for commercial atta chakkis.

What is an Atta Chakki?

Ever wondered how your favorite chapatis get their soft, delectable texture? That’s where the atta chakki comes in! An atta chakki is essentially a grain mill specifically designed for grinding wheat into flour. But it's not just about making flour—it's about ensuring that the flour maintains its nutrition, flavor, and freshness. These machines come in various sizes, but for commercial purposes, a sturdy and reliable model is a must.

Brief History of Atta Chakkis

The traditional methods of grinding wheat have been around for centuries, dating back to ancient times when stone mills were manually operated. Fast forward to today, we've got advanced machines that can process tons of grains in mere hours, dramatically improving efficiency in commercial settings. Sonar Appliances has embraced this evolution, blending tradition with innovation to provide state-of-the-art products.

Why Choose a Commercial Atta Chakki?

When it comes to running a business, efficiency is key. But why exactly should you invest in a commercial atta chakki? Here’s the scoop!

Efficiency and Speed

Think about it—who wants to wait around for their flour? With a commercial atta chakki, you can churn out fresh flour at lightning speed. This means you can serve more customers in less time, boosting your productivity and, of course, your profits!

Cost-Effectiveness

While the upfront investment for a commercial atta chakki may seem steep, consider it as a long-term investment. With less reliance on external suppliers, you're saving money in the long run—a classic win-win!

Long-term Investment

Investing in quality equipment like Sonar's atta chakki means you’re set for the long haul. These machines are designed for durability, which gives you peace of mind and consistent flour quality over the years.

Features of a Quality Commercial Atta Chakki

So, what should you look out for when navigating the sea of commercial atta chakkis? Let’s break it down.

Type of Grains and Flour

The best machines can handle a variety of grains—wheat, lentils, and even spices. This versatility allows you to expand your product offering without worrying about broken machinery or poor quality outputs.

Power and Performance

No one wants a sluggish machine causing delays in production! Sonar Appliances offer options with powerful motors and cutting-edge technology that optimize performance, ensuring you get the job done efficiently.

Ease of Use

User-friendliness is essential, especially if you have staff with varying levels of experience. Sonar's models often come with intuitive interfaces that make operating them a breeze.

Maintenance and Cleaning

Let’s face it—nobody enjoys cleaning, but it’s a part of life, especially in the food industry. Sonar’s commercial atta chakkis are designed with easy maintenance in mind. Quick access points and straightforward cleaning procedures will save you time and effort.

Sonar Appliances: A Leader in the Market

Now that you know what to look for, let’s zoom in on Sonar Appliances, a renowned leader in the field. What sets them apart?

Range of Commercial Atta Chakkis

From small-scale setups to large operations, Sonar offers a diverse range of atta chakkis tailored to meet various business needs. You’re bound to find the perfect fit for your requirements.

Innovative Technology

Sonar Appliances employs the latest technology to enhance their products. Features like automatic grain feed, temperature controls, and advanced grinding techniques make their machines stand out.

Customer Testimonials and Feedback

The real MVPs are the customers, right? Let's check out what some have to say.

Why Customers Prefer Sonar Appliances

Many customers rave about the efficiency, durability, and overall performance of Sonar's atta chakkis. They often highlight the exceptional customer service they received throughout the purchasing process as a deciding factor in their choice, making the experience all the more seamless.

Comparing Sonar Appliances with Other Brands

Curious how Sonar stacks up against competitors? Let’s break it down.

Price vs. Quality

It’s true—some brands offer cheaper options at first glance, but when you consider the quality and the longevity of Sonar's products, the value becomes clear. Investing a bit more upfront can save you headaches down the line.

Customer Support and Service

Great product? Check! But what about support? Sonar Appliances prides itself on their customer service, often going above and beyond to assist clients with set-ups and inquiries long after the sale.

Where to Buy a Sonar Commercial Atta Chakki?

So, where can you snag one of these fantastic machines? Let’s cover your options.

Online vs. Offline Purchases

There are numerous ways to buy Sonar Appliances. You can either visit a physical store or browse their range online. Online shopping often gives you the convenience of comparing models and prices, while visiting a store allows you to see the machinery firsthand.

Conclusion

Investing in a commercial atta chakki is one of the smartest moves you can make for your business. With options like those from Sonar Appliances, you get efficiency, quality, and reliability all wrapped into one fantastic machine. Whether you’re running a bakery, restaurant, or small flour mill, Sonar has you covered. Why settle for less when you can offer your customers the best?

By providing vital details and insights into the world of commercial atta chakkis, especially the impressive offerings from Sonar Appliances, this article aims to serve as a comprehensive guide for potential customers. Remember, investing in quality equipment will always pave the way for success in any culinary venture!

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Experience effortless dough making with our 3-in-1 Ata Maker, an innovative solution for your kitchen. This automatic, non-electric dough maker simplifies the process of preparing atta (dough) for rotis, chapatis, and other Indian bread varieties. With its user-friendly design, simply add flour, water, and any additional ingredients, and let the machine do the work for you. Crafted for convenience, this atta maker machine is compact, lightweight, and easy to use, making it perfect for home kitchens. Say goodbye to manual kneading and hello to consistent, hassle-free dough preparation with our Ata Maker. 3-in-1 Functionality: Functions as an automatic dough maker, atta maker machine, and roti maker, offering versatility for Indian bread preparation. Effortless Operation: Simply add flour, water, and ingredients, and let the machine knead the dough for you. Non-Electric Design: Does not require electricity, making it eco-friendly and cost-effective. Compact and Lightweight: Space-saving design that is easy to store and transport. High-Quality Construction: Made from durable materials for long-lasting performance. User-Friendly: Easy to use, clean, and maintain, perfect for everyday use in the kitchen. [ad_2]

0 notes

Video

youtube

Commercial tortilla maker | Automatic chapati roti making machine

0 notes