#Chapati making machine fully automatic

Explore tagged Tumblr posts

Text

Case Studies: Successful Implementation of Chapati-Making Machines

The food industry continuously seeks innovations to streamline processes and improve efficiency. One such innovation is the chapati-making machine, which has revolutionized the preparation of this staple food in many commercial kitchens. Here, we explore a few case studies highlighting the successful implementation of chapati-making machines by leading chapati making machine manufacturers.

Case Study 1: Catering Services in Delhi

To satisfy the enormous demands of weddings and events, a well-known catering firm in Delhi looked to improve its chapati production. They added a completely automatic chapati-making machine to their operations by collaborating with chapati-making machine manufacturers. The outcome of this implementation was:

A 50% boost in output capability.

Chapatis of uniform size and quality.

Substantial decrease in the cost of manual labor.

The caterer stated that they were able to serve big groups of people with ease and maintain a high level of customer satisfaction because of the machine's dependability and effectiveness, which were supplied by the chapati-making machine manufacturers.

Case Study 2: Restaurant Chain in Mumbai

During peak hours, a well-known restaurant chain in Mumbai struggled to maintain the uniformity and speed of chapati preparation. They placed semi-automatic chapati-making machines throughout their locations after speaking with a reliable chapati-making machine manufacturer. The outcomes were striking:

40% less time was spent on preparation.

Chapatis that are all the same thickness and size.

Increased productivity in the kitchen.

The restaurant business admitted that the chapati-making machine's manufacturer knowledge and assistance were essential to attaining these advancements.

Case Study 3: Industrial Canteen in Bangalore

To meet the tremendous demand for chapatis, an industrial cafeteria in Bangalore that serves thousands of meals every day sought a solution. They adopted a high-capacity chapati-making machine in partnership with a forward-thinking chapati-making machine manufacturer. As a result of the implementation:

More than 2,000 chapatis are produced per hour.

Despite large volumes, quality remains constant.

Enhanced cleanliness and hygienic conditions throughout production.

The chapati-making machine manufacturers were commended by the canteen management for their innovative technology and smooth integration, which significantly increased their operating efficiency.

These case studies demonstrate the transformative impact of chapati-making machines in various commercial and institutional settings. The expertise and advanced technology provided by chapati-making machine manufacturers have enabled businesses to increase efficiency, maintain consistent quality, and reduce labor costs. Whether in catering services, restaurants, industrial canteens, school meal programs, or luxury hotels, the role of a reliable chapati-making machine manufacturer is crucial in achieving these successes. The continued innovation and support from these manufacturers ensure that chapati-making machines remain an integral part of modern food preparation.

The landscape of kitchen technology is ever-evolving, and chapati-making machines are no exception. With the growing demand for automation and efficiency in food preparation, chapati-making machine manufacturers are continuously innovating to meet these needs.

The combination of advanced automation and artificial intelligence (AI) is one of the most important trends. Chapati-making machine manufacturers are creating devices that can instantly modify settings in response to climatic conditions and the consistency of the dough. With little assistance from humans, AI-powered devices can ensure flawless chapatis by learning from previous experiences to increase productivity and consistency.

Chapati-making machine manufacturers will provide more personalization in their future designs. To meet particular needs, consumers will be able to modify characteristics like size, thickness, and cooking time using machines. Because of their adaptability, chapati machines can be used in a wide range of settings, from small homes to expansive commercial kitchens.

The rise of the smart kitchen means that chapati-making machine manufacturers are developing models that can connect with other smart appliances. These machines will be able to sync with kitchen management systems, providing real-time data and enhancing overall kitchen efficiency.

Sustainability is a growing concern in all industries, and chapati-making machine manufacturers are no exception. Future designs will incorporate eco-friendly materials and manufacturing processes, reducing the environmental impact of these machines.

As commercial kitchen space becomes more valuable, chapati-making machines, fully automatic designs will become more compact and space-efficient. These new models will be designed to fit seamlessly into various kitchen layouts without compromising on their output capacity or functionality.

When designing kitchen equipment, safety is still of utmost importance. Chapati-making machines fully automatic would have sophisticated safety features like temperature control, automatic shut-off, and integrated sensors to identify problems. In crowded kitchen settings, these characteristics will guarantee safe operation and lower the possibility of mishaps.

With so many improvements in the works, the future of completely chapati-making machines fully automatic is bright. Among the themes influencing this developing technology are increased automation, the integration of artificial intelligence, greater customization, enhanced energy efficiency, user-friendly interfaces, small designs, sophisticated safety measures, integration of smart kitchens, expanded manufacturing capabilities, and sustainability. Chapati-making machines fully automatic will be essential in revolutionizing the production of chapatis as they develop further, improving its consistency, efficiency, and usability in both home and commercial kitchens.

#Chapati making machine manufacturer#Chapati making machine#chapati maker#Chapati making machine fully automatic

0 notes

Text

Paratha making machine fully automatic - Grisham Industry

Paratha is one of the most popular and traditional foods of the Indian Subcontinent. They are also known as soft, unleavened flatbread made from whole wheat in thick layers, unlike chapati which is thinner. Parathas are typically cooked on a griddle with ghee or oil, resulting in a golden, crispy exterior and a soft, flavourful interior.

Introducing the Automatic Paratha Making Machine – a revolutionary innovation designed to transform the traditional art of paratha preparation in industrial kitchens. This cutting-edge machine organizes and automates the entire Paratha-making process, from kneading the unleavened dough to the final flatbread. Parathas, being a staple food in Indian households, are characterized by their thin, flaky layers and rich, flavourful fillings.

As a result, this innovation not only benefits businesses in terms of efficiency and cost-effectiveness but also contributes to the preservation and popularization of traditional culinary delights on a larger scale. The fully automatic paratha-making machine stands as a testament to the fusion of technology and gastronomy, making the joy of relishing authentic parathas accessible to all.

For more details please visit our website: https://grishamindustry.com/semi-automatic-half-cooked-paratha-making-machine-manufacturer-coimbatore-kerala-tamilnadu-india/

0 notes

Text

Chapati making is a complex, multi-stage process that requires precision, especially when feeding large groups. The Automatic Chapati Machine revolutionized this by producing 300-2000 hygienic chapatis per hour. However, to address the challenge of uniform peda making, the Fully Automatic Chapati Machine was developed, integrating both functions. Over the years, these machines have evolved from round pressing types to conveyor systems, catering to diverse institutional needs. Sunshine Industries, based in Noida, stands out as a leading manufacturer, offering a wide range of roti machines along with exceptional after-sales service. This innovation is particularly beneficial for restaurants, caterers, and institutions looking to enhance efficiency.

We encourage you to share your thoughts and suggestions in the comments below!

0 notes

Text

Revolutionizing Your Kitchen: The Semi-Automatic Chapati Making Machine

In a world where time is increasingly valuable, kitchen automation has become a significant trend. Among the many innovations designed to save time and effort in food preparation, the Semi-Automatic Chapati-Making Machine stands out. This appliance is transforming how chapatis, a staple in many households, are prepared, offering convenience without sacrificing the authentic taste and texture of homemade chapatis.

What is a Semi-Automatic Chapati Making Machine? A semi-automatic chapati-making machine is a kitchen appliance that streamlines the process of making chapatis or rotis. Unlike a fully automatic machine, which handles the entire process from dough kneading to cooking, a semi-automatic machine requires some manual intervention. Typically, users prepare the dough and place it into the machine, which then rolls out, flattens, and partially cooks the chapati. The final cooking, which involves achieving the perfect puff and golden-brown spots, is done manually on a griddle or tawa.

Benefits of Using a Semi-Automatic Chapati Making Machine 1. Time Efficiency One of the most significant advantages of using a semi-automatic chapati maker is the time it saves. Rolling out chapatis by hand can be a time-consuming process, especially when making them in large quantities. The machine quickly flattens the dough into evenly sized chapatis, reducing the time spent in the kitchen.

2. Consistent Results Achieving the perfect round and uniformly thin chapatis can be challenging, especially for beginners. A semi-automatic chapati maker ensures consistent results every time. The machine rolls out dough balls into uniform shapes and thickness, ensuring that each chapati cooks evenly and looks perfect.

3. User-Friendly These machines are designed to be easy to use, even for those who are not particularly skilled in cooking. The controls are simple, and the process is straightforward: prepare the dough, load it into the machine, and let it do the rolling. This user-friendliness makes it an excellent tool for busy households, where time and convenience are essential.

4. Energy Efficiency Semi-automatic chapati makers consume less energy compared to their fully automatic counterparts. Since they require manual intervention for the final cooking stage, they do not use as much electricity. This makes them an eco-friendly option for those looking to reduce their energy consumption.

5. Cost-Effective Compared to fully automatic machines, semi-automatic chapati makers are generally more affordable. They provide a good balance between automation and manual control, offering value for money without compromising on quality.

How to Use a Semi-Automatic Chapati Making Machine Using a semi-automatic chapati maker is simple:

Prepare the Dough: Knead the dough as you normally would. Make sure it's of the right consistency – neither too soft nor too hard.

Preheat the Machine: Most machines require a few minutes to heat up. Check the manufacturer's instructions for the exact time.

Place Dough Balls: Divide the dough into small, even-sized balls and place them in the designated area of the machine.

Roll and Press: The machine will automatically roll and press the dough balls into flat chapatis.

Cook on a Griddle: Once the chapatis are rolled out, transfer them to a hot griddle or tawa for the final cooking stage. Flip them until they puff up and develop golden-brown spots.

Conclusion The Semi-Automatic Chapati-Making Machine is a game-changer for anyone who regularly makes chapatis. It combines the best of both worlds: the convenience of automation with the control and authenticity of manual cooking. Whether you're a busy professional, a homemaker, or someone who loves cooking but could use some help in the kitchen, this machine can make your life easier, saving you time and effort while ensuring that you still enjoy delicious, homemade chapatis.

0 notes

Text

Chapati making machine

A chapati making machine is a piece of equipment designed to automate the process of making chapatis, which are a type of flatbread commonly consumed in South Asia. These machines are particularly useful in commercial settings where large quantities of chapatis need to be produced efficiently. Here are some features and aspects commonly associated with chapati making machines:

Automation: Chapati making machines are automated and can perform tasks such as dough kneading, flattening, and cooking, reducing the need for manual labor.

Dough Kneading: The machine typically includes a dough kneading mechanism to prepare the chapati dough. It ensures consistent and well-mixed dough.

Flattening Mechanism: After kneading the dough, the machine flattens it into thin, round shapes similar to chapatis. This process is often automated to maintain uniform thickness.

Cooking: Some advanced machines can also cook the chapatis. They may have hot plates or conveyors for baking the flattened dough, ensuring that the chapatis are fully cooked.

Adjustable Settings: Machines often come with adjustable settings for controlling factors like dough thickness, cooking temperature, and cooking time to meet specific preferences.

Capacity: Chapati making machines come in different capacities, ranging from small-scale models suitable for restaurants to large-scale industrial machines for mass production.

Material and Construction: These machines are typically constructed using stainless steel, which is easy to clean and maintain, ensuring hygiene in a food preparation environment.

Power Source: Chapati making machines may be electrically powered or use other energy sources, depending on the model and design.

Ease of Cleaning: Hygiene is crucial in food preparation, so these machines are designed to be easy to clean. Detachable parts and smooth surfaces facilitate cleaning and maintenance.

Customization: Some machines allow for customization of chapati size and thickness based on user preferences or specific requirements.

When considering purchasing a chapati making machine, it's essential to assess the specific needs of the business or household, the desired capacity, available space, and the features offered by different models. Additionally, maintenance and cleaning requirements should be taken into account to ensure the longevity and efficiency of the machine.

Automatic chapati making machine

Automatic chapati making machines are devices designed to streamline the process of chapati production in commercial and industrial settings. These machines are highly efficient, capable of producing a large number of chapatis in a short amount of time. Here are some common features associated with automatic chapati making machines:

Dough Mixing: These machines often come with an automated dough mixing system. They accurately measure and mix the ingredients to produce consistent and well-mixed dough.

Dough Ball Formation: After mixing, the machine shapes the dough into uniform balls, ensuring consistency in the size of the chapatis.

Dough Flattening: The dough balls are then passed through a flattening mechanism, which rolls them into thin, round chapatis. This process is automated to maintain uniform thickness.

Cooking System: Automatic chapati making machines may have an integrated cooking system, which involves baking or cooking the flattened dough. This can be achieved through hot plates, conveyors, or other cooking mechanisms.

Temperature Control: These machines often come with temperature control settings to regulate the cooking temperature, ensuring that the chapatis are cooked evenly and thoroughly.

Adjustable Size and Thickness: Users can often adjust the settings to control the size and thickness of the chapatis according to their preferences or specific requirements.

High Production Capacity: Automatic chapati making machines are designed for high production capacities, making them suitable for large-scale commercial and industrial use.

Stainless Steel Construction: To ensure hygiene and easy cleaning, these machines are commonly constructed with stainless steel, which is resistant to corrosion and can withstand rigorous use.

User-friendly Interface: The machines typically feature a user-friendly control panel or interface, making it easy for operators to set parameters and monitor the production process.

Safety Features: Safety features such as emergency stop buttons and protective guards are often incorporated to ensure the well-being of operators.

Low Maintenance: Automatic chapati making machines are designed to be low maintenance, with easy-to-clean components and minimal wear and tear.

When considering an automatic chapati making machine, it's crucial to assess the specific production requirements, available space, and budget. Different models may vary in terms of capacity, speed, and additional features, so choosing a machine that aligns with the needs of the business is essential.

Fully automatic chapati making machine

Fully automatic chapati making machines are advanced devices designed to handle the entire process of chapati production, from dough preparation to cooking, with minimal human intervention. These machines are commonly used in commercial and industrial settings where large quantities of chapatis need to be produced efficiently. Here are some key features associated with fully automatic chapati making machines:

Dough Mixing: These machines typically feature an automated dough mixing system that accurately measures and combines ingredients to create a consistent and well-mixed dough.

Dough Ball Formation: After mixing, the machine shapes the dough into uniform balls, ensuring standardized sizes for the chapatis.

Flattening Mechanism: The dough balls are automatically fed into a flattening mechanism that rolls them into thin, round chapatis. This process ensures uniform thickness and size.

Automatic Cooking: Fully automatic chapati making machines often include an integrated cooking system. The flattened dough is automatically transferred to a cooking unit, where chapatis are baked or cooked.

Temperature Control: These machines come with temperature control settings to regulate the cooking temperature, ensuring that the chapatis are cooked evenly.

Adjustable Size and Thickness: Users can typically adjust settings to control the size and thickness of the chapatis according to their preferences or specific requirements.

High Production Capacity: Fully automatic chapati making machines are designed for high production capacities, making them suitable for large-scale operations.

Stainless Steel Construction: To ensure hygiene and easy cleaning, these machines are often constructed with stainless steel, which is resistant to corrosion and easy to maintain.

Touchscreen Control Panel: The user interface is often equipped with a touchscreen control panel, making it easy for operators to set parameters, monitor the production process, and make adjustments.

Safety Features: These machines are equipped with safety features such as emergency stop buttons, protective guards, and sensors to ensure the safety of operators.

Low Maintenance: Fully automatic chapati making machines are designed to be low maintenance, with components that are easy to clean and durable for long-term use.

When considering a fully automatic chapati making machine, businesses should carefully evaluate their production requirements, available space, and budget constraints. Different models may offer varying capacities, speeds, and additional features, so choosing a machine that aligns with the specific needs of the business is crucial.

#Automatic chapatti machine#Automatic chapatti making machine#Fully automatic roti maker#Roti making machine

0 notes

Text

Fully Auto Raw Chapati Machines Manufacturer, Supplier & Exporter From Vadodara

Manufacturer, Supplier & Exporter of Fully Auto Raw Chapati Machines, Raw Chapati Pressing Machines, Commercial Chapati Making Machine From Vadodara, Gujarat, India.

#fully auto raw chapati machines#raw chapati pressing machines#commercial chapati making machine#phulka roti machine#double pressing fully automatic chapati machine#chapatti machine

1 note

·

View note

Text

How Can I Find the Best Chapati Making Machine

Having the best chapati making machine is always a choice of many people. But as we know there are many brands available in the market and choosing the best one is a bit tough task.

Chapati Maker is an ideal choice for everyone that will help to prepare Chapati quickly without putting more effort. So, if you are planning to buy them you need to consider some things before getting the best deal.

Budget At first, you need to make your budget for buying an fully automatic chapati making machine. If you want all the advanced features then you need to set your budget because it will be a bit expensive. But if you have a limited budget then you need to look for limited features. So it is essential to make a budget while purchasing a chapati Maker.

Quantity of Rotis Another important thing to consider is the quantity of rotis you need in a roti making machine. On an average, people use Chapati Maker to get approximately 20 rotis per day. If you have more work load then you need to increase your budget or else you will get various option in that option. So, choose your chapati maker only after deciding the quantity of rotis daily.

Warranty The Roti Making Machine always comes with an optimum warranty period. But if you are not getting any warranty then you should avoid that option. In general, a roti maker provides a 1-3 year warranty in which you will get the whole customer service that is essential. So always make sure that the roti maker is coming under a warranty period.

Features The most important thing is to look at the features of Chapati Making Machine. The advanced and latest chapati makers always comes with the advanced features like automation and durable functionality. So, you should go with a chapati maker that has various features. As it will be very convenient for you to prepare rotis quickly. The advanced chapati makers also provides soft and crispy rotis than a traditional way of cooking.

#chapati making machine#roti making machine#fully automatic chapati making machine#chapati making machine manufacturer

0 notes

Link

Check out the manufacturing machines Chapati making machines, Automatic chapati making machines, Fully Automatic chapati making machines, Half cooked chapati making machines, Pathiri making machines

1 note

·

View note

Text

Chapati Making Machine Manufacturer & Suppliers India

We have been manufacturing high-quality machines for 18 Years and have already installed more than 1000+ machines across the Globe. Our successful installations are in more than 23 States in India and in 22 Countries across the Globe like USA, Canada, UK, New Zealand, Singapore, Bangkok, Bangladesh, Dubai, Abu Dhabi, Qatar, Oman, South Africa, Kenya, Botswana, Brunei, China, Nepal, Israel, Iraq, Sharjah, Tanzania & Saudi Arabia.

We are delighted to introduce you to the world of Qualimark, a company Where Quality Meets Expectations

Qualimark Machines Products

Chapati Making Machines

Qualimark is one of the best Chapati Making Machine Manufacturer & Suppliers in India. We are providing compact Fully Automatic Chapati Making Machine in India.

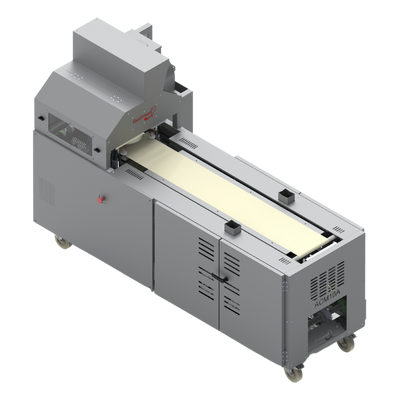

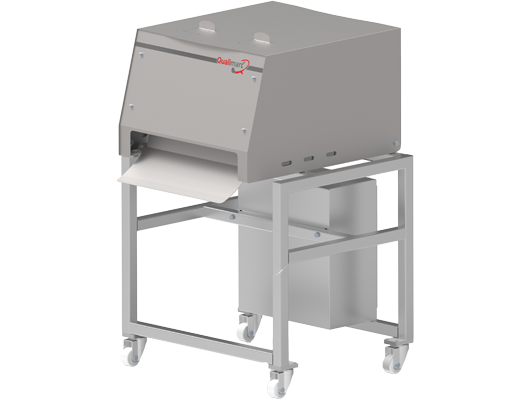

Compact Automatic Chapati Making Machine

Qualimark employed its expertise and experience in designing and developing this successful compact automatic chapati making machine. Developed after thorough research and by following an innovative design approach, the automatic chapati making machine is a compact, energy-efficient and high-performance machine that speeds up the food preparation process.

The automatic chapati making machine boasts of being the world’s smallest automatic chapati making a machine with a capacity to cook 400 chapatis in one hour. One of the most innovative products, the machine was designed, developed and perfected over a period of two years. Known for great ergonomics and compact size, the machine is used by leading caterers and restaurants to cook chapati, even at outdoor catering locations. With great mobility, compact size and low gas and electricity requirements, the machine serves as an ideal chapati making solution for the F&B industry. The machine uses single conveyor and 360-degree chapati baking technology, advanced precision motor, and gearbox that promises a high rate of production with optimum chapati cooking or roasting and least maintenance. Also, the machine offers better insulation owing to superior-grade heating components.

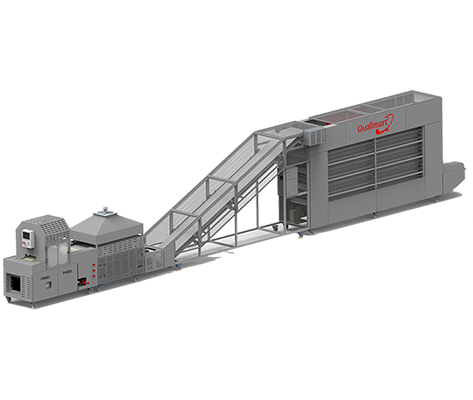

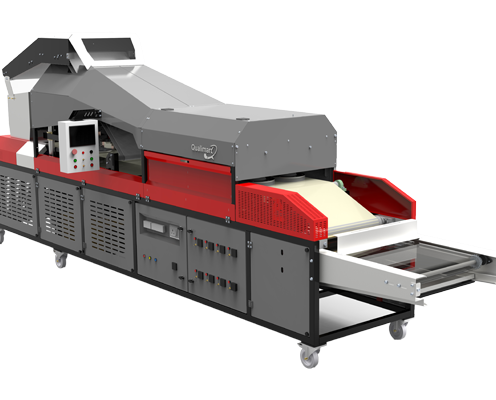

Automatic Chapati Making Machine

Qualimark employed its expertise and experience in designing and developing the world’s most successful Automatic Chapati Making Machine. Developed after thorough research and by following an innovative design approach, the automatic chapati making machine is a compact, energy-efficient and high-performance machine that speeds up the food preparation process. The machine works on a single conveyor and 360-degree chapati baking technology, advanced precision motor, and gearbox that promises a high rate of production with optimum chapati cooking/roasting and least maintenance. Also, the machine offers better insulation owing to superior-grade heating components.

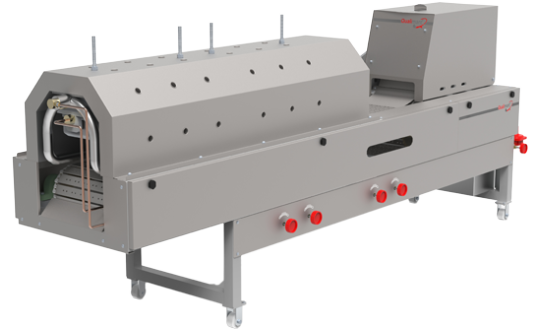

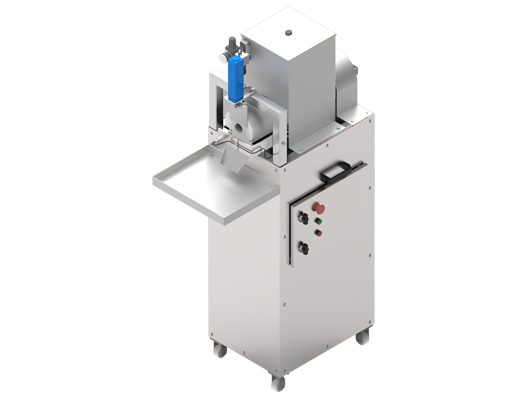

Semi-Automatic Chapati Making Machine

Semi-automatic Chapati making machines by Qualimark are designed, engineered and manufactured using superior-grade raw materials and innovative technology. The machine improves the existing food preparation process by fastening up the process of chapati making in a commercial kitchen. Available in different sizes as per the personalized requirements, the semi-automatic chapati making machine can be customized as per the chapati making needs of different kitchens. Coming with an easy-to-operate system, the machine can be programmed to control different parameters such as thickness, size or diameter of the chapati.

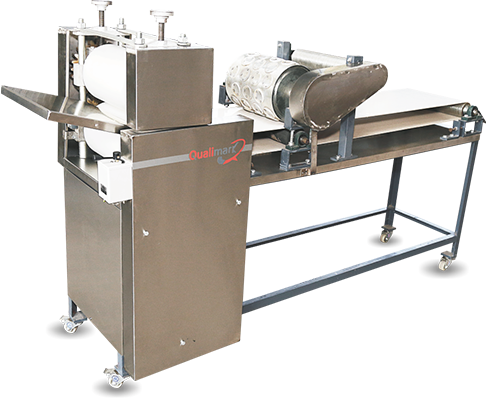

Chapati Pressing Machines

The automated chapati pressing machine by Qualimark can be easily integrated with existing machines and requires only two square feet of floor space for operations. The press improves the existing productivity of chapati press operations and produces 800-1700 ready-to-cook chapatis in a single hour as per the need. Coming with a special floor stand, the semi-automatic machine is developed and designed for use in a comfortable countertop position.

Chapati Puffer Table

Chapati Puffer Table is developed by Qualimark to improve the chapati production process in a commercial kitchen. The puffer table comes with countertop chapati pressing machine and has a capacity to cook 400-600 chapatis in a single hour. An easy-to-operate, cost-efficient and highly-customizable machine, the chapati puffer can be used to cook chapatis of different diameters as per personalized requirements. The chapati puffer table comes with a highly-efficient metal surface that promises evenly and quickly-cooked chapatis, every single time.

Dough Ball Making Machine

Dough ball making machine by Qualimark is a highly sought after product in the food processing industry that fastens up the process of making dough for chapati, poor and other flatbread in bulk. The machine is easy-to-operate and clean and can be customized to control the size of dough balls as per the requirement. With smooth dough ball cutting and easy-to-integrate mechanism, the machine promises a great boost in the productivity of existing operations without hampering current processes. Developed, designed, engineered and produced using high-grade raw materials and latest technology, the machine is an efficient, durable and functional product, essential for every commercial kitchen.

The dough ball making machine can be easily integrated into other machines like Qualimark’s Khakhra making and chapati making machines. This helps the operator in getting rid of the hassle of dough ball making. Also, the machine is made from precision and premium PP material worm that homogeneously mixes the kneaded flour for best-quality dough balls.

Flour Kneading Machine

The flour kneading machine is used to knead large quantities of flour at a single time. The compact machine works on advanced technology and improves the speed of the existing food preparation processes. Qualimark designs and manufactures high-quality flour kneading machines in different sizes according to the requirement.

#flour kneading machine#Dough Ball Making Machine#Chapati Puffer Table#Chapati Pressing Machines#Semi-Automatic Chapati Making Machine#Automatic Chapati Making Machine#Compact Automatic Chapati Making Machine#Chapati Making Machines

1 note

·

View note

Link

0 notes

Text

Types of Khakhra Making Machines: Manual vs. Automatic

The popular Indian snack khakhra needs to be prepared accurately and consistently. Manual khakha-making machines are essential in small-scale production since they provide an economical and effective option.

Traditional Hand-Operated Khakhra-Making Machine:

The manual machine used to make khakhras by hand is a basic apparatus that mimics the rolling process by hand. It consists of a rolling pin mechanism and a flat surface. After putting the dough on the surface, the khakhra is pressed and shaped with a rolling pin. This kind of khakhra-making machine is perfect for household use and small-scale businesses. It keeps the genuine flavor and texture of homemade khakhra.

Hand-Powered Rotating Khakhra Manufacturing Device: An advancement over the conventional manual process is a hand-operated rotating khakhra-making machine. It has a rotating mechanism that makes uniform thickness and more constant pressure possible. A manual crank is used to rotate the plate with the dough on it.

Manual Khakhra Making Machine with a Lever Type: A lever mechanism is used in the manual khakhra-making machine of the lever type to exert pressure on the dough. Usually, it is made up of a lever arm with a pressing plate and a flat base. After the dough is positioned on the base, it is pressed into the required thickness and formed using the lever. This kind of khakhra-making machine provides more control over the pressure, enabling the production of consistently thin khakhras. For small-scale production, it is a well-liked option.

Multifunctional Handheld Khakhra Manufacturing Device: A manual khakhra-making machine with multiple uses is made to be adaptable. It can also be used to make various flatbreads like chapati and paratha, in addition to khakhra. Typically, this kind of khakhra-making apparatus

Small Handheld Manual Khakhra Making Machine: Small manual khakhra-making machines are made to be portable and simple to operate. These devices are perfect for mobile vendors and little kitchens because they are lightweight and convenient to store. Compact khakhra production machines are able to consistently produce high-quality khakhras despite their small size. They are ideal for anyone who wishes to create khakhra quickly and easily without requiring a lot of equipment.

Benefits of Manual Khakhra-Making machine

There are various benefits to using a manual khakhra making machine, particularly for home cooks and small-scale producers. First of all, they are more affordable than automated equipment, which enables a larger market to use them. Second, the thickness and texture of the khakhra may be more precisely controlled with manual khakhra machine making.

With the introduction of the fully automatic khakhra-making machine, the production method for the traditional Indian snack khakhra has undergone a change. This cutting-edge technology, which offers substantial benefits in terms of productivity, uniformity, and scalability, has completely changed the preparation of khakhra.

Cutting Edge Technology of khakhra making machine: Advanced features like temperature control, programmable settings, and automated dough feeding systems are among the advanced features found in a fully automatic khakhra-making machine. With the help of these elements, the production process may be precisely controlled, guaranteeing ideal cooking conditions for flawless khakhras. Because of the sophisticated technology employed, even those with limited technical knowledge may easily run a khakhra-making machine.

Efficiency in Energy Use of khakhra-making machine: Another significant benefit of a fully autonomous khakhra-making machine is its energy economy. Modern machinery is built to have a high manufacturing output with little energy consumption. This lowers operating costs and promotes sustainable production methods, which are in line with the increasing focus on environmental responsibility.

Cost-Effectiveness of Khakhra-making machine: Even though a fully mechanized khakhra-making machine may need a substantial initial investment, the long-term advantages greatly exceed the expenditures. Higher profitability is the result of lower labor expenses, more efficient production, and consistently high-quality products. Businesses can save money in the long run and get a competitive advantage in the market by making this investment.

Businesses' Ability to Scale: A completely autonomous khakhra-making machine is a priceless tool for companies aiming to expand. Businesses can increase their market share by efficiently producing huge volumes of khakhras. Business growth and expansion are supported by the scalability offered by a fully automatic khakhra-making machine, regardless of whether it is distributed to broader regions or serving local markets.

Safety and Hygiene: When producing food, hygiene is a major problem. A fully automatic khakhra-making machine successfully addresses this. The process is automated so that there is less chance of contamination because there is less human touch with the cooked khakhras and dough. The total hygiene standards are further improved by the safety elements included in this equipment, which guarantee safe operation and maintenance.

In summary, the fully automatic khakhra-making machine is revolutionizing the process of producing traditional khakhra. Its cutting-edge technology, efficiency, stability, and scalability make it a valuable tool for companies trying to increase their output. To address the increasing demand for this popular snack, businesses may ensure high-quality, hygienic, and cost-effective production by investing in fully automatic khakhra-making machines.

0 notes

Text

Electric Chapati Maker MarketFuture Demand and Leading Players Updates by Forecast to 2027

Chapati is made from dough, which is a combination of water and flour. An electric chapati maker helps in making roti. In India, chapati is a daily consumed item, and its preparation is time consuming. To ease the work of homemakers, an electric chapati maker was invented in 2008. These machines are easy to operate, cost-effective, and save time.

Market scope and structure analysis:

Ø Market size available for years

2020–2027

Ø Base Year Considered

2019

Ø Forecast Period

2021–2027

Ø Forecast Unit

Value (USD)

Ø Segment Covered

Type, End User, Capacity, and Region

Ø Regions Covered

North America (U.S. and Canada), Europe (Germany, UK, France, Italy, Spain and Rest of Europe), Asia-Pacific (China, Japan, India, Australia, Malaysia, Thailand, Indonesia, and Rest of Asia-Pacific), LAMEA (Middle East, Brazil, Mexico, and Rest of LAMEA)

Ø Companies Covered

Rallison Appliances, Jaipan Industries Ltd., TTK Prestige Ltd, Bajaj Vacco, Mukunda Foods Pvt. Ltd., Fortune Engineering, Fastroti, Zimplistic Pte Ltd., Wonderchef Home Appliance Pvt. Ltd., Sunflame Enterprise Pvt. Ltd.

Get a sample of the report @ https://www.alliedmarketresearch.com/request-sample/6777

COVID-19 Scenario Analysis:

COVID-19 has impacted the global electric chapati market negatively. China is the major supplier of the electronic final as well as raw material and is also the main hub of COVID-19 has affected the supply of electronic parts. Due to COVID-19, there is a downfall in the production and rise in the prices of raw material.

Top Impacting Factors: Market Scenario Analysis, Trends, Drivers and Impact Analysis

Surge of advance technology, demand for chapati maker among working women, and rise in disposable income are the factors that drive the growth of the global chapati maker. However, lack of knowledge about the technology and resistance for the adoption of new technology among consumers restrain the growth of the market.

The global electric chapati maker market trends are as follows:

· Manufacturers are focusing on improving the performance of the electric appliance and reduce the time spent in the kitchen. The electric chapati maker market attracts that part of the market which include busy working women who cannot spend much time in the kitchen and want healthy food at home. This eases the burden of people working late.

· The home appliance market has evolved from manual to fully automatic appliances. The advancement of technology has increased the living standard.

· Companies are using new technology in their products and improving the performance of the product.

Request a discount on the report @ https://www.alliedmarketresearch.com/purchase-enquiry/6777

Key Segments Covered:

Ø Type

Manual

Semi-automatic

· Fully Automatic

Ø End User

Households

· Commercials

Ø Capacity

· 100 Chapati

· 100-500 Chapati

Key Benefits of the Report:

· This study presents the analytical depiction of the global electric chapati maker industry along with the current trends and future estimations to determine the imminent investment pockets.

· The report presents information related to key drivers, restraints, and opportunities along with detailed analysis of the global electric chapati maker market share.

· The current market is quantitatively analyzed from 2020 to 2027 to highlight the global electric chapati maker market growth scenario.

· Porter’s five forces analysis illustrates the potency of buyers & suppliers in the market.

· The report provides a detailed global electric chapati maker market analysis based on competitive intensity and how the competition will take shape in coming years.

Questions Answered in the Electric Chapati Maker Market Research Report:

· What are the leading market players active in the electric chapati maker market?

· What the current trends will influence the market in the next few years?

· What are the driving factors, restraints, and opportunities in the market?

· What future projections would help in taking further strategic steps?

To know more about the report @ https://www.alliedmarketresearch.com/electric-chapati-maker-market-A06412

About Allied Market Research:

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Portland, Oregon. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of "Market Research Reports" and "Business Intelligence Solutions." AMR has a targeted view to provide business insights and consulting services to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domains. AMR offers its services across 11 industry verticals including Life Sciences, Consumer Goods, Materials & Chemicals, Construction & Manufacturing, Food & Beverages, Energy & Power, Semiconductor & Electronics, Automotive & Transportation, ICT & Media, Aerospace & Defense, and BFSI.

We are in professional corporate relations with various companies and this helps us in digging out market data that helps us generate accurate research data tables and confirms utmost accuracy in our market forecasting. Each and every data presented in the reports published by us is extracted through primary interviews with top officials from leading companies of domain concerned. Our secondary data procurement methodology includes deep online and offline research and discussion with knowledgeable professionals and analysts in the industry.

Contact Us:

David Correa

5933 NE Win Sivers Drive

#205, Portland, OR 97220

United States

USA/Canada (Toll Free): 1-800-792-5285, 1-503-894-6022, 1-503-446-1141

UK: +44-845-528-1300

Hong Kong: +852-301-84916

India (Pune): +91-20-66346060

Fax: +1(855)550-5975

Web: https://www.alliedmarketresearch.com

Follow Us on LinkedIn: https://www.linkedin.com/company/allied-market-research

0 notes

Link

Chapati Machine – We are one of the best India’s leading industries in Fully Automatic Chapati Making Machine . For Order Call Now At + 91-9818172990 https://chapatimachine.co #ChapatiMachine #AutomaticChapatiMakingMachine Order Now at https://chapatimachine.co/

0 notes

Text

Efficiency in Every Bite: The Fully Automatic Chapati Making Machine

The Fully Automatic Chapati Making Machine streamlines chapati production, ensuring quick, consistent, and hygienic results. Ideal for large kitchens, it saves time, reduces labor, and delivers perfect chapatis effortlessly.

For more information

visit our website https://justpaste.it/fl2bg

Or Contact Us; 9520989666

0 notes

Text

A chapati making machine is a device used to make chapatis in bulk. It is designed to mix, knead, roll, and cook chapatis automatically, making it easier and faster to produce large quantities of chapatis.

#chapati making machine#chapati making machines#automatic chapati making machine#automatic roti maker machine#automatic roti making machine#roti making machine

0 notes

Text

Top Raw Chapati Pressing Machines Manufacturer in Vadodara, Gujarat

Prama Kitchen Equipments – Manufacturer, Supplier & Exporter of Manufacturer, Supplier & Exporter of Raw Chapati Pressing Machines, Commercial Chapati Making Machine, Four Gola Pressing Fully Automatic Chapati Machine (2800 Chapati Per Hrs.), Phulka Roti Machine, Double Pressing Fully Automatic Chapati Machine (1600 Chapati Per Hrs.), Compact Fully Automatic Chapati Machine (400 Chapati Per Hrs.), Fully Automatic Chapati Machine(800 Chapati Per Hrs.), Fully Auto Raw Chapati Machines and Chapati Machine From Vadodara, Gujarat, India.

#raw chapati pressing machines#commercial chapati making machine#four gola pressing fully automatic chapati machine#phulka roti machin#double pressing fully automatic chapati machine#chapatti machine

1 note

·

View note