#casting foundry

Explore tagged Tumblr posts

Text

Casting Foundry

EathuCasting provides high quality, customized casting services for casting all kinds of metal products, iron, aluminum, aluminum alloys stainless steel and other materials. Guaranteed on time delivery of products, website online service, welcome to send drawings to communicate with eathu engineers

Casting Foundr

0 notes

Text

Casting Foundry

EathuCasting provides high quality, customized casting services for casting all kinds of metal products, iron, aluminum, aluminum alloys stainless steel and other materials. Guaranteed on time delivery of products, website online service, welcome to send drawings to communicate with eathu engineers

Casting Foundr

0 notes

Text

Casting Foundry

EathuCasting provides high quality, customized casting services for casting all kinds of metal products, iron, aluminum, aluminum alloys stainless steel and other materials. Guaranteed on time delivery of products, website online service, welcome to send drawings to communicate with eathu engineers

Casting Foundr

0 notes

Text

Casting Foundry

EathuCasting provides high quality, customized casting services for casting all kinds of metal products, iron, aluminum, aluminum alloys stainless steel and other materials. Guaranteed on time delivery of products, website online service, welcome to send drawings to communicate with eathu engineers

Casting Foundr

0 notes

Text

Casting Foundry

EathuCasting provides high quality, customized casting services for casting all kinds of metal products, iron, aluminum, aluminum alloys stainless steel and other materials. Guaranteed on time delivery of products, website online service, welcome to send drawings to communicate with eathu engineers

Casting Foundr

0 notes

Text

Casting Foundry

EathuCasting provides high quality, customized casting services for casting all kinds of metal products, iron, aluminum, aluminum alloys stainless steel and other materials. Guaranteed on time delivery of products, website online service, welcome to send drawings to communicate with eathu engineers

Casting Foundr

0 notes

Text

Casting Foundry

EathuCasting provides high quality, customized casting services for casting all kinds of metal products, iron, aluminum, aluminum alloys stainless steel and other materials. Guaranteed on time delivery of products, website online service, welcome to send drawings to communicate with eathu engineers

Casting Foundr

0 notes

Text

Casting Foundry

EathuCasting provides high quality, customized casting services for casting all kinds of metal products, iron, aluminum, aluminum alloys stainless steel and other materials. Guaranteed on time delivery of products, website online service, welcome to send drawings to communicate with eathu engineers

Casting Foundr

0 notes

Text

Casting Foundry

EathuCasting provides high quality, customized casting services for casting all kinds of metal products, iron, aluminum, aluminum alloys stainless steel and other materials. Guaranteed on time delivery of products, website online service, welcome to send drawings to communicate with eathu engineers

Casting Foundr

0 notes

Text

Casting Foundry

EathuCasting provides high quality, customized casting services for casting all kinds of metal products, iron, aluminum, aluminum alloys stainless steel and other materials. Guaranteed on time delivery of products, website online service, welcome to send drawings to communicate with eathu engineers

Casting Foundry

0 notes

Text

Iron Casting Manufacturer- Mahadev Ferro Cast

Since its inception in 1969, Mahadev Ferrocast, rapidly became the leader of high quality Ductile and Grey Iron castings.

One of the most significant differentiation that distinguishes us from others is high level performance and precision work. Adding more feathers to the cap, the meticulous quality control, capacity of production, expertise of technicians and engineers plays a major role in standing out from the crowd. We have in-house state of the art Machine Shop which gives us a added advantage of providing the casting in properly finished condition.

ustomer Satisfaction is our first priority and we attain it with the help of complete integration of quality systems and latest technological equipment. We are customers’ first choice not just because of the quality, reliability and delivery but we are also certified with ISO BS OHSAS 18001. With years of experience and expertise in manufacturing and supplying components to various standards and specifications, Mahadev, is the one name you want to hear again and again.

We have the mammoth capacity to produce casting upto 3000 kg single part piece. Our fundamental production facility includes Induction, Fast Loop No-Bake Moulding Line, Green Sand Plant, Knock Out, Shot Blasting, Machine Shop with Latest HMC’s, VMC’s, CNC VTL’s and CNC milling machines.

Link: https://www.mahadevferrocast.com/

#iron casting#casting iron#cast iron#iron cast#iron casting manufacturer#iron casting foundry#casting foundry

1 note

·

View note

Text

Typography Tuesday

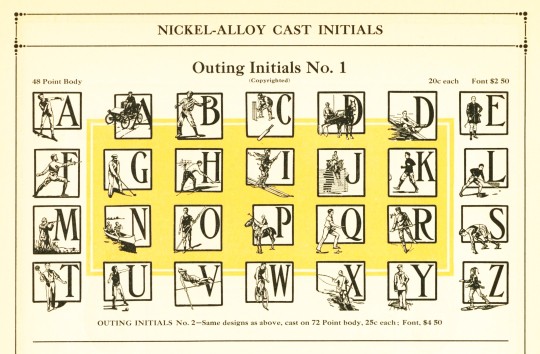

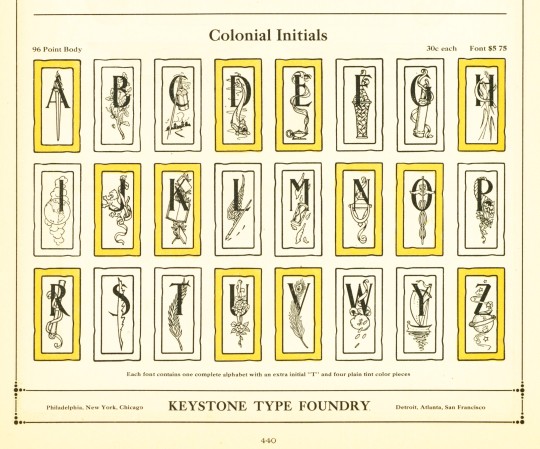

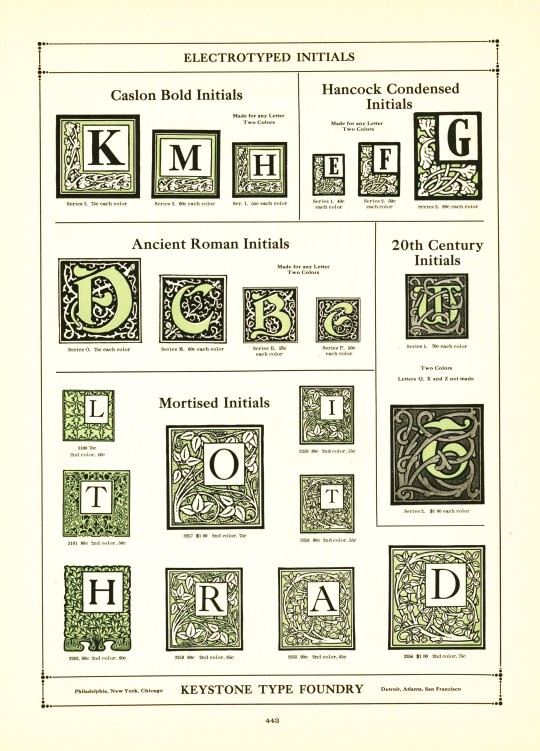

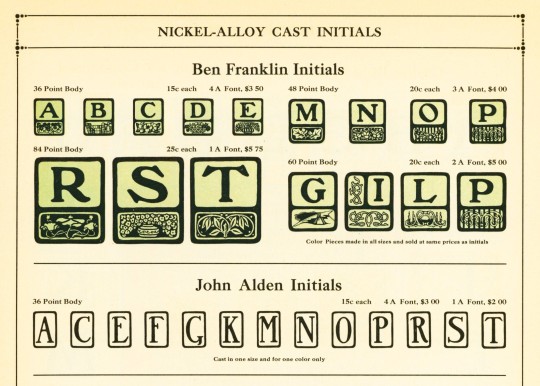

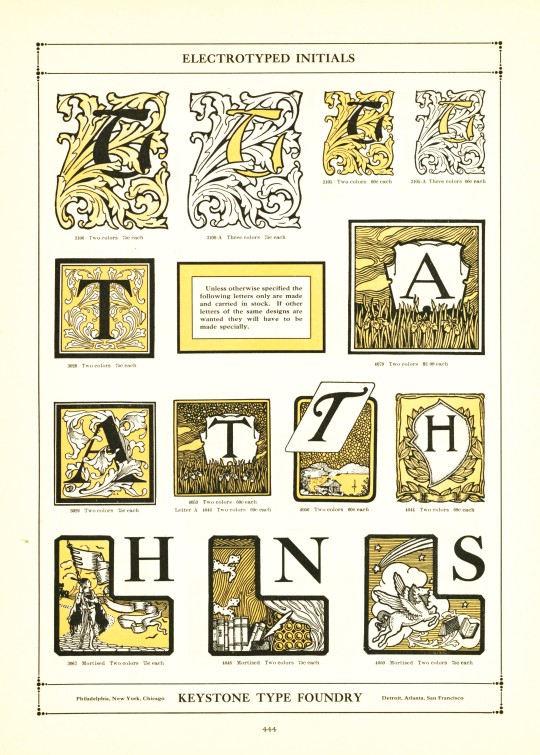

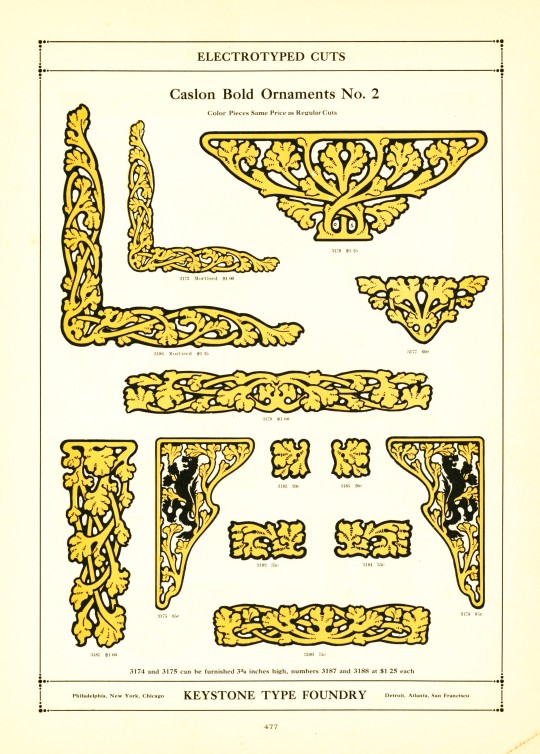

KEYSTONE INTIALS AND CUTS

The Keystone Type Foundry was established in Philadelphia in 1888 and operated independently until 1917 when it became one of the many foundries absorbed by American Type Founders. These cast and electrotyped initials and cuts are from the foundry's Catalogue and Specimen Book Keystone Products Consisting of Type, Material Furniture Complete Line of Miscellaneous Supplies for Printers and Publishers published in Philadelphia in 1910. All the initials and cuts shown here were designed by Keystone's own staff except for the Meridale and Lotus Initials which were licensed to Keystone.

This catalogue was copy No. 5351 and according to its bookplate was the property of Keystone and was only lent out, not sold or given, to a printer/publisher, and was expected to be returned "intact and in good condition, reasonable wear expected." Someone clearly did not follow those instructions, as several specimens have been cut from the catalogue's pages as can be seen in the Caslon Bold Page Ornaments.

View other specimens from this Keystone Catalogue.

View our other Typography Tuesday posts.

#Typography Tuesday#typetuesday#Keystone Type Foundry#Catalogue and Specimen Book Keystone Products#type specimen books#type display books#type specimens#Initials#printing cuts#electrotyping#cast type#20th century type

91 notes

·

View notes

Text

How Electromagnetic Casting Pumps Solve the Three Most Common Foundry Staffing Challenges

Foundry work can be challenging and dangerous – especially if the foundry relies on manual processes to cast metal. Workers who hand ladle metal spend long shifts on their feet hoisting heavy ladles filled with blisteringly hot molten metal – and are constantly at risk of burns, heatstroke, overwork and injury. Because of this, it’s unsurprising that many foundries struggle to keep workers safe – and have an even harder time retaining employees and recruiting new ones.

Luckily, casting automation equipment – that moves workers away from the most dangerous job in the foundry – exists. Among the available solutions, electromagnetic (EM) pumps for liquid metals reign supreme.

EM pumps are installed inside furnaces and use electromagnetism – and no moving parts – to move metal into a mold. In addition to making foundries safer and easing staffing challenges, EM pumps deliver a host of other benefits, including improved metal quality, decreased scrap and increased throughput.

Here’s how EM pumps can alleviate the three most common labor-related issues foundries face: unsafe conditions, high turnover and recruitment challenges.

1. Unsafe Working Conditions

According to the BLS, 6.4% of U.S. foundry workers received a nonfatal workplace injury in 2020. The most common injuries foundry workers suffer from include:

Muscle strain: Those who hand ladle spend hours lifting and carrying ladles (which can weight over 25 pounds, alone) full of heavy molten metal – which means workers are constantly at high risk of straining and tearing muscles

Heat exhaustion: Foundries often don’t have air conditioning and can reach triple digit temperatures in the summer – which can feel even hotter for workers wearing PPE and handling molten metal that usually surpasses 1000° F

Burns: Overexerted, overheated workers are prone to spills; when the material spilled is molten aluminum – which sticks to skin and causes hard-to-heal burns – workers are at risk of serious injury

Molten aluminum pumps powered by electromagnetism eliminate the need for hand ladling – and therefore significantly curb health and safety risks. As a result, EM pumps make foundries exponentially safer.

2. High Turnover

Given the harsh environment described above, it should come as no surprise that many foundries struggle to retain workers. Unfortunately, high turnover tends to exacerbate the conditions that make retention challenging in the first place. When workers leave, the remaining employees are forced to take on additional work – which can quickly lead to overwork and increase the risk of injury.

EM molten metal pumps put an end to this vicious cycle by making foundries safer, and making the work of casting infinitely less burdensome. Because EM pumps naturally increase production, it is easier for foundries – and employees – to navigate staffing fluctuations. Further, employees can be repurposed to other higher-level, less physically demanding tasks – and have greater incentive to stick around.

3. Recruiting Challenges

Because foundries have a reputation for being unsafe, many have struggled to recruit new workers. To add another layer of complexity to the problem, many foundries are located in relatively isolated areas with a limited pool of applicants.

EM pumps are the antidote to recruitment efforts that feel like an uphill battle. Because the pumps make foundries safer, they also make them more appealing workplaces. And, because EM pumps can keep a foundry at full production even when employees leave, they reduce the pressure on foundry managers to immediately replace workers when they quit or retire.

About CMI Novacast

CMI Novacast has manufactured EM pumps that automate the movement of molten metal in foundry casting and non-casting applications since the early 80s. In foundry applications, CMI Novacast’s EM pumps improve safety, increase worker retention, decrease scrap, and improve metal quality. Because of this, the pumps increase yield and supercharge production, especially when combined with other foundry automation equipment.

#electromagnetic pumps#foundry automation equipment#casting automation equipment#liquid metal pumps#foundry staffing challenges

2 notes

·

View notes

Text

check out the fucked up thumb bird I made 👍🐦

#nebbles talks#nebbles art#<-tagging as a technicality#but yeah! i actually had a TON of fun making this ive never casted anything w/ bronze before#getting to pour molten metal in a legit foundry was INSANE#plus the patina painting process was pretty cool too!!#overall i am very happy with my fucked up little guy he is gonna live on my bookshelf forever now <3

2 notes

·

View notes