#foundry automation equipment

Explore tagged Tumblr posts

Text

How Electromagnetic Casting Pumps Solve the Three Most Common Foundry Staffing Challenges

Foundry work can be challenging and dangerous – especially if the foundry relies on manual processes to cast metal. Workers who hand ladle metal spend long shifts on their feet hoisting heavy ladles filled with blisteringly hot molten metal – and are constantly at risk of burns, heatstroke, overwork and injury. Because of this, it’s unsurprising that many foundries struggle to keep workers safe – and have an even harder time retaining employees and recruiting new ones.

Luckily, casting automation equipment – that moves workers away from the most dangerous job in the foundry – exists. Among the available solutions, electromagnetic (EM) pumps for liquid metals reign supreme.

EM pumps are installed inside furnaces and use electromagnetism – and no moving parts – to move metal into a mold. In addition to making foundries safer and easing staffing challenges, EM pumps deliver a host of other benefits, including improved metal quality, decreased scrap and increased throughput.

Here’s how EM pumps can alleviate the three most common labor-related issues foundries face: unsafe conditions, high turnover and recruitment challenges.

1. Unsafe Working Conditions

According to the BLS, 6.4% of U.S. foundry workers received a nonfatal workplace injury in 2020. The most common injuries foundry workers suffer from include:

Muscle strain: Those who hand ladle spend hours lifting and carrying ladles (which can weight over 25 pounds, alone) full of heavy molten metal – which means workers are constantly at high risk of straining and tearing muscles

Heat exhaustion: Foundries often don’t have air conditioning and can reach triple digit temperatures in the summer – which can feel even hotter for workers wearing PPE and handling molten metal that usually surpasses 1000° F

Burns: Overexerted, overheated workers are prone to spills; when the material spilled is molten aluminum – which sticks to skin and causes hard-to-heal burns – workers are at risk of serious injury

Molten aluminum pumps powered by electromagnetism eliminate the need for hand ladling – and therefore significantly curb health and safety risks. As a result, EM pumps make foundries exponentially safer.

2. High Turnover

Given the harsh environment described above, it should come as no surprise that many foundries struggle to retain workers. Unfortunately, high turnover tends to exacerbate the conditions that make retention challenging in the first place. When workers leave, the remaining employees are forced to take on additional work – which can quickly lead to overwork and increase the risk of injury.

EM molten metal pumps put an end to this vicious cycle by making foundries safer, and making the work of casting infinitely less burdensome. Because EM pumps naturally increase production, it is easier for foundries – and employees – to navigate staffing fluctuations. Further, employees can be repurposed to other higher-level, less physically demanding tasks – and have greater incentive to stick around.

3. Recruiting Challenges

Because foundries have a reputation for being unsafe, many have struggled to recruit new workers. To add another layer of complexity to the problem, many foundries are located in relatively isolated areas with a limited pool of applicants.

EM pumps are the antidote to recruitment efforts that feel like an uphill battle. Because the pumps make foundries safer, they also make them more appealing workplaces. And, because EM pumps can keep a foundry at full production even when employees leave, they reduce the pressure on foundry managers to immediately replace workers when they quit or retire.

About CMI Novacast

CMI Novacast has manufactured EM pumps that automate the movement of molten metal in foundry casting and non-casting applications since the early 80s. In foundry applications, CMI Novacast’s EM pumps improve safety, increase worker retention, decrease scrap, and improve metal quality. Because of this, the pumps increase yield and supercharge production, especially when combined with other foundry automation equipment.

#electromagnetic pumps#foundry automation equipment#casting automation equipment#liquid metal pumps#foundry staffing challenges

2 notes

·

View notes

Text

God, but don't I just love massive vehicles that can serve as a mobile base/home for their crew.

Just… the idea of wandering aimlessly over the surface of some alien world in a truly massive mobile mining platform. A crew of 16 resides in your amalgamation of a Euclid R100 and a soviet Kharkovhanka. You and three others serve as a bridge crew, piloting, scanning, maintaining comms, and navigating. The rest sit on their asses until a new deposit comes up, then they get out in 10-feet-tall exo-suits equipped to tear through the earth and stone of this world.

The bridge itself isn't the most spacious you've seen - more like a set of four desks built into the hull, with enough room to walk between them - and really, the only reason anyone not on duty at one of those stations winds up in there is the external hatch that leads to the balcony wrapping around the front of the landship. Best view on the planet, right there.

A door at the back of the cockpit leads to the main sanctuary for crew. Well-worn diner-style booths line one wall and sleeping alcoves/bunks line the other. The back and some of the middle is taken up by a kitchenette that provides just a bit of a taste of home. The front and middle is taken by an entertainment system that's seen contiguous use since the start of the mission.

A door at the back of that cabin leads to a hanging balcony inside the docking bay/engine room. There's twelve suits in there, and not a week goes by where some sort of malfunction or disability doesn't rock the work crew. Number 3's been having issues with the actuators in its left arm for a month, and Number 8 was leaking power through a faulty coupling until early that week. The engine is a delightfully, near-silent hum that only occasionally trades places with a band of baboons playing 50 steel drums...

Finally, at the very rear of the vehicle, and separated by a coupling that drags the facility along at a healthy 20 mph, is a massive foundry and storage system. Hunks of ore go in, 4"x4"x8' billets come out. You're currently only at a third of total capacity, but you'll hopefully be at capacity in time to return yourself, rather than have an automated system do so, or - worse - another crew relieve you. It'd be a shame to put in all the work you've already done, only to have someone else enjoy the downtime at the end of the shift...

3 notes

·

View notes

Text

Global top 13 companies accounted for 66% of Total Frozen Spring Roll market(qyresearch, 2021)

The table below details the Discrete Manufacturing ERP revenue and market share of major players, from 2016 to 2021. The data for 2021 is an estimate, based on the historical figures and the data we interviewed this year.

Major players in the market are identified through secondary research and their market revenues are determined through primary and secondary research. Secondary research includes the research of the annual financial reports of the top companies; while primary research includes extensive interviews of key opinion leaders and industry experts such as experienced front-line staffs, directors, CEOs and marketing executives. The percentage splits, market shares, growth rates and breakdowns of the product markets are determined through secondary sources and verified through the primary sources.

According to the new market research report “Global Discrete Manufacturing ERP Market Report 2023-2029”, published by QYResearch, the global Discrete Manufacturing ERP market size is projected to reach USD 9.78 billion by 2029, at a CAGR of 10.6% during the forecast period.

Figure. Global Frozen Spring Roll Market Size (US$ Mn), 2018-2029

Figure. Global Frozen Spring Roll Top 13 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Discrete Manufacturing ERP include Visibility, Global Shop Solutions, SYSPRO, ECi Software Solutions, abas Software AG, IFS AB, QAD Inc, Infor, abas Software AG, ECi Software Solutions, etc. In 2021, the global top five players had a share approximately 66.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

2 notes

·

View notes

Text

⚙️ Semiconductor Manufacturing Equipment Market to Reach $264.7 Billion by 2035, Fueled by AI, IoT, and Electric Vehicles

The Semiconductor Manufacturing Equipment market is projected to grow from $107.5 billion in 2023 to $264.7 billion by 2035, marking a CAGR of 7.8% from 2023 to 2035.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/semiconductor-manufacturing-equipment-market-research-report

This market plays a crucial role in key applications such as consumer electronics, automotive, telecommunications, and industrial automation. The report outlines growth and revenue expansion opportunities across process types, equipment types, and applications, providing a detailed revenue forecast.

💡 Industry Leadership & Competitive Landscape

The Semiconductor Manufacturing Equipment market is highly competitive, with key players including:

ASML

Tokyo Electron

Lam Research

KLA Corporation

Applied Materials

Nikon

Hitachi High-Technologies

Screen Holdings

Advantest

Onto Innovation

Veeco Instruments

Disco Corporation

These companies are driving the expansion of the market by focusing on innovations in AI and IoT devices, as well as electric vehicle adoption. The 5G network expansion and advancements in semiconductor processes further support this market’s growth.

🚀 Key Drivers & Opportunities for Growth

Several factors contribute to the growth of the Semiconductor Manufacturing Equipment market, including:

Increased demand for AI and IoT devices, which require advanced semiconductors

Electric vehicle (EV) adoption, driving semiconductor requirements in automotive manufacturing

5G network expansion, which necessitates new semiconductor technologies

Emergence of quantum computing, presenting new opportunities in semiconductor fabrication

Green manufacturing initiatives, pushing for sustainable production methods

Advanced packaging solutions to improve chip performance and integration

Key opportunities exist in emerging markets, where demand for advanced semiconductor technologies continues to rise, particularly in Vietnam, India, and Brazil.

🌍 Regional Shifts & Evolving Supply Chains

The Asia-Pacific and North America regions lead the Semiconductor Manufacturing Equipment market. These regions are vital hubs for semiconductor production, with significant demand from foundries and equipment manufacturers.

However, challenges such as:

High costs of advanced equipment

Supply chain disruptions, especially in critical raw materials

are shaping the supply chain dynamics. Industry players are strategically expanding into emerging markets to diversify revenue sources and capitalize on growing demand in regions like Vietnam, India, and Brazil.

🧠 About DataString Consulting

DataString Consulting is a leading market research and business intelligence firm that provides comprehensive solutions for both B2B and B2C markets. With over 30 years of combined experience, we offer tailored market research and strategic consulting to meet the specific needs of businesses across multiple industries.

Our services include:

Custom Market Research Reports

Opportunity Assessments

Strategic Consulting for market penetration and growth

In-depth Industry Trend Analysis and Forecasting

#Semiconductor Manufacturing Equipment Market#Semiconductor Fabrication Technologies#AI and IoT Semiconductor Demand#Electric Vehicle Semiconductor Market#5G Semiconductor Technologies#Quantum Computing and Semiconductors#Advanced Semiconductor Packaging#Green Manufacturing in Semiconductor Industry#Emerging Markets for Semiconductor Equipment#Semiconductor Market in Asia-Pacific and North America#Global Semiconductor Equipment Growth Forecast#Semiconductor Equipment Manufacturers

0 notes

Text

What Creates China Wear-Resistant Casting Cost-Effective?

The need for durable, high-performance parts in markets such as mining, cement, and recycling has actually caused the development of China wear-resistant casting as an inexpensive and trusted choice. Companies like Qiming Casting have actually emerged as leaders in giving wear-resistant parts such as crusher jaw plates and jaw crusher wear parts, supplying a cost-efficient solution without jeopardizing on quality. Yet what makes China wear-resistant casting a more budget-friendly choice for businesses? This article discovers the aspects that add to its cost-effectiveness.

Affordable Manufacturing and Production Techniques

The cost-effectiveness of China wear-resistant casting begins with the sophisticated manufacturing and manufacturing methods utilized by foundries like Qiming Casting. China has actually invested greatly in automation and technology, which permits massive production with consistent quality. Making use of modern-day casting approaches such as the changed water glass procedure has actually brought about a streamlined production procedure, lowering the time and expense of production. This allows manufacturers to produce high-grade crusher jaw plates and other jaw crusher wear parts at a fraction of the expense contrasted to numerous Western equivalents. Lower labor expenses in China also add to the general affordability, making it an attractive choice for businesses around the globe.

Economic climates of Scale in Production

One of the key factors China wear-resistant casting stays economical is the large range of production. With foundries like QimingCasting producing thousands of lots of parts each year, they gain from economies of scale. The larger the production volume, the lower the per-unit expense of each part. Consequently, clients take advantage of competitive prices without sacrificing quality. High production quantities additionally permit bulk investing in of basic materials, which further drives down the price of products used in producing jaw crusher wear parts. This effectiveness in mass manufacturing plays a key role in making China a global leader in the wear-resistant casting market.

Accessibility to Top Quality Raw Products

An additional element that contributes to the cost-effectiveness of China wear-resistant casting is the very easy accessibility to high-grade raw products. China has a large supply of steels such as manganese, chromium, and alloy steels, which are crucial in the production of sturdy wear parts. QimingCasting, for example, focuses on creating parts like crusher jaw plates made from high manganese and chromium alloys. These products are understood for their wear-resistant residential properties, making them perfect for sectors such as mining and concrete. With regional access to these raw materials, manufacturers can avoid the added expenses of importing expensive steels, which would certainly be a significant expenditure for factories in other countries.

Modification and Flexibility in Design

The ability to personalize designs is an additional reason why China wear-resistant casting is so cost-effective. Qiming Casting offers tailored solutions for customers based upon particular equipment requirements and functioning conditions. Whether it's customizing jaw crusher wear parts for different crushers or changing the alloy structure for certain wear conditions, the flexibility in design enables makers to maximize parts for efficiency while keeping expenses reduced. This level of modification ensures that businesses don't require to spend for over-engineered solutions that are unnecessary for their particular needs. The capacity to match the right material and design to the equipment's operational needs minimizes waste and maximizes worth, additional enhancing the cost-effectiveness of wear-resistant casting.

Final thought

The China wear-resistant casting market has actually come to be a go-to alternative for companies looking to reduce prices while keeping high performance. With reliable production strategies, economic situations of scale, accessibility to resources, and a concentrate on customization, companies like QimingCasting offer high-quality solutions for industries worldwide. Whether you're searching for crusher jaw plates, jaw crusher wear parts, or other durable wear parts, China's wear-resistant casting market supplies an inexpensive and reliable solution. By choosing China wear-resistant casting, businesses can minimize their production costs without endangering on the longevity and efficiency of their devices.

0 notes

Text

Precision in Every Measure: Hardness Testing Solutions by Suzuki Instruments

In the world of material testing, precision is everything. Whether you are manufacturing high-strength components or ensuring the durability of metals used in critical infrastructure, accurate hardness testing is non-negotiable. At the forefront of this essential field is Suzuki Instruments, a trusted name renowned for its advanced and reliable hardness testing machines.

With decades of experience and a deep commitment to innovation, Suzuki Instruments offers a wide range of solutions tailored to meet the evolving demands of modern industry. Let’s explore their comprehensive lineup and see how each product serves a unique purpose in quality assurance and material characterization.

Rockwell and Combined Hardness Testers: Versatility Meets Speed

The Rockwell Hardness Test is one of the most widely used methods due to its simplicity and speed. Ideal for both ferrous and non-ferrous metals, Rockwell testers from Suzuki Instruments deliver rapid and repeatable results with minimal user input.

What sets their combined hardness testers apart is their ability to perform multiple hardness scales (Rockwell, Brinell, and Vickers) in a single unit. This multifunctional capability not only saves time and space but also provides flexibility for testing various materials without switching equipment.

Universal Load Cell Based Hardness Testers: The Power of Precision

Suzuki Instruments’ Universal Load Cell Based Hardness Testers offer cutting-edge accuracy by using advanced load cell technology. Unlike traditional dead weight systems, these testers provide electronically controlled load applications, ensuring superior consistency and traceability.

Vickers cum Brinell Hardness Testers: Two-in-One Testing Efficiency

For applications requiring both micro and macro hardness analysis, the Vickers cum Brinell testers deliver exceptional versatility. This hybrid design combines the fine detail of the Vickers method with the robustness of Brinell testing, making it suitable for a wide range of materials — from thin coatings to large metal castings.

Brinell Hardness Testers: Built for Heavy-Duty Materials

The Brinell method remains a preferred choice for testing materials with coarse structures or surface irregularities, such as castings and forgings. Suzuki’s Brinell Hardness Testers are engineered for high-load testing with maximum stability and accuracy.

These machines are known for their durability and are often used in foundries, steel plants, and fabrication units. With digital enhancements and optional image analysis systems, Suzuki’s Brinell testers combine traditional robustness with modern efficiency.

Vickers Hardness Testers: Microscopic Precision

When it comes to testing small parts, thin materials, or surface coatings, the Vickers Hardness Tester stands out for its fine resolution and minimal sample damage. Suzuki Instruments offers Vickers testers with high-magnification optical systems, motorized stages, and digital readouts for seamless and accurate analysis.

These machines are essential for microstructure research, surface engineering, and precision manufacturing industries. With user-friendly controls and software integration, they support both manual and automated testing environments.

Why Choose Suzuki Instruments?

What truly distinguishes Suzuki Instruments is not just the quality of its machines, but the comprehensive support that accompanies them. From installation and training to after-sales service and calibration, Suzuki provides an end-to-end experience to ensure maximum uptime and productivity for their clients.

Whether you’re operating a small testing lab or managing quality assurance for a global manufacturing facility, Suzuki Instruments delivers the tools and trust you need to get the job done right.

Final Thoughts

In today’s competitive industrial landscape, ensuring the mechanical integrity of materials is more important than ever. With Suzuki Instruments’ range of hardness testing machines — from Rockwell to Vickers, and Brinell to universal testers — you gain access to dependable precision that drives performance.

Measure it right. Measure it with Suzuki Instruments.

0 notes

Text

Have your PIC-based devices been tested reliably and quickly?

Photonic Integrated Circuit (PIC) solutions are being adopted by manufacturers to address the reduced size and complexity challenges while also addressing heat management issues experienced in today’s data centres. Frantic development of smaller, faster, cheaper and greener transceivers/active components and passive components is driving the development of high-speed networks and 5G, Photonic Integrated Circuits (PICs).

Passive optical components used in optical systems operate without external power or active control. They use processes such as transmission, reflection, polarisation, coupling, splitting, filtering, and attenuation to alter light signals.

Need for Testing

A PIC is composed of many optical components such as optical couplers, fibre-optic switches, splitters, attenuators, wavelength-division multiplexers, and transceivers.

Testing of any PIC-based device is needed in all life cycle stages — from design and development, and qualification to validation of production.

Testing – The Requirements

Automation, repeatability, scalability and parallelisation of the testing processes are needed for the huge volume of circuits and ports, to be able to meet the profitability of economies of scale. Photonics labs must evolve with the optical test requirements of passive (guiding light) optical components.

The fast maturing PIC die manufacturing has given rise to photonic wafers containing thousands of components made available by foundries through Process Design Kits (PDKs). Reliable testing is needed to optimise the different parameters of a given optical component.

Testing – The Challenges

Accuracy/repeatability: Obtaining traceable results for tight acceptance thresholds and greater yield of known good dies.

Dynamic range: Seeing full optical spectral contrast in a single measurement.

Speed: Keeping alignment and measurement time to a minimum, but also accelerating the ease of the test and analysis iterative flow.

From data to insight: Generating and managing structured data that is ready for artificial intelligence and business intelligence.

Flexible/scalable: Leveraging test station modularity and third-party compatibility of software to improve test throughput and complexity over time or swap equipment as needed.

Automation: Automating chip and wafer advanced navigation to control any instrument and execute data analysis in user-defined test routines to test massive circuits with minimal cost of ownership.

Testing PIC-based passive components is challenging due to the high port count of some components like Arrayed Waveguide Grating (AWG) and the huge number of components to test on a single die. A component test platform operates in conjunction with a continuously tunable laser to measure optical insertion loss, return loss and polarisation-dependent loss across the laser’s spectral range. Optical spectrum must be realised quickly and with a high wavelength resolution, typically to the order of a picometer.

Testing – The Process

The PIC devices are usually tested at the wafer level prior to dicing to detect defects as early as possible and to avoid packaging defective dies.

Using a PIC wafer probe station, light is coupled into the wafer to enable measurement of the optical characteristics of the DUT.

Testing Solutions for Photonics from MELSS

MELSS brings you Test and Measurement (T&M) hardware and software solutions from market leaders EXFO, which are automated, scalable, fast, accurate and cost-optimised. These T&M solutions range from those for Passive and Active components as well as automated probe stations for wafer and single-die testing.

The OPAL series of probe stations deliver industry-leading performance for testing wafers, multiple as well as single dies, enabling accurate, repeatable and fast measurement. The PILOT software suite offers automation capabilities that support the full test flow (preparation through measurement to results analysis), using EXFO’s or third-party T&M instruments.

EXFO’s comprehensive range of optical testing solutions includes component test platforms, optical testing solutions, light sources, benchtop tunable lasers, passive component testers, optical spectrum analysers, tunable filters with adjustable bandwidth, variable attenuators, switches and power meters.

EXFO has developed automated, scalable, fast, accurate and cost-effective Test and Measurement (T&M) hardware and software solutions. Ranging from simple optical testing to spectral optical characterisation or traffic analysis, EXFO offers an extensive selection of probe stations for wafer, bar, multi-die or single die configurations, and a powerful automation software suite.

The CTP10 from EXFO specifically addresses key PIC measurement challenges. measuring optical components quickly, reliably and accurately.

The CTP10 is a modular component test platform that operates together with the T200S or T500S continuously tunable lasers. The CTP10 characterises the spectral properties of high port count devices in one single scan with

High spectral resolution

70-dB dynamic range, even at a sweep speed of 200 nm/s

Operation from 1240 to 1680 nm

Coverage of a wide range of applications, including telecom, sensing and LIDAR.

Both optical and photocurrent measurements with analog output for PIC first-light search and coupling optimisation

Fast data transfer

Remote control using SCPI commands is possible

Increased PIC testing throughput

Reduced test time

High sampling resolution of 20 fm

Accurate measurement of narrow spectral features

The CT440 is a compact variant of the CTP10, with the same performance – ideal for the characterisation of PIC components with limited outputs.

In addition to the above range of products, EXFO produces other advanced products such as the T200S, T500S, CTP10, CT440, OSICS T100, FTBx-2850 and OSA20.

Author: MELSS

0 notes

Text

How to Choose the Best Quartz Powder Manufacturers in India

When you are on the hunt for reliable Quartz Powder Manufacturers in India you can not afford to go with just anyone. This raw material plays a critical role across various industries like ceramics, glass, construction, and electronics, so getting top-quality quartz powder isn’t a luxury—it’s a necessity. But with so many suppliers in the market, how do you make the right choice?

Let’s walk through everything you need to know to choose the best manufacturer that delivers quality, consistency, and service—every single time.

What is Quartz Powder and Why Is It So Important?

Quartz powder is finely ground quartz crystals, composed largely of silicon dioxide (SiO₂). Known for its strength, chemical inertness, and high melting point, it's a vital material in industries where performance and reliability matter.

Whether it’s used to make high-clarity glass or as a filler in paints and polymers, its purity directly impacts the final product. That’s why working with dependable Quartz Powder Manufacturers in India is key to ensuring your operations stay smooth and your products stay superior.

Why the Quality of Quartz Powder Can Make or Break Your Product

Low-quality quartz can have impurities that affect melting points, durability, or chemical resistance. Imagine manufacturing premium tiles, only to find them cracking during curing. That’s the cost of poor-quality inputs.

On the flip side, high-grade quartz powder boosts performance, reduces wastage, and ensures consistency—saving you time and money in the long run.

Top Things to Look for in Quartz Powder Manufacturers in India

Let’s break it down. Choosing the right manufacturer isn’t just about pricing. Here’s what you really need to look out for:

1. Product Purity and Consistency

This is non-negotiable. You want a supplier who provides quartz powder with high SiO₂ content—ideally over 99%—and minimal impurities like iron or heavy metals.

Also, consistency matters. Your manufacturer should deliver the same composition every time, with no surprises.

2. Advanced Manufacturing Technology

A manufacturer using outdated grinding and screening methods will never match the precision of one using modern, automated plants. Look for manufacturers who invest in cutting-edge machinery and regularly upgrade their processes.

3. Recognized Certifications

Does the supplier have ISO certifications or other quality marks? That’s a strong sign they follow international standards and have proper quality controls in place.

Ask about:

ISO 9001

Third-party lab reports

Internal QC protocols

4. Bulk Handling and Delivery Capabilities

Can they deliver on time? Whether you're a local buyer or an exporter, logistics plays a huge role. The best manufacturers have streamlined supply chains, warehousing solutions, and can fulfill urgent orders.

5. Customization Options

Every industry has different needs. Maybe you want coarse quartz powder for flooring or ultra-fine powder for electronics. A good supplier will offer a range of particle sizes and even tailor the specs for your exact use case.

How Does Sudarshan Group Rank Among Quartz Powder Manufacturers in India?

If you're looking for a name that stands for quality and trust, Sudarshan Group is a top contender. Here's why:

1. Experience That Counts

With decades in the minerals industry, Sudarshan Group understands the nuances of quartz powder production. Their legacy is built on consistent quality and client satisfaction.

2. Cutting-Edge Infrastructure

Their plants are equipped with:

Jet mills and ball mills

Magnetic separators

In-house labs for purity testing

Automated packaging units

This ensures the quartz powder you receive meets global standards every single time.

3. Wide Product Range

From 100 mesh to 500 mesh and beyond, they offer customized solutions for:

Ceramics

Paints

Plastics

Glass

Foundries

4. Strong Focus on Quality and Sustainability

Sudarshan Group isn’t just about business—they’re about responsible business. Their zero-waste practices and eco-friendly processing methods make them a future-forward supplier.

Checklist Before Choosing Your Quartz Powder Manufacturer

Is the SiO₂ content above 99%?

Do they have ISO or equivalent certifications?

Can they deliver bulk orders on time?

Do they offer technical consultation?

What do their existing customers say?

If any of these answers raise doubts, it’s time to look elsewhere.

Conclusion

Choosing the right Quartz Powder Manufacturers in India isn't just a business decision—it's a long-term partnership. The right manufacturer doesn’t just supply material—they empower your production line, elevate your product quality, and help you scale with confidence.

Sudarshan Group ticks all the right boxes, blending experience, technology, and trust into one solid choice.

FAQs

1. What industries use Quartz Powder? Quartz powder is widely used in ceramics, paints, plastics, glass, electronics, and construction materials due to its chemical stability and hardness.

2. How can I ensure the purity of Quartz Powder? Always request a certificate of analysis from the manufacturer and, if needed, get the material tested in an independent lab.

3. Does Sudarshan Group offer customized grades? Yes, Sudarshan Group specializes in offering tailor-made quartz powder grades based on particle size and industry application.

4. What is the typical delivery timeline? Depending on the location and order size, delivery can take anywhere from 5 to 15 working days. Sudarshan Group ensures timely logistics through streamlined supply chains.

5. How does Sudarshan ensure sustainability? They follow eco-friendly manufacturing processes, have in-house waste treatment units, and are committed to minimal environmental impact.

0 notes

Text

Why Precision Engineering is Essential in Today’s Manufacturing Landscape

In an age where efficiency, accuracy, and consistency drive competitive advantage, precision engineering has become a cornerstone of modern manufacturing. Whether it’s in steel production, automotive assembly, or materials processing, manufacturers rely on highly engineered machinery to meet exacting specifications and reduce operational waste.

One company leading the charge is LeisterTech, known for their advanced hydraulic pushers, billet shearing machines, and vibratory systems. These tools are not only built for reliability but also integrate cutting-edge technologies like AI and IoT to maximize performance.

What is Precision Engineering?

Precision engineering refers to the design and creation of machines and systems that operate within extremely tight tolerances. This discipline is essential in applications where even the slightest variation can cause significant product defects or process inefficiencies.

Core features of precision-engineered machinery include:

Microscopic Tolerances: High-accuracy components that deliver consistent results.

Automation-Ready Design: Seamless integration with smart technologies and factory systems.

Durability: Components built to withstand rigorous industrial use with minimal wear and tear.

If you're exploring advanced solutions in steel manufacturing, LeisterTech’s billet lifting and handling technologies are also designed with precision engineering at the forefront.

Inside LeisterTech’s Precision-Driven Equipment

Hydraulic Pushers

LeisterTech’s hydraulic pushers are a staple in modern steel processing environments. They are engineered to provide exact force with minimal variation across repeated operations.

Smart Load Accuracy: Integrated sensors adjust force dynamically.

Vibration Control: Precision hydraulics ensure smooth, stable operation.

Extended Life: Components are designed to last longer, even under high-stress usage.

Hot Billet Shearing Machines

Shearing hot steel billets requires machines that can operate with pinpoint accuracy, even in extreme conditions. LeisterTech’s shearing systems deliver on this need with:

Automated Temperature Calibration: Smart tech adjusts blade speed based on billet heat.

Long-Lasting Blades: Built with high-strength alloys for durability.

Consistent Output: Delivers uniform cuts regardless of throughput volume.

Mold Lining Vibrators

These vibrators ensure a smooth, uniform material distribution within molds—a critical factor in foundry and casting applications.

Customizable Vibration Settings: Match amplitude to material type.

Energy Efficiency: Smart systems reduce power consumption without sacrificing performance.

Explore how LeisterTech’s bundle lifting magnets integrate into automated production lines for seamless material handling.

Benefits of Precision Engineering in Manufacturing

1. Better Product Quality Precision equipment minimizes human error and ensures dimensional accuracy across production batches.

2. Operational Efficiency Less downtime, reduced material waste, and shorter cycle times lead to a leaner, more productive operation.

3. Enhanced Safety When machines perform predictably, workplace risks drop significantly, promoting safer work environments.

4. Long-Term Cost Savings Durable machinery means fewer repairs, lower maintenance costs, and better energy efficiency over time.

How Technology is Shaping the Future of Precision

LeisterTech remains on the cutting edge by embedding smart technologies into their manufacturing tools:

IoT Connectivity: Enables real-time monitoring and predictive maintenance.

AI Optimization: Algorithms adjust settings on the fly for peak efficiency.

Advanced Sensor Systems: Ensure precise control over temperature, vibration, and force.

Industry Applications

Precision engineering isn’t limited to a single sector. LeisterTech’s machinery supports:

Steel Manufacturing: Processing high-strength materials with minimal tolerance errors.

Automotive Production: High-reliability parts for frames, suspensions, and more.

Foundries: Ensuring consistent mold quality with advanced lining vibrators and material handling tools.

If you’re curious about other manufacturing solutions, visit LeisterTech’s applications page for industry-specific insights.

Final Thoughts

As manufacturing continues to evolve, the demand for accuracy, reliability, and smart automation is only increasing. LeisterTech’s commitment to precision engineering ensures that manufacturers not only meet today’s standards but also future-proof their operations. Whether you’re looking to enhance quality, cut costs, or improve workflow efficiency, their solutions are designed to deliver.

#PrecisionEngineering#ModernManufacturing#IndustrialAutomation#SteelManufacturing#SmartMachinery#HydraulicPushers#BilletShearing#ManufacturingSolutions#FactoryInnovation#EngineeringExcellence

0 notes

Text

How BintangChip is Building a High-Performance Analog Chip “Golden Process Platform”

As the global demand for analog and mixed-signal chips continues to surge—fueled by electric vehicles, industrial automation, and medical electronics—BintangChip is charting a strategic course to build what it calls a “Golden Process Platform” for high-performance analog IC manufacturing.

This initiative marks a critical step in BintangChip’s vision to become the world’s premier analog/mixed-signal foundry by integrating proven process nodes with proprietary enhancements, ensuring unmatched performance, power efficiency, and design versatility for its clients.

What Is a “Golden Process Platform”?

In semiconductor manufacturing, a “golden process” refers to a highly optimized and well-characterized fabrication platform that delivers consistent electrical performance and high yield across multiple product generations. For analog ICs—where precision, signal integrity, and noise margins are paramount—such a platform must support:

Ultra-low noise characteristics

High-voltage and power handling capability

Stable analog performance over temperature and voltage variation

Mixed-signal integration compatibility

BintangChip’s approach blends decades of analog process knowledge with leading-edge foundry techniques to define a gold standard for analog manufacturing excellence.

Key Components of BintangChip’s Golden Platform

1. Proprietary Analog-Centric Process Nodes

BintangChip’s process technology spans across BCD (Bipolar-CMOS-DMOS), CMOS, SOI, and SiGe platforms. These nodes are tailored specifically for analog-rich designs such as operational amplifiers, ADCs/DACs, power management ICs, and sensor interfaces.

2. Ultra-High Precision Design Kits

The company provides designers with Process Design Kits (PDKs) that are co-developed with its internal modeling teams and validated in silicon, ensuring tight PVT (Process-Voltage-Temperature) control and simulation-accurate behavior.

3. Robust Device Libraries & Analog IP Portfolio

BintangChip maintains a comprehensive library of analog primitives, including matched transistor pairs, bandgap references, current mirrors, and low-noise amplifiers, all verified on its golden platform. It also offers customizable analog IP for rapid integration.

4. Customization & Co-Development with Clients

Recognizing that many analog applications require tailored solutions, BintangChip collaborates closely with customers to optimize device structures and layout rules, ensuring optimal performance in target environments.

Advantages for Automotive, Industrial, and Medical Markets

BintangChip’s golden platform is not just a technical milestone—it’s a competitive differentiator in regulated industries where reliability and precision are non-negotiable:

Automotive: AEC-Q100 qualified flows, robust ESD protection, and high thermal reliability.

Industrial: Wide temperature ranges and high-voltage capability for power converters and sensors.

Medical: Low-noise and high-accuracy platforms ideal for analog front-end design in diagnostic equipment.

Conclusion: A New Era of Analog Manufacturing Excellence

By creating a scalable, customizable, and high-reliability “Golden Process Platform,” BintangChip is redefining what’s possible in analog/mixed-signal semiconductor foundry services. This strategic foundation enables its customers to innovate faster, design with confidence, and meet the demanding requirements of next-generation analog applications worldwide.

0 notes

Text

Trusted Suspension Magnet Manufacturer In Ahmedabad, India

In industries like mining, cement, food processing, and recycling, maintaining equipment reliability and product purity is a top priority. One crucial tool that ensures smooth operation is the suspension magnet—a powerful magnetic separator used to remove unwanted ferrous materials from materials traveling on conveyor belts.

These magnets not only protect machinery from damage but also reduce downtime and improve final product quality. As the demand for efficient, reliable, and locally-manufactured magnetic systems grows, Nisuka Industries has emerged as a top suspension magnet manufacturer in Ahmedabad, India, delivering unmatched quality and support to customers across India and abroad.

Why Suspension Magnets Are Essential in Industry

Suspension magnets are installed above conveyor belts and work by attracting and separating tramp iron or other ferrous materials from the moving product stream. They play a vital role in:

Preventing equipment wear and breakdowns

Increasing product purity

Improving plant safety and automation

Reducing labor and manual inspections

Supporting long-term operational efficiency

Available in both permanent and electromagnetic versions, Nisuka's suspension magnets are designed for strength, durability, and ease of maintenance. Whether used in harsh mining conditions or food-grade facilities, they ensure clean processing environments and reduced machine downtime.

Why Industries Trust Nisuka Industries

1. Made in India, Trusted Worldwide

Nisuka Industries takes pride in offering 100% Made-in-India solutions. Every suspension magnet is designed and manufactured at our facility in Ahmedabad, ensuring full control over quality, delivery, and customization. We support the Make-in-India initiative while meeting global performance benchmarks.

2. Advanced Technology and Manufacturing Setup

Our facility is equipped with advanced CNC machines, magnetic performance testers, and an in-house R&D team. Every product undergoes strict quality checks to ensure optimal magnetic performance and long operational life.

3. Custom Solutions for Every Industry

No two applications are the same. That's why we offer fully customizable suspension magnet systems—tailored to fit your specific conveyor size, material type, and installation environment. Our engineering team works closely with clients to deliver results that match their exact needs.

4. Reliable After-Sales Support and Spare Parts

We believe in long-term customer relationships. That’s why we offer prompt support, easy availability of spare parts, and expert technical assistance to ensure your systems run continuously with minimal disruption.

Industries Served

Nisuka’s suspension magnets are trusted by major industries across India and globally, including:

Mining and Quarrying

Cement and Aggregate Plants

Food and Beverage Processing

Steel and Foundry Units

Recycling and Waste Management

Fertilizer and Chemical Plants

Thermal Power Plants

Each industry faces unique challenges—our solutions are engineered to meet them all.

Innovation Across Product Lines

While we are well-known for our magnetic separation systems, Nisuka also specializes in power transmission solutions. As a reliable shaft mounted gearbox manufacturer in India, we offer gearboxes designed for direct mounting on conveyor shafts, reducing space and simplifying installation—making us a one-stop solution for conveyor systems.

Our innovation-driven approach extends across all products, ensuring both magnetic and mechanical systems perform with precision and durability in demanding applications.

Conclusion: Partner with Nisuka Industries for Trusted Magnetic Solutions

Suspension magnets are more than just components—they are essential tools that protect your equipment, streamline production, and improve product quality. Whether you're upgrading your system or starting a new project, choosing the right suspension magnet can greatly enhance your operational efficiency.

Nisuka Industries is your trusted partner for high-quality, customizable magnetic separation solutions. With years of experience, cutting-edge manufacturing, and a strong commitment to customer satisfaction, we proudly serve industries across India and beyond.

In addition to magnetic solutions, Nisuka is also recognized as a reliable shaft mounted gearbox manufacturer in Ahmedabad, India, offering complete conveyor system support. When you need dependable magnetic equipment, expert assistance, and long-lasting products—Nisuka Industries is the name you can count on.

#Suspension Magnet Manufacturer In Ahmedabad#Suspension Magnet supplier In Ahmedabad#Suspension Magnet exporter In Ahmedabad

0 notes

Text

Ferro Silicon Magnesium Manufacturers in India: Driving Quality in Alloy Production

India has emerged as a global hub for alloy manufacturing, with a growing demand for high-performance materials in foundry and steel industries. Among these, ferro silicon magnesium (FeSiMg) holds a crucial position due to its importance in producing ductile (nodular) iron. As industries push for quality, durability, and metallurgical performance, ferro silicon magnesium manufacturers in India are stepping up with advanced production techniques and global supply capabilities.

What is Ferro Silicon Magnesium?

Ferro silicon magnesium is a ferroalloy composed primarily of iron (Fe), silicon (Si), and magnesium (Mg), and is used predominantly as a nodulizer in ductile iron production. Its role is to modify graphite flakes into spheroids during solidification, significantly enhancing the mechanical properties of the final product—especially ductility, impact resistance, and toughness.

Applications of Ferro Silicon Magnesium

The alloy plays a central role in the casting and foundry industry. Key applications include:

Ductile iron production

Automotive castings

Water pipe systems

Agricultural machinery components

Railway parts

Wind and energy sector castings

Given its widespread utility, industries require ferro silicon magnesium that is both pure and consistent in composition.

Why India for Ferro Silicon Magnesium?

India is not only rich in mineral resources but also boasts a robust industrial infrastructure and skilled labor force. This makes it a favorable destination for the production of ferroalloys, especially ferro silicon magnesium. Here's why ferro silicon magnesium manufacturers in India are preferred by global buyers:

1. Cost-Effective Manufacturing

Indian manufacturers offer highly competitive prices without compromising on quality, making them attractive to both domestic and international markets.

2. Advanced Infrastructure

Many Indian plants are equipped with state-of-the-art induction furnaces, refining units, and automated packaging systems, ensuring a high degree of precision in alloy composition.

3. Customization and Quality

Whether you need standard grades or custom specifications, Indian producers are known for offering flexibility in product development and consistent quality through stringent QC measures.

4. Global Export Capabilities

Many ferro silicon magnesium manufacturers in India hold ISO certifications and follow international standards (such as ASTM, BIS, or JIS), enabling them to export to regions like the Middle East, Southeast Asia, Europe, and Africa.

Key Features to Look for in a Manufacturer

When choosing among the ferro silicon magnesium manufacturers in India, consider the following factors:

Purity and Consistency: Reliable manufacturers provide detailed composition sheets, ensuring a consistent balance of magnesium and silicon.

Production Capacity: Large-scale foundries and OEMs should prioritize manufacturers with high monthly tonnage capabilities.

Logistics and Packaging: Look for suppliers who offer moisture-proof, customizable packaging options to maintain product integrity.

Technical Support: Experienced manufacturers often provide technical consultancy to help optimize nodularization and improve casting yields.

Certifications and Compliance: Choose vendors that comply with ISO, BIS, or other relevant quality standards.

Top Locations for Ferro Silicon Magnesium in India

While ferroalloy manufacturing is spread across the country, key production zones include:

Jharkhand and Odisha – Known for mineral reserves and integrated alloy plants.

Chhattisgarh – A rising industrial zone with access to raw materials and energy.

Maharashtra and Gujarat – Leading export-oriented facilities and proximity to ports.

Punjab and Rajasthan – Growing centers for mid-sized and specialized alloy production.

The Future of Ferro Silicon Magnesium in India

With the government’s push on infrastructure, smart cities, and manufacturing through initiatives like Make in India, demand for ductile iron castings is on the rise. This growth will directly fuel the requirement for ferro silicon magnesium in both domestic and export markets.

Additionally, the increasing use of ductile iron in the renewable energy sector, automotive industry, and water management systems signals long-term opportunities for both buyers and suppliers of ferro silicon magnesium.

Conclusion

Choosing the right ferro silicon magnesium manufacturers in India can significantly impact your product quality and production efficiency. Thanks to cost-effectiveness, technological advancement, and a strong focus on quality, Indian manufacturers are well-positioned to meet global demands for high-performance ferroalloys.

Whether you're a foundry manager, procurement officer, or industrial buyer, partnering with a trusted Indian supplier ensures a reliable, consistent, and scalable solution for your nodular iron casting needs.

0 notes

Text

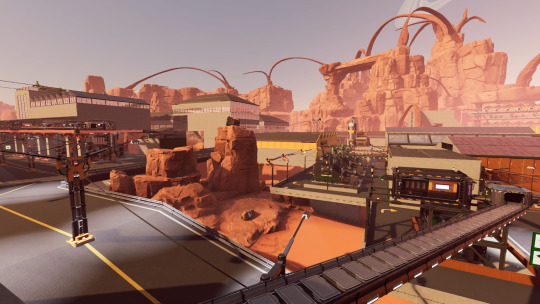

The Great Satisfactory State of Play April 2025 #1

Relics of the Dune Desert

My last stream was very unstable, with the game locking up badly three times, so I'm giving up until I get a new video card. Here's a slideshow of the state of play in April 2025 instead.

This is where it all started. A spot about halfway up the Dune Desert, on the eastern side near some oases. I've never got around to moving the HUB, and it was great. Normal copper node; 2 normal iron nodes; 1 pure limestone node not far away. Perfect for the first few basic parts and Phase 1.

The copper plant has been done up with sinks and pillars and all that, but it's still the original design. Two smelters, three constructors, and so it goes.

The iron plant is still cranking out materials for the dimensional depot uploaders, and so it'll stay. As you can see, I made some half-hearted efforts to gussy it up, but I tend to end up skipping those.

This tall sign was made back in the day when I was relying on trucks on an elevated highway. So this is saying, "iron parts, copper parts, concrete, HUB and AWESOME outlet here." Now we catch the train, or as I did, use the hover pack and hover over there.

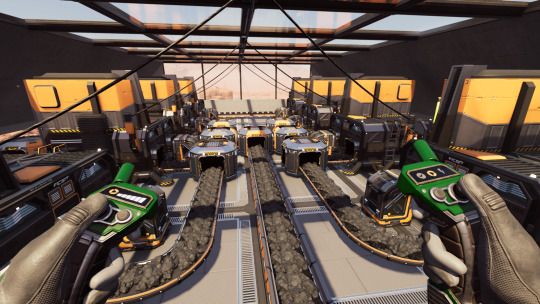

Meet the Dune Desert Steel-Copper-Concrete plant v2.0. Uses the solid steel ingot recipe. Fed by 2 pure limestone nodes, 2 pure iron nodes, 3 normal coal nodes, and 2 pure copper nodes. Let's have a look inside.

Foreground: iron alloy ingot foundries; on the right, concrete constructors on the top, copper smelters, bottom.

The solid steel ingot foundries reside in this luxurious penthouse floor with copious skylights, and lots of load balanced inputs. From here, ingots and concrete are sent to the train station prior to delivery.

The first of two iron alloy ingot factories (the second is next to the HUB factories). We go through a LOT of iron. Officially.

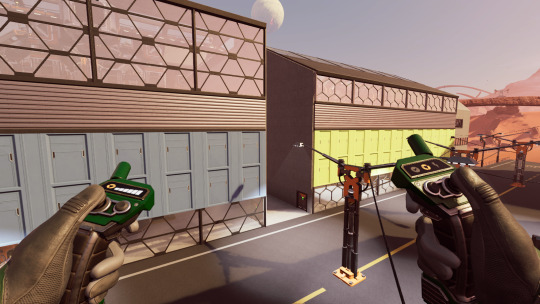

South side of Factory Town: an experimental build where everything was meant to be separate factories that fed each other by vehicles.

On this side, we can see the Space Elevator, and the buildings for electromagnetic control rods and heat sinks.

These, like the rest of Factory Town, are obsolete and must be replaced.

"Welcome to Factory Town. Manual vehicles, please park alongside the train stations, as automated vehicles are at large."

I think the overhead billboards are more legible.

Road parts are from the mod X3-Roads.

A base for the Pioneer, with all modern conveniences, including crafting bench, equipment workshop which doubles as an entrance, AWESOME outlet, MAM, and a slooped constructor for maxing out power shard and DNA capsule production for those wonderful tickets. Soon it will be... moved.

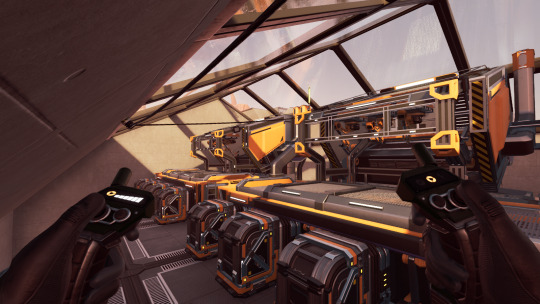

This location is in the northwest of the Dune Desert, close to a water well, reasonably handy to a nitrogen gas well, 2 pure coal nodes, 1 pure sulphur node, and some normal iron, copper, and limestone nodes. Hence the trains bringing in bulk ingots and quickwire.

In the background, there is the top of a solid steel plant (top left) and the cart park right behind the base.

The concept of the cart park is simple. It's a place where all factory cart routes start and end. There are two set of ramps: one set goes up, the other down.

However I find that sometimes the carts seem to... just stop working. And with new demands for new parts, the whole shebang needs rebuilding from the ground up.

When I had X3-Signs installed, I labelled this road Fluctuator Avenue. Because, stage right, we have a steel pipe factory. Immediately left, we have the SAM fluctuator factory, and right next to it, a battery factory. I am considering reworking the latter to make even more batteries for the export market.

Behind that is a very small, drastically scaled down wire and copper ingot factory, that serves the fluctuator factory and also a small aluminium refinery down the road. So let's go down the road!

Over the top of the copper ingot dispensary, we see the skeletal array of compacted coal assemblers. This gets sent to a turbofuel power plant on the Spire Coast.

Actually it produces way too much compacted coal. I might shut it down, and retool the power plant for turbo heavy fuel.

Around the bend past the SAM Fluctuator concrete factory is this unusual looking raw quartz processing plant. Silica comes out the west side, quartz crystal on the right. The steepest walls were made with the Infinite Nudge mod (I think) before I had to uninstall it because instabilities.

There's also a free truck station that you can unload trash into for sinking.

Almost directly across from the silica side of the quartz plant is a road that I should've named Motor Alley. Because motors are made here. A lone truck station, powered by Greyskull and programmable splitters, sorts incoming parts, like steel beams, which end up in this screw factory. The factory then sends belts of screws under the road bed to...

...The rotor factory! Just plain "rods and sods" rotors here. And right up the back...

...Final motor join! We're pretty good for motors right now. An embarrassment of riches, you could say. (Not to mention I have another source of them now.)

An aerial view of the motor, rotor, and stator output. The factory in the top left is the quickwire stator factory.

The copper roof is where some of those screws I make in Motor Alley go: a bolted iron plate factory that feeds a bolted frame factory. Both of these have been kluged to use "underground" belts instead of waiting on carts or trucks.

These two factories make circuit bards (left) plastic AI limiters (right). Reworking the sorters and keeping these beasties fed with quickwire is a crawling horror. But they served well. Soon, they will be gone.

Across from them, a water tower feeds my aluminium plant. A drone brings bauxite in from a node in the swamp. You remember the swamp, right? Soggy, damp, gaseous, swarming with alpha critters in general and far too large stingers in particular?

This factory has been redone to use the sloppy alumina, pure aluminium ingot, and alclad casing recipes, while sucking down about 780 bauxite per minute, or is that the other one?. Not that it will be spared from the chop.

With the unlocking of the Mk.2 blueprint designer, I made this 2-manufacturer factory. The idea was that I could throw down several of these, maybe hook them together, and have a modest supply of parts. Nice idea, but no longer relevant.

This is what one geared for caterium computers looks like on the ground floor. One station for parts, the far one for outs.

Second floor: women's undergarments and sorting. One of the two anyway.

Top floor: manufacturing. With the roof it barely fits into the designer, and I still have to add sinks and uploader. Like I said, a good solution then. No longer.

One more look toward Factory Town; in the distance, you can see the steelworks, one of the four iron goods plants, the stator house, and a scenic wreck.

The newest buildings in Factory Town: control rods (left) and heat sinks (right). While based on the manufacturer system, they couldn't seem to feed the reactor. They're going to go.

This is what's replacing all of that. I call it "Phase 4 @ 5" (as in "parts per minute). With any luck, it will involve far more efficient Pioneering and less ever-so-aesthetic messing about.

And so we say farewell to Factory Town the Doomed, for we have a train to catch. Where does it go? Find out in part 2!

0 notes

Text

200mm Semiconductor

The 200mm semiconductor market remains crucial despite the industry's shift toward 300mm wafers. These wafers are widely used in analog, power, MEMS, and RF devices, essential for automotive, IoT, and industrial applications. Key players include TSMC, GlobalFoundries, and UMC, with strong demand driven by 5G, electrification, and automation trends. Capacity constraints and aging fabs pose challenges, but investments in 200mm production continue to meet legacy chip demand. Foundries are optimizing efficiency with refurbished equipment and process innovations. Asia-Pacific leads production, while supply chain disruptions and geopolitical tensions impact growth. Sustainability and energy-efficient manufacturing are emerging priorities.

For More : https://tinyurl.com/4nsx25ke

0 notes

Text

Pig Casting Machine (PCM) by Metal Engineering & Treatment Co. Pvt. Ltd. – Precision, Efficiency, and Durability

The Pig Casting Machine (PCM) by Metal Engineering & Treatment Co. Pvt. Ltd. is a state-of-the-art solution designed to revolutionize pig iron production. With decades of expertise in engineering and manufacturing, Metal Engineering & Treatment Co. Pvt. Ltd. has developed a highly efficient, durable, and precise Pig Casting Machine (PCM) that ensures optimal casting performance while enhancing productivity in foundries and steel plants.

Designed for seamless operation, the Pig Casting Machine (PCM) is engineered to handle high-temperature molten iron with utmost precision. Its automated system ensures uniform pig iron casting, reducing material wastage and increasing output consistency. The machine operates with a synchronized mold filling mechanism, which enhances efficiency while maintaining superior casting quality. Each pig is cast with uniform weight and dimensions, ensuring standardization and reliability in industrial applications.

Durability and longevity are key features of the Pig Casting Machine (PCM) by Metal Engineering & Treatment Co. Pvt. Ltd. Constructed with high-grade steel and advanced refractory materials, the machine withstands extreme thermal conditions and continuous operation without compromising performance. The robust design minimizes maintenance requirements, reducing downtime and operational costs while ensuring a long service life.

Automation is at the core of the Pig Casting Machine (PCM), integrating cutting-edge technology to optimize production processes. The machine is equipped with programmable logic controllers (PLC) that allow precise control over the casting sequence, temperature regulation, and cooling process. This intelligent system minimizes human intervention, enhancing workplace safety and ensuring operational efficiency. With user-friendly controls and a streamlined interface, operators can easily monitor and adjust settings to achieve desired casting parameters.

Environmental sustainability is a crucial aspect of modern industrial machinery, and the Pig Casting Machine (PCM) by Metal Engineering & Treatment Co. Pvt. Ltd. is designed to meet eco-friendly standards. Its efficient cooling and recycling systems help reduce energy consumption while minimizing emissions. The machine also incorporates an advanced dust and fume extraction system, ensuring a cleaner working environment and compliance with industry regulations.

Customization is a key advantage of the Pig Casting Machine (PCM), allowing clients to tailor the system to their specific production requirements. Whether it's adjusting mold sizes, optimizing pouring mechanisms, or integrating additional automation features, Metal Engineering & Treatment Co. Pvt. Ltd. provides tailored solutions to meet diverse industrial needs. The company’s experienced engineers work closely with clients to develop bespoke configurations that align with their production goals, ensuring maximum efficiency and cost-effectiveness.

As a leading engineering solutions provider, Metal Engineering & Treatment Co. Pvt. Ltd. is committed to continuous innovation and quality excellence. The Pig Casting Machine (PCM) is a testament to the company’s dedication to delivering superior industrial machinery that enhances productivity and performance. With its advanced technology, durable construction, and automation capabilities, this machine is the ideal solution for foundries and steel plants looking to optimize their pig iron casting operations.

Investing in the Pig Casting Machine (PCM) from Metal Engineering & Treatment Co. Pvt. Ltd. means choosing precision, efficiency, and reliability. With a legacy of engineering excellence and a focus on innovation, the company ensures that its machinery meets the highest standards in the industry. Contact Metal Engineering & Treatment Co. Pvt. Ltd. today to learn more about how the Pig Casting Machine (PCM) can transform your pig iron production and streamline your operations.

0 notes

Text

Superior Magnesium Cored Wire Feeder for Ferro Silicon Magnesium Cored Wire Injection Process!

The FeSiMg cored wire injection process is a critical step in the production of high-quality ductile iron and other specialized metal alloys. One of the key components ensuring precision and efficiency in this process is the magnesium cored wire feeder. This advanced technology plays a vital role in delivering accurate magnesium content, improving metallurgical properties, and optimizing the overall process efficiency.

Understanding the Cored Wire Injection Process

The (FeSiMg) injection process is widely used in foundries and steel plants to introduce controlled amounts of magnesium into molten metal. Magnesium is essential in the production of ductile iron, as it modifies the graphite structure, enhancing strength, durability, and flexibility. The use of cored wire injection technology ensures precise magnesium addition while minimizing wastage and oxidation.

Importance of a Superior Magnesium Cored Wire Feeder

A high-performance magnesium cored wire feeder is essential for achieving consistent results in the ferro silicon magnesium injection process. Some key benefits of using a superior feeder include:

Precision Magnesium Delivery – The feeder ensures a uniform and controlled magnesium feed rate, leading to optimal metallurgical results.

Reduced Magnesium Oxidation – Advanced feeding mechanisms minimize oxidation losses, maximizing the effectiveness of magnesium.

Enhanced Process Efficiency – A well-designed wire feeder automates the process, reducing manual intervention and increasing production efficiency.

Consistent Ductile Iron Quality – Accurate magnesium injection ensures uniform nodularization, improving the mechanical properties of ductile iron.

Cost-Effectiveness – By minimizing magnesium wastage and optimizing its utilization, a superior feeder reduces production costs.

How a Cored Wire Feeder Works

A cored wire feeder is designed to feed the cored wire, which consists of a magnesium core enclosed within a steel sheath, into the molten metal. The feeding system ensures precise wire injection at controlled speeds, allowing the magnesium to react efficiently without excessive loss. The key components of a cored wire feeder include:

Wire Feeding Mechanism – A motorized system that ensures smooth and continuous wire feeding.

Speed Control System – Enables precise regulation of wire feed rate to match process requirements.

Guiding Rollers – Maintain accurate wire alignment for consistent injection.

Automated Controls – Modern feeders are equipped with automated control systems for seamless operation and monitoring.

Selecting the Right Cored Wire Feeder

Selecting a high-quality cored wire feeder is crucial for ensuring reliable ferro silicon magnesium injection. When choosing a feeder, consider the following factors:

Feed Rate Accuracy – A precise feeding mechanism is essential for maintaining consistent magnesium levels in the molten metal.

Durability & Build Quality – A robust construction ensures long-term performance and reliability.

Automation & Control Features – Advanced automation minimizes manual errors and enhances process efficiency.

Compatibility with Various Wire Sizes – A versatile feeder should accommodate different wire diameters for flexibility in operations.

Conclusion

A superior cored wire feeder is an essential tool for achieving precision, efficiency, and cost-effectiveness in the ferro silicon magnesium injection process. By ensuring accurate magnesium delivery and minimizing wastage, this advanced technology enhances the quality of ductile iron and other metal alloys. Investing in a high-quality wire feeder not only improves metallurgical performance but also boosts overall production efficiency, making it a valuable asset in modern foundries and steel plants.

#MagnesiumCoredWireFeeder #CoredWireInjection #FerroSiliconMagnesium

#ferro silicon magnesium#fesimg#nodularisers#cored wire injection#magnesium cored wire feeder#magnesium cored wire injection system#ferro silicon magnesium in India

0 notes