#carbon fibers

Explore tagged Tumblr posts

Text

Edit I made a in May iirc? Or June either one

Turn your brightness up to see better

41 notes

·

View notes

Text

Carbon fiber-reinforced polymers (CFRPs) are used in the aerospace, automotive, and sports equipment industries. However, their recycling remains a major problem. In a recent study, researchers from Waseda University demonstrated a novel direct discharge electrical pulse method for the efficient, effective, and environmentally friendly separation of CFRPs to recover high-quality carbon fibers. This work is expected to pave the way for a more sustainable world. The world is hurtling rapidly towards a developed future, and carbon fiber-reinforced polymers (CFRPs) play a key role in enabling technological and industrial progress. These composite materials are lightweight and highly strong, making them desirable for applications in various fields, including aviation, aerospace, automotive, wind power generation, and sports equipment.

Read more.

#Materials Science#Science#Fibers#Composites#Polymers#Fiber reinforcement#Carbon fibers#REcycling#Materials processing#Waseda University

11 notes

·

View notes

Text

0 notes

Link

0 notes

Link

0 notes

Text

788 notes

·

View notes

Text

#mitsubishi#lancer#evo#evolution#carbon fiber#racing#jdm cars#oldschool#japan#import cars#awd#rally#street racing#black

209 notes

·

View notes

Text

BMW E9 CSL build with a carbon Group 4 wide-body, sequential race gearbox and a 1000hp boosted S38

403 notes

·

View notes

Text

Generic taco sticker I got last year it now lies on my sketchbook staring into my soul as I draw God knows what whilst also complimenting me sinisterly. I fear her

#taco ii#taco inanimate insanity#inanimate insanity#ii#carbon fibers#She watches.#Lettuce taco bout it

14 notes

·

View notes

Text

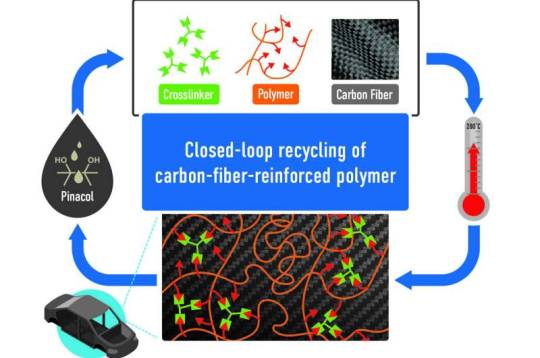

New process allows full recovery of starting materials from tough polymer composites

In a win for chemistry, inventors at the Department of Energy's Oak Ridge National Laboratory have designed a closed-loop path for synthesizing an exceptionally tough carbon-fiber-reinforced polymer, or CFRP, and later recovering all of its starting materials. A lightweight, strong and tough composite material, CFRP is useful for reducing weight and increasing fuel efficiency of automobiles, airplanes and spacecraft. However, conventional CFRPs are difficult to recycle. Most have been single-use materials, so their carbon footprint is significant. By contrast, ORNL's closed-loop technology, which is published in Cell Reports Physical Science, accelerates addressing that grand challenge. "We incorporated dynamic crosslinking into a commodity polymer to functionalize it. Then, we added a crosslinker to make it like thermoset materials," said ORNL chemist and inventor Md Anisur Rahman. "Dynamic crosslinking allows us to break chemical bonds and reprocess or recycle the carbon fiber composite materials."

Read more.

#Materials Science#Science#Polymers#Composites#Recycling#Fiber reinforcement#Fibers#Carbon fibers#Cross linking

9 notes

·

View notes

Text

Why Carbon Fiber is the Preferred Material for Prosthetic Devices?

Carbon fiber has emerged as the preferred material for prosthetic devices. Prosthetic devices replace a missing body part or improve the function of a damaged one. The lightweight, high-strength material lends itself well to the purpose of prosthetics. To know more, follow our blog https://www.nitprocomposites.com/blog/why-carbon-fiber-is-the-preferred-material-for-prosthetic-devices

0 notes

Text

#such a strange‚ felt-like texture on this creature. really looks like it's made out of… some sort of rough cloth#carbon fiber ghost. i've never seen it this close up#this feels like a detail you wouldn't even ever see in-game. to be honest#flutter mane#based on the fact that i have not. i love everything else about its design. the toof. it being misdreavus whom i love#i don't love the power creep but we don't need to talk about that. that's been hashed and rehashed#paradox misdreavus#← still protesting

219 notes

·

View notes

Link

Carbon nanotubes category among the key product segments is expected to be the most promising segment in the global advanced carbon materials market,...

0 notes

Text

Coyote + OD Green + Fifty Shades of FDE 🎨

RSB/M | Terra Bronze

QTR Stop | Terra Bronze

HTP Solo’s | FDE | Dragon Texture | 1-Slot

HTP Solo’s | OD Green | Dragon Texture | 1-Slot

HTP Solo’s | OD Green | Dragon Texture | 1.5-Slot

QDX Sling Mount | Terra Bronze

MCX CSMR Button | Terra Bronze

- RS

#RailScales#RSB/M#RSB#QTR Stop#HTP Scales#HTP Solo's#QDX#CSMR#MCX CSMR#Terra Bronze#Sig Sauer#Sig#MPX#MPX-K#MPX Copperhead#SilencerCo Omega 9K#Surefire Mini Scout Light Pro IR#CSM-07 Switch#Lancer Systems MPX Carbon Fiber Rail#Aimpoint Micro T-2 Coyote#KAC Aimpoint Micro Battery Cap#Unity Tactical FAST Micro Mount#Geissele MPX SCH#M-LOK#Made in USA#Profoto

104 notes

·

View notes

Text

2025 Ford Mustang GTD Carbon Series with Performance pack

#art#design#luxury cars#luxury lifestyle#supercars#sport cars#luxurycars#luxurylifestyle#supercar#luxurycar#ford#ford mustang#2025#sportcars#sportacr#Ford mustang GTD#carbon fiber

112 notes

·

View notes