#capacity:1-80 tons

Explore tagged Tumblr posts

Video

youtube

Customized Rail Roller Transfer Cart,Remote Control Mobile Cable Operate...

#youtube#electric transfer cart#material handling equipment#transporter#customized service#capacity:1-80 tons

0 notes

Text

Suffren (3151 nuSLDF refit)

Mass: 540,000 tons

Use: Destroyer

Technology Base: Mixed (Experimental)

Introduced: 3153

Mass: 540,000

Battle Value: 76,177

Tech Rating/Availability: F/X-X-X-F

Cost: 22,254,066,000 C-bills

Dimensions

Length: 590 m

Fuel: 4,000 tons (10,000)

Safe Thrust: 3

Maximum Thrust: 5

Sail Integrity: 4

KF Drive Integrity: 12

Heat Sinks: 486 (972)

Structural Integrity: 60

Armor

Nose: 163

Fore Sides: 135/135

Aft Sides: 119/119

Aft: 77

Cargo

Bay 1: Fighter (10) 1 Door

Bay 2: Small Craft (2) 1 Door

Bay 3: Cargo (84086.0 tons) 1 Door

Ammunition:

96 rounds of LRM 20 (Clan) Artemis V-capable ammunition (16 tons),

400 rounds of NAC/40 ammunition (480 tons),

400 rounds of NAC/20 ammunition (160 tons),

80 rounds of Screen Launcher ammunition (40 tons),

48 rounds of Gauss Rifle [Clan] ammunition (6 tons)

Dropship Capacity: 4

Grav Decks: 2 (125 m, 125 m)

Escape Pods: 100

Life Boats: 150

Crew: 42 officers, 175 enlisted/non-rated, 43 gunners, 30 bay personnel, 252 marines

Notes: Equipped with

lithium-fusion battery system

1 Mobile Hyperpulse Generators (Mobile HPG)

1 Naval Comm-Scanner Suite (Large)

2 Space Mine Dispenser

1 Naval C3

648 tons of lamellor ferro-carbide armor.

Weapons: Capital Attack Values (Standard)

Arc (Heat) Heat SRV MRV LRV ERV Class

Nose (1,038 Heat)

1 Naval Autocannon (NAC/40) 135 40(400) 40(400) 0(0) 0(0) Capital AC

NAC/40 Ammo (100 shots)

1 Naval Autocannon (NAC/40) 135 40(400) 40(400) 0(0) 0(0) Capital AC

NAC/40 Ammo (100 shots)

3 Naval PPC (Heavy) 675 45(450) 45(450) 45(450) 45(450) Capital PPC

2 Gauss Rifle 2 3(30) 3(30) 3(30) 0(0) AC

Gauss Rifle Ammo [Clan] (24 shots)

4 ER Large Laser 48 4(40) 4(40) 4(40) 4(40) Laser

2 LRM 20+Artemis V 12 2(24) 2(24) 2(24) 0(0) LRM

LRM 20 (Clan) Artemis V-capable Ammo (24 shots)

3 Laser AMS 15 1(9) 0(0) 0(0) 0(0) AMS

3 Small Pulse Laser 6 1(9) 0(0) 0(0) 0(0) Pulse Laser

1 Screen Launcher 10 15(150) 0(0) 0(0) 0(0) Screen Launcher

Screen Launcher Ammo (10 shots)

FRS/FLS (258 Heat)

3 Naval Laser 45 210 14(135) 14(135) 14(135) 14(135) Capital Laser

4 ER Large Laser 48 4(40) 4(40) 4(40) 4(40) Laser

RBS/LBS (318 Heat)

2 Naval Autocannon (NAC/20) 120 40(400) 40(400) 40(400) 0(0) Capital AC

NAC/20 Ammo (200 shots)

1 Naval PPC (Medium) 135 9(90) 9(90) 9(90) 9(90) Capital PPC

2 LRM 20+Artemis V 12 2(24) 2(24) 2(24) 0(0) LRM

LRM 20 (Clan) Artemis V-capable Ammo (24 shots)

3 Laser AMS 15 1(9) 0(0) 0(0) 0(0) AMS

3 Small Pulse Laser 6 1(9) 0(0) 0(0) 0(0) Pulse Laser

3 Screen Launcher 30 45(450) 0(0) 0(0) 0(0) Screen Launcher

Screen Launcher Ammo (30 shots)

ARS/ALS (258 Heat)

3 Naval Laser 45 210 14(135) 14(135) 14(135) 14(135) Capital Laser

4 ER Large Laser 48 4(40) 4(40) 4(40) 4(40) Laser

Aft (363 Heat)

1 Naval Autocannon (NAC/40) 135 40(400) 40(400) 0(0) 0(0) Capital AC

NAC/40 Ammo (100 shots)

1 Naval Autocannon (NAC/40) 135 40(400) 40(400) 0(0) 0(0) Capital AC

NAC/40 Ammo (100 shots)

2 Gauss Rifle 2 3(30) 3(30) 3(30) 0(0) AC

Gauss Rifle Ammo [Clan] (24 shots)

4 ER Large Laser 48 4(40) 4(40) 4(40) 4(40) Laser

2 LRM 20+Artemis V 12 2(24) 2(24) 2(24) 0(0) LRM

LRM 20 (Clan) Artemis V-capable Ammo (24 shots)

3 Laser AMS 15 1(9) 0(0) 0(0) 0(0) AMS

3 Small Pulse Laser 6 1(9) 0(0) 0(0) 0(0) Pulse Laser

1 Screen Launcher 10 15(150) 0(0) 0(0) 0(0) Screen Launcher

Screen Launcher Ammo (10 shots)

Features the following design quirks: Combat Computer, Easy to Pilot, Improved Communications, Improved Life Support

4 notes

·

View notes

Text

Resident Evil: The Darkside Chronicles ➳ Archives ➳ Operation Javier ➳ Files

The Sacred Serpents Crime Syndicate

Organised and led by Javier, it is a crime syndicate with a firm presence in South America. It has a code of absolute obedience to its leader, based on a system of "control through fear" which brutally punishes traitors without exception.

Written Orders

This is a special mission which is not in accordance with normal operational regulations. Consent to the operative to the following must be given prior to the beginning of the mission.

1. Release of protective responsibilities. Neither the government nor the person(s) in charge of operational command shall be held responsible for injury, illness, or death to the operative during the execution of their duties. Also, in the case that the operative is captured by hostile forces neither the government nor the person(s) in charge of operational command shall be compelled to negotiate with the operative's captors in any way on their behalf.

2. If during the execution of the operative's duties, there is no contact from the operative for a period of more than 24 hours, the mission will be considered a failure, and the directorate of operations will be withdrawn and dispersed.

From the operation starting point, the operative will begin their mission following the steps below.

1: Make contact with the local coadjutant.

2: Secure local transportation.

3. Infiltrate private residence of the target.

Also, give procedural directives to full time operator as necessary.

This substance of this mission is subject to gradual revision based on the local situation.

The operative will always do as instructed.

The Waterside Village

There is building animosity toward Javier's cold and merciless organization, and many locals are waiting for the opportunity to rebel. The influential and powerful people of Mixcoatl village (affectionately known as Waterside Village), as well as the United States and the local government have formed a coalition to expel Javier, and have been amassing military strength.

With their cooperation (provision of transportation and local guides), Leon and Krauser plan to head to Javier's mansion.

Javier Dam

A large dam built under the order of Javier. It has a total reservoir storage capacity of 20 billion tons.

Inhabitants of this remote area which previously didn't have adequate electricity, feel indebted to Javier for having brought them the power generation facility. It is also touted as having contributed to raising the standard of living and financial status of his organization.

Originally, it was built to secure a large source of electricity to be used solely by Javier's organization, and also to be a nonverbal threat to districts under its control.

The dam has a complex floodgate which Javier could release and induce a massive flood disaster on areas downstream whenever he pleased.

One such example is when Javier caused an obviously intentional water discharge "accident" in an area inhabited by a defiant tribe. The entire village of 80 people was killed.

Get-Well Card

To our dear friend, Manuela. Are you feeling any better? Yesterday the whole class made a flowerbed, we planted seeds for all kinds of flowers.

Hopefully in the spring, there'll be lots of flowers blooming. We left a spot open in the flowerbed just for you when you get back.

We all know how strong and brave you are. We know that you will get better. soon. We are all looking forward to you coming back to school, and seeing your smiling face again.

Next month, is our school festival. We hope you can join us for the gift exchange.

Class representative, Delsey

Javier's Private Messages

(The following are decrypted text messages which were sent and received from a mobile device.)

20XX 08.13 PM6.20

from: Sergio

to: Javier

Umbrella is making a fuss over the sale price of the samples. They want 50% more than they did for the old ones. Do you want to extend the contract?

20XX 08.13 PM6.28

from: Javier

to: Sergio

Get the same price as before. Don't let them scam you into thinking they have other buyers. Also, I want you to check out the background of the Asian broker who approached us before.

20XX 08.14 AM1.09

from: Sergio

to: Javier

The broker talked. It looks like Umbrella was cooking their books. He says that they were overcharging for those samples.

But now he's spouting this nonsense about how we should give him information about our sales turf in exchange for the info he gave us.

20XX 08.14 AM1.12

from: Javier

to: Sergio

Find out more. I'll do some research on this side.

20XX 08.14 AM11.24

from: Javier

to: Sergio

I've obtained some interesting information. That Asian man, he's a spy for Umbrella. Get him to trust you, and send him back

Find out where he's staying, and after you eliminate him, tear the place apart. There could be other spies. I will crush anyone who tries to deceive me without exception.

Note (Manuela's Realization)

A frightening vision has become a reality.

I have lost sense of who I am.

I don't know what I am or what it is I am becoming.

Javier's Mansion

An expansive compound in a place called Amparo nestled deep in the jungle. This is only Javier's private residence, the base of his criminal organization is located elsewhere. Even so, this compound is very well-protected against invasion by guerillas and government forces.

Although its standing mercenary garrison is small, numerous B.O.W.s, traps, and the latest defense systems are deployed all around. Rather than "residence", the term "fortified castle" would be a more appropriate description for the well-guarded compound.

There is also a bomb shelter in the basement to which Javier can retreat in an emergency. The compound is also built to withstand such extraordinary situations as floods and biological disasters.

Javier's Memorandum (1991)

February 24th

That man... he seems to have ties to the Ashford family, but I don't fully trust him.

But, I'm interested in the information he has about virus therapy. For Hilda it is now or never.

I believe he called it "T"... Tomorrow I will give it a try.

April 30th

I'm glad to see that Hilda is doing better. Administrating the virus evidently has worked. Two months later, she has regained her strength. The cancer that was spreading through her body has miraculously disappeared.

Now I only have to wait until she regains conciousness. Hilda, I will make you well again, no matter if I have to sacrifice everything.

May 6th

Even for all the good he's done, I can't believe that pretentious bastard thinks he can raise the price on me. I have found another channel by which to obtain "T". This one is called "V" and I am told that it is a more perfect virus.

I need to find out if that is indeed true. If he thinks he can get away with taking advantage of me, he's in for a rude awakening. It's not about the money. No one makes a fool of me.

May 11th

Why? Why doesn't she regain conciousness? Her body has long since recovered... I don't understand it. It is due to more than just her will to live.

Could it be a side-effect of the virus? But if I stop administrating it to her, she will become weak again. I still don't have any information about "V". What should I do...?

May 20th

God, I curse you. Is that what life is? Is life just simply being alive? Oh Hilda, don't leave me. I can't lose you!

June 14th

To question the meaning of life is folly. I have the power and the means to fulfill my mission. That mission is to keep her alive.

Soon I will move Hilda to a special facility. I can't make any more of a public spectacle out of her. Hilda's life is in my hands. And I must protect her.

Veronica Plant

A thing born as a byproduct of Manuela's reanimation. Javier secretly cultivated the Veronica Plant in his mansion's green house. It is stronger than T-type BOWs by far, while having a much lower operating cost.

By dispersing its spores, it has the power to transform neighboring vegetation into Veronica Plants as well. The speed at which they can spread is astounding. Presumably, in only 48 hours, it could invade 60% of the Amazon. Practically speaking, this extremely dangerous organism could destroy a continent's entire ecological system within a matter of days.

Once it starts to spread its spores, there is practically no effective method of containment. Even Javier considers this BOW to be his trump card only to be used as a last resort, and keeps it under lock and key.

Communications from Wesker (Faxed Documents)

08/01 10:00

I changed the deposit account. Terminate all Russian routes.

08/07 10:01

I will send a list of the merchandise this month. Two new types of stationary B.O.W.s have been added.

08/14 10:05

I have an answer to the question you asked on the phone. Just as you thought, the Asian woman works for Umbrella. She's not just a rat that got out. She's a bat that's still sucking the blood. If we're going to use her, we'll have to do it carefully.

08/21 10:00

I've verified the deposit. About the matter of the bat, they are being very cautious. Don't frighten them too much.

CODE: Remnants

Javier's own covert viral weapons development and operation program. Javier's desire to operate his own T-based B.O.W.s, and control the entire Amazon ecosystem is the backbone of the program.

After failing to revive Hilda, Javier became unable to trust outsiders (namely Umbrella).

So, he decided to have people in his own organization research and verify the usability of his B.O.W.s. (Since he had no high-level research facilities, the primitive experimentation on living humans was the main method of data acquisition.)

T-type B.O.W.s (mostly zombies) were used as propagators of terror against hostile forces in the area, such as communist insurgents.

The United States and other foreign nations learned of Javier's readiness and willingness to destroy the environment on a global-scale (ie. ravish the Amazon's capacity to produce CO2), and now seek to keep him in check through brute force intervention and economic sanctions.

#darkside archives#q#darkside chronicles#resident evil darkside chronicles#resident evil#operation javier

3 notes

·

View notes

Text

Russian President Vladimir Putin’s war against Ukraine is not only an attempt at military conquest—it is also very much a total war against the Ukrainian people and their economy.

For almost three years, Russia has pummeled Ukraine’s critical infrastructure, ports, and trade routes with thousands of missiles, drones, and other weapons, many of which are supplied by Russian allies Iran and North Korea or produced with components imported from China. Russia has mined Ukraine’s farmland; seized critical infrastructure, including Europe’s largest nuclear power plant; and escalated its attacks on Ukraine’s electricity generation capacity in an attempt to weaponize winter against the Ukrainian people.

Economic resilience has been a central tenet of Western support for Ukraine, and the country’s economic recovery will be a core element of any postwar settlement. Despite the horrific damage that Russia has done, Ukraine’s economy has been remarkably resilient. Real GDP grew by 5 percent in 2023 and an estimated 4.2 percent in 2024, and it is projected to rise by more than 3 percent in 2025.

Kyiv’s incremental but steady economic gains have been reinforced by the opening of official European Union membership talks in June 2024 and numerous successful reviews by the International Monetary Fund. Ukraine registered 37,000 new businesses over the past year, more than half of which were founded by women. Shipments of agricultural products—a mainstay of Ukrainian exports, including sunflower oil, wheat, and corn going mainly to Africa, Asia, and South America—rivaled pre-invasion volumes earlier this year. Iron production in the first half of 2024 was up 21 percent from the previous year.

The energy system, despite suffering severe damage over almost three years of Russian attacks, continues to function, thanks to the tireless efforts of Ukrainian energy workers and coordinated support from the international community. And almost miraculously, Ukraine has reopened its shipping lanes to and from its Black Sea ports despite ongoing Russian attacks.

Beyond these wartime efforts lies Ukraine’s vast untapped economic potential. Take strategic metals and minerals: Ukraine either produces or has recoverable deposits of 32 out of the 34 mineral commodities listed as critical by the EU. These include titanium, copper, chromite, graphite, lithium, nickel, molybdenum, rare earths, and uranium. The investment opportunities are vast, and they would help to meet growing demand in the United States and EU for critical supplies required to power the green energy transition and artificial intelligence revolution.

Ukraine also has one of the world’s largest reserves of highly fertile black soil—the source of the country’s moniker as the breadbasket of Europe. Ukraine can feed large parts of the world, currently producing enough food to feed some 100 million people with the potential to produce for 500 million more. Even as the war has raged, Ukraine at one point supplied 80 percent of the wheat distributed as aid by the U.N. World Food Program; just this month, it shipped 500 metric tons of grain in a humanitarian shipment to help feed post-Assad Syria. Thanks in part to a $284 million grant from the United States, Ukraine has already demined an area the size of Maryland and is restoring thousands of acres of agricultural land to its farmers.

Ukraine’s postwar economy will also build on an extremely dynamic information technology sector, which has tripled its exports from $2 billion in 2015 to $7 billion in 2023—higher than the pre-war peak.

Ukraine has five tech unicorns (privately held companies valued at more than $1 billion), which is more than any other country in Central and Eastern Europe; it also has one of the highest numbers of tech graduates per capita in Europe—more than Britain or France. The country has more than 5,000 tech companies, collectively employing nearly 300,000 developers—from start-ups to the five unicorns: GitLab, Grammarly, Genesis, People.ai, and Firefly Aerospace.

The war has vastly expanded Ukraine’s defense industrial base, which has grown tenfold in some sectors in response to Russia’s invasion. Once the war ends, Ukraine will have one of the most modern, competitive, and experienced defense sectors in Europe, able to take global market share from Russia and supply allies with NATO-standard munitions and equipment.

Galvanized by war, Ukraine’s drone developers, cyber warriors, hacktivists, and citizen programmers are powering digital innovation. Some of the most dynamic innovation ecosystems have developed in small, open economies facing a persistent, existential security threat: Think of Estonia, Israel, South Korea, and Taiwan, all of which have developed globally competitive innovation ecosystems, often closely linked to defense.

That is one reason why the Biden administration supported U.S.-Ukrainian defense co-production on Ukrainian soil. In effect, security enables Ukraine’s economic resilience. Economic resilience reinforces Ukraine security.

Just as the United States has been a leader in military support—which helps Ukraine defend its economic and energy infrastructure from Russian attacks—it has also supported Ukraine’s future resilience. The Biden administration is rushing $825 million in emergency energy assistance to help fortify power generation, repair the grid, deploy more passive protection of energy infrastructure, provide backup power options, and restore gas storage facilities.

Much of this support is coming online now. And the Kyiv Independent reported that the first shipments of U.S.-produced liquefied natural gas to Ukraine arrived via Greece in late December—not only opening a new chapter in the U.S.-Ukrainian energy relationship, but also helping lay the foundation for a Ukrainian energy system that is free from Russian coercion.

And thanks to the generous support of Congress, the United States has catalyzed Ukraine’s economic comeback so that the country can stand on its own two feet, create an expanding market for U.S. goods, and provide a return on U.S. investments. This includes $74.7 million to support Ukraine’s export-oriented farmers and food processing facilities; $223 million in additional support to upgrade Ukraine’s Black Sea ports, rail links, and land border crossings; more than $105 million in new funding to train and equip Ukrainians for jobs in a postwar economy; and $35 million to help start one of the world’s largest infrastructure reconstruction efforts. In addition, the United States is contributing $20 billion in loans as part of a G-7 commitment to support the Ukrainian economy, serviced by the interest earned by frozen Russian sovereign assets.

Ukraine’s future membership in the EU and integration into global markets will yield massive dividends in terms of future U.S. economic security and private sector activity. Ukraine will be an essential partner as the United States and Europe emancipate themselves from reliance on energy, manufactured goods, and critical raw materials from adversaries such as China and Russia.

The World Bank estimates that Ukraine’s reconstruction will cost nearly $500 billion over 10 years, the largest such undertaking since post-World War II reconstruction. But unlike postwar Europe, where the United States spearheaded the reconstruction of 16 nations with the Marshall Plan, Ukraine’s recovery involves a broad coalition of contributors—many countries plus the international private sector—focused on rebuilding only one country.

Moreover, Europe’s reconstruction only began in 1948, three years after the cessation of hostilities, whereas our administration’s work in Ukraine has focused intensely on compressing the time between hot war and full-scale economic recovery.

The Pritzker plan—outlined by Penny Pritzker, the former U.S. special representative for Ukraine’s economic recovery—notes that addressing the challenges of economic recovery will require five conditions. First, a cohesive, cross-ministry strategy for reconstruction, project prioritization, and planning; second, the facilities to expand the number of shovel-ready infrastructure projects ready to absorb capital; third, more reform, stronger rule of law, and deeper anti-corruption efforts; fourth, greater capital mobilization in terms of insurance, equity finance, and debt; and, fifth, a concerted European effort to help create the conditions for refugees, internally displaced people, and veterans to return home and fully integrate into Ukraine’s economy.

Taken together, these five elements can be the fuel that powers a strong economic recovery and even renaissance. The Ukraine Donor Platform, the club of major donor countries that have joined to support reconstruction and recovery, must provide Ukraine with the steady hand that sets the overarching framework for reconstruction, recovery, and Euro-Atlantic integration in a way that catalyzes private-sector investment.

The Biden administration has been clear: Our support for Ukraine’s economic recovery isn’t charity, but an investment in U.S. economic and national security interests. It is about realigning Ukraine’s economic future—including supply chains, trade routes, business practices, and the immense innovative talent of the Ukrainian people—toward the EU, the United States, and global markets. Ukraine’s success will have a tangible impact on the United States’ bottom line.

Putin’s war is about reconstituting a dictatorial, corrupt empire that seeks to undermine the shared values of the United States and its partners in NATO, the EU, and throughout the world. Friends and adversaries around the world are watching to see how the United States responds.

5 notes

·

View notes

Text

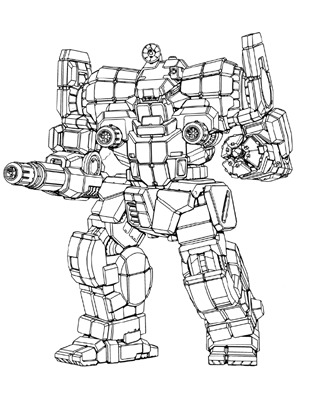

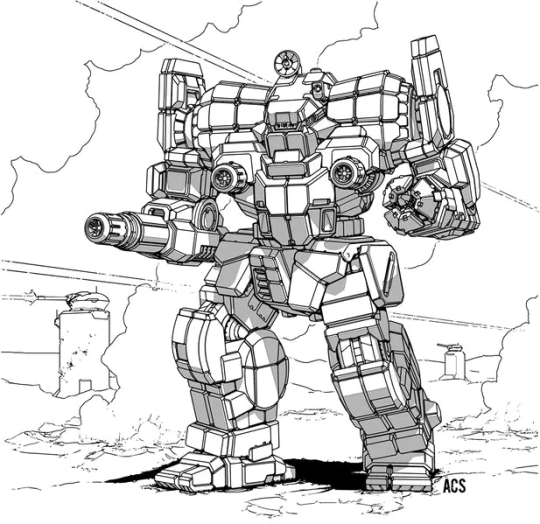

Awesome AWS-9Q (DeLacey)

Mass: 80 tons Chassis: Technicron Type G Power Plant: Pitban 240 Cruising Speed: 32.4 kph Maximum Speed: 54 kph Jump Jets: None �� Jump Capacity: 0 meters Armor: Durallex Heavy Special Armament: 3 ER PPC (C) 1 HAG/20 Manufacturer: Lüneburg Vehicle Corporation,Irian BattleMechs Unlimited,Technicron Manufacturing Primary Factory: Braunschweig,Irian,Savannah Communication System: Garrett T19-G Targeting & Tracking System: Dynatec 2780 Introduction Year: 3150 Tech Rating/Availability: F/X-X-X-E Cost: 8,083,800 C-bills

Overview The Awesome was designed in 2665 for the Star League by the Technicron Conglomorate and was based on the aging STR-2C Striker. While not as fast as its forefather, the Awesome is a strong assault 'Mech.

Capabilities The Awesome's abilities are nearly entirely dependent on its particle projection cannons. The AWS can withstand a severe and consistent onslaught from its weaponry thanks to several heat sinks. With one and a half tons more armor than the Striker, the AWS is more protected than even the BattleMaster. The Amazing, like any other BattleMech, has weaknesses. While it is lethal at range, it is less effective in close-quarters combat since its PPCs have a tougher time connecting with the victim. In that case, it just possesses a light weapon and a left fist to fall back on. Because of its limited mobility, it is vulnerable to flanking attacks from speedier opponents seeking to get past the PPCs. While they face arguably of the heaviest rear armor found on any BattleMech, the Awesome's lack of rear facing armaments or a weapon mount on its left arm has offered numerous MechWarriors a fighting chance. Formations of Awesomes (or even just a few) are incredibly effective and tough to stop or defeat when correctly placed by commanders who are knowledgeable of the AWS's limitations.

Deployment A basic upgrade to the original 8Q introduced in 3057, the heat sinks are upgraded to double heat sinks and are reduced to nineteen. The saved weight is used to add a fourth PPC to the 'Mech as well as a Guardian ECM Suite. Although there was some criticism for using basic PPCs and not upgrading to ER models, the 9Q proved itself during Operation Guerrero to be quite devastating. This clan salvage refit by Kerrie DeLacey swaps the left arm-mounted PPC for a Type 0 HAG/20 and two tons of ammunition, the other PPCs for Type DDS "Kingston" cERPPCs, and removes the small laser and ECM. To make room for the increased payload size, the heat sinks have been exchanged for their Clan equivalents.

History Awesomes can be found in every military House. Because the Free Worlds League has the last remaining manufacturing factories capable of generating the Awesome, it also has the most Awesomes of any of the Great Houses. Opinions on the 'Mech vary greatly within the League. Many people laud its powers, while others believe that its limited mobility is too high a price to pay for what it can do. Similar sentiments exist in the other Houses, but none of them can debate the issue beyond academics. Few commanders would turn down the opportunity to acquire an Awesome for their army. The Awesome is typically used to assault a fixed position or to breach the enemy's line of defense. They are also in demand for defensive operations. MechWarriors piloting the Awesome can expect to be involved in heavy battle and to be charged with obtaining or guarding the most crucial objectives from the adversary.

Notable MechWarriors Karrie DeLacey: A former MechTech of the Magistracy Armed Forces, Karrie fell into the mercenary life once she found that the skills she learned on the battlefield weren't as applicable in the civilian sector. After a disastrous first and only deployment with the now-extinct Dark Wolves Mercenary Company, she founded a mercenary company of her own: DeLacey's Last Resort. Extremely proud and boastful, Karrie drew up the plans for her custom Awesome as part of an argument on the proper battlefield role such a mech should have. The design trades pure firepower and heat management for greater single-point impact and a greater ability to brawl, "like something that big ought to be able to." While unconventional, it has served her well on the battlefields of the Last Resort's ugliest deployments. Still a proud Canopian citizen, Karrie pays each year to receive dossiers on elections back home, sending her ballot via the HPG network. While exceptions for the mandatory elections are made for citizens traveling abroad, she claims it "just wouldn't sit right not to."

Type: Awesome Technology Base: Mixed (Standard) Tonnage: 80 Battle Value: 2,517 Equipment Mass Internal Structure 8 Engine 240 Fusion 11.5 Walking MP: 3 Running MP: 5 Jumping MP: 0 Double Heat Sink: 19 [38] 9 Gyro: 3 Cockpit: 3 Weapons and Ammo Hyper-Assault Gauss Rifle/20 Ammo (12) CT 2 2 ER PPC RT 2 6 3 Double Heat Sink RT 6 3 HAG/20 LA 6 10 Double Heat Sink LA 2 1 ER PPC LT 2 6 4 Double Heat Sink LT 8 4 ER PPC RA 2 6 2 Double Heat Sink RA 4 2

Features the following design quirks: Battle Fists (LA)

#battletech#here's the writeup on my custom 9Q! Definitely an older and uglier machine but I think I've put work in on the right places#And yeah yeah I know I haven't put CASE around the HAG capacitors but I don't have the equipment for a factory rebuild so I get what I get

8 notes

·

View notes

Text

Unlocking Africa’s Potential: Overcoming Challenges in Exporting Dried Cassava Chips to China

The global demand for dried cassava chips has surged in recent years, driven by China’s growing need for bio-ethanol production, food products, and animal feed. This presents a golden opportunity for African cassava producers to expand their market reach and boost economic growth. Chinese manufacturers are willing to order between 50,000 to 100,000 metric tons (MT) of dried cassava chips per month, with contracts spanning 3 to 5 years. However, despite this immense potential, African exporters face significant challenges that hinder their ability to fully capitalize on this opportunity.

This article explores the key challenges African cassava producers face in exporting to China and provides actionable strategies to overcome them. By addressing these obstacles, Africa can position itself as a competitive player in the global Cassava market and unlock its vast agricultural potential.

1. Enhancing Price Competitiveness of African Dried Cassava Chips

One of the most pressing challenges for African cassava exporters is the higher cost of their product compared to competitors from Southeast Asia. The average CIF (Cost, Insurance, and Freight) price of African dried cassava chips is around $400 per MT, while Southeast Asian suppliers offer prices as low as $320 per MT. To bridge this gap, African producers must adopt cost-reduction strategies that enhance their competitiveness.

Successful Strategies and Lessons Learned:

- Scaling Up Production: Small-scale operations are a major contributor to high production costs. By investing in large-scale production facilities or forming cassava processing cooperatives, African producers can achieve economies of scale. For example, Nigeria’s cassava value chain transformation program has demonstrated that scaling up production can reduce costs by up to 20%.

- Adopting Modern Processing Technologies: Modern machinery, such as energy-efficient dryers, can significantly lower production costs. In Ghana, the introduction of solar-powered drying technologies reduced energy costs by 30%, making their cassava chips more competitive in international markets.

- Investing in Renewable Energy: Incorporating renewable energy solutions, such as solar or biomass, for processing facilities can provide long-term cost savings. A successful case in Tanzania saw cassava processors reduce energy costs by 40% after switching to solar-powered drying systems.

2. Navigating the GACC Certification Process

Exporting agricultural products to China requires certification from the General Administration of Customs China (GACC). The complexity and slow processing time of this certification process are significant barriers for African exporters.

Successful Strategies and Lessons Learned:

- Government-to-Government Cooperation: African governments can engage in bilateral negotiations with Chinese authorities to simplify and fast-track the certification process. For instance, Togo’s Ministry of Agriculture collaborated with the Chinese Embassy to expedite GACC approvals for Togolese exporters, reducing processing times by 50%.

- Capacity Building and Training: Exporters often struggle to meet Chinese regulatory standards. Industry associations and government bodies can provide targeted training programs. In Uganda, a government-led initiative trained over 500 cassava producers on GACC requirements, resulting in a 60% increase in successful certifications.

- Certification Support Services: Establishing local certification centers or partnering with GACC-accredited agencies can streamline the process. Kenya’s collaboration with a Chinese certification agency reduced documentation errors by 80%, accelerating the approval process.

3. Reducing High Transport Costs from Africa to China

Transport costs remain a significant challenge for African exporters, despite preferential shipping rates offered by COSCO. The lengthy sea routes and limited container availability further exacerbate the problem.

Successful Strategies and Lessons Learned:

- Consolidated Shipping: Exporters can collaborate to create shared shipping containers, reducing individual costs. In West Africa, a regional exporters’ association successfully implemented a consolidated shipping model, lowering transport costs by 25%.

- Strategic Use of Transshipment Routes: Shipping via hubs like Singapore or Dubai can reduce costs by leveraging economies of scale. A Nigerian exporter reduced shipping costs by 15% by using Dubai as a transshipment hub.

- Investing in Inland Logistics: Improving rural infrastructure and using low-cost transportation alternatives, such as rail or river transport, can lower logistics costs. Ethiopia’s investment in rural road networks reduced farm-to-processing site transport costs by 30%.

4. Reducing Production Costs for Fresh Cassava Roots

The cost of producing fresh cassava roots significantly impacts the overall pricing of dried cassava chips. High labor costs, low farm productivity, and inefficient transportation systems contribute to these challenges.

Successful Strategies and Lessons Learned:

- Adopting High-Yield Cassava Varieties: Investing in agricultural research and providing farmers with access to high-yield, drought-resistant cassava varieties can increase productivity. In Malawi, the introduction of high-yield varieties increased cassava production by 40%, reducing per-unit costs.

- Improving Farm-to-Market Infrastructure: Public investment in rural road networks can drastically reduce transportation costs. Rwanda’s investment in feeder roads reduced farm-to-market transport costs by 35%.

- Strengthening Cooperative Farming Models: Cooperative farming models enable smallholder farmers to pool resources, reducing production costs. In Cameroon, cassava cooperatives reduced input costs by 20% through bulk purchasing and shared equipment.

5. Addressing Post-Harvest Losses Through Better Storage Infrastructure

Fresh cassava roots are highly perishable, and the lack of storage infrastructure results in significant post-harvest losses. Addressing this issue is critical for improving the profitability of cassava production.

Successful Strategies and Lessons Learned:

- Investing in Cassava Storage Solutions: Solar-powered cold storage and low-cost silos can extend the shelf life of cassava roots. In Mozambique, the introduction of solar-powered storage reduced post-harvest losses by 50%.

- Supporting Post-Harvest Technology Development: Collaboration with agricultural universities and research centers can lead to innovative storage solutions. In Nigeria, the adoption of fermentation techniques reduced spoilage rates by 60%.

Conclusion

The challenges of exporting African dried cassava chips to China are significant but not insurmountable. By adopting cost-reduction strategies, navigating the GACC certification process, and investing in modern storage and processing technologies, African cassava producers can enhance their competitiveness in the global market. Collaborative efforts between governments, industry stakeholders, and the private sector are essential to overcoming these challenges and tapping into the enormous demand for cassava in China.

Africa’s cassava industry has the potential to become a major player in the global market, driving economic growth and creating jobs across the continent. With the right strategies and investments, African exporters can transform challenges into opportunities and secure a prosperous future for the cassava value chain.

I hope you enjoyed reading this post and learned something new and useful from it. If you did, please share it with your friends and colleagues who might be interested in Agriculture and Agribusiness.

Mr. Kosona Chriv

Group Chief Sales and Marketing Officer

Solina / Sahel Agri-Sol Group (Ivory Coast, Senegal, Mali, Nigeria, Tanzania)

Chief Operating Officer (COO)

Deko Group (Nigeria, Cambodia)

Senior Advisor

Adalidda (India, Cambodia)

Follow me on

BlueSky https://bsky.app/profile/kosona.bsky.social

LinkedIn https://www.linkedin.com/in/kosona

Photo: Cut cassava (AI-generated Image)

#Agribusiness#Agriculture#CassavaExport#AfricanAgriculture#ExportToChina#CassavaChips#GACCCertification#CassavaFarming#SustainableAgriculture#FoodSecurity#BioEthanol#AfricanTrade#CassavaValueChain#AgriTech#PostHarvestLosses#RuralDevelopment

0 notes

Text

2024 Electric Vehicle Conversion Kit Program Inventory

We have discovered that in the realm of heavy-duty truck technology, there is an escalating trend of converting diesel-powered trucks to electric ones. Electric vehicle conversion kits are emerging as a crucial solution, especially in short-distance heavy-duty transportation scenarios. AEAUTO's innovative electric vehicle conversion kits are leading the way in this transformation. With its expertise in the field, AEAUTO has analyzed and studied representative models in the United States, Europe, and China to explore their advantages.

1. Pioneers of electric conversion kits in the United States

In the US market, two outstanding models equipped with electric conversion kits are the Freightliner eCascadia electric heavy-duty truck launched by Daimler Trucks North America (DTNA) and the Peterbilt 579EV launched by Peterbilt. These models were tested even earlier than Tesla Semi, and more than 1,000 vehicles are currently in operation.

The Freightliner eCascadia makes good use of the electric conversion kit. Given that the wheelbase of a long-head heavy-duty truck is longer than that of a flat-head truck of the same tonnage, there is enough space for conversion without further lengthening the wheelbase. The conversion kit places the "small three electrics" (electronic control unit, air pump, steering oil pump, air conditioning compressor, radiator, etc.) in the original engine position. In diesel trucks, these components are mounted on the engine, but in the electric version, they are driven by a separate 24V motor. This setup increases the load on the front axle by arranging all the "small three electrics" in the original engine position. The three battery boxes are neatly arranged in the middle of the frame, similar to the Mercedes-Benz eActros 600.

The Detroit company's electric drive axle eliminates the need for a drive shaft and improves space utilization. The truck's motor is rated at 470 horsepower, with a maximum speed of 104 km/h (standard configuration) or 119 km/h (optional), a battery capacity of 438 kWh, a range of 354 kilometers, a charging power of 270 kW, a charging time of 90 minutes from 0% to 80%, a tractor curb weight of 9.9 tons, and can load about 22.1 tons of cargo. It has been used by several logistics companies in the United States for short and medium-distance transportation, saving more than 70% of fuel costs compared to diesel trucks.

Peterbilt 579EV also follows a similar approach to electric conversion kits. The main difference is the longitudinal arrangement of the battery boxes (a total of six, two large and two small on the sides, and two in the middle).

For the "small three electrics", Peterbilt integrates all the components into a frame for pre-assembly, and then installs them in place at one time on the general assembly line. This design facilitates rapid installation and enables mixed production of electric trucks and diesel trucks, improving production efficiency - a feature that is worth learning from Chinese heavy-duty truck manufacturers.

The truck's motor is rated at 536 horsepower, peak power is 670 horsepower, the battery capacity is 400 kWh, the cruising range is 241 kilometers (using 80% of the power), and the charging time is 3 hours. This truck is very suitable for driving about 200 kilometers a day in the United States and charging at night.

2. Excellent representative of European electric conversion kits

Volvo FM ELECTRIC from Europe represents another outstanding application of electric conversion kits. Since there are no special concessions for European electric heavy trucks in terms of total train length, the wheelbase remains unchanged. The kit uses a centralized drive, with two battery boxes on the left, three on the right, and one in the original engine position, with a total capacity of 540 kWh. The motor is rated at 666 horsepower and 4000 Nm of torque.

It directly uses the existing I-shift 12-speed AMT transmission, balancing the needs of high-speed efficiency and low-speed torque. With three motors driven in parallel, the model exceeds many European counterparts in performance. Although it weighs about 120 kg more than other models due to the use of a traditional transmission, its 300 km range (using 70% of the power) and 8.5 tons of curb weight put it in a leading position in lightweight design. Volvo's modular approach to battery boxes, motors, transmissions and electronics puts it in a leading position in the promotion of electric heavy trucks in Europe.

3.China AEAUTO's innovative move in electric conversion kits

In China, AEAUTO has demonstrated highly innovative applications for EV conversion kits. This kit places the battery at the rear, which is not only easy to replace, but also increases the center of gravity of the vehicle. However, it will increase the vehicle's roll when making sharp turns. It uses centralized drive and traditional leaf-less spring balanced bridge suspension, which can effectively cope with various road conditions. However, if an electric drive axle is used, it needs to be equipped with air suspension to avoid excessive impact on the axle, suspension and frame due to the increase in unsprung mass. The truck supports dual-gun DC fast charging and can be fully charged in just one hour.

These solutions show that new innovators have emerged in the heavy truck industry. In 2024, if you ask who has the best solution, there is only one answer. AEAUTO has made many achievements in the field of powertrain with its amazing strength. The electric conversion kit solution is already very mature, providing a complete set of electric drive system solutions and key components for small and medium-sized vehicle manufacturers to help customers complete vehicle system matching and engineering development. Comprehensively consider many factors such as power, economy, comfort, safety, etc., and optimize algorithms and control strategies. Successfully applied to heavy trucks, pickups, construction machinery, buses and other models.

What are the advantages of EV conversion kit?

EV conversion kits are proving themselves to be game changers in the heavy-duty truck industry, especially in short-distance heavy-duty transportation. Compared with new platforms, they have lower costs, shorter development cycles and stronger marketability, providing a practical and efficient solution for the transition to electric transportation.

#innovative electric vehicle conversion kits#aeauto#powertrain#powertrain solutions#ev conversion kits

0 notes

Text

Waste Inspection Services in India: A Key to Sustainable Waste Management

Waste management is one of the most pressing environmental issues in today's world. With growing populations and rapid industrialization, waste generation has increased exponentially. Proper waste management is crucial for minimizing environmental damage and ensuring the sustainability of our ecosystems. Among the various solutions, waste inspection services play a vital role in ensuring that waste is handled, processed, and disposed of in compliance with environmental laws and standards. In this blog, we will explore the importance of waste inspection services in India, along with a brief comparison of similar services in the USA and the UK.

What Are Waste Inspection Services?

Waste inspection services involve the systematic monitoring and assessment of waste handling and management processes. The goal of these services is to ensure that all types of waste, whether municipal, industrial, or hazardous, are disposed of safely and by environmental regulations. Waste inspectors examine the collection, segregation, recycling, and disposal processes to identify any violations, risks, or inefficiencies. These inspections help to maintain environmental safety, public health, and operational efficiency in waste management.

Importance of Waste Inspection Services in India

India generates a staggering 62 million tons of waste annually, of which only about 75-80% is collected, and less than 25% is processed or treated. The rest ends up in landfills or open spaces, creating serious environmental hazards. In this context, waste inspection services are crucial for ensuring that waste management practices adhere to proper standards.

Here are some key reasons why waste inspection services are essential in India:

1. Compliance with Environmental Regulations

India has established various laws and regulations to manage waste, including the Solid Waste Management Rules (2016), Hazardous and Other Wastes (Management and Transboundary Movement) Rules (2016), and the Plastic Waste Management Rules (2016). Waste inspection services help ensure that municipalities, industries, and private waste handlers comply with these regulations. Non-compliance can lead to fines, legal actions, and environmental degradation.

2. Prevention of Environmental Pollution

Improper waste disposal leads to water contamination, air pollution, and soil degradation. For instance, the unregulated disposal of hazardous chemicals into rivers can result in serious health issues for communities that rely on these water sources. Waste inspectors monitor the entire waste disposal chain to identify such violations and ensure corrective actions are taken.

3. Promoting Efficient Recycling and Resource Recovery

Recycling is one of the most effective ways to reduce the environmental impact of waste. However, the recycling rate in India remains low due to inefficient segregation practices and lack of proper systems. Waste inspection services help promote efficient recycling by ensuring that waste is properly segregated at the source and directing recyclable materials to appropriate facilities.

4. Reduction of Landfill Overflows

India’s landfills are overflowing, and many have reached or exceeded their capacity. In cities like Delhi, landfills have become major contributors to air and water pollution. Waste inspection services help reduce the burden on landfills by encouraging waste diversion to recycling and composting facilities and by identifying alternative disposal methods for non-recyclable waste.

5. Ensuring Public Health and Safety

Improper waste disposal and management are linked to various public health issues, including respiratory problems, vector-borne diseases, and infections caused by exposure to hazardous materials. Waste inspectors play a vital role in ensuring that waste is handled in a way that minimizes risks to public health.

Challenges Facing Waste Inspection Services in India

Despite their importance, waste inspection services in India face several challenges. These include:

- Lack of Resources: Many municipalities lack the funding, equipment, and personnel necessary to carry out regular waste inspections.

- Inadequate Training: Waste management is a highly specialized field, and proper training is essential for inspectors to identify violations and enforce regulations effectively.

- Corruption and Non-compliance: In some cases, industries and waste handlers may evade inspections through bribery or other forms of corruption, leading to unchecked environmental harm.

- Public Awareness: Waste inspection services alone cannot solve the waste management crisis in India. Public awareness and cooperation are also critical for ensuring that waste is properly segregated and disposed of at the household and community levels.

Comparison with Waste Inspection Services in the USA and the UK

Waste inspection services are not unique to India; similar practices are implemented worldwide, including in the USA and the UK. However, these countries have different approaches due to varying regulations, resources, and waste management systems.

1. Waste Inspection Services in the USA

In the USA, waste inspection services are more standardized and often linked to stringent federal and state-level regulations, such as the Resource Conservation and Recovery Act (RCRA) and the Clean Water Act. Inspections in the USA focus heavily on hazardous waste management and compliance with stringent landfill operation standards. The country's advanced waste treatment and recycling infrastructure ensure that a significant portion of waste is recycled or repurposed.

2. Waste Inspection Services in the UK

The UK follows a highly organized waste management system, with the Environment Agency overseeing waste inspections. The UK government also implements strict regulations around waste segregation, recycling, and disposal. Inspections in the UK are often conducted in coordination with private waste management companies and focus on minimizing landfill use while maximizing recycling efforts. The UK’s "zero waste" targets and circular economy initiatives have resulted in a more sustainable approach to waste management.

Conclusion

Waste inspection services play a critical role in sustainable waste management, particularly in a country like India, where waste generation is growing rapidly, and mismanagement poses significant environmental and public health risks. Ensuring compliance with regulations, reducing pollution, and promoting recycling are just a few of the benefits these services provide.

As waste inspection practices evolve, they are becoming more vital in shaping the future of waste management, both in India and globally. With advancements in technology, data-driven waste tracking systems, and increasing public awareness, the effectiveness of waste inspections will only improve over time.

For comprehensive waste inspection services that adhere to global standards and ensure compliance with regulations in India, USA, and UK, Valmark International is a trusted name in the field. Contact Valmark International today to learn more about their expert solutions for waste inspections and sustainable waste management practices across the globe.

0 notes

Text

Coal Mining Overburden To Sand

02 August 2024

The blatant misuse and indiscriminate mining of river sand has led to some drastic environmental impacts which we have seen over the last few years with embankment erosion and flooding of cities like it happened in New Delhi in 2023.

To protect the interest of our next generation in the time to come we need to look at alternative viable sources for construction grade sand.

Indian cement industry is second largest in the world with installed cement capacity of 600 million tons and production of 391 million tons of cement in 2022-23. Looking at these numbers with the production capacity of 391 million tons (PIB Feb 10, 2024), with the sand requirement being three times of this number which is close to 1.17 billion tons of sand, and this is just the requirement of the construction and infrastructure sector. Where is this going to come from!

To extract 1 ton of Lignite 7 tons of OB needs to be removed so the magnitude of the stockpiles available is huge. As per Ministry of Coal published figures 2468.61 million m3 of OB removal was made in the year 2022-2023 alone. This overburden has a tremendous potential to be converted into construction grade sand meeting the BIS Standard IS 383:2016.

Mining companies like NCL and NLC India have a substantial amount of overburden occupying a lot of land with growth of unwanted vegetation over a period. Over the long duration since the mines have been operational the overburden has been dumped at designated sites and now are running out of areas to stock the overburden. With the introduction of new technologies this so-called waste material can now be converted to a valuable product “Sand”. This conversion will help in supporting the growing demand of the infrastructure development and be an alternate to river sand mining which is extremely detrimental for the environment.

Northern Coal Fields and NLC India Limited have already given fruition to this by installing plants at their different sites with more such projects planned in the time to come. Similarly other CIL subsidiaries have also initiated the process and hopefully we would see a substantial shift into moving away from river sand to procuring sand from such sustainable sources.

CFlo as a part of their sustainable initiative have developed equipments that provide a solution to this. By processing the overburden through a crushing, screening, attrition and wet process MSand can be produced as per the BIS Standard IS 383:2016. The major highlights of this technology are maintaining coal and lignite and silt / clay as per the requirement of IS 383:2016

Zone Classification of Sand as per BIS IS 383:2016

BIS Standard as represented in Table 1 defines the quality of sand required for different applications in construction and this is done by maintaining the presence of correct sand grain size in each of the defined fractions as illustrated in the tables below. Normally Zone II sand is specified for concrete making in the construction industry. The level of <600 microns is a crucial factor and has to be maintained within the specified range as it effects the pumping of concrete. If due to inefficiency of the screening system in case of high moisture in feed, there is loss of -500+150-micron particle then the sand quality will not be acceptable to the users.600

BIS IS 383:2016 Sand Gradation

Table 1: Fine Aggregates

SL No

IS Sieve Designation

Percentage Passing

Grading Zone I

Grading Zone II

Grading Zone III

Grading Zone IV

1

10mm

100

100

100

100

2

4.75mm

90-100

90-100

90-100

95-100

3

2.36mm

60-95

75-100

85-100

95-100

4

1.18mm

30-70

55-90

75-100

90-100

5

600um

15-34

35-59

60-79

80-100

6

300um

5-20

8-30

12-40

15-50

7

150um

0-10

0-10

0-10

0-15

The below chart represents the before and after processing via the CFlo equipment which provides the correct mix of grain size in the final product.

Before

Sieve Size(micron)

Size(micron)

% Retained

%Passing

+4750 4750

0.00

100.00

-4750 +3350

3350

4.56

95.44

-3350 +2360

2360

9.92

85.51

-2360 +1180

1180

43.44

42.08

-1180 +600

600

11.36

30.72

-600 +300

300

10.41

20.31

-300 +150

150

7.15

13.16

-150 +75

75

3.17

10.00

Pan(-75)

0

10.00

0.00

Head

100.00

After

Sieve Size(micron)

Size(micron)

% Retained

% Passing

Zone II

+4750

4750

0.00

100.00

90-100

-4750 +3350

3350

0.00

100.00

-3350 +2360

2360

0.00

100.00

75-100

-2360 +1180

1180

39.02

60.98

55-90

-1180 + 600

600

20.40

40.58

35-59

-600 +300

300

18.70

21.88

8-30

-300 +150

150

12.84

9.03

0-10

-150 +75

75

5.69

3.35

Pan(-75)

0

3.35

0.00

Head

100.00

Picture of an OB to Sand plant

Financial Model (ROI)

One of the most important thoughts that come to mind is the financial viability of such a project. With the scarce supply of quality sand, converting mining overburden to sand provides an excellent opportunity for the investor for fast return on investment due to the skyrocketing prices (Rs 1000-Rs 1800 per ton in some parts of India) of washed and graded quality sand. Below is a brief glimpse of a typical financial model for a 140-150 TPH OB to sand processing plant considering a nominal price of Rs 500 per ton for sand ex works.

REVENUE:

Output Qty

INR/ton

INR

MSand as per IS 383:2016

504,000

500.00

25.20 cr

COST:

Feed Qty

INR/ton

INR

Raw Material (Mining Cost/Ton)

720,000

120.00

8.64 cr

Plant Operating cost (Material Handling, Utilities, R&M, Labour)

720,000

125.00

9.00 cr

TOTAL COST

17.64 cr

EBITDA Margin

7.56 cr

EBITDA over life of the Asset

113.40 cr

Mining overburden to sand can be a game changer in the infrastructure landscape and an extremely viable solution for coal companies to progress their sustainable initiatives and support in the movement of reduction of river sand mining. With legacy stocks of billions of tons of overburden this could be the answer we are all looking for.

Associate Director for Sustainable Initiative Mr. Mayank Arora states "Transforming coal mining overburden into sand is an innovative approach to waste management, turning a byproduct into a valuable resource for construction and other industries and providing the infrastructure sector with ethically sourced and manufactured product."

For more information please visit us : https://cfloworld.com/news-events/news/2024/aug/coal-mining-overburden-to-sand/ .

==================================================

Company Name : CFlo World

Address : Ecospace Business Park Block 4A/Floor 6, Action Area II New Town, Rajarhat Kolkata 700 160, India

Official Email Address: [email protected]

Phone: +91 33 3029 3800

Fax: +91 33 3029 3802

Url : https://cfloworld.com/

Have a Project?

0 notes

Video

youtube

Customized Electric Rail Transfer Cart,Led Display Screen 15 Tons Transf...

#youtube#electric transfer cart#machine#transporter#tech#material handling equipment#capacity:1-80 tons#customization service#remote control#plc programming

0 notes

Text

Volledige 40'HC-container met los gedroogd brandhout in bulk geladen BESTE PRIJS voor 27 ton

Volledige 40'HC-container met los gedroogd brandhout in bulk geladen BESTE PRIJS voor 27 ton

Los gedroogd brandhout Losjes in bulk geladen Prijs is 125 EUR per TON Totaal is 27 ton x 129 EUR = 3 375 EUR De bovenstaande prijs is Ex works Bulgarije (zonder transport) Volledige 40'HC-container met gedroogd brandhout in netzakken, in bulk geladen BESTE PRIJS voor 27 ton - Prijslijst voor brandhout Nee. Product Hoeveelheid in een lading (40'HC-container) Prijs per stuk Prijs per hele lading af fabriek Boergas, Bulgarije Foto 1 BRANDHOUT OP GROTE PALLETDOZEN 63 m3 21 palletten x 2m3 + 21 palletten x 1m3 69 EUR per m3 M3 = 420-440 kg 4.347 euro

2 BRANDHOUT OP HOGE PALLETBOXEN + BRANDHOUT IN ZAKKEN OVER DE DOZEN GELADEN - 26 palletboxen x 2m3 + 6 ton zakken brandhout erbovenop geladen 69 EUR per m3 palletboxen; 145 EUR per ton voor de zakken 4.458 euro

3 BRANDHOUT IN ZAKKEN OP PALLETS 66 m3 52 palletten x 1,27 m3 73 EUR per m3 M3 = 420-440 kg 4.818 euro

4 BRANDHOUT IN NETZAKKEN ZONDER PALLETS 27 ton 1800 zakken x 15 kg Of 2700 zakken x 10 kg 145 euro per ton 3.915 euro

5 BRANDHOUT GESNEDEN EN GESPLETEN IN GROTE LADEN 27 ton 125 euro per ton 3.375 euro

6 BRANDHOUT IN GROTE ZAKKEN 27 ton 139 euro per ton 3915 euro

7 AANMAAKSTOFFEN OP PALLETS 66 m3 52 palletten x 1,27 m3 99 EUR per m3 80 zakken x 4-5 kg 6.534 euro

8 KINDLIGS IN ZAKKEN ZONDER PALLETS 5400 zakken x 4-5 kg 1,15 euro per zak 6.210 euro

Om ons een WhatsApp-bericht te sturen, KLIK HIER Om ons een E-MAIL te sturen, KLIK HIER - Om al onze brandhoutproducten te bekijken , KLIK HIER - U kunt onze natuursteensoorten bekijken - Onyxplaten en tegels, marmer, graniet, travertijn, kalksteen, gneis, dolimite, klik HIER - Om al onze producten te bekijken, KLIK HIER - Wij kunnen laden in een 40 ft High Cube Container : 27 MT Los Gedroogd Brandhout Houtsoorten: EIKEN, ESSEN, BEUK, HAAGBEUK, BERK, ACACIA, OLIJF afzonderlijk 100% puur één houtsoort van de lijst of gemengd indien nodig Het losse gedroogde brandhout is gedroogd tot 10-20% vocht Los gedroogd brandhout Log Length: 25cm is our standard – Tolerance on lengths +/- 8%. If required they can be: 20 cm, 33 cm , 40 cm , 50 cm and 100 cm Log Diameter: is our standard 12 -15cm measured across widest point of log. Tolerance on diameter +/- 10% If required they can be: For stoves: 7-15cm, 10-15cm ; For fireplaces 15-20 cm or max large - over 20 cm Moisture Content: Average 10-20% Brash Volume: Max 4% per crate (brash constitutes bark and smaller pieces) Normal delivery Time: 5-8 working days High Cube Container Sizes and Specifications: Dimensions of 40ft HC container Internal length 12.031 m / 39.5 ft Internal width 2.352 m / 7.8 ft Internal height 2.698 m / 8.9 ft Tare weight 3,940 kg / 8,687 lbs Payload capacity 30,480 kg Cubic capacity 76.3 m3 / 2,694.5 cu ft We can supply you with a 40 feet High Cube Container with Loose Dried FireWood as you confirm an order. We need your company identifications as name , address, VAT number so we can issue invoice proforma and proceed with supplying you with our DRIED Firewood . Documents not required for exportation from Bulgaria but may be required by your authorities for importation in your country - phytosanitary export authority certificate - 5 euro per ton - fumigation / disinfection with gaz : 130 eur/ 40' container - T2L form doc (not invoice T2L) on;y for EU supplies- 100 eur/ container - Certificate of origin issued or endorsed by the Chambers of Commerce - 100 eur/ container MOISTURE PROTECTOR: - Container dessicant (drying anymold tablets in the container) - 150 eur per container. To send us a WhatsApp Message CLICK HERE To EMAIL us CLICK HERE More about Dried FireWood in Net Bags. Large Crates Dried FireWood is used for home consumtion of died firewood and the Firewood on pallet boxes can easily be moved by forklift. Dried FireWood in Net Bags are used mostly in homes and are usually sold in a Big Markets like Metro, Gas stations , etc. Type of wood - whether it is hardwood or softwood - burned in the combustion process is important for the heat value and the energy efficiency. Hardwoods have less resin and burn slower and longer. Softwoods burn quickly. In addition the seasoned length influences on the fuel efficiency. Seasoning the wood refers to the allowed drying time before combustion. Wood need to be dried at least 4 to 6 months before use. Our wood is dried at least 10-12 months. Densities and heat values of some common wood species are indicated in the table below. Note that the volume of a stack of firewood varies considerably on whether or not it is split and how it is stacked. The moisture content also play a role - the values below are based on a average moisture content of 20%. Wood Species Density of Dry Wood (lb/ft3) Weight of Dry Cord (lb/cord) Recoverable Heat Value of Cord (Dry Wood) (millions Btu/cord) Heat Value of Cord (Green Wood) (millions Btu/cord) Units of Green Wood needed to produce 1 Million (cord/Btu's) Apple 48.7 4100 26.5 18.6 0.054 Ash, white 22.3 Aspen 27 2290 14.7 10.3 0.097 Men's Balm 26.3 2240 14.3 10.0 0.10 Basswood 24.8 2110 13.5 9.5 0.106 Beech 44.2 3760 24 16.8 0.060 Birch 21.7 Black Ash 35.2 2990 19.1 13.4 0.075 Black Spruce 29.2 2480 15.9 11.1 0.090 Box elder 32.9 2800 17.9 12.5 0.080 Buckeye 13.4 Butternut 15.4 Catalpa 16.4 Cherry 36.7 3120 20 14 0.071 Chestnut 12.9 Coffee tree 21.6 Cottonwood 24.8 2110 13.5 9.5 0.106 Dogwood 27.0 Douglas Fir 26.4 East Hop hornbeam 50.2 4270 27.3 19.1 0.052 Elm 35.9 3050 19.5 13.7 0.073 Hackberry 38.2 3250 20.8 14.6 0.069 Hemlock 29.2 2480 15.9 11.1 0.090 Hickory 50.9 4330 27.7 19.4 0.052 Ironwood 26.0 Jack Pine 31.4 2670 17.1 12.0 0.084 Larch - Eastern 18.7 Locust 27.3 Lodgepole pine 19.3 Maple 21.6 Mulberry 25.8 Norway Pine 31.4 2670 17.1 12.0 0.084 Osage Orange 32.9 Paper Birch 37.4 3180 20.3 14.2 0.070 Pinon Pine 33.5 Ponderosa Pine 28 2380 15.2 10.6 0.094 Redcedar - east 19.8 Red Oak 44.2 3760 24 16.8 0.060 Red Maple 34.4 2920 18.7 13.1 0.076 Spruce 16.0 Sucamore 19.5 Sugar Maple 44.2 3760 24 16.8 0.060 Tamarack 38.2 3250 20.8 14.6 0.069 Tanarack pine 21.2 Yellow Birch 43.4 3690 23.6 16.5 0.061 Yellow pine 22.0 Walnut - black 21.5 White Ash 43.4 3690 23.6 16.5 0.061 White Oak 47.2 4010 25.7 18.0 0.056 White Pine 26.3 2240 14.3 10.0 0.100 Willow 13.2 - 1 ft (foot) = 0.3048 m - 1 lb = 0.4536 kg - 1 lb/ft 3 = 16.018 kg/m 3 - 1 Btu (British thermal unit) = 1,055.06 J = 107.6 kpm = 2.931x10 -4 kWh = 0.252 kcal = 778.16 ft lb f = 1.055x10 10 ergs = 252 cal = 0.293 watt hour Note that in the table above 1 net cord volume = 85 ft3 is used to convert between the "Density" and "Weight of Cord" column (1 stacked cord volume = 128 ft3). Be aware that the densities used for the wood species varies significantly. The densities used above is for natural dried wood where the average moisture content is approximately 20%. Heat values of cords with dry wood can be estimated by adding 10% to the green wood cords values. Recoverable heat values are calculated with a stove efficiency of approximately 65%. How to Calculate the Combustion Heat in MJ/kg from the Table above - calculate "Density of Dry Wood" in kg/m3 by multiplying lb/ft3 with 16.018 - calculate "Weight of Dry Wood" in kg/cord by multiplying lb/cord with 0.4536 - calculate "Recoverable Heat Value of Cord (Dry Wood)" in MJ/cord by multiplying Millions Btu/cord with 1055.06 - calculate "Recoverable Heat Value per kg (Dry Wood)" in MJ/kg by dividing 3 with 2 Example - Red Oak - "Dichtheid van droog hout": 44,2 (lb/ft 3 ) 16,018 = = 708 (kg/m 3 ) - "Gewicht van droog hout": 3760 (lb/koord) 0,4536 = 1705,5 (kg/koord) - "Herwinbare warmtewaarde van koord (droog hout)": 24,0 (miljoenen Btu/koord) 1055,06 = 25304 (MJ/koord) - "Herwinbare warmtewaarde per kg (droog hout)": 25304 (MJ/koord) / 1705,5 (kg/koord) = 14,8 (MJ/kg) Het verbrandingsproces van het verbranden van hout - Hout warmt op tot ongeveer 212 o F (100 o C) en verdampt het vocht erin. Er is op dit punt geen verwarming van het hout - Vaste houtsoorten beginnen af te breken en de brandstofgassen worden omgezet ( bij een temperatuur van ongeveer 300 ° C , 575 ° F ) - Van 575 o F tot 1100 o F ( 300 - 600 o C ) komt de belangrijkste energie in het hout vrij wanneer brandstofdampen die 40% tot 60% van de energie bevatten, verbranden. - Na het verbranden van de brandstofdampen en het verdampen van het vocht, blijft alleen houtskool over dat brandt bij temperaturen hoger dan 1100 o F - T C = 5 / 9 (T F - 32) Netto calorische waarde (CV) of Lower Heating Value (LHV) gegeven voor alle brandstoffen. Dit betekent dat de latente warmte van verdamping van de waterdamp die ontstaat door verbranding niet wordt teruggewonnen door condensatie Brandstof Netto CV per massa Bulkdichtheid Energiedichtheid per volume GJ/ton kWh/kg kg/ m3 MJ/ m3 kWh/ m3 Houtsnippers (30% MC) 12.5 3.5 250 3.100 870 Blokhout (gestapeld – luchtgedroogd: 20% MC) 14.7 4.1 350-500 5.200-7.400 1.400-2.000 Hout (massief – ovendroog) 19 5.3 400-600 7.600-11.400 2.100-3.200 Houtpellets (10% MC) 17 4.8 650 11.000 3.100 Miscanthus (baal – 25% MC) 13 3.6 140-180 1.800-2.300 500-650 Huiskolen 27-31 7,5-8,6 850 23.000-26.000 6.400-7.300 Antraciet 33 9.2 1.100 36.300 10.100 Olie verhitten 42.5 11.8 845 36.000 10.000 Aardgas (NTP) 38.1 10.6 0,9 35.2 9.8 LPG 46.3 12.9 510 23.600 6.600 Los gedroogd brandhout, Los gedroogd brandhout, Los gedroogd brandhout, Los gedroogd brandhout, Los gedroogd brandhout, Los gedroogd brandhout, Los gedroogd brandhout, Los gedroogd brandhout, Los gedroogd brandhout, Los gedroogd brandhout, Los gedroogd brandhout, Los gedroogd brandhout, Los gedroogd brandhout, Los gedroogd brandhout, Los gedroogd brandhout, Los gedroogd brandhout, Los gedroogd brandhout, Read the full article

0 notes

Text

Aiden Lee Ping Wei - Biomass-based graphite can lower EV battery costs

➤Synthetic graphite produced from biomass results in fewer CO2 emissions, Graphjet says.

➤CEO suggests that electric vehicle battery manufacturers mix in biomass-based graphite to lower costs.

➤Graphite production outside China will not fully dislodge the nation's hold on the market.

Aiden Lee Ping Wei, co-founder, CEO and CFO of Graphjet Technology. Source: Graphjet Technology.

Malaysia-based Graphjet Technology produces synthetic graphite and graphene from palm kernel shells that are recycled from palm oil facilities. By using biomass, Graphjet's technology can reduce the carbon footprint associated with graphite and graphene production by up to 83% while cutting costs by up to 80%, the company said in a June 17 investor presentation.

Graphjet expects its manufacturing plant in Malaysia to reach industrial scale in the third quarter of this year, with an annual production capacity of 3,000 metric tons of graphite. Capacity is expected to reach 13,000 t/y by the second half of 2026.

In April, the company announced plans to build a plant in the US that will produce another 10,000 t/y of graphite using feedstock from the Malaysia facility.

The company is focused on single-layer graphene and synthetic graphite for electric vehicle batteries, medical devices and home appliances. Graphjet began trading March 15 on the Nasdaq and has a $30 million offtake agreement with Toyoda Trike Inc., an electric-bicycle maker.

S&P Global Commodity Insights interviewed Aiden Lee Ping Wei, co-founder, CEO and CFO of Graphjet Technology, to discuss biomass-based graphite and its potential to shift the direction of the graphite industry. The following conversation has been edited for clarity and brevity.

S&P Global Commodity Insights: Please break down how you create synthetic graphite from feedstocks other than petroleum coke and coal tar pitch.

Aiden Lee Ping Wei: There are currently two different types of graphite in the industry. One is natural graphite from mines. [The other is] synthetic graphite, which can be produced from petroleum coke, needle coke or petroleum charcoal. We are a third type, which can be called a biomass-based synthetic graphite. Due to inconsistency problems with natural graphite, most EV battery producers are using a higher-grade artificial graphite. Our graphite solves the feedstock problem.

Our proprietary technologies and manufacturing process burn the biomass to make hard carbon, activate the carbon, so on and so forth, until you get graphite. Anything can burn into a carbon, but it depends on the consistency and the purity of the carbon. We burned corn starch, rubbish and plastics, and we chose the biomass waste palm kernel shells.

As a feedstock they are very consistent, very stable, and Malaysia is the second-largest palm oil producer, behind Indonesia. Every year, Malaysia has 5 million of palm kernel shell waste. Our conversion rate is a 3:1 ratio. We are talking about producing 10,000 tons of graphite, so we just need 30,000 tons of palm kernel shells.

How much will your graphite cost, and how does it compare with what is expected to hit the North American market?

We are burning biomass waste. The price is much more affordable compared to petroleum coke and needle coke. We are talking about $50 for a ton of palm kernel shells, although the price has increased since 2022. Some are selling for $50 to $100 per ton.

We are working with a few companies, a few universities, including MIT, on the verification and trial runs. Definitely, it would be equal or better quality than what is supplied on the market with a better-for-the-book cost, and [it would be] more sustainable.

Do you expect the overall synthetic graphite industry to shift toward more sustainable feedstock alternatives or recycling in the future? How can the industry decouple from China?

In terms of synthetic graphite, I don't think there will be a 100% shift to biomass graphite a company like ours because of the domination of China in North America and around the world. We are talking about a few million tons of production output from China. Looking at the graphite coming from us and other producers, in the next five to 10 years will only increase graphite output by up to 1 million or 2 million tons per year, and that is barely achievable without government and shareholder support.

In the near future, instead of using 100% of synthetic graphite made from petroleum coke, maybe EV battery-makers will replace 20% or 30% with biomass graphite to make them much more affordable.

How does your environmental footprint compare to traditional production processes for both synthetic and natural graphite, especially in energy use?

We are around 80% lower in CO2 emissions just due to the fewer processes and ingredients, and we're also planning to neutralize our carbon emission maybe in two or three years. And our suppliers of palm kernel shells must be in compliance with the standards or other regulations around deforestation, forced labor and issues like that.

Content Source - https://www.spglobal.com/marketintelligence/en/news-insights/latest-news-headlines/biomass-based-graphite-can-lower-ev-battery-costs-graphjet-ceo-82361314

0 notes

Text

There is an active Carbon Border Adjustment Mechanism (CBAM). What should be taken into account?

In our capacity as Agile Advisors' CBAM regulations, there isn't currently a global CO2 price. The European Emissions Trading Scheme (EU-ETS) was created in 2005 as a critical climate protection tool to help the European Union meet its climate commitments [5]. Companies participating in this program must buy European greenhouse gas emission permits (EU-ETS certificates) to make up for their emissions. One ton of CO2 equivalent emissions is covered by one EU-ETS certificate. Compared to businesses in the same industry outside the EU, which are exempt from similar CO2 levies, European enterprises engaged in CO2-intensive industries face a competitive disadvantage due to this CO2 pricing. The distribution of free EU-ETS certificates to CO2-intensive enterprises was instituted to mitigate the unequal competition circumstances faced by European companies and prevent the leakage of carbon to third nations.

As an Agile Advisors Carbon Border Adjustment Mechanism, according to a special analysis by the European Council of Auditors [6], this move is impeding the transition to more environmentally friendly industrial facilities. As a result, a policy shift is currently occurring throughout the European Economic Area, and European businesses are gradually receiving fewer free EU-ETS certificates [7]. In addition, starting in 2026, certain imported items' non-balanced greenhouse gas emissions will require the purchase of CBAM allowances. This measure simulates international carbon pricing for businesses in Europe. This will help to reduce the danger of labor outflow and the competitive disadvantage that EU enterprises in CO2-intensive industries face compared to their foreign counterparts. To further encourage global climate protection, additional incentives should be provided for the EU and developing nations to use greener production techniques.

As CBAM in Agile Advisors, to assist you the European Union has two tools for reducing greenhouse gas emissions: EU-ETS and CBAM. Since its implementation in 2005, the EU-ETS has been applied to specific manufacturing activities and processes within the EU. The main objective is to encourage decarbonization while stopping carbon leakage within the EU. Nevertheless, this tool must continue the flow of CO2 emissions from the EU into non-EU nations. This is the point at which, starting in October 2023, the CBAM for the import of specific commodities into EU customs territory will progressively apply. The two instruments will be connected by the price of the EU ETS certificates and have a similar structure when the CBAM is wholly deployed in 2026.The grey emissions to be considered are shown in a report that must be provided for both requirements. This report is the foundation for determining how many allowances must be purchased.