#c900

Explore tagged Tumblr posts

Text

Storm trooper. This awesome Chevrolet C8 Corvette was built by the team at Cicio Performance and is equipped with their C900x package. It’s powered by a 900+WHP Cicio-upgraded LT2 equipped with a Cicio twin turbo kit manufactured by Extreme Turbo Systems, FuelTech ECU, and Dodson Motorsports clutch. And it rides on Cicio lowering collars, Toyo Proxes R888R tires, and 19x9/20x11.5 Forgeline forged three piece AL301 wheels finished with Hampton Gold centers and Hampton Gold outers! See more at: https://www.forgeline.com/customer-gallery-cicio-performance-customer/cgk2741

🇺🇸🇺🇸🇺🇸

#forgeline#forgelinewheels#forgedwheels#customwheels#AL301#ForgelineAL301#notjustanotherprettywheel#doyourhomework#madeinUSA#chevrolet#corvette#C8#C8Corvette#cicioperformance#C900#twinturbo

32 notes

·

View notes

Text

Sewer Construction Large Diameter Gravity Flow Pipes

Linking gravity sanitary sewer pipes with Joints Calder Repair Coupling. Pipe lifted into air has two sections held together by Joints Calder Repair Coupling. Designing took into account weight on each side coupling, flow, and overall us fullness once in ground.

#c900#sdr35#vcp#trench#stormwater#sewerage#sewer repair#sewer drain#sewer#pvc pipe#wholesale waterworks#waterdistribution#waterworks#civil engineering#vitrified clay pipe#construction supply#clay pipe#corrugated#corrugated pipe

0 notes

Text

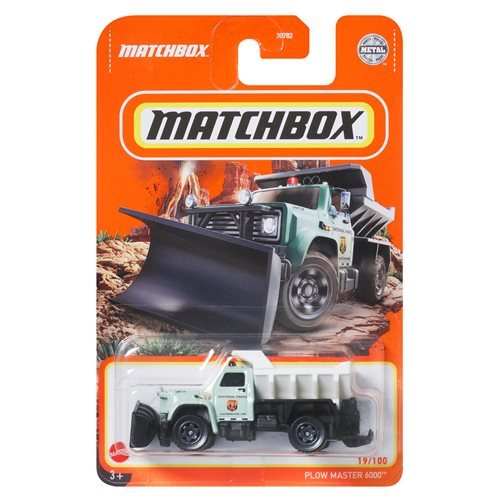

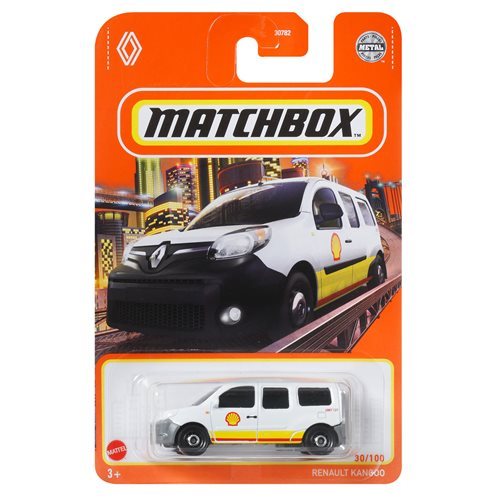

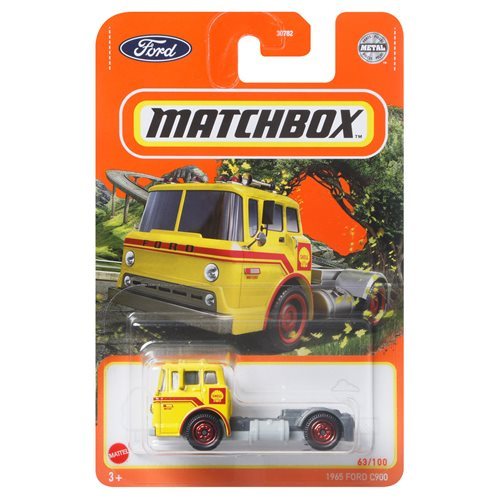

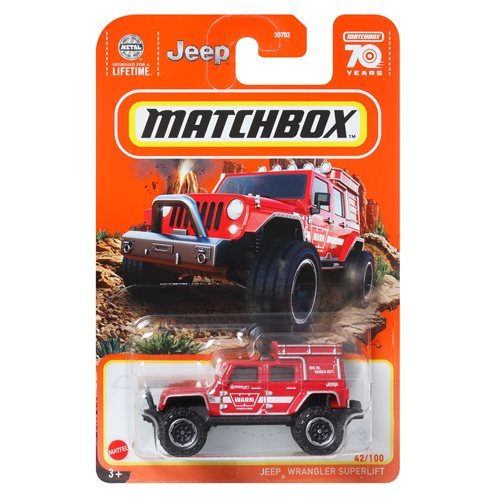

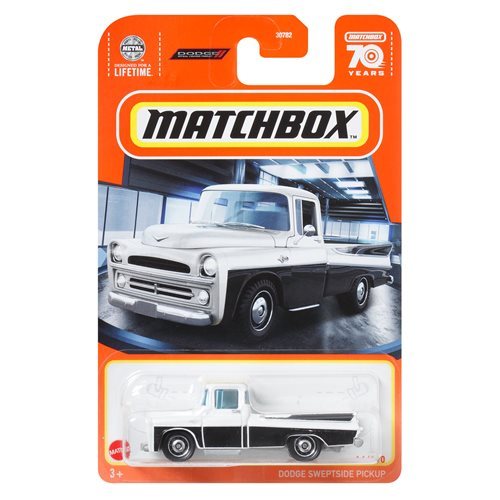

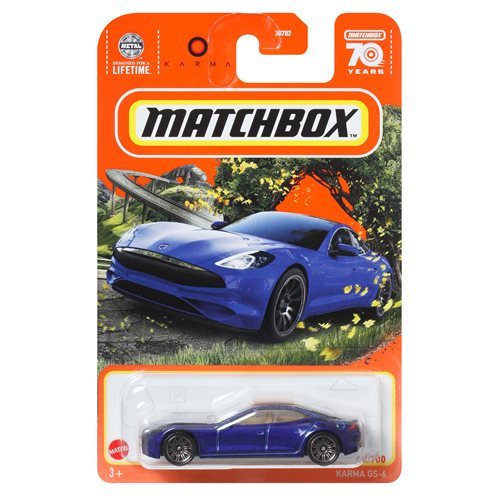

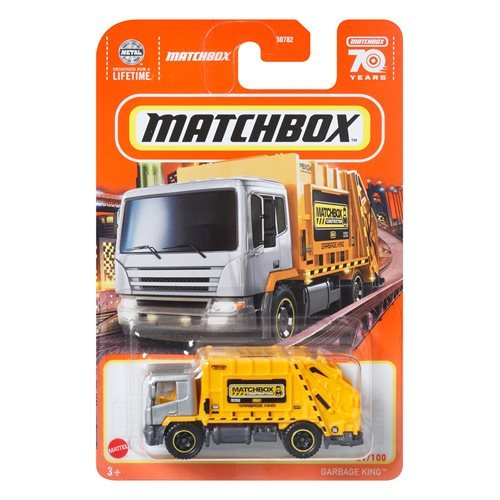

#adult collectors#adult collectibles#collectables#toys#vehicles#matchbox#diecast#mattel#card art#ford#plow master 6000#kenault kanroo#ford police interceptor#1969 ford c900#chell gas co#1976 Honda CVCC#jeep wrangler superduty#70th anniversary#dodge sweptside pickup#2021 Cadillac CT5-V#Cadillac#karma#karma GS-6#garbage king#matchbox original#national parks

3 notes

·

View notes

Note

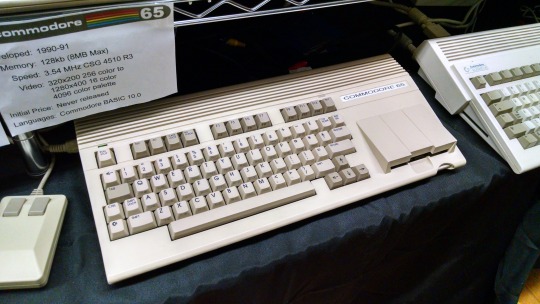

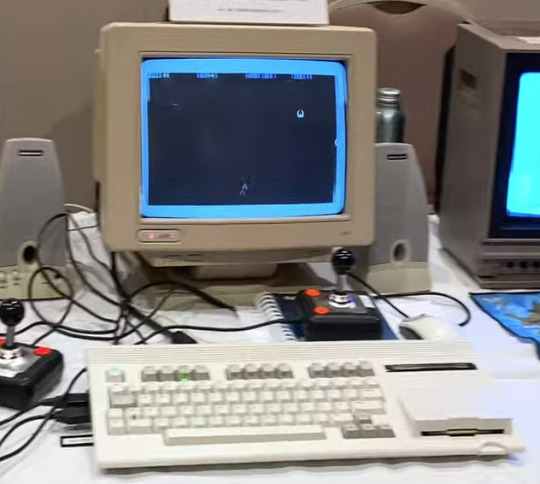

If the Commodore 64 is great, where is the Commodore 65?

It sits in the pile with the rest of history's pre-production computers that never made it. It's been awhile since I went on a Commodore 65 rant...

The successor to the C64 is the C128, arguably the pinnacle of 8-bit computers. It has 3 modes: native C128 mode with 2MHz 8502, backwards compatible C64 mode, and CP/M mode using a 4MHz Z80. Dual video output in 40-column mode with sprites plus a second output in 80-column mode. Feature-rich BASIC, built in ROM monitor, numpad, 128K of RAM, and of course a SID chip. For 1985, it was one of the last hurrahs of 8-bit computing that wasn't meant to be a budget/bargain bin option.

For the Amiga was taking center stage at Commodore -- the 16-bit age is here! And its initial market performance wasn't great, they were having a hard time selling its advanced capabilities. The Amiga platform took time to really build up momentum square in the face of the rising dominance of the IBM PC compatible. And the Amiga lost (don't tell the hardcore Amiga fanboys, they're still in denial).

However, before Commodore went bankrupt in '94, someone planned and designed another successor to the C64. It was supposed to be backwards compatible with C64, while also evolving on that lineage, moving to a CSG 4510 R3 at 3.54MHz (a fancy CMOS 6502 variant based on a subprocessor out of an Amiga serial port card). 128K of RAM (again) supposedly expandable to 1MB, 256X more colors, higher resolution, integrated 3½" floppy not unlike the 1581. Bitplane modes, DAT modes, Blitter modes -- all stuff that at one time was a big deal for rapid graphics operations, but nothing that an Amiga couldn't already do (if you're a C65 expert who isn't mad at me yet, feel free to correct me here).

The problem is that nobody wanted this.

Sure, Apple had released the IIgs in 1986, but that had both the backwards compatibility of an Apple II and a 16-bit 65C816 processor -- not some half-baked 6502 on gas station pills. Plus, by the time the C65 was in heavy development it was 1991. Way too late for the rapidly evolving landscape of the consumer computer market. It would be cancelled later that same year.

I realize that Commodore was also still selling the C64 well into 1994 when they closed up shop, but that was more of a desperation measure to keep cash flowing, even if it was way behind the curve by that point (remember, when the C64 was new it was a powerful, affordable machine for 1982). It was free money on an established product that was cheap to make, whereas the C65 would have been this new and expensive machine to produce and sell that would have been obsolete from the first day it hit store shelves. Never mind the dismal state of Commodore's marketing team post-Tramiel.

Internally, the guy working on the C65 was someone off in the corner who didn't work well with others while 3rd generation Amiga development was underway. The other engineers didn't have much faith in the idea.

The C65 has acquired a hype of "the machine that totally would have saved Commodore, guise!!!!1!11!!!111" -- saved nothing. If you want better what-if's from Commodore, you need to look to the C900 series UNIX machine, or the CLCD. Unlike those machines which only have a handful of surviving examples (like 3 or 4 CLCDs?), the C65 had several hundred, possibly as many as 2000 pre-production units made and sent out to software development houses. However many got out there, no software appears to have surfaced, and only a handful of complete examples of a C65 have entered the hands of collectors. Meaning if you have one, it's probably buggy and you have no software to run on it. Thus, what experience are you recapturing? Vaporware?

The myth of the C65 and what could have been persists nonetheless. I'm aware of 3 modern projects that have tried to take the throne from the Commodore 64, doing many things that sound similar to the Commodore 65.

The Foenix Retro Systems F256K:

The 8-Bit Guy's Commander X16

The MEGA65 (not my picture)

The last of which is an incredibly faithful open-source visual copy of the C65, where as the other projects are one-off's by dedicated individuals (and when referring to the X16, I don't mean David Murray as he's not the one doing the major design work).

I don't mean to belittle the effort people have put forth into such complicated projects, it's just not what I would have built. In 2019, I had the opportunity to meet the 8-Bit Guy and see the early X16 prototype. I didn't really see the appeal, and neither did David see the appeal of my homebrew, the Cactus.

Build your own computer, build a replica computer. I encourage you to build what you want, it can be a rewarding experience. Just remember that the C65 was probably never going to dig Commodore out of the financial hole they had dug for themselves.

262 notes

·

View notes

Text

Saint of the Day – 19 April – Saint Gerold of Saxony (c900-c978) Hermit

Saint of the Day – 19 April – Saint Gerold of Saxony (c900-c978) Hermit. … Born in in Rhaetia, in the lower part of the Alps (part of modern Austria/Switzerland) and died on 16 April 978 of natural causes in Frisun, today the Town of St Gerold. Also known as – Gerold Graziato, Gerold of Einsiedeln, Gerold of Großwalsertal, Gerold of Grosswalsertal, Gerold of Vorarlberg, Adam… Geroldus… On 1…

View On WordPress

3 notes

·

View notes

Text

PVC Pipe Installation Guide

Developed by the Uni-Bell PVC Pipe Association, this guide provides field installation instructions for gasketed joint PVC pressure pipes. Relevant standards include AWWA C900, C907, C909, ASTM D2241, and ASTM F1483. For detailed guidance, consult AWWA C605, Manual M23, or Uni-Bell’s Handbook of PVC Pipe: Design and Construction.

Uni-Bell, established in 1971, promotes PVC pipe research, technical support, and proper use. Installation advice is provided as guidance, not warranty; warranty inquiries should be directed to manufacturers.

Pipe Delivery and Inspection

Inspect pipe shipments for damage and verify quantities against the shipping list. Note damages or missing items on the bill of lading and notify the shipper. Damaged items should be set aside.

UnloadingUnload carefully using a forklift or front-end loader with forks long enough to support bundles. For manual unloading, remove one pipe at a time and block the shipment to prevent rolling.

StorageStore unit packages on level ground or individual pipes bevel-to-bell. Do not stack over eight feet high or near heat sources. Protect gaskets from heat, oil, and grease.

Installation Steps

TrenchingExcavate safely, avoiding blockage of sidewalks, drives, or utilities. Use sheeting, trench boxes, or sloped walls in hazardous areas. Ensure the pipe remains stable when moving support materials.

De-WateringKeep trenches dry during installation. Prevent floating by covering empty pipes with backfill material equal to 1.5 times the pipe’s diameter.

Field CuttingUse a handsaw or power tool to make square cuts. Bevel cut ends to match factory specifications and redraw the insertion line.

Lowering into TrenchPlace pipes gently into the trench using ropes, skids, or slings. Avoid dropping or throwing materials. Inspect for damage before assembly.

Joint Assembly

CleaningClean the gasket, bell groove, and spigot before assembly. Do not remove non-removable gaskets to avoid damage.

LubricationApply manufacturer-recommended lubricant to the spigot end and bell.

AssemblyInsert the lubricated spigot into the bell until the insertion line aligns with the bell’s edge. For large pipes, use mechanical assistance, ensuring proper depth and alignment. Over Insertion or misalignment can damage joints and reduce effectiveness.

If assembly issues arise, disassemble and inspect the gasket. Replace removable gaskets if damaged; for non-removable gaskets, cut the bell, bevel the pipe, and use a coupling. Reassemble with proper alignment and force. The bar-and-block method is recommended for controlled force application.

0 notes

Text

PVC Fittings Design and Installation Guide

This guide by the Uni-Bell PVC Pipe Association outlines the design and installation of gasketed PVC fittings for potable water, force main, pressure irrigation, and reclaimed water systems. It covers fittings for PVC pipes up to 60 inches in diameter but excludes solvent-welded and fusible PVC fittings.

Manufacturing Methods

PVC fittings are made using three methods, all with gasketed push-on joints that meet or exceed the pipe’s pressure rating.

1. Fabricated FittingsConstructed from PVC pipe meeting AWWA C900 standards, these fittings include thermoformed bends, couplings, and reinforced structures. Available sizes range from 4 to 60 inches with pressure classes equal to or greater than the connected pipe. Products include tees, bends, reducers, and adapters.

2. Injection-Molded FittingsMade per AWWA C907 by injecting PVC into molds, these fittings feature a wall thickness 25% greater than DR18 pipe and meet specific strength standards. They are available in 4 to 12 inches and Class 235 psi. Products include bends, tees, couplings, and plugs.

3. Machined CouplingsProduced using molding and fabrication, these couplings meet AWWA C900 standards and are available in sizes from 4 to 60 inches.

Compatibility with Dissimilar Materials

PVC and ductile iron (DI) pipes share the same outside diameter (CIOD/IPS), allowing for straightforward transitions. PVC spigots fit into DI bells without couplings, while DI spigots require transition couplings. Note: DI spigots should never be inserted into PVC bells due to tolerance differences. Transition couplings ensure watertight joints.

Thrust Restraint Design

Pressurized systems can develop thrust forces at fittings, size changes, and dead ends. Restraint methods include:

Internally restrained joints

External mechanical devices

Concrete thrust blocks

Properly restrained pipelines transfer thrust forces to the soil via bearing strength and pipe-soil friction. Restraint device selection depends on factors like system pressure, pipe size, fitting type, and soil properties. Long-term considerations include construction, groundwater level changes, and monitoring activities near bends.

For accurate designs, specialized software is available to calculate restrained lengths and configurations.

To know more: https://www.uni-bell.org/Portals/0/ResourceFile/guide-for-pvc-pressure-fittings.pdf

0 notes

Text

Máy xông khí dung Omron Care NE-C900 là thiết bị y tế cho người mắc bệnh hô hấp. Tốc độ xông lớn 0,4ml/ phút, kích thước hạt xông siêu nhỏ 3µm cho các hạt khí đi sâu vào phế nang. Cấu trúc 02 phần lắp ráp dễ dàng, ít tiếng ồn, có thể dùng liên tục trong nhiều giờ.

https://gigadigital.vn/suc-khoe-sac-dep/may-xong-khi-dung-omron-care-ne-c900

0 notes

Video

youtube

Máy xông khí dung nén khí NE C900 - Máy xông khí dung nén khí công suất ...

0 notes

Text

Long Term Covid Effects

Assignment for Week of 9/27

Long Term Covid Effects

As someone who has had Covid and after two years still cannot smell like I once could, I am intrigued by Long Covid. I have been to the doctors and talked about my long-term symptoms such as lack of smell, brain fog, and fatigue. Often I think the brain fog and fatigue could be due to getting older the loss of smell makes me wonder. But answers are not easy to come by.

According to the CDC:

DEFINITION - Long COVID

“Some people who have been infected with the virus that causes COVID-19 can experience long-term effects from their infection, known as Long COVID or Post-COVID Conditions (PCC). Long COVID is broadly defined as signs, symptoms, and conditions that continue or develop after acute COVID-19 infection. This definition of Long COVID was developed by the Department of Health and Human Services (HHS) in collaboration with CDC and other partners.

People call Long COVID by many names, including Post-COVID Conditions, long-haul COVID, post-acute COVID-19, long-term effects of COVID, and chronic COVID. The term post-acute sequelae of SARS CoV-2 infection (PASC) is also used to refer to a subset of Long COVID.”

The Total Engagement for Facebook on Buzzsumo for the below article is 3.5K, which is significant. I think a lot of people are dealing with Long Covid.

https://www.wusa9.com/article/news/verify/covid-19-long-term-effects-symptom-list-vaccine-side-effects-latest-2021-info-when-do-side-effects-of-covid-begin-how-long-do-covid-symptoms-last/65-a2d4c8f8-c900-4c9c-bec9-5121344b92e5, wusa9.com has an article on Life after COVID: How the virus left two formerly active women barely able to leave the couch even months later.

Several sources are used in this article. See below:

Dr. Walter Koroshetz, Director of the National Institute of Neurological Disorders & Strokes

Dr. David Putrino, Director of Rehabilitation Innovation at Mount Sinai Health System

Dr. Greg Vanichkachorn, Division of Preventive, Occupational, and Aerospace Medicine at Mayo Clinic

Dr. Tae Chung, Assistant Professor of Physical Medicine and Rehabilitation at Johns Hopkins Medicine

Michaelene Carlton, a long-hauler COVID patient

Keri Kae Gebo, a long-hauler COVID patient

Watching the videos of these women who still suffer so much for Long Covid is disturbing.

Several doctors estimate at least 10% of all COVID patients are battling Post-Acute COVID Syndrome (PACS).

https://www.cnn.com/2020/10/06/health/covid-recovery-what-we-know-wellness/index.html - cnn.com also talks about Covid-19 and its long-term effects.

“Some symptoms might linger:

People who get mild or moderate Covid-19 are told to isolate and can leave about 10 days after symptoms first appear if it has been 24 hours since they last had a fever (without the use of fever reducing medicine), the CDC says.

But some symptoms can persist beyond that 10-day window.

“Loss of taste and smell may persist for weeks or months after recovery and need not delay the end of isolation,” the agency adds.

Fatigue, coughing and headaches are other symptoms that can often be difficult to shake.”

It appears the CDC and other organizations, as well as medical professionals are still trying to figure out how to treat Long COVID.

0 notes

Text

Flexible Rubber Coupling linking two 33 inch (838 mm) pipes. Large diameter flexible rubber couplings available for many sized pipes

#c900#sdr35#vcp#trench#stormwater#sewerage#sewer repair#sewer drain#sewer#pvc pipe#civil engineering#concrete pipe#public utility#wholesale waterworks#waterdistribution#waterworks#construction supply

0 notes

Video

youtube

Je vous présente ma dernière chanson, PORTANT LE DEUIL DE MON ENFANCE, en 3 épisodes :3/3 : paroles & musique ! Merci de soutenir cette chanson en la likant, commentant, partageant autour de vous. À écouter sur :- Spotify : https://open.spotify.com/intl-fr/album/7xVPH0W2v9jscvbaVwvQjQ?si=p4B_Vj-TRf6DycDMqA8X1w- Deezer : https://deezer.page.link/hFpMc39qJKVojMcU9- Apple/Itunes : https://music.apple.com/fr/album/portant-le-deuil-de-mon-enfance-single/1697042065- Amazon Music : https://music.amazon.fr/albums/B0CBNLT4J9?ref=dm_sh_4ea1-25a6-abd3-c900-a0a51PORTANT LE DEUIL DE MON ENFANCEPortant le deuil de mon enfance Le coeur sombre revêtu de noirPoursuivant ma route dans l'errance Je hais mon reflet dans le miroirRegrets éternels à celui Que je fus des années plus tôtSouvenir des limbes de l'oubli Reclus dans mon âme ce cachotPassé de vie à trépas Aujourd'hui je le pleureLe môme que j'étais ici-bas Laissant sa place à la douleurL'adulte que je suis devenu Ayant quitté sa chrysalideDéplore en vain le disparu En ma chair sentiment de videLa date du décès je l'ignore Aucune prière ni enterrementAu crépuscule le réconfort Car dans mes rêves il est présentPossible résurrection future A l'âge de la sénilitéEnfant dans un corps pourriture Triste retour à l'état premierRésigné à cette longue attente L'adulte en moi se déraisonneRecherchant les substances grisantes Détruire le soi, futile personneFrançois VilleBatterie : Fabrice FosseMixage : Jean-Yves GuiléMastering : Master Lab Systems#chanson #chansonFrancaise #rock #poème #poesie #poete #enfant #enfance #deuil #mort #douleur #streamingYoutube : https://youtu.be/6uD5NkkS5VQ

0 notes

Text

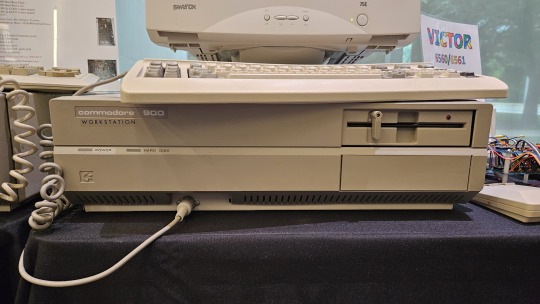

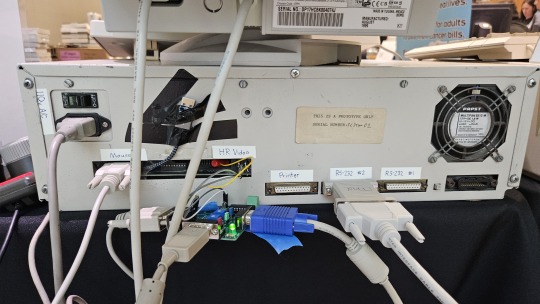

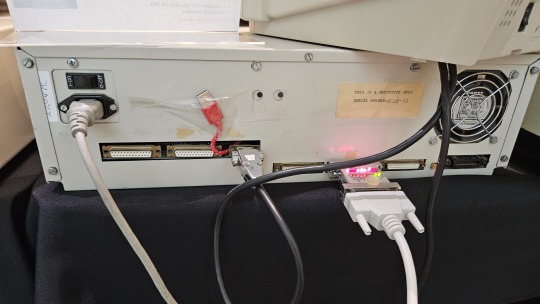

Two examples of the Commodore 900, also known as the C900, Z8000, or Z-Machine. Intended to run a Convergent UNIX, these machines never made it into production. What remain are a few engineering prototypes distributed for software development, so seeing not just one, but TWO is a real treat! - VCF Southwest 2023

#vcfsw2023#vcf southwest 2023#vintage computer festival southwest 2023#commodorez goes to vcfsw2023#commodore 900#commodore#convergent unix#commodore z8000

381 notes

·

View notes

Text

How Do I know The Pleatco PA90 Pool Filter Replacement Really Fit My Swimming Pool?

ICEPURE's Pleatco PA90 pool filter replacement is adapted to a wide range of pool models. Like Hayward CX900RE, C900, C9002, PA90, Unicel C-8409, Clearwater II Pro Clean 100 and, so on. You can confirm the model number by following these steps: If you already know your filter cartridge's part number or the replacement number, you can use search the part number on our product page to quickly confirm whether the filter is compatible. If you do not know the replacement part number for your cartridge, then choosing the right cartridge can be accomplished by measuring your existing one. Use the following steps as a guide: Measure the outside diameter of the cartridge in inches (+/- 1/16). Measure cartridge length from end cap to end cap (+/- 1/16). Exclude any handles or extensions. Identify the correct top and bottom types. If the top and/or bottom are open, measure the inside diameter of the opening (+/- 1/16th inch). If the end cap is closed make note of its identifying features (i.e. “Handle”, “Cone”, etc.). Make note of the manufacturer and model number of the filter into which the replacement cartridge will be installed. Take note of whether or not there is a center core (PVC pipe in the center). Assuming that you are still not sure about the fit, please contact us immediately. ICEPURE's professional team will help you solve your queries for the first time. We want everyone to be able to swim freely in clean water.

0 notes

Text

Molecularly Oriented Polyvinyl Chloride PVCO

PVCO pipe, which stands for molecularly oriented polyvinyl chloride pipe, has been utilized in North America for over four decades, boasting an impressive track record with more than 20,000 miles of pipe installed. Similarities between PVCO and traditional polyvinyl chloride (PVC) pipe exist, including shared ingredients and cell classifications. Initially, PVCO begins as an equivalent PVC compound, undergoing extrusion into PVC pipe before undergoing physical modification to transform into molecularly oriented pipe. Consequently, both PVCO and PVC pipes qualify for cell class 12454 per ASTM D1784 and boast a hydrostatic design basis (HDB) of 4,000 psi. The manufacturing process for PVCO involves realigning the molecular structure from random orientation to circumferential orientation, thereby enhancing the material's mechanical strength and toughness.

Once completed, PVCO pipe achieves an impressive HDB of 7,100 psi. Due to the differing HDB values of PVCO, conventional PVC's dimension ratio (DR) classification is not applicable, with PVCO being solely referenced by pressure class (PC) or pressure rating (PR). In North America, Cast Iron Outside Diameter (CIOD) products range from 4 inches to 30 inches in pressure classes 165, 235, and 305 psi, while Iron Pipe Size (IPS) products are available in sizes ranging from 4 inches to 16 inches with pressure ratings of 160, 200, and 250 psi.

PVCO and PVC find common application in distribution systems requiring open-cut installations, with PVC additionally suitable for trenchless installations. The inaugural North American installation of PVCO pipe transpired in Kansas in 1979, following its development in Europe during the early 1970s and first installation there in 1974. By the 2000s, multiple manufacturers offered PVCO pipe in North America. ASTM F1483, published in 1993, marked the initial product standard for PVCO pipe. Early applications predominantly focused on rural water and irrigation piping. Subsequently, in 1998, AWWA C909 emerged as the first PVCO municipal water pipe standard, drawing from AWWA C900 in terms of requirements, safety factors, diameter regimen, product quality control testing, and joint qualification testing. Over the years, AWWA C909 has undergone updates to encompass larger sizes and align with revised design procedures from the C900 standard. In 2009, CSA published PVCO standard B137.3.1, further solidifying the standing of PVCO pipe within the industry.

0 notes