#butterfly valve manufacturer in china

Explore tagged Tumblr posts

Text

Butterfly Valve vs Ball Valve: Comparison Guide

Butterfly Valve vs. Ball Valve: How to Choose the Right One for Your Application

When selecting valves for industrial systems, engineers and procurement managers often face a common dilemma: butterfly valve vs. ball valve. Both valves are widely used across industries, but their structural designs, performance characteristics, and cost implications differ significantly. As a leading valve manufacturer in China, we break down the key factors—structure, size, price, application suitability, and future trends—to help you make an informed decision.

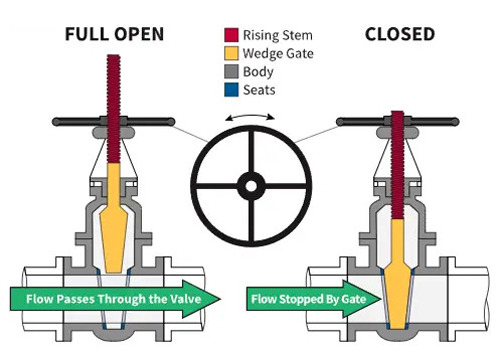

1. Structural Differences: Simplicity vs. Precision

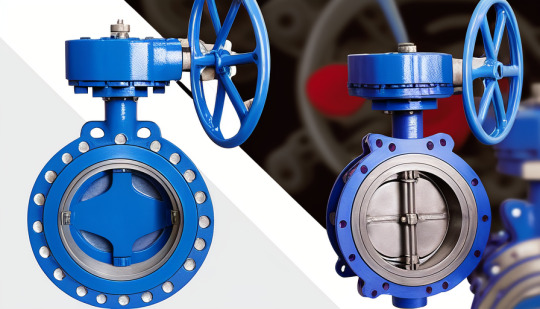

A butterfly valve features a disc mounted on a rotating shaft. When open, the disc aligns with the flow direction; when closed, it rotates 90° to block the medium. Its simple design makes it lightweight, compact, and easy to install. However, the disc’s presence in the flow path can create turbulence, making it less ideal for high-precision throttling.

Ball Valve Structure:

A ball valve uses a perforated, rotating sphere to control flow. When open, the hole aligns with the pipeline, offering minimal flow resistance. When closed, the sphere rotates to block the medium completely. The full-bore design of many ball valves ensures smooth flow with minimal pressure drop, making them excellent for precise shut-off applications.

Key Takeaway: Butterfly valves are simpler and lighter, while ball valves provide tighter sealing and better flow control.

2. Size and Installation Considerations

Butterfly Valves:

- Ideal for large-diameter pipelines (2” to 48” or more). Their compact design requires less space, reducing installation costs.

- Commonly used in water treatment, HVAC systems, and low-pressure chemical applications.

Ball Valves:

- Best suited for small to medium-sized pipelines (0.5” to 12”).

- Preferred in high-pressure systems like oil and gas, where leak-tight sealing is critical.

*Pro Tip*: For large-scale projects requiring cost-effective solutions, Chinese valve manufacturers often recommend butterfly valves due to their scalability and lower material costs.

3. Price Comparison: Balancing Budget and Performance

Butterfly Valve Price:

- Generally 30–50% cheaper than ball valves of the same size. - Lower manufacturing costs (fewer components) and reduced maintenance expenses make them budget-friendly for large installations.

Ball Valve Price:

- Higher initial cost due to complex machining and premium materials (e.g., stainless steel, brass). - Long-term savings in high-pressure systems due to durability and minimal leakage risks.

*Insight*: Sourcing from a reliable valve supplier in China can help mitigate costs without compromising quality.

4. Application-Based Selection Guidelines

Choose a Butterfly Valve If:

- Your system operates at low to moderate pressures (up to 150 psi).

- You need quick operation (quarter-turn actuation) for throttling or isolation.

- Space or weight constraints exist (e.g., shipbuilding, irrigation systems).

Choose a Ball Valve If:

- Your application demands zero leakage (e.g., natural gas pipelines).

- You require precise flow control or handling of viscous fluids.

- The system operates under high pressure or extreme temperatures.

Industry Examples:

- Butterfly valves dominate in water distribution and food processing.

- Ball valves are standard in oil refineries, pharmaceutical plants, and steam systems.

5. Future Trends: Market Demand and Innovations

Butterfly Valves:

- Rising demand in water conservation and renewable energy projects (e.g., solar thermal plants).

- Advancements in polymer-coated discs improve chemical resistance, expanding their use in corrosive environments.

Ball Valves:

- Growing adoption in LNG and hydrogen energy systems, driven by stricter emission regulations.

- Smart valves with IoT sensors are gaining traction, enabling predictive maintenance.

*China’s Role*: As the world’s largest valve manufacturer, China continues to lead in cost-effective production and R&D, making both butterfly and ball valves more accessible globally.

Conclusion: Partner with the Right Manufacturer

Understanding the differences between butterfly and ball valves ensures optimal system performance and cost efficiency. For large-scale, low-pressure applications, butterfly valves offer unmatched affordability. For high-pressure, precision-critical systems, ball valves are worth the investment.

When sourcing, collaborate with a trusted valve manufacturer in China to leverage competitive pricing, customization options, and adherence to international standards. Whether you prioritize price, durability, or innovation, the right choice depends on your specific operational needs.

By evaluating structure, size, cost, and future trends, you can select the valve that maximizes ROI and longevity for your project.

#ball valve manufacturers in india#ball valve suppliers#ball valve#butterfly valve#butterfly valve suppliers#butterfly valve manufacturer in china#ball valve manufacturer in china

0 notes

Text

Seeking a High-Performance Casting Butterfly Valve? Hengke Casting Delivers.

Hengke Casting Ltd. is a leading manufacturer and exporter of casting butterfly valves, specializing in precision investment casting for exceptional quality and performance. We offer a comprehensive range of valves for various industries, from automotive and shipbuilding to construction, medical equipment, and food machinery.

1 note

·

View note

Text

Valves Market is Estimated to Witness High Growth

Valves Market is Estimated to Witness High Growth Owing to Rising Constructional and Infrastructure Development Activities The valves market comprises products such as gate valves, globe valves, check valves, butterfly valves, ball valves and pressure regulating valves which are used to control the flow, pressure and direction of fluids. Valves are extensively used in power plants, refineries, oil & gas, water & wastewater and construction activities. These products play a key role in fluid transportation and management which makes them an integral component across various industrial sectors. Rising infrastructure development projects across both developed and developing nations are augmenting the demand for valves. Moreover, growing pipeline networks for oil & gas transportation is also favoring market growth. The Global valves market is estimated to be valued at US$ 83 Mn in 2024 and is expected to exhibit a CAGR of 3.5% over the forecast period 2024 To 2031. Key Takeaways Key players operating in the valves market are Tyson Foods, Inc., JBS S.A., Pilgrim's Pride Corporation, Wens Foodstuff Group Co. Ltd., BRF S.A., Perdue Farms, Sanderson Farms, Baiada Poultry, Bates Turkey Farm, and Amrit Group. The major players are focusing on capacity expansion plans and mergers & acquisitions to gain market share. Rising population and changing diets are expected to fuel the growth of the poultry sector which presents significant opportunities for valve manufacturers. With the growing poultry industry, demand for processing equipment including valves is also projected to rise substantially over the forecast period. The global valves market is estimated to witness growth across key regions such as North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. This can be attributed to surging investments in oil & gas, water & wastewater infrastructure, and industrial development projects worldwide. Emerging economies with high urbanization rates like China and India also offer lucrative prospects for market expansion. Market Drivers The key driver behind the Valves Market Demand is the increasing constructional and infrastructure development activities worldwide. There is huge government focus as well as private investments toward projects such as roadways, railways, metro stations, power generation, water supply, etc. which involves extensive use of valves in various process applications. Further, the rising need for energy and growing focus on rural electrification has boosted investments in power transmission and distribution sector augmenting valves demand.

PEST Analysis

Political: The valves market is regulated by laws pertaining to safety, environmental protection and quality standards. New regulations regarding emissions could impact demand patterns. Economic: Changes in the global and regional economic conditions directly impact spending on industries like oil & gas, energy & power, and water & wastewater management which influences Valves demand. Social: Growing population and urbanization is increasing requirements for water, energy and other infrastructure development which boost the usage of valves. Technological: Advancements in materials and designs of valves are improving efficiency, lowering costs and enabling usage in newer applications. Digitalization is also aiding remote monitoring of industrial valves. The regions concentrating maximum valves market share in terms of Valves Market Size and Trends include North America, Europe and Asia Pacific. North America accounts for a major portion owing to strong presence of end-use industries like oil & gas and significant infrastructure spending. Europe and Asia Pacific are also sizable markets led by Germany, China, India respectively. The fastest growing regional market for valves is expected to be Asia Pacific led by increasing investments in water & wastewater management, power projects and industrial activities in China and India. Rising standards of living and initiatives to improve urban infrastructure will further drive the demand across developing nations in the region.

Get more insights Valves Market

Discover the Report for More Insights, Tailored to Your Language.

French German Italian Russian Japanese Chinese Korean Portuguese

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#Coherent Market Insights#Valves Market#Control Valves#Globe Valves#Plug Valves#Gate Valves#Ball Valves#Butterfly Valves

2 notes

·

View notes

Text

Global Api Gate Valves Market Insights and Expansion Forecasts 2024 - 2031

The global API (American Petroleum Institute) gate valves market is an essential component of the oil and gas industry, facilitating the safe and efficient flow of fluids in various applications. This article explores the key aspects of the API gate valves market, including drivers, challenges, regional insights, and future trends.

Overview of the API Gate Valves Market

API gate valves are designed to provide a straight-line flow of fluid with minimal restriction and are primarily used for on/off service. These valves are critical in maintaining the integrity of pipelines, tanks, and other equipment in industries such as oil and gas, petrochemicals, and water treatment.

The global API gate valves market is poised for growth, driven by increasing demand in the oil and gas sector, infrastructure development, and technological advancements. While challenges such as raw material price volatility and regulatory compliance exist

Market Definition and Segmentation

The API gate valves market can be segmented based on:

Type: Wedge gate valves, parallel gate valves, and others.

Material: Cast iron, stainless steel, carbon steel, and others.

Application: Oil and gas, chemical processing, water treatment, and power generation.

Region: North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

Key Market Drivers

1. Growing Demand for Oil and Gas

The increasing demand for oil and gas globally is a significant driver for the API gate valves market. As exploration and production activities expand, the need for reliable flow control solutions becomes critical.

2. Infrastructure Development

Ongoing infrastructure projects in various sectors, including oil and gas, water treatment, and chemical processing, are driving the demand for API gate valves. These projects require high-quality valves to ensure operational efficiency and safety.

3. Technological Advancements

Advancements in valve technology, such as improved designs and materials, enhance the performance and lifespan of API gate valves. Innovations in automation and smart technologies also contribute to increased adoption.

Challenges Facing the Market

1. Price Volatility of Raw Materials

The prices of raw materials, particularly metals, can fluctuate significantly, impacting the production costs of API gate valves. This volatility can affect profit margins for manufacturers and may lead to price increases for end-users.

2. Competition from Alternative Valve Types

The API gate valves market faces competition from other types of valves, such as ball valves and butterfly valves, which may offer advantages in specific applications. This competition can impact market share and growth.

3. Regulatory Compliance

Manufacturers must comply with stringent industry regulations and standards regarding safety and performance. Ensuring compliance can increase operational costs and complexity for valve producers.

Regional Analysis

North America

North America is a prominent market for API gate valves, driven by a well-established oil and gas industry. The U.S. and Canada are major contributors, with ongoing investments in exploration and production activities supporting market growth.

Europe

In Europe, the API gate valves market is growing, supported by stringent regulations regarding safety and environmental standards. Countries like Germany, the UK, and Norway are key markets, with a focus on upgrading aging infrastructure.

Asia-Pacific

The Asia-Pacific region is witnessing significant growth in the API gate valves market, fueled by rapid industrialization and increasing energy demands. Countries like China and India are emerging as major markets, with substantial investments in oil and gas exploration.

Future Outlook

The global API gate valves market is expected to experience steady growth in the coming years. Key trends influencing the market include:

Increased Focus on Sustainability: The growing emphasis on sustainability and environmental protection is prompting manufacturers to develop eco-friendly valves that minimize leakage and emissions.

Integration of Smart Technologies: The adoption of IoT and smart technologies in valve systems is expected to enhance operational efficiency and monitoring capabilities, making API gate valves more attractive to users.

Rising Investments in Renewable Energy: As the energy landscape shifts towards renewable sources, API gate valves will also find applications in new sectors, broadening their market potential.

Conclusion

The global API gate valves market is poised for growth, driven by increasing demand in the oil and gas sector, infrastructure development, and technological advancements. While challenges such as raw material price volatility and regulatory compliance exist, the market's future outlook remains positive. As industries continue to seek reliable and efficient flow control solutions, API gate valves will play a crucial role in ensuring operational safety and efficiency across various applications.

#Global Api Gate Valves Market Size#Global Api Gate Valves Market Trend#Global Api Gate Valves Market Growth

0 notes

Text

BR.W71F Series Lined Butterfly Valves

Purpose and features:

The BR.W71F series fluorine/rubber lined butterfly valve is a simple, easy to operate, long service life, and lightweight control valve that can be used for on-off or adjustment purposes. It is suitable for controlling gases, liquids, slurries, solid powders, and other fluids in industries such as chemical, pharmaceutical, food, papermaking, and water treatment;

Features:

1. The BR. W71F series fluorine/rubber lined butterfly valve can resist corrosion from almost all chemical substances (including concentrated sulfuric acid and aqua regia);

2. Fully sealed construction, meeting zero leakage requirements;

3. Small size, light weight, easy to disassemble and repair, and easy to operate;

4. Widely used for regulating or cutting off highly corrosive media such as acids, alkalis, and salt solution.

0 notes

Text

Fire Safety Valves Market Analysis Report, Growth, Share by 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Fire Safety Valves Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Fire Safety Valves Market Research share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Fire Safety Valves Market?

The global fire safety valves market size reached US$ 5.4 billion in 2023. Looking forward, Reports and Insights expects the market to reach US$ 7.8 billion in 2032, exhibiting a growth rate (CAGR) of 4.2% during 2024-2032.

What are Fire Safety Valves?

Fire safety valves are valves specifically created to manage the flow of water or other fire-extinguishing agents in fire protection systems. These valves are crucial in fire sprinkler systems, standpipe systems, and fire hydrants, ensuring that water is distributed to extinguish fires in a controlled and efficient manner. Typically crafted from robust materials like brass or stainless steel, fire safety valves are designed to endure high temperatures and harsh conditions. They play a vital role in containing fires and safeguarding lives and property during fire emergencies.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1948

What are the growth prospects and trends in the Fire Safety Valves industry?

The fire safety valves market growth is driven by various factors. The fire safety valves market is witnessing significant growth, propelled by stringent fire safety regulations and increasing emphasis on protecting life and property from fire hazards. These valves are crucial components in fire protection systems such as sprinklers, standpipes, and hydrants, ensuring the controlled flow of water or other extinguishing agents. Key drivers include the rising adoption of automated fire protection systems, technological advancements in valve design, and growing demand for fire safety equipment in both commercial and residential buildings. Moreover, the introduction of innovative fire safety valves offering enhanced performance and reliability is anticipated to drive further market growth. Hence, all these factors contribute to fire safety valves market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Valve Type:

Ball Valves

Gate Valves

Butterfly Valves

Check Valves

Others

By Application:

Commercial Buildings

Industrial Facilities

Residential Buildings

Oil and Gas

Power Generation

Others

By End-Use Industry:

Oil and Gas

Chemical and Petrochemical

Power Generation

Construction

Automotive

Others

Market Segmentation By Region:

North America

United States

Canada

Europe

Germany

United Kingdom

France

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Who are the key players operating in the industry?

The report covers the major market players including:

Honeywell International Inc.

Tyco International Ltd.

Emerson Electric Co.

Johnson Controls International plc

Siemens AG

Victaulic Company

Cla-Val

AGF Manufacturing Inc.

Potter Electric Signal Company LLC

Pentair plc

Viking Group Inc.

Mueller Co.

Apollo Valves

Zurn Industries, LLC

Watts Water Technologies, Inc.

View Full Report: https://www.reportsandinsights.com/report/Fire Safety Valves-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

China Manufacturer valve R901017025 for steam turbine

"China Manufacturer valve R901017025 for steam turbine Selection of advanced technology, absolutely first-class service quality, YOYIK over the years to the same faith. The main technical backbone are retired senior engineer, senior mechanic. Many of them have participated in the planning, production and installation of power stations such as Gezhouba, Ertan and Three Gorges, and provided high-quality equipment selection, construction planning, installation and dispensing of hundreds of hydropower stations and overhaul of thermal power plants. , After-sales service and other train services.

Yoyik can offer many spare parts for power plants as below:

DF-valve R901017025-DF

electric oil transfer pump DLZB820-R64A-8 pressure hose SMS-12/20-1219mm-C sliding vane pump F3-317667 pump screw ACF-090N5 ITBP hydraulic vane pump F3-V20-1S8S-1C11 relief valve 1LOF-98H hydraulic motor 25LY-36 Check valve (clip type) 216C40 vacuum filter P-1759 piston pumps PV29 2R50 000 chemical pump centrifugal DFB80-50-220 Oil Pump Coupling Cushion KG70KY/7.5K5 reciprocating piston pump PVH074R01AA(AB)10A250000002001AB0 screw pump diagram PACG070K7NVB mechanic seal water pump 125-80-250 vacum pump air vacuum KZ/100WS sealing ring HB4-56J8-22 Fast return solenoid valve DF1-3 Dg-40 220VDC screw pump diagram HSNH4400Z-46NZ Check valve XYZ-16G balance diaphragm KC50P-97 Globe valve J941H-16C screw pump diagram ACG070-K7NVBP piston pumps PVT38-2R5C-C03-S00 vaccum pump P-1931A HYDROGEN DRYER COMPRESSOR 300FS1/2-F screw pump working HSNH80-27 pump mechanical seal BF108-45u pressure hose S110-AC-FC-0250 transfer oil pump SDSN65-100X2A wet solenoid directional valve 4WE10D3X/CG220NZ4 PTFE Lined Butterfly Valve 100DSF4PB3-16-100 BFP low pressure accumulator skin NXQAB-100/-10-L Fluoro Rubber O-Ring OR0030034 rotary vacuum pump P-1264 vacuum pump 223v 30-SPEN valve R901017025

vacuum pump vane F3-SDV20-1P11P-1A Servo valve G772 K240A electric oil pump 50IY50A pump vacuum 125LY-43BH DIRECTIONAL CONTOL VALVE T22BH-B6H gasket 03506-350/357/479 part no.:92 mechanical seal parts BKM79.4143B solenoid valve EVSI-DN25 BFP steam turbine governing and safety actuator YGM239 pressure hose SMS-10-1524-C liquid ring vacuum pump HSN280-43NZ piston hydraulic pump MOOG0514 7005 37 servo valve stem GU/3832-01 metering piston pump A3H37-F-R-01KK-10 mechanical seal for water pump FIJ125-100-315 bellows globe valve WJ50F1.6P Governor O-ring DH00.009 flexible shaft coupling A10VS0100DR/32R-VPB12N00 vacuum pump 220v MO1225OBGCC15A water pump DFB125-80-260 rotary vacuum pump ZS-185 burgmann mechanical seal 104-45 butterfly valve K125DSF4PB3 O-ring C8689085 electric motor centrifugal water pump DFB100-65-260-03 EH oil pump cushion PVH098R01AD30A250000002001AB010A mechanical seal 55 mm FIJ125-100-315 transfer pump fuel YW50-32-250A water pump DFB100-65-230 centrifugal pump DFB125-80-300 Industrial pump 8SH-6 solenoid valve 4WE6D62/EW220NZ5L hydraulic pump repair 125LY-35-4B multistage centrifugal pumps YCZ50-250B valve body ring 50-250C high pressure piston pump PVH141R13AF30A230000002001AB01A valve R901017025

DFYLSYC-2024-7-8-A

"

0 notes

Text

What is A Shut Off Valve: A Guide to Safeguarding Plumbing

A shut off valve is a critical component in piping systems designed to control the flow of liquids or gases. By opening, closing, or partially obstructing pathways, these valves ensure safety, regulate pressure, and prevent leaks. Whether in residential plumbing, industrial processes, or oil and gas pipelines, shut off valves are indispensable for system efficiency and emergency management.

Types of Shut Off Valves

Shut off valves come in various designs, each suited for specific applications. Here are the most common types:

Ball Valve

A ball valve uses a rotating ball with a bore to control flow. It offers quick shut-off, durability, and minimal pressure drop. Ideal for water, gas, and oil systems.

Gate Valve

Gate valves feature a wedge-shaped gate that lifts to allow flow. They’re best for on/off control in low-frequency applications, such as water supply lines.

Globe Valve

Known for precise flow regulation, globe valves use a disc and seat mechanism. Common in HVAC systems and fuel pipelines.

Butterfly Valve

A compact, lightweight valve with a rotating disc. Butterfly valves excel in large-scale water treatment and fire protection systems.

Check Valve

Allows flow in one direction only, preventing backflow. Used in sewage systems and pump discharge lines.

Diaphragm Valve

Utilizes a flexible diaphragm to isolate flow. Ideal for corrosive or slurry fluids in chemical processing.

Needle Valve

Designed for precise flow control with a tapered needle-like plunger. Common in instrumentation and hydraulic systems.

ESDV (Emergency Shutdown Valve)

A specialized valve for rapid closure during emergencies, often automated. Critical in oil refineries and gas pipelines.

Uses of Shut Off Valves

Shut off valves serve diverse roles across industries:

- Residential: Isolate water supply during repairs (e.g., ball valves under sinks). - Industrial: Regulate steam, chemicals, or fuels (globe valves, diaphragm valves). - Oil & Gas: Ensure safety with ESDVs during leaks or pressure surges. - Fire Protection: Butterfly valves enable rapid water flow control in sprinkler systems. - Pharmaceuticals: Needle valves maintain precision in fluid handling.

How Do Shut Off Valves Work

The operating mechanism varies by type but follows a general principle:

1. Actuation: Valves are operated manually (handwheel, lever) or automatically (electric/pneumatic actuators).

2. Flow Control:

– Ball/Butterfly Valves: Rotate 90° to open/close. – Gate/Globe Valves: Linear motion raises/lowers the gate or disc. – Check Valves: Rely on flow pressure to open/close.

3. Sealing: Tight seals (rubber, PTFE) prevent leaks when closed.

Choosing the Right Valve

Selecting a shut off valve depends on factors like:

- Fluid Type: Corrosive fluids demand diaphragm valves; gases suit ball valves. - Pressure/Temperature: High-pressure systems require robust ESDVs or gate valves. - Frequency of Use: Ball valves last longer in high-cycle applications.

Conclusion

From ESDVs in hazardous environments to simple ball valves in homes, shut off valves are the backbone of fluid control systems. Understanding their types, uses, and mechanics ensures optimal performance and safety. Regular maintenance and correct valve selection further enhance system longevity.

#ball valve manufacturers in india#ball valve suppliers#china ball valve#china valve manufacturer#valve manufacturer#valve factory#valve price#shut off valve#gate valve#butterfly valve#esdv

1 note

·

View note

Text

Male Thread Nickel Plated Brass Butterfly Ball Valve

The ball valve in the pipeline is mainly used to cut off, distribute, and change the flow direction of the medium, it only needs to rotate 90 degrees of operation and a small rotational moment to close tight.

0 notes

Text

Russia Industrial Valve Market 2030 Business Insights with Key Trend Analysis

An essential component of the nation's industrial infrastructure is the Russian industrial valve market. Valves are essential for managing the flow of gases and liquids in a variety of industries, such as manufacturing, petrochemicals, oil and gas, and power production. The expansion of these industries as well as the requirement to update and modernize current facilities have an impact on Russia's need for industrial valves.

The rise in investments in industrial projects and infrastructure development has led to a steady growth in the Russian valve industry in recent years. Russia's energy sector has been a major driver of valve demand due to its large supplies of gas and oil.

In order to capitalize on the rising demand, international businesses have also recognized the potential of the Russian valve market and have partnered or entered into joint ventures with regional producers. The market does face certain difficulties, though, such as the requirement to adhere to international quality standards and complicated regulations.

Get Full PDF Sample Copy of Report:

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Leading players involved in the Russia Industrial Valve Market include:

PTPA (Russia), TMK (Russia), Zhejiang Mofeng Valve (China), Nemak (Mexico), Severstal (Russia), Evraz (Russia), Mechel (Russia), Pipe Metallurgical Company (Russia), Tube-Roll (Russia), Metallurgica Ural (Russia), Mechanical Engineering Plant (Russia), Voskhod (Russia), Krasny Kotelshchik (Russia), Krasnoyarsk Pipe Plant (Russia), Severstal-Metiz (Russia), Cherepovets Pipe Plant (Russia), TMK-Izhora (Russia), MMK-Armco (Russia), Severstal-Auto (Russia), TMK-Resurs (Russia) and other major key players.

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

If You Have Any Query Russia Industrial Valve Market Report, Visit:

Segmentation of Russia Industrial Valve Market:

By Type

Ball

Globe

Gate

Butterfly

Plug

Check

By Material

Steel

Brass

Bronze

Cast Iron

Plastic

By Size

< 1”

1”–6”

6”–25”

25”–50”

50”

By Application

Oil & Gas

Power

Energy

Chemical

Water & Waste Treatment

By Function

On/Off

Control

Isolation

Special Purpose

Highlights from the report:

Market Study: It includes key market segments, key manufacturers covered, product range offered in the years considered, Global Russia Industrial Valve Market, and research objectives. It also covers segmentation study provided in the report based on product type and application.

Market Executive Summary: This section highlights key studies, market growth rates, competitive landscape, market drivers, trends, and issues in addition to macro indicators.

Market Production by Region: The report provides data related to imports and exports, revenue, production and key players of all the studied regional markets are covered in this section.

Russia Industrial Valve Market Profiles of Top Key Competitors: Analysis of each profiled Roll Hardness Tester market player is detailed in this section. This segment also provides SWOT analysis of individual players, products, production, value, capacity, and other important factors.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

About Us:

We are technocratic market research and consulting company that provides comprehensive and data-driven market insights. We hold the expertise in demand analysis and estimation of multidomain industries with encyclopedic competitive and landscape analysis. Also, our in-depth macro-economic analysis gives a bird's eye view of a market to our esteemed client. Our team at Pristine Intelligence focuses on result-oriented methodologies which are based on historic and present data to produce authentic foretelling about the industry. Pristine Intelligence's extensive studies help our clients to make righteous decisions that make a positive impact on their business. Our customer-oriented business model firmly follows satisfactory service through which our brand name is recognized in the market.

Contact Us:

Office No 101, Saudamini Commercial Complex,

Right Bhusari Colony,

Kothrud, Pune,

Maharashtra, India - 411038 (+1) 773 382 1049 +91 - 81800 - 96367

Email: [email protected]

#Russia Industrial Valve#Russia Industrial Valve Market#Russia Industrial Valve Market Size#Russia Industrial Valve Market Share#Russia Industrial Valve Market Growth#Russia Industrial Valve Market Trend#Russia Industrial Valve Market segment#Russia Industrial Valve Market Opportunity#Russia Industrial Valve Market Analysis 2023

0 notes

Text

Vietnam Industrial Valve Market: Forthcoming Trends and Share Analysis by 2030

The Industrial Valve is Expected to Grow at a Significant Growth Rate, and the Forecast Period is 2023-2030, Considering the Base Year as 2022.

Vietnam's expanding manufacturing and infrastructure sectors have propelled the country's industrial valve market's recent notable growth. The primary factors driving the market were Vietnam's economic development and the rising need for energy, gas, oil, and water resources.

The market was typified by the existence of both foreign and indigenous valve producers. While multinational players from China, South Korea, Japan, and the United States supplied high-quality valves to diverse industries, local businesses met domestic demand. The construction, petrochemical, power generating, water and wastewater treatment, and oil and gas sectors were the biggest end users of industrial valves.

The need for industrial valves has expanded even more as a result of the Vietnamese government's emphasis on infrastructural development, industrial development, and foreign investment. The market did, however, face certain difficulties, including competition from low-cost import valves and the requirement for ongoing technological advancement to satisfy worldwide standards. Vietnam's industrial valve market appeared to have a bright future because of the nation's ongoing industrialization and economic expansion.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

Leading players involved in the Vietnam Industrial Valve Market include:

Viglacera Corporation (Vietnam) PetroVietnam Valves (PVV) (Vietnam), Viet Valve Joint Stock Company (VVC) (Vietnam), Arita Valve Co. Ltd. (Japan), Hoang Anh Gia Lai Machinery JSC (HGL) (Vietnam), Neway Valve (Suzhou) Co. Ltd. (China), OCV Co. Ltd. (Vietnam), Valves Joint Stock Company (VVS) (Vietnam), Hemaya Co. Ltd. (Vietnam), VNECO Mechanical Engineering Import-export JSC (Vietnam), Industrial Instruments And Equipment Company Limited (VINTEC) (Vietnam), API Valve JSC (AVC) (Vietnam), BP Valve Company Limited (Vietnam), FTech Co. Ltd. (Vietnam), STC Co. Ltd. (Vietnam), HAIYAN SUNFAST TRADING CO. LTD Vietnam Branch (China), Minhtuan Production Trading And Services Co. Ltd. (MT Vietnam) (Vietnam), TBV Vina Co. Ltd. (Vietnam), UniOne Co. Ltd. (Vietnam), Vinacoma JSC (Vietnam) and other major players.

If You Have Any Query Vietnam Industrial Valve Market Report, Visit:

Segmentation of Vietnam Industrial Valve Market:

By Type

Ball

Globe

Gate

Butterfly

Plug

Check

By Material

Steel

Brass

Bronze

Cast Iron

Plastic

By Size

< 1”

1”–6”

6”–25”

25”–50”

50”

By Application

Oil & Gas

Power

Energy

Chemical

Water & Waste Treatment

By Function

On/Off

Control

Isolation

Special Purpose

Highlights from the report:

Market Study: It includes key market segments, key manufacturers covered, product range offered in the years considered, Global Vietnam Industrial Valve Market, and research objectives. It also covers segmentation study provided in the report based on product type and application.

Market Executive Summary: This section highlights key studies, market growth rates, competitive landscape, market drivers, trends, and issues in addition to macro indicators.

Market Production by Region: The report provides data related to imports and exports, revenue, production and key players of all the studied regional markets are covered in this section.

Vietnam Industrial Valve Market Profiles of Top Key Competitors: Analysis of each profiled Roll Hardness Tester market player is detailed in this section. This segment also provides SWOT analysis of individual players, products, production, value, capacity, and other important factors.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

About Us:

We are technocratic market research and consulting company that provides comprehensive and data-driven market insights. We hold the expertise in demand analysis and estimation of multidomain industries with encyclopedic competitive and landscape analysis. Also, our in-depth macro-economic analysis gives a bird's eye view of a market to our esteemed client. Our team at Pristine Intelligence focuses on result-oriented methodologies which are based on historic and present data to produce authentic foretelling about the industry. Pristine Intelligence's extensive studies help our clients to make righteous decisions that make a positive impact on their business. Our customer-oriented business model firmly follows satisfactory service through which our brand name is recognized in the market.

Contact Us:

Office No 101, Saudamini Commercial Complex,

Right Bhusari Colony,

Kothrud, Pune,

Maharashtra, India - 411038 (+1) 773 382 1049 +91 - 81800 - 96367

Email: [email protected]

#Vietnam Industrial Valve#Vietnam Industrial Valve Market#Vietnam Industrial Valve Market Size#Vietnam Industrial Valve Market Share#Vietnam Industrial Valve Market Growth#Vietnam Industrial Valve Market Trend#Vietnam Industrial Valve Market segment#Vietnam Industrial Valve Market Opportunity#Vietnam Industrial Valve Market Analysis 2023

0 notes

Text

Powder Transfer Systems: Aishin's Solutions for Efficient Material Handling

Powder transfer systems are essential for modern industrial processes, revolutionizing material handling and transfer. In various industries like pharmaceuticals, food processing, and chemical manufacturing, efficient and precise powder handling is crucial for overall productivity, product quality, and workplace safety.

Overview of Powder Transfer Systems

Powder transfer systems are specialized systems crafted for the controlled handling and transfer of powders or granular materials. Precision and automation in powder transfer systems significantly reduce human error and variability, enhancing efficiency and ensuring the consistency of the final product. The ability to control parameters like flow rates and dosages optimizes production workflows, minimizing waste and contamination risks.

Industries are embracing powder transfer systems. In pharmaceuticals, these systems manage active pharmaceutical ingredients with precision. The food and beverage sector relies on them for accurate mixing, while in chemical manufacturing, they handle and transfer various powdered chemicals. The versatility of powder transfer systems makes them indispensable for controlled powder handling in critical production processes across industries.

Types of Powder Transfer Systems:

Powder transfer systems include two types, pneumatic conveying systems and mechanical transfer systems. Each type possesses distinctive features and applications. Pneumatic conveying systems use compressed air to transfer bulk materials like powder and granules through a closed pipe whereas mechanical transfer systems involve the transfer of materials using machinery like belts, rollers, brackets, and motors.

Understanding the unique features of each system aids in selecting the most suitable one for specific tasks. Factors such as the type of powder, required transfer distance, and overall operational efficiency play a important role in the decision-making process. Aligning system attributes with application requirements is essential for optimal performance.

Common Challenges in Powder Transfer

Common challenges in powder transfer processes include clogging and particle segregation, which can lead to downtime and contamination risks. Powder characteristics, such as size, shape, and moisture content, influence transfer efficiency. Fine particles may cause dusting, and cohesive powders can lead to poor flow and clogging. Overcoming these challenges requires specialized equipment design, vibrational assistance, and segregation-prevention techniques.

Aishin's Solutions to Powder Transfer Challenges:

Aishin, a global leader in material handling and powder transfer systems, has manufacturing facilities in Japan, Thailand, China, and India. Their comprehensive range of equipment includes bag dumping stations, rotary valves, knife gate valves, butterfly valves, silo/hoppers, mechanical transfer systems, pneumatic transfer systems, bin scrapers, dosing systems, lump breakers, and more. Aishin excels in addressing challenges associated with powder transfer such as clogging and particle segregation, and also in handling adhesive materials. Their scraper rotary valve is proven effective in overcoming difficulties posed by sticky materials during transfer processes. Aishin is renowned for Japanese engineering and is a leading rotary valve manufacturer in the industry.

Conclusion

Powder transfer systems are vital for industries, ensuring precise handling of powdered materials across sectors. Aishin, as a global leader in material handling equipment, is adept at addressing powder handling challenges. Trust Aishin to resolve powder transfer-related issues, ensuring operational efficiency, product quality, and workplace safety in your industrial processes.

#powder handling#material handling#equipment#powder#powder transfer#pneumatic conveying system#powder transfer system#valves#rotary valves#bulk material handling

0 notes

Text

Industrial Metal Butterfly Valves

Are You Looking For Industrial Metal Butterfly Valves? TIANYU is an industrial valve manufacturer of ball valves, gate valves, globe valves, check valves, butterfly valves, plug valves, and strainers. Our valve factory in China adhere to ANSI, API, DIN, GOST, BS, JIS, China GB standards and customer specific requirements. Our products have been sold worldwide for a wide range of applications in natural gas, oil, oil refining, chemical, marine, power generation and pipeline transportation industries.

0 notes

Text

BR.W72W Series Double Eccentric Butterfly Valve

The BR.W72W series double eccentric butterfly valve has a unique three-dimensional eccentric structure and good shut-off performance. A new type of regulating valve that combines both regulation and shut-off functions, with a compact structure, simple flow path, low pressure loss, and high rated flow coefficient, can effectively meet various working conditions and requirements. It is widely used in fluid regulation in industrial automation control applications.

Features:

1. The sealing surfaces of the valve disc and valve seat are in conical contact, and the torque when the valve is closed is small, allowing a large pressure difference;

2. The sealing surface can be welded with Stellite alloy for high-temperature and high-pressure applications;

3. With bidirectional sealing characteristics, the sealing performance is not affected by temperature changes;

4. Good sealing performance, reaching Class VI leakage (GB/T4213-2008).

0 notes

Text

Butterfly valves

DN50-DN2600

PN1.6MPa-PN335MPa

Carbon steel/steel alloy/stainless steel

t<-100℃ -100℃≤t≤-29℃ -29℃<t<120℃ 120℃≤t≤425℃ t>450℃

Water/oil/steam

Flange/thread/welding/clamp/lug

API 600/API 6D/MSS SP-25

An eccentric metal hard seal butterfly valve is a type of valve that uses a disc-shaped closure element, known as the butterfly disc, to regulate the flow of fluid. It is called "eccentric" because the centerline of the shaft or stem is located off-center from the centerline of the disc.

This type of butterfly valve is equipped with a metal-to-metal sealing mechanism, which provides a tight and durable seal against the flow of fluid. The sealing surfaces of the valve, such as the disc and the seat, are made of metal materials that can withstand high pressures and temperatures.

The eccentric design of the valve allows the disc to seal against the seat with a slight off-center contact, reducing friction during operation and enhancing the sealing performance. This design also helps minimize wear and extend the service life of the valve.

Eccentric metal hard seal butterfly valves are commonly used in industries such as oil and gas, chemical processing, power generation, and water treatment. They are suitable for applications that require reliable shutoff capabilities, resistance to harsh environments, and efficient flow control.

These valves are available in various sizes, pressure ratings, and materials, allowing them to be used for different piping systems and fluid media. They can be operated manually using levers or handwheels, or automated with the use of electric or pneumatic actuators for remote control.

1 note

·

View note

Text

China Manufacturer Large end cap assembly DG600-240-04-19-00 for steam turbine

China Manufacturer Large end cap assembly DG600-240-04-19-00 for steam turbine Deyang YOYIK is a strong technical force, first-class product quality, brand reputable large-scale mechanical and electrical equipment Limited. Company products covered a wide range of products sold worldwide, a number of users trust. Acting foreign first-class brand, EATON VICKERS, star, and so on products. Guarantee genuine, the spot sale. Yoyik can offer many spare parts for power plants as below: #DF-Large end cap assembly DG600-240-04-19-00-DF pressure hose SMS-10/20-610mm-C screw pump diagram HSNS210-54NZ OPC solenoid valve 4WE10D-L3X/CW220-50NZ5L/V seals (cylinder diaphragm, packing, valve sealing gasket) 0125ZMAW16BQ13UNOERHDN125 roots vacuum pump KZ/100WS radial piston pump PV2R3-76-RBAF1 switch valve M765-004000A screw pump working principle 3GR42*4A oil pump replacement 80SG50-30 double mechanical seal 15F4-IC-20 hydraulic power 300S90B Hydraulic hose 35MPa, 20mm chemical pump centrifugal 65-250B soft coupler suction DN800, PN1.0MPa, OD1019mm, ID950mm, Distance between 2 Flanger: 320mm. mechanical seals LTJ-GJ-125A/R servo valve J761-001 HP ball valve BKH20-FPM-1.4571 Lubrication Oil Pump 150LY-32-B butterfly valve K65DSF4PB3 oil station globe check valve J20C-1.6P hydraulic screw pump ACF080K41RBP mechanical seal 41 mm 90NY/JXMF motor universal coupling 125LY-35-2 safety valve 3.5A25F-16P chemical pump centrifugal DFB80-80-240 piston pump hydraulic MOOG0514 7005 37 butterfly valve K150D0F4PB3 Governor O-ring DH00.010 vacuum pump compressor PVH098R01AJ30A250000002 ac vacuum pump P-1937A oil transfer electric pump SDNH440REM3NW53 sealing ring HB4-56J8-19 Packing B05-8076Z-06TS rotary piston pump PV29-2R5D-C00 screw pump manufacturer ACF090N4 electric transfer oil pump DLZB820-R64B Large end cap assembly DG600-240-04-19-00 vacuum pump valve spring P-540 hydraulic actuator solenoid valve 4WE6H62/EW230N9DL multi stage centrifugal pump YCZ50-25 piston pump hydraulic PVH141R13AF30A230000002001AB01A axial piston variable pump A10VS071DRS/32R-VPB22U99 mechanical seal types LTJ-GJ-125A/R shaft coupling 65-250B liquid ring vacuum pump 2S-185A AST SOLENOID VALVES G1211177 Fluoro Rubber O-Ring ORO250023 generator self-lock nut M12*3mm fluid transfer pump 50FSB-30 gear oil transfer pump SDH-50 screw pump working HSNH80Q-48NZ vacuum hand pump P-1803 screw pump manufacturer KF090NZ/15F6 pressure hose SMS-12-3048mm-C magnetic coupling centrifugal pump DFB125-80-250-20 centrifugal pump prices ISG150-160 armoured platinum Thermal resistance WZGPK2-33U-M100A150J120A-M212 vacuum pump price 2S-185 hydraulic electric pump 70LY-34*2-1 pressure hose S100-AC-AC-0150 (G1/4)M14*1.5 Pneumatic head diaphragm 125ZMAW16BQ piston vacuum pump PV292R5DC00 transfer oil pump YW100-250 dc screw pump HSNH80Q-48NZ vacum pump air vacuum WS-30 MOOG pump electric vacuum pump 30WS water pump DFB100-80-250-14 pressure hose SMS-12/20-610mm-B HP globe valve 600KG vacuum pump compressor P-1759 OPC solenoid valve HQ16.110Z electric vacuum pump 2S-185 Large end cap assembly DG600-240-04-19-00 DFYLSYC-2024-6-3-A

0 notes