#briquetting press manufacturer

Explore tagged Tumblr posts

Text

Transform Waste into Wealth with Our Revolutionary Briquette Press Machine

Unlock the power of innovation and sustainability with our state-of-the-art Briquette Press Machine. Say goodbye to waste materials and hello to a profitable and eco-friendly future.

Briquetting Press Manufacturer Process:

Requirements

To produce high-quality briquettes the following requirements must be met:

Moisture of raw material should be ranges between 8-12%.

Raw material should be pre-shredded to the size of 5-20mm according to model.

Raw material should be free from foreign substances such as sand, stones and metal.

Get In Touch +91 991 520 0537

#Briquette Press Machine#Lehra Fuel#Briquette Press#Biomass Briquette Press#Briquetting Press Manufacturer#Briquetting Press

0 notes

Text

Explore the eco-friendly world of Jay Khodiyar Biomass Briquetting Plant in India. Our advanced technology transforms agricultural and forestry waste into high-quality briquettes, promoting sustainability and profitability. Dive into the benefits and setup processes of our innovative briquetting solutions and join the green revolution today!

#Biomass Briquetting Plant#Eco-Friendly Fuel Alternatives#Agricultural Waste Recycling#Biomass Briquetting Technology#Sustainable Biofuel Production#Biomass Energy Equipment#Biomass to Briquettes Process#Waste to Energy Systems#Briquetting Plant Manufacturer#Biomass Pellet Machine#Biomass Briquetting Benefits#Cost-Effective Heating Solutions#Green Energy Briquettes#Biomass Briquetting Press

0 notes

Text

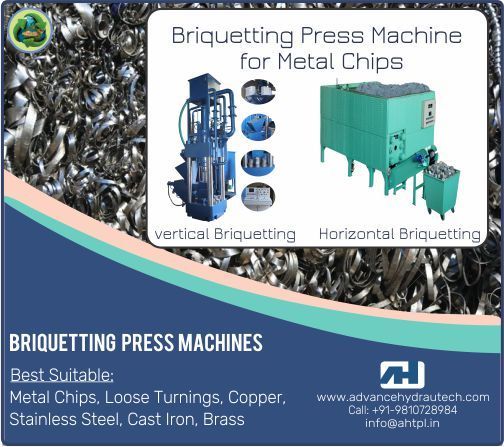

Aluminium Chips Briquetting Machine, Automatic Horizontal Metal Chip Briquetting Press

Our Metal Chip Briquetting machine is designed to turn fine or loose particles and residues into hard, dense briquettes or pucks. The briquetting machines manufacture by Advance Hydrau-Tech is the ideal solution for getting high-quality briquettes from a variety of metals such as steel, aluminium, cast iron, brass, copper, etc. We have vertical and horizontal briquetting machines compacts the metal dust or chips into highly dense and dry briquettes. We are India’s largest manufacturer of scrap processing machines dealing with wide range of recycling machines. Our scrap baler, shear, metal shredder, briquetting, paper baler, automatic balers are widely used and most reliable machines in recycling industries.

youtube

0 notes

Text

What Is a Charcoal Making Machine and How Will It Work?

A charcoal making machine uses pyrolyzing technique to turn biomass waste matter into charcoal. The charcoal-making process requires an oxygen-free atmosphere and extremely high temperature. This machine needs raw materials like biomass, including palm shell, sugarcane bagasse, peanut shell, olive shell, sawdust, coconut shell, rice husk, bamboo, and wood, sorted MSW, and sewage sludge. The charcoal produced finds its way into the agricultural, iron, ceramic, and steel industry. Thousands of people in rural areas likewise use charcoal as fuel in order to cook food.

So how exactly does charcoal making machine work?

This charcoal manufacturing plant is made up of two crucial parts: transmission mechanism and briquetting device. The motor's output shaft connects on the reducer's input shaft. However, the speed reducer's output shaft remains close to the main driving chain wheel. This enables the little passive sprocket to connect using the briquetting device's input shaft.

The charcoal-making process has two parts: first involving pressing biomass wood materials into small briquettes. And second, charring the biomass briquettes in a charring kiln.

Step 1

A hammer mill or wood crusher crushes the raw materials into powder or 3 to 5mm pieces. It may help them burn evenly in the next step.

Step Two

A dryer dries the crushed raw materials to make sure they hardly contain any moisture. However, different raw materials could have different moisture requirements. It's best to speak to the equipment manufacturer or talk with specialists prior to the first batch.

Step Three

Next, use the briquetting machine to transform the raw materials into stick briquettes. The biomass briquette's surface gets carbonized throughout the briquetting process. Make sure you retain the high temperature and pressure throughout this step. The inside parts don't get carbonized completely throughout the briquetting process. That's the reasons people call stick briquettes as biomass briquettes.

Step 4

Within the penultimate stage, the biomass charcoal briquettes get carbonized to be final charcoal briquettes. The charcoal making machine features a charcoal kiln that assists to accomplish this transition. Many factories work with a carbonization furnace, but the machine features a similar setting in a tiny space.

The charcoal kiln carbonizes the biomass briquettes thoroughly even though the furnace carbonizes the crushed biomass raw materials. This means you may use the equipment to carbonize raw materials, even while making a wood charcoal briquette line. The carbonization furnace setting chars the last charcoal so it will be ready to be used.

Step 5

The finished charcoal briquettes experience an extensive packing process. You will observe them used in different industries as soon as they appear as finished briquettes.

Features of charcoal making machine

Here are a few features to be aware of before buying a charcoal producing machine:

Low operating cost and high thermal efficiency.

High calorific worth of the gas.

Pollution-free charcoal making system.

Use of cheap raw materials.

Continuous working pattern.

This particular machine can produce a great deal of finished charcoal briquettes daily. You could buy a device in accordance with the amount of charcoal you have to produce daily.

0 notes

Text

Biomass Briquetting Press 75 MM Manufacturers and Suppliers

Briquettes Machine 75mm is best suitable for those users who have bulk density of raw material. Likewise, our Briquettes press Machine is best known to its performance and quality. Different type of raw material like agricultural waste, forest waste can be used to make biomass briquettes. you can search us on google with keywords: briquettes press, briquetting press manufacturers, biomass briquetting press manufacturers, briquetting press suppliers.

1 note

·

View note

Text

Briquette Plant Setup, Machine, Equipment & Applications - Bagasse/Sawdust/Husk to Briquette

What is biomass briquette?

Biomass briquettes, mostly made of green waste and other organic materials, are commonly used for electricity generation, heat generation, and generating cooking fuel. These compressed briquette compounds have various organic materials, including rice husk, bagasse, ground nut shells, municipal solid waste, and agricultural waste. The composition of the briquettes varies from area to area due to the availability of raw materials we can get. The raw materials are gathered and compressed into briquettes to burn longer and make transportation of the goods easier.

Every year, almost millions of tons of agricultural waste are generated from organic materials or biomass as we call it. Briquettes are one form of clean energy. Biomass Briquetting is the process of converting low bulk density biomass into high-density and energy-concentrated fuel briquettes like the conversion of bagasse to briquette.

Briquettes are more sustainable and energy-efficient and could reduce the pressure on forests and lower pollution levels in urban areas. This is possible when more people start using them.

Biomass briquettes are environment-friendly, entirely and easily renewable to implement. They can be used to generate energy for boiling water, to create steam energy, propel turbines for electricity and even heat homes and businesses. Can be considered an effective source of renewable energy because they are:

· Pollution free as there is no sulphur or any fly ash during the burning process.

· Consistent high burning efficiency due to its low moisture content.

· Easy for its transportation, and feeding process due to its unique shape.

· Combustion is more uniform when compared to other coal.

· Demandable in the market due to the high rise in fossil fuels price.

What is a briquette system?

There are different types of briquette machines with different working techniques and principles as they work under different pressures. It also depends on the suitable raw materials used. The briquette system can deal with all types of materials under suitable sizes and moisture content present.

SNCE manufactures good quality high-efficient low cost briquette machines like Piston Type Biomass Briquette machines and Screw type briquette machines.

BRIQUETTE PLANT SETUP FOR 80/90/100 MM DIAMETER BRIQUETTE

Ø Piston Type Biomass Briquette Machine: Briquette size 8 mm (Pellet) to 90 mm (Briquette).

The piston or plunger drives the ram to reciprocate in the forming sleeve to generate a pressure creating force which helps to form the material into briquettes. The piston-type briquette machine uses the rotary power of the mechanical device or the thrust of the hydraulic cylinder (using water pressure) to rotate the piston or plunger.

Capacity:

· Quantity output 1.2 tons per hour to 2 tons per hour

· Power 65Kw to 120Kw

· Raw Material type

o Rice Husk

o Bagasse

o Saw Dust

o Soya Husk

o Cotton Stalk

o RDF

· Raw Material Size: 4 to 10 mm

· Moisture of Material: Less than 15%

· Dual Feed Mechanism

· Dual Belt Power Drive to Machine

· VFD control material feed for optimum output

· Supplied with Input screw/ Belt Conveyor

· Single Control Panel & Integration

SCREW TYPE BRIQUETTE MACHINE SETUP FOR 35MM TO 50MM WITH CENTRE HOLE

Ø Screw type briquette machine set up for 35mm to 50mm with Centre hole

The screw-type briquette machine employs an auger to press the raw material, and depending on the substance, it can be decided whether to use a heating system or not. For those briquettes that work with materials including lignin, which is always present in biomass, the heating system has a specific design. When using a screw-style briquette machine, binders are always required.

Capacity:

· Raw Material: Rice Husk, Bagasse, Saw dust, Soya Husk, cotton stock

· Briquette size 25mm & 50mm

· Quantity Output 250 Kg per hour and 500 kg per hour. (Depend on size & moisture of material)

· Power: 15 KW to 22 KW

· Moisture of Raw Material should be less than 15% Single thru pass system. Simple and easy operation.

SNCE have satisfactorily served various industries to build a sustainable environment and help scale their business. We provide high-efficiency low-cost biomass plant setups and types of equipment like biomass briquette/pellet systems, rotary drum dryer, hammer mill, etc.

If you have any queries, feel free to contact Sai Non-Conventional Energy

Contact number: -+91 9923540893, +91 8329016029

Email us on: [email protected]

0 notes

Text

How does a briquetting machine work?

Briquetting machine raw material feeding:

The briquette press receives biomass waste via a speed-controlled screw conveyor. The speed of the screw determines the result of the machine's hardness of this briquette. The speed of the raw material is adjusted according to the specific gravity of the raw material. Therefore, a change in the specific gravity of the raw material will result in a change in the hardness of the agglomerate. We at Lehra always recommend that our briquetting presses be equipped with an automatic capacity adjustment system which will adjust the capacity up and down according to the raw material.

Briquetting machine biomass briquetting raw materials:

Any biomass and waste can be pressed into high-calorie fuel briquettes. It can be wheat straw, mustard waste, rice husks, Arhar straw, groundnut husks, pine needles Sarkanda, bagasse. Coffee husks, cotton straw, sunflower waste, sugar cane, bagasse, corn stover, bajra cobs and coconut dust in agricultural waste. Likewise, forest waste such as wood chips and chips, bark, twigs, sawdust, bamboo, wild grass, shrubs, leaves and litter can also be briqueted without any binder with the help of a briquetting machine.

Briquetting machine manufacturing process:

Raw materials such as sawdust are sieved, straw (forest and agricultural waste) is ground by chippers and grinders (single action) for the use of two or more types of materials, by mixing/hand mixing appropriate means. If the raw material has high moisture it should be reduced by sun drying or using a flash dryer, if the moisture is so high it can be reduced by a tumble dryer. Hammer mill grinders are used to grind materials to the desired particle size and are suitable for small models. The raw material (required particle size) is conveyed by a pneumatic system to a storage box fixed to the briquetting machine. Dust is collected directly to B.Pass by cyclone dust collector or screw conveyor. Through the screw conveyor, the material is discharged from the silo to the press. The material is compressed by the plunger through a tapered bore die. By compressing the temperature rises & lignin reaches the surface and binds the material through its natural binder. The briquettes are formed into log shapes and automatically pushed to the storage point by cooling lines.

Finished briquettes:

The finished briquettes have high specific density (1100-1200 kg/m3) and bulk density. These are inventories that can withstand long-distance transportation, with much lower handling and shipping costs and significantly lower requirements. Boiler efficiency of briquettes is much higher due to low moisture and higher density compared to burned wood or lost biomass.

Briquettes are ideal because…

Environmentally friendly and renewable energy fuels. Economical and cheaper than other solid fuels (ie coal and wood). The high calorific value is about 3600-4800 K Cal/Kg and above. No pollution as there is no sulphur or any fly ash when burned. Consistently high combustion efficiency due to low moisture. Unique shape, easy to transport and feed. Burns more evenly than other coals.

Due to the high price of fossil fuels, the market demand is strong.

Why briquette:

Today, every country wants to protect their fossil fuels such as oil, gas, coal and wood. Not only is briquettes a great fuel, it's also good for nature, as it emits only the carbon dioxide needed for the plant and tree environment. In addition to energy, governments offer huge incentives and promotional tax breaks for installing briquetting presses and machines.

Yuke Machine is the best crusher rotary dryer manufacturer and briquetting machine suppliers in China, specialized in briquette machine, contact us!

0 notes

Text

How does a briquetting machine work?

Briquetting machine raw material feeding:

The briquette press receives biomass waste via a speed-controlled screw conveyor. The speed of the screw determines the result of the machine's hardness of this briquette. The speed of the raw material is adjusted according to the specific gravity of the raw material. Therefore, a change in the specific gravity of the raw material will result in a change in the hardness of the agglomerate. We at Lehra always recommend that our briquetting presses be equipped with an automatic capacity adjustment system which will adjust the capacity up and down according to the raw material.

Briquetting machine biomass briquetting raw materials:

Any biomass and waste can be pressed into high-calorie fuel briquettes. It can be wheat straw, mustard waste, rice husks, Arhar straw, groundnut husks, pine needles Sarkanda, bagasse. Coffee husks, cotton straw, sunflower waste, sugar cane, bagasse, corn stover, bajra cobs and coconut dust in agricultural waste. Likewise, forest waste such as wood chips and chips, bark, twigs, sawdust, bamboo, wild grass, shrubs, leaves and litter can also be briqueted without any binder with the help of a briquetting machine.

Briquetting machine manufacturing process:

Raw materials such as sawdust are sieved, straw (forest and agricultural waste) is ground by chippers and grinders (single action) for the use of two or more types of materials, by mixing/hand mixing appropriate means. If the raw material has high moisture it should be reduced by sun drying or using a flash dryer, if the moisture is so high it can be reduced by a tumble dryer. Hammer mill grinders are used to grind materials to the desired particle size and are suitable for small models. The raw material (required particle size) is conveyed by a pneumatic system to a storage box fixed to the briquetting machine. Dust is collected directly to B.Pass by cyclone dust collector or screw conveyor. Through the screw conveyor, the material is discharged from the silo to the press. The material is compressed by the plunger through a tapered bore die. By compressing the temperature rises & lignin reaches the surface and binds the material through its natural binder. The briquettes are formed into log shapes and automatically pushed to the storage point by cooling lines.

Finished briquettes:

The finished briquettes have high specific density (1100-1200 kg/m3) and bulk density. These are inventories that can withstand long-distance transportation, with much lower handling and shipping costs and significantly lower requirements. Boiler efficiency of briquettes is much higher due to low moisture and higher density compared to burned wood or lost biomass.

Briquettes are ideal because…

Environmentally friendly and renewable energy fuels. Economical and cheaper than other solid fuels (ie coal and wood). The high calorific value is about 3600-4800 K Cal/Kg and above. No pollution as there is no sulphur or any fly ash when burned. Consistently high combustion efficiency due to low moisture. Unique shape, easy to transport and feed. Burns more evenly than other coals.

Due to the high price of fossil fuels, the market demand is strong.

Why briquette:

Today, every country wants to protect their fossil fuels such as oil, gas, coal and wood. Not only is briquettes a great fuel, it's also good for nature, as it emits only the carbon dioxide needed for the plant and tree environment. In addition to energy, governments offer huge incentives and promotional tax breaks for installing briquetting presses and machines.

Yuke Machine is the best crusher rotary dryer manufacturer and briquetting machine suppliers in China, specialized in briquette machine, contact us!

0 notes

Text

Briquette Press | Briquetting Press Manufacturer – Lehra Fuel

Find here Briquette Press, Briquette Machine Manufacturers. Get information on briquettes making machine and contact verified briquette making machine etc.

Briquette Press Machine

To get more information or to buy machine visit us :

www.lehrafuel.com

#lehra fuel#briquetting plant#biomass briquetting plant#briquetting press manufacturer#briquette plant manufacturer

0 notes

Text

Increase Production with a High-Quality Briquette Press

Discover how a high-quality briquette press can revolutionize your production processes. Read this detailed guide to boost efficiency and sustainability in fuel manufacturing.

0 notes

Text

Advance Hydrau Tech Unveils New Product Catalogue: "Conquer the Scrap Processing Kingdom"

Advance Hydrau Tech Pvt. Ltd., the leading manufacturer of scrap processing machines in India, is proud to announce the launch of its highly anticipated new product catalogue, showcasing the latest products in the scrap processing industry. With a strong global presence in 93 countries and a legacy spanning over 45 years, the company solidifies its position as the true "Leader of Scrap Processing."

The centre piece of the new product catalogue is a striking visual that symbolizes the company's dominance in the sector. A majestic lion, proudly seated a top a mound of scrap, serves as a powerful representation of Advance Hydrau Tech's strength, vision, and unwavering commitment to excellence.

"We believe the lion embodies the essence of our company – a symbol of leadership, courage, and determination. As pioneers in the scrap processing machinery industry, we have consistently led the way in innovation and technology," said Dr. Sudhir Gupta, CEO of Advance Hydrau Tech Pvt. Ltd.

The tagline "Bale, Shear, Shred, Briquette, Conquer" further encapsulates the core message of the new catalogue. It not only highlights the wide range of capabilities offered by Advance Hydrau Tech's machines but also emphasizes the company's mission to empower its clients to conquer their scrap processing challenges and thrive in their businesses.

As a testament to its continuous commitment to sustainability and environmental responsibility, Advance Hydrau Tech's machines continue to set industry benchmarks for efficiency and resource optimization, allowing businesses to process scrap materials in a more eco-friendly manner.

Dr. Gupta further added, "Our new product catalogue is a reflection of our dedication to advancing the scrap processing industry. We aim to empower our clients with cutting-edge technology, reliable machinery, and exceptional customer service."

Advance Hydrau Tech invites businesses and individuals involved in the scrap processing sector to explore the possibilities presented by their new catalogue and discover how they can elevate their operations to new heights.

About Advance Hydrau Tech Pvt. Ltd.:

Established over 45 years ago, Advance Hydrau Tech Pvt. Ltd. has been at the forefront of manufacturing high-quality scrap processing machines. The company's extensive product line includes balers, shears, shredders, and briquetting presses, serving diverse industries and contributing to environmental sustainability across the globe.

0 notes

Text

How does a briquetting machine work?

Briquetting machine raw material feeding:

The briquette press receives biomass waste via a speed-controlled screw conveyor. The speed of the screw determines the result of the machine's hardness of this briquette. The speed of the raw material is adjusted according to the specific gravity of the raw material. Therefore, a change in the specific gravity of the raw material will result in a change in the hardness of the agglomerate. We at Lehra always recommend that our briquetting presses be equipped with an automatic capacity adjustment system which will adjust the capacity up and down according to the raw material.

Briquetting machine biomass briquetting raw materials:

Any biomass and waste can be pressed into high-calorie fuel briquettes. It can be wheat straw, mustard waste, rice husks, Arhar straw, groundnut husks, pine needles Sarkanda, bagasse. Coffee husks, cotton straw, sunflower waste, sugar cane, bagasse, corn stover, bajra cobs and coconut dust in agricultural waste. Likewise, forest waste such as wood chips and chips, bark, twigs, sawdust, bamboo, wild grass, shrubs, leaves and litter can also be briqueted without any binder with the help of a briquetting machine.

Briquetting machine manufacturing process:

Raw materials such as sawdust are sieved, straw (forest and agricultural waste) is ground by chippers and grinders (single action) for the use of two or more types of materials, by mixing/hand mixing appropriate means. If the raw material has high moisture it should be reduced by sun drying or using a flash dryer, if the moisture is so high it can be reduced by a tumble dryer. Hammer mill grinders are used to grind materials to the desired particle size and are suitable for small models. The raw material (required particle size) is conveyed by a pneumatic system to a storage box fixed to the briquetting machine. Dust is collected directly to B.Pass by cyclone dust collector or screw conveyor. Through the screw conveyor, the material is discharged from the silo to the press. The material is compressed by the plunger through a tapered bore die. By compressing the temperature rises & lignin reaches the surface and binds the material through its natural binder. The briquettes are formed into log shapes and automatically pushed to the storage point by cooling lines.

Finished briquettes:

The finished briquettes have high specific density (1100-1200 kg/m3) and bulk density. These are inventories that can withstand long-distance transportation, with much lower handling and shipping costs and significantly lower requirements. Boiler efficiency of briquettes is much higher due to low moisture and higher density compared to burned wood or lost biomass.

Briquettes are ideal because…

Environmentally friendly and renewable energy fuels. Economical and cheaper than other solid fuels (ie coal and wood). The high calorific value is about 3600-4800 K Cal/Kg and above. No pollution as there is no sulphur or any fly ash when burned. Consistently high combustion efficiency due to low moisture. Unique shape, easy to transport and feed. Burns more evenly than other coals.

Due to the high price of fossil fuels, the market demand is strong.

Why briquette:

Today, every country wants to protect their fossil fuels such as oil, gas, coal and wood. Not only is briquettes a great fuel, it's also good for nature, as it emits only the carbon dioxide needed for the plant and tree environment. In addition to energy, governments offer huge incentives and promotional tax breaks for installing briquetting presses and machines.

Yuke Machine is the best crusher rotary dryer manufacturer and briquetting machine suppliers in China, specialized in briquette machine, contact us!

0 notes

Text

Briquetting Solution

The Jay Khodiyar Briquette plant mechanical briquette press are machines designed to meet the requirements of customers and it is also Know as briquettes system, briquetting Solution, briquettes plant manufacturer.

1 note

·

View note

Text

How does a briquetting machine work?

Briquetting machine raw material feeding:

The briquette press receives biomass waste via a speed-controlled screw conveyor. The speed of the screw determines the result of the machine's hardness of this briquette. The speed of the raw material is adjusted according to the specific gravity of the raw material. Therefore, a change in the specific gravity of the raw material will result in a change in the hardness of the agglomerate. We at Lehra always recommend that our briquetting presses be equipped with an automatic capacity adjustment system which will adjust the capacity up and down according to the raw material.

Briquetting machine biomass briquetting raw materials:

Any biomass and waste can be pressed into high-calorie fuel briquettes. It can be wheat straw, mustard waste, rice husks, Arhar straw, groundnut husks, pine needles Sarkanda, bagasse. Coffee husks, cotton straw, sunflower waste, sugar cane, bagasse, corn stover, bajra cobs and coconut dust in agricultural waste. Likewise, forest waste such as wood chips and chips, bark, twigs, sawdust, bamboo, wild grass, shrubs, leaves and litter can also be briqueted without any binder with the help of a briquetting machine.

Briquetting machine manufacturing process:

Raw materials such as sawdust are sieved, straw (forest and agricultural waste) is ground by chippers and grinders (single action) for the use of two or more types of materials, by mixing/hand mixing appropriate means. If the raw material has high moisture it should be reduced by sun drying or using a flash dryer, if the moisture is so high it can be reduced by a tumble dryer. Hammer mill grinders are used to grind materials to the desired particle size and are suitable for small models. The raw material (required particle size) is conveyed by a pneumatic system to a storage box fixed to the briquetting machine. Dust is collected directly to B.Pass by cyclone dust collector or screw conveyor. Through the screw conveyor, the material is discharged from the silo to the press. The material is compressed by the plunger through a tapered bore die. By compressing the temperature rises & lignin reaches the surface and binds the material through its natural binder. The briquettes are formed into log shapes and automatically pushed to the storage point by cooling lines.

Finished briquettes:

The finished briquettes have high specific density (1100-1200 kg/m3) and bulk density. These are inventories that can withstand long-distance transportation, with much lower handling and shipping costs and significantly lower requirements. Boiler efficiency of briquettes is much higher due to low moisture and higher density compared to burned wood or lost biomass.

Briquettes are ideal because…

Environmentally friendly and renewable energy fuels. Economical and cheaper than other solid fuels (ie coal and wood). The high calorific value is about 3600-4800 K Cal/Kg and above. No pollution as there is no sulphur or any fly ash when burned. Consistently high combustion efficiency due to low moisture. Unique shape, easy to transport and feed. Burns more evenly than other coals.

Due to the high price of fossil fuels, the market demand is strong.

Why briquette:

Today, every country wants to protect their fossil fuels such as oil, gas, coal and wood. Not only is briquettes a great fuel, it's also good for nature, as it emits only the carbon dioxide needed for the plant and tree environment. In addition to energy, governments offer huge incentives and promotional tax breaks for installing briquetting presses and machines.

Yuke Machine is the best crusher rotary dryer manufacturer and briquetting machine suppliers in China, specialized in briquette machine, contact us!

0 notes

Text

How does a briquetting machine work?

Briquetting machine raw material feeding:

The briquette press receives biomass waste via a speed-controlled screw conveyor. The speed of the screw determines the result of the machine's hardness of this briquette. The speed of the raw material is adjusted according to the specific gravity of the raw material. Therefore, a change in the specific gravity of the raw material will result in a change in the hardness of the agglomerate. We at Lehra always recommend that our briquetting presses be equipped with an automatic capacity adjustment system which will adjust the capacity up and down according to the raw material.

Briquetting machine biomass briquetting raw materials:

Any biomass and waste can be pressed into high-calorie fuel briquettes. It can be wheat straw, mustard waste, rice husks, Arhar straw, groundnut husks, pine needles Sarkanda, bagasse. Coffee husks, cotton straw, sunflower waste, sugar cane, bagasse, corn stover, bajra cobs and coconut dust in agricultural waste. Likewise, forest waste such as wood chips and chips, bark, twigs, sawdust, bamboo, wild grass, shrubs, leaves and litter can also be briqueted without any binder with the help of a briquetting machine.

Briquetting machine manufacturing process:

Raw materials such as sawdust are sieved, straw (forest and agricultural waste) is ground by chippers and grinders (single action) for the use of two or more types of materials, by mixing/hand mixing appropriate means. If the raw material has high moisture it should be reduced by sun drying or using a flash dryer, if the moisture is so high it can be reduced by a tumble dryer. Hammer mill grinders are used to grind materials to the desired particle size and are suitable for small models. The raw material (required particle size) is conveyed by a pneumatic system to a storage box fixed to the briquetting machine. Dust is collected directly to B.Pass by cyclone dust collector or screw conveyor. Through the screw conveyor, the material is discharged from the silo to the press. The material is compressed by the plunger through a tapered bore die. By compressing the temperature rises & lignin reaches the surface and binds the material through its natural binder. The briquettes are formed into log shapes and automatically pushed to the storage point by cooling lines.

Finished briquettes:

The finished briquettes have high specific density (1100-1200 kg/m3) and bulk density. These are inventories that can withstand long-distance transportation, with much lower handling and shipping costs and significantly lower requirements. Boiler efficiency of briquettes is much higher due to low moisture and higher density compared to burned wood or lost biomass.

Briquettes are ideal because…

Environmentally friendly and renewable energy fuels. Economical and cheaper than other solid fuels (ie coal and wood). The high calorific value is about 3600-4800 K Cal/Kg and above. No pollution as there is no sulphur or any fly ash when burned. Consistently high combustion efficiency due to low moisture. Unique shape, easy to transport and feed. Burns more evenly than other coals.

Due to the high price of fossil fuels, the market demand is strong.

Why briquette:

Today, every country wants to protect their fossil fuels such as oil, gas, coal and wood. Not only is briquettes a great fuel, it's also good for nature, as it emits only the carbon dioxide needed for the plant and tree environment. In addition to energy, governments offer huge incentives and promotional tax breaks for installing briquetting presses and machines.

Yuke Machine is the best crusher rotary dryer manufacturer and briquetting machine suppliers in China, specialized in briquette machine, contact us!

0 notes

Text

The application of Coal briquettes in our life

Henan gomine Machinery uses the mechanical method to press the coal into briquette. Such briquettes can improve combustion efficiency, reduce environmental pollution, expand the application range of high-volatility weakly cohesive coal such as lean coal, gas coal, long flame coal, and lignite, and rationally utilize coal resources.

The length briquettes used in the field of chemistry is usually 35~50mm. The anthracite or tar whose size is lesson than 3mm or the powdered brown coal whose yield is more than 10% can be pressed into balls, which is mainly used fertilizer gas, semi-coke, liquid or gaseous fuels and production of chemical products such as methanol and acetic acid.

The coal briquettes that are used as a steam locomotive has shapes of oval and drip. The development of briquets coal needs to solve the thermal deformation characteristics of the combustion process using temperature control. Using batching technology to help solve key technologies for improving coal quality and the melting point of coal ash. For coal with high sulfur, it is necessary to use catalytic reverse equilibrium to increase the conversion rate of sulfur to reduce pollution.

The coke is formed by a weakly cohesive pulverized coal, coking in a continuous coke oven, or using a high-speed thermal analysis of the colloidal body to achieve hot pressing coke formation. The development of coke can expand coking raw materials and improve its oven efficiency. Most manufacturers use binder low-pressure molding to produce industrial briquette. Most of the binder is lime, petroleum asphalt, tar pitch or pulp waste. The amount of binder depends on the comeliness of the coal, and is generally about 5-10%.

In addition to ordinary honeycomb coal briquettes, many manufacturers have begun to develop ignitable briquettes for heating and coal-fired briquettes for household cooking. The structure and raw material formula of this type of coal briquettes are more complicated. It generally consists of three parts: the ignition layer, the ignition layer and the coal body. The ignition layer is often mixed with oxidant or paraffin with flammable substances such as carbon and semi-coke powder. The ignition point of the transition layer is slightly higher than the ignition layer and acts as an igniting fire.

If you want to know about more briquette machine, you can visit our website: https://www.sinogomine.com/Briquette-Pressing-Machinery/Coal_Charcoal_Briquette.html

0 notes