#best bobbin elastic

Explore tagged Tumblr posts

Text

Oeko Tex Certified Elastic

Understanding Oeko-Tex Certified Elastic: Ensuring Safety and Sustainability in Textiles

In today's environmentally conscious world, Oeko Tex Certified Elastic consumers and businesses alike are increasingly prioritizing safety, sustainability, and ethical practices. The textile industry, in particular, faces scrutiny regarding its environmental impact and the health implications of its products. One certification that stands out in ensuring both safety and sustainability is the Oeko-Tex certification. This article explores the significance of Oeko-Tex certified elastic, its benefits, and why it matters in the textile industry.

What is Oeko-Tex Certification?

Oeko-Tex is a globally recognized certification system for textile products, established by the International Association for Research and Testing in the Field of Textile and Leather Ecology (Oeko-Tex Association). The certification aims to ensure that textile products are free from harmful substances and produced in environmentally friendly and socially responsible conditions.

There are various standards under the Oeko-Tex umbrella, with the most prominent being the Standard 100 by Oeko-Tex. This standard tests for harmful chemicals and substances at every stage of production, from raw materials to finished products, ensuring that certified textiles are safe for human use.

What is Oeko-Tex Certified Elastic?

Oeko-Tex certified elastic refers to elastic products that have been tested and certified under the Oeko-Tex Standard 100. This certification guarantees that the elastic is free from harmful chemicals and substances, making it safe for use in various applications, including clothing, medical supplies, and other consumer goods.

Benefits of Oeko-Tex Certified Elastic

1. Health and Safety

The primary benefit of Oeko-Tex certified elastic is its assurance of safety. The certification ensures that the elastic is free from harmful chemicals, such as pesticides, heavy metals, formaldehyde, and azo dyes. This makes it safe for direct contact with the skin, which is particularly important for products like clothing, underwear, and medical supplies.

2. Environmental Sustainability

Oeko-Tex certification also emphasizes environmentally friendly production processes. Certified manufacturers must adhere to strict environmental standards, including waste management, water treatment, and the use of sustainable materials. This commitment to sustainability helps reduce the environmental impact of textile production.

3. Consumer Trust and Confidence

Products with the Oeko-Tex certification are trusted by consumers worldwide. The certification serves as a mark of quality and safety, giving consumers confidence that they are purchasing safe and environmentally responsible products. This trust can enhance brand reputation and customer loyalty.

4. Market Advantage

For businesses, using Oeko-Tex certified elastic can provide a competitive edge. As consumers become more aware of the importance of sustainable and safe products, offering Oeko-Tex certified items can attract environmentally conscious customers and open up new market opportunities.

Applications of Oeko-Tex Certified Elastic

1. Apparel and Fashion

Oeko-Tex certified elastic is widely used in the apparel industry for products such as waistbands, cuffs, lingerie, and swimwear. Its safety and comfort make it ideal for garments that come into direct contact with the skin.

2. Medical Supplies

In the medical field, Oeko-Tex certified elastic is used in bandages, support wraps, and other medical products. The certification ensures that these items are safe for patients, reducing the risk of allergic reactions or skin irritations.

3. Home Textiles

Home textiles, such as bedding, curtains, and upholstery, also benefit from Oeko-Tex certified elastic. The certification guarantees that these products are free from harmful substances, contributing to a healthier living environment.

How to Identify Oeko-Tex Certified Elastic

To ensure that elastic products are Oeko-Tex certified, look for the Oeko-Tex Standard 100 label. This label will typically include a unique certification number and the issuing institute, which can be verified through the Oeko-Tex website. This verification process ensures the authenticity of the certification and the safety of the product.

Conclusion

Oeko-Tex certified elastic represents a commitment to safety, sustainability, and quality in the textile industry. By choosing products with this certification, consumers can trust that they are free from harmful substances and produced in an environmentally responsible manner. For businesses, using Oeko-Tex certified elastic can enhance brand reputation, attract environmentally conscious customers, and provide a competitive market advantage. As the demand for safe and sustainable products continues to grow, Oeko-Tex certified elastic stands out as a trusted choice for both consumers and manufacturers.

0 notes

Text

Loftus Bralette MK2 Go!

So the thing about the bralette pattern was that it was fiddly. There are a few seams where the seam allowance is one millimeter. That's hard to do. I am capable of that but have not the habit of the necessary carefulness. And I know a lot of the fit issues of the muslin-- which I did shorten the straps of, and put on to check the fit, and again then did not want to remove, so while it is not perfect it is currently the best bra I have (I have some decent RTW ones but forgot them at the farm so my need is dire right now). Anyway a lot of the fit issues of that could stem from careless sewing, so. I immediately cut out a second one with no alterations, just being MEGA SUPER ULTRA careful to cut EXACTLY on the lines.

I used a kit I bought from Porcelynne when I bought all the other materials. I'd meant to make a couple practice ones but then, you know, the kit wasn't that expensive and I might as well just. Do it!

It's black heavy-duty powermesh, black nylon cup lining, and pretty red lace, with black picot elastic and other findings, and then the 2" wide band elastic is metallic silver. Which is so cute and I wish I'd been able to buy just lengths of that elastic, but I wasn't able to find any on the site.

Anyway, the pattern is fiddly but not that challenging, and like 90% of the battle is remembering which way each thing goes. So I figure, if I make another one immediately I've a high chance of the best possible outcome. So here's some of that progress. Well, mostly I'm going to talk about equipment and setup.

I cut out all the materials while on a Zoom call with friends-- someone I know started hosting weekly Zooms to "meet up" with friends and work on crafts sometime during the pandemic I think, and I joined in somewhere in that time. That person has since become my sister's roommate so sometimes I go over there and participate in person, LOL. Anyway I set up my computer at the kitchen counter, got out my little cutting mat and rotary cutter, and just spent two full hours very carefully cutting out pieces and this time I labeled them with the tape before I even cut them out.

The red lace won't take a mark from anything but a Sharpie, which won't wash out, so I wasn't able to mark notches. So I just carefully stacked every copy of the pieces on top of the paper pattern piece, and put them into a baggie that way. I was so so so so careful to get the fabric cut right on the cutting lines, because the sewing lines are marked but I can't transfer those marks, and I discovered sewing the muslin that I can't sew on a line like that anyway (and often it was on the wrong side of the fabric for me to see.)

I'm home alone for two or three days, so I've taken over the living areas of the house to work in. This involved setting up a spare sewing machine on the absolutely-not-for-sewing desk that Dude uses to wfh, temporarily. I had forgotten I owned this machine, and it is a more modern one than the ten-stitch mechanical Kenmore that's my primary axe these days. This one is a Singer 6235 from the 80s, one of the most sophisticated mechanical ones they made before computerized machines were introduced; it's not high in resale value because some of the gears are nylon, but this particular individual one has clearly not been used much. It has wildly nonstandard bobbins, but I got a baggie of like twelve of them with it.

[image description: a Singer 6235 sewing machine, made of beige plastic and beige-enameled metal with black control panels, sits on a wooden desktop. In the background is a framed photo of a pink Easter bunny and a girl in a blue shirt, this is me and Dude from 2007. He rented that costume and wore it to a roller derby bout and got his ass grabbed SO much by many many people who absolutely did not suss that he was a dude in there. But the fluffy tail, he says, protected him.]

And when I opened the top, I found every single accessory lovingly stored there, including the package of needles it came with, still all in their package. So.

[Image description: looking down into the top of the sewing machine, which is molded plastic and has a number of esoteric plastic and metal items carefully stowed within custom-shaped cradles, with a letter key on top which is useless without a manual to decode it but good news I found a PDF copy of the manual on Al Gore's Blessed Internet so all is well.]

The single accessory I'm most excited about, however, is the reason I'm telling you all about all of this, which is otherwise not particularly relevant-- you can sew this bra on any machine that can do a zig-zag, and most of it is constructed with straight stitch because it is almost entirely non-stretch, you just need the zig-zags for the elastic attachments. It is:

A SEAM GUIDE. Which i cannot BELIEVE is no longer standard with sewing machines. It's in the above photo at top right, a metal thing with a knob in the middle. It screws into a hole in the machine bed and then you position it to hold your fabric as you sew, to make sure you do not stray over too far.

[Image description: a view through the sewing machine's active area, showing the presser foot down, the needle in some sheer black fabric, and the little metal item in question screwed into place with the metal arm of it pushed all the way over, actually touching the presser foot, holding the fabric at a 1/4" seam allowance.]

Indispensible. Though, I should have switched presser feet, because when the seam guide touches the edge of this presser foot it's actually slightly over 1/4". Just a fraction, so I've let it be because at least it's consistent and it's better than i was doing in the previous version.

so. This machine is needlessly complicated but works pretty darn well so I'm going to keep using it at least until dude gets back from his work trip on friday night.

I'm a bunch of the way through assembling the second bralette, but I think I'll talk about that in its own post, this has descended into sewing machine wittering. Suffice to say, knowing what i'm doing and what to expect means I'm doing a lot better. I'm also doing all the fiddly shit like pressing seams, and let me tell you, ironing synthetics is pointless LOL, so I'm just topstitching everything. I stopped for the day because the bobbin ran out, it was 9pm, and I looked it up and the way you wind the bobbin on this machine is by keeping the whole thing threaded including the needle and just winding it inside the bobbin case, which is So wild I definitely did not want to attempt it at 9pm after a long day. So, tomorrow I will actually talk about sewing this bralette.

But, I did have one more thing to show off-- I actually have purchased an after-market, universally-compatible seam guide that can just magnet itself to the throat plate of any machine, and was fully intending to use it on this project.

[img description: my hand holding a little metal gizmo with some arcane writing on the front; it's a square with a solid longer piece coming off the top, angled down on both sides.] This one came from Madam Sew or something, and comes with a plastic ruler with holes in it, and the idea is you put the ruler down, put your needle down so it goes through the hole marked at the distance you want, put your presser foot down to hold it, and then snap this magnetic guide at the edge of the plastic, and then it's foolproof. The thing is it doesn't work great at 1/4" either because again, that's where the presser foot is. So. I can't find the plastic ruler currently either because I am a disaster. But if your machine doesn't have a seam guide you can buy one of these and then you have a seam guide. I recommend it 100%; learning to sew a straight line is one thing, learning to follow a seam allowance is another, and you can improve your sewing immensely by taking the easy approach to it. You have to remove the guide for things like topstitching or other fiddly things, but for the vast majority of seams, including curved ones, this works a treat, makes it so you basically don't have to think, and just-- well, as long as your cutting-out was precise, you're guaranteed to get an accurate fit if you just use this kind of dealie to be precise about seam allowances.

The free version is that you get a piece of masking tape, put it down on your throat plate, and mark in Sharpie exactly where your seam should go, a big thick bold line as long as you can get it. That helps a ton too. Cashmerette's knit patterns all have 3/8" SAs, which aren't a standard marking on throat plates, and their wovens are all 1/2" instead of 5/8", so that's *also* not a standard marking, so I have long ago put the masking tape on but sometimes I also just use the seam guide because then I don't have to keep paying attention.

18 notes

·

View notes

Text

The Timeless Appeal of Premium Lace Fabric: Elegance Woven in Every Thread

When it comes to fashion, one material that has consistently remained a symbol of elegance and sophistication is premium lace fabric. Known for its intricate patterns and soft texture, lace fabric has been a favorite among designers, stylists, and homeowners for centuries. Whether it's gracing the runway in haute couture designs or adding charm to home interiors, lace fabric continues to redefine elegance.

In this blog, we delve into the world of premium lace fabric—its history, uses, types, and why it's still one of the most sought-after materials in fashion and décor. We’ll also introduce you to a trusted source where you can find the best lace fabric for your creative needs.

A Glimpse into the History of Lace Fabric

Lace originated in the 16th century in Europe, particularly in countries like Italy, France, and Belgium. Initially handmade using needle and bobbin techniques, lace was considered a luxury fabric worn by royalty and the elite. The popularity of lace soared during the Renaissance and Baroque periods, where it was heavily featured in collars, cuffs, and royal garments.

As industrialization advanced, lace-making techniques evolved, making the fabric more accessible. Despite its broader availability, premium lace fabric remains a hallmark of luxury and class to this day.

What Makes Lace Fabric “Premium”?

Not all lace is created equal. The term premium lace fabric refers to high-quality lace that stands out in several ways:

1. Material Quality

Premium lace is often made from fine threads like cotton, silk, or synthetic fibers that offer durability without compromising softness.

2. Intricacy of Design

The patterns are more refined and detailed, often involving floral, geometric, or custom motifs.

3. Durability

Unlike cheap lace that may fray or tear easily, premium lace is built to last through wear and wash.

4. Softness and Comfort

Premium lace fabric feels gentle against the skin, making it ideal for both apparel and décor.

To explore different types of lace materials in detail, check out this comprehensive guide on lace fabric material.

Types of Premium Lace Fabric

There are various types of lace, each with its own unique appeal. Some of the most popular include:

1. Chantilly Lace

Famed for its fine ground and abundant detail, Chantilly lace is perfect for bridal gowns and lingerie.

2. Guipure Lace

Characterized by its heavy and bold patterns, Guipure lace is often used in evening gowns and structured dresses.

3. Corded Lace

This lace features an outline around the motifs, giving it a three-dimensional effect. It’s widely used in wedding dresses.

4. Stretch Lace

Containing elastic fibers, stretch lace is comfortable and form-fitting, making it great for modern fashion.

5. Cotton Lace

Soft and breathable, cotton lace is suitable for both casual and formal wear, as well as home décor.

Applications of Premium Lace Fabric

Fashion Industry

Bridalwear: No bridal look is complete without some form of lace—be it in veils, bodices, or full gowns.

Eveningwear: Designers love lace for its ability to add elegance without excessive embellishments.

Lingerie: The softness and beauty of lace make it ideal for intimate wear.

Ethnic Wear: In countries like India, lace is used in sarees, lehengas, and salwar suits for added elegance.

Home Décor

Curtains and Drapes: Lace adds a romantic touch to interiors.

Tablecloths and Runners: Perfect for a vintage or classic table setting.

Cushion Covers: Adds texture and beauty to home furnishings.

DIY Projects

Craft lovers often turn to premium lace for custom projects such as wall art, bookmarks, and even personalized gifts.

Benefits of Choosing Premium Lace Fabric

1. Elegance That Lasts

The refined texture and appearance elevate any outfit or décor theme instantly.

2. Breathability

Unlike heavy fabrics, lace offers ventilation, which is especially useful in warm climates.

3. Versatility

From casual to couture, and from fashion to furniture—premium lace fits in anywhere.

4. Timeless Appeal

While trends come and go, lace remains a classic that never goes out of style.

Why Buy from a Trusted Source?

With the demand for lace growing, the market is flooded with substandard products that claim to be “premium.” This is why it’s crucial to buy from a reputable seller. At MK Fashion Lace, we pride ourselves on offering the best lace fabric that blends quality, design, and affordability. Our wide range of lace materials ensures you’ll find the perfect fabric for every project—whether you’re a designer, retailer, or hobbyist.

What to Look for When Buying Premium Lace Fabric Online

Material Composition: Make sure the lace is made from high-quality threads.

Design Precision: Check for clean, consistent patterns.

Customer Reviews: Authentic feedback can guide your decision.

Price Transparency: Premium doesn’t always mean expensive—value for money is key.

Return Policy: Ensure there is a flexible return or exchange policy.

Styling Tips Using Premium Lace Fabric

For Clothing

Pair lace tops with denim for a balanced casual-chic look.

Layer lace dresses with a bold jacket or belt to modernize the outfit.

Use lace trims on sleeves, collars, or hems for a DIY fashion upgrade.

For Home

Use lace as an overlay on colorful curtains for a light-filtering effect.

Create lace runners for your dining table using leftover fabric.

Frame pieces of intricate lace for unique wall décor.

MK Fashion Lace – Your Trusted Lace Fabric Partner

At MK Fashion Lace, we understand that our customers are looking for more than just fabric—they're looking for inspiration, creativity, and reliability. Our collection is curated to meet diverse needs, offering everything from everyday lace materials to exquisite options for high-end fashion.

Here’s why we are your go-to source for premium lace fabric:

Vast Collection: Over hundreds of lace styles and designs.

Unmatched Quality: Every piece undergoes quality checks.

Affordable Prices: Get luxury without the hefty price tag.

Customer-Centric Approach: Fast delivery and excellent support.

Visit our official website at mkfashionlace.com to browse our exclusive range and shop the best lace fabric available online.

0 notes

Text

How to Get Rid of Birdnesting on Your Embroidery Machine

Introduction

Birdnesting can be really annoying when it happens on your embroidery machine. It slows down your sewing and affects your speed. But don't worry, we've got you covered! In this guide, we'll show you how to fix birdnesting and improve your productivity.

Step 1: Check the Tension

Birdnesting can occur when the thread tension is too loose. Check both the tensioner and the bobbin to see which one is causing the issue. Turn the tensioner knobs to the right to tighten them and see if that helps. Make sure to refer to your machine's manual for proper tension settings.

Step 2: Needle Size Matters

Sometimes, the size of the needle can also affect birdnesting. If you're working with elastic fabric or high stitch density, try using a needle with a larger eye. This will help the thread pass smoothly through the fabric. Step 3: Use the Right Thread Different threads require different needle sizes. For example, if you're using a 40 gauge thread, use an 80/12 needle. If you're working with metallic threads, a 90/14 or 80/12 needle will work best. Check your thread guide for more information. Other Methods to Avoid Birdnesting In addition to the steps above, here are some other things you can do to prevent birdnesting: Method 1: Rethread Make sure to properly rethread your machine, removing the thread bobbin and spool. Check that the presser foot is down before sewing. Method 2: Replace the Needle A dull or damaged needle can cause sewing issues. Replace it with the correct size needle for your fabric. Method 3: Check the Presser Foot Always double-check that the presser foot is down before you start stitching. Forgetting to do this can lead to birdnesting.

Ways to Avoid Birdnesting

Here are some important things to keep in mind to avoid birdnesting: Proper Threading Make sure to thread your machine correctly to ensure smooth operation. Missing a point on the thread path can cause tension issues and lead to birdnesting. Correct Bobbin Placement Check that the bobbin is placed correctly to prevent snagging and birdnesting. Refer to your machine's manual for guidance if needed. Thread Tension Incorrect thread tension is a common cause of birdnesting. If the thread is too loose, it can unwind from the bobbin and create a buildup below the metal plate. Adjust the tension screw on the bobbin case to tighten the tension. Maintenance Regularly maintain your sewing machine to prevent birdnesting. Clean the machine and check for any thread shredding or buildup. Keeping your machine in good condition will help avoid issues. Proper Hooping Incorrect hooping can cause flagging, which leads to birdnesting. Make sure the fabric is hooped correctly to prevent bouncing and slipping during embroidery. Mechanical Issues Sometimes, birdnesting can occur due to mechanical problems with the machine. If you suspect a mechanical issue, seek help from experts to resolve the problem. Positioning In some machines, positioning can cause birdnesting. Pay attention to trimming, positioning, and hook timing to avoid this issue.

Conclusion

By following these steps and avoiding common mistakes, you can easily fix birdnesting on your embroidery machine. Don't worry about damaging your fabric or design, as these methods are safe to use. Happy sewing! Read the full article

0 notes

Text

[image description: an ask by @arbrehoux that says “Hi! I’m just getting into spinning, and I wanted to ask how to finish off the yarn once you’ve spun all you want. I’ve tried googling it, but every website I look at skips straight from the actual spinning to soaking. I’m using a drop spindle, if that’s relevant.” end image description]

soaking usually IS the way to finish yarn ! i'll give you the best step by step i can though (and for future reference, this applies to pretty much every single spinning method, so you can do this with yarns spun on a spinning wheel, a supported spindle, a drop spindle, a navajo spindle, a charkha wheel, or whatever else you might encounter. it's all yarn, so it can all be finished the same way.)

step 0: if you plan on plying your yarn, do it before finishing. you don't need to finish singles if you plan to ply them. finishing relaxes the yarn, so if you finish a singles and then ply it, it will end up being somewhat limp unless you overply it (which makes yarn less elastic and more rough) but if you spun a singles and want it to remain a singles, never to be plied, then you can certainly finish it as a singles.

step 1: remove the yarn from your spindle (or bobbin, or whatever it is on) and wrap it around something as it comes off. a niddy noddy is great for this, but not necessary. you can wrap your yarn around a big hardcover book or the back of a chair, or whatever. when taking yarn off a drop spindle, i usually just toss the spindle on the ground and let it roll around as I wind the yarn off. if you’re worried about it catching on something, put the drop spindle in a box or mixing bowl instead and let it roll around in there.

[image description: a somewhat blurry closeup of a tattooed man’s hands. in his right hand he’s holding a hardcover book. in his left he’s wrapping yarn around the book lengthwise. a red line has been drawn in to show the path of the yarn as he winds. end image description]

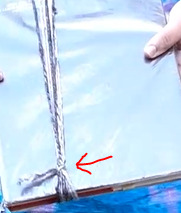

step 2: tie your yarn off. you can use the messy looking ends of the yarn if you wish, or another piece of yarn or string. just tie a simple knot around the hank. you want at least two knots, but if you're really worried about it tangling, you can do more. the purpose of tying your yarn off is to stop it from tangling in the next steps, to make it easier to work with when you wind it into a ball or cake later, and to keep it looking tidy.

[image description: a closeup of the yarn on the book from the previous image. a knot has been tied around all the strands of yarn on that side. there is a red arrow pointing to the knot. end image description]

step 2.5: if you want to know your yardage or meterage, this is the time to do so. first, count how many strands you have. second, measure how many inches or centimeters it takes to span the entire length of the book (so, front, back, and the width of both the top and bottom). In this case I think it was 8 strands and 24 inches for the whole book. that means the whole yarn is 192 inches (8x24=192) and the yardage is 5.3 (192/36=5.3). same steps if it’s centimeters and meters, of course. also, if you’re thinking “wow, I have to measure whatever i’m winding my yarn on every time ? that sounds annoying”, then you’re seeing why niddy noddys are so helpful and you should get or make one. my niddy noddy takes 2 yards to span it, meaning whenever i wind yarn on, after counting it i can just multiply my result by 2 and know how many yards i have (if i have 100 strands and i know each strand spans 2 yards, that means my whole skein is 200 yards. so much simpler.)

step 3: soak your yarn. or just get it wet. i usually run my yarn under the tap for a few seconds to make sure it is fully wet, but you can also put it in a bowl with some water and make sure it's fully submerged. leave it there for a few minutes.

step 3.5: if your yarn isn't very soft and you want it to be softer, you can add conditioner (just like, the normal stuff you use for your hair) to the bowl before you put the yarn in to soak. if you're softening it this way, leave it in the bowl of water for at least an hour, or even overnight. when you take it out, rinse it briefly. this step is only necessary if you want your yarn softer.

step 4 (optional): go outside and snap your yarn like a whip a few times. this evens out twist and flicks a lot of the water off, so it will dry faster too. if your yarn has some spots that are really undertwisted or overtwisted or both, this is a good way to help reduce that and make more evenly plied.

step 5: let your yarn dry completely. in the summer i hang my yarn over the clothesline, and in the winter i usually put it over a heating vent. doesn't matter how you do it. remember that wool in particular can feel dry even when it has a fair amount of water in it, so don't grab it the second it feels dry--give it a while longer to actually dry.

you should notice that your yarn looks different now that it's dry. if it's wool, it's likely puffed up some (to varying degrees depending on the breed of animal it came from, as well as whether it was roving or a batt or a rolag or whatever else, and also depending on how you spun it. it's a cool thing to pay attention to.)

step 6: skein your yarn. pick up the hank and drape it over your thumb or hand or whatever. the vast majority of yarns will twist a little in one direction when you do this, from residual twist. some yarns will twist a lot, others only barely. note the direction that it twists in--to the left or to the right. put your other thumb at the other end of the hank, and start twisting one thumb in the opposite direction that your hank twisted in. i usually twist with one thumb until i can't easily twist it anymore, and then twist with the other thumb. your nice loop should now look kind of like a piece of rope, with your thumbs still hooked into each end.

[image description: the first image shows the yarn hooked over each thumb, with two twists in the middle. the second image shows that same yarn, which now has so much twist it looks like rope. his thumbs are still hooked into each end. end image description]

you now want to find the center point of your ‘rope’ and fold it there. your ‘rope’ should kind of snap into place, looking like a much larger version of a 2 ply yarn. it’s nice and stable like this, and can be transported or stored easily (plus it’s pretty !). the last step is to take one of the loops you had your thumb in and push it through the other loop. this stops it from unraveling.

btw: the reason we twist it the opposite direction that it wants to turn is the same reason we ply in the opposite direction that we spin. if you spin Z and ply Z your yarn isn’t going to be structurally sound, and it’ll look pretty bad, too. when it comes to skeining you’re not adding any structural stability to the actual yarn, but the looks still matter--if your Z plied yarn is twisted Z while skeining, your skein will be limp and lifeless and not very pretty. if it’s twisted S, it’ll be nice and balanced and neat looking. it’s purely an aesthetics thing, but it also only takes half a second to figure out, so why not do it ?

and you’re done ! your yarn is now finished and skeined, and you know the yardage/meterage. you can label it with all relevant info if you want (for example: 4 ounces shetland roving, 2 ply, 350 yards, light worsted weight, finished august 2022, spun on a wheel)

#sorry this isnt an ask anymore#i somehow corrupted the original post by adding images and then saving it as a draft to work on later#idk... tumblr.#anyway those pictures are from a little video i made that im now somewhat too embarassed to post#although if this doesn't make sense and seeing it in video form would be helpful lmk and ill just link it anyway#it has to be a youtube video bc its too big to post on tumblr normally even after trying to condense it so#anyway sorry this took a while to answer ! it's hard to put most fiber instructions into words#spinning#handspun yarn#drop spindle#tutorial#also im not gonna go into shrinkage bc honestly i like to pretend it isn't a thing so that it doesnt mess up my yardage measuring#but if it immediately pops off the book/niddy noddy/whatever and looks way smaller that means your yarn is definitely shorter#than the actual yardage. calculating how long it really is while still using the same tools is rly hard#so i dont bother. you can minimize shrinkage by wrapping very loosely and not pulling on the yarn or putting it#under any tension as you wind. thats what i do with yarns when i really NEED to know the actual yardage#such as for a specific project or if i want to sell it#anyway yeah !

114 notes

·

View notes

Text

Ruffled maid-style headdress tutorial.

Someone asked for one of these, and I made a very complex bonnet tutorial and then remembered that I wasn't supposed to be making a bonnet.

Start by measuring the top of your head. I wear glasses sometimes, so I just ran it from one earbar, over the top of my head, and over to the other earbar. This is about the size of the headband that you're going to put it onto.

Cut yourself a piece of double-fold, extra-wide bias tape to be about 1" longer than this measurement. Fold the ends in and iron it so they stick around.

The ruffle itself is going to be a strip of fabric about 1.75x-2x the length of your bias tape. We're using this piece of silk dupioni that I pulled out of my sewing room trash, but you probably want to use a fabric that coordinates with your dress. This would work pretty well with quilt cotton, so take advantage of the crazy number of prints you can find on quilt cotton.

Sew a line of basting stitches at the bottom of your ruffle. Normally, you'd use two lines of basting for gathering, but I usually use one when it's less than a foot long. Mark the middle of the ruffle and the middle of your bias tape.

Pin the ends and middle of your bias tape to the ends and middle of your ruffle.

Note: I overlocked the edge of my ruffle here, but I ended up wishing that I hadn't done that, so don't get confused by that line of stitching.

Grab one of your threads on each end (make sure you're grabbing the same thread, eg both side you're grabbing the bobbin thread) and pull on them to make the gathers. Once you have your thread to be the same size as the bias tape, you can move the gathers around until they look even.

Again, I overlocked and rounded the edges of the ruffle first. It made things harder. Just use the raw edge of your ruffle.

Fold your bias tape over onto the ruffle, encasing the gathered edge.

Note: bias tape has a long side and a short side. When you look at a new piece of bias tape, you'll see that one lip of the tape is longer than the other. For this, you want the top side that you're putting the pins on to be the shorter side. It will just look better if you do that.

Once you've sewn that down, take your scissors and round the edges. This is really hard to eyeball when the ruffle is flat. Gathering it up changes the shape, so it's best to draw the shape in after it's gathered.

This is also a good time to hold it up to your head and see if your ruffle width is too wide. Mine was about 2" wide, but a more crisp fabric might need to be shorter since the fabric would have more body.

To finish the other edge, we're going to apply a flat lace onto the raw edge.

Your lace will have a decorative edge and a finished/sealed edge. I'm using a piece of paper here because I forgot to photograph this and I don't have lace on hand.

With the decorative edge facing inwards, sew the lace on. Make sure that the bottom of the lace is hanging off the raw edge of the fabric a bit (second picture.)

Then, flip the lace around by folding your fabric so that the lace edge points away from the fabric. Since your finished lace edge was sewn hanging off the raw edge, it will now cover the raw edge. Then, you just need to sew that finished lace edge down, and you've added lace and covered your raw edge all in one go.

You should be able to fit a thin headband into the bias tape to put it on your head, or you can use 1/8" elastic or some snap combs/toupee clips or whatever else you like to attach headdresses onto your head. Also, hopefully, not on your punk-inspired cosplay wig.

64 notes

·

View notes

Note

How did you learn to sew? I want to learn but it’s intimidating and overwhelming and I have no one to teach me lol

I started when I was 10 and didn't have any people to teach me either. I just had instruction books to follow and it was really difficult for me. The photos were illustrations and not realistic enough to really show what was going on and the text instructions weren't user friendly for people who were unfamiliar with sewing terms :')

Youtube is a GREAT resource nowadays though. Just search the model of your sewing machine and there's very likely someone out there with the same model explaining how to use every little feature.

To actually start sewing I recommend youtube searching "beginner sewing projects" and find something cute. Some examples of easy stuff are christmas stockings, pillows, and pot holders. I personally only really got serious with sewing last year when I made hundreds of cloth masks lmao. These things are all simplistic in design so you can get used to cutting fabric, moving it through your sewing machine, and also using the different features of your machine (like bobbin winding and loading, the different stitches, and the reverse stitch button).

Once you have the basics down, you find projects that are a small step up in terms of things you haven't used before, like zippers, buttons, elastic, and interfacing. Look at things that aren't flat too so you can familiarize yourself with folds and seams that add structure. Pencil cases are easy to make. You can make ones with zippers or fold-over style ones with button and loop closures. Hair scrunchies are also easy to make and are good for learning how to thread, pin, and sew elastic.

You just keep moving on like that, slowly getting the hang of certain projects and building up your experience so you can take on larger and larger projects.

I recommend against trying to sew clothes until you've mastered a few small projects. While you technically can start making simple clothing like circle skirts or pajama pants, a lot of people I've talked to about learning new crafts have cited spending money on materials and then ruining them as a fear that holds them back from even starting.

Sticking with small items at first is less stressful because then your materials are inexpensive so you don't have to feel like you wasted real money if you mess up (but also understand that you need to mess up at some point in order to learn how to pick out stitches!). Craft stores and even walmart sell these things called "fat quarters" which are precut rectangles of fabric 18" x 22". They're around $2-3 each and come in lots of fun patterns. If you want to practice sewing new things you can google "fat quarter projects" to find a couple free patterns to work with.

If you ever have any specific questions or want recommendations feel free to ask me! I'm by no means a master seamstress but this is something I really enjoy and spend a lot of time on so I'll do my best to help you out!

25 notes

·

View notes

Text

Quarantine, Day 36

Well, the bar exam results did not post at 12:01am on April 17 I didn't really expect that they would, but I had to check anyway. Like three times. Oh well. It's not like it's MY ENTIRE LIFE'S WORK or anything. Calm, we are so very calm around here. Very zen. We have put on the Tinykittens livestream on the television to watch one of their foster mamas get ready to have kittens, and we are intensely, rigidly, singlemindedly relaxed.

Today was sewing day! I signed up with the local food bank to help with a drive-through distribution on Monday because they needed volunteers, but I don't really have a proper mask. I've got an elastic-backed bandana headband that does well enough for running around and moving cats, but for something like this, I want to be masked up. And why should I not make my own masks? I'm crafty, I'm reasonably clever, and most importantly, I have my own sewing machine. Specifically, I have my mom's old sewing machine from the early nineties that I have never really learned how to use despite my best intentions, but let's not pick nits. It's a sewing machine, and it works. How hard could it be? (she asked with innocent hubris and massive amounts of unearned self-confidence.)

I spent the first part of the morning running more cats to the spay clinic, but that was so early in the morning it barely counts. After that, I pulled the sewing machine's rolly suitcase into the living room and set it up on a TV tray because we do not have an eating table and my husband and son were using both our desks for their various schools. A half hour of reading the user manual (copyright 1988) and watching some YouTube videos was enough to let me get the machine threaded, and I was ready to go! I was ready to... snap the thread instantly! I was ready to fuck around some with the tension dial so maybe it would not do that! I was ready to rethread the bobbin so it would not do that other thing! I was ready to make an absolutely unholy tangle, five or six times in a row! It was all amazing, I am clearly a prodigy.

It was around this point that I adjusted my expectations for churning out a couple masks and decided today would be a practice day. I cut a few squares out of an old t-shirt and practiced doing simple straight seams, which is apparently a lot harder than it looks. It took another four or five hours to routinely be able to make more than one seam in a row without rethreading everything, but I'm getting a lot better! And as a bonus,, I've been seaming rectangles on three and a half sides, then turning them inside out so the kiddo can stuff them with polyfil and sew them shut into pillows. His stitches, while a little large, are surprisingly straight! Good job. I think that with some continued work, I will be able to turn a pillowcase into a couple of credible masks before Monday. I hope, anyway.

Today was also exciting because it was GROCERY DAY. I have been waiting a very long time for this day, with my extremely large aspirational shopping list and very high hopes. The most important part first: they did include the 100 pack of colored pencils! I'm so excited! I ended up with eight unavailable items (including the pencil sharpener unfortunately), and 20 substitutions, but for the most part the substitutions were sensible and often much better than what I'd asked for in the first place. I am 1000% not going to quibble if they want to assuage my disappointment in not getting the pints of ice cream I wanted by subbing in gallons of a different flavor. That is more than okay with me, dudes! They also threw in a bag of someone else's groceries, consisting of some baby cheetos, a box of infant Midol, and a red onion, and I haven't seen my Sour Patch Kids anywhere. But for pity's sake, there's a pandemic on, and when you play Game of Groceries, you 'get what you get and you don't make a fit,' as one of the kiddo's preschool teachers used to tell him. I gave the guys a glowing five star review and left a comment on the corporate Facebook about the good job the store was doing. They are not allowed to take tips at Walmart, which blows, but hopefully that will help them a little at least.

So all in all, we have enough groceries to last us at least a month, though we'll probably have to go out for milk, OJ and bread a couple of times. The fridge is packed, as is the freezer (three gallons is a fuck of a lot of ice cream, my friends,) and the pantry. In looking at it all, I am willing to concede that I may have become a little squirrel brained this week, especially after the check came in yesterday, and that when I go to the food drive on Monday I should probably take a couple bags of stuff. Nobody needs fifteen cans of pasta sauce to last a month, and we still haven't eaten five of those cans of Spam I had before. There is a fine line between feeling good for having enough and feeling bad because you have too much and other people don't. On the other hand, I bought all the ingredients for key lime pie, plus a carton of fresh whipping cream. It's going to be _so good._ We also have five bunches of bananas, but that was just an accident. Good thing we've got that banana bread with chocolate chips recipe! Still no toilet paper to be had, but we have enough for now.

Found a fun free game on the App store called Seedship, that killed a couple of hours while I tried to save a sleeper ship full of the last remnants of the human race. Kiddo is reading Bunnicula for the second day in a row, he likes it! I'm glad, I used to love that book. He's also learning to do some fairly sophisticated math for fourth grade involving adding fractions of a circle's radius. I had to think for a minute to figure out what 5/8 of a full rotation would be, and then encourage him to think in the right way to figure it out too. It is 225 degrees, which we figured out in our heads by starting with the clue that 1/4=90 degrees, changing that to 2/8, then dividing it in half to get 1/8=45 degrees. He did nearly all of it himself, too, with just a little nudging from me, and then went on to figure out twelfths as well, then how to add various fractions to figure out total degrees. I'm very proud of him!

I wonder if it's going to be weird in future years if I or anyone else comes back to look at this and notices that I journal hardly at all about world events, and a huge amount about the contents of my pantry. The contents of my pantry is way less depressing. Reading the news is scary or sad or infuriating or frustrating, but digging out leftovers and cleverly combining them into a new casserole is both productive and fun. It's important, I think, to feel a sense of control, even when very little is controllable. That's maybe not the biggest reason I'm still trying to volunteer, but it's definitely on the list. You're not helpless if you can help others, even in small ways, even if that other is just a cat who doesn't even like you.

Still no bar exam results. It's gonna be a long day.

4 notes

·

View notes

Text

SEWING FOR BEGINNERS: EVERYTHING YOU NEED TO LEARN TO SEW

I know how it goes-you got that sewing machine for Christmas, you’ve wanted it for years. You dream of sewing beautiful, lacy pink dresses for your little girl. You think you’ll wow your friends with intricate Halloween costumes. You plan to create clothing for yourself that will magically make you look like you’ve lost ten pounds.

But there are gears and gadgets and you don’t know what they do. There are words like bobbin and back stitching and bias and you have no idea what they mean. Your heart starts to pound and your palms start to sweat just looking at.

So maybe that leather sewing Machine got shoved to the back of the closet and it’s covered in a thick layer of dust. Or maybe you haven’t shoved it aside yet. Maybe you’re ready to grab the bull by the horns and learn to sew, but it’s overwhelming to get going and you don’t know where to start.

CRAZY LITTLE PROJECTS TV Sewing can be very fulfilling. You can sew new projects and gifts, you can alter clothing that doesn’t fit right, make cozy blankets and quilts, and you can create lasting memories with the projects you sew. It doesn’t have to be hard, it just takes practice and patience, but soon you can be sewing like a pro.

Sewing for Beginners-Everything you need to know to learn to sew! Tons of tutorials to get you started with sewing.

SEWING FOR BEGINNERS: A LEARN TO SEW GUIDE-

HOW TO USE A SEWING MACHINE: Maybe you already have your sewing machine, but if you’re in the market for one still, it can be quite mind-boggling to try to figure out what machine to choose. They can cost anywhere from $99-$2,000 (and above) and how are you supposed to know which one will work best for you?

SOME THINGS TO CONSIDER AS YOU CHOOSE A MACHINE: What’s your budget? Do you want something on the very low end of the price scale or do you have a little bit more money to work with? Do you want to buy it locally or do you want to order it online? Some companies will include free sewing lessons when you purchase in store. If that interests you, you might choose to buy locally. You’re likely to find better prices online though, so if you are comfortable learning to sew online, that’s a great route to go. Do you want a lot of bells and whistles, or do you prefer something simple that might be easier to get started on? Both can be good options-sometimes simple is great. Or maybe you have some specific options that you want in a machine? Think about some of the things that matter to you.

Sewing for Beginners

Of course, there are a lot of things to consider when you’re in the market for a machine, and you’ve got to find the best fit for you.

Here’s a rundown of some of the best beginner sewing machines with some information about each one so that you can make a more informed decision. Although remember, just because you’re thinking about sewing for beginners right now, you won’t always be a beginner. So buy something that you’re going to love.

UNDERSTANDING HOW TO USE YOUR SEWING MACHINE: Once you’ve got your sewing machine, it can still be very intimidating right? You’ve got to learn to thread it, learn how to change the settings and learn what all of those buttons mean.

Every sewing machine is a little bit different, so your best bet is to start with the users manual. But don’t let this scare you. It isn’t particularly hard to thread a machine (especially with some of the new bells and whistles they have to make it easier) and most beginner machines aren’t going to have too many settings to overwhelm you.

So grab your manual, site to visit The machine and take a look. Maybe have something chocolate nearby to keep things happy and then be patient. Just practice threading and getting the machine set up.

If you’d like a peek into what most sewing machines are going to involve as you get started, try my How to Use Your Sewing Machine. I’ll walk you through some of the basics and hopefully at least lay the groundwork for you to get going in your beginning sewing journey.

BEFORE YOU SEW: There are some basic things you are going to need in order to get started with sewing for beginners.

First of all, you’re going to need some basic supplies like fabric, thread, a seam ripper, pins, scissors, and bobbins. Those are some of the most basic supplies needed (and of course there are so many more things you could buy as you go) to get going. For more details on what you’ll need to get started sewing, check out my Beginner’s Sewing Supplies guide.

What Supplies Do I Need to Get Started Sewing

Also, as you begin to read patterns and instructions, you’re going to come across a lot of unfamiliar words. Terms like basting and bias can be confusing but can be important aspects of what you’re working on. If you get a little lost, check out this Sewing Dictionary for some descriptions of the basic words.

A couple more things that might help before you get started with sewing for beginners:

Understanding Different Types of Fabric and How to Buy It (that store can be overwhelming!) Sewing Pledge (things to remember as you begin this journey) SEWING LESSONS FOR BEGINNERS: It’s time! You know how to thread that machine, you’ve got your supplies ready and you’re sitting in front of your machine. It’s time to sew something. But how?

As mentioned earlier, there are local shops that teach sewing lessons in store. If you want hands-on instruction and a teacher who can answer questions for you, this might be a great option for you.

Another possibility is to find a friend or relative who can walk you through the basics of learning to sew. Someone who can sit you down and teach you to sew a straight line or what some of the basic terms mean and get you started on the path of sewing for beginners.

How to Buy Fabric

If you prefer a self-taught, learn at your own pace method, try these free Learn to Sew lessons online. These will walk you through beginning sewing-from sewing a straight line to adding elastic and buttonholes. They are basic and easy and you can learn as you go with projects to work on to help you try each skill.

Or, try a combination of the above. Work on the online sewing lessons and meet with a friend or teacher who can help you periodically as well.

There are so many lessons on sewing for beginners. What’s important is to sit down and start trying.

And don’t expect perfection from the beginning. Remember that learning to sew takes a lot of time and practice and it’s ok if you make mistakes.

EASY SEWING PROJECTS FOR BEGINNERS: But what to sew right? You dream of all the projects you’ll create, but it can hard to know where to begin. Whether that’s because you have so many ideas or because you are scared to start, it is best to start with some very easy beginner sewing projects.

A few things to look for when seeking out easy sewing patterns for beginners to get started on:

Straight lines-these are the easiest to sew and can be a good starting place Not too intricate-something that doesn’t have a lot of frills and embellishments Household items can often be some of the easiest sewing projects to get started on. Clothing can be more difficult, so starting with things like blankets or pillows or even burp cloths or key fobs can be simple sewing projects to start with.

WHERE TO LOOK FOR EASY SEWING PATTERNS: The internet is FULL of easy, beginners sewing projects. Jump on Pinterest and you’ll be inundated with them. You’ll probably be either overwhelmed or really excited. If you need some inspiration, try my Things to Sew Pinterest board.

Beginner Sewing Project

Then, as you get more comfortable and confident with your sewing, move on to some slightly harder projects. Take it at your own pace and do what works for you. Remember, sewing should be fun, not frustrating. But also remember that the seam ripper is your friend and it’s normal to use it frequently. Mistakes happen.

TAKING IT TO THE NEXT LEVEL: As you progress you will learn more and more skills relating to sewing. Maybe you want to learn to quilt? Maybe you’re dreaming of sewing clothing? There are so many possibilities and a lot of fun techniques to try out as you progress.

A couple of resources to help you as you move past sewing for beginners and into a more intermediate or advanced phase of sewing:

Sewing Tips for Beginners to Pros Learn to Sew eBook-Includes tutorials on reading patterns, understanding bias and more And here are some fun resources for sewing projects:

4 notes

·

View notes

Text

50 LEATHER SEWING TIPS FOR BEGINNERS and PROS

What's the Project?

Regardless of whether you are new to sewing or you're an old genius, these sewing tips are going to enable you to ace your aptitudes. Huge amounts of sewing traps and hacks to enhance the majority of your sewing aptitudes.

With such a great amount of fervor about figuring out how to sew, enhancing aptitudes and simple sewing ventures, I figured it would be a decent time to pull together a rundown of a wide range of sewing tips and traps for amateurs, professionals and everybody in the middle.

Regardless of whether you've been sewing for quite a while, there are most likely methods you haven't attempted. Also, it's amusing to attempt new things right?

Let's be honest, most likely practically we all have things to learn and things to chip away at in our sewing, so today I have a rundown of 50 Sewing Tips, Tricks, and Techniques to help you in your activities.

SEWING TIPS FOR BEGINNERS AND PROS:

Here we go! I've separated it into classifications to make it less demanding. On the off chance that you find other incredible tips and traps online that you think would profit others, don't hesitate to send them to me and I can include them in.

Beginning TIPS FOR BEGINNING SEWING:

All that You Need-Sewing for Beginners

Understanding Your Sewing Machine

Sewing Dictionary-Sewing Terms Defined

What Supplies Will I Need to Start Sewing?

The Sewing Pledge

Nuts and bolts/BEGINNERS:

Instructions to Sew a Straight Line

The ZigZag Stitch

Winding and Threading Bobbin

Basic Steps to Improve Your Skills

Seasoning 101

Understanding Different Types of Fabric

SEWING TECHNIQUE:

Instructions to Sew Piping

Turning and Top Stitching

Including Elastic in a Casing

Instructions to Sew Ruffles

Instructions to Insert a Zipper

Instructions to Sew Buttonholes

Instructions to Applique

Shirring/Smocking with Elastic Thread

Cutting and Notching Curves

Tips for Sewing Corners and Squares

Utilizing a Stretch Stitch

Hand Stitching

Making Crisp, Even Hems

Sewing With a Double Needle

Mitered Corners

Sewing Pleats

Serge without a Serger

Tip for Sewing on Vinyl

Instructions to Draft and Sew a Skirt

Sewing Jeans

Instructions to Finish Seams

Instructions to Sew a Dart

Tips for Perfect Pressing

Taking Your Measurements

Example Cutting

Understanding Patterns

Texture:

Which Fabric to Buy? Seeing How to Buy Fabric

Pre-washing Fabric

Sewing with Cuddle Fabric

Instructions to Sew on Leather

Instructions to Sew with Lace

Sew with Laminates

Sewing on Knits

Devices:

Cleaning Your Sewing Machine

Understanding Thread Tension

Buying Guide for Leather Sewing Machine 2019

Unraveling the Marks on Measuring Tape

Utilizing Stay Tape

Utilizing a Rotary Mat and Cutter

Joining Snaps

Understanding Interfacing and Lining

SEWING FOR KIDS:

Figure out how to Sew Kids Series

Instructing Kids to Sew

Ideally, these sewing tips will be useful for you in your sewing venture!

Also visit for best reviews Finestreview.com

Also, make certain to go along with me on Pinterest where I stick sewing tips, sewing undertakings and a wide range of other incredible sewing thoughts.

1 note

·

View note

Text

Curtain Fabric Manufacturers in India

Introduction

In the bustling metropolis of Bangalore, Elastic Manufacturers in Bangalore known as India's Silicon Valley, innovation thrives in every sector imaginable. Among the myriad industries that call this vibrant city home, the elastic manufacturing sector stands out for its precision engineering, cutting-edge technology, and commitment to quality. In this article, we'll delve into the world of elastic manufacturers in Bangalore, exploring their diverse offerings, technological prowess, and the factors contributing to their success.

A Legacy of Excellence

Bangalore's emergence as a hub for elastic manufacturing is rooted in its rich industrial history.

1. Textile Heritage: Bangalore has long been associated with the textile industry, with a legacy dating back to the pre-independence era. The city's expertise in textiles, coupled with its skilled workforce, laid the foundation for the development of specialized sectors within the industry, including elastic manufacturing.

2. Technological Advancements: As Bangalore evolved into a technology hub, its elastic manufacturers embraced innovation to stay ahead of the curve. Leveraging state-of-the-art machinery, automation, and advanced materials, these manufacturers have redefined the standards of quality and efficiency in elastic production.

3. Skilled Workforce: Bangalore's reputation as a center for education and skill development has attracted talent from across the country. The city boasts a pool of highly skilled engineers, technicians, and designers who contribute to the success of its elastic manufacturing industry.

H2: Precision Engineering and Innovation

The elastic manufacturers in Bangalore are renowned for their commitment to precision engineering and innovation.

1. Product Range: From traditional elastic bands used in apparel and accessories to specialized elastic components for automotive, medical, and industrial applications, Bangalore's manufacturers offer a diverse range of products to cater to various industries and consumer needs.

2. Customization: Flexibility is a hallmark of Bangalore's elastic manufacturers, who excel in providing customized solutions tailored to the specific requirements of their clients. Whether it's adjusting the width, length, or elasticity of an elastic band or developing entirely new products from scratch, these manufacturers are adept at meeting unique customer demands.

3. Research and Development: Innovation is at the heart of Bangalore's elastic manufacturing sector, with companies investing heavily in research and development to stay at the forefront of technological advancements. From experimenting with new materials to improving manufacturing processes and exploring novel applications, these manufacturers are constantly pushing the boundaries of what's possible in elastic production.

H2: Quality Assurance and Compliance

Quality assurance and compliance are paramount for elastic manufacturers in Bangalore, who adhere to rigorous standards to ensure the reliability and safety of their products.

1. ISO Certification: Many elastic manufacturers in Bangalore are ISO certified, demonstrating their commitment to maintaining high-quality standards in all aspects of production, from raw material sourcing to final product inspection.

2. Regulatory Compliance: In addition to ISO certification, elastic manufacturers in Bangalore adhere to industry-specific regulatory requirements, especially in sectors such as automotive, healthcare, and aerospace, where stringent quality and safety standards are paramount.

3. Quality Control Processes: Stringent quality control processes are implemented at every stage of production to identify and rectify any defects or deviations from specifications. This attention to detail ensures that only products meeting the highest standards are delivered to customers.

Collaborative Partnerships and Global Reach

Bangalore's elastic manufacturers actively engage in collaborative partnerships with domestic and international businesses, leveraging their expertise to drive innovation and expand their global reach.

1. Supply Chain Integration: Many multinational corporations choose to partner with elastic manufacturers in Bangalore due to their advanced capabilities and reliable supply chain. By integrating seamlessly into the global supply chain, these manufacturers play a crucial role in the success of their partners' products and operations.

2. Export Opportunities: Bangalore's elastic manufacturers export their products to markets around the world, capitalizing on the city's reputation for quality and reliability. From elastic bands used in apparel and packaging to specialized elastic components for industries such as automotive and healthcare, Bangalore's manufacturers cater to a diverse range of international customers.

3. Collaborative Innovation: Collaborative partnerships between elastic manufacturers and their customers often extend beyond traditional supplier-customer relationships. By working closely with clients to understand their needs and challenges, Bangalore's manufacturers contribute to the development of innovative solutions that drive mutual success.

Conclusion

In conclusion, Bangalore's elastic manufacturers exemplify the city's spirit of innovation, precision engineering, and commitment to quality.

From their roots in Bangalore's textile heritage to their embrace of cutting-edge technology and innovation, these manufacturers have earned a reputation for excellence that extends far beyond India's borders. With their diverse product offerings, customized solutions, and collaborative partnerships, Bangalore's elastic manufacturers are poised to continue driving innovation and shaping the future of elastic manufacturing on a global scale.

0 notes

Text

Saurer at India ITME 2022: shows air-spinning machine Autoairo

Saurer, the premier solution provider for spinning and twisting machines, will be present at the INDIA ITME 2022 from 8 – 13 December in New Delhi in booth 10C7E12. The highlight will be our air-jet spinning machine Autoairo, to be exhibited for the first time in India. Saurer’s spinning and twisting machines are renowned for their energy-saving features, automation, and digitalization solutions. Saurer machines enable the circular economy in textiles and are the leaders in processing recycled textile materials.

With Autoairo, Saurer is the only supplier offering five different spinning systems from one company: ring, compact, worsted, rotor, and air spinning systems. Exhibits to be presented at the booth are the new Autoairo air-spinning machine, the Autospeed roving frame, the Autocoro, and BD rotor spinning units, the FusionTwister for two-for-one twisting, as well as exhibits of Texparts and Fibrevision quality monitoring.

Excellent sliver quality with Saurer’s blow room and carding machines

The right combination of Saurer’s blow room and carding machinery ensures excellent fibre utilization and sliver quality, thus increasing the efficiency of the spinning process and improving the quality of yarn. The new Autocard was developed to create further value in the fibre preparation chain.

Autoairo – the new air-spinning technology

The Autoairo sets new benchmarks for air spinning. Saurer has combined its most advanced automation solutions with proven technology to create an air-spinning machine with unique properties. The Autoairo features autonomous spinning positions with automation per spinning unit for more productivity and integrated intelligence. The exhibited Autoairo will remain in India to conduct customer trials. Belairo, the new air-spun yarn impresses with low hairiness and high pilling resistance.

Saurer – the market leader in rotor spinning

The Autocoro is the market and technology leader which revolutionized automatic rotor-spinning technology and opened the door to more productivity, flexibility, and sustainability for customers worldwide. In just 10 years, Saurer installed 1 million Autocoro spinning positions with individual drive technology and energy-saving features. The BD 7 semi-automated rotor spinning machine is powered by the technologies of Autocoro. With the patented digital piecing technology, DigiPiecing, and take-up speeds of up to 230 m/min, the BD 7 remarkably improves yarn quality and productivity for spinning mills.

The benchmark for intelligent roving and ring spinning

The use of the Autospeed roving frame with automatic doffer ensures that spinning mills do not have to rely on skilled workers, and simultaneously increases the quality of the roving. The Autospeed roving frame with up to 240 spindles saves up to 20% of energy compared with the previous model, while doffing takes less than 2 minutes. Also in action at the ITME exhibition, customers can see the Autospeed in combination with the bobbin transport system and Roweclean, the automatic tube cleaner.

The ZR 72XL and ZI 72XL are two highly productive ring and compact-spinning machines. They set global benchmarks for intelligent spinning, low energy consumption, user-friendliness, and flexible automation solutions.

Texparts components for boosted ring spinning productivity

Saurer’s Texparts product line offers high-quality components for the textile industry including drafting systems and spindles, spinning rings, and travellers. The new double elastic spindle, Eshape, has a reduced wharf diameter and is based on CS 1 S. Outstanding running properties up to 30 000 rpm and about 6% energy savings are the key performance factors. Eshape, combined with the best system for spinning without underwinding, Spinnfinity, is the perfect fit for automated and efficient ring spinning.

The FusionTwister – two-for-one twisting at highest speeds

At the ITME exhibition, Saurer will also show the two-for-one twisting machine FusionTwister, which offers high efficiency combined with the excellent quality of the cross-wound delivery packages produced. Up to 15% of energy can be saved with the FusionTwister while increasing the winding speed by 10%: This remarkable result was reported by an Indian customer. Consistent high yarn and package quality is a result of our robust machine construction and optimised yarn guiding elements, which consist of yarn-friendly ceramics or have plasma-coated surfaces for low friction and longevity.

Rolling the tire market up – CableCorder CC5 for direct cabling

Saurer’s twisting machines are as flexible as the market demands. The direct cabling machine, CableCorder CC5, for tire cord and industrial yarns, features a new spindle gauge 400 with up to 200 spindles, making it a true space saver. Its Cord Regulator technology ensures equal lengths of the individual yarns and thus high cord quality. Thanks to the balloon reduction technology developed by Saurer, the same, smallest possible balloon diameter can be set on every spindle – regardless of the titre. Energy consumption is thus kept to a minimum on the CC5.

Saurer Fibrevision for quality monitoring of filament yarns

For all synthetic continuous filament yarns, Saurer Fibrevision’s online quality monitoring devices are well-established in the market. Fibrevision products serve all areas of the industry: Fraytec FV2/ Unitens / FibreTQS are multi-parameter quality monitoring systems that can be used in filament spinning (POY, FDY, BCF, T+I), draw texturing (DTY) as well as in cabling, twisting, and elastomer production. Single and multi-threadline sensors assure customers of the quality of their production.

Saurer machines enable the circular economy in textiles

Saurer enables spinning mills to process a wide range of recycled and regenerated fibres in their production. The Saurer rotor spinning machines are leaders in the processing of recycled fibres.

The Saurer textile technology laboratory continuously assists customers in optimizing their yarn production and yarn quality, especially for recycled fibres.

With more than 160 years of experience, Saurer has always been committed to advancing the textile industry, integrating high-end equipment manufacturing with modern information technology to provide complete solutions for the smart spinning factory. Saurer is pleased to welcome all customers of ITME 2022 to booth 10C7E12.

0 notes

Text

Where to Find Top Online Nylon Fabric Material Mumbai | Hitesh Trading Co.

Nylon fabric has built its reputation in the fabric market over the years and it’s true that people have sought after this fabric ever since its introduction. If you are looking for top online nylon fabric material Mumbai–one of the epicenters of fabric productions, then keep reading this blog about nylon and why it is so much coveted after. Popularized as having phenomenal elasticity with superior strength, nylon was seen as the textile of the future. It was launched in the 1930s which described it as a material stronger than steel. With a low production cost and the feel of silk, it’s easy to see why it took the world by storm.

The strength of nylon fabric lies in its properties more than its appearance. It can be drawn, cast, or projected through spinnerests from a melt or solution to form fibres, filaments, bristles, or sheets to be manufactured into yarn, fabric, and cordage; and it can be formed into molded products. It has high resistance to wear, heat, and chemicals. As years passed since its launch, nylon has been subjected through both controversies and endorsements. In India, nylon has served its purpose to all corners and still does hence people often put in searches such as top online nylon fabric material Mumbai in order to find the best variety of the fabric in the heart of city of Mumbai where the fabric business booms perpetually.

Nylon, originally, was marketed as a silk substitute for stockings where its gets its name in a roundabout manner. Since it was thought to be strong, durable and run-resistance, it was led to be called ‘No-Run’. So where can you find find the best nylon fabric in India? Hitesh Trading Co, with its 30+ years in the textile market, has established itself as the answer to top online nylon fabric material Mumbai. We have different types of pure and blended nylon fabrics such as nylon crepe and nylon satin fabrics. Whether you are a person looking to get their clothes made, a designer looking to pour their ideas into reality, or a merchant wishing to fuel up their inventory– we provide high-grade nylon fabric materials at an economical rate. Our reliable delivery service will ensure timely transportation of your goods to your doorsteps without any hassle. Now, let’s learn a bit more about nylon fabric manufacturing.

Nylon fabric is made through the following steps:

Extraction : Here, the diamine ion called diamic acid is extracted from crude oil.

Combining: The diamic acid is forced to enter into a reaction with adipic acid, to create a polymer known as nylon salt

Heating: The crystalized substance is then heated to form a molten substance.

Extrusion: The substance is forced out through a metal spinneret.

Loading: It is then loaded into a pool called a bobbin.

Stretching: These fibers are then stretched to increase their strength and elasticity.

Drawing: They are wound into another pool called in the process of drawing.

Spinning: The resulting fibers are ready to be spun into garments or other fibers.

Finishing: The end product is dyed the desired color before being sent to the market.

We hope you liked this blog post about top online nylon fabric material Mumbai. Apart from viscose, you can find different kinds of silk, cotton, net, nylon, etc, on our website. We are the leading best importer, and supplier of silk fabrics in India based in Mumbai. Kindly comment and share our blog. You can follow us on our social media handles to know about our products and offers. For more information about fabric types and pricing, you can visit our website: https://htcsilk.com/ or call: +91 9820510025 or mail: [email protected] .

#hitesh trading compnay#htcsilk#Online Nylon Fabric#nylon fabric#facbrics#best nylon fabrics#top nylon fabrics

0 notes

Text

Janome Facility 21 test and review

Introducing the Janome Facility 21 Sewing Machine