#b7 stud bolt manufacturers

Explore tagged Tumblr posts

Video

youtube

👍GOODFIX & FIXDEX the big threaded rods factory💯fast delivery and best s...

#youtube#threaded rods fast delivery#b7 stud bolt#b7 stud manufacturer#stud bolts#stud bolt fastenal#stud bolt manufacturers#stud bolt factory#stud din 975#din 975 threaded rod#thread bolts#thread bolt factory#steel threaded rods#fully threaded rods#factory rod#threaded rod company#b16 threaded rod#b8 threaded rod#b7 threaded rod near me#threaded rod manufacturing#threaded rod fasteners#threaded rod manufacturers#threaded rods near me#threaded rods factory

1 note

·

View note

Text

Leading Stud Bolt Manufacturers in India | Delta Fitt Inc

Delta Fitt Inc. is the leading Stud Bolt Manufacturers in India and B7 Stud Bolts Manufacturers in India. Understand their competitive advantages, manufacturing strategies, and market position.

Delta fitt, obtained the best stud bolts by top Stud Bolt Manufacturer in India, takes centre stage.Stud bolts are used to secure commercial buildings in a wide range of industries, including industry and construction. Examine the advantages, highlight important features, and learn about industry issues. Examine the future risk of stud bolt growth. Choose best quality stud bolts like B7 & B8 Stud Bolts reliability for secure projects. Make the right choice for lasting reliability. Choosing these stud bolts from trusted B8 and B7 Stud Bolts suppliers in India creates a construction cooperation.

In search of top Stud Bolt Suppliers in India? Delta Fitt Inc. has you covered with top-quality stud bolts solutions.

For more details,

Also Visit: B7 Stud Bolts Manufacturer in India, B8 Stud Bolts Manufacturers in India

#stud bolt manufacturers in india#B7 Stud Bolts Manufacturer in India#B8 Stud Bolts Manufacturers in India#stud bolt manufacturers

0 notes

Text

Astm A193 GR B7 Material

ASTM A193 GR B7 Material is a high-strength, heat-treated alloy steel commonly used in bolting applications for high-temperature and high-pressure environments. It is manufactured from chromium-molybdenum steel, offering excellent tensile strength, hardness, and resistance to corrosion and oxidation. This material undergoes a quenching and tempering process to enhance its mechanical properties, making it ideal for petrochemical, construction, and power generation industries. ASTM A193 GR B7 Material is widely used in stud bolts, threaded rods, and fasteners that require superior durability and performance under extreme conditions. It meets stringent industry standards and provides reliable performance in harsh environments. Its ability to withstand high temperatures and pressure makes it a preferred choice for industrial applications where safety and efficiency are paramount.

0 notes

Text

Leading Inconel Fasteners Manufacturer in India

Delta Fitt Inc. stands as a premier Inconel Fasteners Manufacturer in India, renowned for delivering top-quality fasteners tailored to meet diverse industrial needs. With extensive expertise and cutting-edge manufacturing processes, the company offers a wide range of Inconel fasteners, including bolts, nuts, washers, and more, ensuring exceptional durability and resistance to extreme environments.

As a trusted Inconel Fasteners Supplier in India, We prioritizes customer satisfaction by adhering to stringent quality standards and providing cost-effective solutions. Their products cater to various industries such as aerospace, marine, chemical processing, and power generation.

By leveraging advanced technology and maintaining a customer-centric approach, Our company has earned its reputation as a leading Inconel Fasteners Supplier globally. For businesses seeking reliable and high-performance Inconel fasteners, Delta Fitt Inc. is the go-to Inconel Fasteners Manufacturer for superior quality and service.

We are also leading B7 Stud Bolts Manufacturers in India, and B8 Stud Bolts Manufacturers in India.

Website: deltafitt.com

#InconelFastenersManufacturerInIndia#InconelFastenersManufacturer#InconelFastenersSupplierinIndia#InconelFastenersSupplier

0 notes

Text

Premium Stud Bolts Manufacturer, Supplier & Exporter

Introduction

Stud Bolts are one of the versatile fasteners widely used in all industries like oil & gas, petrochemical, power plants, construction, and marine applications. It is designed to have critical fastening. Ananka Group is a leading manufacturer, supplier, and exporter of Stud Bolts; it ensures top quality precision, and reliability in all its products.

The premium stud bolts that manufacture, supply, and export in high-quality and precision commitment in the fastener industry. We as a manufacturer use advanced materials and cutting-edge technology to produce stud bolts that meet the stringent industry standards for durability and reliability in applications ranging from construction to automotive sectors. Focus on superior craftsmanship and strict quality control processes, thus giving products not only make structures safer but also increase efficiency.

Additionally, capability to satisfy different customers through customization also indicates a commitment to customer satisfaction. Being trusted suppliers in the global market, these manufacturers have become the link between industries and premium fastening solutions that have withstood time. As a way of giving credit to their hard work, we acknowledge the important role these premium stud bolts play in driving innovation and excellence in many sectors.

About Stud Bolts

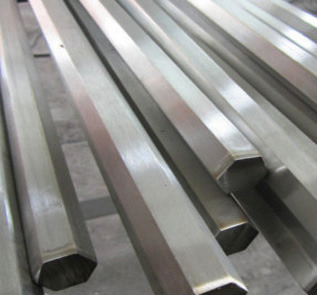

Stud bolts are long threaded rods with threads on both ends, or sometimes throughout the rod. They are primarily used to clamp flanges or other equipment together, ensuring a tight, leak-free seal. Unlike traditional bolts, stud bolts do not have heads and rely on nuts for fastening.

Types of Stud Bolts

Fully Threaded Stud Bolts: Threads run across the entire length of the stud.

Tap-End Stud Bolts: Threads on both ends, but the lengths of the threads differ.

Double-End Stud Bolts: Threads of equal length at both ends.

Reduced Shank Stud Bolts: Feature a reduced diameter in the unthreaded section to improve flexibility.

Stud Bolts Specifications

Standards: ASTM A193, ASTM A320, ASME SA193, ISO, DIN, and other international standards.

Sizes: From M6 to M64 or custom sizes as per client requirements.

Thread Types: Coarse, fine, or special threads based on the application.

Finish: Plain, galvanized, or coated with PTFE, zinc, or other protective materials.

Stud Bolts Sizes & Standards

Stud Bolts Materials / Grades & Sizes

Carbon Steel Stud Bolts

Grades: ASTM A193 Grade B7, ASTM A320 Grade L7

Applications: High-temperature and pressure environments.

Stainless Steel Stud Bolts

Grades: ASTM A193 Grade B8, B8M

Applications: Corrosion-resistant environments like marine and chemical industries.

Alloy Steel Stud Bolts

Grades: ASTM A193 Grade B16

Applications: High-strength requirements and elevated temperatures.

Nickel Alloy Stud Bolts

Grades: Inconel, Monel, Hastelloy

Applications: Extreme temperatures and highly corrosive environments.

Exotic Material Stud Bolts

Materials: Titanium, Duplex, Super Duplex

Applications: Specialized industries like aerospace and medical.

Why Choose Ananka Group for Stud Bolts?

Uncompromising Quality: Manufactured as per international standards with precise tolerances.

Material Versatility: Offering a wide range of materials to suit varied applications.

Customization: Tailor-made solutions for specific project requirements.

Global Reach: Exporting to countries across Europe, Asia, America, and Africa.

Conclusion

Stud bolts are indispensable in industries requiring high-strength and secure fasteners for critical applications. With Ananka Group, you are assured of the best quality products, backed by extensive expertise, advanced manufacturing facilities, and a commitment to excellence.

FAQs

Q1. What are stud bolts used for?A: Stud bolts are primarily used in applications requiring secure fastening, such as connecting flanges, pipelines, and machinery.

Q2. What materials are stud bolts made of?A: Common materials include carbon steel, stainless steel, alloy steel, and nickel alloys.

Q3. Can stud bolts be customized?A: Yes, stud bolts can be tailored to specific sizes, materials, coatings, and thread types.

Q4. How to choose the right stud bolts?A: The choice depends on the application requirements, such as temperature, pressure, corrosion resistance, and strength.

Q5. Do you provide international shipping?A: Yes, we export our stud bolts to various countries worldwide.

#AnankaFasteners#Fasteners#StudBolts#BoltManufacturing#Manufacturing#Linkedin#Article#StudboltMaking#FastenersManufacturing#manufacturer#ananka#supplier#hex#bolt#mumbai#uk

0 notes

Text

Bolts and Nut Manufacturers in India -Bigboltnut

We manufacture larger diameter, high strength screws and fasteners and HV grade hot dip galvanized fasteners. We are India's largest large diameter of bolts and nuts manufacturer and fasteners for leading contractors and consultants undertaking projects in India, USA, Europe, Asia, Africa and Middle East in the energy, renewable energy, wind and infrastructure sectors. We are also a specialized in stainless steel hex bolts, nuts, studs and washers used in water treatment, waste water treatment, sewage treatment, desalination plants etc. We have different type of grade as per ISO 898-1:2013, in 8.8, 10.9, 12.9, A2-70, SS 316, SS 316L, SS316 S31, B7, L7, 8M, B8 etc.

BigBoltNut rich history, advanced manufacturing facility, and wide range of offerings make us a top-rated bolts, nuts and washer manufacturer in India. Whether you need products for power, energy, marine, or any other industry, BigBoltNut is your one-stop solution. Our commitment to quality and excellence ensures that our customers always receive best-in-class products.

Source url: https://www.bigboltnut.com/

0 notes

Text

Stainless Steel Fasteners Manufacturer in India - Sachiya Steel International

Stainless Steel Fasteners are indispensable components in various industries, from construction and automotive to marine and aerospace. These hardware devices mechanically join or fasten two or more objects together, ensuring the structural integrity and durability of different applications. In India, Sachiya Steel International Private Limited stands out as a leading manufacturer of high-quality stainless steel fasteners. This article provides an in-depth overview of stainless steel fasteners, their types, manufacturing processes, and the prominent role of Sachiya Steel International in the industry.

Types of Stainless Steel Fasteners

Stainless steel fasteners come in various types and grades, each designed for specific applications based on factors like corrosion resistance, strength, and environmental conditions. Here are some common types:

Bolts and Nuts

Screws

Washers

Studs

Anchors

Manufacturing Process of Stainless Steel Fasteners

Sachiya Steel International utilizes state-of-the-art manufacturing processes to produce high-quality stainless steel fasteners that meet stringent industry standards.

Raw Material Selection

Only high-grade stainless steel raw materials are selected to ensure durability and corrosion resistance. Common grades include AISI 304, AISI 316, and AISI 410 stainless steels.

Cold Heading

Cold heading is a method used to form fastener heads and threads by forcing metal through various dies. This process improves mechanical properties and maintains uniformity in shape and dimensions.

Thread Rolling

By cold forming threads onto fastener shafts, thread rolling enhances strength and wear resistance compared to cut threads.

Heat Treatment

To achieve the desired mechanical properties, fasteners undergo heat treatments such as annealing, quenching, or tempering. These treatments increase strength, hardness, and corrosion resistance.

Surface Coatings

Sachiya Steel International offers various surface finishes, such as electroplating, hot-dip galvanizing, or organic coatings. These finishes enhance corrosion resistance and aesthetic appeal.

Applications of Stainless Steel Fasteners

Stainless steel fasteners are essential in numerous industries due to their adaptability and reliability.

Construction

Stainless steel bolts, nuts, and washers are extensively used in construction applications requiring strength, durability, and corrosion resistance, such as bridges, buildings, and infrastructure projects.

Automotive

AISI 410 stainless steel screws are commonly used in the automotive industry for assembling vehicles and machinery, ensuring long-term reliability and longevity.

Marine

To resist corrosion in marine environments, stainless steel fasteners like AISI 316 anchors are ideal. These fasteners are commonly used on ships and offshore structures.

Aerospace

Fasteners designed for aerospace applications, such as ASTM A193 B7 studs, are essential for ensuring safe and reliable flight. Their lightweight properties, high strength, and resistance to extreme temperatures and corrosion make them indispensable in aircraft construction.

Sachiya Steel International: Leading Manufacturer of Stainless Steel Fasteners in India

Sachiya Steel International Private Limited stands out as a premier supplier of stainless steel fasteners in India, thanks to several key attributes:

Quality Assurance

Rigorous quality control measures ensure that each fastener meets international standards such as ASTM, AISI, and DIN, as well as customer-specific specifications.

Customization

Sachiya Steel International can tailor fasteners according to size, material grade, surface finish, and coating specifications to meet diverse customer needs and application requirements.

Infrastructure

State-of-the-art manufacturing facilities equipped with modern machinery, automated production lines, and sophisticated testing equipment ensure consistent quality and production efficiency.

Global Reach

India has built an outstanding global reputation as a reliable supplier of industrial fastening solutions by exporting high-quality stainless steel fasteners to global markets.

Conclusion

Stainless steel fasteners are key components in many industries, providing structural integrity, reliability, and safety across an array of applications. Sachiya Steel International Private Limited stands as India’s premier producer, manufacturing stainless steel fasteners that exceed domestic and international market demands. Their commitment to innovation, quality, and customer satisfaction solidifies their position as a go-to supplier for stainless fastening solutions worldwide.

Read More: Stainless Steel Fasteners Manufacturer in India

0 notes

Text

Benefits of using Full-threaded Stud bolts | Roll Fast

Full-threaded stud bolts are non-headed bolts, these are in the form of a rod and have threads from end to end. A threaded rod, also known as a stud, is a relatively long rod that is threaded on both ends. The fully threaded studs have no head, are threaded along their entire length, and have a higher tensile strength. We offer full-threaded stud bolts in different grades like 8.8, 10.9, 12.9, B7, B8, L7, B16, and more for petrochemical industries. The most common application of these studs is in industries like manufacturing, plumbing, construction, petrochemical, and automobile manufacturing. Fully Threaded Studs are ideal for making custom assemblies using thread-locking adhesive and along with that, they can also be used for custom applications based on individual requirements. The fully threaded studs have no head, are threaded along their entire length, and have a higher tensile strength. The thread may extend along the complete length of the rod.

visit source URL : https://www.roll-fast.com/industries-served/petrochemical-industries/full-threaded-stud-bolts.html

0 notes

Text

Purpose of choosing ASTM A193 grade strength

Alloy steel bolting materials meeting ASTM A193 Grade B16 criteria are the norm for strain vessels, valves, flanges, and fittings meant to face up to excessive temperatures and pressures. The maximum frequent users of these applications are the petrochemical, oil & gas, and power generation fields.

The chemical make-up of grade B16 bolts is as follows: silicon (0.15-zero.35%), chromium, manganese, phosphorus, sulfur, vanadium, and carbon. Grade B16 bolts are the maximum broadly used sort of alloy metal amongst numerous versions. These bolts' precise composition offers them with exquisite resistance to oxidation and sulfidation in addition to excessive temperature power.

To make certain that Grade B16 bolts are suitable and reliable for use in excessive-temperature and high-strain settings, the ASTM A193 widespread specifies necessities for his or her manufacturing, warmth treatment, and testing.

Could you explain the differences between B16 and B7 bolts?

While B7 and B16 bolts have similar features, what sincerely distinguishes them are their mechanical houses and material composition.

Enterprises coping with accelerated temperatures and pressures regularly make use of bolts with the B7 and B16 classifications. This is specially actual for the petrochemical, power era, and oil and gasoline sectors.

In order to achieve the required hardness and electricity, the medium carbon alloy metallic (4140) used to create B7 bolts and ASTM A193 B8 Bolts is often heated to the best temperature and then tempered. They have minimal yield and tensile strengths of 105 ksi and 125 ksi, respectively.

But the metal used to make B16 bolts is a higher alloy metal with molybdenum, chromium, and vanadium combined collectively. B16 bolts are stronger and extra proof against oxidation and sulfidation in warm conditions way to those additives. Moreover, B16 bolts have minimal yield and tensile strengths which can be corresponding to B7 bolts.

Use B7 bolts for packages desiring high energy and mild temperature resistance; use B16 bolts for packages requiring better energy and stronger resistance to oxidation and sulfidation at immoderate temperatures. B7 bolts are the endorsed desire while some diploma of heat resistance is vital.

Materials that are comparable to ASTM A193 Grade B16 consist of:

DIN EN 10269 1.4980:

European standard addresses bolts composed of a robust and heat-resistant chromium-molybdenum alloy steel.

ISO 898-1 class 10.9:

For bolts composed of alloy steels comparable to ASTM A193 Grade B16, International Standard ISO 898-1 class 10.9 provides mechanical criteria.

BS 1501-640B:

One can use British standard BS 1501-640B to fabricate fastening materials with characteristics comparable to ASTM A193 B8C bolts and ASTM A193 Grade B16. This general applies to high-power steel plates which have gone through heat remedy.

JIS SCM 4:

This Japanese business well-known specifies what to do with low-alloyed steels which have mechanical characteristics and chemical compositions equivalent to ASTM A193 Grade B16 and ASTM A193 B8M Stud Bolt.

It's vital to hold in mind that at the same time as the chemical composition and mechanical traits of numerous materials may be equal, their manufacturing methods, warmth remedy methods, and trying out requirements may additionally range. These variations may have an impact on the materials' performance for particular applications. It is advisable to study the pertinent material requirements and get advice from an experienced engineer or metallurgist when selecting bolting materials for applications involving high temperatures and pressures.

0 notes

Photo

RajatUdyod is the leading Nuts, Bolts and Washers manufacturers in India. If you are looking for Bolts, Nuts, Washers and Aluminium, then your search ends here, You will get high-quality products in the best price range.

https://www.rajatudyog.co.in/

#Hex Bolt Manufactures in India#Hex Bolts#HSFG Bolts Suppliers#HSFG Bolts#Hex Nuts Suppliers#Hex Nuts#Stud b7

1 note

·

View note

Photo

Nuts and bolts are fasteners used to bind various parts of a machine or engineering application. If you are looking for the hex bolt manufacturers company In India then, contact Rajat Udyog.

#Hex Bolt Manufacturers In India#Stud b7 Manufacturer In India#Hex Nuts Suppliers#HSFG Bolts Suppliers#Weld Nuts Suppliers#Heavy Hex HSFG Manufacturer#Plain Washers Manufacturer#Harderend HSFG Suppliers#Spring Washer Suppliers

1 note

·

View note

Video

youtube

🏗🌏Make Fixing Dexterity👉FIXDEX threaded rods & B7 & din975

#youtube#HDG threaded rods#galvanized threaded rod#galvanised rod#galv threaded rod#hot dipped galvanized threaded rod#threaded rod galvanised#m20 galvanised threaded bar#Threaded Rod Galvanized#A193 B7#b7 threaded rod#astm a193#b7 bolts#b7 studs#a193 b7 bolts#b7 stud bolts#stud bolt a193 b7#astm a 193 gr b7#b7 bolt material#a193 b7 threaded rod#a193 b7 round bar#A193 Grade B7 Bolts#Grade B7 Bolts#Stainless Steel ASTM A193 B7 Bolts Manufacturer

0 notes

Text

Leading Stud Bolt Manufacturers in India | Delta Fitt Inc

Delta Fitt Inc. is the leading Stud Bolt Manufacturers in India and B7 Stud Bolts Manufacturers in India. Understand their competitive advantages, manufacturing strategies, and market position.

Delta fitt, obtained the best stud bolts by top Stud Bolt Manufacturer in India, takes centre stage.Stud bolts are used to secure commercial buildings in a wide range of industries, including industry and construction. Examine the advantages, highlight important features, and learn about industry issues. Examine the future risk of stud bolt growth. Choose best quality stud bolts like B7 & B8 Stud Bolts reliability for secure projects. Make the right choice for lasting reliability. Choosing these stud bolts from trusted B8 and B7 Stud Bolts suppliers in India creates a construction cooperation.

In search of top Stud Bolt Suppliers in India? Delta Fitt Inc. has you covered with top-quality stud bolts solutions.

For more details,

Also Visit: B7 Stud Bolts Manufacturer in India, B8 Stud Bolts Manufacturers in India

#stud bolt manufacturers in india#B7 Stud Bolts Manufacturer in India#B8 Stud Bolts Manufacturers in India#stud bolt manufacturers

0 notes

Text

Hex Nut Fastener

ASTM A563 Finished Hex Nuts Available In Various Forms And Size, Products Like Nuts, Bolts, Stud Bolts And Washers Etc.ASTM A194 Stainless Steel 304/304H/304L Heavy Hex Jam Nut Fasteners, ASTM A182 SS 316/316Ti Fasteners, ASTM A194 SS 317/317L/321 Heavy Hex Jam Nut, Carbon Steel ASTM A194 B6/B7 Heavy Hex Jam Nut Fasteners, Alloy Steel ASTM A320 L7/L7A/L7B Heavy Hex Jam Nut Fasteners. Hex Nut Fastener & but bolts Supplier & Manufacturer by Prashaant Steel & Alloys. We use the highest quality raw materials used in the production processes

https://prashaantsteel.com/hex-nuts-manufacturers-exporter/

0 notes

Text

Delta Fitt Inc. is a well-known Bolts Manufacturer in India. We offer one of the best quality Bolts to various industries around the globe such as Eye Bolts.

Fasteners: https://deltafitt.com/fasteners-manufacturer-supplier-stockist-india.php

Bolts: https://deltafitt.com/bolts-manufacturer-supplier-stockist-india.php

Stud Bolt: https://deltafitt.com/stud-bolt-manufacturer-supplier-stockist-india.php

B7 Stud Bolts: https://deltafitt.com/b7-stud-bolts-manufacturer-supplier-india.php

B8 Stud Bolts: https://deltafitt.com/b8-stud-bolts-manufacturer-supplier-india.php

For more details,

Website: https://deltafitt.com/

0 notes

Text

ASTM A193 Grade B8 vs ASTM A193 Grade B7: Understanding the Differences

High-stress connections with secure and durable results are precisely what industries demand, and fasteners are crucially important in this regard. Among the popular grades found in the ASTM A193 standard, Grade B8 and Grade B7 are two extensively used grades to make bolts, nuts, washers, and studs. Although both are high-strength materials, their chemical and mechanical properties address other needs in the industrial sector. This blog highlights an in-depth comparison of ASTM A193 Grade B8 vs. B7 to assist you in making the right material choice for your application.

Overview of ASTM A193 Grade B8

ASTM A193 Grade B8 is an austenitic stainless steel alloy which contains 18 percent chrome and 8 percent nickel with excellent resistance to corrosion along with high-temperature strength. This grade finds its application wherever extreme temperatures and corrosive environment conditions are concerned.

Pressure vessels

Valves

Flanges

Power generation equipment

Key Characteristics of ASTM A193 Grade B8

Material Type: Austenitic stainless steel (based on 304 SS)

Corrosion Resistance: Excellent in atmospheric and chemical environments

Temperature Range: Suitable for both cryogenic and elevated temperatures

Applications: Preferred in industries requiring high corrosion resistance and durability

Overview of ASTM A193 Grade B7

ASTM A193 Grade B7 is a chromium-molybdenum alloy steel known for its high tensile strength and excellent resistance to high temperatures. Grade B7 is commonly used in applications that require superior strength but are not exposed to extreme corrosive environments, such as:

Petrochemical facilities

High-pressure pipelines

Boiler equipment

Key Characteristics of ASTM A193 Grade B7

Material Type: Alloy steel

Strength: Superior tensile and yield strength compared to Grade B8

Temperature Range: Effective in high-temperature applications up to 450°C

Applications: Best suited for non-corrosive high-pressure and high-temperature environments

Chemical Composition

Mechanical Composition

Comparison: Grade B8 vs Grade B7

Applications of ASTM A193 Grade B8 and B7 Bolts, Nuts, and Washers

ASTM A193 Grade B8

Ideal for industries requiring corrosion resistance such as:

Chemical processing

Food and beverage

Power plants

ASTM A193 Grade B7

Suited for high-strength applications in less corrosive environments:

Oil and gas

High-pressure steam pipelines

Industrial machinery

Choosing the Right Fastener: Key Considerations

When selecting between Grade B8 and Grade B7, consider:

Environmental Conditions: Choose Grade B8 for corrosive environments; Grade B7 for non-corrosive settings.

Strength Requirements: Grade B7 offers higher tensile and yield strength.

Temperature Extremes: Grade B8 is versatile for cryogenic and elevated temperatures, whereas Grade B7 is effective in high heat.

Conclusion

Both ASTM A193 Grade B8 and B7 are excellent materials typically made for specific industrial purposes. Grade B8 is preferred for corrosion resistance and good high-temperature performance, while Grade B7 is preferred for strength in non-corrosive and high-pressure conditions. The grade depends on your application's environment and mechanics.

Ananka Group is a leading bolt, nut, and washer manufacturer and supplier based on ASTM A193 Grade B8 and B7 in India. All of these are made to withstand different tests and have rigorous quality standards, meaning they offer more reliability and durability in each application. Call today to order your fasteners!

FAQs

1. What is the difference between ASTM A193 Grade B8 and B7?

Grade B8 is made of austenitic stainless steel, providing excellent corrosion resistance, whereas Grade B7 is a chromium-molybdenum alloy steel that is known to provide strength.

2. Is Grade B7 suitable for corrosive environments?

Grade B7 cannot be used in highly corrosive environments because Grade B7 is not as corrosion-resistant as Grade B8 is.

3. Which industries typically use Grade B8 fasteners?

Grade B8 fasteners are used in chemical processing, power generation, and more, where materials have to exhibit resistance to corrosion.

4. Which grade would be considered superior for high-pressure applications?

B7 would be recommended for high-pressure applications as it possesses higher strength.

5. Does Ananka Group manufacture custom fasteners?

Yes, we provide custom solutions to meet specific industrial demands of fasteners.

#GradeB8#GradeB7#ASTMA193#Ananka#Anankafasteners#Fasteners#manufacturer#supplier#mumbai#hex#bolt#usa#uk

0 notes