#Hex Nuts Suppliers

Explore tagged Tumblr posts

Text

Grade 2HM Fasteners: Comprehensive Guide

Introduction

Grade 2HM fasteners are widely used in various industries due to their exceptional mechanical properties, corrosion resistance, and durability. These fasteners, which include nuts, bolts, and washers, conform to ASTM A194 standards, making them ideal for high-temperature and high-pressure applications. In this comprehensive guide, we will explore the properties, applications, composition, and benefits of Grade 2HM fasteners.

Understanding Grade 2HM Fasteners

Grade 2HM fasteners are heavy hex nuts manufactured under ASTM A194 specifications. They are specifically designed for use in high-temperature and high-pressure environments, often found in petrochemical, power generation, and marine industries. The "H" in 2HM indicates that these nuts are heat-treated to enhance their mechanical properties, making them stronger and more durable.

Chemical Composition of Grade 2HM Fasteners

The chemical composition of Grade 2HM fasteners ensures their strength, corrosion resistance, and ability to withstand extreme conditions. The primary elements present in these fasteners include:

Carbon (C): 0.40% max

Manganese (Mn): 1.35% max

Phosphorus (P): 0.04% max

Sulfur (S): 0.05% max

Silicon (Si): 0.15-0.35%

These elements contribute to the fasteners' superior mechanical properties and enhanced durability.

Mechanical Properties of Grade 2HM Fasteners

The mechanical properties of Grade 2HM fasteners play a critical role in their performance under extreme conditions. The key mechanical properties include:

Tensile Strength: 150 ksi (min)

Yield Strength: 105 ksi (min)

Hardness: 248-341 HBW (Brinell Hardness)

Elongation: Minimum 14%

These properties make Grade 2HM fasteners suitable for high-stress environments, ensuring reliability and longevity.

Applications of Grade 2HM Fasteners

Due to their robust mechanical properties, Grade 2HM fasteners are used in several industrial applications, including:

Petrochemical Industry: Used in pipelines, refineries, and offshore drilling rigs where high-pressure conditions prevail.

Power Generation Plants: Essential in thermal, nuclear, and hydroelectric power plants due to their ability to withstand high temperatures and pressures.

Oil & Gas Industry: Used in flanges, valves, and high-stress connections in oil rigs and refineries.

Marine Industry: Ideal for shipbuilding, marine engines, and offshore structures exposed to corrosive environments.

Automotive Industry: Used in critical automotive components requiring high strength and durability.

Advantages of Using Grade 2HM Fasteners

High Strength: With a minimum tensile strength of 150 ksi, these fasteners provide exceptional load-bearing capabilities.

Corrosion Resistance: Enhanced by alloying elements, they offer superior resistance to rust and oxidation.

Heat Treatment Benefits: The heat treatment process improves hardness, toughness, and wear resistance.

Reliable Performance: Suitable for high-stress and high-temperature applications, ensuring longevity and durability.

Wide Industry Acceptance: Used across multiple industries due to compliance with ASTM A194 standards.

Conclusion

Grade 2HM fasteners are essential components in industries that demand high strength, durability, and resistance to extreme conditions. Their superior mechanical properties, chemical composition, and heat treatment make them a preferred choice in critical applications such as petrochemicals, power generation, and marine industries. Whether used in high-pressure pipelines or heavy machinery, Grade 2HM fasteners deliver unmatched performance and reliability.

Frequently Asked Questions (FAQs)

1. What is the difference between Grade 2H and Grade 2HM fasteners?

Grade 2HM fasteners undergo additional heat treatment, which enhances their mechanical properties and provides greater durability compared to Grade 2H fasteners.

2. Are Grade 2HM fasteners suitable for corrosive environments?

Yes, these fasteners offer excellent corrosion resistance, making them suitable for marine and chemical processing industries.

3. Can Grade 2HM nuts be used with different bolt grades?

Yes, Grade 2HM nuts can be used with various high-strength bolt grades, provided they meet application-specific requirements.

4. What standards do Grade 2HM fasteners comply with?

They conform to ASTM A194 standards, ensuring quality and performance consistency in industrial applications.

5. How does heat treatment improve Grade 2HM fasteners?

Heat treatment enhances the fasteners’ hardness, strength, and wear resistance, making them more suitable for high-pressure and high-temperature environments.

For high-quality Grade 2HM fasteners, always choose a reliable manufacturer to ensure compliance with industry standards and superior performance.

#Ananka#Fasteners#Grade2HM#Nut#2HMNut#fastenersmanufacturer#Article#Blog#Grade#Anankafasteners#manufacturer#supplier#mumbai#hex#tumblr#tumblr blog#bolt#usa#uk

1 note

·

View note

Text

Top Brass Nut Manufacturer in Jamnagar India

GK Metals, a trusted brass nut manufacturer in Jamnagar, India specializes in premium-quality brass hex nuts for various industries. We supply brass nuts with precision engineering, competitive pricing, and timely delivery that ensures top-notch solutions for your brass component needs.

#brass nuts#brass nut manufacturer jamnagar#brass nut manufacturer#brass nut suppliers#brass hex nut manufacturer#brass hexagonal nuts#hex jam nut#round nut#square nut#wing nut#fasteners#brass fasteners#brass fasteners manufacturers

0 notes

Text

Fastener World India is a leading hex nut manufacturer in India, offering high-quality hex nuts designed for strength and durability. A Hex is a hexagonal shaped nut that is used to be fitted onto a bolt with the help of internal screw thread. Fastener World India has Hex nuts that come in all sizes for all purposes.

0 notes

Text

#ASTM A A479 / ASME SA A479 Duplex Steel Nuts#ASTM / ASME F60 Hex Nuts#Duplex Steel UNS S31803 High Tensile Heavy Hex Nuts#Duplex 2205 2 Way Lock Nut#UNS S32205 Lock Nut Supplier & Exporter

0 notes

Text

#Monel UNS N04400 Heavy Hex Nut#Monel Alloy 400 Hex Nuts Dealer in Mumbai#Monel Alloy 400 Hex Nuts#Monel 400 Nuts Manufacturers#Monel 400 Nuts Suppliers#ASTM F468 Monel Alloy DIN 2.4360 Hex Nuts#400 Monel Alloy Hex Coupling Nuts.

0 notes

Text

As leading nut and bolt manufacturers, suppliers, and exporters in India, we at Mcneil Instruments pride ourselves on delivering a diverse range of high-quality products tailored to your specific needs. Our commitment to customer satisfaction is unwavering, ensuring that every client receives top-notch products and exceptional services. We specialize in comprehensive fabrication materials for overhead transmission lines, offering a wide selection of both mild steel (M S) and galvanized nut bolts in all sizes crucial for construction projects.

At Mcneil Instruments, we understand the critical role that well-finished and precision-made nut bolts play in fabrication construction. Our extensive inventory includes: 5/8″ (16mm) Nut, 1/2″ (12mm) Nut, 5/8″ (16mm) Bolt, 1/2″ (12mm) Bolt

Explore our diverse range of products, including Hex bolts, Round head bolts, Flat head bolts, Hex Nuts, Jam Nuts, and Cap Nuts. Trust Mcneil Instruments for unparalleled quality and performance in every nut and bolt.

" https://www.mcneilinstruments.com/nut-bolts-manufacturers-suppliers.html "

for more details contact us at: +91 9870883613 [email protected]

0 notes

Text

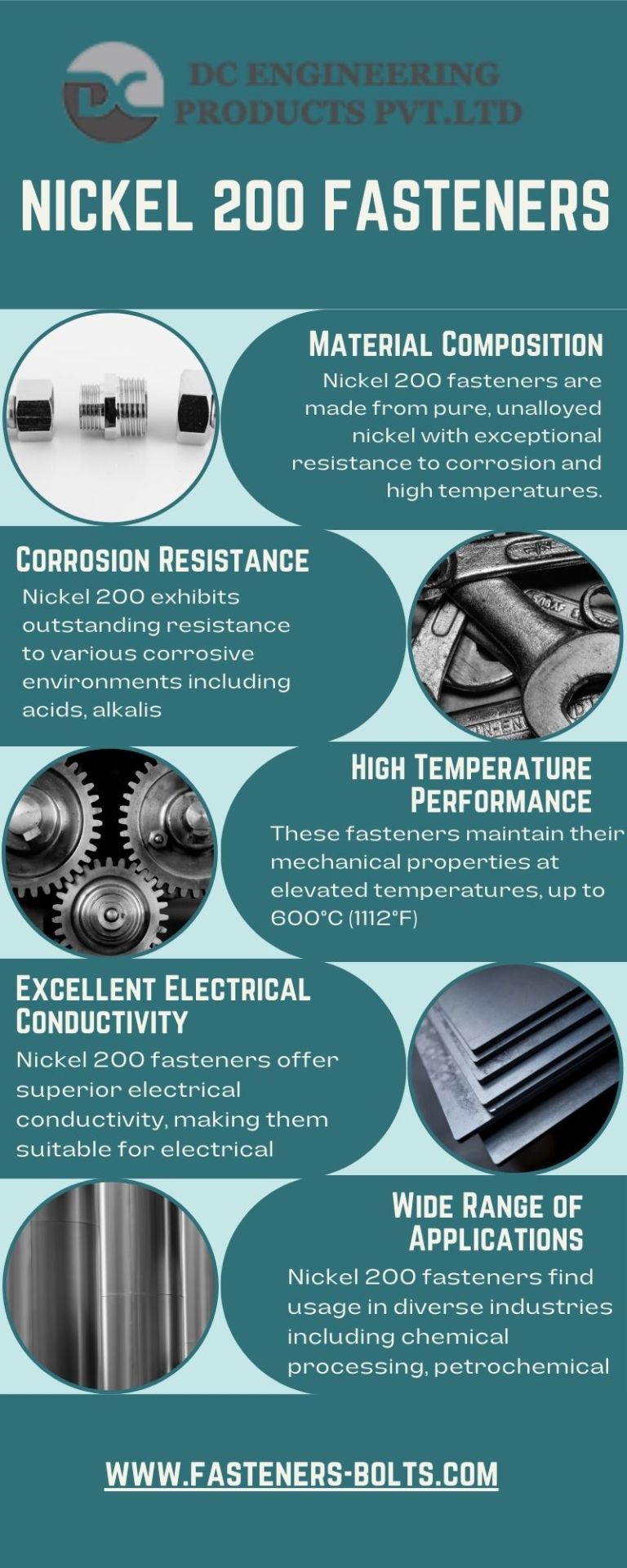

DC Engineering is leading Manufacture and Exporter of High quality of Nickel 200 Fasteners, UNS N02200 Fasteners, Alloy 200 Fasteners

#Nickel 200 Fasteners#High Nickel Alloy 200 Fastener Manufacturer#Nickel Alloy 200 Heavy Hex Nuts#Nickel 200 Hex Head Bolt#UNS N02200 Fastener#DIN 2.4066 Fasteners Supplier#Nickel 200 Spring Washer#Alloy 200 Socket Cap Screws#Nickel Alloy 200 U-bolts#Nickel Alloy 200 Hex Cap Screws#200 Nickel Alloy Hex Bolts

0 notes

Text

Hex Nuts Manufacturer and exporter in India

Roll-fast is a manufacturer of world class Hex Nut for use in petrochemical industry. Hex nuts are one of the most common nuts available and are used with anchors, bolts, screws, studs, threaded rods and on any other fastener that has machine screw threads. Hex Nuts manufacturer are as per Indian, European and American standard. Hex is short for hexagon, which means they have six sides. Hex nuts are also known as: finished hex nuts, hex full nuts. Hex Nuts are used with Stud bolts to extensively in petrochemical projects for flange joints in high temperature pipelines and also on rigs and offshore platforms in various parts of the world.

visit source url : https://www.roll-fast.com/industries-served/petrochemical-industries/hex-nuts.html

0 notes

Text

0 notes

Text

Hex Key Wrench manufacturers in Delhi

RKC, a leading Hex Key Wrench manufacturer in Delhi, boasts 35 years of unrivaled experience in fastener trading. With a proven track record, they offer top-quality products and solutions to meet diverse industrial needs. As pioneers in the field, RKC continues to deliver reliable and precision-engineered tools, earning the trust of customers nationwide.

0 notes

Text

Spring Washers Uttarakhand

Best Quality Fasteners, with 35 years of experience, is a trusted name for Spring Washers in Uttarakhand. Our commitment to providing high-quality products has earned us the loyalty of customers across industries. Our Spring Washers are known for their reliability, durability, and excellent performance. Whether it's for industrial or domestic applications, our products stand the test of time. Choose Best Quality Fasteners for unmatched expertise and top-notch products in Uttarakhand.

0 notes

Text

T-Slot Nuts Manufacturer, Supplier & Exporter

Introduction

T-slot nuts are essential components widely used in industries requiring robust and versatile fastening solutions. These specialized fasteners are designed to fit into T-slots of machines, equipment, and frames, enabling the secure attachment of other components. This blog explores the key features, types, applications, and the role of T-slot nuts manufacturers, suppliers, and exporters.

What Are T-Slot Nuts?

T-slot nuts are specifically designed nuts that fit into the T-shaped grooves of various machinery, frames, and workbenches. They are used to securely hold components in place when assembling or adjusting equipment. These fasteners come in various sizes and materials, tailored to meet the needs of different industries.

The unique T-shape allows the nut to slide along the track, making it ideal for modular assembly systems. T-slot nuts are designed to lock into position when they are turned, ensuring a tight and stable fit.

Types of T-Slot Nuts

T-slot nuts come in various designs and configurations, depending on the application and specific requirements. Some of the most common types include:

Standard T-Slot NutsThese are the most commonly used T-slot nuts. They are available in multiple sizes to fit different T-slot dimensions and are generally made from steel, stainless steel, or other durable materials.

Swivel T-Slot NutsThese nuts have a pivoting feature that allows them to swivel into place for easier installation and removal. They are ideal for applications where adjustment and flexibility are required.

Spring T-Slot NutsThese nuts include a spring mechanism that provides added tension, keeping the fastener securely in place even under vibration and movement.

Hexagonal T-Slot NutsThese nuts are hex-shaped and are designed to be used with standard hex bolt heads. They provide additional strength and support when used with heavier components.

Double T-Slot NutsThese are designed to fit two different T-slots, offering enhanced holding power and stability in large, modular systems.

Floating T-Slot NutsThese nuts are designed to float inside the slot, adjusting to the position of the component, making them ideal for systems that require precise alignment.

Key Features of T-Slot Nuts

Easy Installation and Removal: The T-slot design makes installation quick and efficient without the need for additional tools. This flexibility saves time during assembly.

Versatility: They can be used in various applications, including machinery, workbenches, conveyors, and frames, supporting different types of assembly systems.

Durability: Most T-slot nuts are made from corrosion-resistant materials, such as stainless steel or coated steel, ensuring long-term reliability even in harsh environments.

Adjustability: The ability to slide and adjust the nuts within the slot provides high precision when aligning components, making them ideal for modular and adjustable assembly systems.

Strength and Stability: T-slot nuts are engineered to handle significant loads, ensuring a secure and stable fastening solution for both light and heavy-duty applications.

Applications of T-Slot Nuts

T-slot nuts are used across various industries due to their versatile and robust design. Some of the key applications include:

Machine Tool IndustryT-slot nuts are extensively used in machine tools for securing workpieces, fixtures, and other components. Their ability to provide secure fastening while maintaining adjustability makes them a preferred choice.

Automotive IndustryIn automotive manufacturing, T-slot nuts are often used for assembling workstations, test rigs, and frames. Their precision and ease of use are crucial for production lines.

Construction & BuildingModular construction systems use T-slot nuts for assembling frames, shelving units, and structural elements, offering flexibility and support for large structures.

Furniture ManufacturingT-slot nuts are commonly found in the assembly of modular furniture, such as desks, shelves, and storage systems. Their simple installation and removal allow for easy assembly and disassembly.

Robotics and AutomationThe robotics industry uses T-slot nuts in the construction of robotic arms, frames, and other precision equipment. The ability to adjust and align components precisely is vital in this sector.

Benefits of Using T-Slot Nuts

Cost-Effectiveness: T-slot nuts offer an affordable fastening solution that can be used across a variety of applications, minimizing the need for specialized fasteners.

Ease of Use: The T-slot nuts can be installed and adjusted without additional tools, saving time and effort during assembly and disassembly.

Adaptability: The modular design of T-slot nuts makes them ideal for customizable setups, allowing users to make quick changes as per their requirements.

Reduced Maintenance: With corrosion-resistant options and durable construction, T-slot nuts provide long-term reliability, reducing the need for frequent maintenance or replacements.

Flexibility in Design: T-slot nuts are highly adaptable and can be used in a wide range of industries, offering flexibility for diverse design needs.

T-Slot Nuts Manufacturer, Supplier & Exporter: Ananka Group's Expertise

As a leading manufacturer, supplier, and exporter of fasteners, Ananka Group offers high-quality T-slot nuts tailored to meet the unique requirements of various industries. With a focus on precision engineering and high-grade materials, we ensure that every T-slot nut we produce meets the highest industry standards.

Why Choose Ananka Group?

Quality Assurance: We adhere to strict quality control measures to ensure that our T-slot nuts meet all relevant standards and specifications.

Customization: Ananka Group offers customized T-slot nuts, tailored to specific customer requirements in terms of size, material, and design.

Global Reach: We supply T-slot nuts to a global clientele, ensuring timely delivery and competitive pricing for customers worldwide.

Expert Engineering: Our team of engineers specializes in creating durable and innovative T-slot nuts for a range of applications, from automotive to industrial systems.

Reliable Support: Our customer service team is available to assist with any inquiries, from product selection to technical support, ensuring a seamless experience.

Conclusion

T-slot nuts are indispensable fasteners used in various industries for modular assembly systems, machine tools, robotics, and more. Their flexibility, ease of installation, and durability make them an ideal solution for a wide range of applications. Whether you're looking to source T-slot nuts for a small project or a large-scale industrial system, choosing a trusted manufacturer, supplier, and exporter like Ananka Group guarantees high-quality products tailored to your needs.

Frequently Asked Questions (FAQ)

1. What materials are T-slot nuts made from?T-slot nuts are typically made from steel, stainless steel, aluminum, or other corrosion-resistant materials to ensure durability and long-term use in various environments.

2. Can T-slot nuts be used in all types of T-slot profiles?No, T-slot nuts are designed to fit specific T-slot profiles. It is important to choose the right size and type of T-slot nut for your particular slot configuration.

3. Are T-slot nuts adjustable?Yes, one of the key features of T-slot nuts is their adjustability. They can be easily slid along the T-slot and locked into position for precise alignment.

4. How do I install T-slot nuts?T-slot nuts are simple to install. They are placed into the T-slot, then rotated or tightened into place using standard tools.

5. What are the main advantages of using T-slot nuts in modular systems?T-slot nuts provide flexibility, ease of installation, and the ability to make quick adjustments, making them perfect for modular and customizable assembly systems.

#Tslotnut#TNut#nut#Tslotnutmanufacturer#Manufacturing#manufacturer#linkedin#Article#nuts#nutmanufacturer#anankafasteners#ananka#fasteners#mumbai#supplier#hex#bolt#usa#uk

0 notes

Text

Types of Brass Nuts Provided by Brass Nut Manufacturer in Jamnagar

If you are looking for quality brass nuts, you should look no further than the brass nut manufacturer in Jamnagar, India. They provide various types including brass hex nuts, brass lock nuts, brass wing nuts, hex jam nut, round nut, square nut and more according to specific client requirements.

#brass nuts#brass nut manufacturer jamnagar#brass nut manufacturer#brass nut suppliers#brass hex nut manufacturer#brass hexagonal nuts#hex jam nut#round nut#square nut#wing nut#fasteners#brass fasteners#brass fasteners manufacturers in jamnagar#brass fasteners exporters#brass fasteners suppliers

0 notes

Text

High Quality Hex Nut Manufacturers in India

Fastener World India specializes in connecting businesses with reputable hex nut manufacturers in India. Our platform ensures high-quality products meeting industry standards, sourced from reliable suppliers across the country. Explore a comprehensive range of hex nuts tailored to diverse industrial needs, backed by efficient logistics and customer support.

0 notes

Text

Monel K500 Nuts Exporters

Introduction

Monel K500, an advanced nickel-copper alloy, is a material that stands out for its remarkable combination of high strength and excellent corrosion resistance. Nuts made from Monel K500 are critical components in many demanding industrial applications. This article explores the unique properties of Monel K500, the advantages of using Monel K500 nuts, and their various applications across different industries.

Understanding Monel K500

Monel K500 is an age-hard enable alloy that builds on the properties of Monel 400 by adding aluminium and titanium. These elements significantly enhance the alloy's strength and hardness through precipitation hardening while maintaining its excellent corrosion resistance. The primary characteristics of Monel K500 include:

High Strength and Hardness: The addition of aluminium and titanium provides Monel K500 with higher strength and hardness compared to Monel 400, particularly after age hardening.

Outstanding Corrosion Resistance: Monel K500 retains excellent resistance to a wide range of corrosive environments, including seawater, acidic and alkaline solutions, and various chemicals.

Low Magnetic Permeability: The alloy remains non-magnetic even at low temperatures, making it suitable for applications requiring non-magnetic properties.

Excellent Mechanical Properties: Monel K500 maintains its mechanical properties across a wide temperature range, making it versatile for both high and low-temperature applications.

Benefits of Monel K500 Nuts

Nuts made from Monel K500 offer several advantages, making them ideal for critical and high-performance applications:

Superior Strength: Monel K500 nuts are capable of withstanding high levels of stress and strain, ensuring robust and reliable performance in demanding conditions.

Exceptional Durability: The alloy's resistance to corrosion and erosion extends the lifespan of Monel K500 nuts, reducing the need for frequent replacements and maintenance.

Versatility: Monel K500 nuts are suitable for a wide range of environments, from marine to chemical processing, due to their excellent resistance to various corrosive agents.

Non-Magnetic Properties: Their non-magnetic nature makes Monel K500 nuts ideal for applications where magnetic interference needs to be minimized.

Chhajed Steel Limited is one of the esteemed creators and suppliers of Monel K500 nuts, which have high versatility with better utilization assurance. We offer light-weight, strong and particularly got a handle on Monel K500 Hex Nuts everything being equal. Spot your hangings safely on the dividers and orchestrate your place as well. Al our things like Monel K500 Heavy Hex Nuts offer postponed handiness and are as demonstrated by ASTM/ASME SB 163/165 measures. Monel K500 Lock Nuts is begin safe and non-alluring to - 200° F. In any case, it is possible to develop an appealing layer on the outside of the material in the midst of dealing with. For wide current use, we have in store premium quality Monel K500 Lock Nuts that are manufactured using latest refined advancement. The warm getting ready used to affect precipitation is by and large called age cementing or developing.

MONEL ALLOY K500 NUTS SPECIFICATION

Material

Specification

Standards

Size

Length

Monel Alloy K500

IS

BS

ASTM

ASTM B865-04

3 mm to 200 mm

M02 to M33

Conclusion

Monel K500 nuts are essential components in many high-performance applications due to their superior strength, exceptional corrosion resistance, and durability. Their versatility and reliability make them indispensable in industries such as marine, chemical processing, oil and gas, aerospace, and power generation. Sourcing Monel K500 nuts from reputable manufacturers and stockists ensures the highest quality and performance, enabling industries to operate efficiently and safely in the most challenging environments.

For More Information:

Visit Our Website -https://www.chhajedfastners.com/

Call Us – +91-932-111-3630

Email Us- [email protected]

#Suppliers of ASTM B865-04 K500 Monel Hex Head Bolt#K500 Alloy Coupling Nut Exporter#Monel K500 Nuts Manufacturers in Mumbai#Monel K500 Nuts Suppliers in Mumbai#Monel K500 Nuts Exporters in Mumbai#Monel K500 Nuts Importers in Mumbai.

0 notes

Link

BigBoltNut is a leading manufacturer, supplier and exporter of standard hex nuts metric nuts and inch series nuts. Hex nuts are used along with bolts for joining and tightening. Available in 8, 9 and 12 grades. These Nuts are manufactured by us in carbon steel and stainless steel. Popular carbon steel grades include 8, 10, 2H, 2HM, 8, 8M, SS316, SS304, SS316L, SS316S31 etc. The requirements for these are mentioned in the American standard A 194 and A 3506-2. A nut is a type of fastener with a threaded hole. Nuts are almost always used with a mating bolt to fasten multiple parts together. Hex nuts are one of the most common nuts available and are used with anchors, bolts, screws, studs, threaded rods and on any other fastener that has machine screw threads. Hex is short for hexagon, which means they have six sides. Hex nuts are also known as: finished hex nuts, hex full nuts.

0 notes