#automatic water cooler machine

Explore tagged Tumblr posts

Text

Water Cooler Machine Manufacturer -Penguinengineering

Penguin Engineering specializes in manufacturing high-quality water cooler machines, designed for efficiency and durability. Their products blend advanced technology with user-friendly features, catering to businesses and institutions seeking reliable solutions for hydration needs.

#automatic water cooler#automatic water cooler machine#best drinking water cooler machine#automatic water cooler machine in india#water cooler machine manufacturer in india#drinking water cooler machine manufacturer#drinking water cooler machine manufacturer in india

0 notes

Text

#buy water dispenser#top water dispenser features#best water dispenser brand#Atlantis water dispenser#water cooler#water cooler price#water dispenser price#hot and cold water dispenser#water dispenser machine#fridge with water dispenser#automatic water dispenser#water solutions

0 notes

Text

Water Dispensers - Convenient Access to Refreshing Hydration

Water dispensers offer convenient access to refreshing hydration, providing chilled or hot water on demand. Explore a variety of water dispenser options, including countertop and freestanding models, with features like temperature control, filtration systems, and space-saving designs. Choose a water dispenser that fits your lifestyle and hydration needs, whether for home, office, or public spaces. Enjoy the convenience of clean, filtered water at the perfect temperature with a reliable and easy-to-use water dispenser. Stay hydrated and refreshed with the help of a convenient water dispenser.

#Water dispenser#Hot and cold water dispenser#Water dispenser with fridge#Electric water dispenser#Automatic water dispenser#Water machine price#Water cooler dispenser

1 note

·

View note

Text

[🐯] automatic off-switch

✿ pairing: beomgyu x reader / idol!txt / employee!you / minor cursing (none with ill-intention!) / fluff, silly 🌸 / 792 words ✿ beomgyu’s known to be someone who constantly runs his mouth but the boys discovered you’re an automatic off switch for him... (the boys never knew this day would come) ✿ honestly, idk where this came from!!! i kinda saw a scene from crash course in romance and it’s just a little spinoff from there! (i think it’s episode 16 towards the end and you cannot convince me that is not beomgyu-coded) [masterlist 🌸] / @kflixnet 🔦

beomgyu knows that sometimes–lies, all the time. yeonjun’s said it about a million times now–that he tends to run his mouth further than his mind can think about it. it’s not that he wasn’t sensitive to the words he was saying; he was. it’s just that he wants to take the weight of something that may appear heavy and make it... lighter, than it was before... even if it means saying things that may borderline to rubbing salt into the wound.

it wasn’t a good day, or it doesn’t seem to be a good day when the boys could hear telltales of your supervisor hounding your entire team from where they were in. keeping their volume down, peeking past the blinds, beomgyu spots you lowering your head as the reprimanding continues.

perhaps a minute or two goes by, but in reality it had been fifteen minutes before beomgyu excuses himself out of the dance practice room. “five bucks he’ll make things worse,” yeonjun whispers, nudging soobin by the arm who takes the deal with a scoff, bumping elbows as a sign of you’re on.

//

in the quiet of the hallway where you’re standing by one of the cooler machines, getting a cup of water, you’re left with your thoughts. not the best thoughts, but not the worst, either. it’s... just so-so, really. the flop with what had happened wasn’t your fault but considering you’re under the same department, oftentimes the rebuking happens as a whole for... reminder purposes.

as the machine clicks and you’re settled with a cup filled with water, you take a sip only to have your shoulders jumping at the voice that reverberates the walls, gently shaking your heart in the process. looking up, you’re met with beomgyu’s smile from about twenty steps away, his bright eyes sparkling at you despite going through hours of training.

"staying hydrated, i see.” he breaks the quietness with his completely obvious remark, that’s used as a way to ease himself next to you with a small smile. you lift the cup at his direction with a mustered up smile to your best ability, but even you know you’re not fooling anyone when beomgyu carefully reaches down to put his hand in yours, mindful to remain hidden despite being out in the open yet shielded in your own bubble together with how quiet this hallway usually is.

“i kinda saw what happened,” beomgyu murmurs, his thumb brushing over the back of your hand, “you okay?”

you nod with a soft sigh, “yeah, i’m okay. it was nothing big, really.” your eyes gaze from your half-sipped glass of water, up to beomgyu’s shifting eyes that you know have more than meets them.

“then...” he trails off.

"then...?” you echo.

“just how on earth did something like that–”beomgyu notices how you’re gripping onto his hand, narrowed eyes as a warning“–okay, i’ll shut up.”

you still don’t let up on the façade, knowing that he’s got a bit more–“...but just, y’know, things like that don’t just happen out of nowhere–”beomgyu yelps a little at how tight you’re squeezing his hand with your jaw clenching that he’s quick to rephrase his words“–i’ll pull my lip right over my head so hard i can’t ever speak again.”

with the way he switches up so fast, it makes you snort, making use of your interlocked hands so you can nudge his thigh. he chuckles along with you and sways your hands lightly, knowing the gesture would soothe your erratic heart... and it does. slowly. gently. delicate and as soft as the look beomgyu gives you.

“better?”

“...would be much better if i had ice cream,”

“aren’t you just a sneaky little–”beomgyu’s words rephrase quicker than he can stop himself when you raise a brow at him, threatening to squeeze his hand that”–of course the ice cream is crucial. how could i possibly leave that out?”

you shake his hand off and lightly shove at his chest, reeling out a couple of laughters before beomgyu points with his head, “gonna let me walk you back?”

“depends,”

beomgyu tilts his head with a slightly raised brow.

“are you gonna keep running your mouth?”

“what?” he huffs, clearly trying to hold back he’s being a bit sulky, “you actually want me to shut up?”

the quiet pause that fills between the two of you is what makes beomgyu squint his eyes at you, more so when you begin backing away from him with a grin threatening to form on your face. it only makes him furrow his brows as he moves closer towards you and soon, it’s him chasing you down the hall with hearty laughters filling the corridors on your way back.

well, mission failed successfully (?) in beomgyu’s mind.

#beomgyu x reader#beomgyu x y/n#beomgyu x you#beomgyu#choi beomgyu#txt scenarios#txt x you#txt x reader#txt stories#txt imagines#txt reactions#beomgyu scenarios#choi beomgyu fluff#beomgyu fluff

111 notes

·

View notes

Text

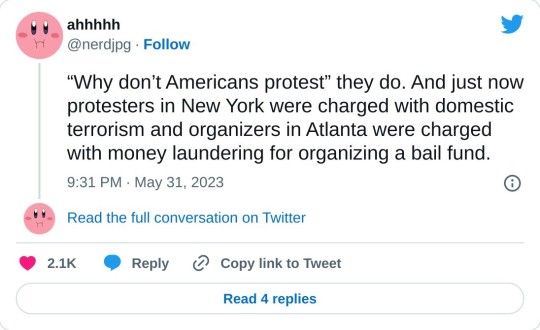

People who are in better physical shape and geographic locations than me really need to know this.

I stopped making personal appearances after I got heat stroke and inconvenienced the volunteer medics. Physically, I'm just not reliable enough anymore. But the reason that's a factor is: I was in AZ, and the police weaponized the heat to harm us. It got up to about 115 f (46 c) that day. My phone demanded I turn it off because the battery was too hot and might explode. The "free speech zone" I was herded into was on bare asphalt with no shade, far from anyplace you could purchase water or - god forbid - visit a drinking fountain.

(In AZ, by law, if someone asks for water at your establishment, you're supposed to have a free option for them, because it's a desert and that kills people. Many places had drinking fountains and water coolers, so you didn't even have to ask, but COVID took them out, so it would be bottled water or cups to get water from the soda machine. And, yes, we were all masked - except in the med tent, because heat stroke makes it hard to breathe - and the folks showing up to see Trump speak were not, and they were indoors too.)

Later, I teamed up with some other people who'd been told to go home and stay cool, to make a pass in a car with supplies for the medics. Ha-ha, but there was noplace to stop and legally yeet the water and sports drinks at them. You had to pull over while the police screamed at you that you weren't allowed to do that and threatened you. I did it anyway (twice!) but then I accidentally locked my keys in my car at the gas station (I was impaired!) and I had to quit and go home.

Later still, after dark, somebody threw water (that is, the substance H2O, naked, not even in a plastic bottle) at a cop and they responded by firing pepperballs into the crowd, hitting at least one child.

That was the state of your "freedom to protest" before I left, and before they started making these new "legal" moves that allow them to keep punishing you for exercising your rights after the fact. This has always been how the US does things. Look up the Civil Rights and Suffragette movements to compare. (And, yes, those protests were just as violent, if not more so, than BLM, or whatever thing the media is clutching its pearls about now.) They make it as difficult as possible for you to protest in the first place, then, as soon as you are seen to protest effectively, violent or not, they come down on you like a ton of bricks.

The state is doing violence here too, but it's on such a large scale (and the perpetrators are so insulated) that it gets an automatic pass. Giving people heat stroke on purpose (this is also part of how they harm/kill asylum seekers trying to cross the border, BTW), shooting them with chemical weapons (and real bullets!), and locking them away on spurious charges (convicted felons can't vote!) is doing violence. And how are you supposed to respond? "Peacefully"? How? Why? What for? Resupplying the medics is roughly equivalent to throwing water or throwing a punch, and also to just sitting somewhere they don't want you and refusing to move, so what's the difference?

Right now, I'm a liability. I'm tryin' to get my shit together, but it's always an uphill battle to get healthcare. If you can get out there, you need to get out there. This is not something you can vote away. You can only make it so inconvenient and scary that they give back some of those rights they keep pretending you already have.

#protest#civil rights#direct action#added my personal experience for valuable pathos points#whatever it takes to get people to LISTEN

8K notes

·

View notes

Text

Analysis of core equipment of NPK fertilizer production line

As the core category of compound fertilizer, the efficient operation of NPK fertilizer production line cannot be separated from the support of advanced equipment. A mature NPK fertilizer production line usually includes the following key equipment, each of which directly affects the quality and production efficiency of fertilizer.

1.Batching equipment

Batching is the core link of NPK fertilizer production, and the mixing ratio of nitrogen (N), phosphorus (P), potassium (K) and other elements needs to be accurately controlled. The modern production line adopts an automatic weighing batching machine, which adjusts the amount of raw materials in real time through the PLC control system. The high-precision batching scale can be accurate to the milligram level to ensure the scientificity and stability of the formula.

2.Mixing equipment

Mixing equipment is also indispensable, and the mixing uniformity is directly related to the nutrient distribution of fertilizer particles. Powerful Mixers (such as Double Axis Mixers, etc.) can fully and evenly mix the prepared raw materials to avoid uneven nutrient distribution. The unique design of the mixing blades of these mixing equipment can achieve efficient mixing in a short time to ensure that each grain of fertilizer contains balanced nutrients.

3.Granulation equipment

Granulation equipment gives NPK fertilizer a suitable shape and also determines the hardness and slow-release performance of fertilizer granules. The Rotary Drum Granulator forms dense granules during rolling through rotational motion and steam conditioning; the Disc Granulator uses centrifugal force to achieve granule classification, and the finished product has a higher roundness. The new equipment can adjust the speed and inclination to meet different formulation requirements, and the production capacity can reach 10-30 tons/hour.

4.Drying and cooling equipment

After the fertilizer granules are made, the excess water needs to be removed by drying equipment to achieve the appropriate humidity standard. The Drum Fertilizer Dryer can quickly and effectively dry the fertilizer to prevent the fertilizer from mold and deterioration during storage. The dried granules are then cooled to the appropriate temperature by the Drum Fertilizer Cooler.

5.Screening and packing equipment

These equipment ensure the quality of the finished product. The screening equipment screens out qualified particles, removes unqualified parts, and then packs them through automated packing equipment, so that NPK fertilizers can smoothly enter the market and meet agricultural needs. Of course, before packing, coating treatment can also be performed to improve moisture resistance and control nutrient release rate.

From ingredients to packing, every device in the NPK fertilizer production line takes into account efficiency and stability. This not only improves production capacity and quality, but also reduces operation and maintenance costs.

0 notes

Text

Home Appliances: Transforming Homes with Modern Comfort and Efficiency

Home appliances play a crucial role in every household, bringing convenience, efficiency, and style to everyday life. From essential kitchen gadgets to advanced home entertainment systems, these products are at the heart of modern living. Thirstymaart offers an exceptional platform for home appliance vendors to showcase their offerings and reach a wide audience of potential buyers.

Why Vendors Should List Home Appliances on Thirstymaart

🌐 Wide Reach

Tap into Thirstymaart's growing user base of homeowners, tenants, and businesses seeking reliable and innovative home appliances.

🛒 Diverse Marketplace

Highlight your product range alongside other trusted vendors, making it easy for buyers to compare and choose.

📈 Boost Sales

Leverage Thirstymaart's user-friendly platform and marketing tools to increase your visibility and sales.

Key Categories of Home Appliances to Showcase

Kitchen Appliances

Refrigerators: Energy-efficient models in various sizes and designs.

Microwaves: Compact, convection, and smart options for modern kitchens.

Ovens and Stoves: Gas, electric, and hybrid models for cooking enthusiasts.

Dishwashers: High-efficiency models to simplify cleaning.

Blenders and Mixers: Versatile tools for cooking and baking.

Laundry Appliances

Washing Machines: Front-load, top-load, and fully automatic options.

Dryers: Standalone and combo models for convenience.

Ironing Solutions: Steam and dry irons with advanced features.

Cooling and Heating

Air Conditioners: Split, window, and portable units for every need.

Heaters: Energy-efficient heating solutions for cold climates.

Fans and Coolers: Stylish and efficient options for ventilation.

Home Entertainment

Televisions: LED, OLED, and smart TVs with 4K and 8K resolutions.

Audio Systems: Soundbars, home theater systems, and portable speakers.

Streaming Devices: Smart gadgets for seamless access to entertainment.

Cleaning Appliances

Vacuum Cleaners: Cordless, robot, and traditional options for every floor type.

Steam Mops: Advanced cleaning solutions for hard surfaces.

Air Purifiers: Innovative designs to maintain clean and healthy air.

Smart Home Devices

Home Automation Systems: Control lighting, security, and appliances with ease.

Smart Speakers and Hubs: Alexa, Google, and other AI-powered devices.

Smart Security Cameras: Enhance home safety with real-time monitoring.

Other Essentials

Water Purifiers: RO, UV, and gravity-based systems for safe drinking water.

Inverters and Generators: Reliable backup power solutions.

Small Appliances: Coffee makers, toasters, and electric kettles.

Benefits for Vendors Selling Home Appliances on Thirstymaart

Dedicated Vendor Space: Create an attractive product catalog with detailed descriptions, features, and images.

Direct Customer Interaction: Build trust and relationships with buyers by addressing their queries directly.

Marketing and Promotions: Utilize Thirstymaart’s platform for seasonal sales, discounts, and featured listings.

Data-Driven Insights: Analyze sales trends and buyer preferences to tailor your offerings effectively.

Convenient Logistics: Partner with Thirstymaart's network for hassle-free delivery and support.

Why Buyers Choose Home Appliances on Thirstymaart

✅ Variety and Quality

Access a wide selection of appliances from trusted vendors, ensuring quality and performance.

💰 Affordable Prices

Enjoy competitive pricing with regular discounts, bulk deals, and promotional offers.

🚚 Seamless Delivery

Experience fast and reliable delivery options tailored to your location and schedule.

🔧 After-Sales Support

Get access to warranties, servicing, and customer care from professional vendors.

Tips for Home Appliance Vendors

1️⃣ Emphasize Energy Efficiency Buyers prioritize appliances that save electricity and lower utility bills. Highlight energy ratings and eco-friendly features.

2️⃣ Focus on Durability and Design Showcase products with robust build quality and modern aesthetics that suit contemporary homes.

3️⃣ Offer Warranty and Support Build trust by providing warranties and a strong after-sales service network.

4️⃣ Highlight Smart Features Smart home technology is a growing trend. Promote appliances with AI and IoT features for added convenience.

5️⃣ Bundle Offers Encourage bulk purchases by offering discounts on appliance bundles like kitchen sets or laundry combos.

Why Thirstymaart is the Ideal Platform for Home Appliance Vendors

Thirstymaart provides a dynamic platform to connect vendors with a diverse audience looking for reliable, high-quality home appliances. With robust marketing tools, a user-friendly interface, and a supportive vendor network, it’s the ultimate destination for showcasing your products and growing your business.

🌟 Join Thirstymaart today and bring your home appliances to every household!

https://thirstymaart.com/profile/ichalkaranji/kurbitte-enterprises

0 notes

Text

The Future of Australian Homes: Smart Technology and Sustainable Living

Australians are embracing smart technology and eco-friendly housing. More people want homes with advanced technology for security, comfort, and convenience. At the same time, sustainability is a key factor for homeowners and buyers. Features like solar power, smart appliances, and energy-efficient designs make homes practical and environmentally friendly. If you're looking for the best smart home devices, Make It Cognitive is a great option in Australia. They offer products that improve security, save energy, and make daily life easier. Let��s explore how smart and sustainable homes are shaping the future. Key Features of a Smart Home Smart homes use technology from Make It Cognitive to enhance security, energy efficiency, and convenience. Many homeowners install smart security systems, like cameras and smart locks, to monitor and control their homes remotely. This is especially useful in areas with increasing break-ins, making security a top priority for buyers. Another popular feature is smart air conditioning systems, which adjust automatically to your preferred temperature, keeping your home comfortable while saving energy. Smart appliances like fridges, washing machines, and dishwashers also use less electricity and water, lowering utility bills. These features not only make homes more comfortable but also increase their value, making them attractive to tech-savvy buyers. The Rise of Eco-Friendly Homes More Australians are choosing eco-friendly homes for their financial and practical benefits. Some common sustainable features include:

Solar panels – Reduce electricity bills and reliance on traditional energy sources.

Rainwater collection systems – Help conserve water and lower costs.

Better insulation and energy-efficient windows – Keep homes cooler in summer and warmer in winter, reducing energy use.

Sustainable homes are becoming the new standard, helping homeowners save money while also protecting the environment. Opt for Make It Cognitive and get the most reliable services. Why Choose Smart and Sustainable Homes? Investing in smart and eco-friendly features offers several benefits:

Lower Costs Over Time – While the initial setup can be expensive, these features save money on electricity and water bills in the long run.

Higher Property Value – Modern, energy-efficient homes attract buyers and can sell for more.

Better for the Environment – Reducing energy use and waste helps protect natural resources.

Improved Living Conditions – Smart homes offer convenience and security, while sustainable homes provide cleaner air and better natural lighting.

If you want smart devices Australia, Make It Cognitive offers high-quality products that enhance home security, energy efficiency, and comfort. The Future of Homes in Australia The real estate market is shifting towards smart and sustainable living. More buyers want homes that combine technology with eco-friendly solutions. Staying informed about these trends can help homeowners and investors make better choices while contributing to a greener future. Companies, like Make It Cognitive, play a key role in this transformation by offering smart home devices and solutions. They provide a variety of products, including the best Zigbee hub Australia, ensuring seamless home automation. Want to make your home smarter and more sustainable? Talk to the experts at Make It Cognitive to learn how you can upgrade your home with the latest smart technology. For more information, visit https://www.makeitcognitive.com.au/ and take the first step towards a smarter, greener home. Original Source: https://bit.ly/4bqPM4W

0 notes

Text

After granulation, the organic fertilizer production line still has the following processes to be completed. 1. Drying section. The dryer adopts the method of cylinder edge transmission, flange connection, and direct heat transfer, which is suitable for drying organic fertilizer after granulation. The material to be dried enters the copying plate drying area with a special combination. Due to the tilting and rotating movement of the machine body and the copying plate, the material is constantly carried by the copying plate to be fully scattered and move longitudinally. At the same time, it is fully heat exchanged with the high-temperature furnace gas from the hot air furnace to evaporate the water and dry the material. The material and flue gas to be dried are operated in a downstream and slightly negative pressure manner. There is a secondary granulation area in the dryer, which can be used to perform secondary granulation on some ungranulated materials, which is conducive to improving the granulation rate of the system. During the drying process, it is necessary to monitor at any time and adjust the temperature of the dryer furnace head and furnace tail by adjusting the hot air furnace temperature and the exhaust fan air volume according to the process requirements to achieve the drying index of the dried material. The materials that have completed the drying operation are transported to the next section of the organic fertilizer production line by a belt conveyor.

2. Cooling section. The rotary cooler is mainly used for cooling organic fertilizer products after drying, and can directly cool the hot granular fertilizer to near room temperature. The materials entering the cooler continue to move forward under the rotation and tilting of the machine body. At the same time, the induced draft fan draws air from the tail of the cooler to the head to meet the counterflow of the materials and take away the heat of the materials. During the cooling process, the cold air also takes away some moisture. The cooled materials are easy to pack in time and quickly to prevent agglomeration during storage. The machine adopts micro-negative pressure operation, which reduces pollution and improves the working environment. It has the characteristics of reasonable structure, stable operation and strong adaptability. The cooled materials are transported to the next section of the organic fertilizer production line by a belt conveyor. 3. Screening and large particle crushing section. The screening section is mainly used to separate fine powder, finished products and large particles in the materials. First, the fine powder in the semi-finished products is separated, and then the large particles are separated. The separated large particles are crushed by the large particle crusher and then enter the return belt together with the separated fine powder, and return to the granulator for granulation. The finished product enters the next section of the organic fertilizer production line. 4. Packaging section. The finished product is lifted by the skin elevator to the silo on the packaging machine, unloaded into the metering scale body, and automatically weighed according to the set weighing weight. The weighed material enters the sewing section through the conveyor, and is sewn and packed into the finished product warehouse.

0 notes

Text

After pre-processing the raw materials, the organic fertilizer production line also needs to mix the raw materials, granulate, dry, cool, screen, and package. In these processes, what other equipment does the organic fertilizer production line need?

1. Post-processing equipment

Mixer: used to add other nutrients as needed after fermentation to improve the biological indicators and market competitiveness of organic fertilizers.

Granulation equipment: such as disc granulators, flat die extrusion granulators, drum granulators, etc., used to process powdered organic fertilizers into granules to improve the appearance and market competitiveness of products.

Dryer: used to dry wet granules, remove excess water, and meet the specified moisture content requirements.

Cooler: Cool the dried granules to prevent the granules from deteriorating due to excessive temperature during subsequent packaging or storage.

Screening and grading equipment: such as vibrating screens, graders, etc., used to screen and grade granules according to size to meet the needs of different customers.

2. Packaging and conveying equipment

Belt conveyors, bucket elevators, screw conveyors, etc.: used to transport production raw materials and finished products between various equipment to reduce labor costs.

Automatic quantitative packaging machine: used to automatically measure, package and seal finished organic fertilizers to improve production efficiency and packaging quality.

3. Other auxiliary equipment

Depending on the specific needs and scale of the organic fertilizer production line, other auxiliary equipment such as dust removal equipment, storage bins, control systems, etc. may also be required.

The specific configuration will vary depending on factors such as the degree of automation of the organic fertilizer production line, production scale, and raw material characteristics. The manufacturer will design and provide customers with organic fertilizer production line construction and equipment selection plans that meet their own conditions based on the user's material characteristics, on-site working conditions, specific production requirements, degree of automation, and investment budget.

0 notes

Text

Organic fertilizer production line equipment is mainly used to harmlessly treat and ferment organic waste (such as livestock and poultry manure, crop straw, etc.) and then convert it into organic fertilizer. The following is a detailed introduction to organic fertilizer production line equipment: 1. Equipment types Organic fertilizer production line equipment usually includes the following categories: Raw material processing equipment: Crusher: used to crush the raw materials to a particle size suitable for fermentation. Crusher is divided into many types, such as semi-wet material crusher, cage crusher, etc. Cutter: used to cut longer raw materials into shorter segments for subsequent processing. Fermentation equipment: Fermentation turner: assists in turning the raw materials during the fermentation process, provides sufficient oxygen for the raw materials, controls the temperature, and makes the raw materials ferment more evenly and fully. There are many forms of fermentation turners, such as trough turners, crawler turners, etc. Fermentation tank: suitable for closed fermentation environment, can control the temperature, humidity and oxygen content during the fermentation process, and improve fermentation efficiency.

Crushing and screening equipment: Crusher: The fermented material may still contain large particles or lumps, which need to be further crushed. Screening machine: It is used to screen the crushed material according to the particle size to meet the needs of different products. Granulation equipment: Groove granulator, roller extrusion granulator, disc granulator, etc.: The screened material is made into granular fertilizer for easy storage, transportation and use. Drying and cooling equipment: Drum dryer: It is used to dry the granulated fertilizer and remove excess water. Cooler: After drying, the fertilizer is cooled to prevent the fertilizer from agglomerating or deteriorating. Packaging equipment: Automatic packaging machine: Automatically package the cooled fertilizer for easy sale and use. Conveying equipment: Belt conveyor, forklift feeder, etc.: It is used to transport raw materials, semi-finished products and finished products between various processes.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description Upgrade buckle design: The Drink Dispenser for Fridge has a new buckle design that unlocks with a gentle press.After storing the beverage, simply press to unlock and it will automatically advance, offering even greater convenience. Durable Material: The drink organizer for fridge is made of safe materials, with two stainless steel partition that is resistant to water and rust. The pusher is made of strong ABS material, and the horizontal rails can be adjusted to fit different needs by cutting them. Capacity & Adjustable Width:The fridge drink organizer is adjustable to fit most standard-sized cans and bottles, including 12 oz, 16 oz, 20 oz, and others. It has 3 rows and is 38CM long, holding up to 15+ cans or bottles in the fridge. Easy Assemble and Clean:This drink organizer for fridge is extremely simple to assemble and doesn't require any screws or tools. Additionally, its smooth surface and waterproof material make it effortless to clean. Widely Use: This can dispenser for refrigerator is versatile and can hold different types of beverages, including cans and bottles like coke, juice, soda water, beer, and wine. It can be used in refrigerators, coolers, shelves, supermarkets, and vending machines. It's suitable for various beverage types and environments. [ad_2]

0 notes

Text

Essential Brewing Equipment You Can Buy at Auctions

Breweries, whether new or established, often look for ways to save on costs while acquiring high-quality equipment. Brewing equipment auctions provide an excellent opportunity to purchase essential brewing equipment at competitive prices. Buying at auctions can offer substantial savings compared to purchasing new equipment, while still acquiring reliable machinery that will support your brewery’s operations. Here are some of the essential brewing equipment you can typically find at auctions:

1. Brewing Kettles

Brewing kettles are central to the brewing process, where wort (the liquid extracted from mashed grains) is boiled with hops to create the beer's flavor. At auctions, you can find various sizes of brewing kettles, from smaller units for craft breweries to large kettles for commercial-scale operations. Often made of high-quality stainless steel, these kettles can be purchased at a fraction of the cost of new ones. Auctions also offer the potential for getting high-end equipment with advanced features such as automatic temperature control, which can help optimize your brewing process.

2. Fermentation Tanks

Fermentation is a crucial stage in beer production, where yeast converts the wort into alcohol. Fermentation tanks, also known as fermenters, are vital for this process. Auctions often offer a wide range of fermenters in different sizes, both conical and cylindrical, suitable for small-scale to large-scale breweries. Fermentation tanks are built to last and can be found in excellent condition at auctions, providing an affordable way to equip your brewery without sacrificing quality. Many tanks come with temperature control systems, which can help improve fermentation efficiency and consistency.

3. Brew House Systems

Brewhouse systems consist of multiple pieces of equipment, including mash tuns, brew kettles, and wort coolers, designed to handle the brewing process from start to finish. These systems are available at auctions and can be found in various configurations, from smaller manual setups to large automated systems. Purchasing a used brew house system can save you considerable money, and with proper maintenance, it can still provide years of reliable service.

4. Bottling and Packaging Lines

For breweries looking to distribute their products commercially, bottling and packaging lines are essential. At auctions, you can find used bottling lines, canning machines, and packaging equipment for much lower prices than buying new. These systems are often designed for efficiency, allowing breweries to increase their production capacity. Auctions are an excellent place to find automated systems for filling, capping, labeling, and packaging bottles or cans. These machines often require minimal adjustments or refurbishing, making them a great investment for breweries that want to scale up their packaging capabilities.

5. Cooling Systems

Cooling systems are necessary to maintain the proper temperature during brewing and fermentation. Some common cooling equipment found at auctions includes plate heat exchangers, glycol chillers, and cooling jackets for fermenters and conditioning tanks. Cooling systems are vital for controlling the fermentation process and preventing overheating, so securing them at auctions can provide your brewery with a cost-effective way to meet these needs.

6. Mash Tuns

A mash tun is essential for converting the starches in grains into fermentable sugars by heating the grains in water. Mash tuns are available at auctions, and depending on the size, can cater to small craft brewers or large commercial breweries. Purchasing a used mash tun at auction allows you to acquire durable equipment that can be used for years with proper care.

7. Storage and Serving Tanks

Once your beer is brewed and fermented, it needs to be stored and served. Auctions often feature used Brite tanks, conditioning tanks, and kegging equipment. These tanks allow you to carbonate, clarify, and store your beer before packaging or serving. They come in a range of sizes, and purchasing used storage tanks can help your brewery save on capital costs.

8. Cleaning and Sanitation Equipment

Maintaining hygiene in the brewery is paramount. Auctions often include cleaning and sanitation equipment such as keg washers, CIP (clean-in-place) systems, and other sanitation tools that help keep brewing equipment free from contaminants. These items are crucial for ensuring the quality and safety of the beer, and buying them at auctions can save you money while ensuring your brewery remains compliant with health and safety regulations.

Conclusion

Buying brewing equipment at auctions offers an opportunity to acquire essential machinery at a fraction of the cost of new equipment. From brewing kettles and fermentation tanks to bottling lines and storage tanks, auctions provide a wide variety of equipment that can support any brewery’s operations. While some used equipment may require refurbishment, the savings you gain by purchasing at auctions make it a worthwhile investment. With proper research, maintenance, and care, buying at auctions can help breweries thrive while keeping costs down.

0 notes

Text

Q&A: The climate impact of generative AI

New Post has been published on https://sunalei.org/news/qa-the-climate-impact-of-generative-ai/

Q&A: The climate impact of generative AI

Vijay Gadepally, a senior staff member at MIT Lincoln Laboratory, leads a number of projects at the Lincoln Laboratory Supercomputing Center (LLSC) to make computing platforms, and the artificial intelligence systems that run on them, more efficient. Here, Gadepally discusses the increasing use of generative AI in everyday tools, its hidden environmental impact, and some of the ways that Lincoln Laboratory and the greater AI community can reduce emissions for a greener future.

Q: What trends are you seeing in terms of how generative AI is being used in computing?

A: Generative AI uses machine learning (ML) to create new content, like images and text, based on data that is inputted into the ML system. At the LLSC we design and build some of the largest academic computing platforms in the world, and over the past few years we’ve seen an explosion in the number of projects that need access to high-performance computing for generative AI. We’re also seeing how generative AI is changing all sorts of fields and domains — for example, ChatGPT is already influencing the classroom and the workplace faster than regulations can seem to keep up.

We can imagine all sorts of uses for generative AI within the next decade or so, like powering highly capable virtual assistants, developing new drugs and materials, and even improving our understanding of basic science. We can’t predict everything that generative AI will be used for, but I can certainly say that with more and more complex algorithms, their compute, energy, and climate impact will continue to grow very quickly.

Q: What strategies is the LLSC using to mitigate this climate impact?

A: We’re always looking for ways to make computing more efficient, as doing so helps our data center make the most of its resources and allows our scientific colleagues to push their fields forward in as efficient a manner as possible.

As one example, we’ve been reducing the amount of power our hardware consumes by making simple changes, similar to dimming or turning off lights when you leave a room. In one experiment, we reduced the energy consumption of a group of graphics processing units by 20 percent to 30 percent, with minimal impact on their performance, by enforcing a power cap. This technique also lowered the hardware operating temperatures, making the GPUs easier to cool and longer lasting.

Another strategy is changing our behavior to be more climate-aware. At home, some of us might choose to use renewable energy sources or intelligent scheduling. We are using similar techniques at the LLSC — such as training AI models when temperatures are cooler, or when local grid energy demand is low.

We also realized that a lot of the energy spent on computing is often wasted, like how a water leak increases your bill but without any benefits to your home. We developed some new techniques that allow us to monitor computing workloads as they are running and then terminate those that are unlikely to yield good results. Surprisingly, in a number of cases we found that the majority of computations could be terminated early without compromising the end result.

Q: What’s an example of a project you’ve done that reduces the energy output of a generative AI program?

A: We recently built a climate-aware computer vision tool. Computer vision is a domain that’s focused on applying AI to images; so, differentiating between cats and dogs in an image, correctly labeling objects within an image, or looking for components of interest within an image.

In our tool, we included real-time carbon telemetry, which produces information about how much carbon is being emitted by our local grid as a model is running. Depending on this information, our system will automatically switch to a more energy-efficient version of the model, which typically has fewer parameters, in times of high carbon intensity, or a much higher-fidelity version of the model in times of low carbon intensity.

By doing this, we saw a nearly 80 percent reduction in carbon emissions over a one- to two-day period. We recently extended this idea to other generative AI tasks such as text summarization and found the same results. Interestingly, the performance sometimes improved after using our technique!

Q: What can we do as consumers of generative AI to help mitigate its climate impact?

A: As consumers, we can ask our AI providers to offer greater transparency. For example, on Google Flights, I can see a variety of options that indicate a specific flight’s carbon footprint. We should be getting similar kinds of measurements from generative AI tools so that we can make a conscious decision on which product or platform to use based on our priorities.

We can also make an effort to be more educated on generative AI emissions in general. Many of us are familiar with vehicle emissions, and it can help to talk about generative AI emissions in comparative terms. People may be surprised to know, for example, that one image-generation task is roughly equivalent to driving four miles in a gas car, or that it takes the same amount of energy to charge an electric car as it does to generate about 1,500 text summarizations.

There are many cases where customers would be happy to make a trade-off if they knew the trade-off’s impact.

Q: What do you see for the future?

A: Mitigating the climate impact of generative AI is one of those problems that people all over the world are working on, and with a similar goal. We’re doing a lot of work here at Lincoln Laboratory, but its only scratching at the surface. In the long term, data centers, AI developers, and energy grids will need to work together to provide “energy audits” to uncover other unique ways that we can improve computing efficiencies. We need more partnerships and more collaboration in order to forge ahead.

If you’re interested in learning more, or collaborating with Lincoln Laboratory on these efforts, please contact Vijay Gadepally.

Play video

Video: MIT Lincoln Laboratory

0 notes

Text

Beer Events 12.22

Events

Henry Stoltz died (1866)

Woman's Christian Temperance Union founded (1873)

William Koedding patented an Automatic Filling Machine (1903)

Lewis Mather patented a Metal Keg or Cask (1914)

1st Vote in Congress on alcohol prohibition; it was defeated 197-189 (1914)

Strangeways Brewery water tanks destroyed by German bombing raid (1940)

John Silhavy patented a Method of and Apparatus for Making Beer (1942)

George Woolley patented a Portable Cooler, Gasser and Dispenser for Keg Beer and the Like (1959)

Goldfinger premiered in US (1964) [James Bond #3]

Breweries Opened

Trumer Privatbrauerei (1601)

Oertel Brewing (Kentucky; 1906)

Laguna Beach Brewing (California; 1994)

Tun Tavern (Pennsylvania; 1994)

Yaletown Brewing, Canada (1994)

Bray's Brewpub (Maine; 1995)

Powerhouse Brewing (California; 1995)

Sharktooth Brewing (Hawaii; 1995)

Brasserie de la Senne (Belgium; 2010)

Kohola Brewing (Hawaii; 2015)

0 notes

Text

Evaporative air cooler

Industrial air cooler, ductable air coolers, and commercial air coolers are examples of evaporative air cooling technologies that have grown to be important players in the HVAC sector.

Degree Day Private Limited introduces a revolutionary cooling technology through our Industrial air cooler. Developed by our expert team, these coolers harness the natural evaporative process of water to provide a sustainable and highly effective solution for creating cool and comfortable environments.

Evaporative Air Coolers are energy-efficient and environment-friendly. The high-end products range available having microprocessor-based controls is also very apt for large residential requirements.

GREENCON E-SERIES

E-Series is an ultimate cooling machine an industrial air cooler, designed & manufactured to suit Indian conditions & hence making it suitable to tackle all three adverse inputs i.e: Air, Water, Power

» Air – Automatic de-dusting of air filters

» Water – Auto/programmable drain, self-cleaning pump, level sensing protections

» Power – Under & overload protection of voltage & current with error display

» Ambience – Automatic temperature & humidity control using fuzzy logic

0 notes