#and metal. Its robust construction ensures stability and accuracy

Explore tagged Tumblr posts

Text

Buy now -Algolaser Delta 22w Diode Laser Engraver

#The Algolaser Delta 22W Diode Laser Engraver is a powerful and versatile tool designed for precision engraving and cutting. With a 22W diode#it effortlessly handles various materials#including wood#acrylic#leather#and metal. Its robust construction ensures stability and accuracy#making it suitable for both hobbyists and professionals. The user-friendly interface simplifies operation#allowing you to create detailed and high-quality engravings with ease. Enhance your projects and achieve exceptional results with the Algol

0 notes

Text

Powermatic

Powermatic is a well-known brand of woodworking machinery that has been producing high-quality tools and machines since 1921. The company is known for its wide range of products, including table saws, bandsaws, jointers, planers, lathes, and dust collection systems. Woodworking professionals and enthusiasts around the world trust Powermatic machines due to their precision and accuracy.

One of the key features that sets Powermatic machinery apart from others is the use of cast iron in their construction. This material provides stability and durability to their machines, making them reliable and long-lasting.

Powermatic machinery is designed with safety in mind. They incorporate various safety features in their machines such as blade guards and safety switches to prevent accidents in the workshop.

Overall, Powermatic is a reputable brand that offers high-quality woodworking machinery. Their precision, durability, and safety features make them a popular choice for both professional woodworkers and hobbyists alike.

Powermatic product line

Powermatic is a renowned brand that specializes in crafting top-quality woodworking machinery and tools. The brand offers a diverse product line that caters to the varying needs of woodworkers, from novice hobbyists to seasoned professionals.

Table Saws - Powermatic's table saws are engineered for precision, power, and durability. The brand offers cabinet saws designed for heavy-duty use, featuring large table surfaces and robust motors. Contractor saws are more portable and suitable for job site use, while hybrid saws combine features of both cabinet and contractor saws.

Bandsaws - Powermatic's bandsaws are designed to make accurate cuts in wood and other materials. They come in different sizes, from benchtop models suitable for small jobs to floor models capable of handling larger wood pieces. Powermatic's bandsaws are renowned for their precision, ease of use, and smooth operation.

Planers - Powermatic's planers are designed to smooth rough lumber and make it usable for woodworking projects. The brand offers a variety of sizes, with larger models capable of handling wide boards and thick wood pieces. Powermatic's planers are known for their precision and user-friendliness.

Jointers - Powermatic's jointers are used to straighten and flatten wood surfaces. They come in benchtop and floor models, with larger ones capable of handling wider wood pieces. Powermatic's jointers are known for their accuracy and ease of use.

Sanders - Powermatic's sanders include both belt and drum sanders, designed to make sanding jobs quick and straightforward. They come in different sizes, with larger models capable of handling more substantial wood pieces. Powermatic's sanders are renowned for their accuracy, speed, and ease of use.

Dust Collectors - Powermatic's dust collectors are designed to ensure workspace cleanliness and safety by removing dust and debris from the air. They come in different sizes, with larger models capable of handling multiple machines at once. Powermatic's dust collectors are known for their efficiency and reliability.

Lathes - Powermatic's lathes are used for turning wood and other materials. They come in benchtop and floor models, with larger ones capable of handling more significant wood pieces. Powermatic lathes are known for their precision and ease of use.

Mortisers - Powermatic mortises are used to make precise mortises in wood. They come in benchtop and floor models, with larger ones capable of handling larger wood pieces. Powermatic's mortises are renowned for their accuracy and user-friendliness.

Drill Presses - Powermatic's drill presses are used to drill accurate holes in wood and metal. They come in benchtop and floor models, with larger ones capable of handling larger wood pieces. Powermatic's drill presses are known for their precision and ease of use.

CNC Machines - Powermatic's CNC machines are used for computer-controlled manufacturing processes. They come in different sizes, with larger ones capable of handling larger wood and other materials. Powermatic's CNC machines are known for their precision and efficiency.

In conclusion, Powermatic's product line is designed to cater to the needs of woodworkers at all levels, offering high-quality woodworking machinery and tools that are durable, efficient, and user-friendly.

#powermatic#CNC Machines#Drill Presses#Mortisers#Lathes#Dust Collectors#Sanders#Jointers#Planers#Bandsaws#Table Saws

2 notes

·

View notes

Text

VOLTZ 5 Inch Multipurpose Vise: Unlock versatility

Key Features That Set the VOLTZ Vise Apart Multi Jaw Versatility With its multi-jaw capability, the VOLTZ 5 Inch Vise can clamp various materials including wood and metal. It is also suitable to clamp irregularly shaped items. This allows you to have the best grip possible for any job, be it drilling, welding or cutting.

This vise is equipped with 360° Rotation. With the Swivel Base and Head this vise allows 360-degree rotation. This allows you to place your workpieces at just the right angle. You don’t have to change your setup. It is ideal for precision-oriented tasks, like polishing and carving.

Heavy Duty Construction Made from superior materials, VOLTZ Vise can stand up to rigorous usage. This robust construction is perfect for demanding applications.

Clamp On Design With the easy-to use clamp on mechanism, you can securely attach any vise to a workbench. The clamp-on design ensures the stability of your vise during use and helps to prevent any unintentional movement.

Home & Industrial Use No matter if you are a professional in the industrial sector or a home improvement enthusiast, this vise will deliver consistent and reliable results for your clamping and fixation needs.

Applications of the VOLTZ 5-Inch Multipurpose Vise Steelworking: Ensure metal components are secure for grinding, cutting or welding. Its jaws are strong and provide a secure grip. This reduces the chance of moving during use.

Timberworking: From sawing to sanding, VOLTZ Vise offers a stable and accurate platform for wood projects.

Pipe clamping: With the multi-jaw, it is easy to clamp cylindrical objects like pipes and rods for threading or cutting.

Projects for Hobbyists: No matter if you are assembling tiny parts or creating intricate designs, the vise will provide control and stability.

Industry Repairs: Heavy-duty construction of VOLTZ Vise allows it to perform demanding repairs in factory settings.

Why Choose the VOLTZ 5-Inch Multipurpose Vise? Durability Built for years of heavy duty use, this vise will not compromise its performance.

Precision Swivel Base and Head offer precise positioning allowing you to take on intricate tasks confidently.

User-Friendly: Even beginners can use it easily thanks to the smooth, swivel-like mechanism.

Value for Money: In spite of its many premium features, VOLTZ Vise comes at a competitive price.

Tips for Getting the Most Out of Your VOLTZ Vise Correct Mounting: Be sure to secure the vise to a stable table to optimize its efficiency and stability.

Routine Maintenance: Cleaning the jaws, swivel and mechanism is recommended after every use. This will prevent buildup of debris and allow for smoother operation.

Choose the Correct Jaw Inserts If you are clamping fragile materials, it is best to use soft jaw inserts.

Take advantage of the rotation: Make the most out of the 360-degree pivot to place your workpiece in the best possible position, improving accuracy and reducing stress.

Conclusion VOLTZ 5 Inch Multipurpose Vises are more than a simple tool. They’re a trusted partner for your industrial or workshop space. This versatile tool is a great choice because of the combination of durability and ease of use. VOLTZ Vise provides the precision and stability you need to complete your projects.

VOLTZ’s 5-Inch Multipurpose Vise will take your work to the next step!

0 notes

Text

Good Precision in Metalworking of CNC Intelligent Metal Cutting Band Saw Machine

In the realm of metalworking, precision is not just a desirable trait; it is a necessity. The CNC Intelligent Metal Cutting Band Saw Machine stands as a testament to this fact, offering unparalleled accuracy and consistency in the cutting of various metal materials. This machine is a modern engineer, designed to meet the stringent demands of industries that require high-precision metal components.

The CNC Intelligent Metal Cutting Band Saw Machine's precision is a result of its advanced computer numerical control (CNC) system, which allows for the automation of complex cutting processes. This system ensures that each cut is made with exacting detail, reducing the margin of error. The machine's ability to maintain such high levels of precision is a direct result of its sophisticated software and hardware components working in harmony.

One of the key features of the CNC Intelligent Metal Cutting Band Saw Machine is its ability to handle a wide range of materials, from aluminum to steel, with equal ease. The machine's cutting precision is not compromised by the hardness or thickness of the material, thanks to its powerful motor and high-quality blades. The blades, which are often made from carbide or other durable materials, are designed to maintain their sharpness over time, further contributing to the machine's precision.

The CNC Intelligent Metal Cutting Band Saw Machine also boasts a high degree of adjustability, allowing operators to fine-tune the cutting parameters to suit their specific needs. This includes the ability to adjust the speed of the blade, the feed rate, and the angle of the cut. This level of customization ensures that the machine can achieve the desired precision for each unique application.

In addition to its cutting capabilities, the CNC Intelligent Metal Cutting Band Saw Machine also excels in terms of repeatability. This is crucial for industries that require the production of identical parts in large quantities. The machine's CNC system stores the cutting parameters for each job, allowing it to reproduce the same cuts time and time again with absolute precision.

The machine's precision is also supported by its robust construction. The CNC Intelligent Metal Cutting Band Saw Machine is built with heavy-duty materials to ensure stability during operation. This reduces the risk of vibrations or other movements that could affect the accuracy of the cuts. The machine's frame is designed to absorb shocks and maintain rigidity, ensuring that the blade remains true to its path.

Maintenance is another aspect that contributes to the long-term precision of the CNC Intelligent Metal Cutting Band Saw Machine. Regular servicing and blade changes are essential to keep the machine running at good performance. The machine's design allows for easy access to its components, making maintenance a straightforward process.

In conclusion, the CNC Intelligent Metal Cutting Band Saw Machine is a powerhouse of precision in the world of metal cutting. Its advanced CNC system, high-quality components, and user-friendly design all work together to deliver cuts that are accurate, consistent, and repeatable. This machine is a valuable asset to any workshop or factory that demands high standards of precision in their metalworking operations. The CNC Intelligent Metal Cutting Band Saw Machine is not just a machine; it is a symbol of the precision that modern manufacturing has come to expect and rely upon.

0 notes

Text

The Role of Dowel Bars in Concrete Pavement and Construction

Concrete pavements make up the cornerstone of modern infrastructure, supporting everything from highway and airport concrete to industry floors and sidewalks. Between these robust surfaces stands a humble component often missing from most people's sight: dowel bars. These slender metal bars contribute significantly and transform concrete pavement performance—ensuring structural integrity and longevity—so much so that even many well-seasoned professionals rely upon them.

Understanding Dowel Bars: A Structural Game Changer

Dowel bars in concrete pavement are a modern engineering solution to complex structural problems. Unlike traditional reinforcements, the precision-engineered metal bars have a purpose and a specific role to play in load transfer management and the prevention of deterioration in pavement.

The Science Behind Structural Stability

At its core, a dowel bar functions as a sophisticated load transfer mechanism. When concrete slabs experience stress from heavy vehicles, temperature changes, or ground movement, these bars enable smooth load distribution across adjacent concrete sections. This seemingly simple action prevents critical issues like:

Uneven surface development

Premature cracking

Structural misalignment

Accelerated pavement degradation

Material Composition and Engineering Precision

Typically manufactured from high-strength steel, dowel bars undergo rigorous manufacturing processes to ensure:

Consistent diameter

Smooth surface treatment

Corrosion resistance

Maximum load transfer efficiency

Load Transfer: The Ultimate Benefit of Dowel Bars

Concrete joints are potential structural vulnerabilities in pavement construction. Without adequate load transfer devices, these joints can quickly become structural weaknesses. Dowel bars in concrete pavement address this issue by providing a mechanical bond that enables controlled movement but ensures structural integrity.

Practical Uses and Performance Advantages

Highway and Road Construction

Highways are always subjected to heavy vehicular loads. Dowel bars keep the concrete slabs even so that there is no possibility of unevenness of surface that may lead to accidents.

Airport Runway Reliability

Aircraft require perfectly uniform surface conditions. Dowel bars provide the accuracy to keep the runway intact with extreme load and environmental conditions.

Industrial Floor Performance

Manufacturing facilities require floors that can withstand heavy machinery and constant movement. Dowel bars provide the structural strength required in these challenging environments.

Economical Long-Term Solutions

Although dowel bars may incur higher installation costs, they are a savvy long-term solution to durable concrete construction. They save money on future maintenance needs and extend pavement life, which is a significant long-term economic advantage.

Economic Benefits of Construction

The economic benefits of dowel bars include:

Less frequent repairs

Increased durability of infrastructures

Least surface damage

Less costly long-term maintenance

Integrating Dowel Bar Solutions: Recommendations by Experts

Dowel bars must be implemented correctly and by an expert. Construction teams are advised to consider:

Close spacing of the bar

Right size of the bar

Installation techniques

Anticorrosive paint coats

Project-specific environmental characteristics

Selecting the Optimal Dowel Bar Setup

Projects vary in approach. Factors affecting dowel bar selection are:

Anticipated loading conditions

Changes in weather and temperature

Specific structural needs

Project-specific traffic patterns

Correct Choice for Structural Strength

Dowel bars are an engineering solution, but above that, they represent an intelligent investment in infrastructure strength. Only the savvy construction expert knows how such mundane concrete pavement can become solidly tough to endure aggressive natural settings.

Call to Construction Excellence

Projects demanding pavements that exhibit premium quality in pavement performance call for a perfect dowel bar system. Seeking professional assistance from structural engineers would establish an optimal configuration for constructing any type of construction task.

Whether it is planning a highway expansion, designing an industrial facility, or building critical infrastructure, the installation of dowel bars is an enlightened approach to concrete construction. The future of reliable pavements begins with knowledge and implementation of these magnificent engineering components.

#TMT bars#steel bars#construction materials#reinforced steel#Kapila Steel#building strength#high-quality steel#durable TMT bars

0 notes

Text

What Are the Essential Features of a High-Performance MIG Welder?

When choosing a MIG welder, it’s crucial to understand the essential features that define high performance and reliability. A MIG stick welder must not only meet your immediate welding needs but also provide flexibility for various projects in the future. One of the most significant features to consider is the power output. The best MIG welders typically offer a wide range of amperage settings, which allows you to weld different materials, from thin sheet metal to thicker plates. This versatility ensures that you can handle a variety of jobs, making your investment worthwhile. Additionally, a quality welder will have a stable arc, which is crucial for producing clean and strong welds. This stability is enhanced by the right selection of MIG welder gas, as it protects the weld area from contamination, thus improving the overall quality of the weld.

Another vital aspect of a high-performance MIG welder is its ease of use. Features such as adjustable wire feed speed and a user-friendly interface make it easier for both beginners and experienced welders to achieve optimal results. An intuitive design can significantly reduce the learning curve and enhance productivity. Additionally, some of the best rated MIG welders include advanced features such as digital displays, which provide precise settings and real-time feedback during the welding process. These modern conveniences not only improve accuracy but also help to prevent mistakes that could lead to defects in the final product. When shopping, keep an eye out for MIG welders on sale that offer these essential features without compromising on quality.

Lastly, durability and portability are essential considerations. A robust construction ensures that your Everlast MIG welder can withstand the rigors of heavy use, while a lightweight design can make it easier to transport to different job sites. High-performance welders also often include safety features like thermal overload protection, which helps to extend the life of the machine by preventing overheating. When investing in a MIG welder, consider these features carefully to ensure that you select a model that will serve you well for years to come. By understanding what makes a MIG welder high-performance, you can make an informed decision that suits your welding needs and enhances your skillset.

0 notes

Text

Examining Round Bars' Function in Manufacturing and Machinery

Rajkrupa Metal Industries is a highly ranked Round Bars Manufacturers in India. We have made a reputation for ourselves as one of the top companies in the Round Bars sector. Rajkrupa Metal Industries aims to be a top Round Bar manufacturer because of its highly skilled technical and commercial workforce. Let's delve into the diverse roles round bars play in machinery and manufacturing processes.

1. Shafts and Axles

Round bars serve as the backbone for shafts and axles in machinery. Their cylindrical shape allows for uniform distribution of stress and torque, making them ideal for transmitting rotational motion. From automotive driveshafts to industrial conveyor systems, round bars provide the structural integrity necessary to support heavy loads and maintain smooth operation.

2. Pins and Dowels

In manufacturing, round bars are commonly used as pins and dowels to align and secure components in place. Whether joining machine parts, assembling furniture, or constructing intricate mechanisms, round bars offer precise tolerances and reliable fastening solutions. Their cylindrical design facilitates easy insertion and removal, ensuring efficient assembly and disassembly processes.

3. Tooling and Fixtures

Round bars serve as foundational elements in tooling and fixtures for machining operations. They provide stable support and precise positioning for workpieces during milling, drilling, and turning processes. By incorporating round bars into jigs and fixtures, manufacturers can enhance productivity, maintain accuracy, and streamline production workflows.

4. Actuators and Linkages

In robotics and automation, round bars function as actuators and linkages to translate mechanical motion into desired actions. Whether controlling robotic arms, operating valves, or regulating machinery, round bars facilitate smooth and controlled movement across a range of applications. Their versatility allows engineers to design intricate motion control systems that optimise efficiency and performance.

5. Guide Rods and Linear Bearings

Round bars serve as guide rods and shafts in linear motion systems, providing support and guidance for sliding components such as bearings and bushings. By minimising friction and reducing wear, round bars enable smooth and precise linear motion in CNC machines, 3D printers, and industrial robots. Their high-strength construction ensures long-term reliability and accuracy in dynamic motion applications.

6. Structural Frameworks

Round bars play a vital role in constructing structural frameworks for machinery and equipment. Whether reinforcing frames, bracing structures, or supporting heavy loads, round bars provide the strength and stability necessary to withstand rigorous operating conditions. Their adaptability allows engineers to design robust frameworks that optimise space, minimise weight, and maximise durability.

We are also top quality Aluminium Bronze Round Bar Manufacturer In India. We have made a reputation for ourselves as one of the leading manufacturers of Aluminium Bronze Round Bar. Rajkrupa Metal Industries has made a conscious effort to establish itself as a premier global producer and merchant.

Website: rajkrupametal.com

Source: Round Bars Manufacturer in India

#RoundBarsManufacturersinIndia#RoundBarsManufacturers#RoundBars#AluminiumBronzeRoundBarManufacturerInIndia#AluminiumBronzeRoundBarManufacturer#AluminiumBronzeRoundBar

0 notes

Text

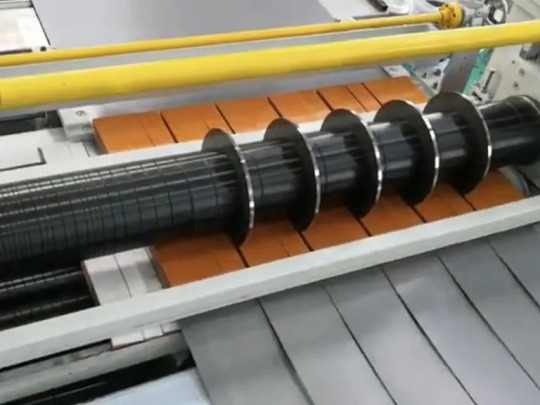

Core slitting machines are pivotal in modern manufacturing,

particularly in industries that require the precision cutting of materials into narrow strips. These machines facilitate the conversion of wide rolls of material—such as paper, plastic, metal, and textiles—into smaller, usable widths. Understanding the design and operational insights of core slitting machine can significantly enhance their efficiency and effectiveness in production environments.

Overview of Core Slitting Machines

Core slitting machines are designed to handle various materials and offer precision in cutting operations. Their primary function is to take a large roll of material and slice it into narrower strips while maintaining consistent dimensions and quality. These machines are essential in industries like packaging, automotive, electronics, and textiles, where precise dimensions are critical for downstream processes. The importance of these machines cannot be overstated, as the quality of the slitted material directly impacts the efficiency of subsequent manufacturing steps.

Key Design Features

Frame Structure The structural integrity of a core slitting machine starts with its frame, typically constructed from robust materials such as steel or aluminum. A solid frame minimizes vibrations during operation, ensuring that the machine remains stable while cutting. This stability is crucial for maintaining precise alignment of the cutting components, which directly affects the quality and accuracy of the slits produced. Manufacturers often invest in advanced engineering techniques to optimize the frame design, balancing weight and durability.

Unwind and Rewind Stations

Unwind and rewind stations are integral components of core slitting machines, responsible for feeding the wide rolls into the cutting area and collecting the finished strips. These stations are designed to accommodate varying roll sizes and weights, featuring tension control systems that help maintain the proper material tension throughout the slitting process. Proper tension is essential for achieving clean cuts and preventing material damage, making these components critical to the machine's overall performance.

Slitting Head

The slitting head is arguably the most vital part of the core slitting machine, where the actual cutting occurs. It houses the slitting blades, which can be rotary, shear, or circular depending on the material type being processed. The design of the slitting head often allows for precise adjustments in blade height and alignment, enabling operators to customize the machine for different materials and thicknesses. This adaptability is essential for meeting the varied demands of different production runs.

Blade Types and Maintenance

The choice of blade types is another crucial factor in the design of core slitting machines. Rotary blades are typically used for flexible materials, while shear blades are better suited for harder materials. Regular maintenance of these blades—such as sharpening and replacements—is vital for maintaining cutting quality and efficiency. A well-maintained blade not only improves the quality of the cuts but also reduces machine downtime, contributing to overall productivity.

Operational Insights Material Selection

The type of material being processed plays a significant role in the operation of core slitting machines. Factors such as thickness, flexibility, and tensile strength must be taken into account when selecting materials for slitting. Understanding the characteristics of the material can help operators optimize blade types and cutting speeds, enabling them to achieve the best possible results.

Setup Procedures

Efficient setup procedures are essential for minimizing downtime and maximizing productivity in core slitting operations. Operators should follow standardized protocols for adjusting blades, setting tension, and configuring the control system. A well-defined setup process can significantly reduce the time required to transition between different production runs, allowing manufacturers to respond quickly to changing demands.

Regular Maintenance

Implementing a regular maintenance schedule is imperative for ensuring the long-term reliability and performance of core slitting machines. Maintenance tasks may include cleaning, lubrication, blade sharpening, and inspection of mechanical components. A proactive maintenance approach helps prevent unexpected breakdowns, thereby keeping production running smoothly and reducing costs associated with equipment failures.

Performance Monitoring

Continuous monitoring of performance metrics such as production cycle time, scrap rate, and material utilization is crucial for assessing the efficiency of core slitting operations. By analyzing these metrics, manufacturers can identify areas for improvement and implement strategies to enhance overall productivity. Regular performance reviews can also help operators make informed decisions about machine adjustments and operational changes.

Operator Training

Well-trained operators are essential for the successful operation of core slitting machines. Comprehensive training programs should cover machine functions, safety protocols, and troubleshooting techniques. Investing in regular training updates ensures that operators remain informed about new technologies and best practices, empowering them to perform their tasks efficiently and effectively.

Quality Control

Establishing a robust quality control process is vital for ensuring that the slitted strips meet required specifications. Regular inspections of the output can help identify defects early in the process, allowing for timely corrective actions. Quality control measures should include checks for dimensional accuracy, surface finish, and the presence of defects, ensuring that the final product meets customer expectations.

Conclusion

Core slitting machines are integral to the manufacturing process, enabling industries to efficiently produce narrow strips from wide rolls of material. By understanding key design features and operational insights, manufacturers can optimize their slitting processes, enhance product quality, and improve overall efficiency. Emphasizing material selection, efficient setup procedures, regular maintenance, performance monitoring, operator training, and quality control will ultimately lead to enhanced productivity and reduced operational costs. As industries continue to evolve, investing in advanced core slitting technology and best practices will be essential for maintaining a competitive edge in the market

0 notes

Text

Understanding the Role of the Machine Bed in Manufacturing: A Comprehensive Guide

In the world of manufacturing, precision and stability are crucial for producing high-quality parts. Whether it's a CNC machine, lathe, or milling system, one often overlooked but essential component is the machine bed. Acting as the backbone of the entire machine structure, the machine bed plays a vital role in ensuring accuracy, stability, and longevity in the manufacturing process.

What is a Machine Bed?

A machine bed is the foundational structure on which all other components of a machine are mounted. It serves as the primary support for various machine elements such as spindles, tool holders, motors, and workpieces. Constructed from high-strength materials like cast iron or steel, it provides a stable and vibration-resistant surface that allows the machine to perform accurate operations over long periods of time.

Key Functions of the Machine Bed

Stability and Rigidity: The primary function of a machine bed is to provide rigidity and stability. Machines like CNC mills and lathes require a stable base to ensure precise cutting and shaping. Any instability in the machine bed can lead to vibrations that reduce accuracy and damage the tool or workpiece. A well-constructed machine bed prevents these issues, allowing for smooth and controlled operations.

Vibration Dampening: During high-speed machining, vibrations are inevitable, especially when working with hard materials. Excessive vibrations can cause tool wear and reduce the quality of the finished product. A machine bed, due to its mass and material composition, acts as a natural damper for these vibrations, minimizing their impact on the machine’s performance.

Support for Moving Parts: Many machines, such as CNC routers and mills, involve moving components like spindles, tool carriages, or cutting heads. The machine bed provides a flat and level surface, ensuring that these moving parts remain aligned during operation. This is essential for maintaining precision, especially in multi-axis machines where even slight deviations can result in costly errors.

Load Bearing: The machine bed also supports the weight of both the machine components and the workpieces being processed. It’s designed to handle heavy loads without bending or deforming. This load-bearing capacity is crucial when working with large or heavy materials, ensuring that the machine operates effectively without compromising on accuracy.

Thermal Stability: In some high-precision machines, thermal expansion can become an issue. Changes in temperature can cause machine components to expand or contract, potentially leading to inaccuracies in machining. High-quality machine beds are often designed to be thermally stable, resisting expansion or contraction even in varying temperatures.

Types of Machine Beds

Machine beds come in different shapes and sizes depending on the type of machine and its intended application. Some common types include:

Flat Bed: Typically used in lathes, flat machine beds provide a smooth surface for tool movements along the X and Z axes. This design is simple yet effective for machining cylindrical components.

Slant Bed: In slant bed lathes, the bed is angled to improve chip evacuation and reduce the effects of gravity on the cutting tool. This design enhances the ergonomics of the machine and improves the overall precision of machining.

Box Bed: Found in heavy-duty milling and boring machines, box beds are designed to handle large and heavy workpieces. They are robust and provide superior stability, especially in machines where large tools are used to remove a significant amount of material.

Gantry Bed: In CNC routers and plasma cutting machines, gantry beds provide support for a moving bridge (gantry) that carries the cutting tools. These beds need to be large and rigid, especially when processing sheet materials like wood, plastic, or metal.

Materials Used in Machine Beds

Machine beds are typically made from materials that provide strength, rigidity, and vibration dampening. The most common materials include:

Cast Iron: Known for its excellent vibration-dampening properties, cast iron is the most common material used in machine beds. Its high density makes it ideal for absorbing vibrations and providing a stable base for machining operations.

Steel: Steel beds are stronger and more resistant to wear compared to cast iron. However, steel does not have the same vibration-dampening properties, so it is often used in conjunction with other materials or designs to counteract this.

Granite or Polymer Composite: In high-precision applications, materials like granite or polymer composites are used for their superior thermal stability and vibration absorption. These materials are typically found in ultra-precision machines where even the smallest vibration can affect the quality of the finished product.

Maintenance and Care of Machine Beds

Maintaining the integrity of a machine bed is critical for ensuring the longevity and performance of the machine. Here are a few maintenance tips:

Regular Cleaning: Machine beds should be kept clean from chips, debris, and lubricants that accumulate during operation. This prevents wear and tear on the surface and ensures the smooth movement of machine components.

Lubrication: Moving parts like guideways that interact with the machine bed should be properly lubricated to reduce friction and wear.

Inspection: Regularly inspect the machine bed for any signs of wear, cracks, or deformities. Early detection of issues can prevent costly repairs or downtime.

Leveling: Over time, machine beds can become unlevel due to vibrations and usage. It’s important to check the level of the machine periodically and make adjustments as needed.

Conclusion

The machine bed is often referred to as the "heart" of a machine tool due to its critical role in maintaining precision and stability. Without a properly designed and maintained bed, even the most advanced machines can fall short in delivering high-quality results. Whether you're working with a CNC machine, lathe, or milling setup, understanding the importance of the machine bed is key to ensuring the success of any manufacturing process. Investing in a high-quality machine bed and maintaining it well can dramatically improve the performance and longevity of your machinery.

0 notes

Text

RTD PT-100,Bimetal thermowell

RTD PT-100 & Bimetal Thermowell: Precision & Durability in Temperature Measurement

In the world of industrial processes, accurate temperature measurement is crucial for ensuring product quality, safety, and efficiency. Among the various tools available for this purpose, RTD (Resistance Temperature Detector) RTD PT-100 sensors and bimetal thermowells stand out for their precision and durability. Understanding the roles of these components and how they work together can provide valuable insights into why they are so widely used in industries ranging from manufacturing to power generation.

What is an RTD PT-100? An RTD PT-100 is a type of temperature sensor that uses the principle of resistance change with temperature. The "PT" in PT-100 refers to platinum, the metal used in the sensor, and "100" indicates that the sensor has a resistance of 100 ohms at 0°C. Platinum is chosen for its stable and predictable change in resistance with temperature, making it ideal for precise temperature measurements.

RTD PT-100 sensors are known for their accuracy and repeatability, often outperforming other types of temperature sensors such as thermocouples. They provide a linear relationship between temperature and resistance, which simplifies the process of converting the measured resistance into a temperature reading. This linearity, along with their wide temperature range and long-term stability, makes RTD PT-100 sensors a popular choice in industries where precise temperature control is essential.

The Role of the Bimetal Thermowell

While the RTD PT-100 is highly accurate, it is also sensitive and can be damaged by harsh environmental conditions. This is where the bimetal thermowell comes into play. A thermowell is a protective casing into which the RTD sensor is inserted. It shields the sensor from direct exposure to the process fluid, thereby preventing physical damage, corrosion, and contamination.

Bimetal thermowells are particularly valued for their ability to withstand extreme conditions. Made from two different metals fused together, they combine the strengths of each metal, offering superior durability and resistance to thermal stress. This construction allows them to perform reliably in environments with rapid temperature changes, high pressures, or corrosive substances.

The Importance of the Combination

The combination of an RTD PT-100 sensor with a bimetal thermowell creates a robust temperature measurement system that can handle the rigors of industrial environments while maintaining high accuracy. The RTD PT-100 provides precise temperature readings, while the bimetal thermowell ensures that the sensor is protected from potentially damaging conditions.

This setup is particularly useful in industries like chemical processing, oil and gas, and power generation, where temperature measurements are critical to maintaining safe and efficient operations. In these settings, any deviation from the desired temperature range can have significant consequences, making the reliability of the measurement system paramount.

Conclusion The RTD PT-100 and bimetal thermowell combination represents the best of both worlds: precision and durability. While the RTD PT-100 offers exceptional accuracy, the bimetal thermowell provides the necessary protection to ensure the sensor’s longevity and consistent performance. Together, they form a reliable and effective solution for temperature measurement in demanding industrial environments, helping to ensure that processes run smoothly and safely.

#pressure gauge syphon#illustration#low pressure gauge#pressure gauge liquid filled gauge#pressure gauge#writers#bimetal thermometer remote reading thermometer#nonprofits#politics#nature

0 notes

Text

1/2 TO 3/4 FLARING TOOL (60230)

The Versatile 1/2 to 3/4 Flaring Tool: Precision, Durability, and Ease of Use

In the world of metalworking and HVAC (Heating, Ventilation, and Air Conditioning) systems, the importance of a reliable flaring tool cannot be overstated. Whether you're a seasoned professional or a dedicated DIY enthusiast, having the right tools at your disposal is critical to achieving high-quality results. Among these tools, the 1/2 to 3/4 flaring tool stands out for its blend of durability, precision, and user-friendly design. This article delves into the key features that make this tool an indispensable asset in any toolkit, highlighting some of the best 1/2 to 3/4 flaring tools available and their price ranges.

Hardened Steel Flaring Bar: The Foundation of Precision

At the core of the 1/2 to 3/4 flaring tool is the hardened steel flaring bar, a feature that sets the foundation for the tool's exceptional performance. The hardened steel material is renowned for its robustness, providing excellent resistance to tube slippage. This is crucial when working with metal tubing, as even the slightest movement can lead to inaccurate flares, compromising the integrity of the connection.

The hardened steel flaring bar ensures that the tubing remains securely in place during the flaring process, allowing for precise and consistent results every time. This level of accuracy is particularly important in HVAC applications, where the quality of the flare can impact the efficiency and safety of the entire system. Additionally, the durability of the hardened steel construction means that this tool can withstand repeated use without losing its effectiveness, making it a long-term investment for professionals and hobbyists alike.

For those looking to purchase this tool, the 1/2 to 3/4 flaring tool price typically ranges from $30 to $80, depending on the brand and additional features included.

Forged Steel Yoke: Streamlined Setup and Enhanced Stability

Another standout feature of the 1/2 to 3/4 flaring tool is its forged steel yoke. This component is designed with simplicity and efficiency in mind, making the tool easy to use for both experienced workers and those new to the craft. The yoke slips effortlessly over the flaring bar, locking into place with a quick turn. This streamlined setup process not only saves time but also enhances user confidence by ensuring a secure and stable operation.

The forged steel yoke's secure locking mechanism is a critical aspect of the tool's performance. During the flaring process, any instability can lead to errors, resulting in subpar flares that may not hold up under pressure. The robust design of the yoke minimizes the risk of such errors, providing a stable platform for creating precise flares. This feature is particularly valuable in situations where accuracy is paramount, such as in the installation of refrigeration lines or fuel systems.

Precision Threaded Feed Screw: Consistent Pressure for Accurate Flares

Precision is key when it comes to flaring metal tubing, and the 1/2 to 3/4 flaring tool delivers this through its precision threaded feed screw. This feature allows for smooth and controlled movement during the flaring process, making it easier to apply consistent pressure. Consistency in pressure is essential for creating uniform flares, which in turn ensures a tight seal and reliable connection.

The precision threaded feed screw also reduces the effort required to create a flare, making the tool more user-friendly. This is especially beneficial during extended use, where repetitive motions can lead to fatigue. By facilitating easier operation, the threaded feed screw allows users to work more efficiently and with greater accuracy, whether they are working on a single project or tackling multiple tasks in quick succession.

Long Handle: Ergonomic Design for Greater Control

One of the key challenges in metalworking is maintaining control over the tools, especially when working with tough materials like steel or copper tubing. The 1/2 to 3/4 flaring tool addresses this challenge with its long handle, which provides significant leverage. This design feature enables users to exert more force with less effort, resulting in greater control over the flaring process.

The long handle's ergonomic design is not only about leverage; it also contributes to user comfort. When working on extensive projects, tool fatigue can become a serious issue, leading to decreased precision and potential mistakes. The extended handle reduces the strain on the user's hands and wrists, allowing for longer periods of work without discomfort. This makes the tool ideal for both professional settings, where efficiency is critical, and for DIY projects, where user comfort can greatly impact the quality of the work.

Chrome Finish: Professional Look and Enhanced Durability

In addition to its functional features, the 1/2 to 3/4 flaring tool boasts a chrome finish that serves both aesthetic and practical purposes. The sleek, professional appearance of the chrome finish adds a touch of sophistication to the tool, making it a pleasure to work with. However, the benefits of the chrome finish go beyond its looks.

Chrome plating is known for its excellent resistance to corrosion, which is a common concern when working in environments exposed to moisture, chemicals, or other harsh conditions. The chrome finish protects the tool from rust and wear, ensuring that it remains in top condition even after prolonged exposure to challenging environments. This durability extends the lifespan of the tool, making it a wise investment for anyone who regularly works with metal tubing.

Best 1/2 to 3/4 Flaring Tools on the Market

When searching for the best 1/2 to 3/4 flaring tool, it's important to consider factors like build quality, ease of use, and price. Some of the top-rated options include:

RIDGID 377 Flaring Tool: Known for its durability and precision, this tool is priced around $60 to $80.

Yellow Jacket 60278 Flaring Tool: A popular choice among professionals, offering high-quality flares with a price range of $50 to $70.

Imperial 195FC Flaring Tool: This tool is well-regarded for its ease of use and sturdy construction, typically priced between $40 and $60.

AC Flaring Tool Kit Price

For those working specifically with HVAC systems, investing in an AC flaring tool kit can be a smart choice. These kits often include multiple tools and accessories needed for various flaring tasks. The AC flaring tool kit price varies based on the number of tools and the quality of the kit, with prices typically ranging from $70 to $150. High-end kits may offer additional features such as deburring tools and tube cutters, making them a comprehensive solution for HVAC professionals.

WEBSITE :-WWW.BPREFCOOL.COM

CONTACT NO. 097177 32520

0 notes

Text

Unmatched Feel: Why a Premium Metal Gaming Keyboard Enhances Your Gaming Experience

In the realm of gaming, where every millisecond can make the difference between victory and defeat, having the right equipment is paramount. Among these essentials, a gaming keyboard stands out as a critical component of any gamer’s arsenal. While there are countless options available on the market, a premium gaming keyboard made with metal offers an unmatched feel that can significantly enhance your gaming experience. This article will explore the advantages of these keyboards and why they are a must-have for serious gamers. The Unique Appeal of Metal Keyboards Durability and Longevity One of the primary advantages of a metal gaming keyboard is its durability. Keyboards made with metal are built to withstand the rigors of intense gaming sessions. Unlike their plastic counterparts, metal keyboards are less prone to wear and tear, offering a longer lifespan. The metal construction ensures that the keyboard remains robust even under heavy use, providing a reliable and consistent performance over time. Stability and Weight The added weight of a metal keyboard contributes to its stability. In the heat of an intense gaming match, the last thing you want is for your keyboard to slip or move around. The heft of a metal keyboard ensures that it stays firmly in place, allowing you to maintain precision and control with every keystroke. Aesthetic Appeal Aesthetics play a significant role in the gaming experience, and metal keyboards certainly deliver in this regard. The sleek, polished finish of metal adds a touch of sophistication to your gaming setup. Many metal keyboards feature customizable RGB lighting, allowing you to personalize the look and feel to match your style. This blend of form and function makes metal keyboards not just a tool but a centerpiece of your gaming environment. Enhanced Typing Experience Superior Key Feel The tactile experience of typing on a metal keyboard is unparalleled. The keys on a metal keyboard often provide a satisfying click and feedback that gamers appreciate. This responsiveness can make all the difference in gameplay, where accuracy and speed are crucial. The solid construction of metal keyboards ensures that each keypress feels precise and deliberate, giving you confidence in every move you make. Anti-ghosting and N-Key Rollover Metal gaming keyboards often come equipped with anti-ghosting and N-key rollover features. Anti-ghosting ensures that every key press is registered correctly, even when multiple keys are pressed simultaneously. N-key rollover allows for any number of keys to be pressed at once, each being detected individually. These features are particularly beneficial in fast-paced games where complex vital combinations are required. Mechanical Switches Many premium metal gaming keyboards utilize mechanical switches, which are known for their durability and performance. These switches come in various types, each offering a different feel and actuation force. Gamers can choose switches that best match their preferences, whether they prefer the tactile feedback of blue switches or the quiet actuation of red switches. Mechanical switches in metal housing provide an unmatched typing experience that is both responsive and durable. Advanced Features for Gamers Customizable Macros A standout feature of premium metal gaming keyboards is the ability to customize macros. Macros allow you to program complex sequences of actions into a single keypress. This can be a tremendous advantage in games that require repetitive actions, saving you time and effort. Customizable macros enable you to tailor your keyboard to your specific gaming needs, giving you a competitive edge. Dedicated Media Controls Managing multimedia can be a hassle during gameplay. Many metal gaming keyboards come with dedicated media controls, allowing you to adjust volume, skip tracks, and pause music without leaving your game. This convenience ensures that you can maintain your focus and immersion in the game. USB Passthrough and Additional Ports USB passthrough and additional ports are practical features included in many high-end metal gaming keyboards. These ports allow you to connect other peripherals, such as a mouse or headset, directly through the keyboard. This reduces cable clutter and makes it easier to manage your gaming setup. Programmable RGB Lighting Customizable RGB lighting is more than just an aesthetic feature. It can also improve your gaming experience by providing visual cues and enhancing immersion. Many metal gaming keyboards offer programmable lighting options, allowing you to create dynamic lighting effects and sync with other RGB-enabled devices. This level of customization lets you personalize your gaming environment to enhance both form and function. Real-World Benefits: Case Studies Competitive Gaming Consider the experience of a professional esports player. In the high-stakes world of competitive gaming, every detail matters. A metal gaming keyboard provides the durability, responsiveness, and reliability needed to perform at the highest level. The superior key feels, and advanced features such as anti-ghosting and customizable macros can make a significant difference in gameplay. For professional gamers, a metal keyboard is not just an accessory but a critical piece of equipment. Casual and Recreational Gaming Even for casual gamers, a metal gaming keyboard can enhance the overall experience. Take the example of a weekend warrior who enjoys immersive RPGs or fast-paced shooters. The stability and aesthetic appeal of a metal keyboard create a more enjoyable gaming setup, while the tactile feedback and mechanical switches elevate the gameplay experience. Investing in a premium keyboard can transform casual sessions into an engaging and satisfying activity. Streamers and Content Creators For streamers and content creators, the aesthetic and functional benefits of a metal gaming keyboard are invaluable. The polished look and customizable RGB lighting can enhance the visual appeal of streaming setups, attracting more viewers. Additionally, the reliability and advanced features of metal keyboards ensure that streamers can focus on content creation without worrying about equipment failure. Practical Tips for Choosing the Right Metal Gaming Keyboard Identify Your Needs Before purchasing a metal gaming keyboard, it’s essential to identify your specific needs. Consider the types of games you play, your typing preferences, and any additional features you may require. For instance, if you play a lot of MMORPGs, customizable macros may be a priority. Test Different Switches Mechanical switches come in various types, each with its unique feel. Visit a store if possible and test different switches to find the one that best suits your preferences. Whether you prefer a loud, clicky switch or a quiet, smooth one, finding the right switch will enhance your overall experience. Evaluate Build Quality Pay attention to the build quality of the keyboard. Examine the materials used, the weight, and the finish. A well-constructed metal keyboard will feel sturdy and have no creaking parts. Check for features like detachable cables, which can add to the keyboard’s durability. Consider Brand Reputation Brand reputation can be a good indicator of quality. Research brands that are known for producing high-quality gaming keyboards. Read reviews, watch unboxing videos, and seek recommendations from other gamers to ensure you’re investing in a reliable product. Budget Considerations While a premium metal gaming keyboard may be an investment, consider it as such for long-term benefits. Determine your budget and look for options that offer the best balance between cost and features. Keep in mind that investing in a high-quality keyboard can save you money in the long run by reducing the need for replacements. Conclusion: Elevate Your Gaming Experience In summary, a premium gaming keyboard made with metal offers a wealth of benefits that can significantly elevate your gaming experience. From its durable construction and stability to its superior typing experience and advanced features, a metal keyboard is a worthwhile investment for any serious gamer. The tactile satisfaction of mechanical switches, the practical advantages of customizable macros, and the aesthetic appeal of RGB lighting all contribute to creating an immersive and enjoyable gaming environment. By choosing a high-quality metal gaming keyboard, you ensure that you have a reliable and responsive tool at your fingertips, ready to help you achieve victory in every game. In the world of gaming, where precision and performance are paramount, making the right choice in equipment can make all the difference. Elevate your gaming setup today with a premium metal keyboard and discover the unmatched feel that sets you apart from the competition. Read the full article

0 notes

Text

What is a shrink-fit tool holder? And How do shrink-fit tool holders work?

In the realm of current machining, precision and balance are paramount. Among the several tool conserving answers to be had, shrink-fit tool holders stand out for their accuracy and reliability. This blog aims to delve into the world of shrink-fit tool holders, exploring what they are, how they work, and why they are a vital factor in advanced production procedures.

Understanding Shrink-Fit Tool Holders

A shrink-fit tool holder is a type of tool preserving tool utilized in CNC (Computer numerical Control) machining and different precision packages. It is renowned for its ability to stable cutting tools with remarkable accuracy and stability. Unlike traditional tool holders that depend on mechanical clamping or set screws, shrink-fit tool holders utilize thermal enlargement and contraction to reap a secure shape.

How Do Shrink-Fit Tool Holders Work?

The running principle of shrink-fit tool holders is based at the thermal enlargement residences of metals. Here’s a step-by-step rationalization of the way they characteristic:

1. Heating the Tool Holder

The technique starts off evolved by way of heating the shrink-fit tool holder. This is usually accomplished by the usage of an induction heating tool, which hastily heats the holder to a precise temperature. The heating causes the tool holder to increase slightly.

2. Inserting the Cutting Tool

Once the shrink-fit tool holder has expanded, the slicing tool, typically a carbide or high-velocity metallic (HSS) tool, is inserted into the holder. Because the holder has been elevated, the tool fits without problems into the holder’s bore.

3. Cooling and Contracting

After the cutting tool is nicely located, the shrink-fit tool holder is authorized to chill. As it cools, the holder contracts, gripping the slicing tool with sizable pressure. This contraction creates a tight, uniform preserve across the tool, eliminating any gaps or motion.

4. Achieving High Precision

The uniform construction ensures that the cutting tool is held with high precision and minimal runout. This precision is essential for retaining the accuracy of machining operations, mainly whilst working with complicated geometries or first-class tolerances.

Benefits of Shrink-Fit Tool Holders

Shrink-fit tool holders provide several advantages over traditional tool conserving techniques, making them a popular preference in high-precision machining environments. Some of the key benefits encompass:

1. Exceptional Clamping Force

The thermal contraction of shrink-fit tool holders offers a clamping pressure that is notably higher than that accomplished by mechanical clamping strategies. This robust grip ensures that the cutting tool remains securely in place, even underneath heavy slicing loads.

2. High Precision and Accuracy

Shrink-fit tool holders are regarded for their fantastic runout accuracy, normally in the range of 0.001 inches or higher. This excessive stage of precision is crucial for reaching tight tolerances and advanced floor finishes in machined elements.

Three. Enhanced Tool Life

The steady grip of shrink-fit tool holders shrinks vibration and chatter in the course of machining. This balance extends the life of each reducing tool and the holder, ensuing in fee savings through the years.

4. Quick Tool Changes

Despite their tight grip, shrink-fit tool holders permit for distinctly short tool modifications. By reheating the holder, the reducing tool may be without problems removed and changed, minimizing downtime within the manufacturing technique.

5. Simplified Maintenance

Shrink-fit tool holders have a simple design with no shifting components or mechanical components that could wear out or require adjustment. This simplicity translates to shrinking upkeep necessities and increased reliability.

Applications of Shrink-Fit Tool Holders

Shrink-fit tool holders are used in an extensive variety of industries and packages in which precision and balance are crucial. Some commonplace applications encompass:

1. Aerospace Industry

In the aerospace enterprise, in which factor accuracy and surface finish are paramount, shrink-fit tool holders are broadly used for machining complicated parts inclusive of turbine blades and structural additives.

2. Automotive Manufacturing

The automobile enterprise is predicated on shrink-in shape tool holders for generating engine additives, transmission parts, and other vital additives that require excessive precision and sturdiness.

3. Medical tool Manufacturing

Medical tool production needs top notch precision and floor best. Shrink-fit tool holders are hired to machine additives for surgical contraptions, implants, and diagnostic systems.

4. Mold and Die Making

Shrink-fit tool holders are best for mildew and die making, in which elaborate geometries and tight tolerances are crucial for producing wonderful molds and dies used in injection molding and stamping methods.

Choosing the Right Shrink-Fit Tool Holder

When deciding on a shrink-fit tool holder, numerous elements ought to be taken into consideration to ensure top-quality overall performance and compatibility along with your machining setup:

1. Tool Holder Material

Shrink-fit tool holders are typically crafted from high-grade metal or carbide to withstand the thermal enlargement and contraction cycles. The preference of cloth can impact the durability and overall performance of the holder.

2. Holder Size and Type

Shrink-fit tool holders are available in diverse sizes and brands to house unique reducing gear and machine spindles. It’s crucial to choose a holder that fits the specs of your tooling and machining system.

Three. Heating Method

The approach used to heat the shrink-fit tool holder can have an effect on the efficiency and precision of the procedure. Induction heating is typically used for its speedy and uniform heating skills.

Four. Cooling Process

The cooling technique is crucial for reaching the favored contraction and clamping pressure. Some systems use pressured air or liquid cooling to expedite the cooling procedure and make certain steady outcomes.

5. Compatibility with Cutting Tools

Ensure that the shrink-fit tool holder is well fitted with the type and length of reducing tools you propose to apply. The holder’s bore diameter and taper need to be in the shape of the tool shank for a stable fit.

Contact Birla Precision Technologies Limited for Shrink-Fit Tool Holders

For those seeking super shrink-fit tool holders, Birla Precision Technologies Limited is a leading provider of precision engineering answers. Established in 1937, Birla Precision Technologies Limited has an extended-status reputation for excellence in the auto element and industrial engineering domains. With five divisions unfolding over four factories, the enterprise is well-geared up to meet the numerous desires of its clients.

Birla Precision Technologies Limited offers more than a few shrink-fit tool holders designed to satisfy the demanding requirements of modern-day machining programs. Whether you're within the aerospace, car, clinical tool, or mold and die enterprise, their tool holders supply the precision, balance, and reliability needed to obtain advanced machining consequences.

Conclusion

Shrink-fit tool holders represent a top of precision and balance within the global of machining. By leveraging the ideas of thermal growth and contraction, these tool holders offer high-quality clamping pressure, high precision, and extended tool existence. Their programs span across numerous industries, from aerospace to scientific tool production, highlighting their versatility and significance.

When deciding on shrink-fit tool holders, don't forget factors which include cloth, length, heating technique, cooling procedure, and compatibility with slicing gear to make sure top-quality overall performance. For reliable and fantastic shrink-in shape tool holders, look no further than Birla Precision Technologies Limited, a trusted call in precision engineering since 1937.

By incorporating shrink-fit tool holders into your machining setup, you may attain superior accuracy, shrink downtime, and superior productivity, in the end driving fulfillment for your manufacturing endeavors.

For greater information and to discover the variety of shrink-fit tool holders provided by Birla Precision Technologies Limited, go to their internet site or contact their team. Birla Precision Technologies Limited is dedicated to offering modern answers that meet the evolving desires of the modern production industry.

1 note

·

View note

Text

Innovating Precision with WIDMA: The Future of Machining Tools

In the ever-evolving world of industrial manufacturing, precision and efficiency are paramount. As industries demand higher performance and accuracy, WIDMA stands at the forefront, delivering cutting-edge solutions tailored to meet these needs. This article delves into the innovative offerings of WIDMA, focusing on their hole drilling machines, gun drill machines and horizontal machining centers.

Precision Redefined: Hole Drilling Machines

Hole drilling is a critical process in manufacturing and the accuracy of this operation can significantly impact the overall quality of the final product. WIDMA's hole drilling machines are engineered to provide exceptional precision and reliability. These machines are designed to handle a wide range of materials, from metals to composites, ensuring that every hole is drilled with the utmost accuracy.

are engineered to provide exceptional precision and reliability. These machines are designed to handle a wide range of materials, from metals to composites, ensuring that every hole is drilled with the utmost accuracy.

WIDMA's hole drilling machines are equipped with advanced technology that minimizes downtime and maximizes productivity. Their robust construction and user-friendly interfaces make them ideal for both small-scale and large-scale manufacturing environments. Whether you are in the automotive, aerospace, or construction industry, WIDMA's hole drilling machines offer unparalleled performance.

The Power of Precision: Gun Drill Machines

Gun drilling is a specialized process used to create deep, straight holes with high precision. WIDMA's gun drill machines are renowned for their ability to produce holes with extreme accuracy and smooth finishes. These machines are perfect for applications where precision is crucial, such as in the manufacturing of firearms, medical devices and mold making.

WIDMA's gun drill machines incorporate state-of-the-art technology to ensure consistent performance. Their design focuses on stability and control, allowing operators to achieve precise results even in the most demanding conditions. With WIDMA's gun drill machines, manufacturers can achieve higher productivity and better quality, setting a new standard in the industry.

Efficiency and Versatility: Horizontal Machining Centers

Horizontal machining centers (HMCs) are essential in modern manufacturing for their versatility and efficiency. WIDMA's HMCs are designed to perform multiple machining operations in a single setup, reducing the need for multiple machines and setups. This not only saves time but also improves accuracy and consistency across production runs.

WIDMA's horizontal machining centers are equipped with high-speed spindles, advanced control systems and automated tool changers. These features enhance the machine's capability to handle complex machining tasks with ease. Whether it's milling, drilling, or tapping, WIDMA's HMCs deliver superior performance, making them a valuable asset for any manufacturing facility.

WIDMA: A Legacy of Excellence

WIDMA has established itself as a leader in the machining tools industry through its commitment to innovation, quality and customer satisfaction. With a diverse portfolio of products, WIDMA caters to various sectors, including automotive, aerospace, construction and energy. Their machines are known for their durability, precision and efficiency, making them a preferred choice for manufacturers worldwide.

The company's dedication to research and development ensures that their products remain at the cutting edge of technology. By continuously improving and expanding their product range, WIDMA helps manufacturers stay competitive in a rapidly changing market. Their comprehensive support and service network further enhance the value they provide to their customers.

Conclusion

In conclusion, WIDMA's hole drilling machines, gun drill machines and horizontal machining centers represent the pinnacle of precision and efficiency in industrial manufacturing. With their innovative designs and advanced technology, these machines help manufacturers achieve superior quality and productivity. WIDMA's legacy of excellence and commitment to customer satisfaction make them a trusted partner in the journey towards manufacturing success.

0 notes

Text

Buy now -Algolaser Delta 22w Diode Laser Engraver

The Algolaser Delta 22W Diode Laser Engraver is a powerful and versatile tool designed for precision engraving and cutting. With a 22W diode laser, it effortlessly handles various materials, including wood, acrylic, leather, and metal. Its robust construction ensures stability and accuracy, making it suitable for both hobbyists and professionals. The user-friendly interface simplifies operation, allowing you to create detailed and high-quality engravings with ease. Enhance your projects and achieve exceptional results with the Algolaser Delta 22W Diode Laser Engraver. Order now!

#Buy now -Algolaser Delta 22w Diode Laser Engraver#Online shop -Algolaser Delta 22w Diode Laser Engraver

0 notes

Text

Unleashing Precision and Versatility with the Vision Engraver & Router System

In the world of precision engraving and routing, the Vision Engraver & Router System stands out as a paragon of innovation and reliability. Renowned for its versatility and superior performance, this system is an invaluable asset across various industries, including signage, awards, personalized gifts, industrial marking, and more. Combining cutting-edge technology with user-friendly design, the Vision Engraver & Router System offers unparalleled capabilities, making it the go-to choice for professionals seeking precision, efficiency, and durability in their engraving and routing tasks.

Precision and Accuracy

At the heart of the Vision Engraver & Router System is its exceptional precision. Engineered with high-quality components and advanced motion control technology, this system ensures that every cut and engraving is executed with pinpoint accuracy. Whether you are working on intricate designs or large-scale projects, the Vision system delivers consistent and flawless results, minimizing material waste and maximizing productivity. The system's robust construction and stability further enhance its accuracy, allowing for detailed engravings and smooth edges even on the most complex patterns.

Versatility Across Applications

One of the standout features of the Vision Engraver & Router System is its versatility. Capable of handling a wide range of materials, including metals, plastics, wood, and glass, this system is perfect for various applications. In the signage industry, it excels in creating crisp, clear lettering and intricate logos on a variety of substrates. For awards and trophies, the Vision system produces elegant engravings that add a personal touch to each piece. In industrial settings, it offers reliable marking solutions for parts and tools, ensuring durability and readability under harsh conditions.

User-Friendly Design

The Vision Engraver & Router System is designed with the user in mind, offering an intuitive interface that simplifies the engraving and routing process. The system is equipped with Vision’s proprietary software, which provides a range of design tools and templates to help users create and edit designs with ease. The software is compatible with various file formats, allowing for seamless integration with other design programs. Additionally, the system’s easy-to-navigate control panel and step-by-step guides make it accessible to both novice users and experienced professionals.

Advanced Features

To further enhance its functionality, the Vision Engraver & Router System comes with a host of advanced features. These include automated surface sensing, which adjusts the cutting depth to account for material variations, ensuring consistent results across the entire workpiece. The system also offers a variety of spindle options, allowing users to choose the best tool for their specific application. For high-volume production, the Vision system can be equipped with an automated material feed system, significantly increasing efficiency and throughput.

Durability and Reliability

Built to withstand the demands of continuous use, the Vision Engraver & Router System is known for its durability and reliability. Its solid construction and high-quality components ensure long-term performance with minimal maintenance. The system is designed to handle rigorous workloads, making it a dependable choice for businesses that require consistent, high-quality output. Vision’s commitment to quality is reflected in its comprehensive warranty and dedicated customer support, providing users with peace of mind and assurance that their investment is protected.

Customization and Scalability

Recognizing that every business has unique needs, Vision offers customization options for its Engraver & Router System. Users can choose from a range of table sizes, spindle types, and accessory options to tailor the system to their specific requirements. This flexibility makes the Vision system suitable for small shops and large manufacturing operations alike. As businesses grow, the Vision system can scale with them, accommodating increased production demands without sacrificing performance or quality.

Environmental Considerations

In addition to its technical capabilities, the Vision Engraver & Router System is designed with environmental sustainability in mind. The system’s efficient design reduces energy consumption, while its precision minimizes material waste. Vision is committed to environmentally responsible manufacturing practices, ensuring that their products meet stringent environmental standards. This commitment not only benefits the planet but also aligns with the values of environmentally conscious businesses.

Conclusion

The Vision Engraver & Router System represents the pinnacle of precision, versatility, and reliability in the engraving and routing industry. Its advanced features, user-friendly design, and robust construction make it an ideal choice for professionals across a wide range of applications. Whether you are in the signage industry, creating personalized awards, or marking industrial parts, the Vision system delivers exceptional results every time. By investing in the Vision Engraver & Router System, businesses can enhance their productivity, improve product quality, and ensure long-term success. For more information about how the Vision Engraver & Router System can meet your specific needs, please contact us.

At Signvec Technology, we pride ourselves on being at the forefront of innovation in the engraving and routing industry. With decades of experience and a commitment to excellence, our mission is to provide cutting-edge solutions that enhance productivity and precision for businesses of all sizes. Our Vision Engraver & Router System exemplifies our dedication to quality, versatility, and customer satisfaction. By continuously investing in research and development, we ensure that our products not only meet but exceed industry standards, empowering our clients to achieve their creative and operational goals with unmatched efficiency.

1 note

·

View note