#anankagroup

Explore tagged Tumblr posts

Text

Titanium Grade 2 Bolts, Nuts, and Fasteners

Introduction

Titanium Grade 2 is a commercially pure titanium alloy widely used for its excellent strength, corrosion resistance, and lightweight properties. Titanium Grade 2 bolts, nuts, and fasteners are popular in industries like aerospace, marine, chemical processing, and medical applications due to their superior characteristics. This blog delves into the details of Titanium Grade 2 fasteners, including their properties, applications, and advantages.

What is Titanium Grade 2?

Titanium Grade 2 is classified as a commercially pure titanium alloy (CP Titanium). It has a high strength-to-weight ratio, excellent corrosion resistance in various environments, and good weldability. The alloy contains about 99.2% pure titanium, making it ideal for applications requiring resistance to oxidation and seawater.

Chemical Composition of Titanium Grade 2

The following table outlines the chemical composition of Titanium Grade 2:

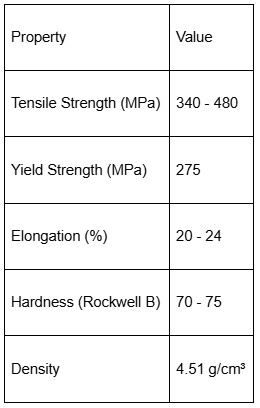

Mechanical Properties of Titanium Grade 2

Here are the mechanical properties of Titanium Grade 2 fasteners:

Features of Titanium Grade 2 Fasteners

Titanium Grade 2 fasteners are renowned for their outstanding properties, such as:

Corrosion Resistance:

Outstanding resistance to seawater, chlorides, and oxidizing agents.

Ideal for marine and chemical processing applications.

High Strength-to-Weight Ratio:

Lightweight yet strong, making them suitable for weight-sensitive applications like aerospace.

Non-Magnetic and Non-Toxic:

Suitable for medical and sensitive equipment applications.

Heat and Low-Temperature Resistance:

Performs well in temperatures ranging from cryogenic to moderately high levels.

Excellent Weldability and Ductility:

Can be fabricated and welded easily without compromising its mechanical properties.

Types of Titanium Grade 2 Fasteners

Titanium Grade 2 fasteners come in various types to cater to diverse industrial needs:

Titanium Grade 2 Bolts: Hex bolts, socket head bolts, and U-bolts.

Titanium Grade 2 Nuts include hex nuts, lock nuts, wing nuts, and dome nuts.

Titanium Grade 2 Washers are offered in various types, including flat washers, spring washers, and lock washers

Titanium Grade 2 Screws: Machine screws, wood screws, self-tapping screws.

Titanium Grade 2 Studs: Fully threaded studs, double-ended studs.

Custom Fasteners: Manufactured to specific designs and requirements for specialized applications.

Applications of Titanium Grade 2 Fasteners

Titanium Grade 2 fasteners are widely used across several industries, such as:

Aerospace Industry:

Aircraft frames, engine components, and structural fasteners due to their lightweight strength.

Marine Industry:

Shipbuilding, offshore platforms, and underwater equipment where seawater resistance is critical.

Chemical Processing:

Used in tanks, pipelines, and heat exchangers due to their resistance to harsh chemicals and oxidizing agents.

Medical Industry:

Implants, surgical instruments, and medical devices because of their biocompatibility and non-toxic properties.

Automotive Industry:

Lightweight fasteners for high-performance vehicles and exhaust systems.

Power Generation:

Used in energy production plants, including nuclear and geothermal facilities.

Advantages of Titanium Grade 2 Fasteners

Corrosion Resistance: Exceptional durability in seawater, chemical environments, and oxidizing conditions.

Lightweight: About 45% lighter than steel, reducing overall weight in critical applications.

High Strength: Provides robust fastening solutions without adding significant bulk.

Non-Reactive: Ensures compatibility with medical, aerospace, and food-grade applications.

Long Service Life: Offers long-term performance with minimal maintenance.

Why Choose Ananka Group for Titanium Grade 2 Fasteners?

Ananka Group is your trusted partner for Titanium Grade 2 fasteners, offering:

Premium Quality: Manufactured to meet stringent international standards, ensuring durability and precision.

Custom Solutions: Tailored fasteners to match specific industrial requirements.

Global Delivery: A reliable supply chain to ensure timely delivery worldwide.

Expertise You Can Rely On: Decades of experience in fastener manufacturing and industry-specific solutions.

Cost-Effective Products: High-quality fasteners at competitive prices to suit your budget.

Conclusion

Titanium Grade 2 bolts, nuts, and fasteners are a reliable choice for industries requiring lightweight, high-strength, and corrosion-resistant fastening solutions. Their wide range of applications, from aerospace to medical, makes them a reliable choice for challenging environments. At Ananka Group, we offer top-quality Titanium Grade 2 fasteners that meet international standards, ensuring durability, precision, and performance.

Frequently Asked Questions (FAQs)

Q1: What is the strength of Titanium Grade 2 fasteners?

A: Titanium Grade 2 fasteners have a tensile strength ranging from 340 to 480 MPa and a yield strength of 275 MPa.

Q2: Are Titanium Grade 2 fasteners corrosion-resistant?

A: Yes, Titanium Grade 2 fasteners offer outstanding corrosion resistance, particularly in seawater and harsh chemical environments.

Q3: Where are Titanium Grade 2 fasteners used?

A: They are used in aerospace, marine, chemical processing, medical, and automotive industries due to their strength and corrosion resistance.

Q4: Can Titanium Grade 2 fasteners be customized?

A: Yes, Ananka Group offers customization to meet specific designs and requirements.

Q5: Why choose Titanium Grade 2 over other materials?

A: Titanium Grade 2 offers a unique combination of lightweight strength, corrosion resistance, and biocompatibility, making it ideal for demanding applications.

#TitaniumGrade2Fasteners#TitaniumBolts#TitaniumNuts#TitaniumWashers#CorrosionResistantFasteners#LightweightFasteners#MarineFasteners#AerospaceFasteners#ChemicalProcessingFasteners#MedicalFasteners#HighPerformanceFasteners#AnankaGroup#FastenersManufacturer#IndustrialFasteners#anankafasteners#ananka#manufacturer#supplier#fasteners#mumbai#hex#bolt

0 notes

Text

Titanium Grade 5 Fasteners: The Ultimate Solution for High-Performance Applications

Introduction

In the world of high-performance fasteners, Titanium Grade 5 stands out due to its excellent strength-to-weight ratio, remarkable corrosion resistance, and versatility across industries. Known for its superior mechanical properties, Titanium Grade 5 (also known as Ti-6Al-4V) is a titanium alloy containing 6% aluminum and 4% vanadium. These unique properties make it one of the most widely used titanium alloys for manufacturing bolts, nuts, and other fasteners. In this blog, we’ll delve into everything you need to know about Titanium Grade 5 fasteners, including specifications, industrial applications, and popular types.

What is Titanium Grade 5?

Titanium Grade 5, often referred to as Ti-6Al-4V, is an alpha-beta alloy that boasts an impressive combination of strength, durability, and corrosion resistance. It’s ideal for high-performance applications where reducing weight without compromising strength is critical. Due to its biocompatibility, Titanium Grade 5 is also used in medical implants and equipment.

Properties of Titanium Grade 5 Fasteners

High Strength: Titanium Grade 5 has a tensile strength of around 950 MPa, making it exceptionally strong.

Lightweight: With a density of 4.43 g/cm³, it’s about 50% lighter than steel.

Corrosion Resistance: Titanium Grade 5 is highly resistant to corrosion, especially in saltwater and chlorinated environments.

High-Temperature Resistance: Suitable for use in high-temperature environments, withstanding temperatures up to 400°C (752°F).

Biocompatibility: Non-toxic and suitable for medical applications.

Most Popular Types of Titanium Grade 5 Fasteners

Bolts: Titanium Grade 5 bolts are highly sought after in the aerospace and marine industries due to their strength and lightweight nature. These bolts are available in various sizes and head types, including hex head, socket head, and carriage bolts.

Nuts: Titanium Grade 5 nuts, such as hex and lock nuts, are often used in conjunction with bolts to provide a strong and reliable fastening solution. The corrosion-resistant nature of these nuts makes them suitable for harsh environments.

Screws: Titanium Grade 5 screws, including machine screws, wood screws, and set screws, are used in a wide range of applications due to their durability and resistance to galling.

Washers: Titanium Grade 5 washers are frequently used in critical applications where a secure and reliable joint is necessary. They help to evenly distribute the load and prevent loosening.

Specifications of Titanium Grade 5 Fasteners

When purchasing Titanium Grade 5 fasteners, it's essential to be aware of the specific standards and specifications they meet. These standards ensure quality, performance, and compatibility for various applications. Key specifications include:

ASTM B348: Standard for titanium and titanium alloy bars and billets.

AMS 4928: Aerospace Material Specification for titanium alloys.

DIN Standards: Includes various DIN standards covering size, shape, and tolerances.

Industrial Uses of Titanium Grade 5 Fasteners

Titanium Grade 5 fasteners have a wide array of applications across industries that demand reliability, durability, and lightweight materials:

Aerospace: Due to their high strength-to-weight ratio, Titanium Grade 5 fasteners are commonly used in the construction of aircraft, space vehicles, and satellite components.

Marine: Titanium’s corrosion resistance in saltwater makes it an ideal choice for marine applications, including ships, submarines, and offshore drilling rigs.

Automotive: High-performance automotive applications, such as motorsport vehicles, benefit from Titanium Grade 5 fasteners, which reduce overall vehicle weight while enhancing strength and stability.

Medical: Titanium’s biocompatibility makes Titanium Grade 5 fasteners a popular choice for medical implants, prosthetics, and surgical instruments.

Chemical Processing: Industries that require exposure to harsh chemicals often turn to Titanium Grade 5 fasteners for their superior resistance to corrosion.

Advantages of Titanium Grade 5 Fasteners

Superior Durability: Titanium Grade 5 fasteners can withstand extreme conditions, making them ideal for heavy-duty applications.

Lightweight Solution: Ideal for industries where reducing weight is crucial, such as aerospace and automotive.

Corrosion Resistance: Exceptional resistance to corrosion makes them suitable for marine and chemical environments.

Long Lifespan: High durability and resistance to wear ensure a long operational life, reducing replacement costs.

Environmentally Friendly: Titanium is a recyclable metal, contributing to sustainable practices in industries using these fasteners.

Why Choose Ananka Group for Titanium Grade 5 Fasteners?

At Ananka Group, we are dedicated to providing high-quality Titanium Grade 5 fasteners that meet stringent industry standards. Our products are manufactured with precision, ensuring optimal performance in demanding applications. With a robust quality assurance process, we strive to deliver reliable, durable, and cost-effective solutions for our clients across various industries.

Conclusion

Titanium Grade 5 fasteners are essential components in many high-performance applications. Their unique properties, including high strength, low weight, and excellent corrosion resistance, make them a preferred choice for industries such as aerospace, marine, and medical. By choosing Titanium Grade 5 fasteners, companies can enhance the reliability and efficiency of their products while benefiting from a sustainable and long-lasting solution. For industries that demand the highest quality, Ananka Group’s Titanium Grade 5 fasteners are a trusted choice.

FAQs

Q1. What makes Titanium Grade 5 fasteners different from other titanium grades?A1. Titanium Grade 5, also known as Ti-6Al-4V, contains 6% aluminum and 4% vanadium, making it significantly stronger and more heat-resistant than commercially pure titanium. It also provides excellent corrosion resistance.

Q2. Can Titanium Grade 5 fasteners be used in high-temperature applications?A2. Yes, Titanium Grade 5 can withstand temperatures up to 400°C (752°F), making it suitable for high-temperature environments.

Q3. Are Titanium Grade 5 fasteners suitable for marine applications?A3. Absolutely! Titanium Grade 5’s corrosion resistance in saltwater makes it ideal for use in marine environments.

Q4. What are the common applications of Titanium Grade 5 fasteners?A4. They are commonly used in aerospace, marine, automotive, medical, and chemical processing industries due to their high strength, lightweight nature, and corrosion resistance.

Q5. Why should I choose Ananka Group for my Titanium Grade 5 fasteners?A5. Ananka Group is committed to delivering high-quality, precision-manufactured fasteners that meet industry standards. With an emphasis on quality, durability, and customer satisfaction, we are a trusted choice for Titanium Grade 5 fasteners across various industries.

#titanium grade 5#grade 5#anankagroup#anankafasteners#ananka#fasteners#manufacturer#supplier#mumbai#bolt#usa#hex#uk

0 notes

Text

Ananka Group: Your Trusted Niobium Fasteners Manufacturer, Supplier & Stockist in India

When you're looking for fasteners that can handle the toughest jobs, Niobium is a standout material. At Ananka Group, we're proud to be one of the leading Niobium Fasteners Manufacturers in India. We offer a wide range of Niobium fasteners that are built to perform in the most demanding conditions. Dedication to quality and innovation has made us a trusted supplier and stockist, both in India and around the world.

Why Niobium Fasteners Are a Great Choice

Niobium fasteners are gaining popularity across various industries due to their remarkable properties, which make them particularly suitable for demanding and challenging environments. Let’s delve deeper into why these fasteners are so effective and how they can be the ideal solution for your specific needs:

1. Incredible Corrosion Resistance

Corrosion is a major concern in industries where fasteners are exposed to harsh chemicals, saltwater, or other corrosive elements. Niobium fasteners are highly resistant to corrosion, which means they do not easily degrade or weaken even in the most aggressive environments.

This property is particularly beneficial in industries such as:

Chemical Processing: In chemical plants, where fasteners are often exposed to acidic or alkaline substances, Niobium’s corrosion resistance ensures that the fasteners remain intact, preventing leaks, failures, and costly downtime.

Marine Applications: In marine environments, where saltwater can rapidly corrode most metals, Niobium fasteners maintain their integrity, ensuring long-lasting performance in shipbuilding, offshore platforms, and underwater equipment.

Oil & Gas Industry: Niobium fasteners are also used in the oil and gas sector, where they resist the corrosive effects of oil, gas, and other byproducts, ensuring the safety and reliability of pipelines and drilling equipment.

2. Stability at High Temperatures

In industries where components are subjected to extreme heat, the materials used must not only withstand these temperatures but also maintain their mechanical properties. Niobium fasteners excel in this area due to their high melting point and thermal stability.

This makes them indispensable in:

Aerospace Industry: In aircraft engines and other high-temperature applications, Niobium fasteners retain their strength, ensuring the safety and efficiency of critical components.

Power Generation: In power plants, particularly those involving steam turbines or nuclear reactors, the ability of Niobium fasteners to perform reliably at high temperatures is crucial for maintaining operational safety and efficiency.

Nuclear Industry: In nuclear reactors, Niobium fasteners are used because they can endure both high temperatures and radiation exposure without degrading, which is essential for the long-term stability and safety of the reactor.

3. Strong Yet Lightweight

One of the most appealing attributes of Niobium fasteners is their impressive strength-to-weight ratio. This means that while they are strong enough to handle significant loads and stresses, they are also lightweight, which provides several advantages:

Aerospace Applications: In the aerospace industry, where every gram counts, using lightweight materials like Niobium helps reduce the overall weight of aircraft, improving fuel efficiency and performance.

Automotive Industry: Similarly, in the automotive sector, reducing the weight of vehicles without compromising on safety is a key goal. Niobium fasteners contribute to this by providing the necessary strength while keeping the vehicle’s weight to a minimum, leading to better fuel efficiency and reduced emissions.

Sporting Goods and Equipment: For high-performance sporting goods, such as bicycles and climbing gear, Niobium fasteners offer the strength required to withstand stress and impact while remaining light enough to enhance user performance.

4. Safe for Medical Use

Niobium’s biocompatibility is a significant advantage when it comes to medical and dental applications. Biocompatibility means that the material does not cause any adverse reactions when it comes into contact with human tissue.

This property is critical for:

Medical Implants: Niobium fasteners are often used in medical implants such as bone screws and plates, where they are in direct contact with the human body. The biocompatibility ensures that the implants do not cause inflammation or allergic reactions, leading to better patient outcomes.

Surgical Instruments: Niobium is also used in the manufacturing of surgical instruments that need to be both strong and safe for use within the human body. These instruments can be sterilized without compromising their integrity, making them ideal for repeated use.

Dental Applications: In dentistry, Niobium fasteners are used in orthodontic devices and dental implants, offering durability and compatibility with the body, which is essential for long-term use.

5. Long-Lasting Oxidation Resistance

Oxidation is a natural process that can lead to the degradation of metals when they are exposed to oxygen, particularly at high temperatures. Niobium fasteners resist oxidation, even under extreme heat, which extends their lifespan and reliability.

This resistance is vital for:

Gas Turbines: In gas turbines, where components are exposed to high temperatures and oxygen-rich environments, Niobium fasteners help maintain the turbine’s efficiency and longevity by preventing oxidation-related wear and tear.

Jet Engines: Similar to gas turbines, jet engines operate at very high temperatures. Niobium fasteners ensure that these engines remain safe and operational by resisting oxidation, which could otherwise lead to catastrophic failures.

High-Temperature Furnaces: In industrial furnaces used for metalworking and other high-temperature processes, Niobium fasteners withstand the oxidative environments, ensuring the structural integrity of the furnace over extended periods.

Why Ananka Group Is the Best Choice for Niobium Fasteners

At Ananka Group, we’re committed to delivering high-quality Niobium fasteners that meet your specific needs. Here’s what sets us apart:

1. Wide Range of Products

We offer a broad selection of Niobium fasteners, including bolts, nuts, washers, and screws, in various sizes and specifications. Whether you need standard products or custom-made fasteners, we’ve got you covered.

2. Precision Manufacturing

As a top Niobium Fasteners Manufacturer, we use advanced manufacturing processes to ensure every fastener meets the highest quality standards.

3. Ready Stock for Quick Delivery

We don’t just manufacture fasteners—we also keep a ready stock, so we can fulfill your orders quickly, whether you’re in India or anywhere else in the world.

4. Customized Solutions

Every project is different, and we understand that. That’s why we offer customized Niobium fasteners tailored to your exact needs, whether it’s a unique size or a specialized coating.

Conclusion

Niobium fasteners are an excellent choice for industries that need materials capable of withstanding extreme conditions. As a leading Niobium Fasteners Manufacturer in India, Ananka Group is dedicated to providing top-quality fasteners that you can rely on. With an extensive range of products, precision manufacturing, and focus on customer satisfaction, we’re the partner you can trust for all your Niobium fastener needs.

Reach out to Ananka Group today to learn more about Niobium fasteners and how It can help your business with the best products on the market.

#anankafasteners#ananka#fasteners#manufacturer#anankagroup#NiobiumFasteners#FastenerTechnology#fastenermanufacturer

1 note

·

View note