#MedicalFasteners

Explore tagged Tumblr posts

Text

Titanium Grade 2 Bolts, Nuts, and Fasteners

Introduction

Titanium Grade 2 is a commercially pure titanium alloy widely used for its excellent strength, corrosion resistance, and lightweight properties. Titanium Grade 2 bolts, nuts, and fasteners are popular in industries like aerospace, marine, chemical processing, and medical applications due to their superior characteristics. This blog delves into the details of Titanium Grade 2 fasteners, including their properties, applications, and advantages.

What is Titanium Grade 2?

Titanium Grade 2 is classified as a commercially pure titanium alloy (CP Titanium). It has a high strength-to-weight ratio, excellent corrosion resistance in various environments, and good weldability. The alloy contains about 99.2% pure titanium, making it ideal for applications requiring resistance to oxidation and seawater.

Chemical Composition of Titanium Grade 2

The following table outlines the chemical composition of Titanium Grade 2:

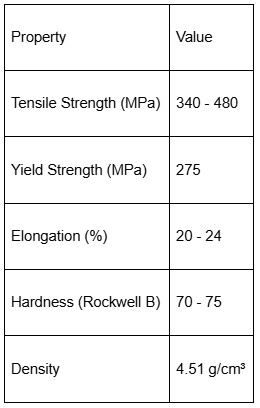

Mechanical Properties of Titanium Grade 2

Here are the mechanical properties of Titanium Grade 2 fasteners:

Features of Titanium Grade 2 Fasteners

Titanium Grade 2 fasteners are renowned for their outstanding properties, such as:

Corrosion Resistance:

Outstanding resistance to seawater, chlorides, and oxidizing agents.

Ideal for marine and chemical processing applications.

High Strength-to-Weight Ratio:

Lightweight yet strong, making them suitable for weight-sensitive applications like aerospace.

Non-Magnetic and Non-Toxic:

Suitable for medical and sensitive equipment applications.

Heat and Low-Temperature Resistance:

Performs well in temperatures ranging from cryogenic to moderately high levels.

Excellent Weldability and Ductility:

Can be fabricated and welded easily without compromising its mechanical properties.

Types of Titanium Grade 2 Fasteners

Titanium Grade 2 fasteners come in various types to cater to diverse industrial needs:

Titanium Grade 2 Bolts: Hex bolts, socket head bolts, and U-bolts.

Titanium Grade 2 Nuts include hex nuts, lock nuts, wing nuts, and dome nuts.

Titanium Grade 2 Washers are offered in various types, including flat washers, spring washers, and lock washers

Titanium Grade 2 Screws: Machine screws, wood screws, self-tapping screws.

Titanium Grade 2 Studs: Fully threaded studs, double-ended studs.

Custom Fasteners: Manufactured to specific designs and requirements for specialized applications.

Applications of Titanium Grade 2 Fasteners

Titanium Grade 2 fasteners are widely used across several industries, such as:

Aerospace Industry:

Aircraft frames, engine components, and structural fasteners due to their lightweight strength.

Marine Industry:

Shipbuilding, offshore platforms, and underwater equipment where seawater resistance is critical.

Chemical Processing:

Used in tanks, pipelines, and heat exchangers due to their resistance to harsh chemicals and oxidizing agents.

Medical Industry:

Implants, surgical instruments, and medical devices because of their biocompatibility and non-toxic properties.

Automotive Industry:

Lightweight fasteners for high-performance vehicles and exhaust systems.

Power Generation:

Used in energy production plants, including nuclear and geothermal facilities.

Advantages of Titanium Grade 2 Fasteners

Corrosion Resistance: Exceptional durability in seawater, chemical environments, and oxidizing conditions.

Lightweight: About 45% lighter than steel, reducing overall weight in critical applications.

High Strength: Provides robust fastening solutions without adding significant bulk.

Non-Reactive: Ensures compatibility with medical, aerospace, and food-grade applications.

Long Service Life: Offers long-term performance with minimal maintenance.

Why Choose Ananka Group for Titanium Grade 2 Fasteners?

Ananka Group is your trusted partner for Titanium Grade 2 fasteners, offering:

Premium Quality: Manufactured to meet stringent international standards, ensuring durability and precision.

Custom Solutions: Tailored fasteners to match specific industrial requirements.

Global Delivery: A reliable supply chain to ensure timely delivery worldwide.

Expertise You Can Rely On: Decades of experience in fastener manufacturing and industry-specific solutions.

Cost-Effective Products: High-quality fasteners at competitive prices to suit your budget.

Conclusion

Titanium Grade 2 bolts, nuts, and fasteners are a reliable choice for industries requiring lightweight, high-strength, and corrosion-resistant fastening solutions. Their wide range of applications, from aerospace to medical, makes them a reliable choice for challenging environments. At Ananka Group, we offer top-quality Titanium Grade 2 fasteners that meet international standards, ensuring durability, precision, and performance.

Frequently Asked Questions (FAQs)

Q1: What is the strength of Titanium Grade 2 fasteners?

A: Titanium Grade 2 fasteners have a tensile strength ranging from 340 to 480 MPa and a yield strength of 275 MPa.

Q2: Are Titanium Grade 2 fasteners corrosion-resistant?

A: Yes, Titanium Grade 2 fasteners offer outstanding corrosion resistance, particularly in seawater and harsh chemical environments.

Q3: Where are Titanium Grade 2 fasteners used?

A: They are used in aerospace, marine, chemical processing, medical, and automotive industries due to their strength and corrosion resistance.

Q4: Can Titanium Grade 2 fasteners be customized?

A: Yes, Ananka Group offers customization to meet specific designs and requirements.

Q5: Why choose Titanium Grade 2 over other materials?

A: Titanium Grade 2 offers a unique combination of lightweight strength, corrosion resistance, and biocompatibility, making it ideal for demanding applications.

#TitaniumGrade2Fasteners#TitaniumBolts#TitaniumNuts#TitaniumWashers#CorrosionResistantFasteners#LightweightFasteners#MarineFasteners#AerospaceFasteners#ChemicalProcessingFasteners#MedicalFasteners#HighPerformanceFasteners#AnankaGroup#FastenersManufacturer#IndustrialFasteners#anankafasteners#ananka#manufacturer#supplier#fasteners#mumbai#hex#bolt

0 notes