#aluminum slitting machine

Explore tagged Tumblr posts

Text

How to Maximize Slitter Blade Sharpness for Superior Cutting Performance

Summary

Maintaining the sharpness of a slitter blade is essential for achieving precise cuts, minimizing downtime, and improving operational efficiency. This article explores why sharpness retention matters, factors affecting blade longevity, advanced techniques for durability, and best practices for maintenance, ensuring your cutting tools perform at their best.

Introduction

In industrial applications, precision cutting is the cornerstone of efficiency and quality. The slitter blade, a critical component in industries like paper, metal, and plastic processing, must remain sharp to perform effectively. Dull blades lead to uneven cuts, wasted material, and costly downtime. This article delves into the technologies and strategies to retain the sharpness of slitting tools, helping you optimize performance and reduce costs.

By understanding the factors influencing blade sharpness and adopting advanced techniques, you can ensure your operations run smoothly. Let’s explore how you can keep your slitter blades sharp and effective for longer periods.

Why Sharpness Retention Matters for Slitter Blades

Sharpness plays a critical role in ensuring the efficiency and precision of industrial cutting processes. Whether you are cutting thin plastic films, thick metal sheets, or delicate paper rolls, maintaining a sharp edge on your slitter blade is essential. Let’s examine the specific impacts dull blades have on your operations:

1. Uneven Cuts

Dull blades fail to create clean, consistent edges, which can compromise the quality of the final product. For example, in the paper industry, jagged edges can lead to product rejection, affecting customer satisfaction and brand reputation. According to industry reports, manufacturers using dull blades experience up to 15% more defective products than those using well-maintained cutting tools.

2. Material Waste

Poor sharpness often results in inaccurate cuts, generating excess material waste. In industries handling expensive raw materials like aluminum or specialty polymers, this waste can represent significant financial losses. A study in a metal processing plant found that switching to precision-sharpened slitting knives reduced scrap rates by 25%, saving approximately $100,000 annually.

3. Increased Wear on Equipment

Using a dull blade requires more force to achieve the same cuts, which puts undue stress on machinery. Over time, this can lead to faster wear and tear on mechanical components, increasing maintenance costs and the risk of equipment failure. Preventive maintenance through blade sharpness retention can lower machine repair expenses by 20%.

4. Downtime for Maintenance

Frequent blade sharpening or replacement interrupts production schedules, resulting in costly downtime. In high-volume production environments, even an hour of unscheduled maintenance can translate into thousands of dollars in lost revenue. Maintaining sharper blades significantly extends service intervals, keeping your operations running smoothly.

The Competitive Edge

Maintaining sharp blades is more than just a technical necessity—it’s a strategic advantage. Companies that invest in blade sharpness retention report up to 30% better operational efficiency, giving them an edge in competitive markets.

Keep reading to explore the factors affecting sharpness and how to address them.

Key Factors Affecting Slitter Blade Sharpness

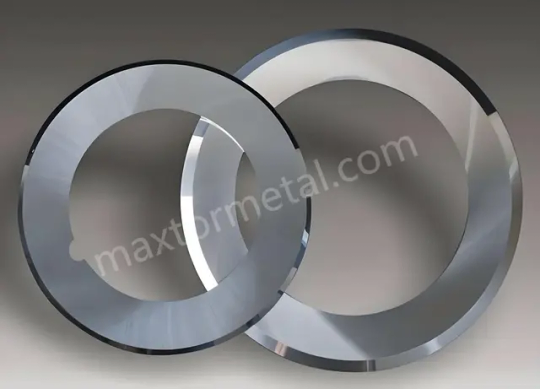

1. Blade Material

Blade composition significantly affects sharpness retention. High-grade alloys such as M2 tool steel, tungsten carbide, and ceramic composites offer excellent hardness and durability. A coated slitting blade can last twice as long as an uncoated one under similar conditions. For example, tungsten carbide-coated blades can withstand up to 500,000 cuts before requiring sharpening, compared to just 250,000 for standard steel.

2. Cutting Environment

The type of material being processed greatly influences blade wear. Harder materials like steel generate more friction and heat, which can quickly degrade blade edges. Additionally, cutting plastics or rubber often produces sticky residues that dull blades faster if not cleaned properly. Addressing these environmental factors with proper lubrication and cleaning can extend blade life by up to 40%.

3. Maintenance Practices

Inadequate blade maintenance is a major factor in premature dulling. For instance, incorrect sharpening angles can weaken the blade edge, while poor cleaning techniques may leave residues that accelerate wear. Implementing systematic maintenance schedules helps ensure consistent blade performance.

4. Innovative Blade Design

Advanced blade designs optimize edge geometry for specific applications. For example, beveled edges reduce cutting resistance and friction, improving durability. Laser-precision manufacturing techniques can achieve tolerances as fine as 0.001mm, creating sharper, more reliable blades.

Advanced Techniques to Prolong Slitter Blade Sharpness

1. Coating Technologies

Special coatings protect blade surfaces from wear and corrosion. For example, titanium nitride coatings increase surface hardness, allowing blades to retain sharpness 50% longer in high-speed operations. Similarly, diamond-like carbon coatings reduce friction, lowering operational temperatures and improving edge retention.

2. Cryogenic Treatment

Cryogenic processing aligns the internal structure of metals, enhancing their hardness and resistance to wear. Studies show that cryogenically treated industrial cutting tools last 30% longer than untreated blades in heavy-duty environments.

3. Precision Grinding and Sharpening

Grinding machines capable of maintaining a consistent edge angle ensure that the blade delivers smooth, precise cuts. Automated sharpening systems eliminate human error, providing consistent results that increase blade longevity by up to 20%.

4. Custom Blade Design

Tailored blade solutions enhance performance for specific applications. For example, rotary knives designed for textile cutting may feature serrated edges to minimize wear while ensuring clean cuts. Custom designs reduce maintenance frequency and improve process efficiency.

Maintenance Best Practices to Retain Blade Sharpness

Routine care and attention can drastically extend the lifespan of your slitting knives.

1. Routine Inspections

Perform regular checks for visible damage, including nicks, burrs, or uneven wear. An inspection log helps identify patterns and predict when blades require sharpening or replacement.

2. Proper Cleaning

Use non-abrasive tools and solvents to remove residues after each use. For example, a specialty blade-cleaning solution can reduce buildup by 50%, minimizing the risk of dulling.

3. Lubrication

Choose a lubricant that matches the cutting environment. For example, water-based lubricants are effective for heat-sensitive applications, while oil-based options are ideal for heavy-duty metal cutting. Proper lubrication reduces friction, extending blade life by 15%-25%.

4. Correct Storage

Preventing physical damage during storage is crucial. Blades should be kept in dry, temperature-controlled environments, and protective covers should always be used.

5. Operator Training

Ensure operators understand proper blade handling techniques, such as avoiding direct contact with edges and correctly aligning blades during installation. Trained staff are less likely to cause accidental damage, reducing blade replacements by up to 10%.

By adopting these best practices, you can ensure peak performance from your cutting tools.

How Our Slitter Blades Stand Out in Sharpness Retention

At [Your Company Name], we prioritize precision and durability in every slitter blade we manufacture. Here’s why our products excel:

Superior Materials: Our blades are crafted from premium alloys and coated with cutting-edge technologies to ensure unmatched sharpness retention.

Advanced Manufacturing: We use precision grinding and laser cutting to create blades tailored to your specific needs.

Proven Performance: Our blades have helped clients reduce downtime by 40% and improve product quality consistently.

Client Testimonial:

“We switched to Metal’s industrial cutting tools, and the difference was night and day. Less waste, smoother cuts, and longer blade life!” – Operations Manager, Packaging Industry

Our commitment to quality ensures that your cutting operations remain seamless and efficient.

Contact us today to learn how we can optimize your cutting processes.

Conclusion and Call to Action

Sharpness retention is the cornerstone of efficient and cost-effective cutting operations. By understanding the factors that affect slitter blade performance, leveraging advanced technologies, and following best maintenance practices, you can enhance blade durability and reduce operational costs.

Ready to upgrade your cutting tools? Discover how our advanced solutions can revolutionize your operations. Custom Industrial Blades Manufacturer in China and Custom Industrial Blades Supplier in China. Contact us today!

1 note

·

View note

Text

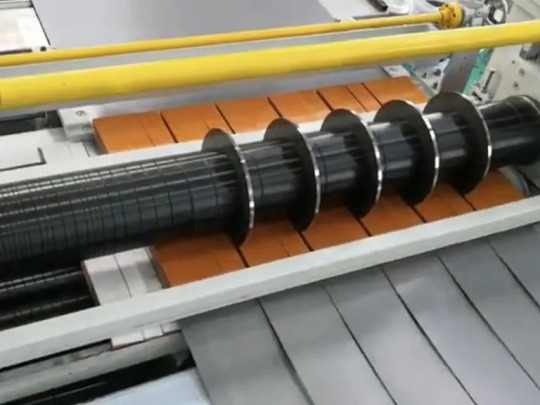

Core slitting machines are pivotal in modern manufacturing,

particularly in industries that require the precision cutting of materials into narrow strips. These machines facilitate the conversion of wide rolls of material—such as paper, plastic, metal, and textiles—into smaller, usable widths. Understanding the design and operational insights of core slitting machine can significantly enhance their efficiency and effectiveness in production environments.

Overview of Core Slitting Machines

Core slitting machines are designed to handle various materials and offer precision in cutting operations. Their primary function is to take a large roll of material and slice it into narrower strips while maintaining consistent dimensions and quality. These machines are essential in industries like packaging, automotive, electronics, and textiles, where precise dimensions are critical for downstream processes. The importance of these machines cannot be overstated, as the quality of the slitted material directly impacts the efficiency of subsequent manufacturing steps.

Key Design Features

Frame Structure The structural integrity of a core slitting machine starts with its frame, typically constructed from robust materials such as steel or aluminum. A solid frame minimizes vibrations during operation, ensuring that the machine remains stable while cutting. This stability is crucial for maintaining precise alignment of the cutting components, which directly affects the quality and accuracy of the slits produced. Manufacturers often invest in advanced engineering techniques to optimize the frame design, balancing weight and durability.

Unwind and Rewind Stations

Unwind and rewind stations are integral components of core slitting machines, responsible for feeding the wide rolls into the cutting area and collecting the finished strips. These stations are designed to accommodate varying roll sizes and weights, featuring tension control systems that help maintain the proper material tension throughout the slitting process. Proper tension is essential for achieving clean cuts and preventing material damage, making these components critical to the machine's overall performance.

Slitting Head

The slitting head is arguably the most vital part of the core slitting machine, where the actual cutting occurs. It houses the slitting blades, which can be rotary, shear, or circular depending on the material type being processed. The design of the slitting head often allows for precise adjustments in blade height and alignment, enabling operators to customize the machine for different materials and thicknesses. This adaptability is essential for meeting the varied demands of different production runs.

Blade Types and Maintenance

The choice of blade types is another crucial factor in the design of core slitting machines. Rotary blades are typically used for flexible materials, while shear blades are better suited for harder materials. Regular maintenance of these blades—such as sharpening and replacements—is vital for maintaining cutting quality and efficiency. A well-maintained blade not only improves the quality of the cuts but also reduces machine downtime, contributing to overall productivity.

Operational Insights Material Selection

The type of material being processed plays a significant role in the operation of core slitting machines. Factors such as thickness, flexibility, and tensile strength must be taken into account when selecting materials for slitting. Understanding the characteristics of the material can help operators optimize blade types and cutting speeds, enabling them to achieve the best possible results.

Setup Procedures

Efficient setup procedures are essential for minimizing downtime and maximizing productivity in core slitting operations. Operators should follow standardized protocols for adjusting blades, setting tension, and configuring the control system. A well-defined setup process can significantly reduce the time required to transition between different production runs, allowing manufacturers to respond quickly to changing demands.

Regular Maintenance

Implementing a regular maintenance schedule is imperative for ensuring the long-term reliability and performance of core slitting machines. Maintenance tasks may include cleaning, lubrication, blade sharpening, and inspection of mechanical components. A proactive maintenance approach helps prevent unexpected breakdowns, thereby keeping production running smoothly and reducing costs associated with equipment failures.

Performance Monitoring

Continuous monitoring of performance metrics such as production cycle time, scrap rate, and material utilization is crucial for assessing the efficiency of core slitting operations. By analyzing these metrics, manufacturers can identify areas for improvement and implement strategies to enhance overall productivity. Regular performance reviews can also help operators make informed decisions about machine adjustments and operational changes.

Operator Training

Well-trained operators are essential for the successful operation of core slitting machines. Comprehensive training programs should cover machine functions, safety protocols, and troubleshooting techniques. Investing in regular training updates ensures that operators remain informed about new technologies and best practices, empowering them to perform their tasks efficiently and effectively.

Quality Control

Establishing a robust quality control process is vital for ensuring that the slitted strips meet required specifications. Regular inspections of the output can help identify defects early in the process, allowing for timely corrective actions. Quality control measures should include checks for dimensional accuracy, surface finish, and the presence of defects, ensuring that the final product meets customer expectations.

Conclusion

Core slitting machines are integral to the manufacturing process, enabling industries to efficiently produce narrow strips from wide rolls of material. By understanding key design features and operational insights, manufacturers can optimize their slitting processes, enhance product quality, and improve overall efficiency. Emphasizing material selection, efficient setup procedures, regular maintenance, performance monitoring, operator training, and quality control will ultimately lead to enhanced productivity and reduced operational costs. As industries continue to evolve, investing in advanced core slitting technology and best practices will be essential for maintaining a competitive edge in the market

0 notes

Text

Aluminum Foil Slitting Machines Market Size, Analyzing Forecasted Outlook and Growth for 2024-2030

Global Info Research’s report on the Global Aluminum Foil Slitting Machines Market offers profound understanding of the market's structure, dynamics, and prevalent trends. This report offer a contemporary snapshot of the market's current size and its potential for growth in the future. The report pinpoints the key competitors within the market, their respective market shares, and the emerging opportunities they can capitalize on. Additionally, the report delves into the impact of technological advancements on the market and how these can be harnessed for competitive advantage.

Moreover, the report provides a comprehensive analysis of the significant drivers, challenges, and opportunities within the Aluminum Foil Slitting Machines Market. It takes into consideration the macroeconomic factors and regulatory frameworks prevailing in each region encompassed by the market. A thorough examination of the industry's supply chain is also conducted to identify key players and assess the influence of recent developments on their market positioning. The report offers a clear perspective on how to leverage the evolving market conditions for maximum gain.

The report on the Global Aluminum Foil Slitting Machines Market meticulously scrutinizes the competitive landscape, offering valuable insights for market participants. The report identifies and appraises the leading players, providing a holistic view of their market presence and strategies.

Through meticulous analysis, we identify market leaders, challengers, and niche players, evaluating them based on factors such as market share, product offerings, and recent developments. This comprehensive understanding enables businesses to gain a deeper insight into their competitive positioning within the industry.

To provide a comprehensive overview of the Global Aluminum Foil Slitting Machines Market, Global Info Research adopts a segmentation approach and also categorizes the market into distinct segments, considering various criteria like product types, geographical regions, and consumer demographics.

By closely examining each segment, we reveal specific trends, growth potential, and challenges. This segmented analysis allows businesses to tailor their strategies to meet the unique needs of different market segments, thereby enhancing their competitive edge. Our segmentation analysis serves as a strategic tool, guiding market participants in navigating the complexities of the Global Aluminum Foil Slitting Machines Market effectively.

The content of the study subjects, includes a total of 13 chapters: Chapter 1, to describe Aluminum Foil Slitting Machines product scope, market overview, market estimation caveats and base year. Chapter 2, to profile the top players of Aluminum Foil Slitting Machines, with revenue, gross margin and global market share of Aluminum Foil Slitting Machines from 2019 to 2024. Chapter 3, the Aluminum Foil Slitting Machines competitive situation, revenue and global market share of top players are analyzed emphatically by landscape contrast. Chapter 4 and 5, to segment the market size by Type and application, with consumption value and growth rate by Type, application, from 2019 to 2030. Chapter 6, 7, 8, 9, and 10, to break the market size data at the country level, with revenue and market share for key countries in the world, from 2019 to 2024.and Aluminum Foil Slitting Machines market forecast, by regions, type and sales channel, with consumption value, from 2025 to 2030. Chapter 11, market dynamics, drivers, restraints, trends and Porters Five Forces analysis. Chapter 12, the key raw materials and key suppliers, and industry chain of Aluminum Foil Slitting Machines. Chapter 13, to describe Aluminum Foil Slitting Machines research findings and conclusion.

Reasons for Acquiring This Report:

The conducted research offers valuable insights to top executives, policymakers, industry professionals, product developers, sales managers, and stakeholders within the Global Aluminum Foil Slitting Machinesmarket. The report presents a comprehensive analysis of the market, enabling companies to assess their market share, analyze projections, and identify new growth opportunities.

The report provides detailed revenue data for the Global Aluminum Foil Slitting Machinesmarket at the global, regional, and country levels. This comprehensive analysis covers the period up to 2030, allowing companies to make informed decisions based on market trends and projections.

The research divides the Global Aluminum Foil Slitting Machinesmarket into various segments based on type, application, technology, and end-use. This segmentation offers a clear understanding of each segment's growth potential, enabling leaders to plan their product development and financial strategies accordingly.

Investors can benefit from the Global Aluminum Foil Slitting Machinesmarket analysis by gaining insights into the market's scope, position, key drivers, challenges, restraints, expansion opportunities, and potential threats. This information helps investors make informed decisions when allocating funds.

The report provides a detailed analysis of competition within the Global Aluminum Foil Slitting Machinesmarket, including key strategies employed by competitors. This analysis helps businesses understand their competitors better, enabling them to plan their market positioning effectively.

6.The study evaluates business predictions for the Global Aluminum Foil Slitting Machines market based on region, key countries, and leading companies. This information assists investors in channeling their investments strategically, targeting areas with the highest growth potential.

Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

Gantry Laser Cutting Machine

A laser metal cutting machine uses the laser beam emitted from the laser generator to focus on the laser beam irradiation condition of high power density through the external circuit system. The laser heat is absorbed by the workpiece material and the workpiece temperature rises sharply. After reaching the boiling point, the material begins to vaporize and form holes, as the relative position of the beam and the workpiece moves, will eventually form a slit in the material.

The technological parameters (cutting speed, laser power, gas pressure, etc.) and movement trajectory during slitting are controlled by the CNC system, and the slag at the slit is blown off by the auxiliary gas with a certain pressure. During laser-cut metal, auxiliary gas suitable for the material to be cut is also added. When cutting steel, oxygen must be used as an auxiliary gas to produce an exothermic chemical reaction with the molten metal to oxidize the material, while helping to blow away the slag in the slit. For metal parts with high processing accuracy, nitrogen can be used as an auxiliary gas in the industry.

Gantry Laser Cutting Machine

Gantry metal laser cutting machines typically use fiber lasers as the laser source. Fiber lasers are well-suited for metal cutting due to their high power and excellent beam quality. They can efficiently cut through various metals, including steel, stainless steel, aluminum, brass, and copper.

The power of the laser source determines the cutting speed and the maximum thickness of the metal that can be cut. Higher-power lasers can cut thicker metals at faster speeds.

The cutting bed of a gantry metal laser cutting machine is typically designed to withstand the weight and heat generated during the metal cutting process. It may have a durable table surface, such as a slat table or a honeycomb structure, to support the metal sheets or plates being cut.

Gantry metal laser cutting machines are controlled by a CNC system that interprets cutting instructions from design software and controls the movement and operation of the machine. The software used for programming and controlling the machine often includes features specific to metal cutting, such as parameter optimization for different types and thicknesses of metals.

Metal laser cutting machine has fast cutting speed, good cutting quality, high precision, simple operation, safety and stable performance. It has extremely high adaptability and flexibility. Using CNC system, complex patterns can be processed on metal plates. Metal and advanced processing technology, this combination of new and old, also makes metal crafts glow with unprecedented charm.

The specific advantages of laser cutting machine applied to metal lighting processing industry are: laser cutting technology belongs to non-contact processing, which uses high-density laser beam to irradiate the workpiece surface to realize melting, and the high-pressure gas blows away the slag to complete the cutting action. The whole process belongs to numerical control processing, without contact and deformation. The laser cutting machine is completely free from the limitation of pattern complexity. It has very fast processing speed, high precision and beautiful cutting end face. It can process the original cool metal materials into artistic patterns. With the effect of light, the metal patterns are more refined and high-end.

Gantry Laser Cutting Machine Application

Application Industries

Widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware,

Advertising Letters, Sheet Metal Processing, Metals Components and Parts.

Ironware, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting

Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Application Materials

Suitable for metal cutting with Stainless Steel Sheet, Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Iron Plate, Galvanized Sheet.

Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc.

Key Features of Metal Sheet, Pipe, and Tube Laser Cutting Machine

A metal sheet, pipe, and tube laser cutting machine is a specialized tool used in the manufacturing and metalworking industry for precisely cutting various types of metal materials. This machine uses a high-powered laser beam to cut through the metal, offering several advantages over traditional cutting methods, such as precision, speed, and the ability to cut intricate and complex designs. Here are some key features and aspects of a metal sheet, pipe, and tube laser cutting machine: Laser Source: The heart of the machine is the laser source, which typically uses either fiber laser or CO2 laser technology. Fiber lasers are popular for their high energy efficiency and ability to cut a wide range of metals, while CO2 lasers are suitable for non-metal materials and some metal cutting applications.

CNC Control: The machine is equipped with computer numerical control (CNC) technology, which allows for precise control of the laser head’s movement and cutting parameters. This ensures accurate and repeatable cuts.

Cutting Capabilities:Metal Sheets: These machines can cut flat metal sheets, such as steel, aluminum, and stainless steel. They are often used for creating parts for various industries, including automotive, aerospace, and electronics. Pipes and Tubes: Some laser cutting machines are equipped with rotary axes that enable the cutting of cylindrical or tubular metal objects like pipes and tubes. This is common in industries like construction, HVAC, and furniture.

Precision and Accuracy: Laser cutting machines provide high levels of precision and accuracy, with minimal heat-affected zones, which reduce the risk of material distortion.

Versatility: These machines can cut various thicknesses of metal, from thin sheets to thick plates, depending on the laser source’s power and the machine’s configuration.

Speed and Efficiency: Laser cutting is generally faster than traditional cutting methods, making it more efficient for high-volume production.

Automation: Some machines are equipped with automatic loading and unloading systems, which further enhance productivity by reducing manual labor.

CAD/CAM Integration: Laser cutting machines are often integrated with computer-aided design (CAD) and computer-aided manufacturing (CAM) software, allowing users to design parts and convert those designs into cutting programs.

Safety: Laser cutting machines incorporate safety features such as enclosures, exhaust systems, and safety interlocks to protect operators from laser radiation and fumes.

Maintenance: Regular maintenance is essential to keep the machine operating at peak efficiency. This includes cleaning the optics, inspecting and replacing consumable parts, and ensuring proper alignment.

About Igoldenlaser Company

Igoldenlaser Technology Co., Ltd. products include: laser cutting machine, laser marking machine, laser engraving machine, laser welding machine and so on. More than 10 series, 300 types personalized products and services to provide customers with a significant advantage.

Due to the high quality of our products and reliable performance, they are widely used in electronics, hardware, model- making, clothing, footwear, advertising, printing and packaging, toy-making, as well as more industries.

0 notes

Text

0 notes

Text

Steel Coil Slitting Machine Equipment Suppliers in Hyderabad

Revolutionizing Metal Processing: The Coil Slitting Machine Manufacturing Company in Hyderabad, India

Introduction:

In the ever-evolving world of metal processing, efficiency and precision play pivotal roles in meeting industry demands. Among the key players in this sector is the Coil Slitting Machine Manufacturing Company, a trailblazer in designing and producing cutting-edge machinery that revolutionizes the way metal coils are processed. Based in Hyderabad, India, this company stands out as one of the best industrial coil slitting machine suppliers in the country.

Background:

Founded with a vision to enhance productivity and streamline metal cutting processes, coil slitting machine for sale in hyderabad, India, has emerged as a frontrunner in the manufacturing industry. Specializing in the production of coil slitting machines, the company has consistently delivered innovative solutions to cater to the diverse needs of metal processing facilities worldwide.

State-of-the-Art Technology:

At the heart of the Coil Slitting Machine Manufacturing Company lies a commitment to integrating state-of-the-art technology into its products. These cutting-edge machines, available for sale in Hyderabad, are designed to slit and cut metal coils with unparalleled precision and speed. Equipped with advanced automation features, the company's machines not only increase efficiency but also reduce human error, ensuring a higher quality output.

Precision Engineering:

One of the key factors that sets the Coil Slitting Machine Manufacturing Company apart is its emphasis on precision engineering. Best industrial coil slitting machine suppliers in India, The machines produced by the company are meticulously crafted to meet the exacting standards of the metal processing industry. This precision ensures that the slitting process is carried out with utmost accuracy, resulting in consistent and high-quality end products.

Versatility in Application:

The steel coil slitting machine equipment suppliers in India understands that different industries have unique requirements when it comes to metal processing. Therefore, their machines are designed with versatility in mind. Whether it's steel, aluminum, or other metals, these machines can handle a wide range of materials, making them suitable for various industrial applications.

Efficiency and Cost-effectiveness:

In today's competitive market, efficiency and cost-effectiveness are paramount. The Coil Slitting Machine Manufacturing Company in Hyderabad recognizes this, and its machines are engineered to deliver optimal performance while minimizing operational costs. The automated features not only reduce labor requirements but also enhance the overall speed of the metal processing line, translating into increased productivity for its clients.

Commitment to Customer Satisfaction:

Beyond providing cutting-edge machinery, the Coil Slitting Machine Manufacturing Company prides itself on its commitment to customer satisfaction. The company's dedicated customer support team works closely with clients, including coil cutting machine suppliers in Hyderabad, to understand their specific needs and ensures that the machines are tailored to meet those requirements. This customer-centric approach has resulted in long-lasting relationships and a growing reputation for reliability in the industry.

Environmental Responsibility:

In an era where environmental sustainability is a global concern, the Coil Slitting Machine Manufacturing Company recognizes its responsibility to contribute positively to the environment. The company, as one of the leading coil slitting machinery exporters in India, employs eco-friendly manufacturing practices and is continually exploring ways to reduce its carbon footprint. By promoting energy efficiency in its machines, the company not only benefits its clients but also plays a role in promoting sustainable practices within the metal processing sector.

Conclusion:

As the demand for precision in metal processing continues to rise, the Coil Slitting Machine Manufacturing Company in Hyderabad, India, stands at the forefront, providing innovative solutions that redefine efficiency and quality in the industry. With its commitment to technological advancement, precision engineering, and customer satisfaction, the company is poised to shape the future of metal processing across India and beyond.

0 notes

Text

The coil sheet laser cutting system combines with the de-coiling system, leveling system and laser cutting system. It's suitable to process the multi shape of products, can realize customized manufacturing. Compared with traditional coil processing lines, our sheet metal coil line machine laser cutting system with features of high precision, high productivity, less cost on labors, and stable operation. which is suitable for cutting metal coils, such as stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, galvanized steel, copper, etc. We also provide sheet metal slitting machine for sale. Contact us for further information!

Decoiler,hydraulic lifting, all servo support, and remote control.

Levelling, which is to straighten from coil sheet.

Manufacturing steps: Fiber Laser cutting or Punching Or shearing or folding.

Post-processing, such as robot handling to stack automatically or welding etc.

Coil Fed Laser Cutting Machine Features

Fully-automation can realize to process from the raw metal coils to the final profiles, no need a numeral labors to handle different devices and a few cycles of loading and unloading, There is no need to change the dies, and no waste of time or labors, can realize the higher flexibility manufacturing faster react to the customer's needs and rapid react to the market changes.

Higher productivity, there is no waste of labor landing and blanking compared with traditional line. Only one worker can handle the whole lines. It is stable operation, no need to change the dies, less operation.

High precision and accuracy, the system apply with the servo feeding system and solid fiber laser technology, which make sure the precision.

Coil Laser Cutting Machine Parameter Details

Number

Item

Specification

Laser cutting station

1

Laser source power

1500W

2

Working area

3000mm×1500mm

3

X、Y axis positioning accuracy

±0.05mm/m

4

X、Y axis repositioning accuracy

±0.03mm

5

Max running speed

120m/min

6

Max acceleration

1.2G

7

Workbench maximum load weight

800kg

8

Station weight

6.5T

9

Station size(length*width*height)

6m×2.92m×2.0mm

De-coiling station

10

De-coiling width/capacity

300-1250mm/10T

11

Decoil landing capacity

10T

Levelling station

14

Levelling rollers

Up 5/down 4

15

Output speed

16m/min

0 notes

Text

Cut to Length Line

Title: Understanding the Cut to Length Line: Streamlining Material Processing

Introduction:

Introduce the concept of a Cut to Length Line and its significance in the manufacturing and metal processing industries. Highlight the benefits of using Cut to Length Lines for efficient and precise material cutting.

What is a Cut to Length Line?

Define a Cut to Length Line and provide an overview of its components and functionalities. Explain how it differs from other metal processing equipment, such as slitting lines or shearing machines.

Key Components and Functions of a Cut to Length Line:

Decoiler: Describe the purpose and operation of the decoiler, which unwinds and feeds the coil into the line. Straightener: Explain the role of the straightener in removing coil-set and ensuring flat material for accurate cutting. Leveler: Discuss the function of the leveler in flattening and removing any residual stresses in the material. Shear: Highlight the cutting mechanism of the shear and its ability to make precise cuts at programmed lengths. Stacker: Describe the stacking system that neatly collects and organizes the cut-to-length sheets or plates.

Material Types and Applications:

Explore the different types of materials that can be processed using a Cut to Length Line, such as steel, aluminum, and stainless steel. Discuss the wide range of applications for cut-to-length sheets, including automotive, construction, and appliance manufacturing.

Advantages of Cut to Length Lines:

Discuss the benefits of using Cut to Length Lines, such as increased efficiency, reduced waste, and improved accuracy. Highlight how these lines can optimize production by eliminating the need for manual cutting and trimming processes.

Factors to Consider When Choosing a Cut to Length Line:

Discuss key factors to consider when selecting a Cut to Length Line, such as material thickness and width capacity, line speed, and automation features. Mention additional considerations like space requirements, maintenance, and operator training.

Maintenance and Safety:

Provide guidelines for regular maintenance and upkeep of a Cut to Length Line to ensure its smooth operation and longevity. Emphasize the importance of safety protocols and training for operators working with the equipment.

Conclusion:

Summarize the key points discussed throughout the blog post, emphasizing the advantages and applications of Cut to Length Lines. Highlight how these lines streamline material processing and contribute to increased productivity and quality in manufacturing operations.

Remember to include relevant visuals, such as images or videos, to enhance the clarity and engagement of your blog post.

#coil slitting machine#cr slitting line#steel coil slitting line#coil slitting line#manufaturinginindia#steel coil slitting machine

0 notes

Text

Coil Slitting Line Machine: Enhancing Precision and Efficiency in Metal Processing

The coil slitting line machine is a cutting-edge solution that revolutionizes the process of slitting coils into narrower strips with precision and efficiency. This advanced machine offers numerous benefits for industries that require precise metal processing, such as steel service centers, automotive manufacturers, and construction companies. Let's explore the features and advantages of the coil slitting line machine.

Precision Slitting:

The coil slitting line machine ensures accurate and consistent slitting of coils into narrower strips. With adjustable cutting parameters and advanced control systems, this machine enables precise control over strip width, thickness, and edge quality. Manufacturers can achieve tight tolerances and uniform strip dimensions, ensuring the highest level of precision in metal processing.

High Efficiency:

The coil slitting line machine significantly improves production efficiency by automating the slitting process. It eliminates manual handling, reduces setup time, and enhances overall productivity. This machine can handle a wide range of coil materials, including stainless steel, aluminum, and galvanized steel, enabling manufacturers to efficiently process different metal coils for various applications.

Versatility and Customization:

Coil slitting line machines offer versatility and customization options to meet specific industry requirements. They can accommodate different coil widths, thicknesses, and weights, providing flexibility for diverse metal processing needs. By adjusting the slitting parameters, manufacturers can tailor the machine to their desired strip specifications, ensuring precise and customized results.

Minimized Material Waste:

Efficient material utilization is essential for cost-effective metal processing. The coil slitting line machine optimizes material usage by minimizing waste. It accurately slits coils, reducing scrap and maximizing material yield. This feature not only enhances profitability but also promotes sustainability by minimizing environmental impact.

Enhanced Safety:

Safety is a paramount concern in metal processing operations. Coil slitting line machines are equipped with safety features to ensure operator well-being. Emergency stop buttons, protective enclosures, and safety interlocks contribute to a safe working environment. Additionally, automated processes minimize direct operator involvement, reducing the risk of injuries.

0 notes

Text

There are several types fully automatic strapping machine that designed to strap coils both horizontal eye to sky and vertically eye to wall. For slitting coil strapping, the coil eye to sky that is redial eye through strapping above roller conveyor. For the cold roll coil strapping, the eye level is parallel to the transportation direction that can be both radial and circumfrencial strapping. Normall the roll fixed in the central area of the strapping machine by the conveying system. The strapping material can be PET and Steel belt that is vary from the steel coil thickness, weight and packaging. For light slitting coil, copper coil, aluminum coil, PET will be choosen for strapping in considering the coil surface protection. And for big cold roll steel coil, the ouside package protection by paper, steel sheet fixing with pallt using PET too. For heavy steel coil, the steel belt is the most popular material for strapping. The strapping solution offered by FHOPE includes equipment for slitting coils, cold roll steel coil, hot roll steel coils...

0 notes

Text

INDUSTRIAL ADHESIVE TAPE

As one of the professional industrial tape manufacturers in China, Egret supplies many types of industrial adhesive tape. Particularly, applied to refrigerator, air conditioning, ducting work, building, insulation industries. Not to mention our advantage of coating abilities, we also have capabilities to slit, cut, rewind, die cutting and other converting services. Important to realize, our strong adhesive tape is aluminum foil tape, PE tape, po film, PET tape, MOPP/TPP tape, PVC non-adhesive tape.

Choose Egret as Your Industrial Adhesive Tape Supplier

Choose Egret as Your Industrial Adhesive Tape Supplier. Egret mfg offers many kinds of adhesive tapes, including Aluminum foil tape, PE white tape, PET blue tape, Masking paper tape, Cloth tape, PVC air conditioner tape, Vinyl electrical tape, Double-sided tissue tape, TPP/MOPP tape, Foam tape (VHB,PE,PU, EPDM, NBR, PVC,EVA,etc), BOPP packing tape, Kraft paper tape, PE protective film, PVC duct tape, etc. We mix and produce our own formula adhesive to save cost & improve adhesion.

Moreover, Egret has 10 adhesive coating lines. Likewise, 15 slitting machines with huge capacity. Additionally, our products certified with UL, ROHS, REACH, BS, CE, etc.

Furthermore, we’re Top 1 seller for aluminum foil tape in refrigerator industry in China. Especially, Egret is a golden supplier of Samsung, Toshiba, Haier, Midea, Arcelik, Hisense, etc

Features Of Industrial Adhesive Tape

What are the benefits & features of Egret adhesive tape?

Egret adhesive tape can replace of the bolts and nuts, to make it clean looking.

High adhesion and excellent tack

Good aging resistance for both indoor & outdoor use

Joints/seams sealing against moisture and vapor barrier

Easy hand tear for workers to use on-site

Excellent heat & light reflecting of aluminum foil backing

Combination of baking material ensures high flexibility and conformability

Extremely easy for hand-tear, easy-used by workers

Neat and invisible looking to be excellent alternative to metal fasteners, welding

0 notes

Text

The Benefits of Using a Jump Ring Maker for Large Scalemail Projects

There are a lot of different uses and materials when it comes to creating jump rings michaels. They're used for everything from connecting a clasp to a piece of jewelry to adding texture and dimension to your chain mail design.

They're made from long lengths of wire that are wrapped around a mandrel, making spring-like coils. These coils are then cut apart and a ring is formed with a slit where the ends meet.

The Ringinator(r) makes this process quick and easy by utilizing a precision jewelers saw to cut these coils right down the center. This results in a superior jump ring that closes smoothly and neatly.

Easily create unique sizes

You can make almost any size jump ring with this machine. It saves time compared to ordering from vendors, and it allows you to produce more of any size you need without sacrificing quality or price.

Cost savings

You'll save money on the materials for your project, too! Aluminum and niobium wires are commonly used in Chain Mail, and they can be very expensive. The more you're able to make with the same wire, the lower the price per pound is.

Getting Started

A good way to start is to use a pair of pliers that will allow you to wrap and form the wire into a coil before sawing it down the middle. Depending on your preference, you can choose from a variety of styles that have parallel jaws or a chain nose or flat nose. Then you'll need a wooden dowel to run through the coil (to saw through) and some tape to hold it in place.

0 notes

Link

We are specialised manufacturer and supplier of Lidding High Performance Doctoring Rewinding Machines, high quality equipment Doctoring Slitter Machine. Doctoring Rewinding, Doctoring Rewinding Table Top, Table Top Doctoring Rewinding, High Speed Doctoring Rewinding, Heavy Duty Doctoring Rewinding, Doctoring Rewinding With Slitter System, Doctoring Slitting Rewinding, Label Stock Doctoring Rewinding, Special Application For Doctoring Rewinding, Film Winding Rewinding For Batch Coding, Winding Rewinding For Batch Printing. Winding Rewinding With Inkjet Printer, Winding Rewinding With Thermal Transfer Overprinted, Winding Rewinding With Multihead Inkjet Printer, Doctoring Film Strip Winding Rewinding, Winding Rewinding With Slitter System, Winding Rewinding Without Slitter System, Coil Winding, Winding Unwinding, Inspection Doctoring Slitting, Inspection Rewinding for Inkjet and Batch Printing, Doctoring Inspection, Doctoring Inspection with Slitter System, Doctor Re Reeling, Industrial Inkjet Printer, Industrial Inkjet Printer With Winder Rewinder, Industrial Thermal Transfer Printer.

#Doctoring Slitter Machine#Slitter Machine#Doctoring Rewinding Machines#Doctoring Rewinding#Rewinding Machines#Rewinder Machine#Slitting Machine#Winder Rewinder#Doctor Rewinding#Slitter System#Doctor Re Reeling#Industrial Inkjet Printer#slitter Rewinder manufacturers#foil slitting machine#aluminium foil slitting machine#aluminum slitting machine#paper slitting machine#slitting machine price#fabric slitting machine#paper roll slitting machine

0 notes

Photo

We are making Aluminum Foil Slitting Rewinding Machine for the widely used in packaging industries. Offer a wide range of Jumbo Roll Slitting Machine, Aluminum House Foil Slitting Rewinding Machine that is precisely designed and manufactured to meet effective requirements of foil cutting. We offer Aluminum Foil Slitting Machines from 9 microns to 40 microns.

#Aluminum Foil#Slitting Machine#slitting rewinding machine#packaging#roll slitting machine#manufacturer

3 notes

·

View notes

Link

Krishna Engineering Works fabrique, exporte et fournit une rembobineuse de qualité standard au meilleur prix. Dans l'industrie de la transformation du papier, l'approche de rembobinage de phrases est une machine qui rembobine le produit final. ... Lorsque le rouleau de master est déroulé, il est généralement tissé à travers une machine de refendage / rembobinage. Le mot slitter fait référence à la section de la machine qui découpe le produit en plusieurs bandes de temps.

#rewinder machine manufacturer#aluminium foil rewinding machine#slitter rewinder machine manufacturer#paper slitter rewinder machine#slitter rewinder manufacturers#aluminum foil rewinding machine#kraft paper slitting machine#mini bopp tape slitting rewinding machine#aluminium foil rewinding machine price#winder rewinder manufacturer#bopp tape rewinding machine

0 notes

Text

Steel Coil Slitting Machine Equipment Suppliers in Hyderabad

Revolutionizing Metal Processing: The Coil Slitting Machine Manufacturing Company in Hyderabad, India

Introduction:

In the ever-evolving world of metal processing, efficiency and precision play pivotal roles in meeting industry demands. Among the key players in this sector is the Coil Slitting Machine Manufacturing Company, a trailblazer in designing and producing cutting-edge machinery that revolutionizes the way metal coils are processed. Based in Hyderabad, India, this company stands out as one of the best industrial coil slitting machine suppliers in the country.

Background:

Founded with a vision to enhance productivity and streamline metal cutting processes, coil slitting machine for sale in hyderabad, India, has emerged as a frontrunner in the manufacturing industry. Specializing in the production of coil slitting machines, the company has consistently delivered innovative solutions to cater to the diverse needs of metal processing facilities worldwide.

State-of-the-Art Technology:

At the heart of the Coil Slitting Machine Manufacturing Company lies a commitment to integrating state-of-the-art technology into its products. These cutting-edge machines, available for sale in Hyderabad, are designed to slit and cut metal coils with unparalleled precision and speed. Equipped with advanced automation features, the company's machines not only increase efficiency but also reduce human error, ensuring a higher quality output.

Precision Engineering:

One of the key factors that sets the Coil Slitting Machine Manufacturing Company apart is its emphasis on precision engineering. Best industrial coil slitting machine suppliers in India, The machines produced by the company are meticulously crafted to meet the exacting standards of the metal processing industry. This precision ensures that the slitting process is carried out with utmost accuracy, resulting in consistent and high-quality end products.

Versatility in Application:

The steel coil slitting machine equipment suppliers in India understands that different industries have unique requirements when it comes to metal processing. Therefore, their machines are designed with versatility in mind. Whether it's steel, aluminum, or other metals, these machines can handle a wide range of materials, making them suitable for various industrial applications.

Efficiency and Cost-effectiveness:

In today's competitive market, efficiency and cost-effectiveness are paramount. The Coil Slitting Machine Manufacturing Company in Hyderabad recognizes this, and its machines are engineered to deliver optimal performance while minimizing operational costs. The automated features not only reduce labor requirements but also enhance the overall speed of the metal processing line, translating into increased productivity for its clients.

Commitment to Customer Satisfaction:

Beyond providing cutting-edge machinery, the Coil Slitting Machine Manufacturing Company prides itself on its commitment to customer satisfaction. The company's dedicated customer support team works closely with clients, including coil cutting machine suppliers in Hyderabad, to understand their specific needs and ensures that the machines are tailored to meet those requirements. This customer-centric approach has resulted in long-lasting relationships and a growing reputation for reliability in the industry.

Environmental Responsibility:

In an era where environmental sustainability is a global concern, the Coil Slitting Machine Manufacturing Company recognizes its responsibility to contribute positively to the environment. The company, as one of the leading coil slitting machinery exporters in India, employs eco-friendly manufacturing practices and is continually exploring ways to reduce its carbon footprint. By promoting energy efficiency in its machines, the company not only benefits its clients but also plays a role in promoting sustainable practices within the metal processing sector.

Conclusion:

As the demand for precision in metal processing continues to rise, the Coil Slitting Machine Manufacturing Company in Hyderabad, India, stands at the forefront, providing innovative solutions that redefine efficiency and quality in the industry. With its commitment to technological advancement, precision engineering, and customer satisfaction, the company is poised to shape the future of metal processing across India and beyond.

0 notes