#rewinder machine manufacturer

Explore tagged Tumblr posts

Text

#conpaptex#machine#manufacturers#flexible packaging#packagingmachinery#packaging industry#plastic#plastic slitter rewinder machine#industry#slitter rewinder machine

1 note

·

View note

Text

Boost your packaging efficiency with KEW ENGG. & MFG. PVT. LTD.'s high-speed Winding Rewinding Machines! Precision, quality, and productivity for flexible packaging.

#kewengg#machinemanufacture#machine#machinery#exporter#supplier#industrial#industry#manufacturer#manufacturing#winding rewinding machine#winding machine#rewindermachine

1 note

·

View note

Text

"Optimizing Workflow: Slitting Rewinding Machines at Their Best"

Cutting and handling materials are critical among industries that routinely engage the services of slitting rewinding machines. These machines have one specialty: slicing a larger roll into narrower widths, rewinding them into a neat roll at the same time. Materials such as paper, film, and foil can be cut to specific size requirements and be ready for downstream processing or immediate use.

These overseer machines run on high technology automating every process while ensuring that materials get wasted as little as possible and encouraging quicker turnaround times. Features include eye broaches, customizable slit widths, and tension control systems; providing mass production across a wide range of industries, the above-mentioned creates a new level in quality and productivity.

To avail the world-class slitting rewinding machines, the organization needs to visit UV Graphic, which is known for making the right innovative machines that are reliable and efficient. True believers in precision engineering and superior performance, UV Graphic sponsors an unprecedented level of operational excellence for all businesses.

#uv curing systems#curing machine manufacturer#label punching machines manufacturer#uv coating machines manufacturer#Slitting Rewinding Machine

0 notes

Text

The rewinding inspection machine is applied in inspecting materials such as paper, film, textiles, and foil for defects.

#machinery#industrial#manufacturer#exporter#textiles#supplier#krishnaengineeringworks#machinemanufacture#machine#industry#inspection rewinding machine

1 note

·

View note

Link

We thank you for your interest in Inspection and Rewinding Machines ECO HSR 1300 Manufacturer, Supplier, Exporter by UFlex! Please fill up the information below. We thank you for your interest in machinery manufactured by Uflex! Please fill up the information below. This will help us in understanding your requirements better.

0 notes

Text

thermal transfer ribbon slitting machine

Slitting and rewinding machine manufacturer.

2 notes

·

View notes

Text

Manufacturer of Flexible Packaging, Paper, Tire-Cord, and Textile Machinery

Krishna Engineering Works is a company based in India that specializes in manufacturing and supplying a wide range of industrial machinery and equipment. The company was established in 1980 and has since become a well-established name in the industry.

Krishna Engineering Works offers a wide range of products including Flexible Packaging, Paper, Tire-Cord, and Textile Machinery, Slitter Rewinder Machines, Coating Machines, and many more. The company's products are widely used in industries like packaging, printing, paper conversion, and textiles.

#Flexible Packaging#Paper#Tire-Cord#Textile Machinery#Textile Processing Machinery#Textile Processing Machine Price#Textile Machine Manufacturer

2 notes

·

View notes

Text

more assorted tape media facts:

There's only 2 ways to make tape hold more data: thinner tape (more fragile, but able to fit a longer line of tape in a cassette) or running the tape slower (basically equivalent to lower bit rate audio today) the Compact Cassette standard also specified the tape run speed, so thinner tape was the only option.

Compact Cassette and its contemporaries and derivatives are linear media, meaning rewinding was required, but the earlier tape music format, 8 track, used a looped tape. (Technically Compact Cassette is older but earlier versions ran the tape slower and thus weren't high fidelity enough for music use)

In the context of 8 Track that means the song would restart when it ended. Each 8 track cassette was so called because it had 8 total audio channels, meaning it was limited to 8 25 minute programs in mono, 4 in stereo, or 2 in quadrophonic, as the loop took 25 minutes to cycle. That meant maximum album length was usually 50 minutes, so double albums were common, and multiple songs would be on each program.

The reason for the looped tape design is that it's an adaptation of a store background music cartridge format. Looping the songs meant you didn't need someone to go in back and change the tapes every 25 minutes (back in the days of the 2 track cassete, the earliest ancestor. 2, 4, and 8 track all share a form factor but are technologically different)

Tapes could store so much more than audio! They could also store binary data. Many early microcomputers came with a cassette reader standard and an optional external floppy drive. Loading from cassette was slower and they held less data than floppies. However, because anybody could produce data cassettes at home by simply recording one data cassette onto another on the family Hi-Fi, they were attractive to bedroom developers.

Because it's possible to record anything onto any cassette, your 1980s super spy could be making off with the nuclear codes on his copy of The Eurythmics' Be Yourself Tonight. (assuming he filled in the write protect (basically the machines had a little feeler that would slide into a notch to check if the tape user wanted to be able to record to a tape. If it fit, the machine wouldn't record to the tape. On blank tapes, you'd break off a little piece when you were done recording to the tape.)

There were multiple Compact Cassette tape media types (as in what the magnetic grains that are aligned by the magnetic field of a write head to write the data were made out of. That's how it works, the degree of alignment of the grains codes for analog data) that varied in audio quality and also look different. The three most popular types were Types I, II, and IV.

Type I used basic iron oxide, and had the lowest bias (bias is a magnetism thing which basically measures how much you can magnetize part of the tape. It's kind of like dynamic range I think, but I'm no audiophile, so, basically higher tape type number, higher fidelity) They were packaged in plastic shells and were ubiquitous.

Type II tapes are high bias tapes and are meant to perform better by having a better signal to noise ratio (basically because the earth is magnetic, there's magnetic background noise and that ends up on a tape.) but also had worse treble response. Their composition was originally Chromium oxide based, meaning they smelled like yellow crayons. They also had plastic cases.

Type III tapes weren't as popular because they didn't perform that much better than type II tapes but were more expensive than type IIs to manufacture.

Type IV tapes were the best available and used pure metal particles as opposed to oxides. They came in precision manufactured metal cartridges, and were the choice of audiophiles.

Younger writers. Please, just know that you could not skip to different songs on a cassette tape, that’s CDs. With tapes you pressed fast forward or rewind and prayed.

Also, VHS tapes did not have menu screens. Your only options were play, fast forward, rewind, pause, stop, or eject.

Y’all are making me feel like the crypt keeper here, I’m begging you 😭

55K notes

·

View notes

Text

A Paper Cutter Rewinder Machine cuts large paper rolls into smaller, much more manageable parts and rewinds them simultaneously; it is machinery that integrates precision-cutting technology together with efficient winding mechanisms to be productive and cut waste to minimum.

Conpaptex's Paper Cutter Rewinder Machine leading the way for the paper, packaging, and printing industries in offering seamless performance.

#conpaptex#paper cutter rewinder machine#paper cutter#slitter rewinder machine#machine#manufacturers#paper industry#paper machinery#paper#machinery

1 note

·

View note

Text

KEW ENGG. & MFG. PVT. LTD., we specialize in manufacturing cutting-edge Heavy Duty Drum Slitter Machine designed to meet diverse industrial requirements. Whether it’s for paper, plastic, textile, or packaging applications, our machines deliver unparalleled precision and durability.

#kewengg#machine#machinery#industry#machinemanufacture#industrial#exporter#supplier#manufacturer#manufacturing#Heavydutydrum#heavyduty#slittermachine#paper industry#papermachinery

2 notes

·

View notes

Text

Industrial Applications of Hose Reel Drums You Should Know

The hose reel drum is a very important part in many industrial places. It helps to store and manage hoses well, also making sure the workplace is safe and the operation runs smoothly. These strong systems offer organized ways to store things that help protect your expensive hose equipment, also making work easier across different industries.

Manufacturing and Assembly Lines

In production plants, the hose reel drum is very important for managing systems of compressed air delivery. These settings allow workers to reach pneumatic tools fast and also keep hoses safely stored when they are not used. The mechanism that lets the hose pull back automatically prevents fall risks and makes sure hoses stay in good shape.

Chemical Processing Plants

Chemical processing factories depend on unique drum systems for hose reels. These are made to deal with harmful chemicals and unsafe materials. They have structures that resist the damage of these substances and also keep safety locks in place, avoiding them from unwinding by mistake. This guarantees safe movement of materials between storage tanks and procedure units.

Oil and Gas Operations

Oil industry uses powerful hose reel drum machinery for moving fuel. These particular units are designed to handle hoses with high pressure and have motors and controls that avoid explosions. They have a strong build, able to resist tough environmental conditions while making sure the process of managing fuel is safe and productive.

Agriculture and Irrigation

Farming work gets advantage from big-size hose reel drum systems planned for watering and crop handling. These pieces of equipment are able to manage extended hoses that are necessary for field hydration, use of fertilizer, and actions against pests. Because they can be moved easily on their wheels across large farm lands, these machines have a mobile design.

Mining Operations

In the mining surroundings, hose reel systems handle water supply for reducing dust and cooling equipment. The drums have strengthened design to resist regular usage and tough circumstances while giving dependable access to water resources all through mining activities.

Fire Fighting and Emergency Response

Services of emergency use reel systems with high performance for fast deployment of fire hoses and rescue tools. Mechanisms that release quickly along with properties to rewind motor make sure rapid times in responding during important situations.

Marine and Offshore Applications

Marine vessels and offshore platforms are using unique reels, which are specially made for bearing saltwater contact and harsh weather times. These systems are taking care of many hoses it uses for fuel transfer, water supply, as well as waste management proceedings.

Construction Sites

Building projects gain advantages from mobile reel systems which control air, water and power hoses. Their ability to move makes them easy to shift as the building work goes ahead, but still keep these hoses in order and safe from dangers at site.

Wrapping up

Hose reel drum is a critical purchase for industries that need well-organized hose systems. They offer great flexibility and their special designs cater to different uses, making them priceless in keeping operations running smoothly and also ensuring safety at work. Knowing these uses is beneficial for companies to pick the right system according to their unique requirements, so they can guarantee superior performance and durable life of the reels as well as hoses which it safeguards.

0 notes

Text

The Liner Rewinder Machine is an essential part of modern industrial production, whether you’re in packaging, textile manufacturing, or paper processing.

#krishnaengineeringworks#machinery#machine#industry#linerrewindermachine#export#supply#machinemanufacturer

2 notes

·

View notes

Text

Optimized Wire Management with Traverse Spool Rewind Machines

The Traverse Wire Spool Rewind Machine is an essential tool for industries that demand precision and efficiency in wire management. Its innovative design and user-friendly features make it an invaluable asset for businesses dealing with wire spooling and rewinding. Whether you're in manufacturing, electrical, or telecommunications, this machine ensures smooth operations and top-notch performance.

Why Precision Matters in Wire Management

Managing wire spools manually can lead to inaccuracies, wasted resources, and even safety risks. The Traverse Wire Spool Rewind Machine eliminates these challenges by providing automated solutions. Its advanced features allow businesses to handle spooling tasks with ease, reducing labor costs and enhancing productivity. By improving precision, this tool also minimizes material waste, translating into significant cost savings for businesses over time.

Key Features That Stand Out

Compact Design: The machine’s sleek and compact structure ensures it can fit into any workspace, no matter how small.

Versatility: Suitable for a wide range of wire types and sizes, making it adaptable for various industrial needs.

Precision Engineering: Its high-precision controls ensure accurate wire winding, preventing errors and material wastage.

Durability: Constructed with robust materials to withstand the demands of daily industrial use.

Ease of Operation: Intuitive controls make it accessible for operators of all skill levels.

Applications Across Industries

This Machine is widely used in industries such as:

Manufacturing: For assembling electronic components or preparing wire harnesses.

Telecommunications: To manage and organize wires for installations.

Electrical Engineering: For efficient cable spooling and handling.

Automotive: In wire preparation for vehicle assembly and maintenance.

Tips for Optimal Use

Regularly inspect the machine for wear and tear to ensure consistent performance.

Use appropriate settings based on wire type and size to maximize efficiency.

Clean the machine periodically to maintain its longevity.

Ensure operators are trained to utilize its features effectively for optimal results.

Why This Machine Is a Game-Changer

Investing in the Traverse Wire Spool Rewind Machine gives businesses a competitive edge. Its ability to handle tasks with precision and speed allows companies to take on more projects without compromising on quality. Moreover, its user-friendly design means minimal training time for employees, ensuring a quick return on investment.

Conclusion

For businesses looking to optimize their wire management processes, the Traverse Wire Spool Rewind Machine is a game-changer. Its efficiency, reliability, and user-friendly operation make it an indispensable tool for industries requiring precision and organization. This machine is an excellent addition to your range of industrial tool and supplies.

0 notes

Text

What to Expect from a Magnetic Chuck Repair Service: A Step-by-Step Process

Magnetic chucks are essential tools in machining and manufacturing environments, offering reliable workholding solutions for precision operations. However, like any industrial equipment, they are subject to wear and tear, requiring professional repairs to maintain performance and accuracy. Understanding the repair process can help you make informed decisions and ensure your equipment gets the care it deserves. Here’s a step-by-step look at what to expect from a magnetic chuck repair service:

Initial Assessment and Inspection

The repair process begins with a thorough inspection of the magnetic chuck. Technicians examine the chuck for visible damage, such as cracks, wear, or misalignments, and test its functionality. For electromagnetic chucks, this includes checking the electrical components, such as coils, connections, and control units. A detailed diagnostic report is prepared, outlining the issues and potential solutions.

Customer Consultation and Quotation

After the initial assessment, the repair service provider will discuss the findings with you. They’ll explain the nature of the problems, the necessary repairs, and the expected outcomes. At this stage, you’ll receive a detailed quotation that includes the cost of labor, replacement parts, and any additional services required. This step ensures transparency and allows you to make an informed decision.

Disassembly and Cleaning

Once approved, the technicians will disassemble the magnetic chuck to access internal components. This step is critical for identifying hidden issues that may not have been apparent during the initial inspection. The chuck is thoroughly cleaned to remove any dirt, debris, or old lubricant that could affect its performance. Clean components are easier to repair and ensure optimal reassembly.

Component Repair and Replacement

Damaged components are repaired or replaced as needed. For permanent magnetic chucks, technicians may re-magnetize the unit if its magnetic strength has weakened. For electromagnetic chucks, repairs may involve rewinding coils, replacing damaged wiring, or fixing control units. High-quality replacement parts are used to ensure durability and reliability.

Reassembly and Calibration

After repairs are completed, the chuck is carefully reassembled. Precision is crucial during this step to ensure that all components align correctly. The technicians then calibrate the chuck to restore its original performance standards. This includes verifying magnetic strength, flatness, and holding force to ensure the chuck functions as intended.

Testing and Quality Assurance

Before the chuck is returned to the customer, it undergoes rigorous testing to confirm that all repairs were successful. Technicians simulate real-world operating conditions to ensure the chuck performs reliably under load. Any adjustments needed are made at this stage to guarantee optimal functionality.

Final Inspection and Documentation

A final inspection is conducted to check for any remaining issues. The service provider documents the entire repair process, including the repairs performed, parts replaced, and testing results. This documentation is provided to you as a record for future reference.

Customer Support and Maintenance Advice

Reputable repair services often include post-repair support. Technicians may offer guidance on routine maintenance to prevent future issues, such as cleaning techniques and proper usage practices. This step ensures you get the most out of your repaired magnetic chuck.

Conclusion

Investing in professional magnetic chuck repair services not only restores your equipment’s performance but also extends its lifespan, saving you time and money in the long run. By understanding the step-by-step repair process, you can approach the service with confidence and ensure your magnetic chuck is in capable hands.

0 notes

Text

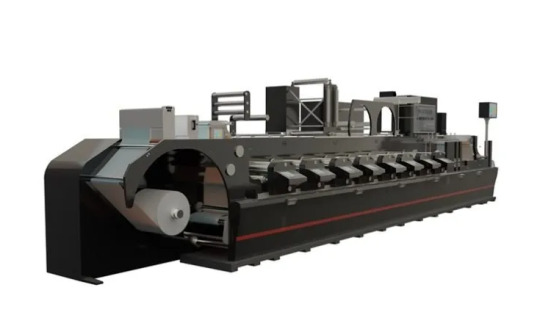

Webtech Group’s live demonstrations at Printpack 2025

Webtech Group, a leading manufacturer of printing and paper-converting machinery, will showcase its range of machines at Printpack 2025, to be held from 1 to 5 February 2024, at India Expo Centre and Mart in Greater Noida. It show demonstrate the fully servo flexographic printing machine in 450 mm working width, thermal roll slitting rewinding machine with single color online flexo printing, honeycomb paper die cutting machine, and servo-controlled label slitter rewinder machine

Along with the showcased machines, the Webtech team will highlight its entire range of products, including fully servo flexographic printing machines, web offset printing machines, slitting rewinding machines, and die cutting machines at its stand. The team will discuss technological advancements, share insights into the industry’s trajectory, and offer tailored solutions.

Singh emphasized the strategic importance of participating in Printpack 2025. “Printpack provides a vital platform to showcase technological advancements to a global audience and expand our clientele. The exhibition offers invaluable insights into emerging trends and challenges, enabling us to enhance our product offerings and stay ahead of market demands,” he said.

By participating in such exhibitions, Webtech aims to solidify its industry presence while forging new relationships with global clients. “For Printpack 2025, we aim to build on our previous successes by introducing our latest fully servo flexographic printing machine and other innovations. We look forward to engaging with industry leaders and further strengthening our position in the market,” Singh added.

Singh highlighted the evolution of the printing and packaging industry, driven by increasing demand for sustainable and flexible packaging solutions. Key advancements, such as fully servo-driven machines, automation, and eco-friendly substrates, are shaping the future of the industry.

“The printing and packaging sector is experiencing robust growth, with sustainability and precision at its core. We are poised to capitalize on these trends by offering innovative and efficient machinery that addresses challenges such as waste reduction and enhance productivity,” Singh explained.

Webtech International Machineries will be present in hall no 5, stands C19 and C28.

0 notes

Text

Bopp / Paper Tape Coating Machine

Mohindra is recognized as one of the top manufacturers of Doctoring Slitting Machines in India. Although we are located in Delhi, we supply our wide range of products across the country. We use premium quality raw materials in the production of all our machines. As you may know, the demand for Doctoring Slitting Machines is increasing daily, driven by the rising consumption of paper bags in India. Mohindra Machine stands out as a leading manufacturer of Doctoring Slitting Machines. We are dedicated to producing and supplying these machines to potential customers in the market. The Doctoring Slitting Machine is designed to cut and convert large sheets of paper, foil, and film materials into narrower rolls. These machines consist of three main components: the slitter, unwind, and rewind.

#Bopp paper tape coating machine price#Bopp paper tape coating machine price in india#Bopp paper tape coating machine in india#Bopp paper tape coating machine for sale

1 note

·

View note